High Electromagnetic Shielding Effect of Carbon Nanotubes/Waterborne Polyurethane Composites Prepared by “Break-Adsorption” Method

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Fabrication of OCNT/WPU Composite Emulsion

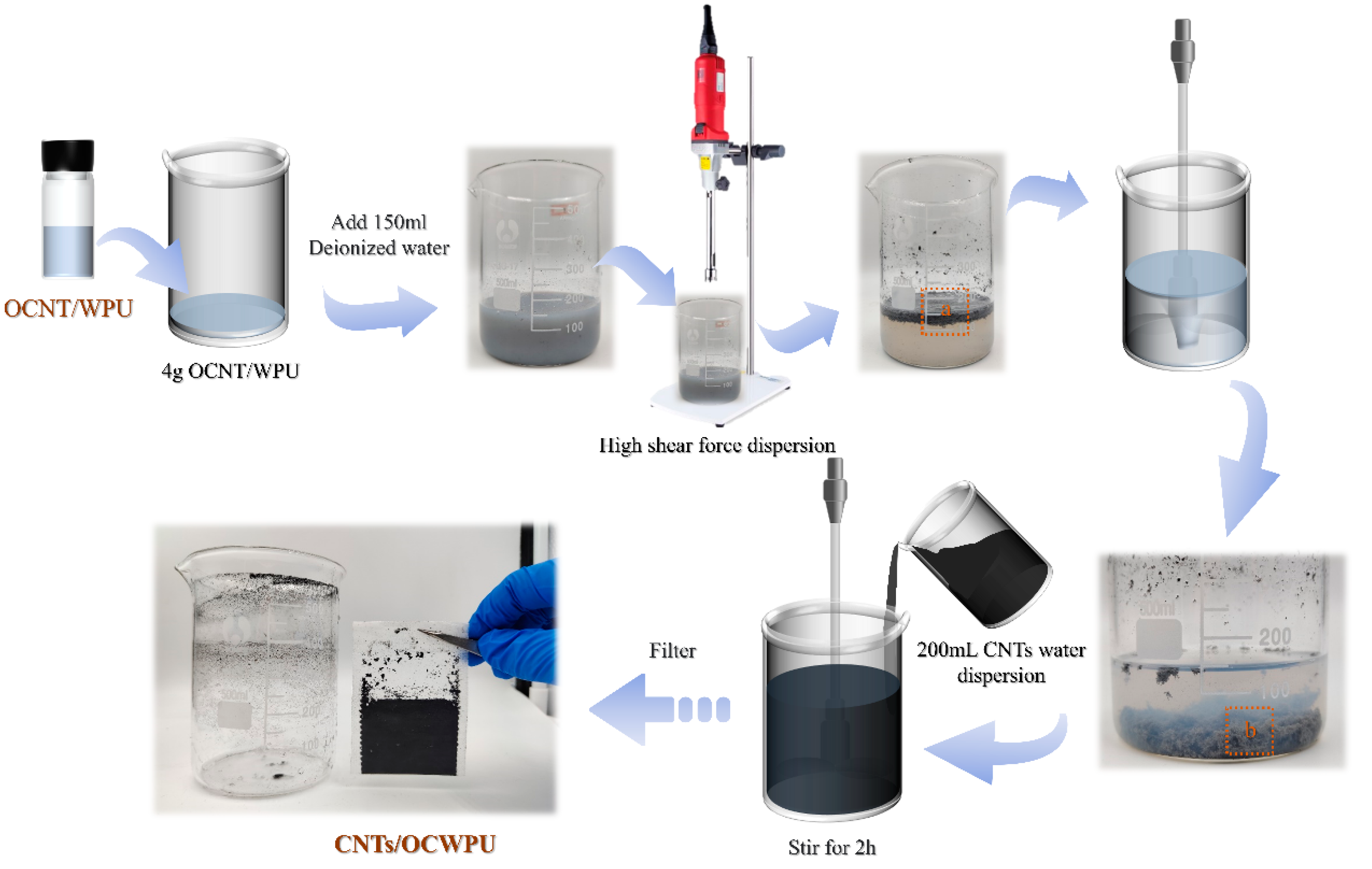

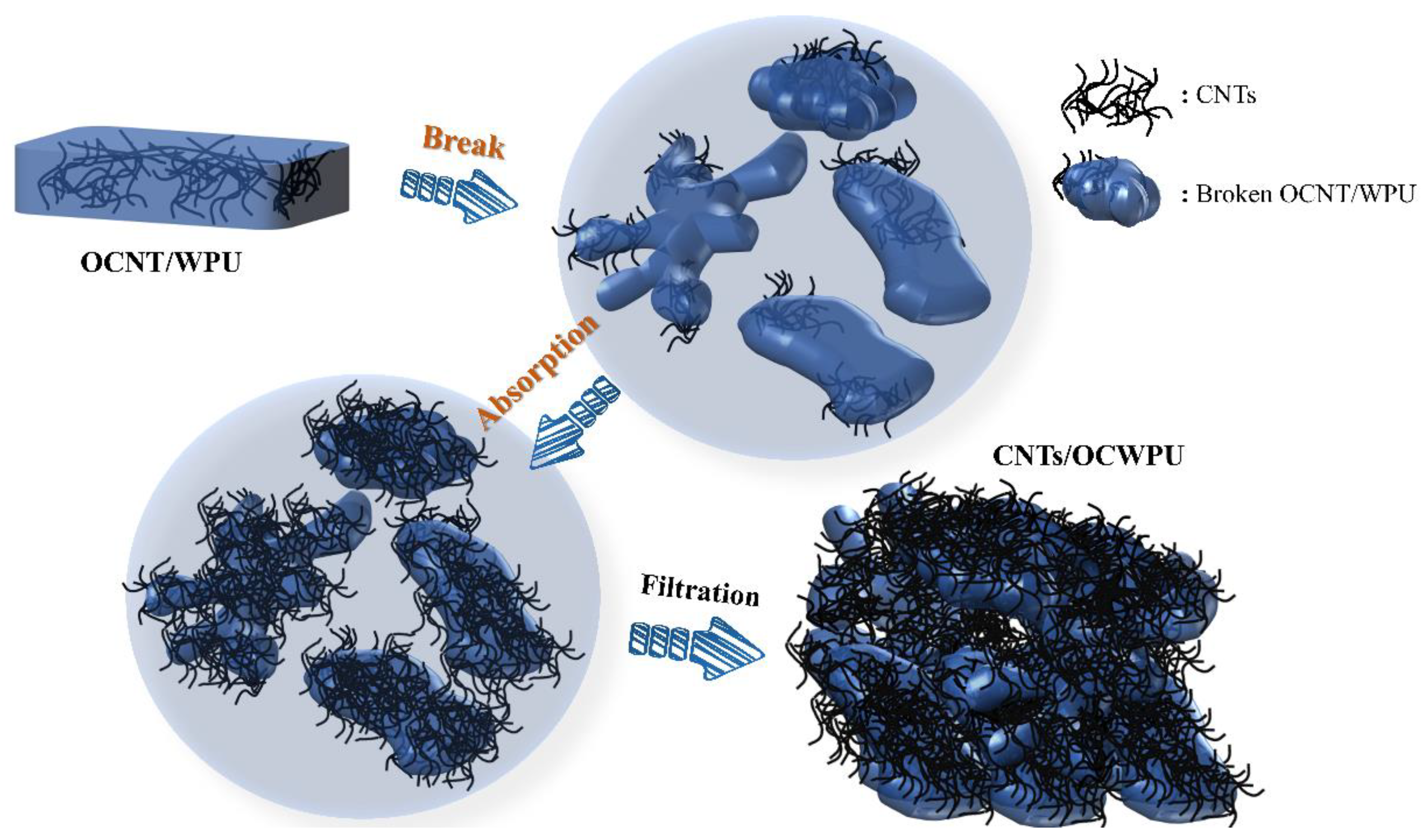

2.3. Fabrication of CNTs/OCWPU composites

2.4. Characterization

3. Results and Discussion

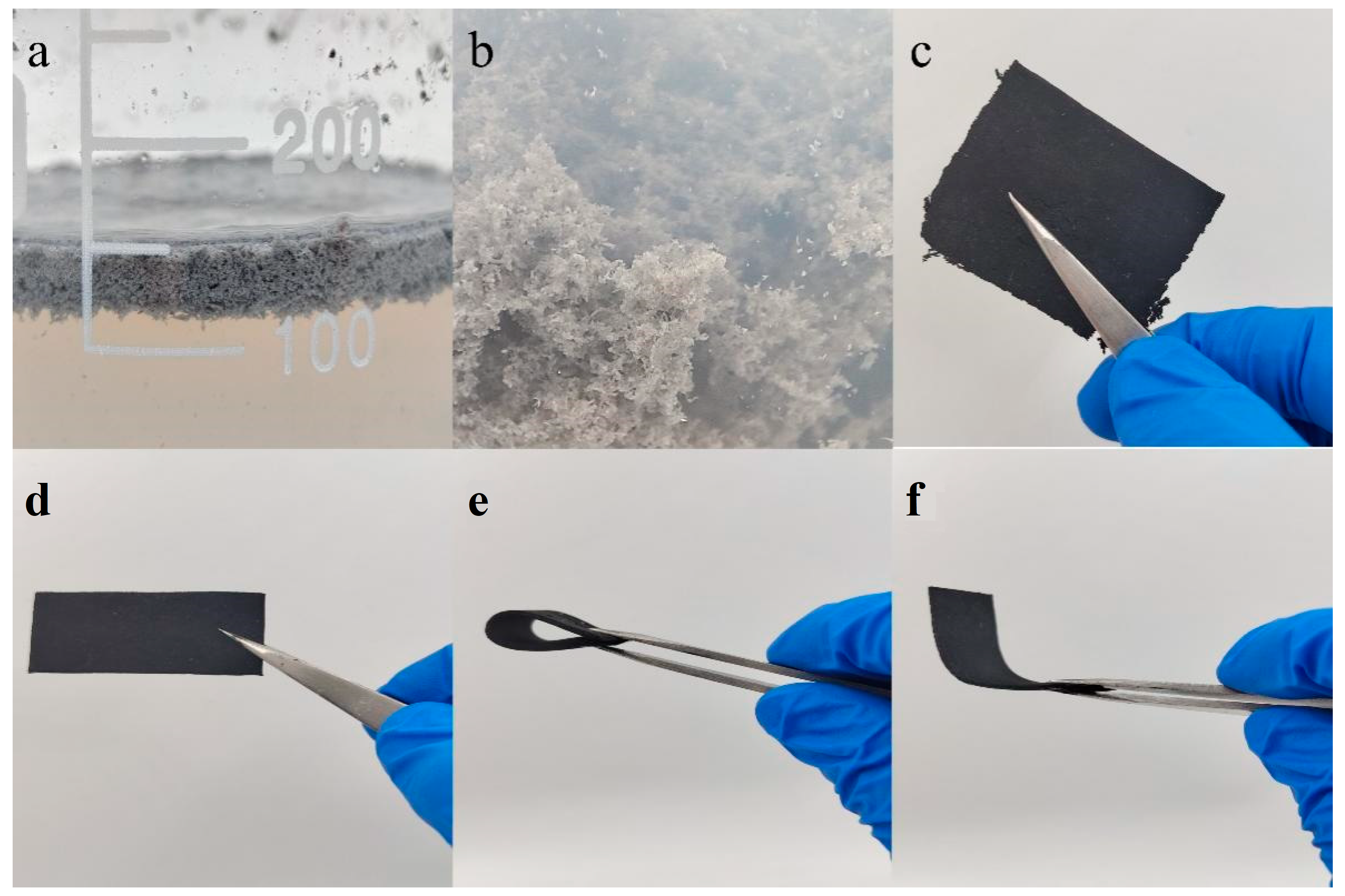

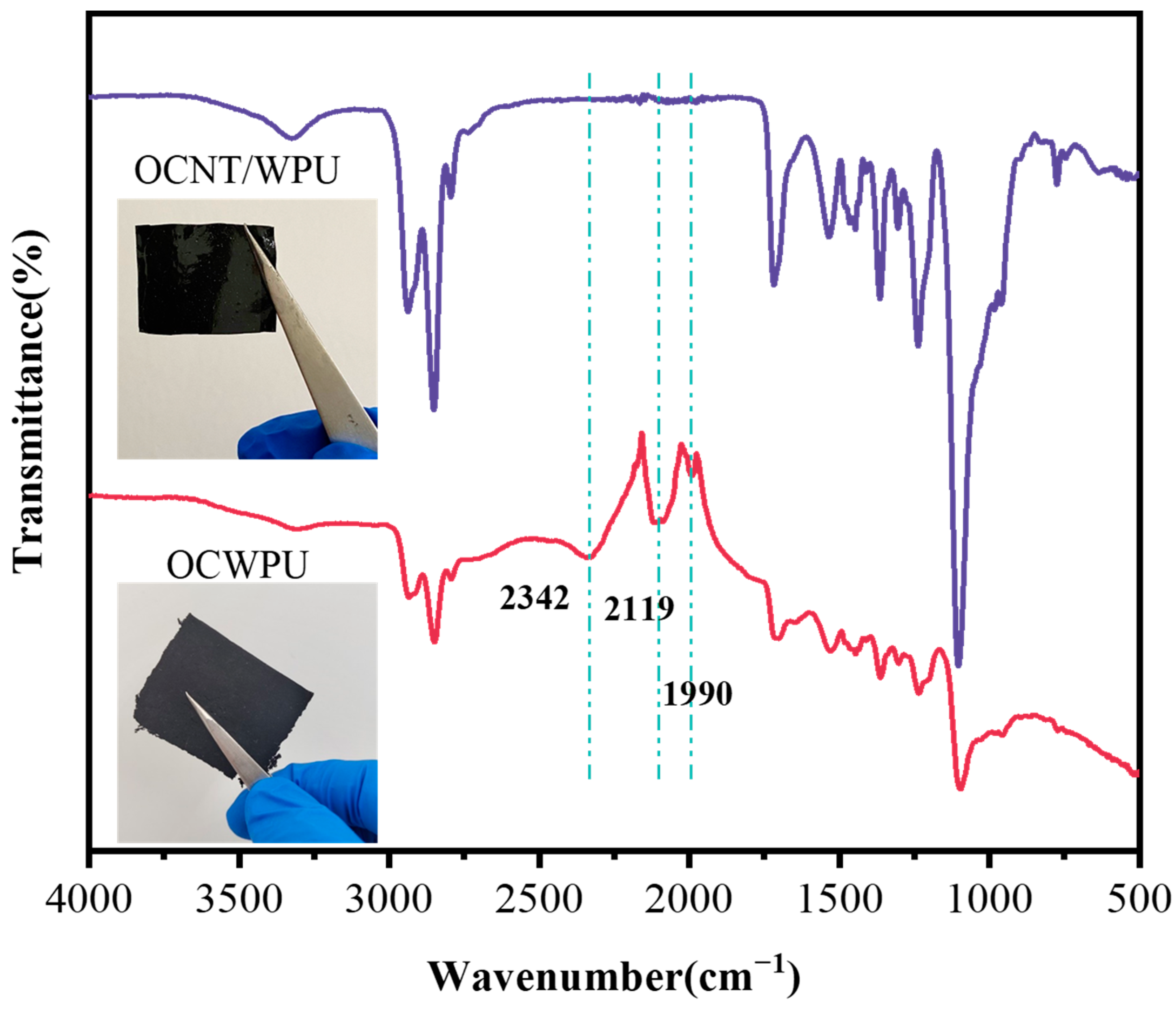

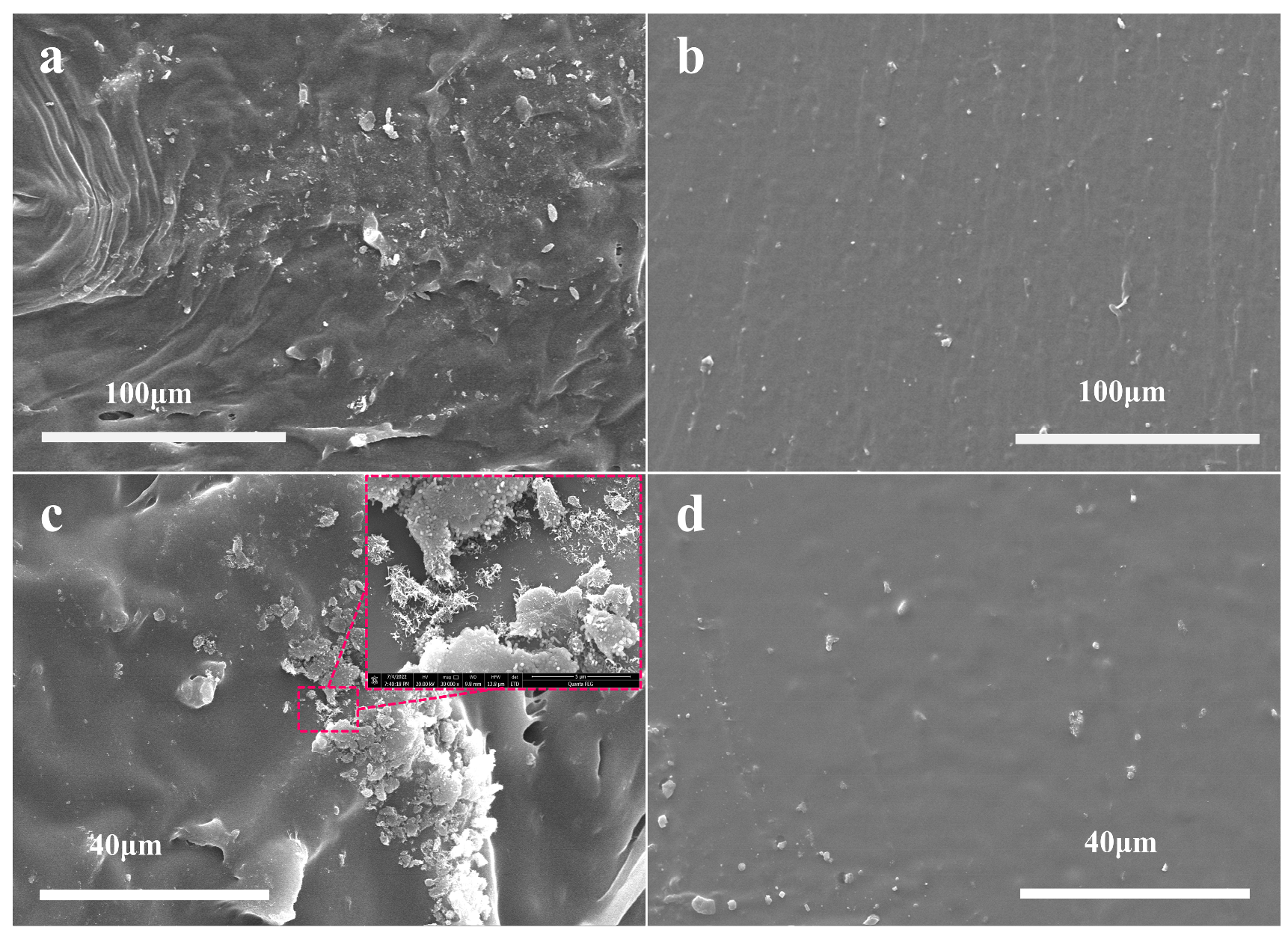

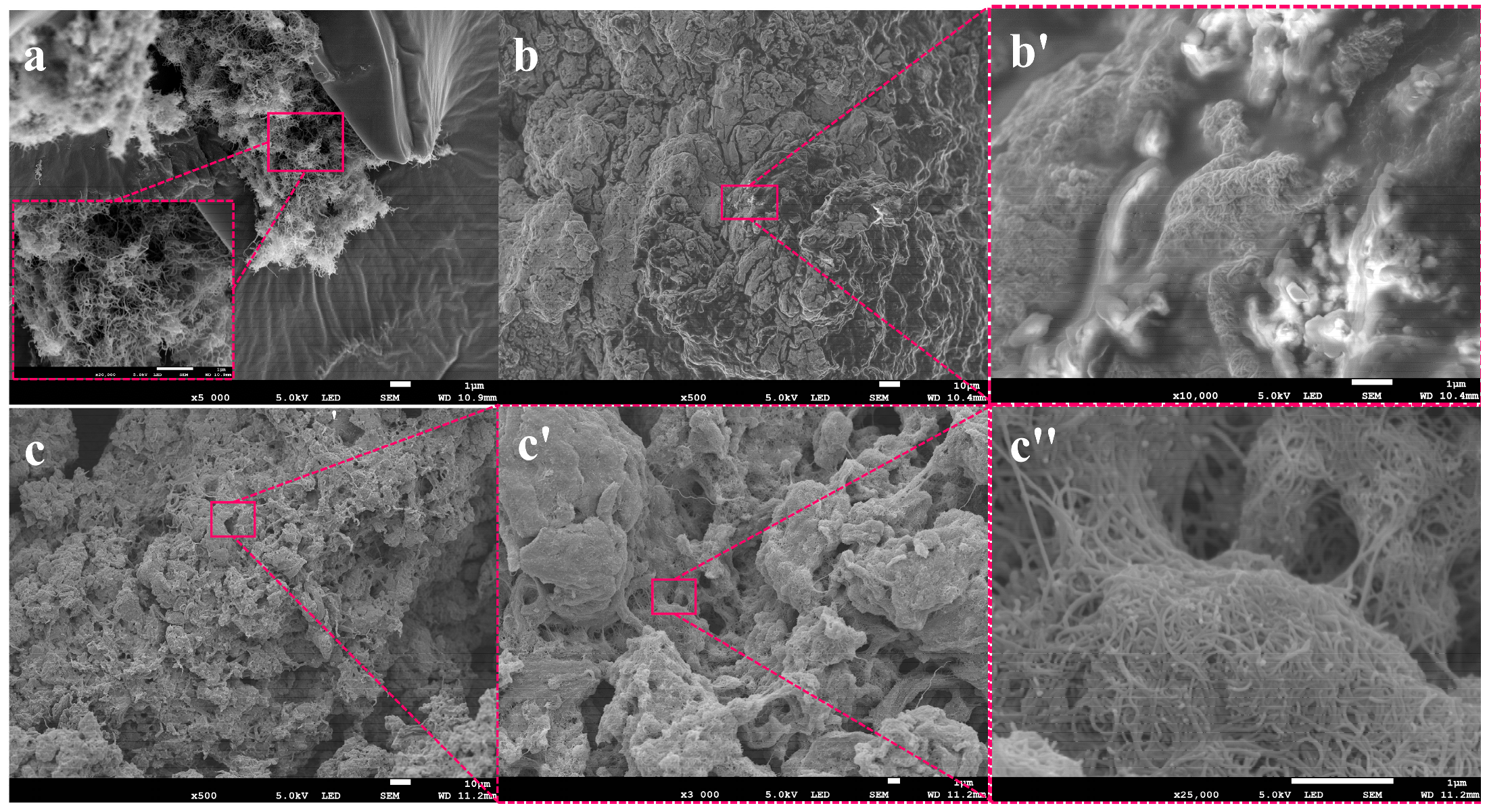

3.1. Morphologies of the Composites

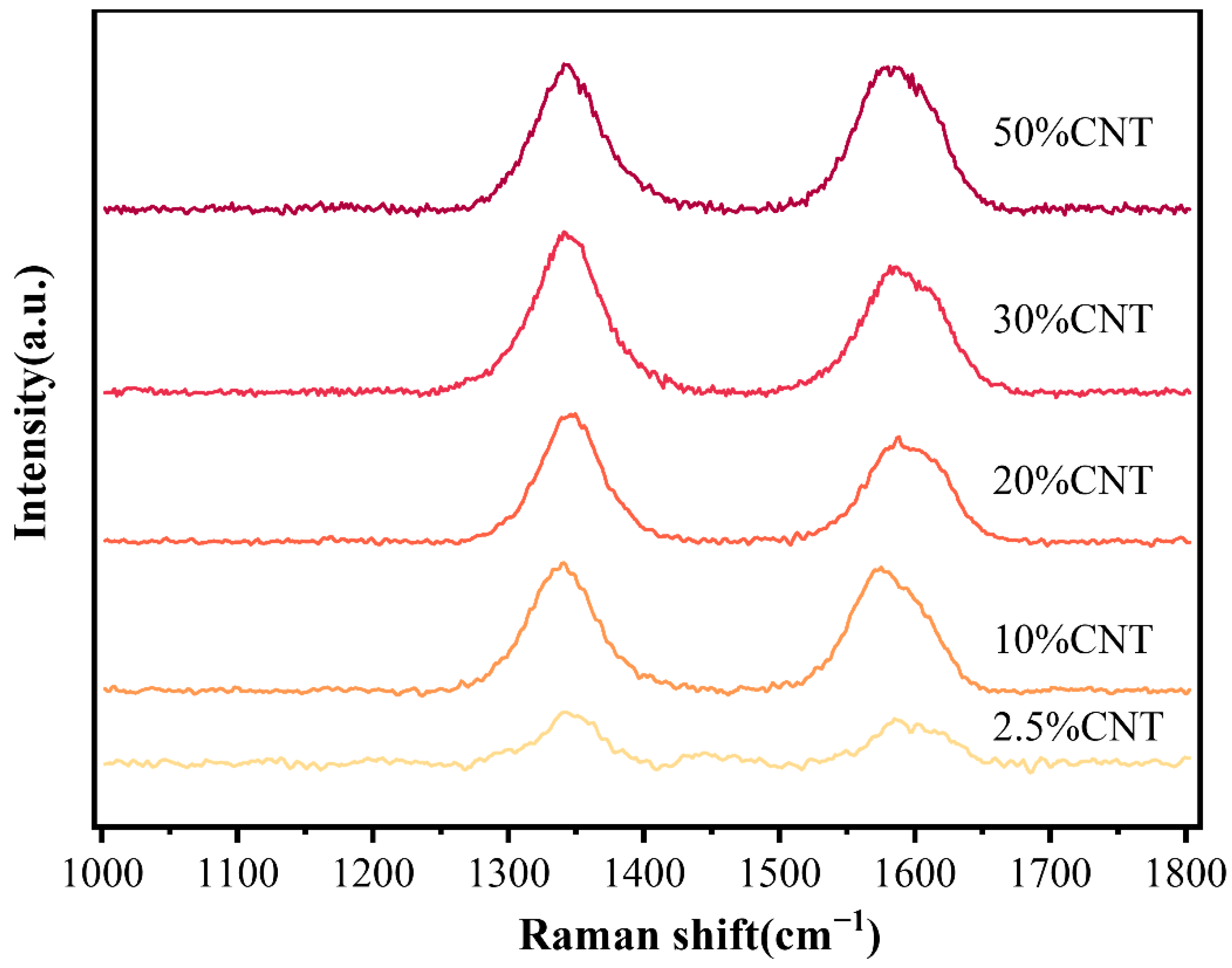

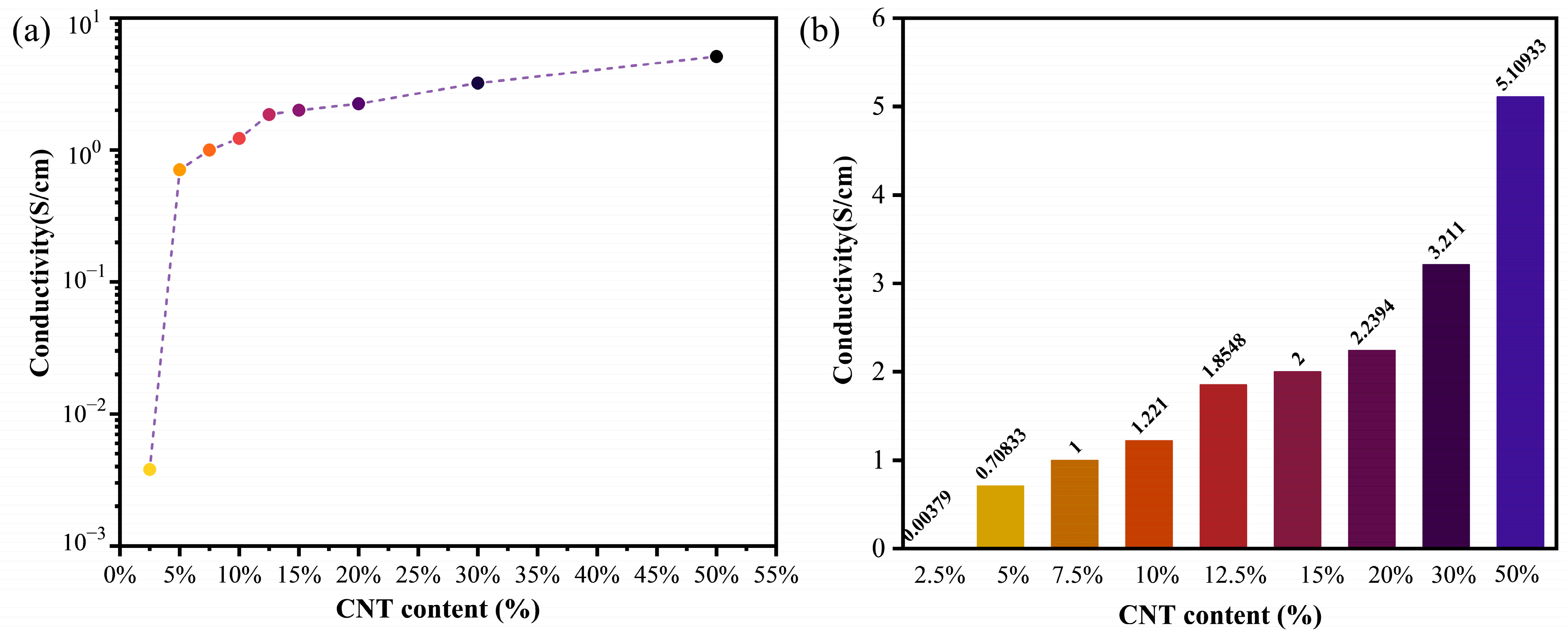

3.2. Electrical Property

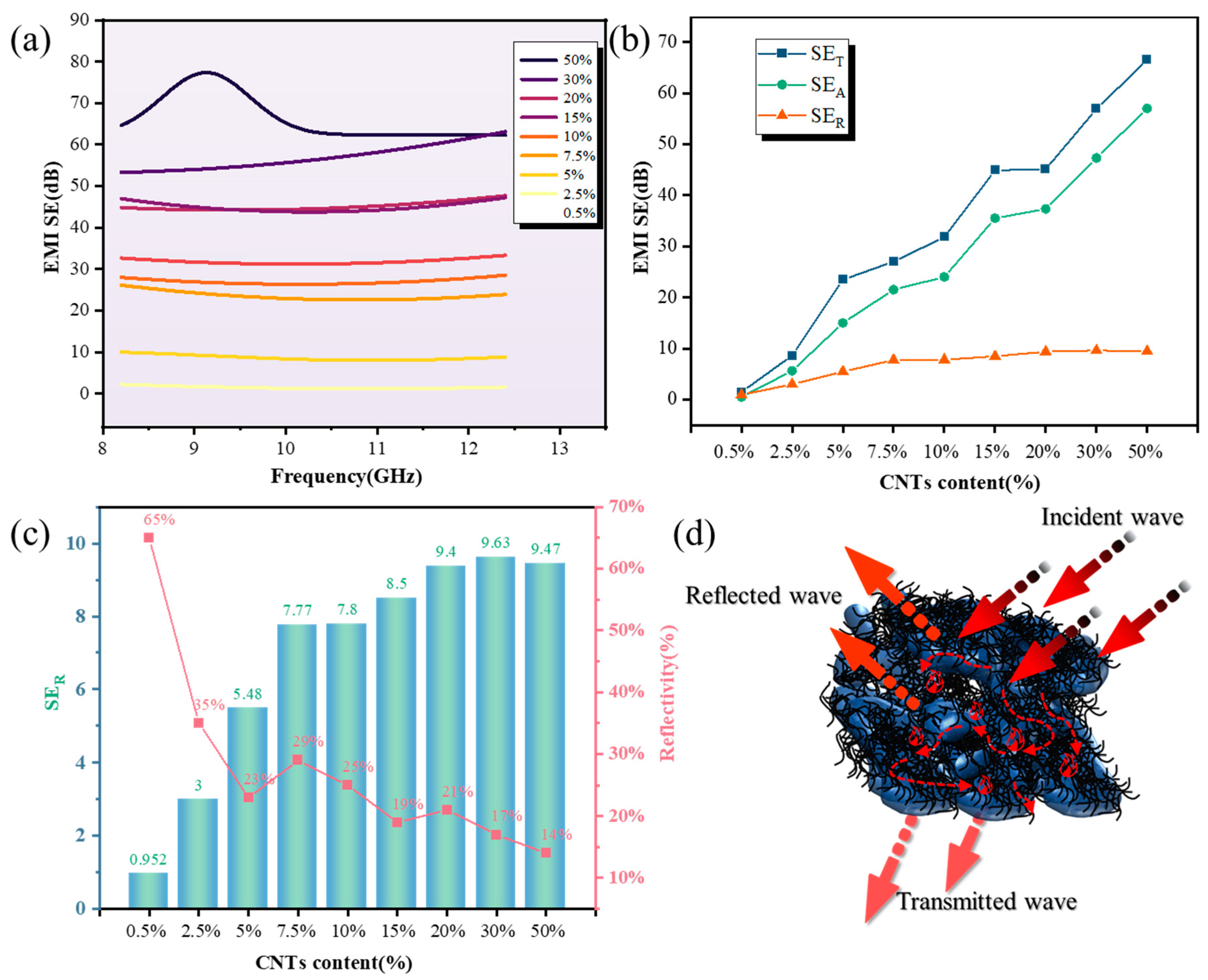

3.3. EMI Shielding Effectiveness

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Moazen, S.; Sahebian, S.; Haddad-Sabzevar, M. Low percolation behavior of HDPE/CNT nanocomposites for EMI shielding application: Random distribution to segregated structure. Synth. Met. 2021, 281, 116900. [Google Scholar] [CrossRef]

- Wang, T.; Yu, W.-C.; Zhou, C.-G.; Sun, W.-J.; Zhang, Y.-P.; Jia, L.-C.; Gao, J.-F.; Dai, K.; Yan, D.-X.; Li, Z.-M. Self-healing and flexible carbon nanotube/polyurethane composite for efficient electromagnetic interference shielding. Compos. Part B Eng. 2020, 193, 108015. [Google Scholar] [CrossRef]

- Joseph, J.; Munda, P.R.; John, D.A.; Sidpara, A.M.; Paul, J. Graphene and CNT filled hybrid thermoplastic composites for enhanced EMI shielding effectiveness. Mater. Res. Express 2019, 6, 085617. [Google Scholar] [CrossRef]

- Feng, D.; Liu, P.; Wang, Q. Exploiting the piezoresistivity and EMI shielding of polyetherimide/carbon nanotube foams by tailoring their porous morphology and segregated CNT networks. Compos. Part A Appl. Sci. Manuf. 2019, 124, 105463. [Google Scholar] [CrossRef]

- Feng, D.; Wang, Q.; Xu, D.; Liu, P. Microwave assisted sinter molding of polyetherimide/carbon nanotubes composites with segregated structure for high-performance EMI shielding applications. Compos. Sci. Technol. 2019, 182, 107753. [Google Scholar] [CrossRef]

- Jang, M.G.; Ryu, S.C.; Juhn, K.J.; Kim, S.K.; Kim, W.N. Effects of carbon fiber modification with multiwall CNT on the electrical conductivity and EMI shielding effectiveness of polycarbonate/carbon fiber/CNT composites. J. Appl. Polym. Sci. 2018, 136, 47302. [Google Scholar] [CrossRef]

- Zhan, Y.; Oliviero, M.; Wang, J.; Sorrentino, A.; Buonocore, G.G.; Sorrentino, L.; Lavorgna, M.; Xia, H.; Iannace, S. Enhancing the EMI shielding of natural rubber-based supercritical CO2 foams by exploiting their porous morphology and CNT segregated networks. Nanoscale 2018, 11, 1011–1020. [Google Scholar] [CrossRef]

- Lu, D.; Mo, Z.; Liang, B.; Yang, L.; He, Z.; Zhu, H.; Tang, Z.; Gui, X. Flexible, lightweight carbon nanotube sponges and composites for high-performance electromagnetic interference shielding. Carbon 2018, 133, 457–463. [Google Scholar] [CrossRef]

- Donald, M. The United Nations Conference on the Human Environment. Int. Negot. 1996, 1, 223–229. [Google Scholar] [CrossRef]

- Geetha, S.; Kumar, K.K.S.; Rao, C.R.K.; Vijayan, M.; Trivedi, D.C.K. EMI shielding: Methods and materials-A review. J. Appl. Polym. Sci. 2009, 112, 2073–2086. [Google Scholar] [CrossRef]

- Liao, S.-Y.; Wang, X.-Y.; Li, X.-M.; Wan, Y.-J.; Zhao, T.; Hu, Y.-G.; Zhu, P.-L.; Sun, R.; Wong, C.-P. Flexible liquid metal/cellulose nanofiber composites film with excellent thermal reliability for highly efficient and broadband EMI shielding. Chem. Eng. J. 2021, 422, 129962. [Google Scholar] [CrossRef]

- Sridhar, V.; Lee, I.; Park, H. Metal Organic Frameworks Derived Fe-N-C Nanostructures as High-Performance Electrodes for Sodium Ion Batteries and Electromagnetic Interference (EMI) Shielding. Molecules 2021, 26, 1018. [Google Scholar] [CrossRef]

- Kittur, J.; Desai, B.; Chaudhari, R.; Loharkar, P.K. A comparative study of EMI shielding effectiveness of metals, metal coatings and carbon-based materials. IOP Conf. Series Mater. Sci. Eng. 2020, 810, 12019. [Google Scholar] [CrossRef]

- Amanuel, G.; Jonathan, T.O.; Tanyaradzwa, S.M.; Suprakas, S.R. Cellulose-Based Sustainable Composites: A Review of Systems for Applications in EMI Shielding and Sensors. Macromol. Mater. Eng. 2022, 2200185. [Google Scholar] [CrossRef]

- Khan, R.; Khan, Z.M.; Bin Aqeel, H.; Javed, S.; Shafqat, A.; Qazi, I.; Basit, M.A.; Jan, R. 2D nanosheets and composites for EMI shielding analysis. Sci. Rep. 2020, 10, 1–7. [Google Scholar] [CrossRef]

- Raagulan, K.; Ghim, J.S.; Braveenth, R.; Jung, M.J.; Lee, S.B.; Chai, K.Y.; Kim, B.M.; Lee, J. EMI Shielding of the Hydrophobic, Flexible, Lightweight Carbonless Nano-Plate Composites. Nanomaterials 2020, 10, 2086. [Google Scholar] [CrossRef]

- Cheng, K.; Li, H.; Zhu, M.; Qiu, H.; Yang, J. In situ polymerization of graphene-polyaniline@polyimide composite films with high EMI shielding and electrical properties. RSC Adv. 2020, 10, 2368–2377. [Google Scholar] [CrossRef]

- Chandra, R.B.J.; Shivamurthy, B.; Kulkarni, S.D.; Kumar, M.S. Hybrid polymer composites for EMI shielding application- a review. Mater. Res. Express 2019, 6, 082008. [Google Scholar] [CrossRef]

- Wang, M.; Tang, X.-H.; Cai, J.-H.; Wu, H.; Shen, J.-B.; Guo, S.-Y. Construction, mechanism and prospective of conductive polymer composites with multiple interfaces for electromagnetic interference shielding: A review. Carbon 2021, 177, 377–402. [Google Scholar] [CrossRef]

- Zhao, B.; Hamidinejad, M.; Wang, S.; Bai, P.; Che, R.; Zhang, R.; Park, C.B. Advances in electromagnetic shielding properties of composite foams. J. Mater. Chem. A 2021, 9, 8896–8949. [Google Scholar] [CrossRef]

- Sun, Z.; Chen, J.; Jia, X.; Wang, G.; Shen, B.; Zheng, W. Humidification of high-performance and multifunctional polyimide/carbon nanotube composite foams for enhanced electromagnetic shielding. Mater. Today Phys. 2021, 21, 100521. [Google Scholar] [CrossRef]

- Zhang, W.; Wei, L.; Ma, Z.; Fan, Q.; Ma, J. Advances in waterborne polymer/carbon material composites for electromagnetic interference shielding. Carbon 2021, 177, 412–426. [Google Scholar] [CrossRef]

- Jiang, D.; Murugadoss, V.; Wang, Y.; Lin, J.; Ding, T.; Wang, Z.; Shao, Q.; Wang, C.; Liu, H.; Lu, N.; et al. Electromagnetic Interference Shielding Polymers and Nanocomposites—A Review. Polym. Rev. 2019, 59, 280–337. [Google Scholar] [CrossRef]

- Lee, Y.S.; Lee, J.H.; Yoon, K.H. EMI Shielding and Mechanical Properties of Polycarbonate Nanocomposites Containing CNT Composite Powder. Fibers Polym. 2021, 22, 1704–1710. [Google Scholar] [CrossRef]

- Tan, X.; Yuan, Q.; Qiu, M.; Yu, J.; Jiang, N.; Lin, C.-T.; Dai, W. Rational design of graphene/polymer composites with excellent electromagnetic interference shielding effectiveness and high thermal conductivity: A mini review. J. Mater. Sci. Technol. 2022, 117, 238–250. [Google Scholar] [CrossRef]

- Wang, S.; Tang, Z.; Cen, W.; Zhang, C.; Guo, B. Creating molecular bridges across the interfaces in segregated composites toward improved conductive and mechanical properties. Compos. Sci. Technol. 2022, 222, 109377. [Google Scholar] [CrossRef]

- Bonetti, L.; Fiorati, A.; Serafini, A.; Masotti, G.; Tana, F.; D’Agostino, A.; Draghi, L.; Altomare, L.; Chiesa, R.; Farè, S. Graphene nanoplatelets composite membranes for thermal comfort enhancement in performance textiles. J. Appl. Polym. Sci. 2021, 138, 49645. [Google Scholar] [CrossRef]

- Liang, J.; Bai, M.; Gu, Y.; Wang, S.; Li, M.; Zhang, Z. Enhanced electromagnetic shielding property and anisotropic shielding behavior of corrugated carbon fiber felt composite and its sandwich structure. Compos. Part A Appl. Sci. Manuf. 2021, 149, 106481. [Google Scholar] [CrossRef]

- Merizgui, T.; Gaoui, B.; Sebaey, T.A.; Prakash, V.A. Electromagnetic shielding behavior of epoxy multi-hybrid composites comprises of E-glass fiber, Ag nanoparticle, and Ni nanosheet: A novel approach. Polym. Compos. 2021, 42, 2484–2491. [Google Scholar] [CrossRef]

- Wang, M.; Qin, Y.; Gao, W.; Liang, S. Lightweight MWCNT/hollow mesoporous carbon/WPU composite material with excellent electromagnetic shielding performance. RSC Adv. 2021, 11, 37194–37204. [Google Scholar] [CrossRef]

- Dai, M.; Zhai, Y.; Zhang, Y. A green approach to preparing hydrophobic, electrically conductive textiles based on waterborne polyurethane for electromagnetic interference shielding with low reflectivity. Chem. Eng. J. 2021, 421, 127749. [Google Scholar] [CrossRef]

- Li, H.; Yuan, D.; Li, P.; He, C. High conductive and mechanical robust carbon nanotubes/waterborne polyurethane composite films for efficient electromagnetic interference shielding. Compos. Part A Appl. Sci. Manuf. 2019, 121, 411–417. [Google Scholar] [CrossRef]

- Sit, S.; Nath, K.; Das, N.C.; Chakraborty, G. Superior electromagnetic interference shielding effectiveness of functionalized MWCNTs filled flexible thermoplastic polymer nanocomposites. J. Elastomers Plast. 2022, 54, 136517855. [Google Scholar] [CrossRef]

- Zhao, G.; Cao, X.; Zhang, Q.; Deng, H.; Fu, Q. A novel interpenetrating segregated functional filler network structure for ultra-high electrical conductivity and efficient EMI shielding in CPCs containing carbon nanotubes. Mater. Today Phys. 2021, 21, 100483. [Google Scholar] [CrossRef]

- Dresselhaus, M.S.; Dresselhaus, G. R saito, and A Jorio. Phys. Rep. 2005, 409, 47. [Google Scholar] [CrossRef]

- Do Amaral Montanheiro, T.L.; Cristóvan, F.H.; Machado, J.P.B.; Tada, D.B.; Durán, N.; Lemes, A.P. Effect of MWCNT functionalization on thermal and electrical properties of PHBV/MWCNT nanocomposites. J. Mater. Res. 2015, 30, 55–65. [Google Scholar] [CrossRef]

- Qi, H.; Liu, J.; Mäder, E. Smart cellulose fibers coated with carbon nanotube networks. Fibers 2014, 2, 295–307. [Google Scholar] [CrossRef]

- Liu, W.; Yao, T.; Jia, K.; Gu, J.; Wang, D.; Wei, X. Flexible and thermal conducting multi-walled carbon nanotubes/waterborne polyurethane composite film from in situ polymerization for efficient electromagnetic interference shielding. J. Mater. Sci. Mater. Electron. 2021, 32, 4393–4403. [Google Scholar] [CrossRef]

- Schelkunoff, S.A. On diffraction and radiation of electromagnetic waves. Phys Rev. 1939, 56, 308. [Google Scholar] [CrossRef]

- Schulz, R.B.; Plantz, V.C.; Brush, D.R. Shielding theory and practice. IEEE T. Electromagn. C 1988, 30, 187–201. [Google Scholar] [CrossRef]

- Singh, A.P.; Mishra, M.; Hashim, D.P.; Narayanan, T.; Hahm, M.G.; Kumar, P.; Dwivedi, J.; Kedawat, G.; Gupta, A.; Singh, B.; et al. Probing the engineered sandwich network of vertically aligned carbon nanotube–reduced graphene oxide composites for high performance electromagnetic interference shielding applications. Carbon 2015, 85, 79–88. [Google Scholar] [CrossRef]

- Zeng, Z.; Jin, H.; Chen, M.; Li, W.; Zhou, L.; Zhang, Z. Lightweight and anisotropic porous MWCNT/WPU composites for ultrahigh performance electromagnetic interference shielding. Adv. Funct. Mater. 2016, 26, 303–310. [Google Scholar] [CrossRef]

- Sheng, A.; Ren, W.; Yang, Y.; Yan, D.; Duan, H.; Zhao, G.; Liu, Y.; Li, Z. Multilayer WPU conductive composites with controllable electro-magnetic gradient for absorption-dominated electromagnetic interference shielding. Compos. Part A Appl. Sci. Manuf. 2020, 129, 105692. [Google Scholar] [CrossRef]

| Matrix | Filler | Loading (%) | EMI SE (dB) | Reference |

|---|---|---|---|---|

| WPU | MWCNTs | 48.1 | 38.9 | [42] |

| WPU | MWCNTs | 40 | 30 | [38] |

| WPU | MWCNTs | 76.2 | 49.2 | [30] |

| WPU | MWCNTs | 60 | 40 | [30] |

| WPU | MWCNTs | 60 | 28.6 | [43] |

| WPU | MWCNTs | 45 | 25 | [43] |

| WPU | MWCNTs | 10.6 | 24.7 | [32] |

| WPU | MWCNTs | 10 | 31.8 | This work |

| WPU | MWCNTs | 30 | 56.9 | This work |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Shang, Y.; Li, M.; Zhang, X.; He, J. High Electromagnetic Shielding Effect of Carbon Nanotubes/Waterborne Polyurethane Composites Prepared by “Break-Adsorption” Method. Materials 2022, 15, 6430. https://doi.org/10.3390/ma15186430

Li Y, Shang Y, Li M, Zhang X, He J. High Electromagnetic Shielding Effect of Carbon Nanotubes/Waterborne Polyurethane Composites Prepared by “Break-Adsorption” Method. Materials. 2022; 15(18):6430. https://doi.org/10.3390/ma15186430

Chicago/Turabian StyleLi, Yasen, Yudong Shang, Mingyue Li, Xiang Zhang, and Jiangping He. 2022. "High Electromagnetic Shielding Effect of Carbon Nanotubes/Waterborne Polyurethane Composites Prepared by “Break-Adsorption” Method" Materials 15, no. 18: 6430. https://doi.org/10.3390/ma15186430

APA StyleLi, Y., Shang, Y., Li, M., Zhang, X., & He, J. (2022). High Electromagnetic Shielding Effect of Carbon Nanotubes/Waterborne Polyurethane Composites Prepared by “Break-Adsorption” Method. Materials, 15(18), 6430. https://doi.org/10.3390/ma15186430