Study on Welding Deformation and Optimization of Fixture Scheme for Thin-Walled Flame Cylinder

Abstract

:1. Introduction

2. Numerical Simulation Calculation

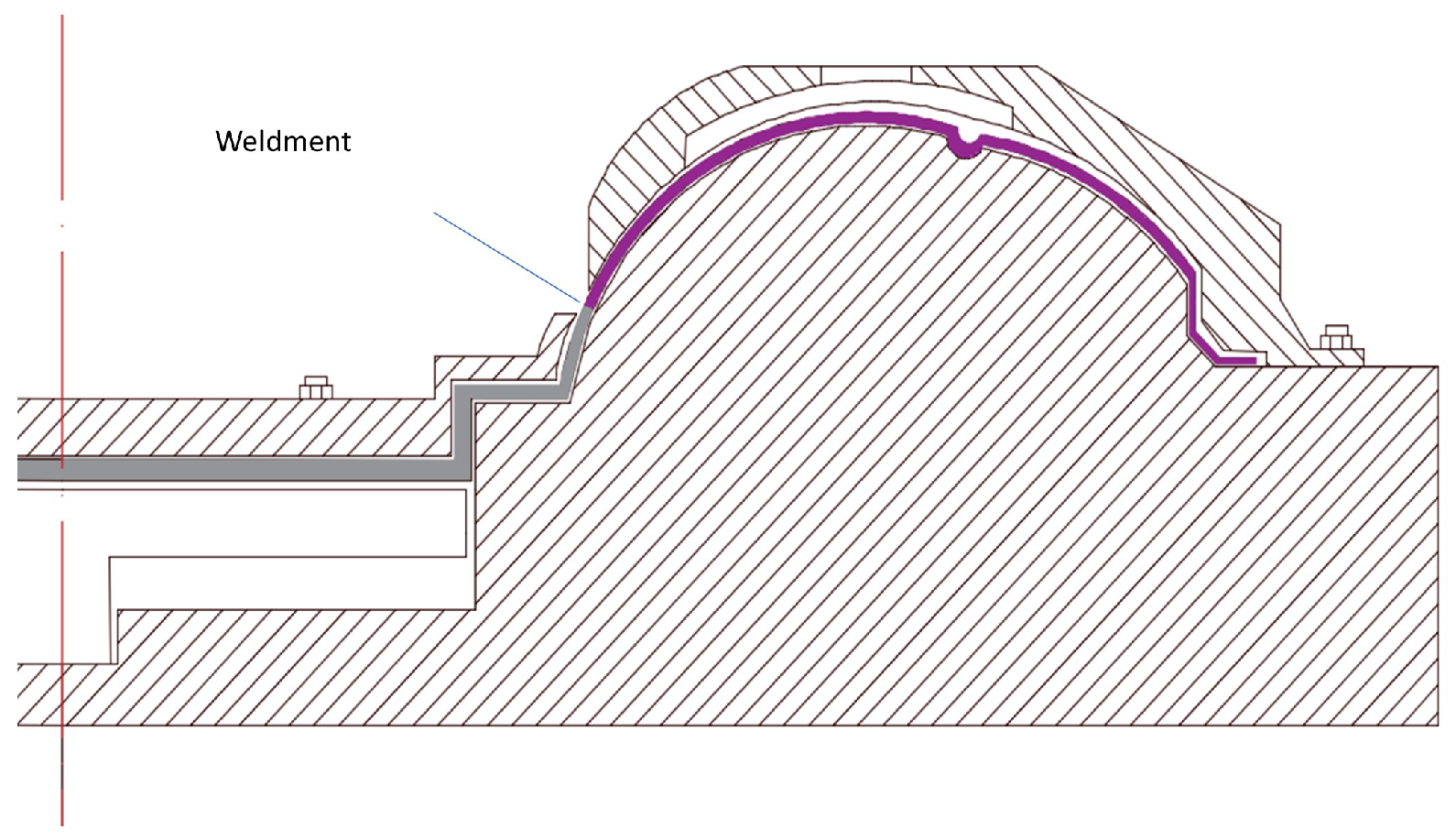

2.1. The Finite Element Model of the Flame Cylinder

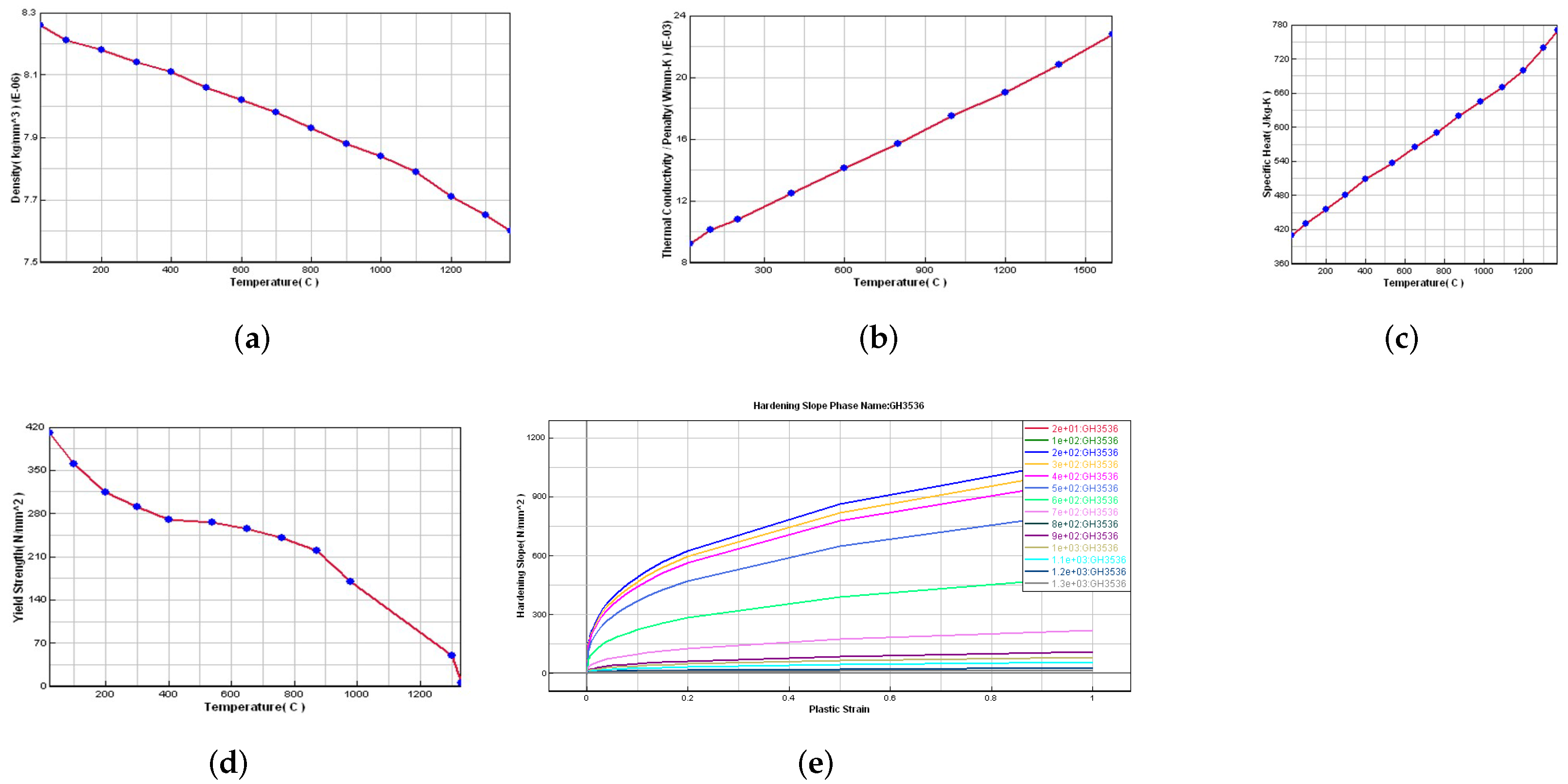

2.2. Establishment of Material Database for Nickel-Base Superalloy GH3536

2.3. Selection of Heat Source Model

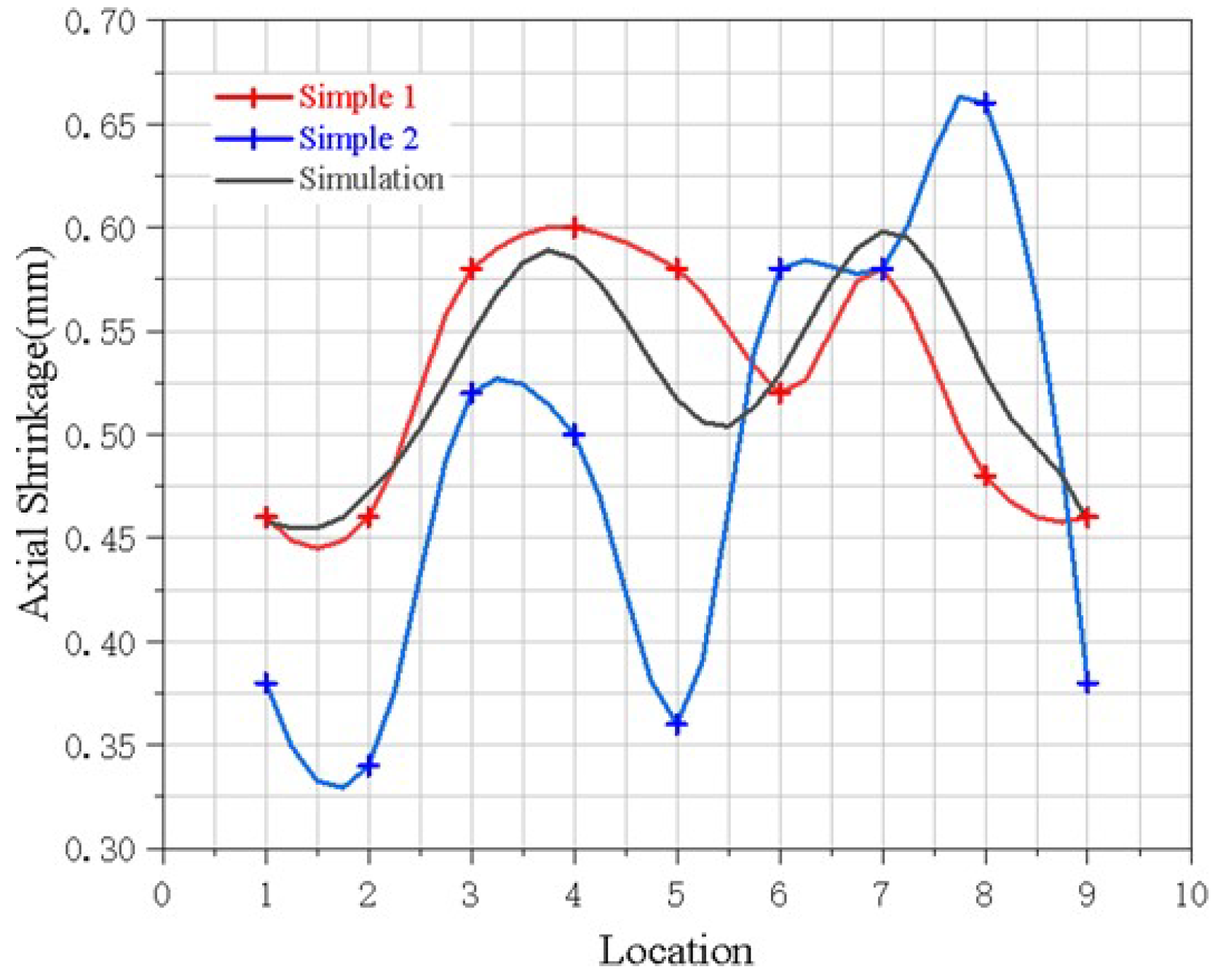

3. Experiment

4. Influence of Clamping Conditions on Welding Stress and Deformation

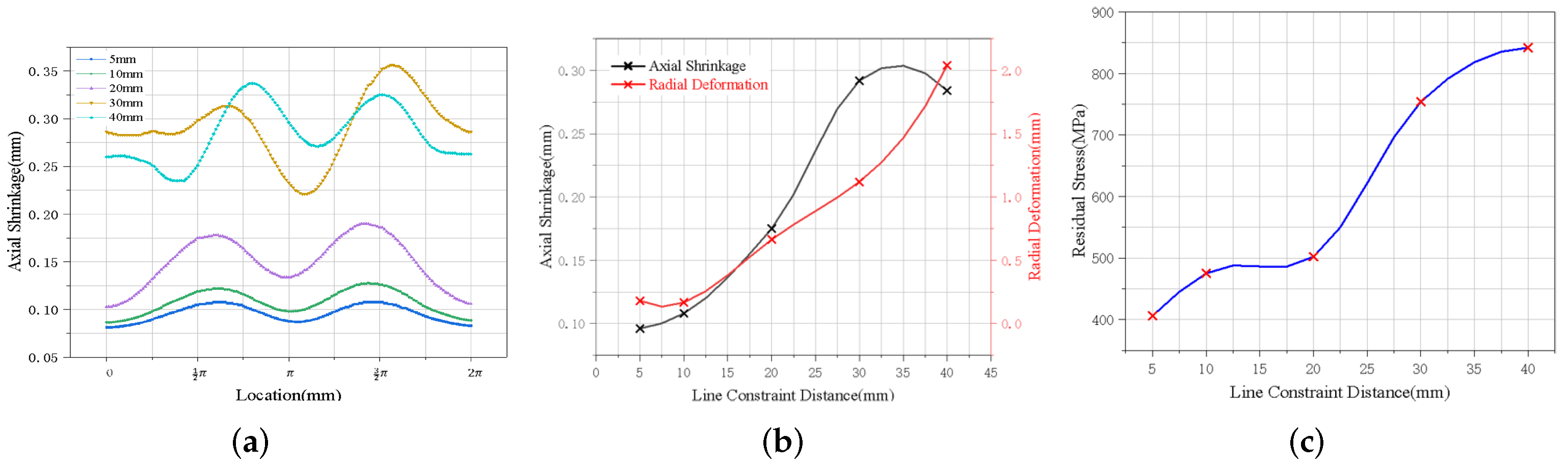

4.1. Influence of Line Restraint Distance on Welding Stress and Deformation

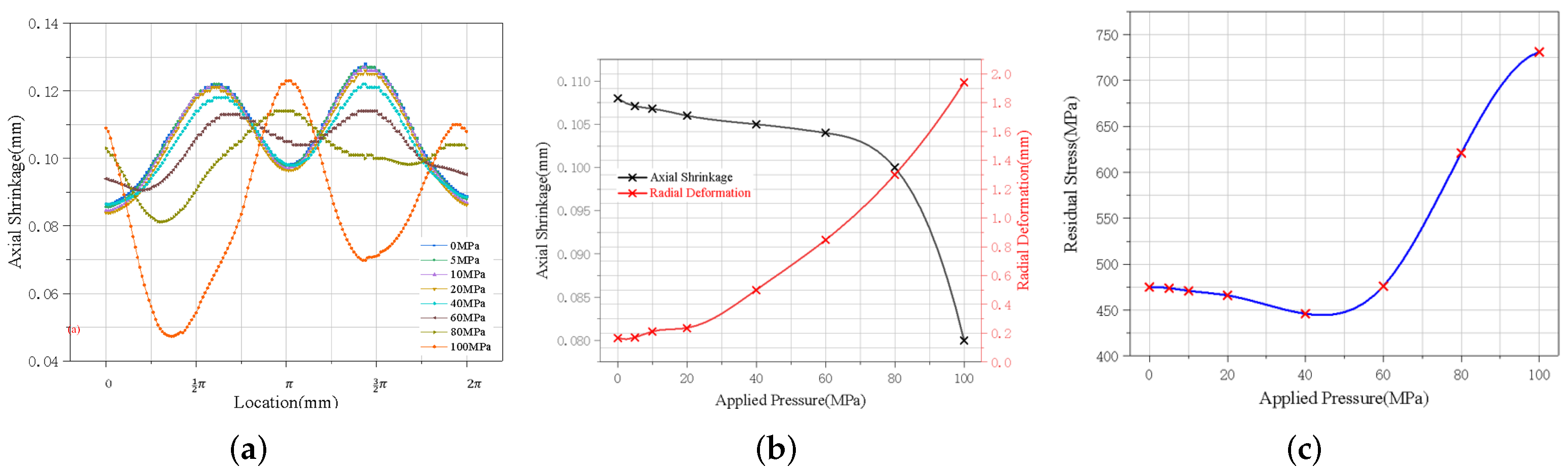

4.2. Influence of Applied Pressure on Welding Stress and Deformation

5. Optimization of Clamping Conditions

5.1. Determination of Comprehensive Evaluation Function

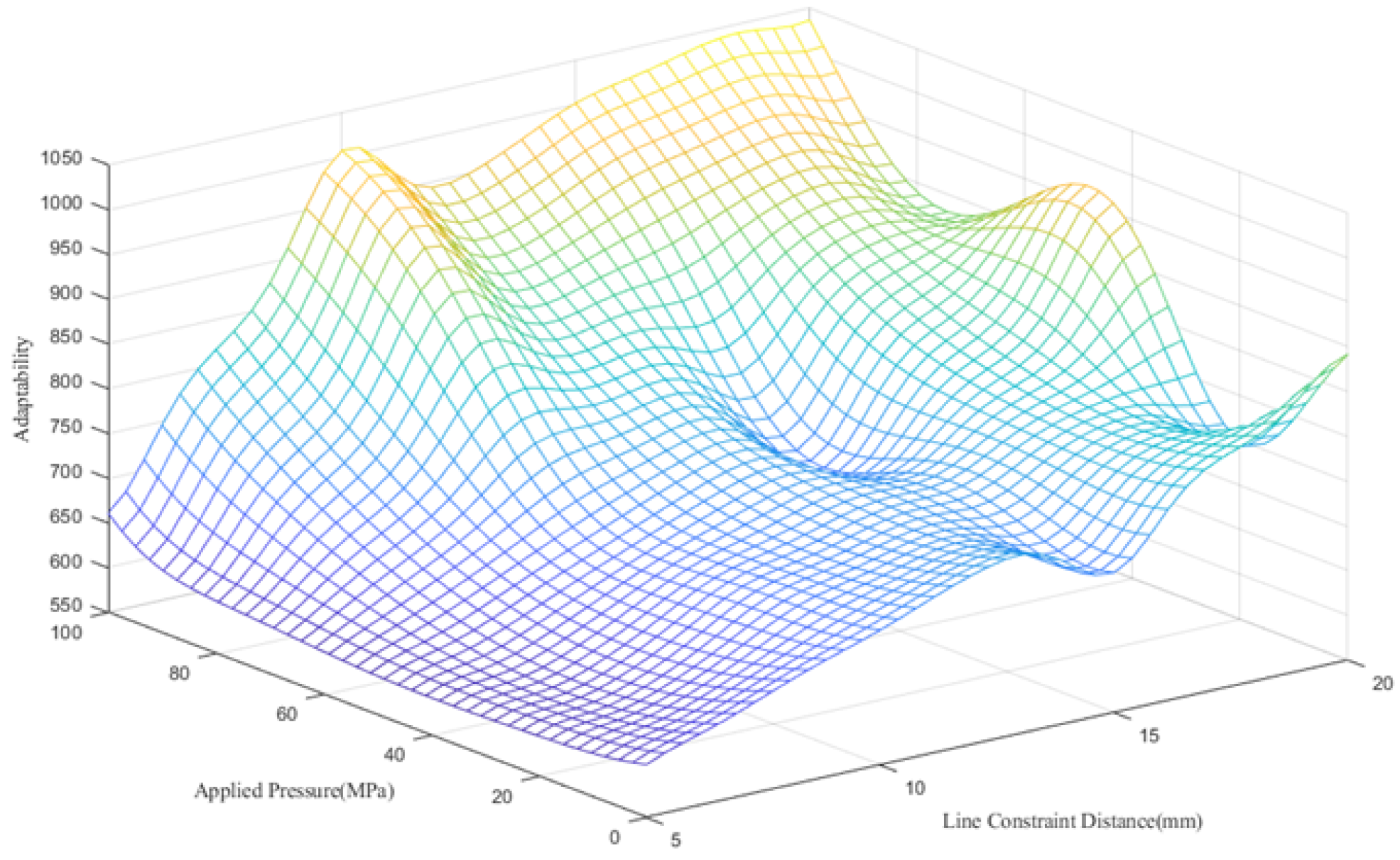

5.2. Determination of Kriging Model

5.3. Particle Swarm Optimization Algorithm (PSO)

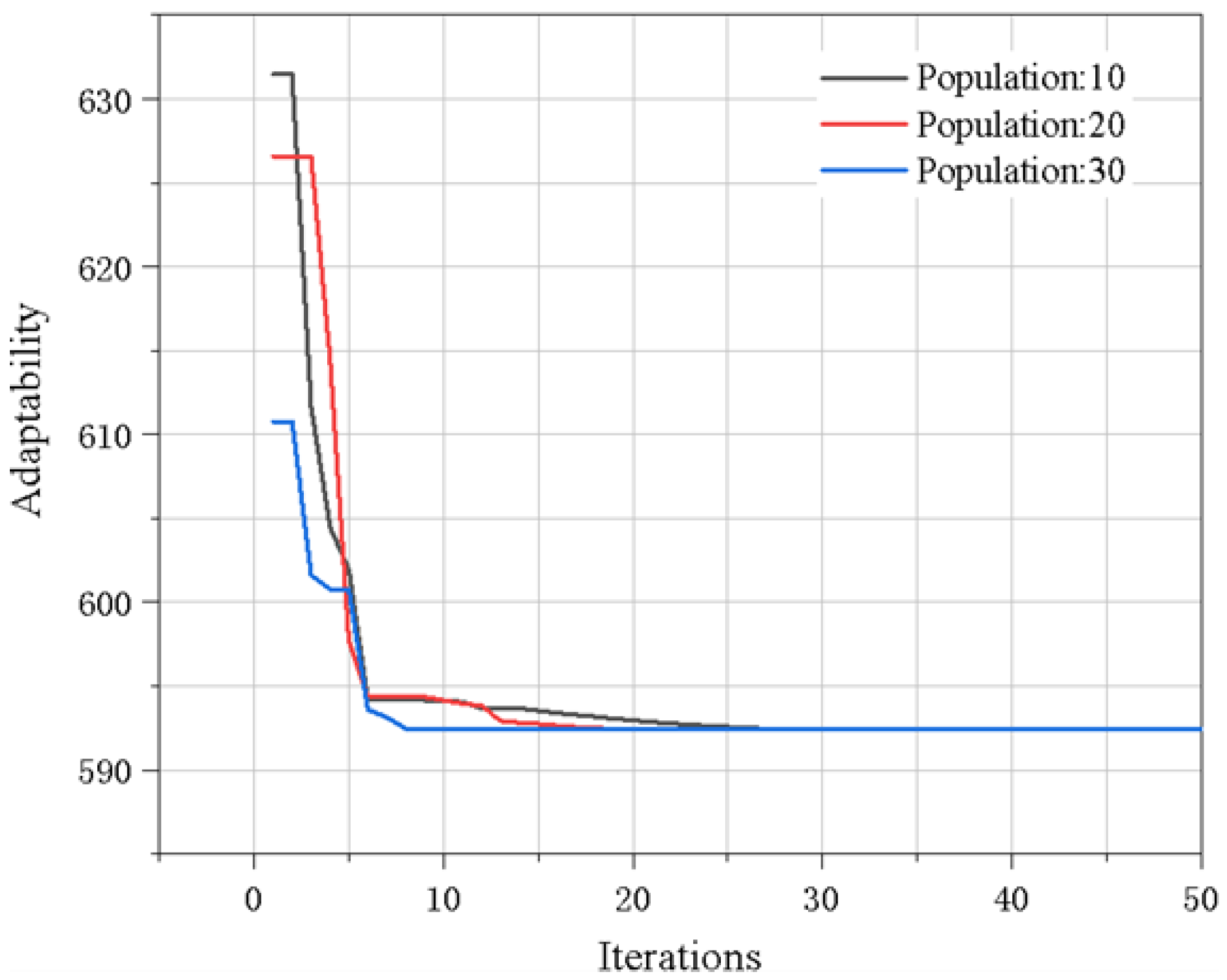

5.3.1. Theory of PSO

5.3.2. The Optimization Results of the Fixture Scheme of the Flame Cylinder

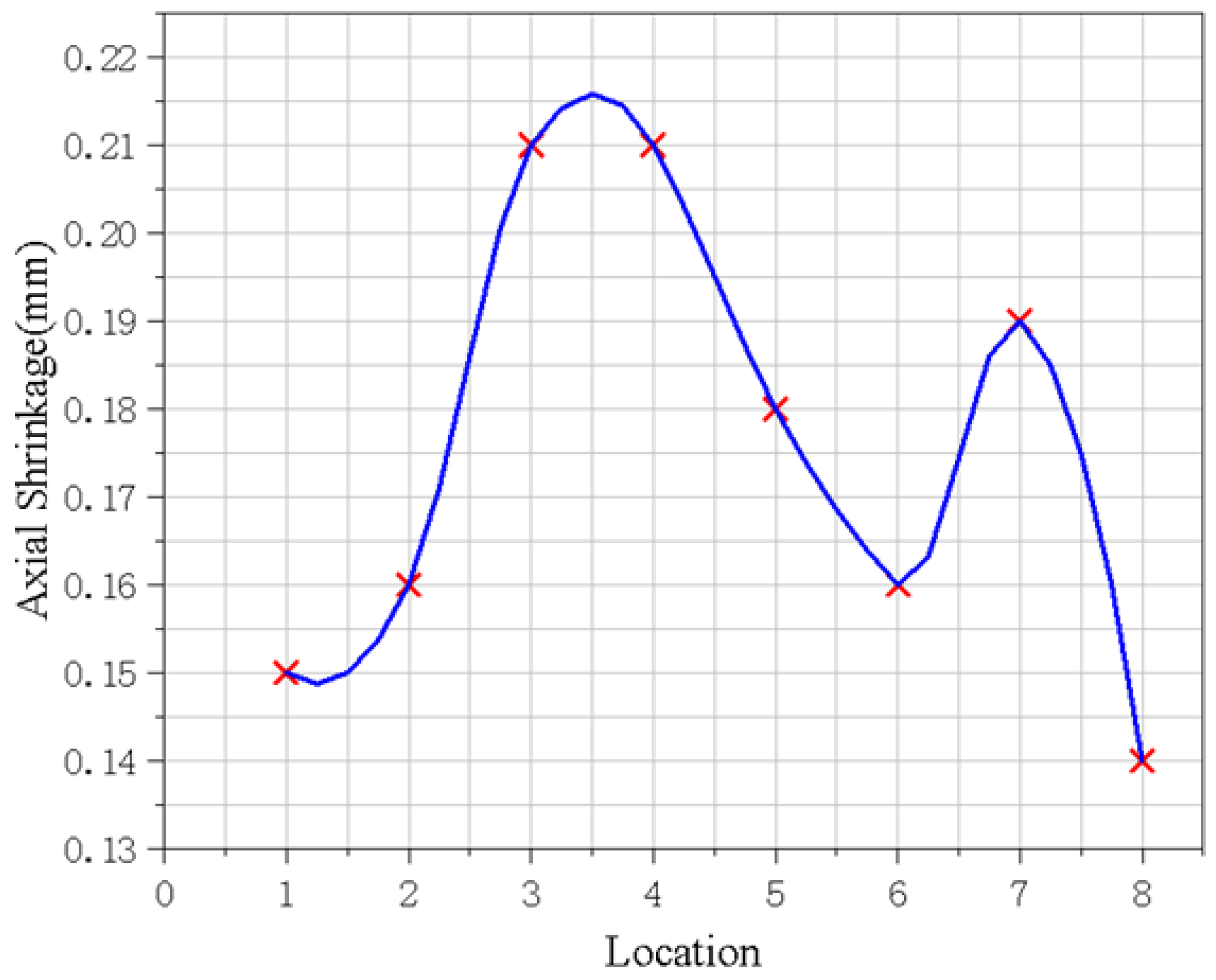

5.3.3. Experimental Verification of the Optimized Fixture Scheme

6. Conclusions

- (1)

- The simulation results of different line constraint clamping schemes show that applying line constraints near the weld can effectively reduce the axial deformation of the outer ring of the flame cylinder and the highest residual stress. Applying different pressures near the line clamping constraint can reduce the axial deformation and improve the residual stress distribution, but the radial deformation will increase. When the applied pressure exceeds 60 MPa, the excessive applied pressure will cause instability and deformation in the thin-walled parts.

- (2)

- Through the particle swarm optimization algorithm, the clamping condition scheme with a comprehensive optimal evaluation of welding deformation and residual stress can be obtained: under the scheme of an online constraint distance of 5 mm and external pressure of 39.69 Mpa, the welding quality of the flame barrel is better, the average axial deformation is reduced from 0.52 mm to 0.091 mm, the axial shrinkage is reduced by 82.5%, and the maximum radial shrinkage is reduced by 60.6%, compared with the original clamping scheme. The maximum residual stress is reduced by 60.3%.

- (3)

- By changing the initial clamping force of the clamp on the workpiece, an external pressure of 39.69 MPa is achieved, in which the width of the bead is 2 mm and the distance from the weld is 5 mm. The initial clamping force is about 46 kn. The average axial deformation of the outer ring part of the flame barrel after welding is 0.17 mm, which is 63.0% less than that before the optimization of the clamping conditions and 0.2 mm less than the process requirements. The optimized clamp meets the process requirements.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, B. Status and Development of Aeroengine Combustors. Aeroengine 2013, 39, 67–73. [Google Scholar]

- Su, H.; Chang, R.; Ni, J. Welding simulation based on SYSWELD. J. Dalian Jiaotong Univ. 2013, 34, 79–82. [Google Scholar]

- Ji, Y. The Status and Development of the Numerical Simulations of an Aero-Engine Combustion Chamber. Aero-Engine 2003, 29, 25–29. [Google Scholar]

- Zhao, L.; Xu, L.; Nikbin, K. Predicting failure modes in creep and creep-fatigue crack growth using a random grain/grain boundary idealised microstructure meshing system. Mater. Sci. Eng. A 2017, 704, 274–286. [Google Scholar] [CrossRef]

- Wang, J.H.; Lu, H. Some Discussions on Principle of Causing and Relieving Welding Residual Stress. Trans. China Weld. Inst. 2002, 3, 75–79. [Google Scholar]

- Deng, D.; Murakawa, H. Prediction of welding distortion and residual stress in a thin plate butt-welded joint. Comput. Mater. Sci. 2008, 43, 353–365. [Google Scholar] [CrossRef]

- Ueda, Y.; Murakawa, H.; Ma, N. Welding Deformation and Residual Stress Prevention; Elsevier: Amsterdam, The Netherlands, 2012. [Google Scholar]

- Wang, J.; Chen, X.; Yang, L.; Zhang, G. Sequentially combined thermo-mechanical and mechanical simulation of double-pulse MIG welding of 6061-T6 aluminum alloy sheets. J. Manuf. Process. 2022, 77, 616–631. [Google Scholar] [CrossRef]

- Lu, Z.; Han, X.; Lun, W. Application of welding process in commercial aircraft engines. Weld. Join. 2016. [Google Scholar]

- Guo, Y.; Wu, D.; Ma, G.; Yang, Y.B.; Tong, Y.; Guo, D.M. Influence of fixture restraint distance on pulsed laser welding distortion of Hastelloy C-276 thin sheet. Opt. Precis. Eng. 2012, 20, 2465–2471. [Google Scholar] [CrossRef]

- Ma, N.; Huang, H. Efficient simulation of welding distortion in large structures and its reduction by jig constraints. J. Mater. Eng. Perform. 2017, 26, 5206–5216. [Google Scholar] [CrossRef]

- Tang, Y.B. Study on Welding Deformation and Optimization of Fixture Scheme for Large Scale thin-walled Structures. Master’s Thesis, Shanghai Jiao Tong University, Shanghai, China, 2019. [Google Scholar]

- Wang, C.; Tang, W.C. Numerical simulation of flange welding deformation based on dynamic restraint. Trans. China Weld. Inst. 2020, 41, 8. [Google Scholar]

- Ding, Q.; Bei, H.; Wei, X.; Gao, Y.; Zhang, Z. Nano-twin-induced exceptionally superior cryogenic mechanical properties of a Ni-based GH3536 (Hastelloy X) superalloy. Mater. Today Nano 2021, 14, 100110. [Google Scholar] [CrossRef]

- Chandra, K.; Singhal, R.; Kain, V.; Raja, V. Low temperature embrittlement of duplex stainless steel: Correlation between mechanical and electrochemical behavior. Mater. Sci. Eng. A 2010, 527, 3904–3912. [Google Scholar] [CrossRef]

- Sridhar, N.; Kolts, J. Effects of nitrogen on the selective dissolution of a duplex stainless steel. Corrosion 1987, 43, 646–651. [Google Scholar] [CrossRef]

- China Aviation Materials Manual Commission. China Aviation Materials Manual; Tsinghua University Press: Beijing, China, 2002. [Google Scholar]

- LI, M.s.; Wang, C.b. Exploration of Applicability on Heat Source Model in TIG Welding. Hot Work Technol. 2007, 15, 70–72. [Google Scholar]

- Liu, Z.; Zhang, J.; Wang, C.; Tan, C.; Sun, J. Hybrid structure reliability method combining optimized Kriging model and importance sampling. Acta Aeronaut. Astronaut. Sin. 2013, 34, 1347–1355. [Google Scholar]

- Saternus, Z.; Piekarska, W. Numerical analysis of thermomechanical phenomena in laser welded pipe-to-flat. Procedia Eng. 2017, 177, 196–203. [Google Scholar] [CrossRef]

- Wang, G.; Zhao, G.; Li, H.; Guan, Y. Multi-objective optimization design of the heating/cooling channels of the steam-heating rapid thermal response mold using particle swarm optimization. Int. J. Therm. Sci. 2011, 50, 790–802. [Google Scholar] [CrossRef]

- Wang, J.; Sun, Z. The stepwise accuracy-improvement strategy based on the Kriging model for structural reliability analysis. Struct. Multidiscip. Optim. 2018, 58, 595–612. [Google Scholar] [CrossRef]

- Ma, X.y.; Sun, Z.l.; Zhang, Y.b.; Zang, X. Optimization of welding process parameters based on kriging-PSO intelligent algorithm. J. Northeast. Univ. (Nat. Sci.) 2019, 40, 370. [Google Scholar]

- Shi, Y.; Eberhart, R. A modified particle swarm optimizer. In Proceedings of the 1998 IEEE International Conference on Evolutionary Computation Proceedings. IEEE World Congress on Computational Intelligence (Cat. No.98TH8360), Anchorage, AK, USA, 4–9 May 1998; IEEE: Piscataway, NJ, USA, 1998; pp. 69–73. [Google Scholar]

- Kennedy, J.; Eberhart, R. Particle Swarm Optimization. In Proceedings of the Icnn95-international Conference on Neural Networks, Perth, WA, Australia, 27 November–1 December 1995. [Google Scholar]

- Yi, W.; Xiao-meng, L.; Guo-hua, G.; Lin, Z.; Yan-zhong, D. Hybrid Particle Swarm Optimization Algorithm Based on Intuitionistic Fuzzy Entropy. Acta Electonica Sin. 2021, 49, 2381. [Google Scholar]

- Wang, Y.; Han, Z.; Yang, Z.; Lu, C.; Xue, X. Time-varying reliability analysis of compressor blisk based on particle swash optimization extreme Kriging model. Xibei Gongye Daxue Xuebao/J. Northwestern Polytech. Univ. 2021, 39, 1240–1248. [Google Scholar] [CrossRef]

- Lin, X.; Li, K.; Wang, L. A driving-style-oriented adaptive control strategy based PSO-fuzzy expert algorithm for a plug-in hybrid electric vehicle. Expert Syst. Appl. 2022, 201, 117236. [Google Scholar] [CrossRef]

- Marini, F.; Walczak, B. Particle swarm optimization (PSO). A tutorial. Chemom. Intell. Lab. Syst. 2015, 149, 153–165. [Google Scholar] [CrossRef]

| C | Cr | Ni | Co | W | Mo | Fe |

|---|---|---|---|---|---|---|

| 0.05–0.15 | 20.5–23.0 | remaining | 0.50–2.50 | 0.20–1.00 | 8.0–10.0 | 17.0–20.0 |

| Al | Ti | B | Cu | Mn | Si | P |

| Not more than | ||||||

| 0.5 | 0.15 | 0.010 | 0.05 | 1.00 | 1.00 | 0.025 |

| Current (A) | Voltage (U) | Stick Out Distance (mm) | Welding Speed (mm/s) | Heat Input (KJ/mm) | |

|---|---|---|---|---|---|

| Sample 1 | 17 | 10 | 1 | 2.14 | 0.079 |

| Sample 2 | 16 | 12 | 2 | 2.14 | 0.090 |

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | Average (mm) | ||

|---|---|---|---|---|---|---|---|---|---|---|

| Part 0 | Before | 66.3 | 66.3 | 66.3 | 66.3 | 66.3 | 66.3 | 66.3 | 66.3 | 66.3 |

| After | 65.842 | 65.828 | 65.752 | 65.715 | 65.783 | 65.771 | 65.702 | 65.771 | 65.77 | |

| Part 1 | Before | 66.34 | 66.24 | 66.36 | 66.28 | 66.26 | 66.26 | 66.28 | 66.46 | 66.31 |

| After | 65.88 | 65.78 | 65.78 | 65.68 | 65.68 | 65.74 | 65.7 | 65.98 | 65.78 | |

| Part 2 | Before | 66.32 | 66.2 | 66.1 | 65.98 | 66 | 66.1 | 66.18 | 66.22 | 66.13 |

| After | 65.94 | 65.86 | 65.58 | 65.48 | 65.64 | 65.52 | 65.6 | 65.56 | 65.65 |

| Distance (mm) | Pressure (MPa) | Axial (mm) | Radial (mm) | Residual Stress (MPa) | Value |

|---|---|---|---|---|---|

| 5.00 | 0.00 | 0.10 | 0.18 | 406.41 | 609.24 |

| 5.00 | 20.00 | 0.09 | 0.25 | 393.45 | 595.43 |

| 5.00 | 40.00 | 0.09 | 0.50 | 378.89 | 592.40 |

| 5.00 | 60.00 | 0.09 | 0.88 | 363.57 | 598.07 |

| 5.00 | 80.00 | 0.09 | 1.37 | 346.69 | 608.97 |

| 20.00 | 80.00 | 0.11 | 2.54 | 507.26 | 889.38 |

| 20.00 | 100.00 | 0.11 | 3.15 | 618.59 | 1035.53 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Li, Y.; Ma, X.; Zhang, X.; Fu, D.; Yan, Q. Study on Welding Deformation and Optimization of Fixture Scheme for Thin-Walled Flame Cylinder. Materials 2022, 15, 6418. https://doi.org/10.3390/ma15186418

Li Y, Li Y, Ma X, Zhang X, Fu D, Yan Q. Study on Welding Deformation and Optimization of Fixture Scheme for Thin-Walled Flame Cylinder. Materials. 2022; 15(18):6418. https://doi.org/10.3390/ma15186418

Chicago/Turabian StyleLi, Yi, Yihao Li, Xiuping Ma, Xuhao Zhang, Dingyao Fu, and Qitong Yan. 2022. "Study on Welding Deformation and Optimization of Fixture Scheme for Thin-Walled Flame Cylinder" Materials 15, no. 18: 6418. https://doi.org/10.3390/ma15186418

APA StyleLi, Y., Li, Y., Ma, X., Zhang, X., Fu, D., & Yan, Q. (2022). Study on Welding Deformation and Optimization of Fixture Scheme for Thin-Walled Flame Cylinder. Materials, 15(18), 6418. https://doi.org/10.3390/ma15186418