Micro-Mechanical Properties of Slag Rim Formed in Cement–Slag System Evaluated by Nanoindentation Combined with SEM

Abstract

:1. Introduction

2. Materials and Methodology

2.1. Sample Information

2.2. Experimental Methods

2.3. Analytical Methods

3. Results

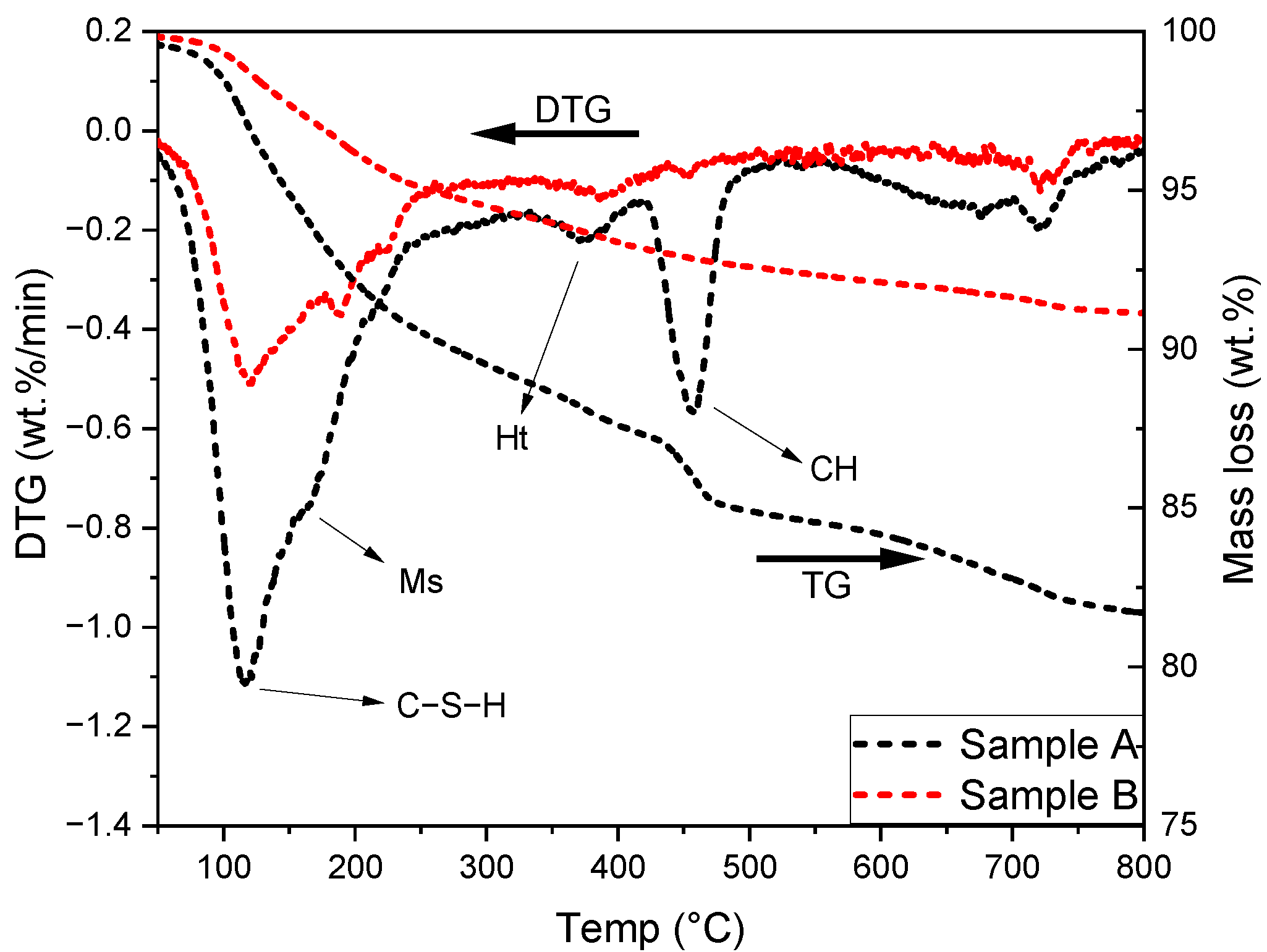

3.1. Subsection Hydration Products

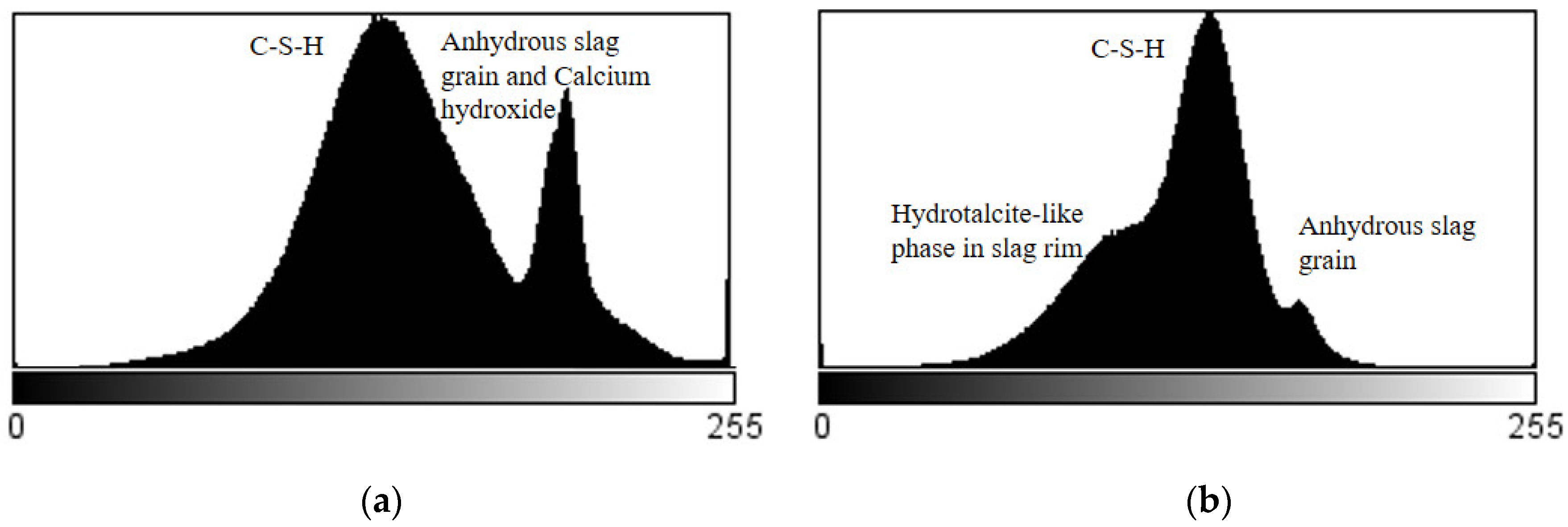

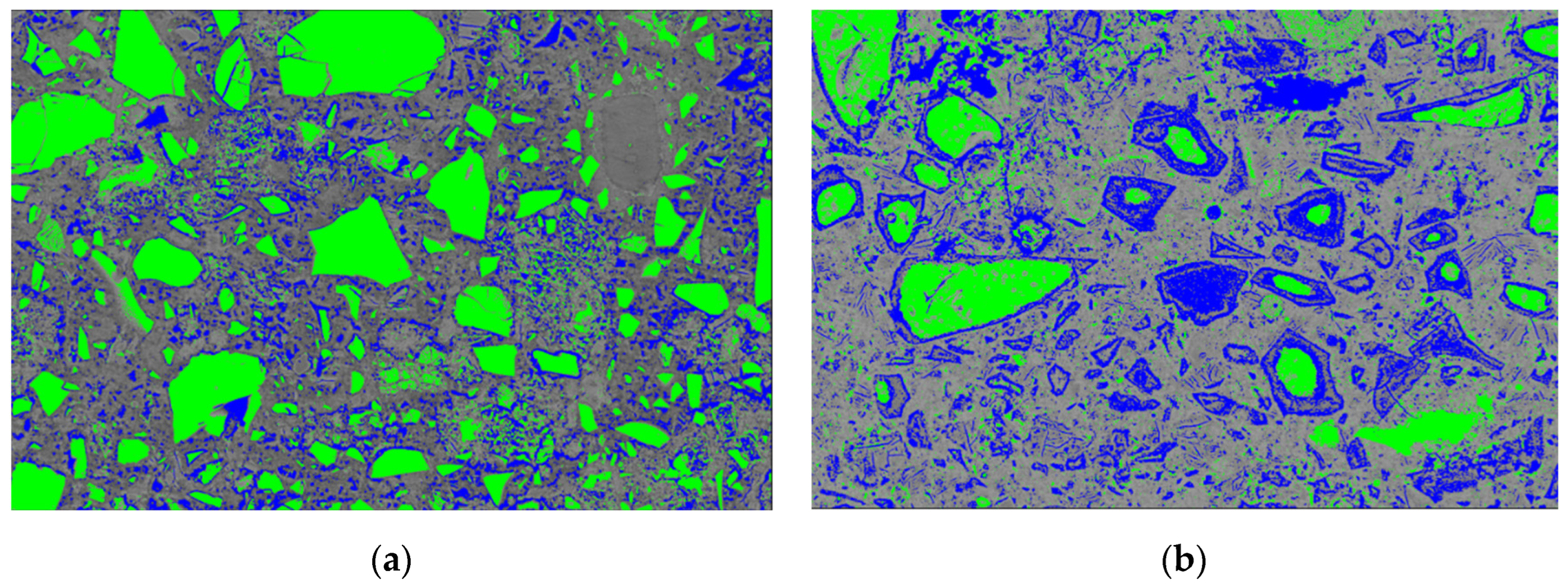

3.2. Microstructure Characterization

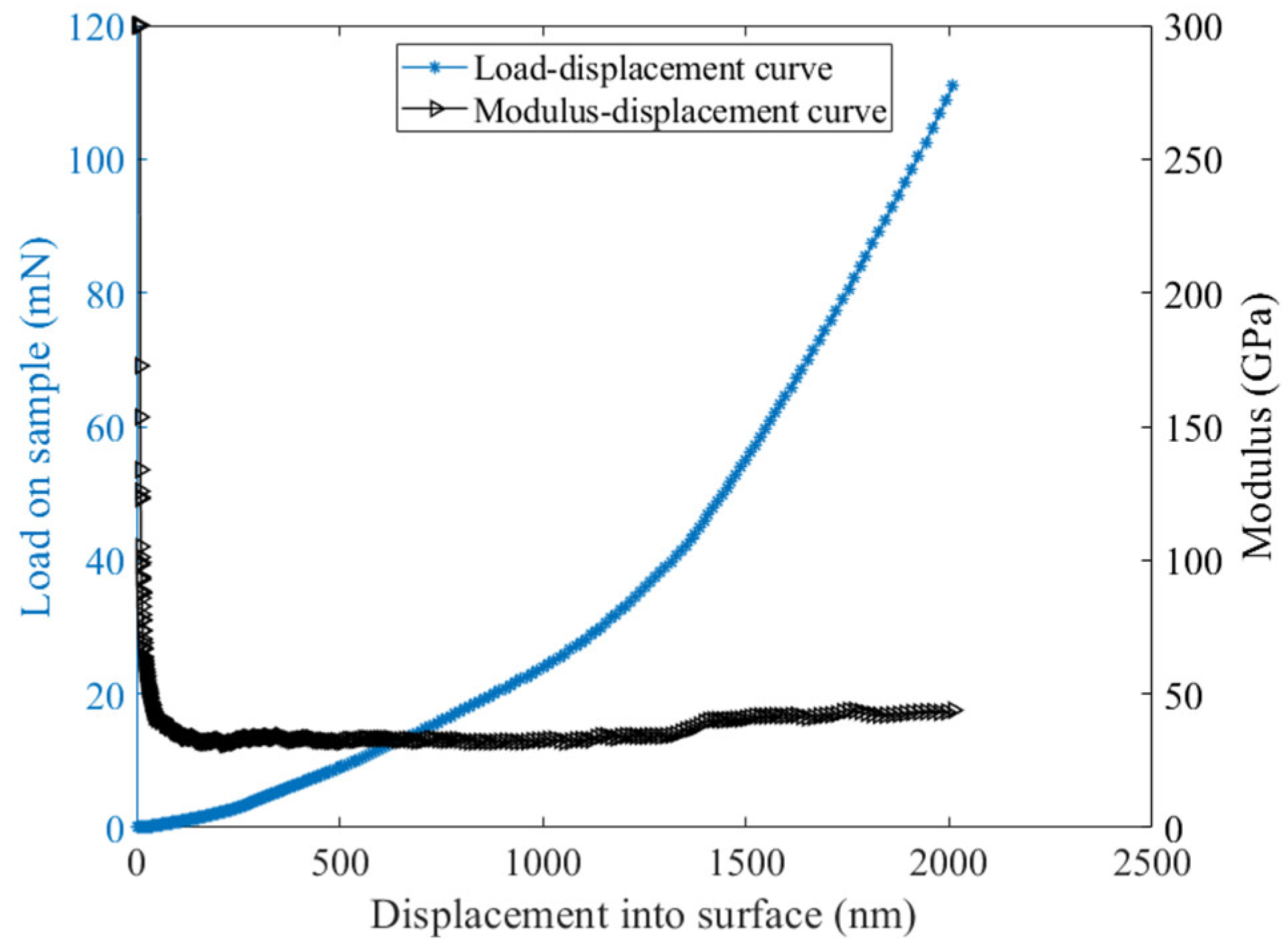

3.3. Micro-Mechanical Properties of Slag Rim

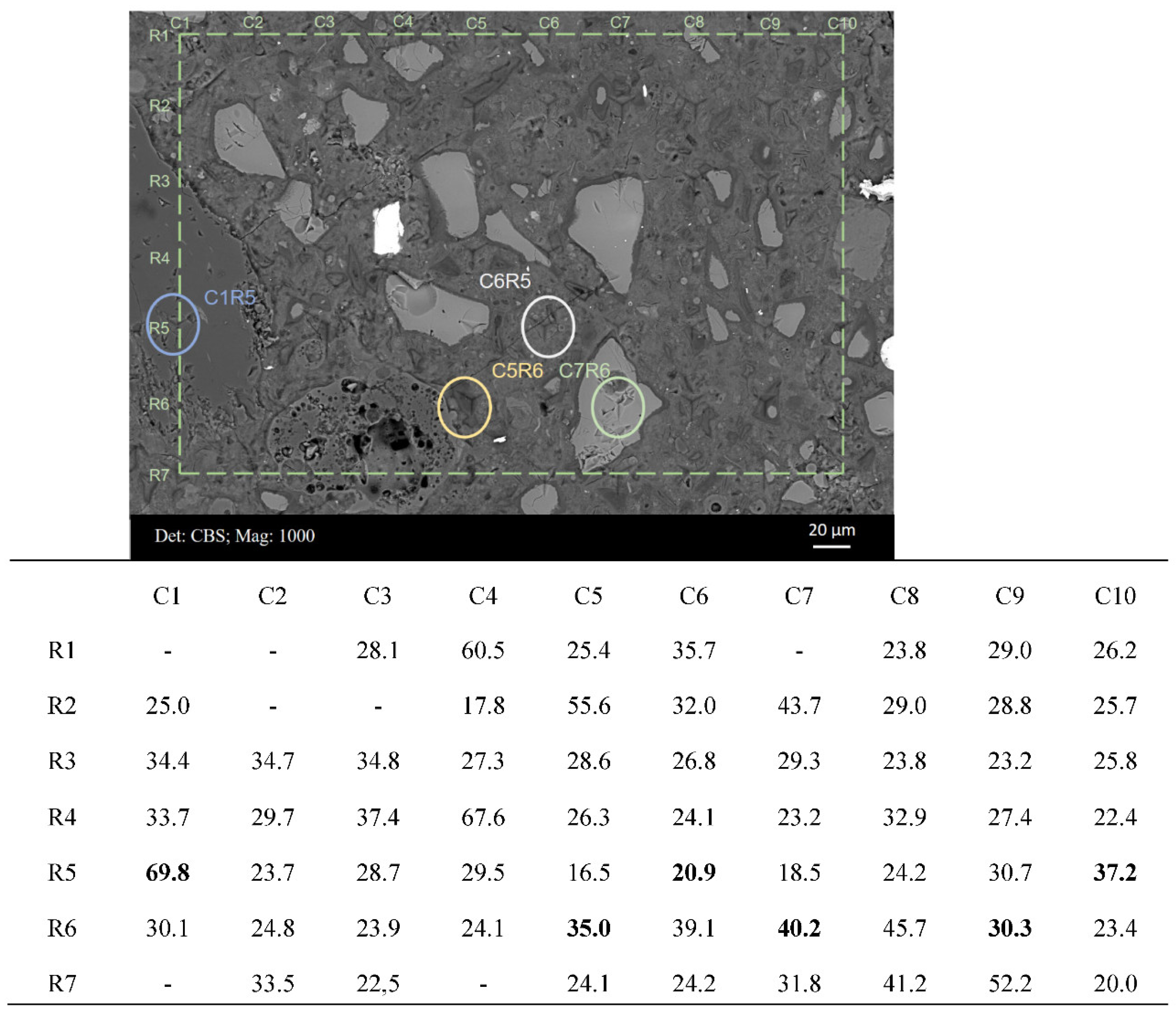

3.3.1. Nanoindentation Combined with SEM-EDS

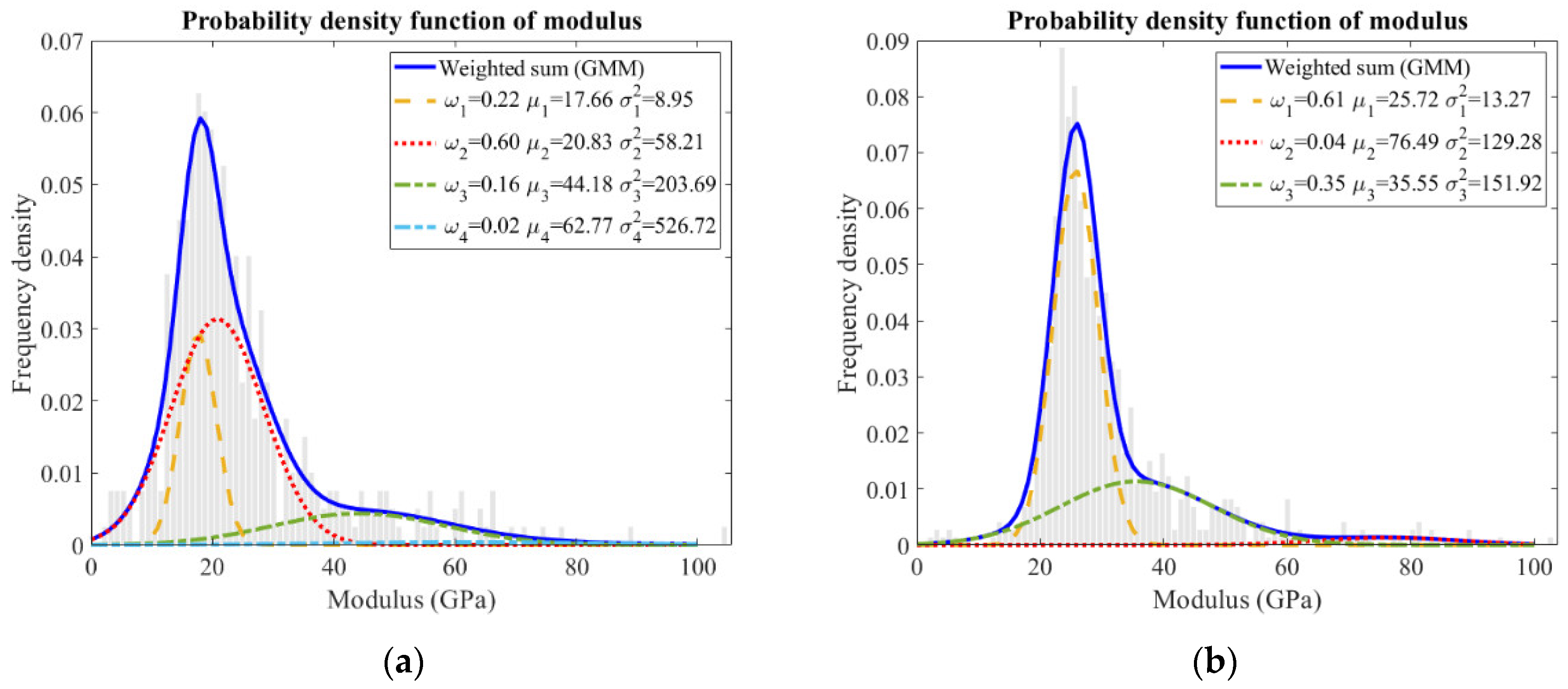

3.3.2. Frequency Histogram of Indentation Modulus and Hardness

4. Discussion

5. Conclusions

- (1)

- First, ~15 GPa higher modulus was obtained for slag rim compared with that of the C–S–H gel phase. Considering that the modulus of the C–S–H gel phase commonly varied around 20 GPa and it was in the range of 30~40 GPa for slag rim, it was concluded reasonably that the indentation modulus of the hydrotalcite-like phase was larger than ~40 GPa roughly.

- (2)

- At early age, slag cement paste mainly consisted of low-density C–S–H gel phase, high-density C–S–H gel phase, and unhydrated slag particles, as well as calcium hydroxide; at later age, the system contained C–S–H gel phase, slag rim (a mixture of C–S–H gel phase and hydrotalcite-like phase), and unhydrated slag particles.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bijen, J. Benefits of slag and fly ash. Constr. Build. Mater. 1996, 10, 309–314. [Google Scholar] [CrossRef]

- Juenger, M.; Winnefeld, F.; Provis, J.L.; Ideker, J.J. Advances in alternative cementitious binders. Cem. Concr. Res. 2011, 41, 1232–1243. [Google Scholar] [CrossRef]

- Crossin, E. The greenhouse gas implications of using ground granulated blast furnace slag as a cement substitute. J. Clean. Prod. 2015, 95, 101–108. [Google Scholar] [CrossRef]

- Li, Y.; Liu, Y.; Gong, X.; Nie, Z.; Cui, S.; Wang, Z.; Chen, W. Environmental impact analysis of blast furnace slag applied to ordinary Portland cement production. J. Clean. Prod. 2016, 120, 221–230. [Google Scholar] [CrossRef]

- Chen, W.; Brouwers, H. The hydration of slag, part 2: Reaction models for blended cement. J. Mater. Sci. 2007, 42, 444–464. [Google Scholar] [CrossRef]

- Taylor, H.F. Cement Chemistry; Thomas Telford: London, UK, 1997; Volume 2. [Google Scholar]

- Richardson, I. Tobermorite/jennite-and tobermorite/calcium hydroxide-based models for the structure of CSH: Applicability to hardened pastes of tricalcium silicate, β-dicalcium silicate, Portland cement, and blends of Portland cement with blast-furnace slag, metakaolin, or silica fume. Cem. Concr. Res. 2004, 34, 1733–1777. [Google Scholar]

- Luke, K.; Lachowski, E. Internal composition of 20-year-old fly ash and slag-blended ordinary Portland cement pastes. J. Am. Ceram. Soc. 2008, 91, 4084–4092. [Google Scholar] [CrossRef]

- Taylor, R.; Richardson, I.; Brydson, R. Composition and microstructure of 20-year-old ordinary Portland cement–ground granulated blast-furnace slag blends containing 0 to 100% slag. Cem. Concr. Res. 2010, 40, 971–983. [Google Scholar] [CrossRef]

- He, Z.; Qian, C.; Zhang, Y.; Zhao, F.; Hu, Y. Nanoindentation characteristics of cement with different mineral admixtures. Sci. China Technol. Sci. 2013, 56, 1119–1123. [Google Scholar] [CrossRef]

- Hu, C.; Li, Z.; Gao, Y.; Han, Y.; Zhang, Y. Investigation on microstructures of cementitious composites incorporating slag. Adv. Cem. Res. 2014, 26, 222–232. [Google Scholar] [CrossRef]

- Zadeh, V.Z.; Bobko, C.P. Nanoscale mechanical properties of concrete containing blast furnace slag and fly ash before and after thermal damage. Cem. Concr. Compos. 2013, 37, 215–221. [Google Scholar] [CrossRef]

- Plassard, C.; Lesniewska, E.; Pochard, I.; Nonat, A. Intrinsic elastic properties of Calcium Silicate Hydrates by nanoindentation. In Proceedings of the 12th International Congress on the Chemistry of Cement, Montreal, QC, Canada, 8–13 July 2007; p. 44. [Google Scholar]

- Thomas, R.; Gebregziabiher, B.S.; Giffin, A.; Peethamparan, S. Micromechanical properties of alkali-activated slag cement binders. Cem. Concr. Compos. 2018, 90, 241–256. [Google Scholar] [CrossRef]

- Ma, Y.; Ye, G.; Hu, J. Micro-mechanical properties of alkali-activated fly ash evaluated by nanoindentation. Constr. Build. Mater. 2017, 147, 407–416. [Google Scholar] [CrossRef]

- Hu, C.; Li, Z. Property investigation of individual phases in cementitious composites containing silica fume and fly ash. Cem. Concr. Compos. 2015, 57, 17–26. [Google Scholar] [CrossRef]

- Rong, Z.; Sun, W.; Xiao, H.; Wang, W. Effect of silica fume and fly ash on hydration and microstructure evolution of cement based composites at low water–binder ratios. Constr. Build. Mater. 2014, 51, 446–450. [Google Scholar] [CrossRef]

- Zadeh, V.Z.; Bobko, C. Nanomechanical characteristics of lightweight aggregate concrete containing supplementary cementitious materials exposed to elevated temperature. Constr. Build. Mater. 2014, 51, 198–206. [Google Scholar] [CrossRef]

- Copuroglu, O.; Schlangen, H. Selective nanoindentation analysis on polished-thin sections. In Proceedings of the 12th Euroseminar on Microscopy Applied to Building Materials, Dortmund, Germany, 15–19 September 2009; pp. 264–270. [Google Scholar]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Bückle, H. Use of the hardness test to determine other material properties. In The Science of Hardness Testing Its Research Applications; American Society for Metals: Cleveland, OH, USA, 1973; Volume 453. [Google Scholar]

- Chen, J.J.; Sorelli, L.; Vandamme, M.; Ulm, F.J.; Chanvillard, G. A Coupled nanoindentation/SEM-EDS study on low water/cement ratio Portland cement paste: Evidence for C–S–H/Ca(OH)2 nanocomposites. J. Am. Ceram. Soc. 2010, 93, 1484–1493. [Google Scholar] [CrossRef]

- Krakowiak, K.J.; Thomas, J.J.; Musso, S.; James, S.; Akono, A.-T.; Ulm, F.-J. Nano-chemo-mechanical signature of conventional oil-well cement systems: Effects of elevated temperature and curing time. Cem. Concr. Res. 2015, 67, 103–121. [Google Scholar] [CrossRef]

- Tabor, D. A simple theory of static and dynamic hardness. Proc. R. Soc. London. Ser. A. Math. Phys. Sci. 1948, 192, 247–274. [Google Scholar]

- Constantinides, G.; Ulm, F.-J. The nanogranular nature of C–S–H. J. Mech. Phys. Solids 2007, 55, 64–90. [Google Scholar] [CrossRef]

- Němeček, J.; Králík, V.; Vondřejc, J. Micromechanical analysis of heterogeneous structural materials. Cem. Concr. Compos. 2013, 36, 85–92. [Google Scholar] [CrossRef]

- Bishop, C.M. Pattern Recognition and Machine Learning; Springer: Berlin/Heidelberg, Germany, 2006; Volume 128. [Google Scholar]

- Scrivener, K.; Snellings, R.; Lothenbach, B. A Practical Guide to Microstructural Analysis of Cementitious Materials; CRC Press: New York, NY, USA, 2016. [Google Scholar]

- Kocaba, V.; Gallucci, E.; Scrivener, K.L. Methods for determination of degree of reaction of slag in blended cement pastes. Cem. Concr. Res. 2012, 42, 511–525. [Google Scholar] [CrossRef]

- Hu, C.; Li, Z. A review on the mechanical properties of cement-based materials measured by nanoindentation. Constr. Build. Mater. 2015, 90, 80–90. [Google Scholar] [CrossRef]

- Constantinides, G.; Ulm, F.-J.; Van Vliet, K. On the use of nanoindentation for cementitious materials. Mater. Struct. 2003, 36, 191–196. [Google Scholar] [CrossRef]

- Constantinides, G.; Ulm, F.-J. The effect of two types of CSH on the elasticity of cement-based materials: Results from nanoindentation and micromechanical modeling. Cem. Concr. Res. 2004, 34, 67–80. [Google Scholar] [CrossRef]

- Davydov, D.; Jirasek, M.; Kopecký, L. Critical aspects of nano-indentation technique in application to hardened cement paste. Cem. Concr. Res. 2011, 41, 20–29. [Google Scholar] [CrossRef]

- Luke, K.; Glasser, F.P. Selective dissolution of hydrated blast furnace slag cements. Cem. Concr. Res. 1987, 17, 273–282. [Google Scholar] [CrossRef]

- Lumley, J.; Gollop, R.; Moir, G.; Taylor, H. Degrees of reaction of the slag in some blends with Portland cements. Cem. Concr. Res. 1996, 26, 139–151. [Google Scholar] [CrossRef]

- Miyata, S. Physico-chemical properties of synthetic hydrotalcites in relation to composition. Clays Clay Miner. 1980, 28, 50–56. [Google Scholar] [CrossRef]

- Miyata, S. Anion-exchange properties of hydrotalcite-like compounds. Clays Clay Miner. 1983, 31, 305–311. [Google Scholar] [CrossRef]

- Reichle, W.T. Synthesis of anionic clay minerals (mixed metal hydroxides, hydrotalcite). Solid State Ion. 1986, 22, 135–141. [Google Scholar] [CrossRef]

- Chen, J.J.; Thomas, J.J.; Taylor, H.F.; Jennings, H.M. Solubility and structure of calcium silicate hydrate. Cem. Concr. Res. 2004, 34, 1499–1519. [Google Scholar] [CrossRef]

- Haha, M.B.; Lothenbach, B.; Le Saout, G.; Winnefeld, F. Influence of slag chemistry on the hydration of alkali-activated blast-furnace slag—Part I: Effect of MgO. Cem. Concr. Res. 2011, 41, 955–963. [Google Scholar] [CrossRef]

- Bernal, S.A.; San Nicolas, R.; Myers, R.J.; de Gutiérrez, R.M.; Puertas, F.; van Deventer, J.S.; Provis, J.L. MgO content of slag controls phase evolution and structural changes induced by accelerated carbonation in alkali-activated binders. Cem. Concr. Res. 2014, 57, 33–43. [Google Scholar] [CrossRef] [Green Version]

| CaO | SiO2 | Al2O3 | MgO | FeO/Fe2O3 | TiO2 | MnO/Mn2O3 | Na2O | K2O | SO3 | Residual | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Cement | 64 | 20 | 5 | - | 3 | - | - | 0.58 | - | 2.93 | 4.49 |

| Slag | 37.04 | 37.79 | 14.51 | 8.83 | 0.28 | 0.70 | 0.17 | 0.24 | 0.25 | 0.01 | 0.18 |

| Phase | Pore | Hydrotalcite-Like Phase | C–S–H Gel Phase 1 | Anhydrous Slag Grains 2 |

|---|---|---|---|---|

| Grey Value | 0~50 | 50~100 | 100~160 | 160~255 |

| Sample A | 0.91 ± 0.25 | 8.62 ± 1.32 | 47.34 ± 4.12 | 43.13 ± 3.38 |

| Sample B | 0.32 ± 0.24 | 26.15 ± 2.46 | 51.59 ± 5.39 | 21.94 ± 2.79 |

| Aggregate | Unhydrated Slag Particle | C–S–H | Slag Rim | ||||

|---|---|---|---|---|---|---|---|

| Indent | C1R5 | C7R6 | C6R5 | C7R5 | C5R6 | C9R6 | C10R5 |

| Hardness | 4.80 | 3.00 | 0.62 | 0.45 | 0.64 | 0.96 | 0.98 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Liang, M.; Gan, Y.; Çopuroğlu, O. Micro-Mechanical Properties of Slag Rim Formed in Cement–Slag System Evaluated by Nanoindentation Combined with SEM. Materials 2022, 15, 6347. https://doi.org/10.3390/ma15186347

Zhang Y, Liang M, Gan Y, Çopuroğlu O. Micro-Mechanical Properties of Slag Rim Formed in Cement–Slag System Evaluated by Nanoindentation Combined with SEM. Materials. 2022; 15(18):6347. https://doi.org/10.3390/ma15186347

Chicago/Turabian StyleZhang, Yu, Minfei Liang, Yidong Gan, and Oğuzhan Çopuroğlu. 2022. "Micro-Mechanical Properties of Slag Rim Formed in Cement–Slag System Evaluated by Nanoindentation Combined with SEM" Materials 15, no. 18: 6347. https://doi.org/10.3390/ma15186347

APA StyleZhang, Y., Liang, M., Gan, Y., & Çopuroğlu, O. (2022). Micro-Mechanical Properties of Slag Rim Formed in Cement–Slag System Evaluated by Nanoindentation Combined with SEM. Materials, 15(18), 6347. https://doi.org/10.3390/ma15186347