A Short Overview of Recent Developments in the Application of Polymeric Materials for the Conservation of Stone Cultural Heritage Elements

Abstract

:1. Introduction

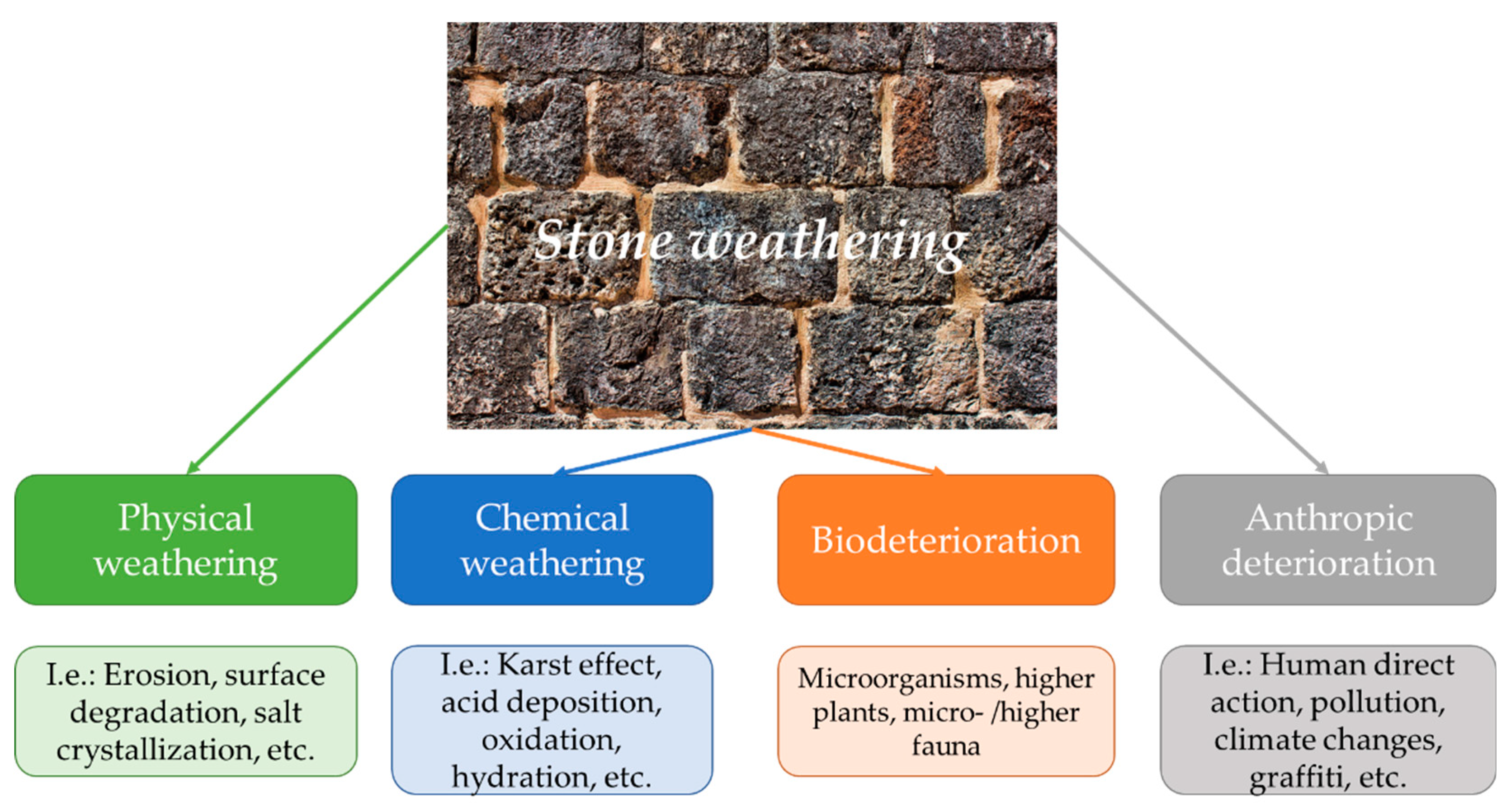

2. Deterioration of Natural Stones

2.1. Physical Weathering

2.2. Chemical Weathering

2.3. Biodeterioration

2.4. Deterioration Induced by other Anthropic Factors

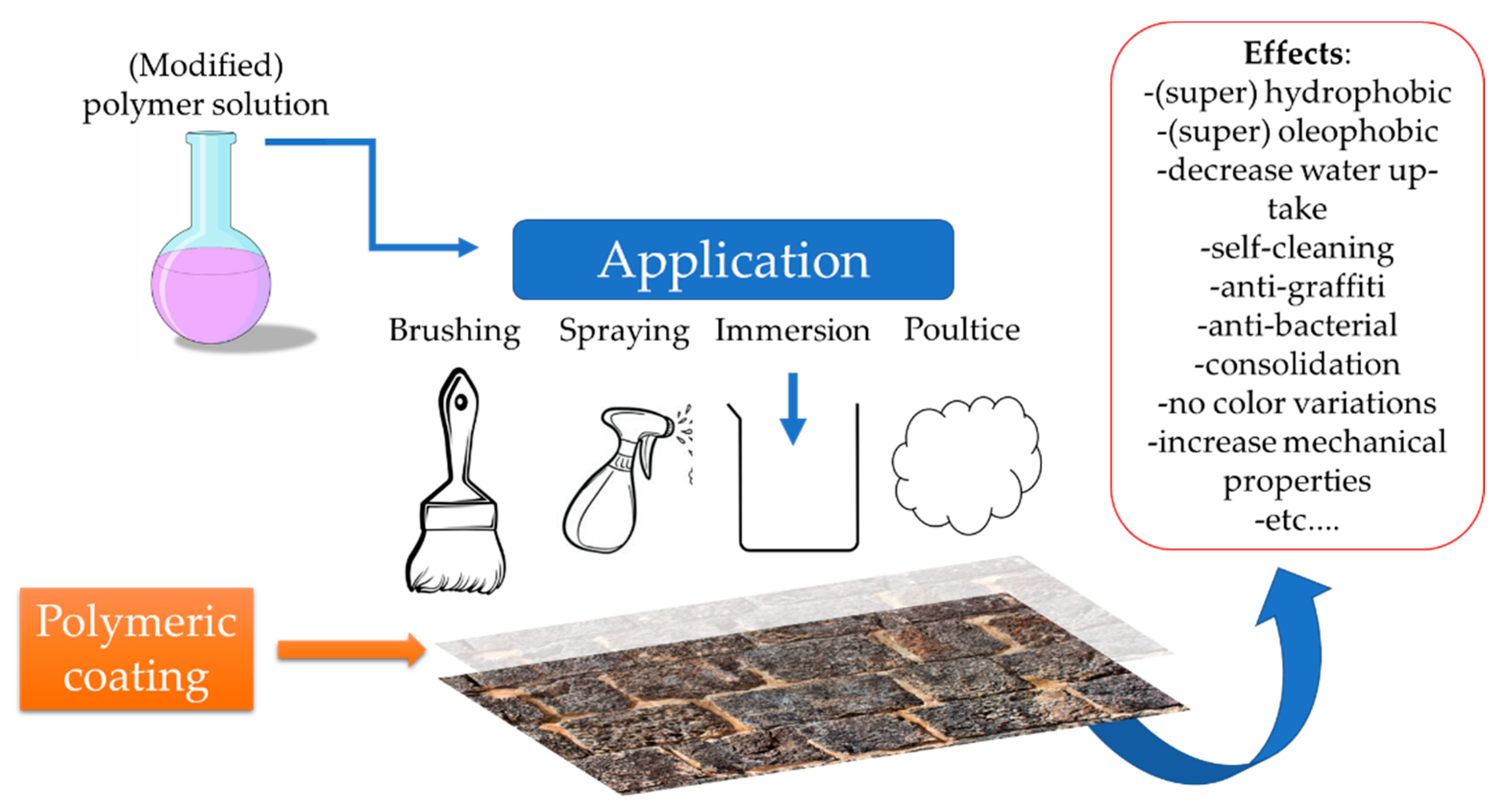

3. Recent Advances in Polymeric Materials for the Protection of Stones of Cultural Importance

3.1. Hydrophobic Coating Materials

3.2. Superhydrophobic and Superamphiphobic Coating Materials

3.3. Polymer Incorporation in Other Materials

4. Concluding Remarks and Possible Developments

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Castro, N.F.; Becerra, J.E.; Bellopede, R.; Marini, P.; Dino, G.A. Introduction to ‘natural stones and cultural heritage promotion and preservation. Resour. Policy 2022, 78, 102775. [Google Scholar] [CrossRef]

- Dietrich, L.; Götting-Martin, E.; Hertzog, J.; Schmitt-Kopplin, P.; McGovern, P.E.; Hall, G.R.; Petersen, W.C.; Zarnkow, M.; Hutzler, M.; Jacob, F.; et al. Investigating the function of Pre-Pottery Neolithic stone troughs from Göbekli Tepe—An integrated approach. J. Archaeol. Sci. Rep. 2020, 34, 102618. [Google Scholar] [CrossRef]

- Flouda, G.; Philippidis, A.; Mikallou, A.; Anglos, D. Materials analyses of stone artifacts from the EBA to MBA Minoan Tholos tomb P at Porti, Greece (Crete), by means of Raman spectroscopy: Results and a critical assessment of the method. J. Archaeol. Sci. Rep. 2020, 32, 102436. [Google Scholar] [CrossRef]

- Hatipoğlu, M.; Güney, H. Archaeo-gemmological investigation of gemstone glyptics (seal stones and ceremonial stones) and ancient jewelleries mounted gemstones in İzmir Archaeological Museum (Turkey). J. Cult. Herit. 2013, 14, 165–168. [Google Scholar] [CrossRef]

- Storta, E.; Borghi, A.; Perotti, L.; Palomba, M.; Deodato, A. Minero-petrographic characterization of stone materials used for the roman amphitheater of Eporedia (Ivrea, To): A scientific-dissemination proposal in the Cultural Heritage. Resour. Policy 2022, 77, 102668. [Google Scholar] [CrossRef]

- Chen, X.; Qi, X.B.; Xu, Z.Y. Determination of weathered degree and mechanical properties of stone relics with ultrasonic CT: A case study of an ancient stone bridge in China. J. Cult. Herit. 2020, 42, 131–138. [Google Scholar] [CrossRef]

- Previato, C.; Monego, M.; Menin, A.; Achilli, V. A multi-scalar approach for the study of ancient architecture: Structure for Motion, laser scanning and direct survey of the Roman theatre of Nora (Cagliari, Sardinia). J. Archaeol. Sci. Rep. 2022, 43, 103440. [Google Scholar] [CrossRef]

- Columbu, S. Petrographic and geochemical investigations on the volcanic rocks used in the Punic-Roman archaeological site of Nora (Sardinia, Italy), Environ. Earth Sci. 2018, 77, 577. [Google Scholar] [CrossRef]

- Barroso, C.E.; Oliveira, D.V.; Ramos, L.F. Physical and mechanical characterization of vernacular dry stone heritage materials: Schist and granite from Northwest Portugal. Constr. Build. Mat. 2020, 259, 119705. [Google Scholar] [CrossRef]

- Li, Y.H.; Gu, J.D. A more accurate definition of water characteristics in stone materials for an improved understanding and effective protection of cultural heritage from biodeterioration. Int. Biodeter. Biodegrad. 2022, 166, 105338. [Google Scholar] [CrossRef]

- Fierascu, R.C.; Doni, M.; Fierascu, I. Selected Aspects Regarding the Restoration/Conservation of Traditional Wood and Masonry Building Materials: A Short Overview of the Last Decade Findings. Appl. Sci. 2020, 10, 1164. [Google Scholar] [CrossRef]

- Vidal, F.; Vicente, R.; Silva, J.M. Review of environmental and air pollution impacts on built heritage: 10 questions on corrosion and soiling effects for urban intervention. J. Cult. Herit. 2019, 37, 273–295. [Google Scholar] [CrossRef]

- Sabbioni, C. Mechanisms of air pollution damage to stone. In The Effects of Air Pollution on the Built Environment; Brimblecombe, P., Ed.; Springer: New York, NY, USA, 2003; pp. 63–106. [Google Scholar] [CrossRef]

- Hall, K.; Hall, A. Weathering by wetting and drying: Some experimental results. Earth Surf. Process. Landf. 1996, 21, 365–376. [Google Scholar] [CrossRef]

- Verges-Belmin, V. Illustrated Glossary on Stone Deterioration Patterns. 2008. Available online: https://www.icomos.org/publications/monuments_and_sites/15/pdf/Monuments_and_Sites_15_ISCS_Glossary_Stone.pdf (accessed on 5 August 2022).

- Elert, K.; Rodriguez-Navarro, C. Degradation and conservation of clay-containing stone: A review. Constr. Build. Mat. 2022, 330, 127226. [Google Scholar] [CrossRef]

- Carta, L.; Calcaterra, D.; Cappelletti, P.; Langella, A.; de’Gennaro, M. The stone materials in the historical architecture of the ancient center of Sassari: Distribution and state of conservation. J. Cult. Herit. 2005, 6, 277–286. [Google Scholar] [CrossRef]

- Baglioni, P.; Giorgi, R.; Chelazzi, D. The degradation of wall paintings and stone: Specific ion effects. Curr. Opin. Colloid Interface Sci. 2016, 23, 66–71. [Google Scholar] [CrossRef]

- Wang, X.; Li, H.; Wang, Y.; Zhao, X. Assessing climate risk related to precipitation on cultural heritage at the provincial level in China. Sci. Total Environ. 2022, 835, 155489. [Google Scholar] [CrossRef]

- Cardell-Fernández, C.; Vleugels, G.; Torfs, K.; Van Grieken, R. The processes dominating Ca dissolution of limestone when exposed to ambient atmospheric conditions as determined by comparing dissolution models. Environ. Geol. 2002, 43, 160–171. [Google Scholar] [CrossRef]

- Anovitz, L.M.; Cheshire, M.C.; Hermann, R.P.; Gu, X.; Sheets, J.M.; Brantley, S.L.; Cole, D.R.; Ilton, E.S.; Mildner, D.F.R.; Gagnon, C.; et al. Oxidation and associated pore structure modification during experimental alteration of granite. Geochim. Cosmochim. Acta 2021, 292, 532–556. [Google Scholar] [CrossRef]

- Bams, V.; Dewaele, S. Staining of white marble. Mat. Character. 2007, 58, 1052–1062. [Google Scholar] [CrossRef]

- Dreesen, R.; Nielsen, P.; Lagrou, D. The staining of blue stone limestones petrographically unraveled. Mat. Character. 2007, 58, 1070–1081. [Google Scholar] [CrossRef]

- La Iglesia, A.; del Cura, M.A.G.; Ordoñez, S. The physicochemical weathering of monumental dolostones, granites and limestones; dimension stones of the Cathedral of Toledo (Spain). Sci. Total Environ. 1994, 152, 179–188. [Google Scholar] [CrossRef]

- Pinheiro, A.C.; Mesquita, N.; Trovão, J.; Soares, F.; Tiago, I.; Coelho, C.; de Carvalho, H.P.; Gil, F.; Catarino, L.; Piñar, G.; et al. Limestone biodeterioration: A review on the Portuguese cultural heritage scenario. J. Cult. Herit. 2019, 36, 275–285. [Google Scholar] [CrossRef]

- Liu, X.; Koestler, R.J.; Warscheid, T.; Katayama, Y.; Gu, J.D. Microbial deterioration and sustainable conservation of stone monuments and buildings. Nat. Sustain. 2020, 3, 991–1004. [Google Scholar] [CrossRef]

- Zhang, G.; Gong, C.; Gu, J.; Katayama, Y.; Someya, T.; Gu, J.D. Biochemical reactions and mechanisms involved in the biodeterioration of stone world cultural heritage under the tropical climate conditions. Int. Biodeter. Biodegrad. 2019, 143, 104723. [Google Scholar] [CrossRef]

- Branysova, T.; Demnerova, K.; Durovic, M.; Stiborova, H. Microbial biodeterioration of cultural heritage and identification of the active agents over the last two decades. J. Cult. Herit. 2022, 55, 245–260. [Google Scholar] [CrossRef]

- Gaylarde, C.; Little, B. Biodeterioration of stone and metal—Fundamental microbial cycling processes with spatial and temporal scale differences. Sci. Total Environ. 2022, 823, 153193. [Google Scholar] [CrossRef]

- Liu, X.; Qian, Y.; Wang, Y.; Wu, F.; Wang, W.; Gu, J.D. Innovative approaches for the processes involved in microbial biodeterioration of cultural heritage materials. Curr. Opin. Biotechnol. 2022, 75, 102716. [Google Scholar] [CrossRef]

- Romani, M.; Warscheid, T.; Nicole, L.; Marcon, L.; Di Martino, P.; Suzuki, M.T.; Lebaron, P.; Lami, R. Current and future chemical treatments to fight biodeterioration of outdoor building materials and associated biofilms: Moving away from ecotoxic and towards efficient, sustainable solutions. Sci. Total Environ. 2022, 802, 149846. [Google Scholar] [CrossRef]

- Clim, D.A.; Groll, L.; Diaconu, L.I. Moisture—The main cause of the degradation of historic buildings. Bulet. Inst. Politeh. Iaşi 2017, 63, 65–78. [Google Scholar]

- Gomez-Heras, M.; McCabe, S. Weathering of stone-built heritage: A lens through which to read the Anthropocene. Anthropocene 2015, 11, 1–13. [Google Scholar] [CrossRef]

- El Jazouli, B.; Tsangouri, E. Fire-exposed stones in constructions: Residual strength, performance loss and damage mode shift due to mineralogical transformation and micro-cracking. Eng. Geol. 2022, 302, 106638. [Google Scholar] [CrossRef]

- Amrutkar, S.; More, A.; Mestry, S.; Mhaske, S.T. Recent developments in the anti-graffiti coatings: An attentive review. J. Coat. Technol. Res. 2022, 19, 717–739. [Google Scholar] [CrossRef]

- Gomes, V.; Dionísio, A.; Pozo-Antonio, J.S. Conservation strategies against graffiti vandalism on Cultural Heritage stones: Protective coatings and cleaning methods. Prog. Org. Coat. 2017, 113, 90–109. [Google Scholar] [CrossRef]

- Sassoni, E. Hydroxyapatite and Other Calcium Phosphates for the Conservation of Cultural Heritage: A Review. Materials 2018, 11, 557. [Google Scholar] [CrossRef]

- Rampazzi, L. Calcium oxalate films on works of art: A review. J. Cult. Heri. 2019, 40, 195–214. [Google Scholar] [CrossRef]

- Ricca, M.; La Russa, M.F. Challenges for the Protection of Underwater Cultural Heritage (UCH), from Waterlogged and Weathered Stone Materials to Conservation Strategies: An Overview. Heritage 2020, 3, 402–411. [Google Scholar] [CrossRef]

- Franco-Castillo, I.; Hierro, l.; de la Fuente, J.M.; Seral-Ascaso, A.; Mitchell, S.G. Perspectives for antimicrobial nanomaterials in cultural heritage conservation. Chem 2021, 7, 629–669. [Google Scholar] [CrossRef]

- Sbardella, F.; Pronti, L.; Santarelli, M.L.; Asua Gonzàlez, J.M.; Bracciale, M.P. Waterborne Acrylate-Based Hybrid Coatings with Enhanced Resistance Properties on Stone Surfaces. Coatings 2018, 8, 283. [Google Scholar] [CrossRef]

- Andreotti, S.; Franzoni, E.; Degli Esposti, M.; Fabbri, P. Poly(hydroxyalkanoate)s-Based Hydrophobic Coatings for the Protection of Stone in Cultural Heritage. Materials 2018, 11, 165. [Google Scholar] [CrossRef] [Green Version]

- Colangiuli, D.; Lettieri, M.; Masieri, M.; Calia, A. Field study in an urban environment of simultaneous self-cleaning and hydrophobic nanosized TiO2-based coatings on stone for the protection of building surface. Sci. Total Environ. 2019, 650, 2919–2930. [Google Scholar] [CrossRef] [PubMed]

- Lettieri, M.; Masieri, M.; Pipoli, M.; Morelli, A.; Frigione, M. Anti-Graffiti Behavior of Oleo/Hydrophobic Nano-Filled Coatings Applied on Natural Stone Materials. Coatings 2019, 9, 740. [Google Scholar] [CrossRef]

- Sbardella, F.; Bracciale, M.P.; Santarelli, M.L.; Asua, J.M. Waterborne modified-silica/acrylates hybrid nanocomposites as surface protective coatings for stone monuments. Prog. Org. Coat. 2020, 149, 105897. [Google Scholar] [CrossRef]

- Lettieri, M.; Masieri, M.; Frigione, M. Durability to simulated bird guano of nano-filled oleo/hydrophobic coatings for the protection of stone materials. Prog. Org. Coat. 2020, 148, 105900. [Google Scholar] [CrossRef]

- Fruth, V.; Todan, L.; Codrea, C.I.; Poenaru, I.; Petrescu, S.; Aricov, L.; Ciobanu, M.; Jecu, L.; Ion, R.M.; Predoana, L. Multifunctional Composite Coatings Based on Photoactive Metal-Oxide Nanopowders (MgO/TiO2) in Hydrophobic Polymer Matrix for Stone Heritage Conservation. Nanomaterials 2021, 11, 2586. [Google Scholar] [CrossRef]

- Weththimuni, M.L.; Chobba, M.B.; Sacchi, D.; Messaoud, M.; Licchelli, M. Durable Polymer Coatings: A Comparative Study of PDMS-Based Nanocomposites as Protective Coatings for Stone Materials. Chemistry 2022, 4, 60–76. [Google Scholar] [CrossRef]

- Corcione, C.E.; De Simone, N.; Santarelli, M.L.; Frigione, M. Protective properties and durability characteristics of experimental and commercial organic coatings for the preservation of porous stone. Prog. Org. Coat. 2017, 103, 193–203. [Google Scholar] [CrossRef]

- Gemelli, G.M.C.; Zarzuela, R.; Alarcón-Castellano, F.; Mosquera, M.J.; Gil, M.L. A Alkoxysilane-based consolidation treatments: Laboratory and 3-years In-Situ assessment tests on biocalcarenite stone from Roman Theatre (Cádiz). Constr. Build. Mat. 2021, 312, 125398. [Google Scholar] [CrossRef]

- Lettieri, M.; Masieri, M.; Aquaro, M.; Dilorenzo, D.; Frigione, M. Eco-Friendly Protective Coating to Extend the Life of Art-Works and Structures Made in Porous Stone Materials. Coatings 2021, 11, 1270. [Google Scholar] [CrossRef]

- Li, W.; Lin, J.; Zhao, Y.; Pan, Z. The Adverse Effects of TiO2 Photocatalycity on Paraloid B72 Hybrid Stone Relics Protective Coating Aging Behaviors under UV Irradiation. Polymers 2021, 13, 262. [Google Scholar] [CrossRef]

- Pargoletti, E.; Comite, V.; Fermo, P.; Sabatini, V.; Annunziata, L.; Ortenzi, M.A.; Farina, H.; Cappelletti, G. Calcitic-based stones protection by a low-fluorine modified methacrylic coating. Environ. Sci. Pollut. Res. 2022, 29, 29455–29466. [Google Scholar] [CrossRef] [PubMed]

- Li, T.; Fan, Y.; Wang, K.; Song, S.; Liu, X.; Bu, N.; Li, R.; Zhen, Q.; Bashir, S. Methyl-modified silica hybrid fluorinated Paraloid B-72 as hydrophobic coatings for the conservation of ancient bricks. Constr. Build. Mat. 2021, 299, 123906. [Google Scholar] [CrossRef]

- Karapanagiotis, I.; Manoudis, P.N. Superhydrophobic and superamphiphobic materials for the conservation of natural stone: An overview. Constr. Build. Mat. 2022, 320, 126175. [Google Scholar] [CrossRef]

- Cassie, A.B.D.; Baxter, S. Wettability of porous surfaces. Trans. Faraday Soc. 1944, 40, 546–551. [Google Scholar] [CrossRef]

- Brugnara, M.; Degasperi, E.; Della Volpe, C.; Maniglio, D.; Penati, A.; Siboni, S.; Toniolo, L.; Poli, T.; Invernizzi, S.; Castelvetro, V. The application of the contact angle in monument protection: New materials and methods. Colloid. Surf. A 2004, 241, 299–312. [Google Scholar] [CrossRef]

- Samara, C.; Melfos, V.; Kouras, A.; Karali, E.; Zacharopoulou, G.; Kyranoudi, M.; Papadopoulou, L.; Pavlidou, E. Morphological and geochemical characterization of the particulate deposits and the black crust from the Triumphal Arch of Galerius in Thessaloniki, Greece: Implications for deterioration assessment. Sci. Total Environ. 2020, 734, 139455. [Google Scholar] [CrossRef]

- Cappelletti, G.; Fermo, P.; Camiloni, M. Smart hybrid coatings for natural stones conservation. Prog. Org. Coat. 2015, 78, 511–516. [Google Scholar] [CrossRef]

- Gherardi, F.; Roveri, M.; Goidanich, S.; Toniolo, L. Photocatalytic Nanocomposites for the Protection of European Architectural Heritage. Materials 2018, 11, 65. [Google Scholar] [CrossRef] [PubMed]

- Tian, S.; Liu, S.; Gao, F.; Ren, J. Preparation and assessment of superhydrophobic organic-inorganic hybrid coatings for conservation of Yungang Grottoes. Mater. Res. Soc. Symp. Proc. 2011, 1319, 333–338. [Google Scholar] [CrossRef]

- Manoudis, P.N.; Karapanagiotis, I.; Tsakalof, A.; Zuburtikudis, I.; Kolinkeová, B.; Panayiotou, C. Superhydrophobic films for the protection of outdoor cultural heritage assets. Appl. Phys. A 2009, 97, 351–360. [Google Scholar] [CrossRef]

- Aldosari, M.A.; Darwish, S.S.; Adam, M.A.; Elmarzugi, N.A.; Ahmed, S.M. Using ZnO nanoparticles in fungal inhibition and self-protection of exposed marble columns in historic sites. Archaeol. Anthrop. Sci. 2019, 11, 3407–3422. [Google Scholar] [CrossRef]

- Hefni, Y.K. Hydrophobic zinc oxide nanocomposites for consolidation and protection of quartzite sculptures: A case study. J. Nano Res. 2020, 63, 64–75. [Google Scholar] [CrossRef]

- Ugur, I. Surface characterization of some porous natural stones modified with a waterborne fluorinated polysiloxane agent under physical weathering conditions. J. Coat. Technol. Res. 2014, 11, 639–649. [Google Scholar] [CrossRef]

- Cao, Y.; Salvini, A.; Camaiti, M. Superhydrophobic fluorinated oligomers as protective agents for outdoor stone artworks. J. Cult. Herit. 2020, 44, 90–97. [Google Scholar] [CrossRef]

- Adamopoulos, F.G.; Vouvoudi, E.C.; Pavlidou, E.; Achilias, D.S.; Karapanagiotis, I. TEOS-Based Superhydrophobic Coating for the Protection of Stone-Built Cultural Heritage. Coatings 2021, 11, 135. [Google Scholar] [CrossRef]

- Ghaffari, S.; Aliofkhazraei, M.; Barati Darband, G.; Zakeri, A.; Ahmadi, E. Review of superoleophobic surfaces: Evaluation, fabrication methods, and industrial applications. Surf. Interf. 2019, 17, 100340. [Google Scholar] [CrossRef]

- Aslanidou, D.; Karapanagiotis, I.; Panayiotou, C. Tuning the wetting properties of siloxane-nanoparticle coatings to induce superhydrophobicity and superoleophobicity for stone protection. Mater. Des. 2018, 2016, 736–744. [Google Scholar] [CrossRef]

- Lettieri, M.; Masieri, M.; Morelli, A.; Pipoli, M.; Frigione, M. Oleo/Hydrophobic Coatings Containing Nano-Particles for the Protection of Stone Materials Having Different Porosity. Coatings 2018, 8, 429. [Google Scholar] [CrossRef]

- Mosquera, M.J.; Carrascosa, L.A.M.; Badreldin, N. Producing superhydrophobic/oleophobic coatings on cultural heritage building materials. Pure Appl. Chem. 2018, 90, 551–561. [Google Scholar] [CrossRef]

- Monaco, M.; Aurilio, M.; Tafuro, A.; Guadagnuolo, M. Sustainable Mortars for Application in the Cultural Heritage Field. Materials 2021, 14, 598. [Google Scholar] [CrossRef]

- Gao, Y.; Luo, J.; Zhang, J.; Zhou, X.; Teng, F.; Liu, C.; Sun, X. Repairing performances of novel cement mortar modified with graphene oxide and polyacrylate polymer. Nanotechnol. Rev. 2022, 11, 1778–1791. [Google Scholar] [CrossRef]

- Idrees, M.; Hussain, A.T.; Saeed, F.; Hussain, T. Effectiveness of metakaolin and hybrid polymers incorporated mortar for the compressive strength and acid resistance of industrial and wastewater infrastructure. Environ. Prog. Sustain. Energy 2021, 40, 13534. [Google Scholar] [CrossRef]

- Tan, Y.; Chen, H.; Wang, Z.; Xue, C.; He, R. Performances of Cement Mortar Incorporating Superabsorbent Polymer (SAP) Using Different Dosing Methods. Materials 2019, 12, 1619. [Google Scholar] [CrossRef] [PubMed]

- Liu, Q.; Liang, R.; Li, Z.; Guo, S.; Sun, G. Mechanical strong and durable cement mortars reinforced by controlling the polymer phase size. Mater. Res. Express 2019, 6, 075203. [Google Scholar] [CrossRef]

- Lynn, M.E. Polymer-Modified Cement Mortars and Concretes and Processes for the Production Thereof. European Patent Office Patent No. EP0069586B1, 7 July 1981. [Google Scholar]

- Seok, J.Y.; Hee, K.H.; Gilyong, L. Polymer Mortar Composition for Repair Section and Constructing Methods Using Thereof. South Korea Patent No. KR102079509B1, 23 September 2019. [Google Scholar]

- Il, H.B. Eco-Friendly Polymer Mortar Coposition for Improving Long-Term Durability and Method of Cross Section Recovery Using the Same. South Korea Patent No. KR102274310B1, 2 February 2021. [Google Scholar]

- Ciuperca, R.I. Concrete Mix Composition, Mortar Mix Composition and Method of Making and Curing Concrete or Mortar and Concrete or Mortar Objects and Structures. U.S. Patent No. US8545749B2, 25 September 2012. [Google Scholar]

- Frigione, M.; Lettieri, M.; Sarcinella, A.; Barroso de Aguiar, J.L. Applications of Sustainable Polymer-Based Phase Change Materials in Mortars Composed by Different Binders. Materials 2019, 12, 3502. [Google Scholar] [CrossRef]

- Sarcinella, A.; de Aguiar, J.L.B.; Frigione, M. Physical Properties of Eco-Sustainable Form-Stable Phase Change Materials Included in Mortars Suitable for Buildings Located in Different Continental Regions. Materials 2022, 15, 2497. [Google Scholar] [CrossRef] [PubMed]

- Sarcinella, A.; Aguiar, J.L.B.d.; Frigione, M. Physical Properties of an Eco-Sustainable, Form-Stable Phase Change Material Included in Aerial-Lime-Based Mortar Intended for Different Climates. Materials 2022, 15, 1192. [Google Scholar] [CrossRef]

- Nývlt, M.; Pazderka, J.; Reiterman, P. Comparative Study of Different Types of Waterproofing Screeds with a Focus on Cohesion with Selected Building Materials after the Freeze-Thaw Exposure. Appl. Sci. 2021, 11, 11256. [Google Scholar] [CrossRef]

- Bell, G. Euros are not the only fruit—Reaping the full harvest of cultural heritage. In Cultural Heritage as Economic Value; Mergos, G., Patsavos, N., Eds.; Technical University of Crete: Chania, Greeece, 2016; pp. 50–60. Available online: https://ayla.culture.gr/wp-content/uploads/2017/10/arxiki.pdf (accessed on 8 August 2022).

- Nilson, T.; Thorell, K. Cultural Heritage Preservation: The Past, the Present and the Future; Halmstad University Press: Halmstad, Sweden, 2018; Available online: http://hh.diva-portal.org/smash/get/diva2:1224014/FULLTEXT01.pdf (accessed on 8 August 2022).

- Baglioni, M.; Poggi, G.; Chelazzi, D.; Baglioni, P. Advanced Materials in Cultural Heritage Conservation. Molecules 2021, 26, 3967. [Google Scholar] [CrossRef]

- Borg, B.; Dunn, M.; Ang, A.; Villis, C. The application of state-of-the-art technologies to support artwork conservation: Literature review. J. Cult. Herit. 2020, 44, 239–259. [Google Scholar] [CrossRef]

- Daffara, C.; Marchioro, G.; Ambrosini, D. Smartphone diagnostics for cultural heritage. In Proceedings of the Optics for Arts, Architecture, and Archaeology VII, Munich, Germany, 24–26 June 2019. [Google Scholar]

- Lucchi, E. Review of preventive conservation in museum buildings. J. Cult. Herit. 2018, 29, 180–193. [Google Scholar] [CrossRef]

- Bülow, A.E.; Stitt, J.; Brokerhof, A.W. I Can See Further Now: Preventive Conservation in a Changing Heritage World. Stud. Conserv. 2018, 63, 35–42. [Google Scholar] [CrossRef]

- Feilden, B.M.; Jokilehto, J. Management Guidelines for World Heritage Sites; ICCROM—International Centre for the Study of the Preservation and Restoration of Cultural Property: Rome, Italy, 1998; pp. 5–10. Available online: https://www.iccrom.org/sites/default/files/2018-02/1998_feilden_management_guidelines_eng_70071_light_0.pdf (accessed on 8 August 2022).

- Favaro, M.; Mendichi, R.; Ossola, F.; Russo, U.; Simon, S.; Tomasin, P.; Vigato, P.A. Evaluation of polymers for conservation treatments of outdoor exposed stone monuments. Part I: Photo-oxidative weathering. Polym. Degrad. Stabil. 2006, 91, 3083–3096. [Google Scholar] [CrossRef]

- Baglioni, P.; Chelazzi, D.; Giorgi, R. Nanotechnologies in the Conservation of Cultural Heritage; Springer: New York, NY, USA, 2015. [Google Scholar]

- Sassoni, E.; Franzoni, E.; Stefanova, M.; Kamenarov, Z.; Scopece, P.; Verga Falzacappa, E. Comparative Study Between Ammonium Phosphate and Ethyl Silicate Towards Conservation of Prehistoric Paintings in the Magura Cave (Bulgaria). Coatings 2020, 10, 250. [Google Scholar] [CrossRef]

- Roncon, R.; Borsoi, G.; Parracha, J.L.; Flores-Colen, I.; Veiga, R.; Nunes, L. Impact of Water-Repellent Products on the Moisture Transport Properties and Mould Susceptibility of External Thermal Insulation Composite Systems. Coatings 2021, 11, 554. [Google Scholar] [CrossRef]

| Coating Material | Support Material | Stone Characteristics | Application | Solvent/Application Method | Results | Ref. |

|---|---|---|---|---|---|---|

| Polyacrylate/silica hybrid (SiO2 nanoparticles) | Lecce stone, Carrara marble | Not provided by the authors | Decreasing water penetration (water up-take by capillary adsorption) | Waterborne miniemulsion, applied by brushing | AC = 10.90–13.65 kg/m2 × h0.5 (Lecce stone, control 108.5), 0.07-0.10 (Carrara marble, control 54.08); RCI = 0.78–0.85 (Lecce stone); 0.60–0.94 (Carrara marble), control = 1; θ = 88.93–93.95° (Lecce stone, control = 0), 88.28-94.60° (Carrara marble, control = 54.08) | [41] |

| Poly(hydroxyalkanoate)s(PHBVV and PHB) | Sandstone (Siena stone), limestone (Lecce stone) and marble (Carrara marble) | P: 0.1–10 µm; calcite: 88% in sandstone, 86% in limestone and 98% in marble; 2% dolomite (in marble), quartz (in sandstone), fluoropatite (in limestone), by XRD analysis | Decreasing water penetration (water up-take by capillary adsorption) | Solvent-chloroform, applied by dip coating, poultice, spraying | Best results: sandstone—Rp after 48 h—86–92% (all PHBVV treatments, commercial treatment 89–97%, dip coating and spray); limestone—Rp after 48 h—91–96% (all PHBVV treatments, commercial treatment 87–95%, dip coating and spray); θ = 123 ± 0°—poultice PHBVV (control 15 ± 4°); Limestone θ = 126 ± 7°—poultice PHBVV (control 0 ± 0°); marble θ = 109 ± 10°—poultice PHBVV (control 41 ± 7°); WVT (g/m2 day) = 59—PHB spray, 60—PHBVV dip coating (sandstone, control 86); 126—PHBVV dip coating (limestone, control 278); 11—PHB spray (marble, control 21) | [42] |

| TiO2 NPs/fluoropolymer, at 11, respectively 50% NPs | Limestone | Not provided by the authors | Hydrophobic and self-cleaning coating | Water dispersion, applied by brushing | D = 90%/95%; ΔE after 1 year = 1.01/2.46 (2.96, without NPs); Contact angle: >100° before exposure, 50–80° after 1 year of exposure and washing | [43] |

| Fluorine resin containing SiO2 NPs | Calcareous stones (porous calcarenite, compact limestone) | Calcarenite: calcite (93–97%), P = 39%, pore size: 0.5–6 μm; limestone: calcite (>95%), clay, iron oxides, P = 2%, pore size: 0.025–0.001 μm | Anti-graffiti barrier | Water dispersion, applied by brushing | Calcarenite: WCA 139°, OCA 114° (control 40/13, commercial products: 106–114/56–93); Limestone: WCA 142°, OCA 122° (control not determinable, commercial products: 119–122/56–114); ΔE after staining and cleaning—comparable with the commercial products | [44] |

| (3-(trimethoxysilyl)propyl methacrylate containing 2–10% silica | Carrara Marbleand Lecce stone | θ = 30–79°; Young’s modulus(MPa) = 8–122 | Reducing water absorption, | Waterborne coating, applied by brushing | θ = up to 94°, dependent on silica modification matrix and silica content; Young’s modulus (MPa—nt), Tensile Strength (MPa)—up to 9.60, water uptake—10–70% ΔE = 1.4 for the methanol modified silica, 5% silica coating (untreated sample = 1.7) | [45] |

| Fluorine resin containing SiO2 NPs | Calcareous stones (porous calcarenite, compact limestone) | P = 42/1.98, pore radius 1.23/0.010 μm, pore size 0.5–4/0.01–0.03 μm. Initial colorimetric parameters (L*, a* and b*): 80.33; 1.42; 16.45/83.87; 1.20; 6.03 | Guano protective layers | Waterborne coating, applied by brushing | G [(g/h)∙10−3] = 18.7/4.0 WVT (g/m2∙day) = 230/58; ΔVP after pancreatin test = −22/−30 (control −34/−68); ΔE = 0.96/1.65 (control 3.97/4.29, commercial products 2.10, 3.92/1.70, 3.43), WCA = 144/141° | [46] |

| Sodium polyacrylate (NaPAC16); MgO, and respectively TiO2 composite | Mosaic stone (limestone and marble) | Periclase and anatase (XRD), total pore volume (cm2/g)—0.16–0.68, pore diameter (nm)—6.04–33.1 | Antibacterial and hydrophobic coating | Water dispersion, applied by immersion | Reduction of OD (Staphylococcus aureus), IZ = 11/14 (S. aureus), 9/6 (Aspergillus niger), 7/4 (Candida albicans); θ = 106/107, ΔE < 1 for all samples and stones treated | [47] |

| ZrO2-doped-ZnO-PDMS | Lecce stone, brick, and marble | Not provided by the authors | Protection and self-cleaning effect | Solvent-ethanol, applied by brushing | Qf = 479.04 ± 8.16 mg cm−2 (Lecce stone), Qf = 346.66 ± 10.49 mg cm−2 (brick), and Qf = 15.34 ± 1.60 mg cm−2 (marble) D* = 6.05–72.25% | [48] |

| Acrylic resin (TMPTMA), silanes (MEMO) and nano-particles of boehmite | Calcarenitic stones (Leccese stone and Gentile stone) | P = 33.5/21.9, bioclasts size 150/200 μm | Water repellent | Trimethylolpropane trimethacrylate base, applied by brushing | θ = 130/118°, ΔE = 6.8/3.6, PE = 68/52% | [49] |

| Monomeric and oligomeric ethoxysilanes with SiO2 | Ostionera stone (bioclastic sandstone) | WAOP = 27.8%, WCs = 13.5% WPP = 4.5 × 10−6 m2/s | Consolidation, in situ application | Water dispersion, applied by brushing | Increase of mechanical properties (>25%), WPP—6% decrease, LWM-19% decrease, ΔE = 1.5, PD | [50] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fistos, T.; Fierascu, I.; Doni, M.; Chican, I.E.; Fierascu, R.C. A Short Overview of Recent Developments in the Application of Polymeric Materials for the Conservation of Stone Cultural Heritage Elements. Materials 2022, 15, 6294. https://doi.org/10.3390/ma15186294

Fistos T, Fierascu I, Doni M, Chican IE, Fierascu RC. A Short Overview of Recent Developments in the Application of Polymeric Materials for the Conservation of Stone Cultural Heritage Elements. Materials. 2022; 15(18):6294. https://doi.org/10.3390/ma15186294

Chicago/Turabian StyleFistos, Toma, Irina Fierascu, Mihaela Doni, Irina Elena Chican, and Radu Claudiu Fierascu. 2022. "A Short Overview of Recent Developments in the Application of Polymeric Materials for the Conservation of Stone Cultural Heritage Elements" Materials 15, no. 18: 6294. https://doi.org/10.3390/ma15186294

APA StyleFistos, T., Fierascu, I., Doni, M., Chican, I. E., & Fierascu, R. C. (2022). A Short Overview of Recent Developments in the Application of Polymeric Materials for the Conservation of Stone Cultural Heritage Elements. Materials, 15(18), 6294. https://doi.org/10.3390/ma15186294