Surface Roughening Behavior of the 6063-T4 Aluminum Alloy during Quasi-in Situ Uniaxial Stretching

Abstract

:1. Introduction

2. Experiments

2.1. Quasi-in Situ Tension Testing

2.2. Surface Roughness Characterization

2.3. Microstructure Characterization

3. Results and Discussion

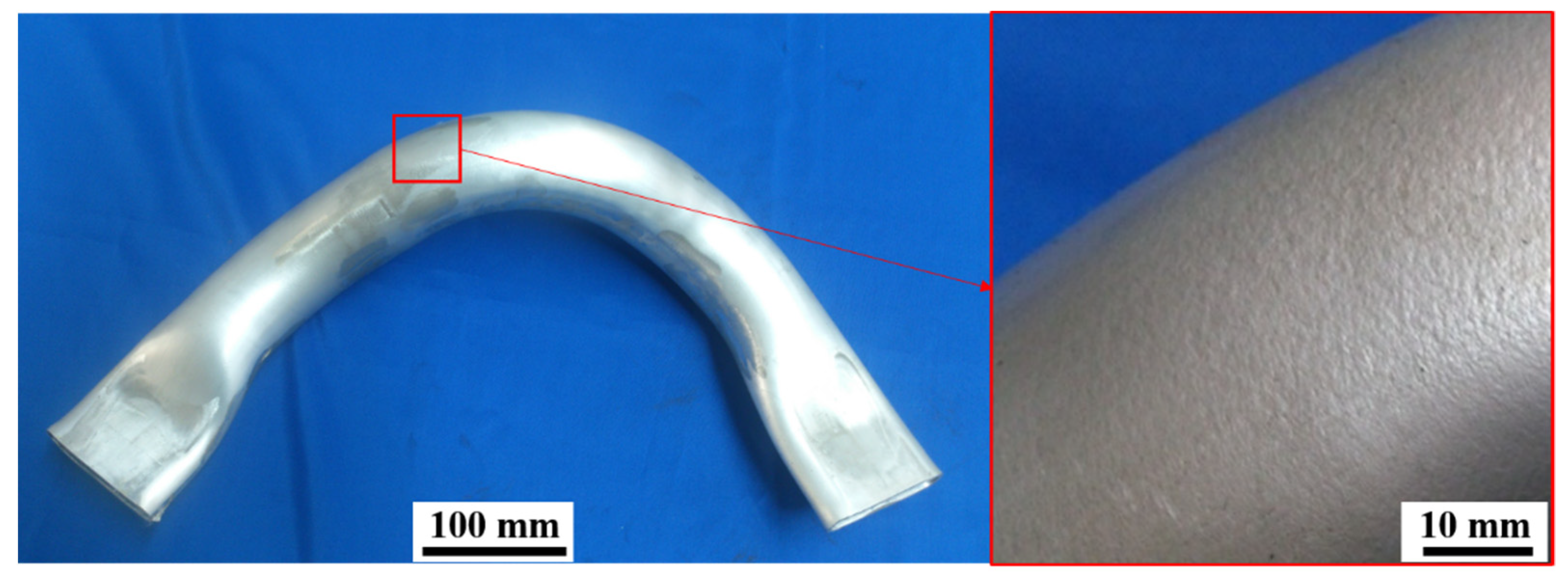

3.1. Surface Morphology

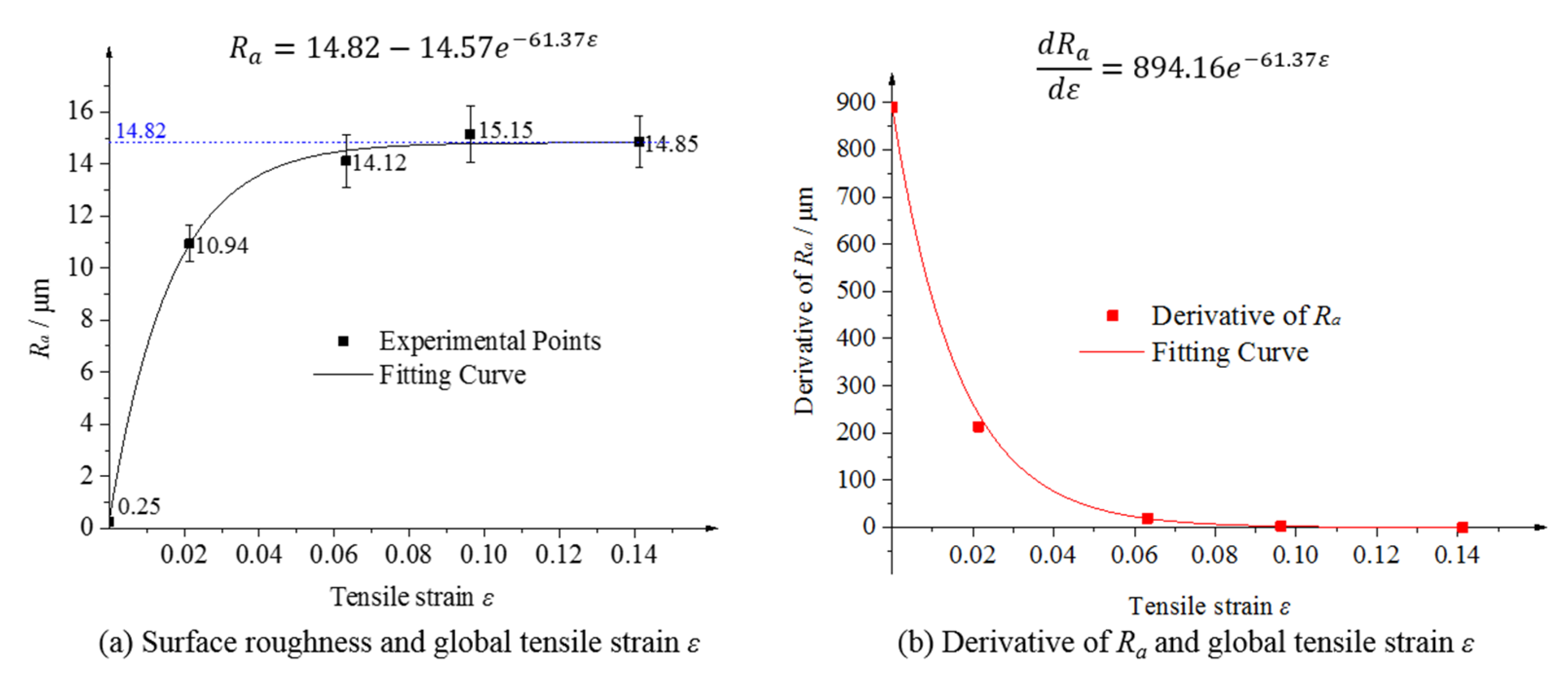

3.2. Surface Roughness

3.3. Microstructure

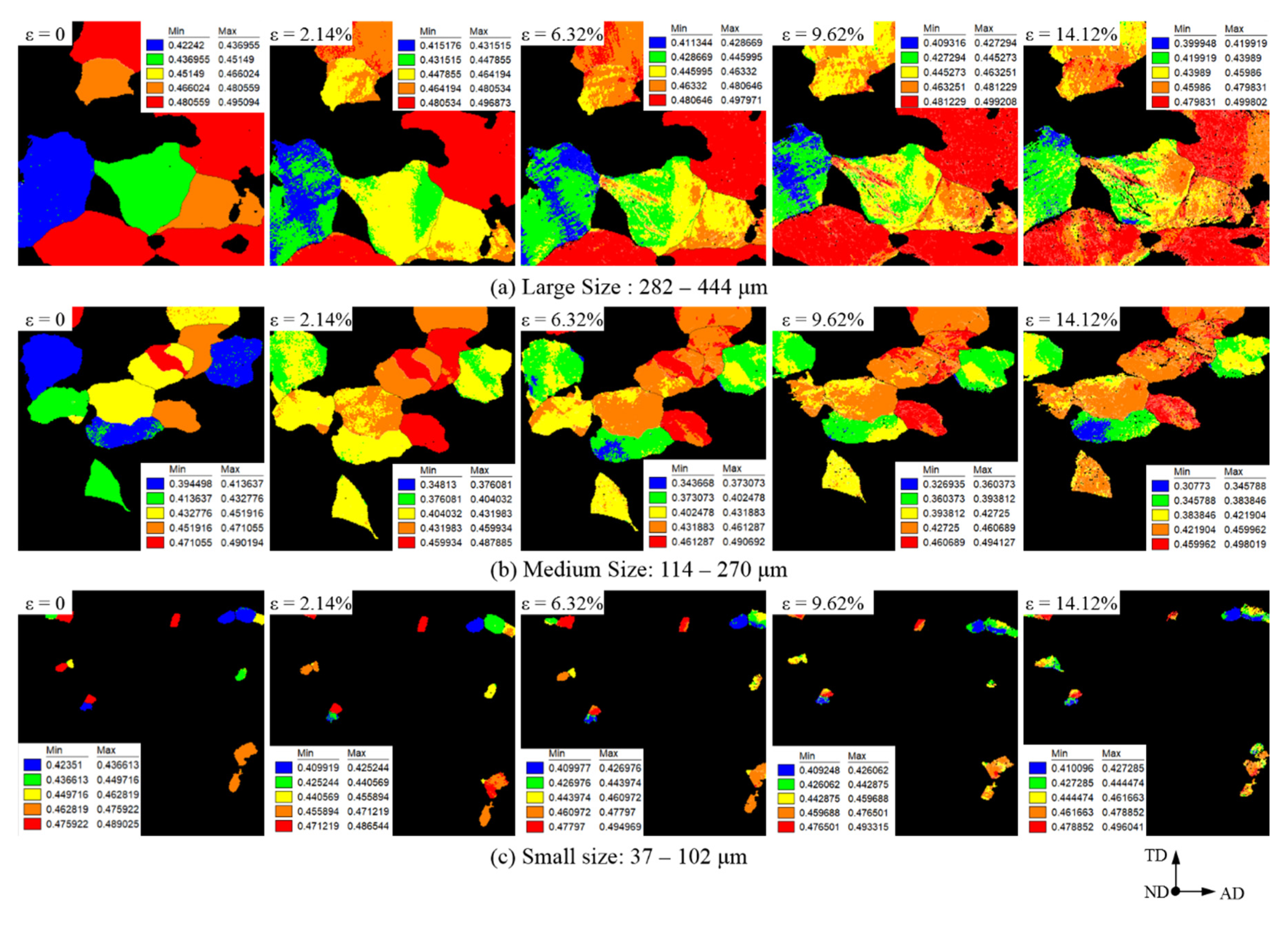

3.3.1. Grain-Orientation Variation

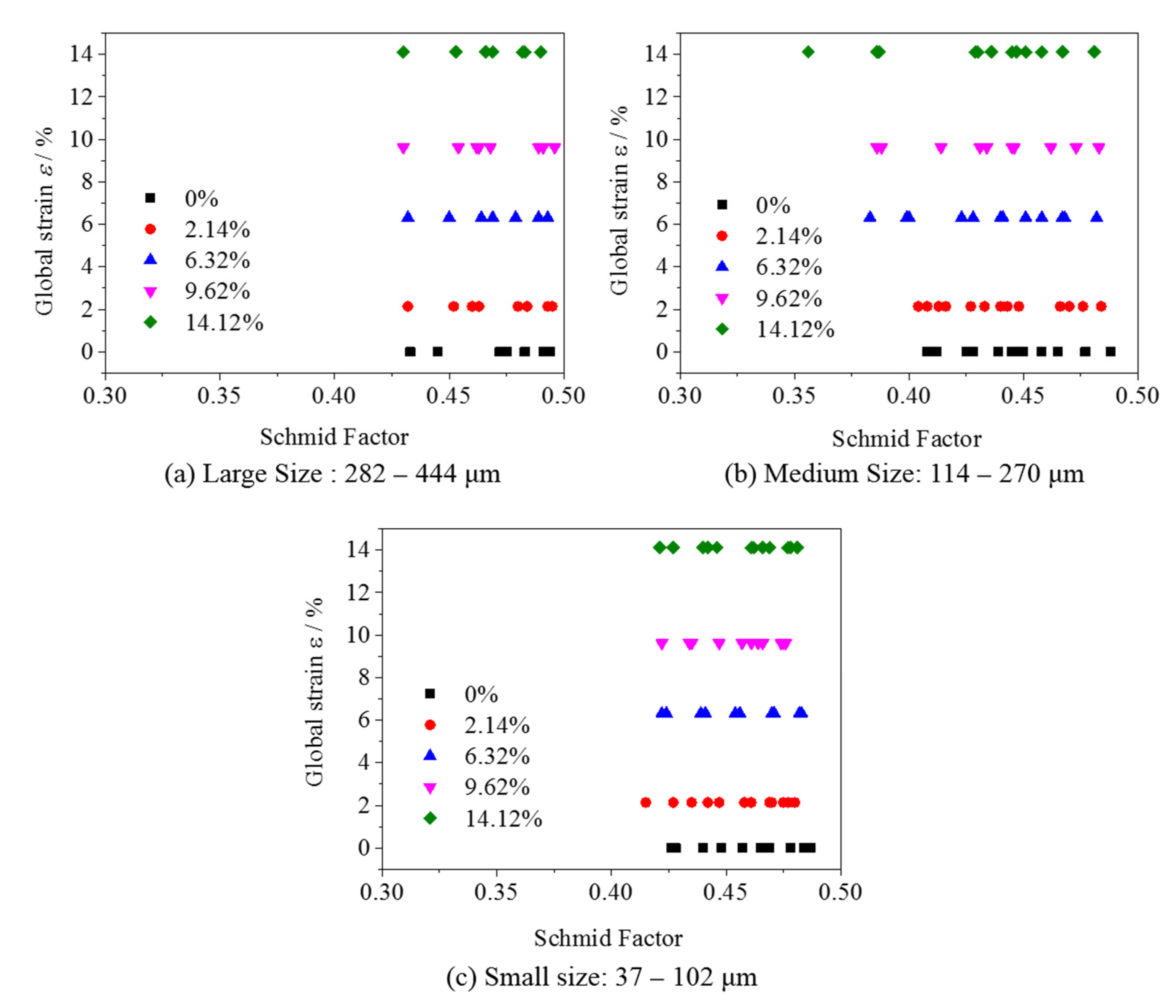

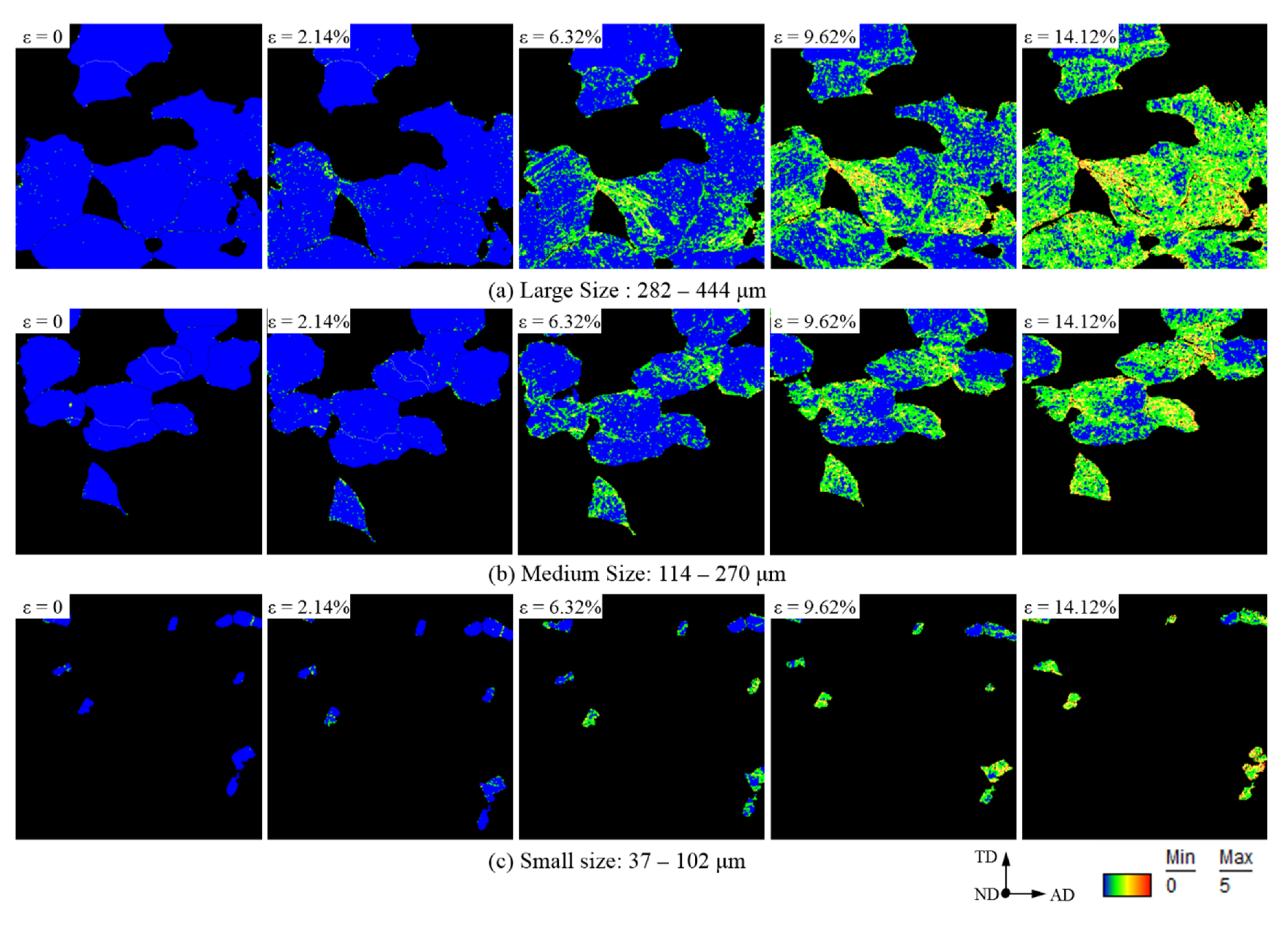

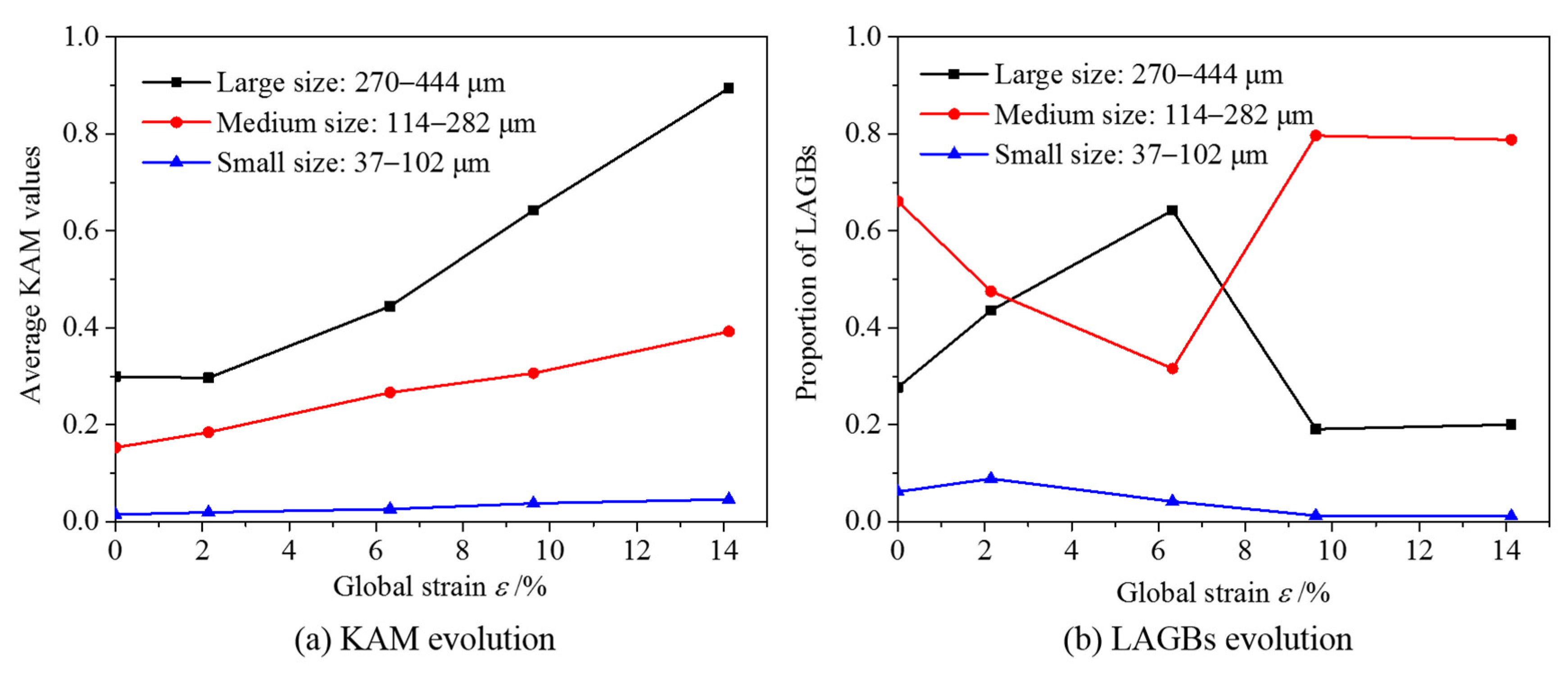

3.3.2. Strain Localization

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yuan, S.J.; Liu, W.; Wang, G.F.; He, Z.B.; Fan, X.B. Advance in fluid pressure forming of complex light metal thin-walled components. Aerosp. Shanghai 2019, 36, 35–41. [Google Scholar]

- Yuan, S.J. Fundamentals and Processes of Fluid Pressure Forming Technology for Complex Thin-Walled Components. Engineering 2021, 7, 358–366. [Google Scholar] [CrossRef]

- Liu, C.S.; Xu, W.J.; Liu, M.Y.; Zhang, L. Effect of strain path on roughness evolution of free surface during plastic deformation. Int. J. Mech. Sci. 2020, 173, 105475. [Google Scholar] [CrossRef]

- Romanova, V.A.; Balokhonov, R.R.; Panin, A.V.; Batukhtina, E.E.; Kazachenok, M.S.; Shikhijanov, V.S. Micromechanical Model of Deformation-Induced Surface Roughening in Polycrystalline Materials. Phys. Mesomech. 2017, 20, 324–333. [Google Scholar] [CrossRef]

- Romanova, V.; Balokhonov, R.; Panin, A.; Kazachenok, M.; Kozelskaya, A. Micro-and mesomechanical aspects of deformation-induced surface roughening in polycrystalline titanium. Mater. Sci. Eng. A 2017, 697, 248–258. [Google Scholar] [CrossRef]

- Cheng, C.; Wan, M.; Meng, B.; Fu, M.W. Characterization of the microscale forming limit for metal foils considering free surface roughening and failure mechanism transformation. J. Mater. Processing Technol. 2019, 272, 111–124. [Google Scholar] [CrossRef]

- Kishimoto, T.; Suematsu, S.; Sakaguchi, H.; Tashima, K.; Kajino, S.; Gondo, S.; Suzuki, S. Effect of crystal orientation on inner surface roughness of micro metal tubes in hollow sinking. Mater. Sci. Eng. A 2021, 805, 140792. [Google Scholar] [CrossRef]

- Al-Ghamdi, K.A.; Hussain, G. On the Free-Surface Roughness in Incremental Forming of a Sheet Metal: A Study from the Perspective of ISF Strain, Surface Morphology, Post-Forming Properties, and Process Conditions. Metals 2019, 9, 553. [Google Scholar] [CrossRef]

- Irani, N.; Nicola, L. Modelling surface roughening during plastic deformation of metal crystals under contact shear loading. Mech. Mater. 2019, 132, 66–76. [Google Scholar] [CrossRef]

- Bong, H.J.; Lee, J. Crystal Plasticity Finite Element–Marciniak-Kuczynski Approach with Surface Roughening Effect in Predicting Formability of Ultra-Thin Ferritic Stainless Steel Sheets. Int. J. Mech. Sci. 2021, 191, 106066. [Google Scholar] [CrossRef]

- Cheng, C.; Wan, M.; Meng, B. Size effect on the forming limit of sheet metal in micro-scaled plastic deformation considering free surface roughening. Procedia Eng. 2017, 207, 1010–1015. [Google Scholar] [CrossRef]

- Romanova, V.; Balokhonov, R.; Emelianova, E.; Pisarev, M.; Dymnich, E. Numerical study of the texture effect on deformation-induced surface roughening in titanium polycrystals. Eng. Fail. Anal. 2020, 110, 104437. [Google Scholar] [CrossRef]

- Ma, X.G.; Zhao, J.W.; Du, W.; Zhang, X.; Jiang, Z.Y. Analysis of surface roughness evolution of ferritic stainless steel using crystal plasticity finite element method. J. Mater. Res. Technol. 2019, 8, 3175–3187. [Google Scholar]

- Feng, Z.Y.; Li, H.; Yang, J.C.; Huang, H.; Li, G.J.; Huang, D. Macro-meso scale modeling and simulation of surface roughening: Aluminum alloy tube bending. Int. J. Mech. Sci. 2018, 144, 696–707. [Google Scholar] [CrossRef]

- Panin, A.V.; Kazachenok, M.S.; Romanova, V.A.; Balokhonov, R.R.; Kozelskaya, A.I.; Sinykova, E.A.; Krukovskii, K.V. Strain-Induced Surface Roughening in Polycrystalline VT1-0 Titanium Specimens under Uniaxial Tension. Phys. Mesomech. 2018, 21, 249–257. [Google Scholar] [CrossRef]

- Furushima, T.; Sato, H.; Manabe, K.; Alexandrov, S. Identification of an Empirical Equation for Predicting Free Surface Roughness Evolution in Thin Sheets of Aluminum Alloy and Pure Copper. J. Manuf. Sci. Eng. Trans. ASME 2018, 140, 034501. [Google Scholar] [CrossRef]

- Furushima, T.; Tsunezaki, H.; Hirose, Y. Fracture and surface roughening behaviors in micro metal forming. Procedia Manuf. 2018, 15, 1481–1486. [Google Scholar] [CrossRef]

- Cai, Y.; Wang, X.S.; Yuan, S.J. Analysis of surface roughening behavior of 6063 aluminum alloy by tensile testing of a trapezoidal uniaxial specimen. Mater. Sci. Eng. A 2016, 672, 184–193. [Google Scholar] [CrossRef]

- Emelianova, E.; Romanova, V.; Zinovieva, O.; Balokhonov, R. The effects of surface-layer grain size and texture on deformation-induced surface roughening in polycrystalline titanium hardened by ultrasonic impact treatment. Mater. Sci. Eng. A 2020, 793, 139896. [Google Scholar] [CrossRef]

- Leu, D.K. Free surface roughening under simple tension. Int. J. Adv. Manuf. Technol. 2018, 95, 2349–2356. [Google Scholar]

- Solhjoo, S.; Halbertsma, P.J.; Veldhuis, M.; Toljaga, R.; Pei, Y. Effects of loading conditions on free surface roughening of AISI 420 martensitic stainless steel. J. Mater. Processing Technol. 2020, 275, 116311. [Google Scholar] [CrossRef]

- Romanova, V.; Dymnich, E.; Balokhonov, R.; Zinovieva, O. Mechanical Aspects of Deformation-Induced Surface Roughening in the Presence of Inclusions in a Subsurface Layer. Numerical Modeling. Front. Mech. Eng. 2020, 6, 66. [Google Scholar] [CrossRef]

- Romanova, V.; Balokhonov, R.; Zinovieva, O.; Shakhidjanov, V. Numerical study of the surface hardening effect on the deformation-induced roughening in titanium polycrystals. Comput. Mater. Sci. 2016, 116, 96–102. [Google Scholar] [CrossRef]

- Jung, J.; Yoon, J.I.; Moon, J.H.; Park, H.K.; Kim, H.S. Effect of coarse precipitates on surface roughening of an FCC polycrystalline material using crystal plasticity. Comput. Mater. Sci. 2017, 126, 121–131. [Google Scholar]

- Wouters, O.; Vellinga, W.P.; Tijum, R.V.; de Hosson, J.T.M. On the evolution of surface roughness during deformation of polycrystalline aluminum alloys. Acta Mater. 2005, 53, 4043–4050. [Google Scholar]

- Shi, Y.; Wu, P.D.; Lloyd, D.J.; Embury, D. Numerical study of surface roughening in blow-formed aluminum bottle with crystal plasticity. Mater. Sci. Eng. A 2015, 638, 97–105. [Google Scholar]

- Muhammad, W.; Ali, U.; Brahme, A.P.; Kang, J.; Mishra, R.K.; Inal, K. Experimental analyses and numerical modeling of texture evolution and the development of surface roughness during bending of an extruded aluminum alloy using a multiscale modeling framework. Int. J. Plast. 2019, 117, 93–121. [Google Scholar] [CrossRef]

- Cai, Y.; Wang, X.S.; Yuan, S.J. Quantitative analysis of orange peel during tension of 6063 alloy spun tubes. Trans. Nonferrous Met. Soc. China 2018, 5, 858–865. [Google Scholar] [CrossRef]

- Raabe, D.; Sachtleber, M.; Weiland, H.; Scheele, G.; Zhao, Z. Grain-scale micromechanics of polycrystal surfaces during plastic straining. Acta Mater. 2003, 51, 1539–1560. [Google Scholar] [CrossRef]

- Sachtleber, M.; Raabe, D.; Weiland, H. Surface roughening and color changes of coated aluminum sheets during plastic straining. J. Mater. Processing Technol. 2004, 148, 68–76. [Google Scholar]

- Sabat, R.K.; Muhammad, W.; Mishra, R.K.; Inal, K. Mechanism of microstructure and texture evolution during shear loading of AA6063 alloys. J. Alloys Compd. 2021, 889, 161607. [Google Scholar]

- Wang, S.W.; Zhang, S.H.; Song, H.W.; Chen, Y. Surface roughness improvement of the bent thin-walled copper tube by controlling the microstructure and texture components. Procedia Manuf. 2020, 50, 613–617. [Google Scholar]

- Zhao, Z.; Ramesh, M.; Raabe, D.; Cuitiño, A.M.; Radovitzky, R. Investigation of three-dimensional aspects of grain-scale plastic surface deformation of an aluminum oligocrystal. Int. J. Plast. 2008, 24, 2278–2297. [Google Scholar]

- Abe, T. Surface roughening and formability in sheet metal forming of polycrystalline metal based on r-value of grains. Int. J. Mech. Sci. 2014, 86, 2–6. [Google Scholar]

- Cai, Y.; Wang, X.S.; Yuan, S.J. Surface Roughening Behavior of 6063 Aluminum Alloy during Bulging by Spun Tubes. Materials 2017, 10, 299. [Google Scholar]

- Li, H. Analysis of slip activity and heterogeneous deformation in tension and tension-creep of Ti–5Al–2.5Sn (wt %) using in-situ SEM experiments. Philos. Mag. 2012, 92, 2923–2946. [Google Scholar]

- Le, G.M.; Godfrey, A.; Hansen, N.; Liu, W.; Winther, G.; Huang, X. Influence of grain size in the near-micrometre regime on the deformation microstructure in aluminium. Acta Mater. 2013, 61, 7072–7086. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cai, Y.; Wang, X.; Du, Y. Surface Roughening Behavior of the 6063-T4 Aluminum Alloy during Quasi-in Situ Uniaxial Stretching. Materials 2022, 15, 6265. https://doi.org/10.3390/ma15186265

Cai Y, Wang X, Du Y. Surface Roughening Behavior of the 6063-T4 Aluminum Alloy during Quasi-in Situ Uniaxial Stretching. Materials. 2022; 15(18):6265. https://doi.org/10.3390/ma15186265

Chicago/Turabian StyleCai, Yang, Xiaosong Wang, and Yan Du. 2022. "Surface Roughening Behavior of the 6063-T4 Aluminum Alloy during Quasi-in Situ Uniaxial Stretching" Materials 15, no. 18: 6265. https://doi.org/10.3390/ma15186265

APA StyleCai, Y., Wang, X., & Du, Y. (2022). Surface Roughening Behavior of the 6063-T4 Aluminum Alloy during Quasi-in Situ Uniaxial Stretching. Materials, 15(18), 6265. https://doi.org/10.3390/ma15186265