Direct Writing of Functional Layer by Selective Laser Sintering of Nanoparticles for Emerging Applications: A Review

Abstract

:1. Introduction

2. Materials

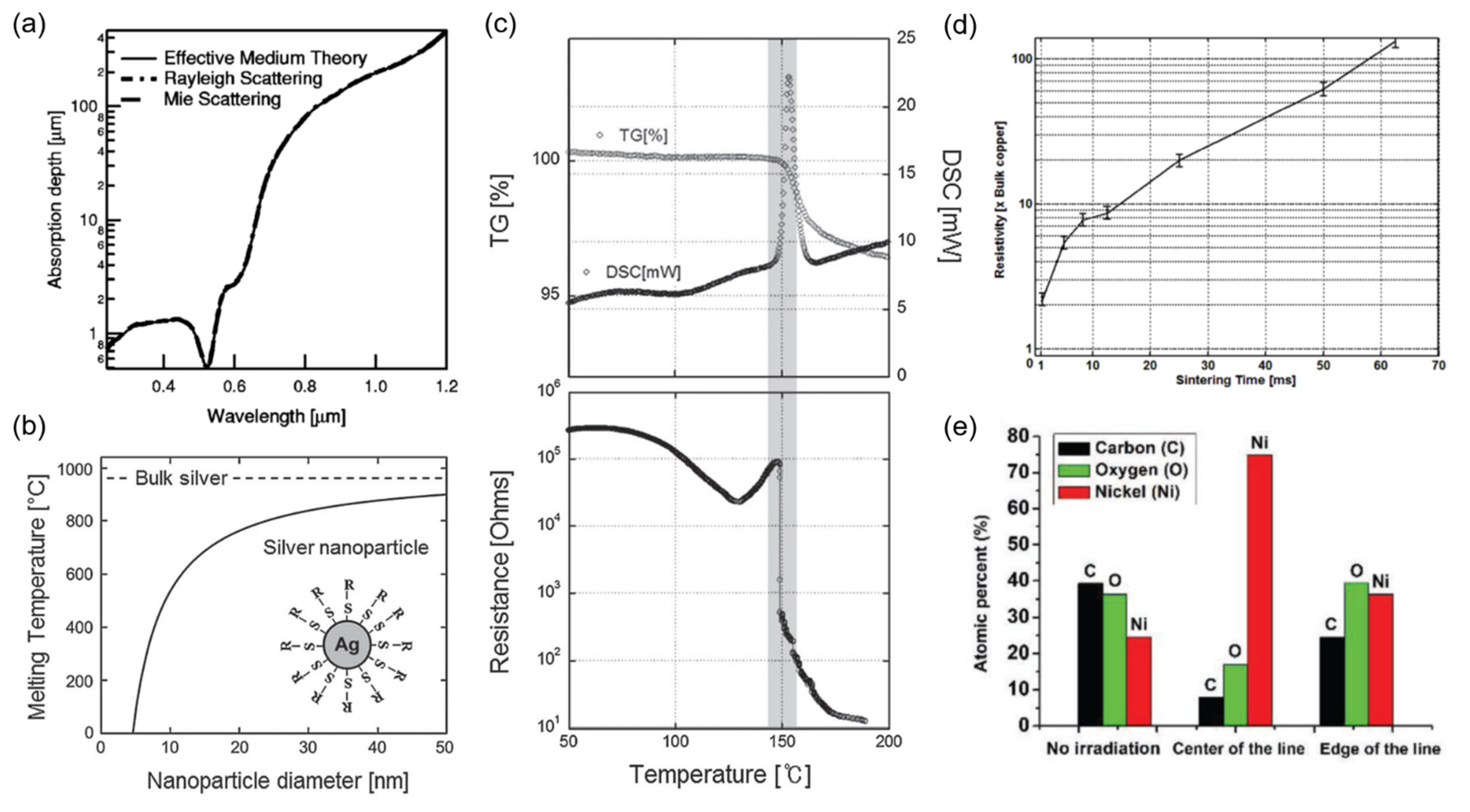

2.1. Noble Metals

2.2. Copper

2.3. Oxides and Others

3. Experimental Schemes

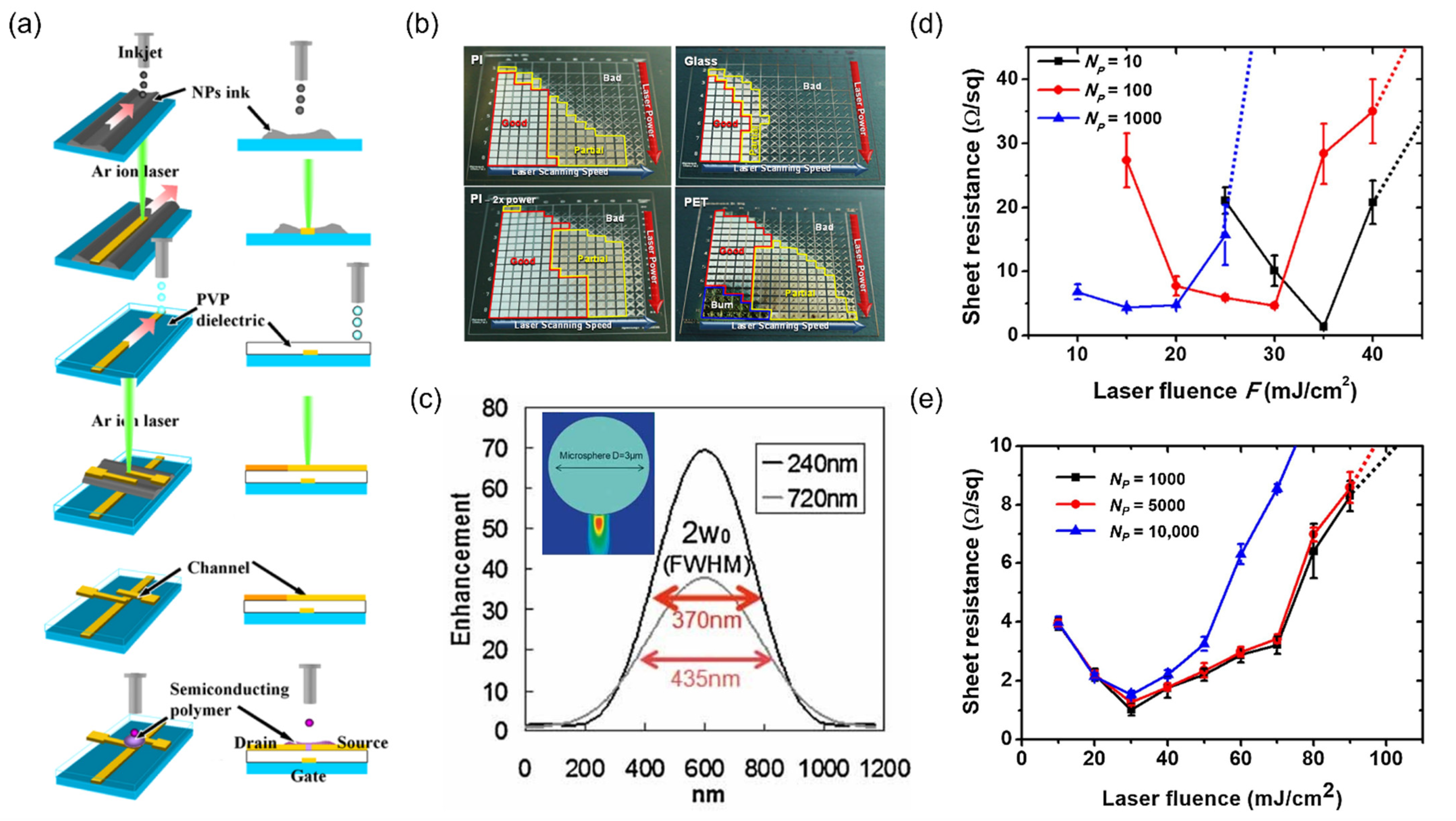

3.1. Material Deposition

3.2. Beam Focusing and Scanning Strategies

3.3. Laser Parameters

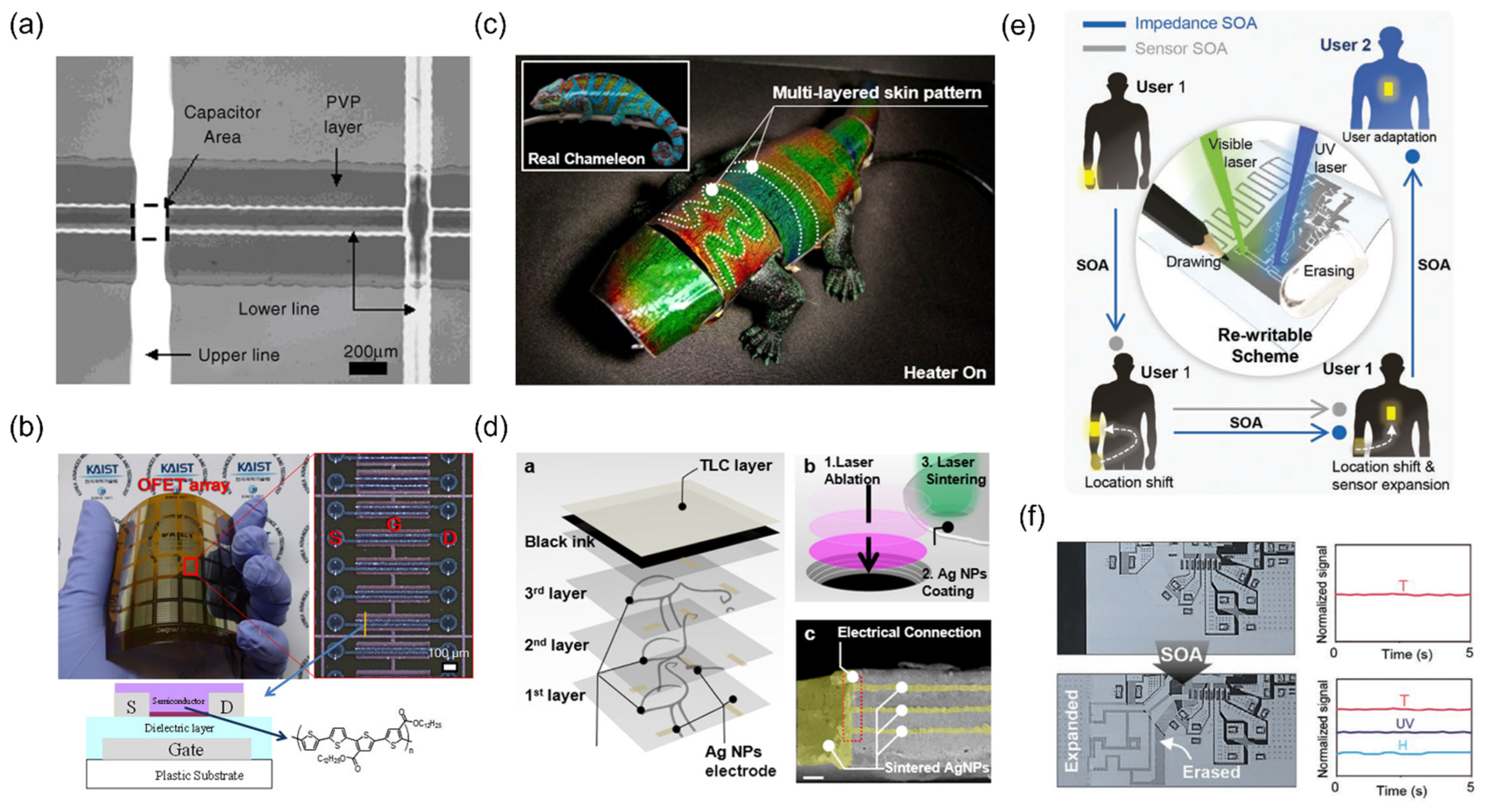

4. Applications

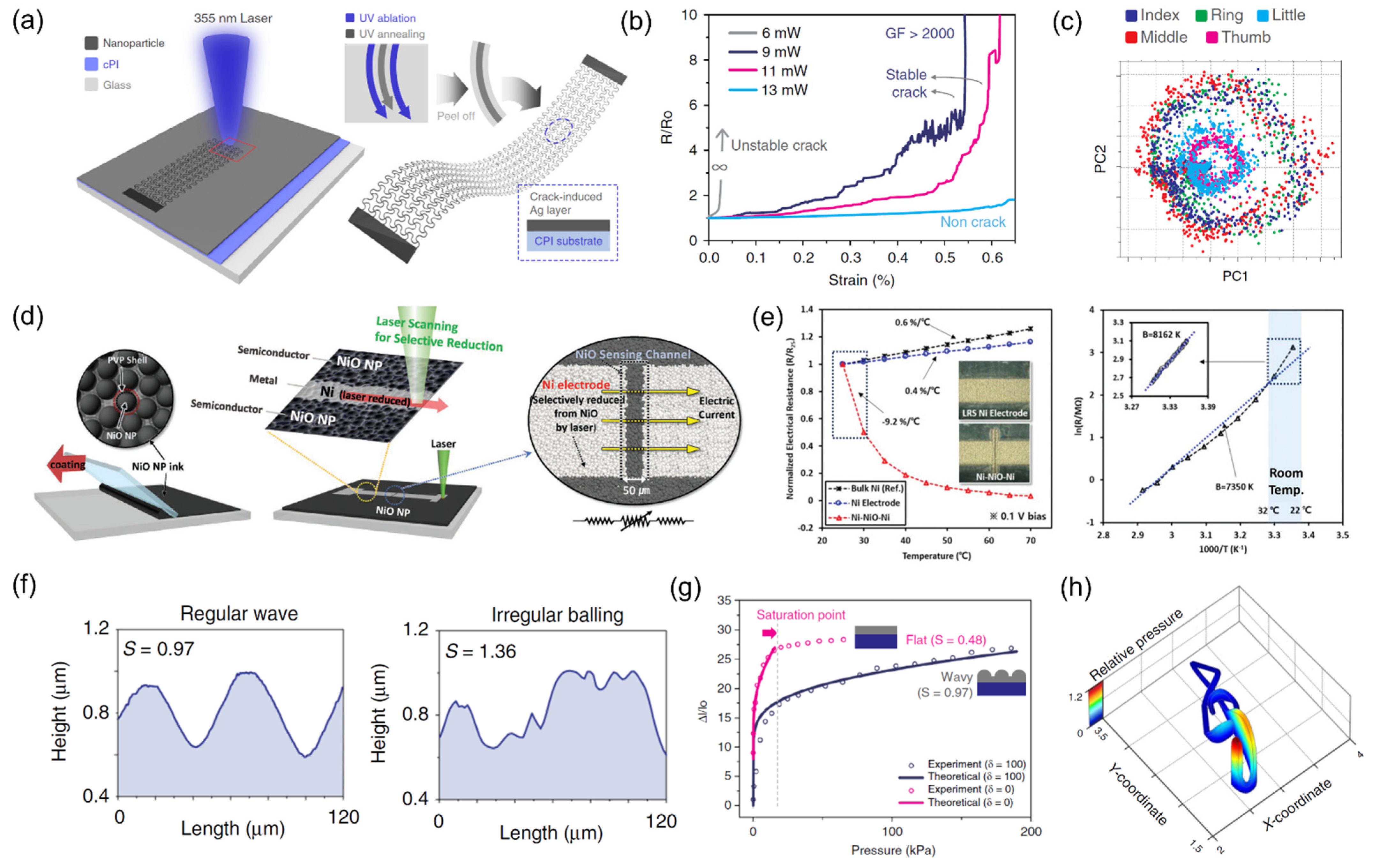

4.1. Electrical Interconnections

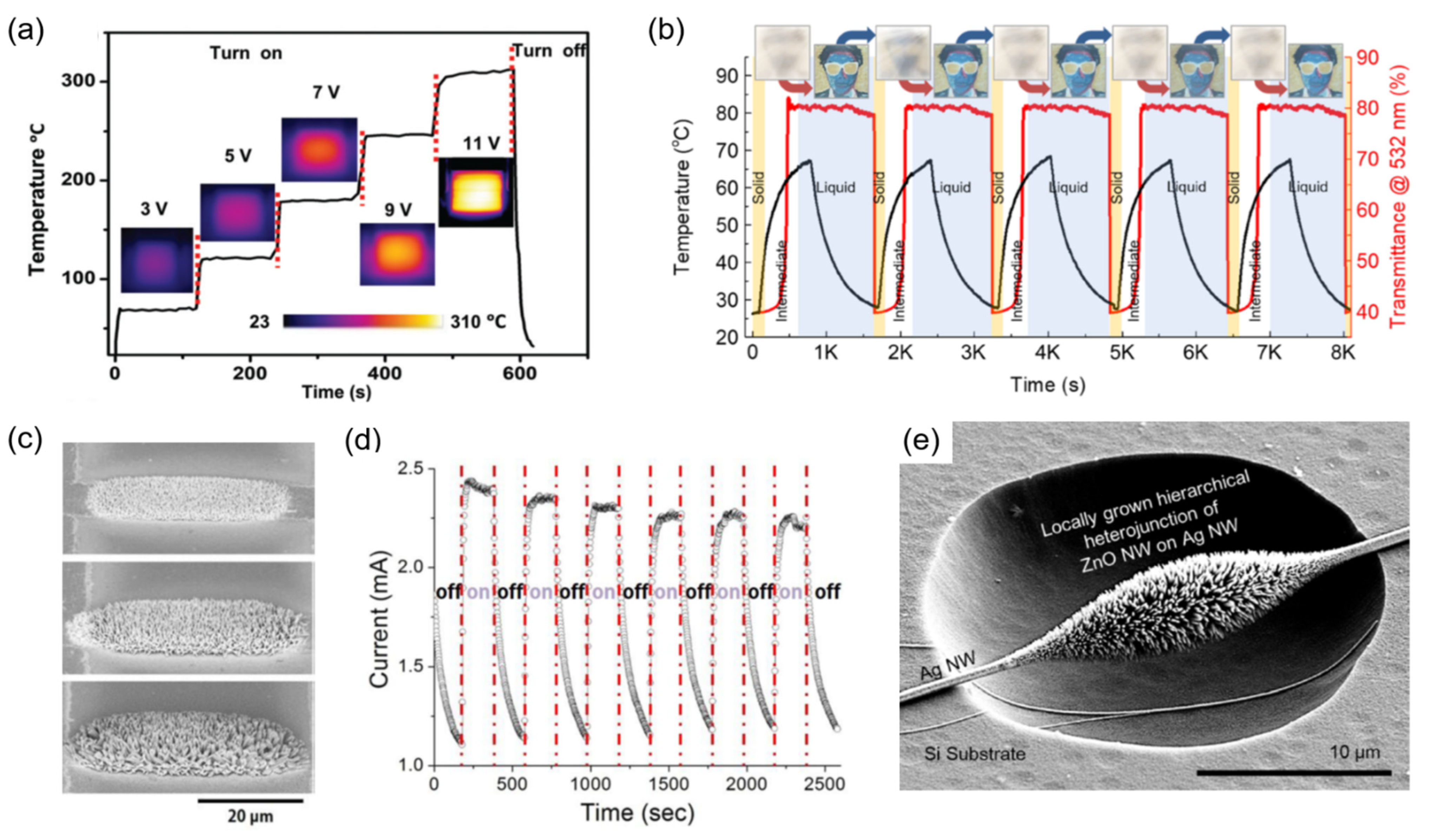

4.2. Sensors

4.3. Heaters

5. Conclusions and Perspective

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kim, H.; Pyun, K.R.; Lee, M.T.; Lee, H.B.; Ko, S.H. Recent Advances in Sustainable Wearable Energy Devices with Nanoscale Materials and Macroscale Structures. Adv. Funct. Mater. 2022, 32, 2110535. [Google Scholar] [CrossRef]

- Kim, K.K.; Choi, J.; Ko, S.H. Energy harvesting untethered soft electronic devices. Adv. Healthc. Mater. 2021, 10, 2002286. [Google Scholar] [CrossRef]

- Won, P.; Kim, K.K.; Kim, H.; Park, J.J.; Ha, I.; Shin, J.; Jung, J.; Cho, H.; Kwon, J.; Lee, H. Transparent soft actuators/sensors and camouflage skins for imperceptible soft robotics. Adv. Mater. 2021, 33, 2002397. [Google Scholar] [CrossRef] [PubMed]

- Huang, Q.; Zhu, Y. Printing conductive nanomaterials for flexible and stretchable electronics: A review of materials, processes, and applications. Adv. Mater. Technol. 2019, 4, 1800546. [Google Scholar] [CrossRef]

- Jung, D.; Lim, C.; Shim, H.J.; Kim, Y.; Park, C.; Jung, J.; Han, S.I.; Sunwoo, S.-H.; Cho, K.W.; Cha, G.D. Highly conductive and elastic nanomembrane for skin electronics. Science 2021, 373, 1022–1026. [Google Scholar] [CrossRef]

- May, G.S.; Spanos, C.J. Fundamentals of Semiconductor Manufacturing and Process Control; John Wiley & Sons: Hoboken, NJ, USA, 2006. [Google Scholar]

- Shin, J.; Ko, J.; Jeong, S.; Won, P.; Lee, Y.; Kim, J.; Hong, S.; Jeon, N.L.; Ko, S.H. Monolithic digital patterning of polydimethylsiloxane with successive laser pyrolysis. Nat. Mater. 2021, 20, 100–107. [Google Scholar] [CrossRef] [PubMed]

- Shishkovsky, I. Sintering of Functional Materials; BoD–Books on Demand: Norderstedt, Germany, 2018. [Google Scholar]

- Buffat, P.; Borel, J.P. Size effect on the melting temperature of gold particles. Phys. Rev. A 1976, 13, 2287. [Google Scholar] [CrossRef]

- Huang, X.; El-Sayed, M.A. Gold nanoparticles: Optical properties and implementations in cancer diagnosis and photothermal therapy. J. Adv. Res. 2010, 1, 13–28. [Google Scholar] [CrossRef]

- Heiligtag, F.J.; Niederberger, M. The fascinating world of nanoparticle research. Mater. Today 2013, 16, 262–271. [Google Scholar] [CrossRef]

- Khan, I.; Saeed, K.; Khan, I. Nanoparticles: Properties, applications and toxicities. Arab. J. Chem. 2019, 12, 908–931. [Google Scholar] [CrossRef]

- Bieri, N.R.; Chung, J.; Haferl, S.E.; Poulikakos, D.; Grigoropoulos, C.P. Microstructuring by printing and laser curing of nanoparticle solutions. Appl. Phys. Lett. 2003, 82, 3529–3531. [Google Scholar] [CrossRef]

- Son, Y.; Yeo, J.; Moon, H.; Lim, T.W.; Hong, S.; Nam, K.H.; Yoo, S.; Grigoropoulos, C.P.; Yang, D.-Y.; Ko, S.H. Nanoscale Electronics: Digital Fabrication by Direct Femtosecond Laser Processing of Metal Nanoparticles. Adv. Mater. 2011, 23, 3176–3181. [Google Scholar] [CrossRef] [PubMed]

- Zenou, M.; Ermak, O.; Saar, A.; Kotler, Z. Laser sintering of copper nanoparticles. J. Phys. D Appl. Phys. 2013, 47, 025501. [Google Scholar] [CrossRef]

- Nam, V.B.; Shin, J.; Yoon, Y.; Giang, T.T.; Kwon, J.; Suh, Y.D.; Yeo, J.; Hong, S.; Ko, S.H.; Lee, D. Highly Stable Ni-Based Flexible Transparent Conducting Panels Fabricated by Laser Digital Patterning. Adv. Funct. Mater. 2019, 29, 1806895. [Google Scholar] [CrossRef]

- Chung, J.; Ko, S.; Bieri, N.R.; Grigoropoulos, C.P.; Poulikakos, D. Conductor microstructures by laser curing of printed gold nanoparticle ink. Appl. Phys. Lett. 2004, 84, 801–803. [Google Scholar] [CrossRef]

- Ko, S.H.; Pan, H.; Grigoropoulos, C.P.; Luscombe, C.K.; Fréchet, J.M.J.; Poulikakos, D. Air stable high resolution organic transistors by selective laser sintering of ink-jet printed metal nanoparticles. Appl. Phys. Lett. 2007, 90, 141103. [Google Scholar] [CrossRef]

- Yamaguchi, M.; Araga, S.; Mita, M.; Yamasaki, K.; Maekawa, K. On-demand infrared laser sintering of gold nanoparticle paste for electrical contacts. IEEE Trans. Compon. Packag. Manuf. Technol. 2015, 5, 1160–1168. [Google Scholar] [CrossRef]

- Ko, S.H.; Pan, H.; Grigoropoulos, C.P.; Luscombe, C.K.; Fréchet, J.M.J.; Poulikakos, D. All-inkjet-printed flexible electronics fabrication on a polymer substrate by low-temperature high-resolution selective laser sintering of metal nanoparticles. Nanotechnology 2007, 18, 345202. [Google Scholar] [CrossRef]

- Lim, J.; Ham, J.; Lee, W.; Hwang, E.; Lee, W.C.; Hong, S. A Transformative Gold Patterning through Selective Laser Refining of Cyanide. Nanomaterials 2021, 11, 1921. [Google Scholar] [CrossRef]

- Chung, J.; Bieri, N.R.; Ko, S.; Grigoropoulos, C.P.; Poulikakos, D. In-tandem deposition and sintering of printed gold nanoparticle inks induced by continuous Gaussian laser irradiation. Appl. Phys. A 2004, 79, 1259–1261. [Google Scholar] [CrossRef]

- Chung, J.; Ko, S.; Grigoropoulos, C.P.; Bieri, N.R.; Dockendorf, C.; Poulikakos, D. Damage-Free Low Temperature Pulsed Laser Printing of Gold Nanoinks On Polymers. J. Heat Transf. 2005, 127, 724–732. [Google Scholar] [CrossRef]

- Park, S.; Kwon, J.; Lim, J.; Shin, W.; Lee, Y.; Lee, H.; Kim, H.-J.; Han, S.; Yeo, J.; Ko, S.H. Micropatterning of metal nanoparticle ink by laser-induced thermocapillary flow. Nanomaterials 2018, 8, 645. [Google Scholar] [CrossRef] [PubMed]

- Pan, H.; Ko, S.H.; Grigoropoulos, C.P. The Solid-State Neck Growth Mechanisms in Low Energy Laser Sintering of Gold Nanoparticles: A Molecular Dynamics Simulation Study. J. Heat Transf. 2008, 130, 092404. [Google Scholar] [CrossRef]

- Yang, L.; Gan, Y.; Zhang, Y.; Chen, J.K. Molecular dynamics simulation of neck growth in laser sintering of different-sized gold nanoparticles under different heating rates. Appl. Phys. A 2012, 106, 725–735. [Google Scholar] [CrossRef]

- Pan, H.; Ko, S.H.; Grigoropoulos, C.P. The coalescence of supported gold nanoparticles induced by nanosecond laser irradiation. Appl. Phys. A 2008, 90, 247–253. [Google Scholar] [CrossRef]

- Yeo, J.; Hong, S.; Lee, D.; Hotz, N.; Lee, M.-T.; Grigoropoulos, C.P.; Ko, S.H. Next Generation Non-Vacuum, Maskless, Low Temperature Nanoparticle Ink Laser Digital Direct Metal Patterning for a Large Area Flexible Electronics. PLoS ONE 2012, 7, e42315. [Google Scholar] [CrossRef]

- Wani, I.A.; Khatoon, S.; Ganguly, A.; Ahmed, J.; Ganguli, A.K.; Ahmad, T. Silver nanoparticles: Large scale solvothermal synthesis and optical properties. Mater. Res. Bull. 2010, 45, 1033–1038. [Google Scholar] [CrossRef]

- Hong, S.; Yeo, J.; Kim, G.; Kim, D.; Lee, H.; Kwon, J.; Lee, H.; Lee, P.; Ko, S.H. Nonvacuum, Maskless Fabrication of a Flexible Metal Grid Transparent Conductor by Low-Temperature Selective Laser Sintering of Nanoparticle Ink. ACS Nano 2013, 7, 5024–5031. [Google Scholar] [CrossRef]

- Kurnoothala, R.; Vishnubhatla, K.C. Facile fabrication of integrated microfluidic SERS substrate by femtosecond laser sintering of silver nano particles. Opt. Mater. 2021, 111, 110518. [Google Scholar] [CrossRef]

- Son, Y.; Yeo, J.; Ha, C.W.; Lee, J.; Hong, S.; Nam, K.H.; Yang, D.-Y.; Ko, S.H. Application of the specific thermal properties of Ag nanoparticles to high-resolution metal patterning. Thermochim. Acta 2012, 542, 52–56. [Google Scholar] [CrossRef]

- Yang, Y.; Li, Z.; Yang, S.; Li, Y.; Huang, J. Multiscale simulation study of laser sintering of inkjet-printed silver nanoparticle inks. Int. J. Heat Mass Transf. 2020, 159, 120110. [Google Scholar] [CrossRef]

- Ko, S.H.; Pan, H.; Ryu, S.G.; Misra, N.; Grigoropoulos, C.P.; Park, H.K. Nanomaterial enabled laser transfer for organic light emitting material direct writing. Appl. Phys. Lett. 2008, 93, 151110. [Google Scholar] [CrossRef]

- Yang, M.; Chon, M.-W.; Kim, J.-H.; Lee, S.-H.; Jo, J.; Yeo, J.; Ko, S.H.; Choa, S.-H. Mechanical and environmental durability of roll-to-roll printed silver nanoparticle film using a rapid laser annealing process for flexible electronics. Microelectron. Reliab. 2014, 54, 2871–2880. [Google Scholar] [CrossRef]

- Liu, Y.-K.; Lee, M.-T. Laser Direct Synthesis and Patterning of Silver Nano/Microstructures on a Polymer Substrate. ACS Appl. Mater. Interfaces 2014, 6, 14576–14582. [Google Scholar] [CrossRef] [PubMed]

- Tsai, S.-L.; Liu, Y.-K.; Pan, H.; Liu, C.-H.; Lee, M.-T. The coupled photothermal reaction and transport in a laser additive metal nanolayer simultaneous synthesis and pattering for flexible electronics. Nanomaterials 2016, 6, 12. [Google Scholar] [CrossRef]

- Kang, B.; Ko, S.; Kim, J.; Yang, M. Microelectrode fabrication by laser direct curing of tiny nanoparticle self-generated from organometallic ink. Opt. Express 2011, 19, 2573–2579. [Google Scholar] [CrossRef] [PubMed]

- Cai, Z.X.; Zeng, X.Y.; Duan, J. Fabrication of platinum microheater on alumina substrate by micro-pen and laser sintering. Thin Solid Film. 2011, 519, 3893–3896. [Google Scholar] [CrossRef]

- Kang, T.Y.; Yoo, K.; Lee, J.A.; Lee, W.; Kim, K.; Lee, D.-K.; Kim, H.; Ko, M.J. A facile and rapid process to fabricate platinum counter electrode in dye-sensitized solar cell using nanosecond pulsed laser sintering at room temperature. J. Nanosci. Nanotechnol. 2014, 14, 5309–5312. [Google Scholar] [CrossRef] [PubMed]

- Tsuji, T.; Suzuki, Y.; Sakaki, S.; Ishikawa, Y.; Koshizaki, N. Preparation of binder-free spherical submicron-sized platinum particles using laser melting in liquids. Electron. Commun. Jpn. 2021, 104, e12330. [Google Scholar] [CrossRef]

- Edri, E.; Armon, N.; Greenberg, E.; Moshe-Tsurel, S.; Lubotzky, D.; Salzillo, T.; Perelshtein, I.; Tkachev, M.; Girshevitz, O.; Shpaisman, H. Laser printing of multilayered alternately conducting and insulating microstructures. ACS Appl. Mater. Interfaces 2021, 13, 36416–36425. [Google Scholar] [CrossRef]

- Hayati-Roodbari, N.; Wheeldon, A.; Hendler, C.; Fian, A.; Trattnig, R. Ohmic contact formation for inkjet-printed nanoparticle copper inks on highly doped GaAs. Nanotechnology 2021, 32, 225205. [Google Scholar] [CrossRef] [PubMed]

- Halonen, E.; Heinonen, E.; Mäntysalo, M. The Effect of Laser Sintering Process Parameters on Cu Nanoparticle Ink in Room Conditions. Opt. Photonics J. 2013, 3, 5. [Google Scholar] [CrossRef]

- Soltani, A.; Vahed, B.K.; Mardoukhi, A.; Mäntysalo, M. Laser sintering of copper nanoparticles on top of silicon substrates. Nanotechnology 2015, 27, 035203. [Google Scholar] [CrossRef]

- Yang, G.; Xu, G.; Li, Q.; Zeng, Y.; Zhang, Y.; Hao, M.; Cui, C. Understanding the sintering and heat dissipation behaviours of Cu nanoparticles during low-temperature selective laser sintering process on flexible substrates. J. Phys. D Appl. Phys. 2021, 54, 375304. [Google Scholar] [CrossRef]

- Joo, M.; Lee, B.; Jeong, S.; Lee, M. Laser sintering of Cu paste film printed on polyimide substrate. Appl. Surf. Sci. 2011, 258, 521–524. [Google Scholar] [CrossRef]

- Joo, M.; Lee, B.; Jeong, S.; Lee, M. Comparative studies on thermal and laser sintering for highly conductive Cu films printable on plastic substrate. Thin Solid Film. 2012, 520, 2878–2883. [Google Scholar] [CrossRef]

- Yu, J.H.; Kang, K.-T.; Hwang, J.Y.; Lee, S.-H.; Kang, H. Rapid sintering of copper nano ink using a laser in air. Int. J. Precis. Eng. Manuf. 2014, 15, 1051–1054. [Google Scholar] [CrossRef]

- Kwon, J.; Cho, H.; Eom, H.; Lee, H.; Suh, Y.D.; Moon, H.; Shin, J.; Hong, S.; Ko, S.H. Low-temperature oxidation-free selective laser sintering of Cu nanoparticle paste on a polymer substrate for the flexible touch panel applications. ACS Appl. Mater. Interfaces 2016, 8, 11575–11582. [Google Scholar] [CrossRef]

- Kwon, J.; Cho, H.; Suh, Y.D.; Lee, J.; Lee, H.; Jung, J.; Kim, D.; Lee, D.; Hong, S.; Ko, S.H. Flexible and transparent cu electronics by low-temperature acid-assisted laser processing of Cu nanoparticles. Adv. Mater. Technol. 2017, 2, 1600222. [Google Scholar] [CrossRef]

- Min, H.; Lee, B.; Jeong, S.; Lee, M. Fabrication of 10 µm-scale conductive Cu patterns by selective laser sintering of Cu complex ink. Opt. Laser Technol. 2017, 88, 128–133. [Google Scholar] [CrossRef]

- Pan, H.; Misra, N.; Ko, S.H.; Grigoropoulos, C.P.; Miller, N.; Haller, E.E.; Dubon, O. Melt-mediated coalescence of solution-deposited ZnO nanoparticles by excimer laser annealing for thin-film transistor fabrication. Appl. Phys. A 2009, 94, 111–115. [Google Scholar] [CrossRef]

- Pan, H.; Ko, S.H.; Misra, N.; Grigoropoulos, C.P. Laser annealed composite titanium dioxide electrodes for dye-sensitized solar cells on glass and plastics. Appl. Phys. Lett. 2009, 94, 071117. [Google Scholar] [CrossRef]

- Lee, D.; Pan, H.; Ko, S.H.; Park, H.K.; Kim, E.; Grigoropoulos, C.P. Non-vacuum, single-step conductive transparent ZnO patterning by ultra-short pulsed laser annealing of solution-deposited nanoparticles. Appl. Phys. A 2012, 107, 161–171. [Google Scholar] [CrossRef]

- Sandmann, A.; Notthoff, C.; Winterer, M. Continuous wave ultraviolet-laser sintering of ZnO and TiO2 nanoparticle thin films at low laser powers. J. Appl. Phys. 2013, 113, 044310. [Google Scholar] [CrossRef]

- Ming, L.; Yang, H.; Zhang, W.; Zeng, X.; Xiong, D.; Xu, Z.; Wang, H.; Chen, W.; Xu, X.; Wang, M. Selective laser sintering of TiO2 nanoparticle film on plastic conductive substrate for highly efficient flexible dye-sensitized solar cell application. J. Mater. Chem. A 2014, 2, 4566–4573. [Google Scholar] [CrossRef]

- Pan, H.; Lee, D.; Ko, S.H.; Grigoropoulos, C.P.; Park, H.K.; Hoult, T. Fiber laser annealing of indium-tin-oxide nanoparticles for large area transparent conductive layers and optical film characterization. Appl. Phys. A 2011, 104, 29–38. [Google Scholar] [CrossRef]

- Cho, H.; Min, J.; Won, D.; Kwon, J.; Ko, S.H. Selective photo-thermal conversion of tungsten oxide sol precursor for electrochromic smart window applications. Acta Mater. 2020, 201, 528–534. [Google Scholar] [CrossRef]

- Wang, J.; Lisco, F.; Hutt, D.A.; Jones, L.C.; Bowers, J.W.; Isherwood, P.J.; Zhou, Z.; Conway, P.P. Laser sintering and patterning of gallium-doped zinc oxide/indium-tin oxide nanoparticle films with tailorable electrical and optical properties. Mater. Des. 2020, 194, 108865. [Google Scholar] [CrossRef]

- Kang, B.; Han, S.; Kim, J.; Ko, S.; Yang, M. One-Step Fabrication of Copper Electrode by Laser-Induced Direct Local Reduction and Agglomeration of Copper Oxide Nanoparticle. J. Phys. Chem. C 2011, 115, 23664–23670. [Google Scholar] [CrossRef]

- Rahman, M.K.; Lu, Z.; Kwon, K.-S. Green laser sintering of copper oxide (CuO) nano particle (NP) film to form Cu conductive lines. AIP Adv. 2018, 8, 095008. [Google Scholar] [CrossRef] [Green Version]

- Nam, V.B.; Giang, T.T.; Lee, D. Laser digital patterning of finely-structured flexible copper electrodes using copper oxide nanoparticle ink produced by a scalable synthesis method. Appl. Surf. Sci. 2021, 570, 151179. [Google Scholar]

- Liu, H.; Liu, Y.; Guo, W.; Zhou, X.; Lin, L.; Peng, P. Laser assisted ink-printing of copper oxide nanoplates for memory device. Mater. Lett. 2020, 261, 127097. [Google Scholar] [CrossRef]

- Lee, D.; Paeng, D.; Park, H.K.; Grigoropoulos, C.P. Vacuum-Free, Maskless Patterning of Ni Electrodes by Laser Reductive Sintering of NiO Nanoparticle Ink and Its Application to Transparent Conductors. ACS Nano 2014, 8, 9807–9814. [Google Scholar] [CrossRef] [PubMed]

- Rho, Y.; Kang, K.-T.; Lee, D. Highly crystalline Ni/NiO hybrid electrodes processed by inkjet printing and laser-induced reductive sintering under ambient conditions. Nanoscale 2016, 8, 8976–8985. [Google Scholar] [CrossRef] [PubMed]

- Nam, V.B.; Lee, D. Evaluation of Ni-based flexible resistance temperature detectors fabricated by laser digital pattering. Nanomaterials 2021, 11, 576. [Google Scholar] [CrossRef] [PubMed]

- Paeng, D.; Lee, D.; Yeo, J.; Yoo, J.-H.; Allen, F.I.; Kim, E.; So, H.; Park, H.K.; Minor, A.M.; Grigoropoulos, C.P. Laser-induced reductive sintering of nickel oxide nanoparticles under ambient conditions. J. Phys. Chem. C 2015, 119, 6363–6372. [Google Scholar] [CrossRef]

- Yu, Y.; Chen, M.; Wang, S.; Hill, C.; Joshi, P.; Kuruganti, T.; Hu, A. Laser sintering of printed anodes for al-air batteries. J. Electrochem. Soc. 2018, 165, A584. [Google Scholar] [CrossRef]

- Shou, W.; Mahajan, B.K.; Ludwig, B.; Yu, X.; Staggs, J.; Huang, X.; Pan, H. Low-Cost Manufacturing of Bioresorbable Conductors by Evaporation–Condensation-Mediated Laser Printing and Sintering of Zn Nanoparticles. Adv. Mater. 2017, 29, 1700172. [Google Scholar] [CrossRef]

- Suh, Y.D.; Jung, J.; Lee, H.; Yeo, J.; Hong, S.; Lee, P.; Lee, D.; Ko, S.H. Nanowire reinforced nanoparticle nanocomposite for highly flexible transparent electrodes: Borrowing ideas from macrocomposites in steel-wire reinforced concrete. J. Mater. Chem. C 2017, 5, 791–798. [Google Scholar] [CrossRef]

- Liu, S.; Yuen, M.C.; White, E.L.; Boley, J.W.; Deng, B.; Cheng, G.J.; Kramer-Bottiglio, R. Laser sintering of liquid metal nanoparticles for scalable manufacturing of soft and flexible electronics. ACS Appl. Mater. Interfaces 2018, 10, 28232–28241. [Google Scholar] [CrossRef]

- Xie, K.; Mork, K.; Held, J.T.; Mkhoyan, K.A.; Kortshagen, U.; Gupta, M.C. Quasi continuous wave laser sintering of Si-Ge nanoparticles for thermoelectrics. J. Appl. Phys. 2018, 123, 094301. [Google Scholar] [CrossRef] [Green Version]

- Xie, K.; Gupta, M.C. Thermoelectric properties of SiGe thin films prepared by laser sintering of nanograin powders. J. Alloy. Compd. 2020, 820, 153182. [Google Scholar] [CrossRef]

- Titkov, A.I.; Logutenko, O.A.; Vorobyev, A.M.; Borisenko, T.A.; Bulina, N.V.; Ulihin, A.S.; Baev, S.G.; Bessmeltsev, V.P.; Lyakhov, N.Z. Laser sintering of Cu@ Ag core-shell nanoparticles for printed electronics applications. Mater. Today Proc. 2020, 25, 447–450. [Google Scholar] [CrossRef]

- Ko, S.H.; Chung, J.; Pan, H.; Grigoropoulos, C.P.; Poulikakos, D. Fabrication of multilayer passive and active electric components on polymer using inkjet printing and low temperature laser processing. Sens. Actuators A Phys. 2007, 134, 161–168. [Google Scholar] [CrossRef]

- Suh, Y.D.; Kwon, J.; Lee, J.; Lee, H.; Jeong, S.; Kim, D.; Cho, H.; Yeo, J.; Ko, S.H. Maskless fabrication of highly robust, flexible transparent Cu conductor by random crack network assisted Cu nanoparticle patterning and laser sintering. Adv. Electron. Mater. 2016, 2, 1600277. [Google Scholar] [CrossRef]

- Khabarov, K.; Kornyushin, D.; Masnaviev, B.; Tuzhilin, D.; Efimov, A.; Saprykin, D.; Ivanov, V. Laser sintering of silver nanoparticles deposited by dry aerosol printing. J. Phys. 2019, 1410, 012217. [Google Scholar] [CrossRef]

- Yeo, J.; Kim, G.; Hong, S.; Kim, M.S.; Kim, D.; Lee, J.; Lee, H.B.; Kwon, J.; Suh, Y.D.; Kang, H.W. Flexible supercapacitor fabrication by room temperature rapid laser processing of roll-to-roll printed metal nanoparticle ink for wearable electronics application. J. Power Sources 2014, 246, 562–568. [Google Scholar] [CrossRef]

- Lee, H.; Hong, S.; Kwon, J.; Suh, Y.D.; Lee, J.; Moon, H.; Yeo, J.; Ko, S.H. All-solid-state flexible supercapacitors by fast laser annealing of printed metal nanoparticle layers. J. Mater. Chem. A 2015, 3, 8339–8345. [Google Scholar] [CrossRef]

- Pan, H.; Hwang, D.J.; Ko, S.H.; Clem, T.A.; Fréchet, J.M.J.; Bäuerle, D.; Grigoropoulos, C.P. High-Throughput Near-Field Optical Nanoprocessing of Solution-Deposited Nanoparticles. Small 2010, 6, 1812–1821. [Google Scholar] [CrossRef]

- Noh, J.; Ha, J.; Kim, D. Femtosecond and nanosecond laser sintering of silver nanoparticles on a flexible substrate. Appl. Surf. Sci. 2020, 511, 145574. [Google Scholar] [CrossRef]

- Lee, M.-T.; Lee, D.; Sherry, A.; Grigoropoulos, C.P. Rapid selective metal patterning on polydimethylsiloxane (PDMS) fabricated by capillarity-assisted laser direct write. J. Micromech. Microeng. 2011, 21, 095018. [Google Scholar] [CrossRef]

- Shin, W.; Lim, J.; Lee, Y.; Park, S.; Kim, H.; Cho, H.; Shin, J.; Yoon, Y.; Lee, H.; Kim, H.-J. Shear-assisted laser transfer of metal nanoparticle ink to an elastomer substrate. Materials 2018, 11, 2511. [Google Scholar] [CrossRef] [PubMed]

- Lim, J.; Kim, Y.; Shin, J.; Lee, Y.; Shin, W.; Qu, W.; Hwang, E.; Park, S.; Hong, S. Continuous-Wave Laser-Induced Transfer of Metal Nanoparticles to Arbitrary Polymer Substrates. Nanomaterials 2020, 10, 701. [Google Scholar] [CrossRef]

- Zacharatos, F.; Theodorakos, I.; Karvounis, P.; Tuohy, S.; Braz, N.; Melamed, S.; Kabla, A.; De la Vega, F.; Andritsos, K.; Hatziapostolou, A. Selective laser sintering of laser printed Ag nanoparticle micropatterns at high repetition rates. Materials 2018, 11, 2142. [Google Scholar] [CrossRef] [PubMed]

- Koritsoglou, O.; Theodorakos, I.; Zacharatos, F.; Makrygianni, M.; Kariyapperuma, D.; Price, R.; Cobb, B.; Melamed, S.; Kabla, A.; de la Vega, F. Copper micro-electrode fabrication using laser printing and laser sintering processes for on-chip antennas on flexible integrated circuits. Opt. Mater. Express 2019, 9, 3046–3058. [Google Scholar] [CrossRef]

- Liu, Q.; Xu, B.; Zhang, Y.; Wang, X.; Mei, X.; Wang, X. Picosecond laser sintering of silver paste printed by laser induced forward transfer. Opt. Laser Technol. 2021, 135, 106712. [Google Scholar] [CrossRef]

- Breckenfeld, E.; Kim, H.; Auyeung, R.C.; Piqué, A. Laser-induced forward transfer of Ag nanopaste. JoVE 2016, 109, e53728. [Google Scholar] [CrossRef]

- Podder, C.; Gong, X.; Yu, X.; Shou, W.; Pan, H. Submicron Metal 3D Printing by Ultrafast Laser Heating and Induced Ligand Transformation of Nanocrystals. ACS Appl. Mater. Interfaces 2021, 13, 42154–42163. [Google Scholar] [CrossRef]

- Bäuerle, D. Laser Processing and Chemistry; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Lee, H.; Kwon, J.; Shin, W.S.; Kim, H.R.; Shin, J.; Cho, H.; Han, S.; Yeo, J.; Hong, S. Large-area compatible laser sintering schemes with a spatially extended focused beam. Micromachines 2017, 8, 153. [Google Scholar] [CrossRef]

- An, K.; Hong, S.; Han, S.; Lee, H.; Yeo, J.; Ko, S.H. Selective Sintering of Metal Nanoparticle Ink for Maskless Fabrication of an Electrode Micropattern Using a Spatially Modulated Laser Beam by a Digital Micromirror Device. ACS Appl. Mater. Interfaces 2014, 6, 2786–2790. [Google Scholar] [CrossRef]

- Park, H.; Oh, Y.; Park, E.; Park, J.; Jeong, H.; Kim, J. High-power ytterbium-doped fibre master-oscillator power-amplifier at 1018 nm. Laser Phys. 2022, 32, 025103. [Google Scholar] [CrossRef]

- Lee, C.; Hahn, J.W. Calculating the threshold energy of the pulsed laser sintering of silver and copper nanoparticles. J. Opt. Soc. Korea 2016, 20, 601–606. [Google Scholar] [CrossRef]

- Lee, H.; Yang, M. Effect of solvent and PVP on electrode conductivity in laser-induced reduction process. Appl. Phys. A 2015, 119, 317–323. [Google Scholar] [CrossRef]

- Hernandez-Castaneda, J.C.; Lok, B.K.; Zheng, H. Laser sintering of Cu nanoparticles on PET polymer substrate for printed electronics at different wavelengths and process conditions. Front. Mech. Eng. 2020, 15, 303–318. [Google Scholar] [CrossRef]

- Paeng, D.; Lee, D.; Grigoropoulos, C.P. Characteristic time scales of coalescence of silver nanocomposite and nanoparticle films induced by continuous wave laser irradiation. Appl. Phys. Lett. 2014, 105, 073110. [Google Scholar] [CrossRef]

- Paeng, D.; Yeo, J.; Lee, D.; Moon, S.-J.; Grigoropoulos, C.P. Laser wavelength effect on laser-induced photo-thermal sintering of silver nanoparticles. Appl. Phys. A 2015, 120, 1229–1240. [Google Scholar] [CrossRef]

- Cheng, C.-W.; Chen, J. Femtosecond laser sintering of copper nanoparticles. Appl. Phys. A 2016, 122, 289. [Google Scholar] [CrossRef]

- Roy, N.K.; Dibua, O.G.; Jou, W.; He, F.; Jeong, J.; Wang, Y.; Cullinan, M.A. A comprehensive study of the sintering of copper nanoparticles using femtosecond, nanosecond, and continuous wave lasers. J. Micro Nano-Manuf. 2018, 6, 10903. [Google Scholar] [CrossRef]

- Ko, S.H.; Pan, H.; Hwang, D.J.; Chung, J.; Ryu, S.; Grigoropoulos, C.P.; Poulikakos, D. High resolution selective multilayer laser processing by nanosecond laser ablation of metal nanoparticle films. J. Appl. Phys. 2007, 102, 093102. [Google Scholar] [CrossRef]

- Kim, H.; Choi, J.; Kim, K.K.; Won, P.; Hong, S.; Ko, S.H. Biomimetic chameleon soft robot with artificial crypsis and disruptive coloration skin. Nat. Commun. 2021, 12, 4658. [Google Scholar] [CrossRef]

- Kim, K.K.; Choi, J.; Kim, J.H.; Nam, S.; Ko, S.H. Evolvable skin electronics by in situ and in operando adaptation. Adv. Funct. Mater. 2022, 32, 2106329. [Google Scholar] [CrossRef]

- Kim, H.; Shin, J.; Hong, S.; Ko, S.H. Ag Electrode Strain Sensor Fabrication Using Laser Direct Writing Process. J. Sens. Sci. Technol. 2015, 24, 215–218. [Google Scholar] [CrossRef]

- Kim, K.K.; Ha, I.; Kim, M.; Choi, J.; Won, P.; Jo, S.; Ko, S.H. A deep-learned skin sensor decoding the epicentral human motions. Nat. Commun. 2020, 11, 2149. [Google Scholar] [CrossRef]

- Kang, D.; Pikhitsa, P.V.; Choi, Y.W.; Lee, C.; Shin, S.S.; Piao, L.; Park, B.; Suh, K.-Y.; Kim, T.-I.; Choi, M. Ultrasensitive mechanical crack-based sensor inspired by the spider sensory system. Nature 2014, 516, 222–226. [Google Scholar] [CrossRef]

- Ho, L.D.-A.; Nam, V.B.; Lee, D. Flexible Ni/NiOx-Based Sensor for Human Breath Detection. Materials 2021, 15, 47. [Google Scholar] [CrossRef] [PubMed]

- Shin, J.; Jeong, B.; Kim, J.; Nam, V.B.; Yoon, Y.; Jung, J.; Hong, S.; Lee, H.; Eom, H.; Yeo, J. Sensitive wearable temperature sensor with seamless monolithic integration. Adv. Mater. 2020, 32, 1905527. [Google Scholar] [CrossRef]

- Kim, K.K.; Ha, I.; Won, P.; Seo, D.-G.; Cho, K.-J.; Ko, S.H. Transparent wearable three-dimensional touch by self-generated multiscale structure. Nat. Commun. 2019, 10, 2582. [Google Scholar] [CrossRef]

- Hong, S.; Yeo, J.; Lee, J.; Lee, H.; Lee, P.; Lee, S.S.; Ko, S.H. Selective laser direct patterning of silver nanowire percolation network transparent conductor for capacitive touch panel. J. Nanosci. Nanotechnol. 2015, 15, 2317–2323. [Google Scholar] [CrossRef]

- Jung, J.; Cho, H.; Choi, S.H.; Kim, D.; Kwon, J.; Shin, J.; Hong, S.; Kim, H.; Yoon, Y.; Lee, J. Moiré-free imperceptible and flexible random metal grid electrodes with large figure-of-merit by photonic sintering control of copper nanoparticles. ACS Appl. Mater. Interfaces 2019, 11, 15773–15780. [Google Scholar] [CrossRef]

- Nam, V.B.; Shin, J.; Choi, A.; Choi, H.; Ko, S.H.; Lee, D. High-temperature, thin, flexible and transparent Ni-based heaters patterned by laser-induced reductive sintering on colorless polyimide. J. Mater. Chem. C 2021, 9, 5652–5661. [Google Scholar] [CrossRef]

- Cho, H.; Kwon, J.; Ha, I.; Jung, J.; Rho, Y.; Lee, H.; Han, S.; Hong, S.; Grigoropoulos, C.P.; Ko, S.H. Mechano-thermo-chromic device with supersaturated salt hydrate crystal phase change. Sci. Adv. 2019, 5, eaav4916. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kwon, J.; Hong, S.; Kim, G.; Suh, Y.D.; Lee, H.; Choo, S.-Y.; Lee, D.; Kong, H.; Yeo, J.; Ko, S.H. Digitally patterned resistive micro heater as a platform for zinc oxide nanowire based micro sensor. Appl. Surf. Sci. 2018, 447, 1–7. [Google Scholar] [CrossRef]

- Lee, H.; Manorotkul, W.; Lee, J.; Kwon, J.; Suh, Y.D.; Paeng, D.; Grigoropoulos, C.P.; Han, S.; Hong, S.; Yeo, J. Nanowire-on-nanowire: All-nanowire electronics by on-demand selective integration of hierarchical heterogeneous nanowires. ACS Nano 2017, 11, 12311–12317. [Google Scholar] [CrossRef]

- Yeo, J.; Kim, G.; Hong, S.; Lee, J.; Kwon, J.; Lee, H.; Park, H.; Manoroktul, W.; Lee, M.T.; Lee, B.J. Single Nanowire Resistive Nano-heater for Highly Localized Thermo-Chemical Reactions: Localized Hierarchical Heterojunction Nanowire Growth. Small 2014, 10, 5015–5022. [Google Scholar] [CrossRef] [PubMed]

- Hong, S.; Lee, H.; Yeo, J.; Ko, S.H. Digital selective laser methods for nanomaterials: From synthesis to processing. Nano Today 2016, 11, 547–564. [Google Scholar] [CrossRef]

- Eliceiri, M.; Grigoropoulos, C.P. Optical Trapping and Positioning of Silicon Nanowires via Photonic Nozzling. Nano Lett. 2022, 22, 3777–3783. [Google Scholar] [CrossRef]

- Kang, M.; Lee, H.; Hong, S.; Choi, J. Molecular mechanics of Ag nanowire transfer process subjected to contact loadings by PDMS substrate. Nanoscale Horiz. 2022, 7, 1073–1081. [Google Scholar] [CrossRef]

- Han, S.; Hong, S.; Ham, J.; Yeo, J.; Lee, J.; Kang, B.; Lee, P.; Kwon, J.; Lee, S.S.; Yang, M.Y. Fast plasmonic laser nanowelding for a Cu-nanowire percolation network for flexible transparent conductors and stretchable electronics. Adv. Mater. 2014, 26, 5808–5814. [Google Scholar] [CrossRef]

- Chyan, Y.; Ye, R.; Li, Y.; Singh, S.P.; Arnusch, C.J.; Tour, J.M. Laser-induced graphene by multiple lasing: Toward electronics on cloth, paper, and food. ACS Nano 2018, 12, 2176–2183. [Google Scholar] [CrossRef]

- Austin, D.; Gliebe, K.; Muratore, C.; Boyer, B.; Fisher, T.S.; Beagle, L.K.; Benton, A.; Look, P.; Moore, D.; Ringe, E. Laser writing of electronic circuitry in thin film molybdenum disulfide: A transformative manufacturing approach. Mater. Today 2021, 43, 17–26. [Google Scholar] [CrossRef]

- Rho, Y.; Kim, H.; Javey, A.; Grigoropoulos, C.P. Laser-Assisted Thermomechanical Thinning of MoTe2 in Nanoscale Lateral Resolution. Adv. Mater. Interfaces 2022, 9, 2200634. [Google Scholar] [CrossRef]

- Lim, J.; Park, S.; Cho, H.; Lee, Y.; Ha, I.; Kim, Y.; Hwang, E.; Lee, H.; Shin, J.; Kwon, J. Monolithic digital patterning of polyimide by laser-induced pyrolytic jetting. Chem. Eng. J. 2022, 428, 131050. [Google Scholar] [CrossRef]

- Lim, J.; Goh, B.; Qu, W.; Kim, Y.; Choi, J.; Hong, S. Adhesive-free bonding of PI/PDMS interface by site-selective photothermal reactions. Appl. Surf. Sci. 2022, 571, 151123. [Google Scholar] [CrossRef]

- Yang, Y.; Song, Y.; Bo, X.; Min, J.; Pak, O.S.; Zhu, L.; Wang, M.; Tu, J.; Kogan, A.; Zhang, H. A laser-engraved wearable sensor for sensitive detection of uric acid and tyrosine in sweat. Nat. Biotechnol. 2020, 38, 217–224. [Google Scholar] [CrossRef]

- Zhou, H.; Lee, J.; Kang, M.; Kim, H.; Lee, H.; In, J.B. All Laser-Based Fabrication of Microchannel Heat Sink. Mater. Des. 2022, 221, 110968. [Google Scholar] [CrossRef]

- Wang, Y.M.; Voisin, T.; McKeown, J.T.; Ye, J.; Calta, N.P.; Li, Z.; Zeng, Z.; Zhang, Y.; Chen, W.; Roehling, T.T. Additively manufactured hierarchical stainless steels with high strength and ductility. Nat. Mater. 2018, 17, 63–71. [Google Scholar] [CrossRef] [PubMed]

- Gu, D.; Shi, X.; Poprawe, R.; Bourell, D.L.; Setchi, R.; Zhu, J. Material-structure-performance integrated laser-metal additive manufacturing. Science 2021, 372, eabg1487. [Google Scholar] [CrossRef]

- Carlotti, M.; Mattoli, V. Functional Materials for Two-Photon Polymerization in Microfabrication. Small 2019, 15, 1902687. [Google Scholar] [CrossRef]

- Robert, F. An isotropic three-dimensional structure with Poisson’s ratio =− 1. J. Elast 1985, 15, 427–430. [Google Scholar]

- Wojciechowski, K. Two-dimensional isotropic system with a negative Poisson ratio. Phys. Lett. A 1989, 137, 60–64. [Google Scholar] [CrossRef]

- Lakes, R. Deformation mechanisms in negative Poisson’s ratio materials: Structural aspects. J. Mater. Sci. 1991, 26, 2287–2292. [Google Scholar] [CrossRef]

- Milton, G.W. Composite materials with Poisson’s ratios close to—1. J. Mech. Phys. Solids 1992, 40, 1105–1137. [Google Scholar] [CrossRef]

- Grima, J.N.; Evans, K.E. Auxetic Behavior from Rotating Squares; Springer: Berlin/Heidelberg, Germany, 2000; Volume 19, pp. 1563–1565. [Google Scholar]

- Ishibashi, Y.; Iwata, M. A microscopic model of a negative Poisson’s ratio in some crystals. J. Phys. Soc. Jpn. 2000, 69, 2702–2703. [Google Scholar] [CrossRef]

- Wojciechowski, K. Non-chiral, molecular model of negative Poisson ratio in two dimensions. J. Phys. A Math. Gen. 2003, 36, 11765. [Google Scholar] [CrossRef]

- Lakes, R.; Wojciechowski, K. Negative compressibility, negative Poisson’s ratio, and stability. Phys. Status Solidi 2008, 245, 545–551. [Google Scholar] [CrossRef]

- Kolken, H.M.; Zadpoor, A. Auxetic mechanical metamaterials. RSC Adv. 2017, 7, 5111–5129. [Google Scholar] [CrossRef]

- Mazur, E.; Shishkovsky, I. Additively Manufactured Hierarchical Auxetic Mechanical Metamaterials. Materials 2022, 15, 5600. [Google Scholar] [CrossRef]

- McCann, R.; Obeidi, M.A.; Hughes, C.; McCarthy, É.; Egan, D.S.; Vijayaraghavan, R.K.; Joshi, A.M.; Garzon, V.A.; Dowling, D.P.; McNally, P.J. In-situ sensing, process monitoring and machine control in Laser Powder Bed Fusion: A review. Addit. Manuf. 2021, 45, 102058. [Google Scholar] [CrossRef]

- Kim, D.; Zohdi, T. Tool path optimization of selective laser sintering processes using deep learning. Comput. Mech. 2022, 69, 383–401. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hwang, E.; Hong, J.; Yoon, J.; Hong, S. Direct Writing of Functional Layer by Selective Laser Sintering of Nanoparticles for Emerging Applications: A Review. Materials 2022, 15, 6006. https://doi.org/10.3390/ma15176006

Hwang E, Hong J, Yoon J, Hong S. Direct Writing of Functional Layer by Selective Laser Sintering of Nanoparticles for Emerging Applications: A Review. Materials. 2022; 15(17):6006. https://doi.org/10.3390/ma15176006

Chicago/Turabian StyleHwang, Eunseung, Jungmin Hong, Jonghun Yoon, and Sukjoon Hong. 2022. "Direct Writing of Functional Layer by Selective Laser Sintering of Nanoparticles for Emerging Applications: A Review" Materials 15, no. 17: 6006. https://doi.org/10.3390/ma15176006

APA StyleHwang, E., Hong, J., Yoon, J., & Hong, S. (2022). Direct Writing of Functional Layer by Selective Laser Sintering of Nanoparticles for Emerging Applications: A Review. Materials, 15(17), 6006. https://doi.org/10.3390/ma15176006