Effect of Bonding Protocols on the Performance of Luting Agents Applied to CAD–CAM Composites

Abstract

1. Introduction

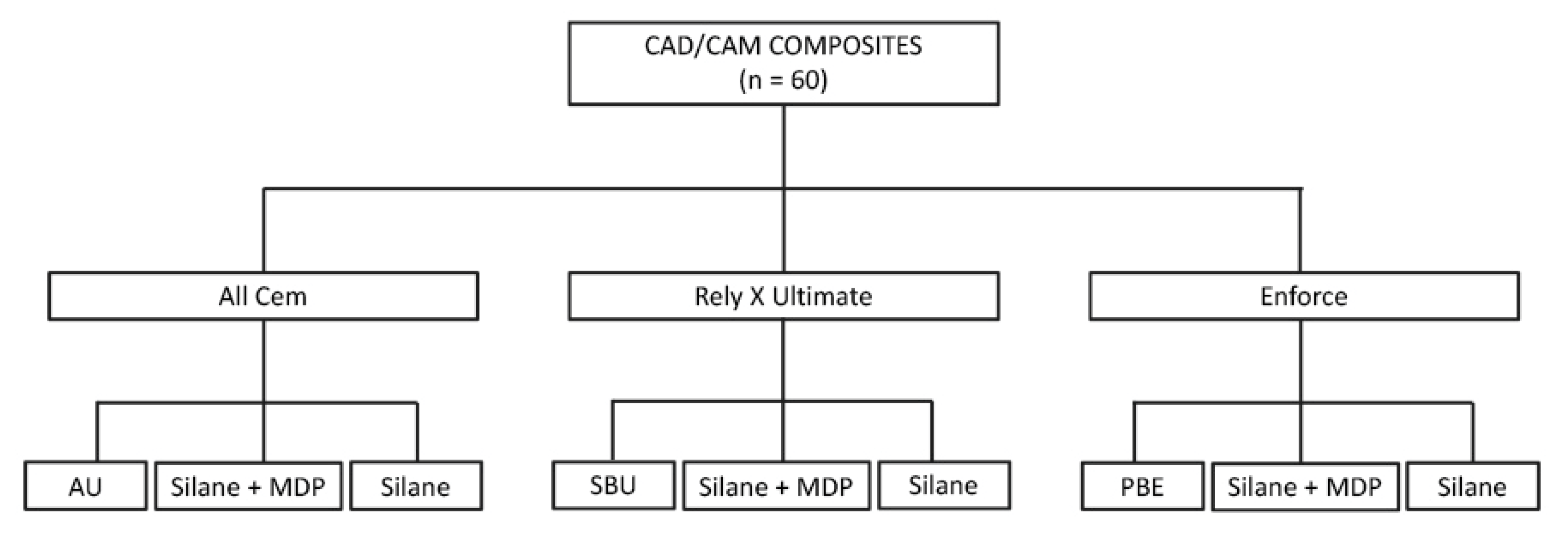

2. Materials and Methods

2.1. Specimen Preparation

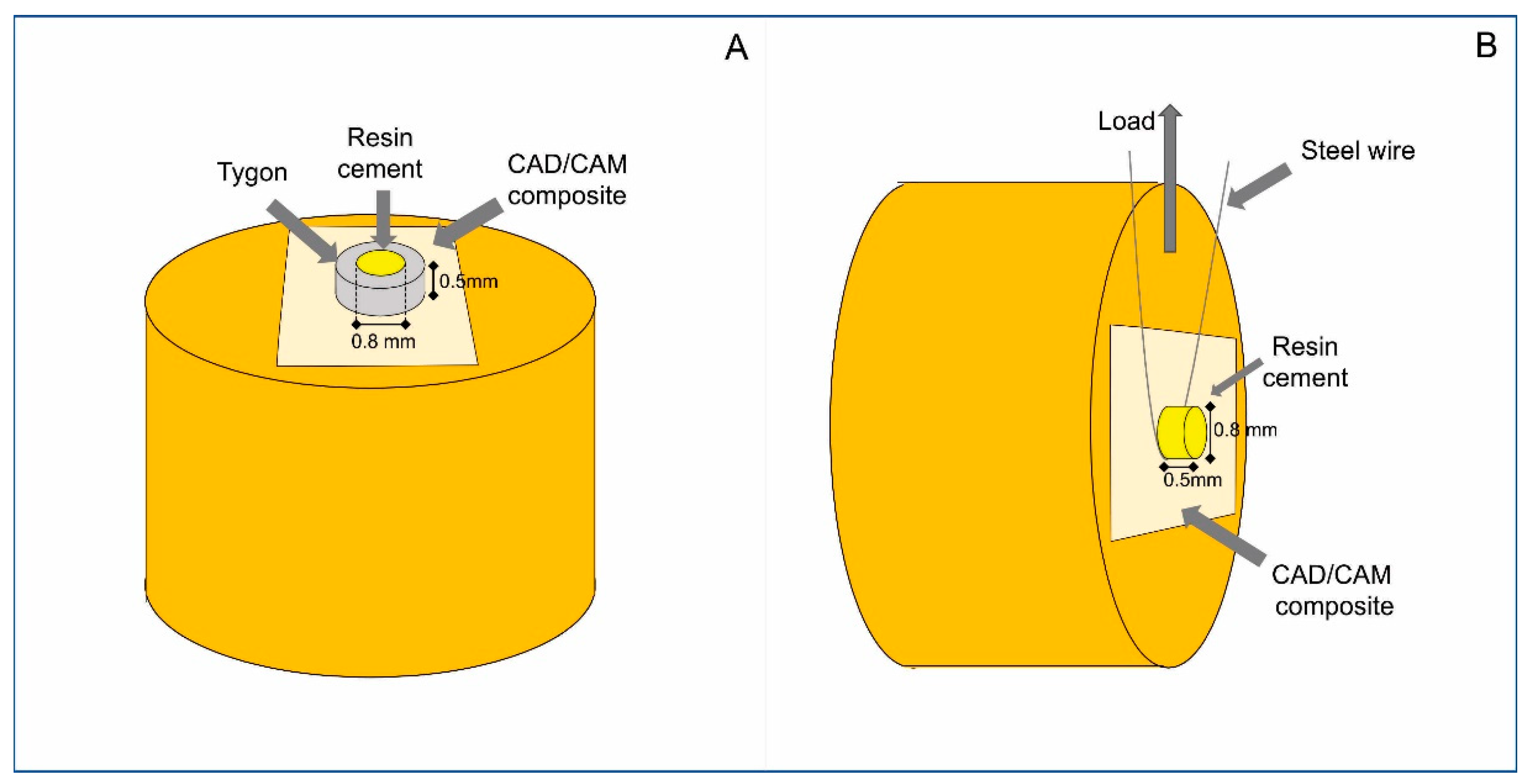

2.2. μSBS Test

2.3. Surface Scanning Electron Microscopy (SEM) and Spectroscopy by Energy-Dispersive X-ray Spectroscopy (EDS)

2.4. Statistical Analysis

3. Results

3.1. μSBS Test

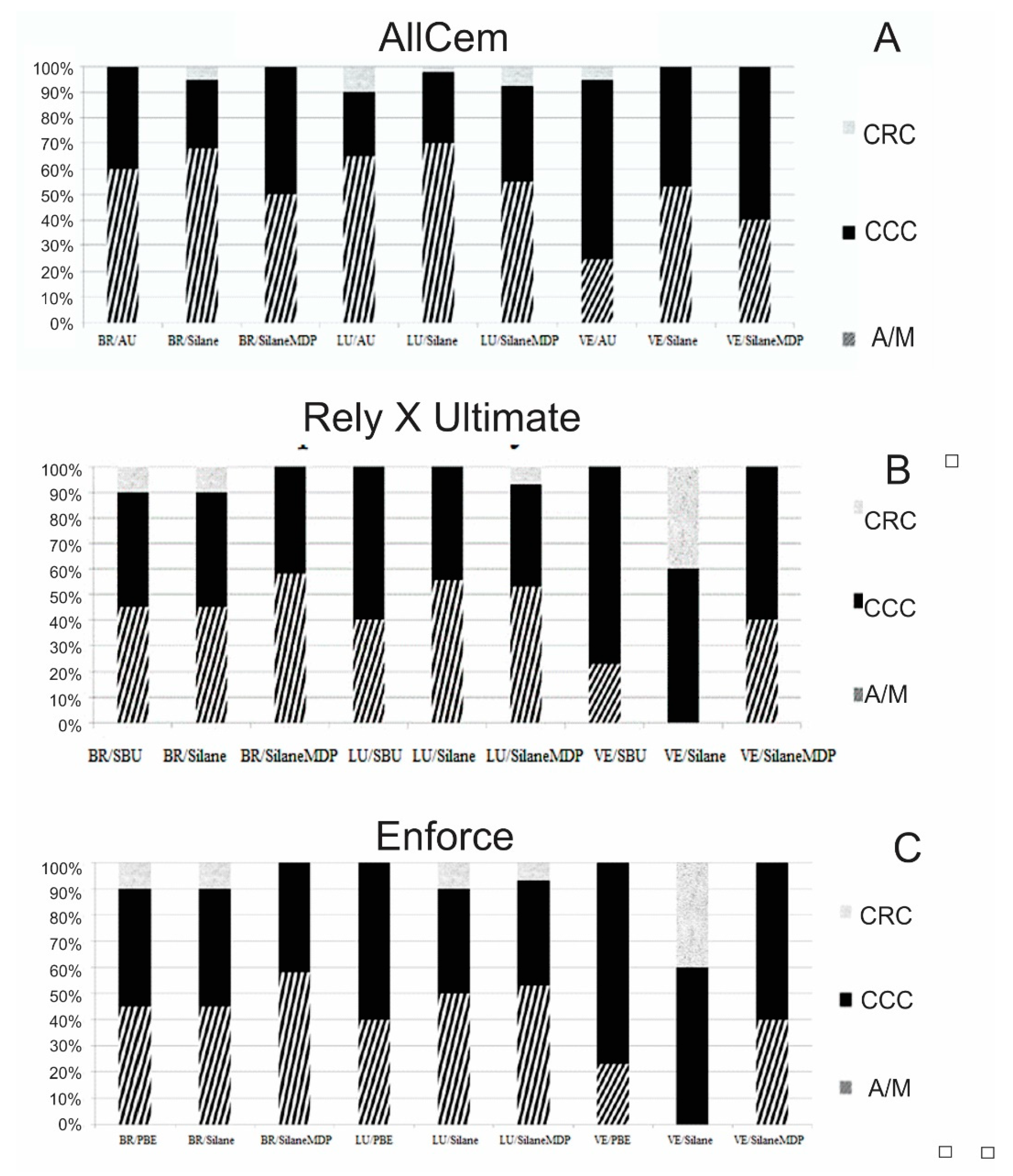

3.2. Fracture Pattern (PF)

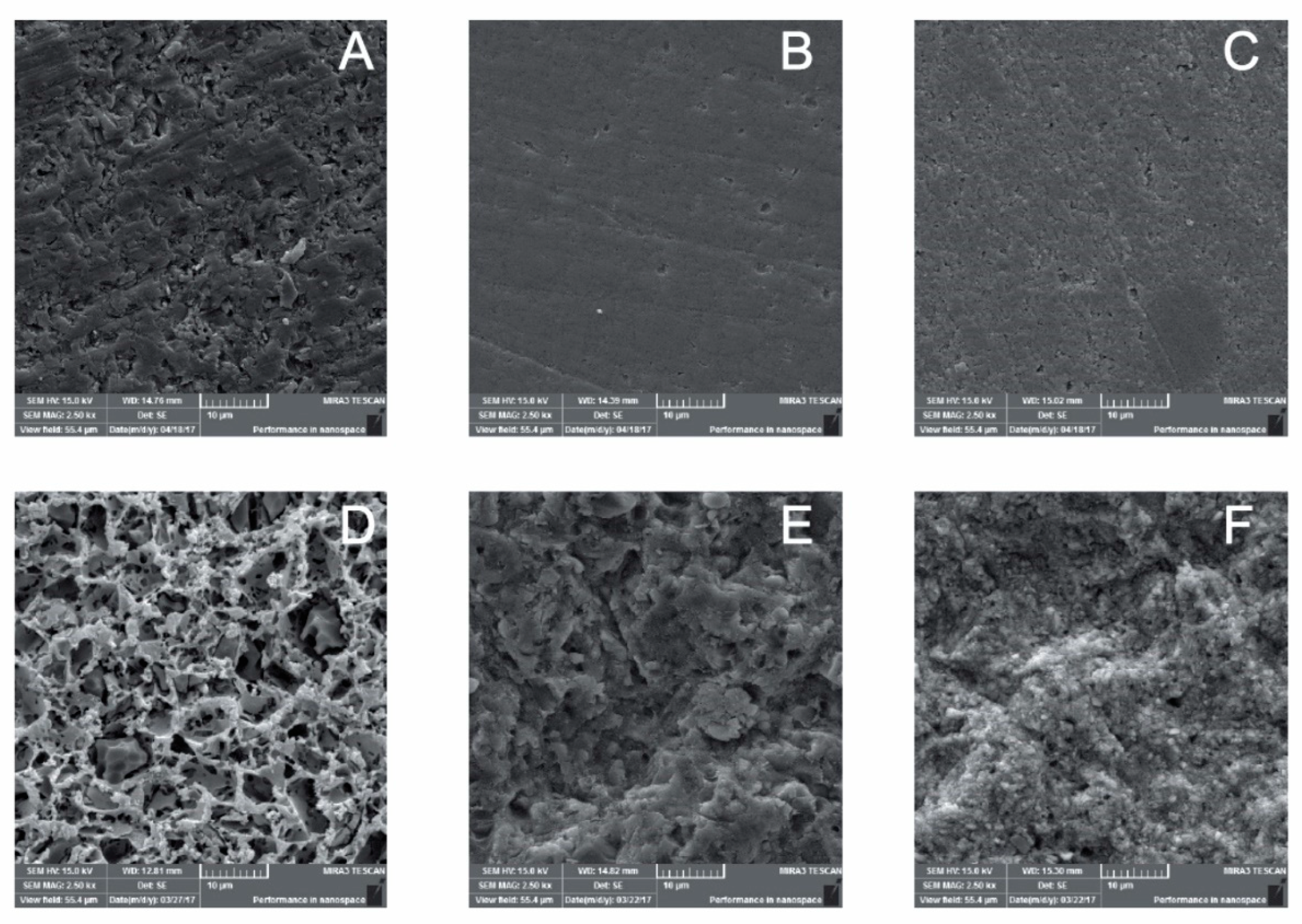

3.3. Surface Scanning Electron Microscopy (SEM)

3.4. Energy-Dispersive X-ray Spectroscopy (EDS)

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Emsermann, I.; Eggmann, F.; Krastl, G.; Weiger, R.; Amato, J. Influence of Pretreatment Methods on the Adhesion of Composite and Polymer Infiltrated Ceramic CAD-CAM Blocks. J. Adhes. Dent. 2019, 21, 433–443. [Google Scholar] [CrossRef] [PubMed]

- Park, S.H.; Yoo, Y.J.; Shin, Y.J.; Cho, B.H.; Baek, S.H. Marginal and internal fit of nano-composite CAD/CAM restorations. Restor. Dent. Endod. 2016, 41, 37–43. [Google Scholar] [CrossRef]

- Spitznagel, F.A.; Horvath, S.D.; Guess, P.C.; Blatz, M.B. Resin bond to indirect composite and new ceramic/polymer materials: A review of the literature. J. Esthet. Restor. Dent. 2014, 26, 382–393. [Google Scholar] [CrossRef]

- Awad, M.M.; Alqahtani, H.; Al-Mudahi, A.; Murayshed, M.S.; Alrahlah, A.; Bhandi, S.H. Adhesive Bonding to Computer-aided Design/ Computer-aided Manufacturing Esthetic Dental Materials: An Overview. J. Contemp. Dent. Pract. 2017, 18, 622–626. [Google Scholar] [CrossRef] [PubMed]

- Stawarczyk, B.; Ozcan, M.; Trottmann, A.; Schmutz, F.; Roos, M.; Hammerle, C. Two-body wear rate of CAD/CAM resin blocks and their enamel antagonists. J. Prosthet. Dent. 2013, 109, 325–332. [Google Scholar] [CrossRef]

- Tsitrou, E.A.; Northeast, S.E.; van Noort, R. Evaluation of the marginal fit of three margin designs of resin composite crowns using CAD/CAM. J. Dent. 2007, 35, 68–73. [Google Scholar] [CrossRef]

- Gungor, M.B.; Nemli, S.K.; Bal, B.T.; Unver, S.; Dogan, A. Effect of surface treatments on shear bond strength of resin composite bonded to CAD/CAM resin-ceramic hybrid materials. J. Adv. Prosthodont. 2016, 8, 259–266. [Google Scholar] [CrossRef]

- Naves, L.Z.; Soares, C.J.; Moraes, R.R.; Goncalves, L.S.; Sinhoreti, M.A.; Correr-Sobrinho, L. Surface/interface morphology and bond strength to glass ceramic etched for different periods. Oper. Dent. 2010, 35, 420–427. [Google Scholar] [CrossRef]

- Sato, K.; Matsumura, H.; Atsuta, M. Effect of three-liquid bonding agents on bond strength to a machine-milled ceramic material. J. Oral Rehabil. 1999, 26, 570–574. [Google Scholar] [CrossRef]

- Graiff, L.; Piovan, C.; Vigolo, P.; Mason, P.N. Shear bond strength between feldspathic CAD/CAM ceramic and human dentine for two adhesive cements. J. Prosthodont. 2008, 17, 294–299. [Google Scholar] [CrossRef]

- Campos, F.; Almeida, C.S.; Rippe, M.P.; de Melo, R.M.; Valandro, L.F.; Bottino, M.A. Resin Bonding to a Hybrid Ceramic: Effects of Surface Treatments and Aging. Oper. Dent. 2016, 41, 171–178. [Google Scholar] [CrossRef]

- Siqueira, F.; Cardenas, A.M.; Gutierrez, M.F.; Malaquias, P.; Hass, V.; Reis, A.; Loguercio, A.D.; Perdigao, J. Laboratory Performance of Universal Adhesive Systems for Luting CAD/CAM Restorative Materials. J. Adhes. Dent. 2016, 18, 331–340. [Google Scholar] [CrossRef] [PubMed]

- Kassotakis, E.M.; Stavridakis, M.; Bortolotto, T.; Ardu, S.; Krejci, I. Evaluation of the Effect of Different Surface Treatments on Luting CAD/CAM Composite Resin Overlay Workpieces. J. Adhes. Dent. 2015, 17, 521–528. [Google Scholar] [CrossRef] [PubMed]

- Ceci, M.; Pigozzo, M.; Scribante, A.; Beltrami, R.; Colombo, M.; Chiesa, M.; Poggio, C. Effect of glycine pretreatment on the shear bond strength of a CAD/CAM resin nano ceramic material to dentin. J. Clin. Exp. Dent. 2016, 8, e146–e152. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Nejat, A.H.; Lee, J.; Shah, S.; Lin, C.P.; Kulkarni, P.; Chavali, R.; Lawson, N.C. Retention of CAD/CAM resin composite crowns following different bonding protocols. Am. J. Dent. 2018, 31, 97–102. [Google Scholar] [PubMed]

- Eldafrawy, M.; Greimers, L.; Bekaert, S.; Gailly, P.; Lenaerts, C.; Nguyen, J.F.; Sadoun, M.; Mainjot, A. Silane influence on bonding to CAD-CAM composites: An interfacial fracture toughness study. Dent. Mater. 2019, 35, 1279–1290. [Google Scholar] [CrossRef]

- Frankenberger, R.; Hartmann, V.E.; Krech, M.; Kramer, N.; Reich, S.; Braun, A.; Roggendorf, M. Adhesive luting of new CAD/CAM materials. Int. J. Comput. Dent. 2015, 18, 9–20. [Google Scholar]

- Elsaka, S.E. Bond strength of novel CAD/CAM restorative materials to self-adhesive resin cement: The effect of surface treatments. J. Adhes. Dent. 2014, 16, 531–540. [Google Scholar] [CrossRef]

- Blatz, M.B.; Phark, J.H.; Ozer, F.; Mante, F.K.; Saleh, N.; Bergler, M.; Sadan, A. In vitro comparative bond strength of contemporary self-adhesive resin cements to zirconium oxide ceramic with and without air-particle abrasion. Clin. Oral. Investig. 2010, 14, 187–192. [Google Scholar] [CrossRef]

- Cekic-Nagas, I.; Ergun, G.; Egilmez, F.; Vallittu, P.K.; Lassila, L.V. Micro-shear bond strength of different resin cements to ceramic/glass-polymer CAD-CAM block materials. J. Prosthodont. Res. 2016, 60, 265–273. [Google Scholar] [CrossRef]

- Ustun, S.; Ayaz, E.A. Effect of different cement systems and aging on the bond strength of chairside CAD-CAM ceramics. J. Prosthet. Dent. 2020, 125, 334–339. [Google Scholar] [CrossRef] [PubMed]

- Cardenas, A.M.; Siqueira, F.; Hass, V.; Malaquias, P.; Gutierrez, M.F.; Reis, A.; Perdigao, J.; Loguercio, A. Effect of MDP-containing silane and adhesive used alone or in combination on the long-term bond strength and chemical interaction with lithium disilicate ceramics. J. Adhes. Dent. 2017, 19, 203–212. [Google Scholar] [CrossRef] [PubMed]

- Gutierrez, M.F.; Perdigao, J.; Malaquias, P.; Cardenas, A.M.; Siqueira, F.; Hass, V.; Reis, A.; Loguercio, A.D. Effect of methacryloyloxydecyl dihydrogen phosphate-containing silane and adhesive used alone or in combination on the bond strength and chemical interaction with zirconia ceramics under thermal aging. Oper. Dent. 2020, 45, 516–527. [Google Scholar] [CrossRef]

- Tekce, N.; Tuncer, S.; Demirci, M. The effect of sandblasting duration on the bond durability of dual-cure adhesive cement to CAD/CAM resin restoratives. J. Adv. Prosthodont. 2018, 10, 211–217. [Google Scholar] [CrossRef] [PubMed]

- Shembish, F.A.; Tong, H.; Kaizer, M.; Janal, M.N.; Thompson, V.P.; Opdam, N.J.; Zhang, Y. Fatigue resistance of CAD/CAM resin composite molar crowns. Dent. Mater. 2016, 32, 499–509. [Google Scholar] [CrossRef] [PubMed]

- El-Damanhoury, H.M.; Gaintantzopoulou, M.D. Self-etching ceramic primer versus hydrofluoric acid etching: Etching efficacy and bonding performance. J. Prosthodont. Res. 2018, 62, 75–83. [Google Scholar] [CrossRef]

- Chen, Y.; Lu, Z.; Qian, M.; Zhang, H.; Chen, C.; Xie, H.; Tay, F.R. Chemical affinity of 10-methacryloyloxydecyl dihydrogen phosphate to dental zirconia: Effects of molecular structure and solvents. Dent. Mater. 2017, 33, e415–e427. [Google Scholar] [CrossRef]

- Stawarczyk, B.; Liebermann, A.; Eichberger, M.; Guth, J.F. Evaluation of mechanical and optical behavior of current esthetic dental restorative CAD/CAM composites. J. Mech. Behav. Biomed. Mater. 2015, 55, 1–11. [Google Scholar] [CrossRef]

- Chen, L.; Shen, H.; Suh, B.I. Effect of incorporating BisGMA resin on the bonding properties of silane and zirconia primers. J. Prosthet. Dent. 2013, 110, 402–407. [Google Scholar] [CrossRef]

- Lung, C.Y.; Matinlinna, J.P. Aspects of silane coupling agents and surface conditioning in dentistry: An overview. Dent. Mater. 2012, 28, 467–477. [Google Scholar] [CrossRef]

- Yoshihara, K.; Nagaoka, N.; Sonoda, A.; Maruo, Y.; Makita, Y.; Okihara, T.; Irie, M.; Yoshida, Y.; Van Meerbeek, B. Effectiveness and stability of silane coupling agent incorporated in ‘universal’ adhesives. Dent. Mater. 2016, 32, 1218–1225. [Google Scholar] [CrossRef] [PubMed]

- Yoshihara, K.; Nagaoka, N.; Maruo, Y.; Nishigawa, G.; Irie, M.; Yoshida, Y.; Van Meerbeek, B. Sandblasting may damage the surface of composite CAD-CAM blocks. Dent. Mater. 2017, 33, e124–e135. [Google Scholar] [CrossRef] [PubMed]

- Maño, E.P.; Algarra, R.M.; Fawzy, A.; Leitune, V.C.B.; Collares, F.M.; Feitosa, V.; Sauro, S. In Vitro Bonding Performance of Modern Self-Adhesive Resin Cements and Conventional Resin-Modified Glass Ionomer Cements to Prosthetic Substrates. Appl. Sci. 2020, 10, 8157. [Google Scholar] [CrossRef]

| Trademarks Experimental Groups | Composition | Indication |

|---|---|---|

| Vita Enamic, Vita Zahnfabrik, Bad Säckingen, Alemanha (VE) | Feldspar ceramics reinforced with aluminum oxide + polymer (UDMA and TEGMA). | Single-sided implant tooth crowns, inlays, onlays and veneers. |

| Lava Ultimate 3M Oral Care, St. Paul, MN, USA (LU) | Silicon nanoparticles, zirconia nanoparticles, nanoclusters, silicon union and a resinous matrix. | Permanent unit crowns about implant, facets, inlays and onlays. |

| Brava Block FGM, Joinville, SC, Brazil (BR) | 65 to 80% silanized barium glass, Bis EMA, Bis GMA, Dimethylaminobenzoate and camphorquinone. | Inlays, onlays and laminates. |

| Hydrofluoric acid 5% (Vita ceramics etch) | 1 mL of acid VITA CERAMICS ETCH contains 0.047 g of hydrofluoric acid. | 1—Apply using a microbrush on the surface of restoration for 60 s; 2—Wash abundantly; 3—Apply jet air. |

| Monobond N Ivoclar Vivadent (silane with MDP) | Alcoholic solution of methacrylate silane, ethanol, 10-MDP, and sulfide methacrylate. | 1—Apply a drop with the aid of a microbrush; 2—Let it react for 60 s; 3—Apply air jet strongly. |

| Silane Angelus (Silane without MDP) | Methylene, oxygen and oxygen, silicon, ethanol, hydroxyl. | 1—Apply on the surface; 2—Stand by 60 s; 3—Apply jet air. |

| Single Bond Universal (SBU) 3M Oral Care | MDP, Dimetacrilate resins, HEMA, VitrebondTM copolymer. Filling particles, ethanol, water, initiators, Silane. | 1—Apply an active layer on the surface; 2—Leave solvent to evaporate for 5 s; 3—Jet air for 5 s; 4—Light cure for 20 s. |

| Prime & Bond Elect (PBE) Dentsply Sirona | Mono, di- and trimetacrylate resin, PENTA, diacetone, phosphine organic, stabilizers, ketylamino fluoride, and acetone, water, acetone, catalyst, photoinitiators. | 1—Mix one drop of each vial; 2—Apply a layer over the surface; 3—Allow to evaporate for 20 s; 4—Apply air jet for 5 s; 5—Light cure for 20 s. |

| Ambar Universal (AU) FGM | Methacrylic monomers (MDP and UDMA), photoinitiators, co-conspirators and stabilizers, in addition to inert load (nanoparticles of silica) and vehicle (ethanol). | 1—Actively apply two layers of adhesive on the surface; 2—Jet air for 10 s between the layers; 3—Light cure for 20 s. |

| Rely X Ultimate 3M Oral Care | Glass powder treated with methyl propanoic silane, hydroxymethyl Ester, reaction products with hydroxy propanediol dimethacrylate and phosphorus oxide, TEGDMA, silane-treated silica, glass borosilicate, sodium persulphate, peroxy-trimethylhexanoate-butyl and monohydrated copper acetate. | 1—Mix the two folders; 2—Apply on the surface; 3—Light cure for 40 s. |

| Enforce Dentsply Dentsply Sirona | Base Paste: Glass from Boron, aluminum silicate and Silanized barium, pyrolytic silica Silanized, Bis GMA, BDMA, BHT, Camphorquinone, TEGDMA, Mineral pigments, EDAB. Catalytic Paste: Glass Boron, aluminum silicate and silanized barium, pyrolytic silica silanized, BisGMA, BDMA, BHT, TEGDMA, stains, Benzoyl minerals and peroxide. | 1—Mix the two folders; 2—Apply on the surface; 3—Light cure for 40 s. |

| AllCem FGM | Methacrylic monomers (TEGDMA and HEMA); camphorquinone; co-initiatorsand microparticles of barium glass. | 1—Mix the two folders; 2—Apply on the surface; 3—Light cure for 40 s. |

| AllCem | ||||

|---|---|---|---|---|

| Adhesive with MDP and without Silane (AU) | Silane without MDP | Silane with MDP | Average | |

| Brava Block (BR) | 21.23 ± 1.5 | 22.15 ± 2.3 | 21.11 ± 2.3 | 21.50 C |

| Lava Ultimate (LU) | 24.87 ± 2.0 | 24.88 ± 2.1 | 22.68 ± 1.9 | 24.14 B |

| Vita Enamic (VE) | 25.88 ± 3.2 | 28.50 ± 2.7 | 25.89 ± 3.3 | 26.76 A |

| Average | 23.99 ab | 25.18 a | 23.23 b | |

| Rely X Ultimate | ||||

|---|---|---|---|---|

| Adhesive with Silane and MDP (SBU) | Silane without MDP | Silane with MDP | Average | |

| Brava Block (BR) | 19.16 ± 2.3 a | 20.21 ± 2.4 a | 20.05 ± 1.8 a | 19.80 C |

| Lava Ultimate (LU) | 21.65 ± 2.2 a | 23.16 ± 1.9 a | 23.26 ± 2.7 a | 22.70 B |

| Vita Enamic (VE) | 27.50 ± 3.6 b | 25.9 ± 2.0 b | 30.48 ± 3.2 a | 27.96 A |

| Enforce | ||||

|---|---|---|---|---|

| Adhesive without MDP and Silane (PBE) | Silane without MDP | Silane with MDP | Average | |

| Brava Block (BR) | 20.99 ± 1.7 | 20.58 ± 1.8 | 20.33 ± 2.4 | 20.63 C |

| Lava Ultimate (LU) | 21.87 ± 1.9 | 24.12 ± 2.2 | 22.16 ± 2.2 | 22.72 B |

| Vita Enamic (VE) | 26.99 ± 2.5 | 27.36 ± 3.2 | 25.12 ± 2.8 | 26.49 A |

| Average | 23.28 a | 24.02 a | 22.54 a | |

| Percentage of Chemical Elements (%) | |||||||

|---|---|---|---|---|---|---|---|

| CAD–CAM Composites | K | Al | Ba | Na | Si | Zr | O |

| Brava Block (BR) | 0 | 5.53 | 22.27 | 0 | 30.23 | 0 | 41.96 |

| Lava Ultimate (LU) | 0 | 0 | 0 | 0 | 36.57 | 16.11 | 47.32 |

| Vita Enamic (VE) | 5.14 | 11.8 | 0 | 5.65 | 29.87 | 0 | 47.54 |

| Percentage of Chemical Elements (%) | |||||||

|---|---|---|---|---|---|---|---|

| CAD–CAM Composites | K | Al | Ba | Na | Si | Zr | O |

| Brava Block (BR) | 0 | 5.18 | 24.15 | 0 | 29.56 | 0 | 41.10 |

| Lava Ultimate (LU) | 0 | 1.82 | 0 | 0 | 23.15 | 12.71 | 62.31 |

| Vita Enamic (VE) | 5.76 | 11.41 | 0 | 4.16 | 30.81 | 0 | 47.87 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hilgemberg, B.; Siqueira, F.S.F.d.; Cardenas, A.F.M.; Ribeiro, J.L.; Dávila-Sánchez, A.; Sauro, S.; Loguercio, A.D.; Arrais, C.A.G. Effect of Bonding Protocols on the Performance of Luting Agents Applied to CAD–CAM Composites. Materials 2022, 15, 6004. https://doi.org/10.3390/ma15176004

Hilgemberg B, Siqueira FSFd, Cardenas AFM, Ribeiro JL, Dávila-Sánchez A, Sauro S, Loguercio AD, Arrais CAG. Effect of Bonding Protocols on the Performance of Luting Agents Applied to CAD–CAM Composites. Materials. 2022; 15(17):6004. https://doi.org/10.3390/ma15176004

Chicago/Turabian StyleHilgemberg, Bruna, Fabiana Suelen Figuerêdo de Siqueira, Andres Felipe Millan Cardenas, Josiane Loch Ribeiro, Andrés Dávila-Sánchez, Salvatore Sauro, Alessandro Dourado Loguercio, and Cesar Augusto Galvao Arrais. 2022. "Effect of Bonding Protocols on the Performance of Luting Agents Applied to CAD–CAM Composites" Materials 15, no. 17: 6004. https://doi.org/10.3390/ma15176004

APA StyleHilgemberg, B., Siqueira, F. S. F. d., Cardenas, A. F. M., Ribeiro, J. L., Dávila-Sánchez, A., Sauro, S., Loguercio, A. D., & Arrais, C. A. G. (2022). Effect of Bonding Protocols on the Performance of Luting Agents Applied to CAD–CAM Composites. Materials, 15(17), 6004. https://doi.org/10.3390/ma15176004