Resilient Modulus Behavior and Prediction Models of Unbound Permeable Aggregate Base Materials Derived from Tunneling Rock Wastes

Abstract

:1. Introduction

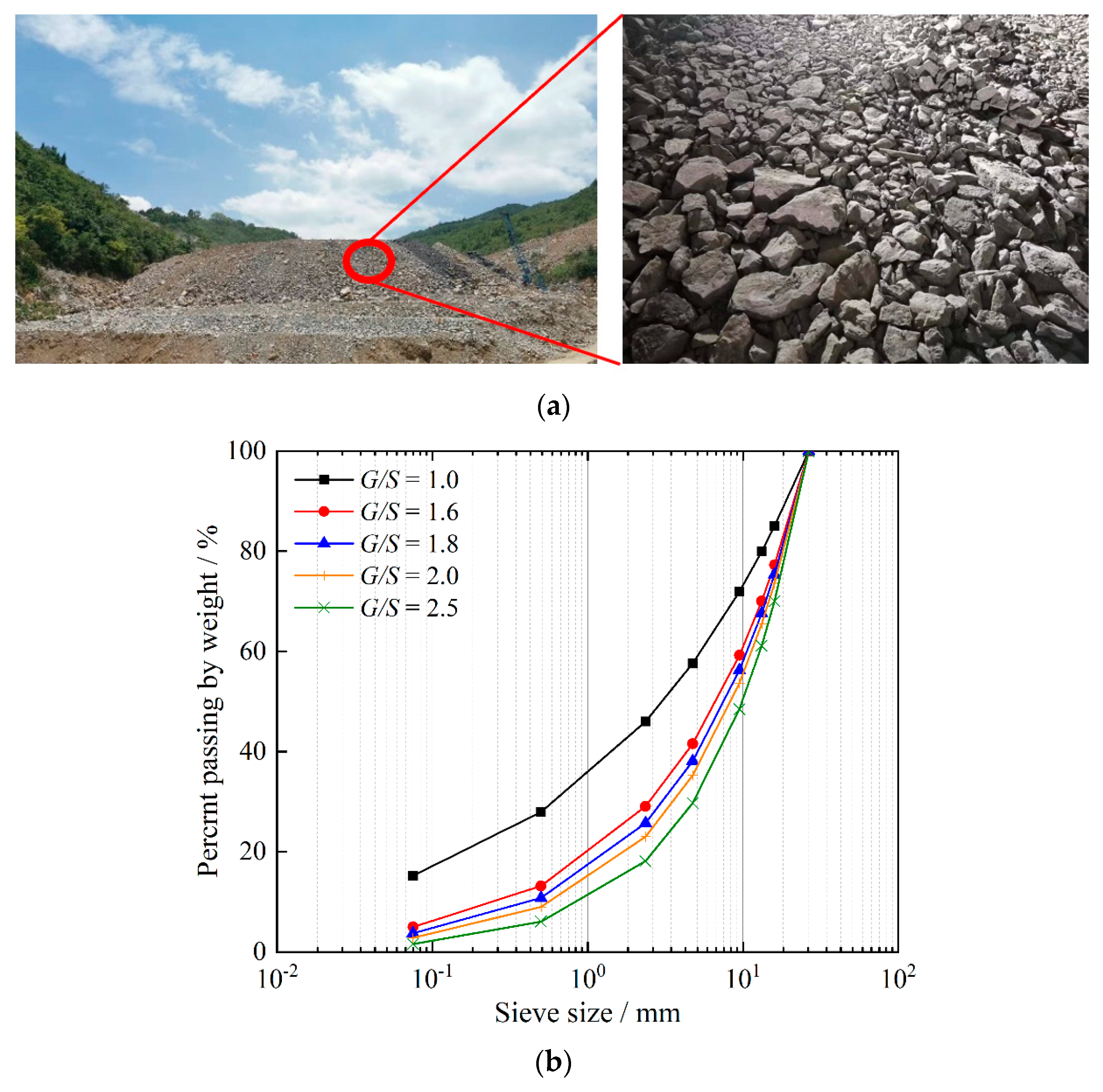

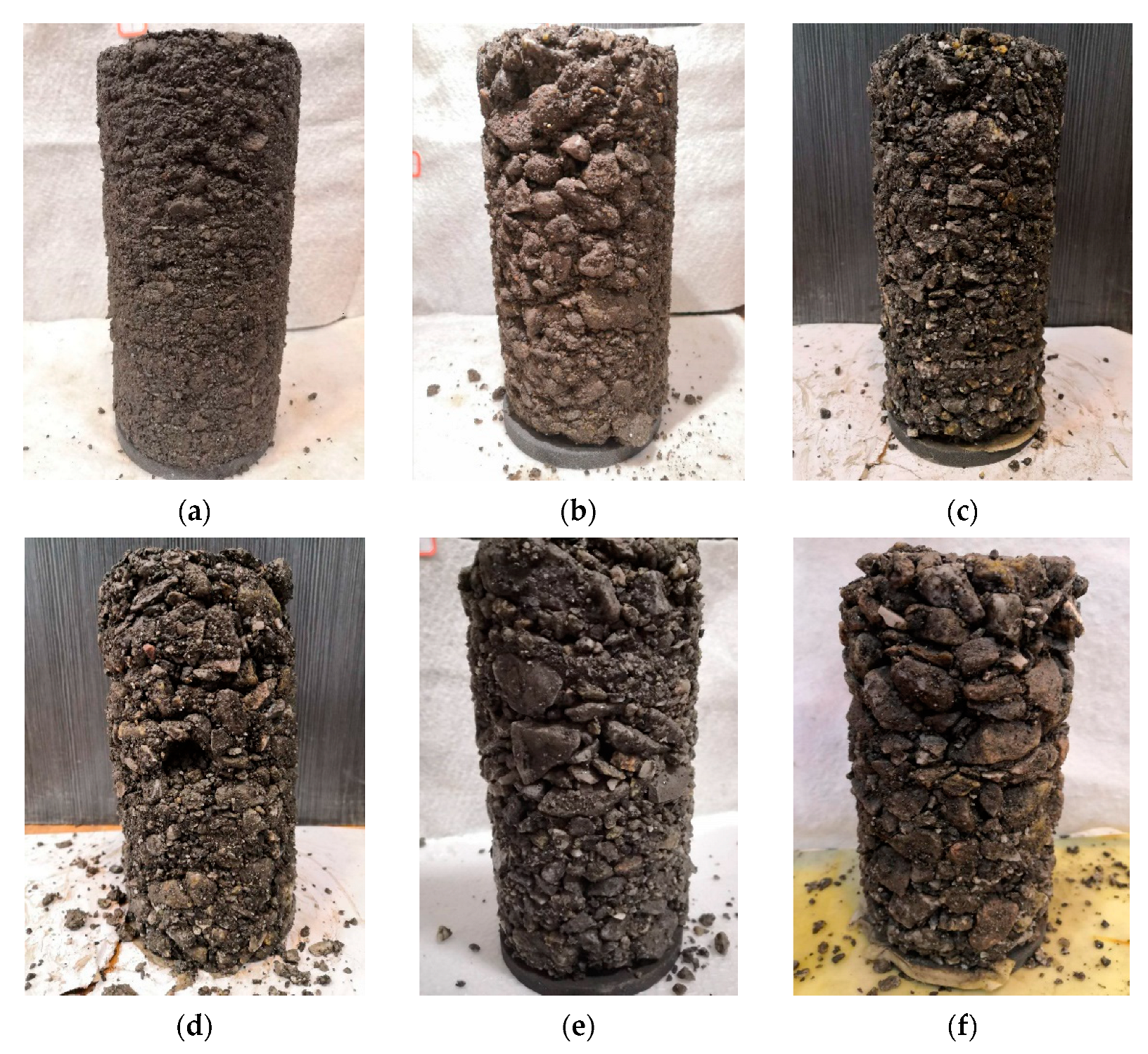

2. Materials and Laboratory Testing Program

2.1. Materials Tested

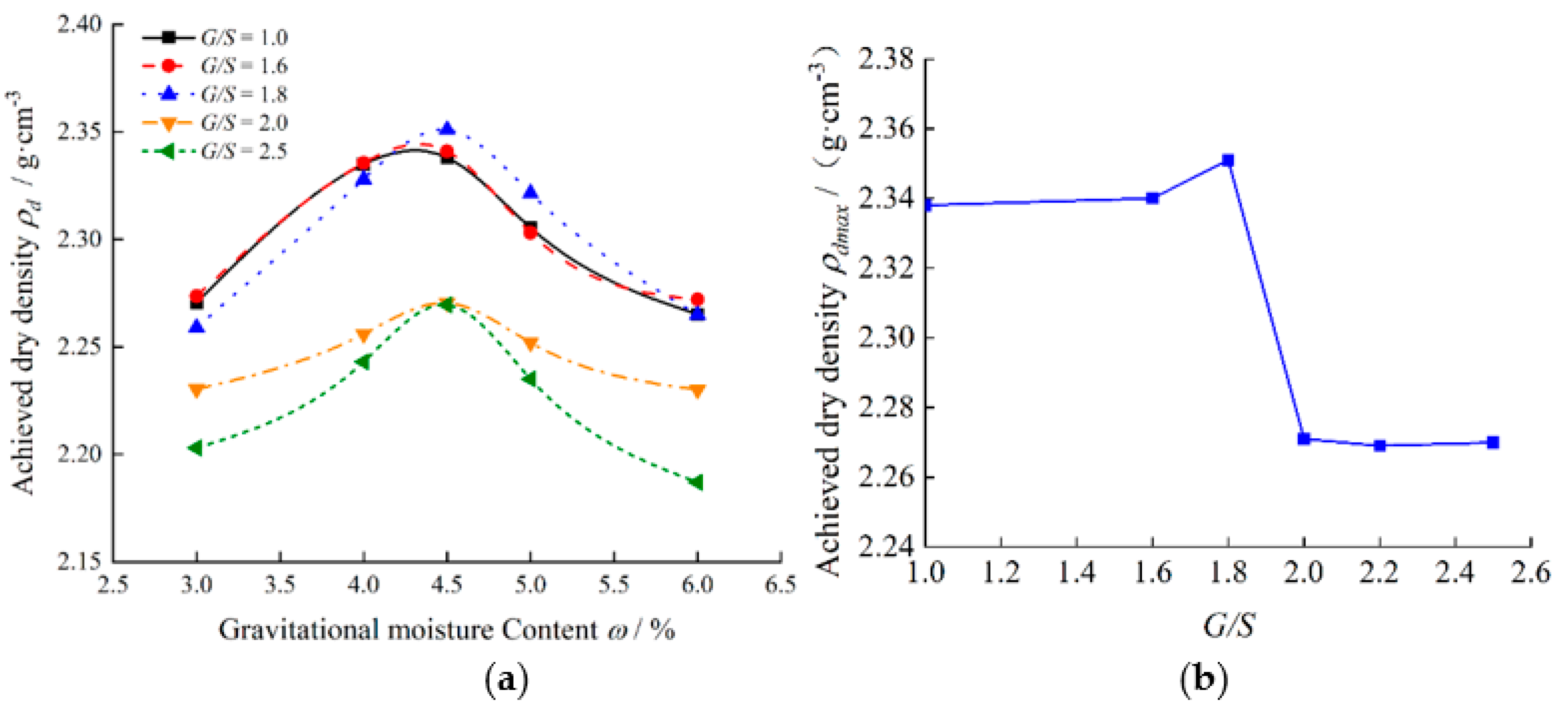

2.2. Laboratory Compaction Tests

2.3. Monotonic Triaxial Compression Tests

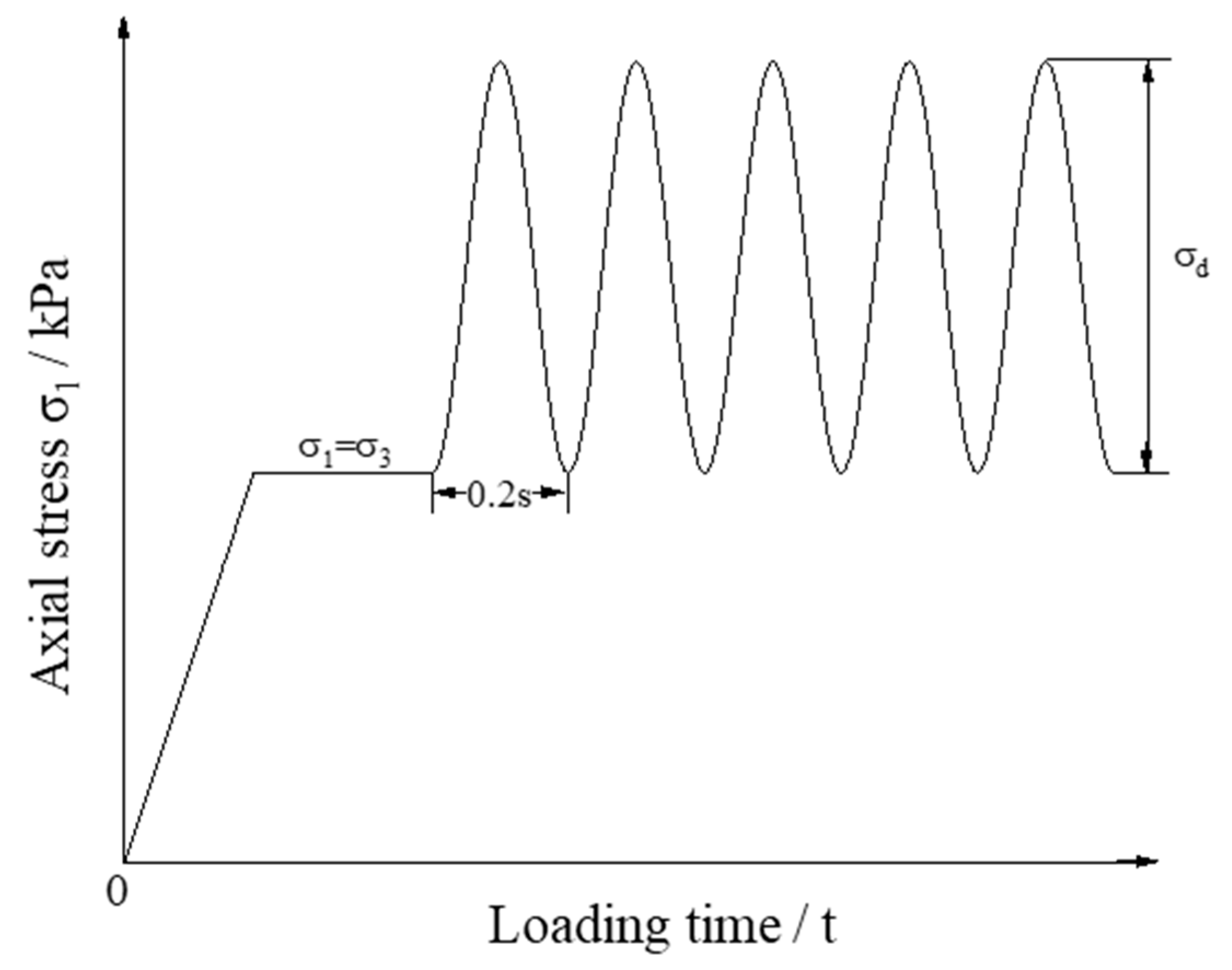

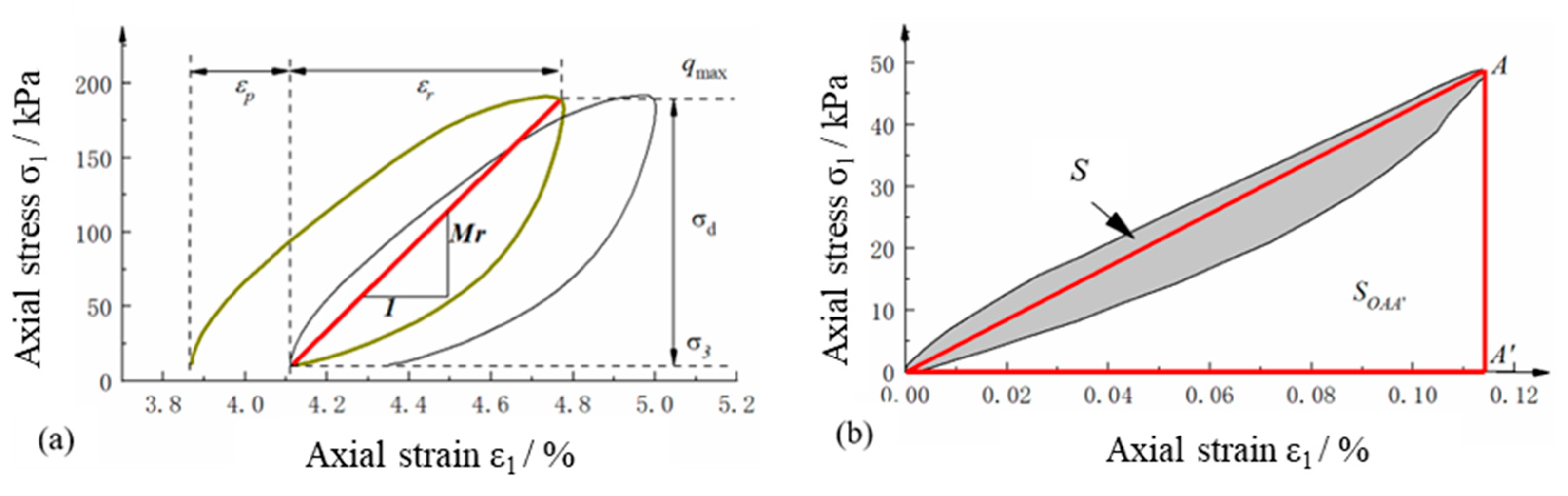

2.4. Repeated Load Triaxial Tests

3. Results and Analysis

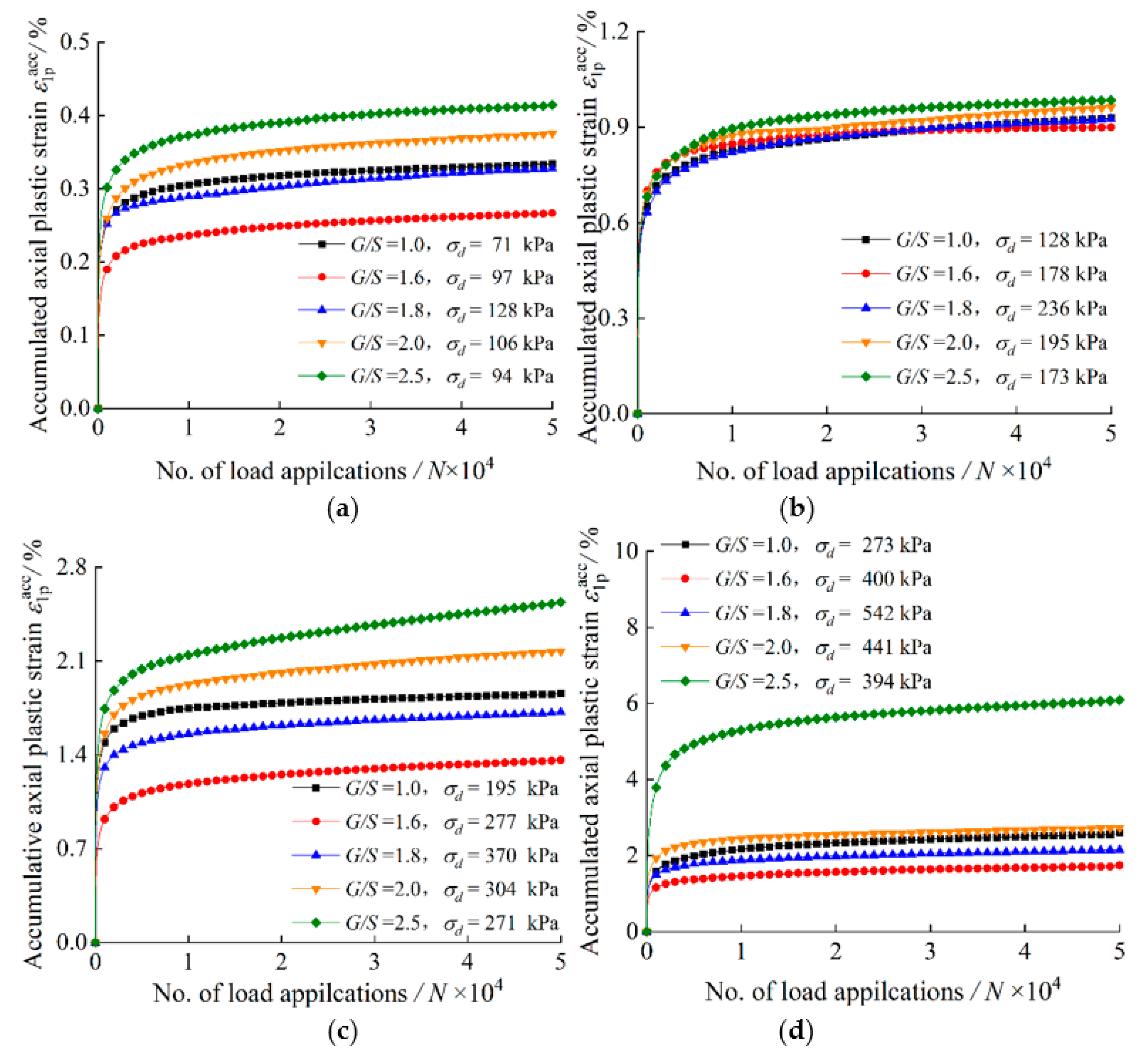

3.1. Plastic Strain Characteristics

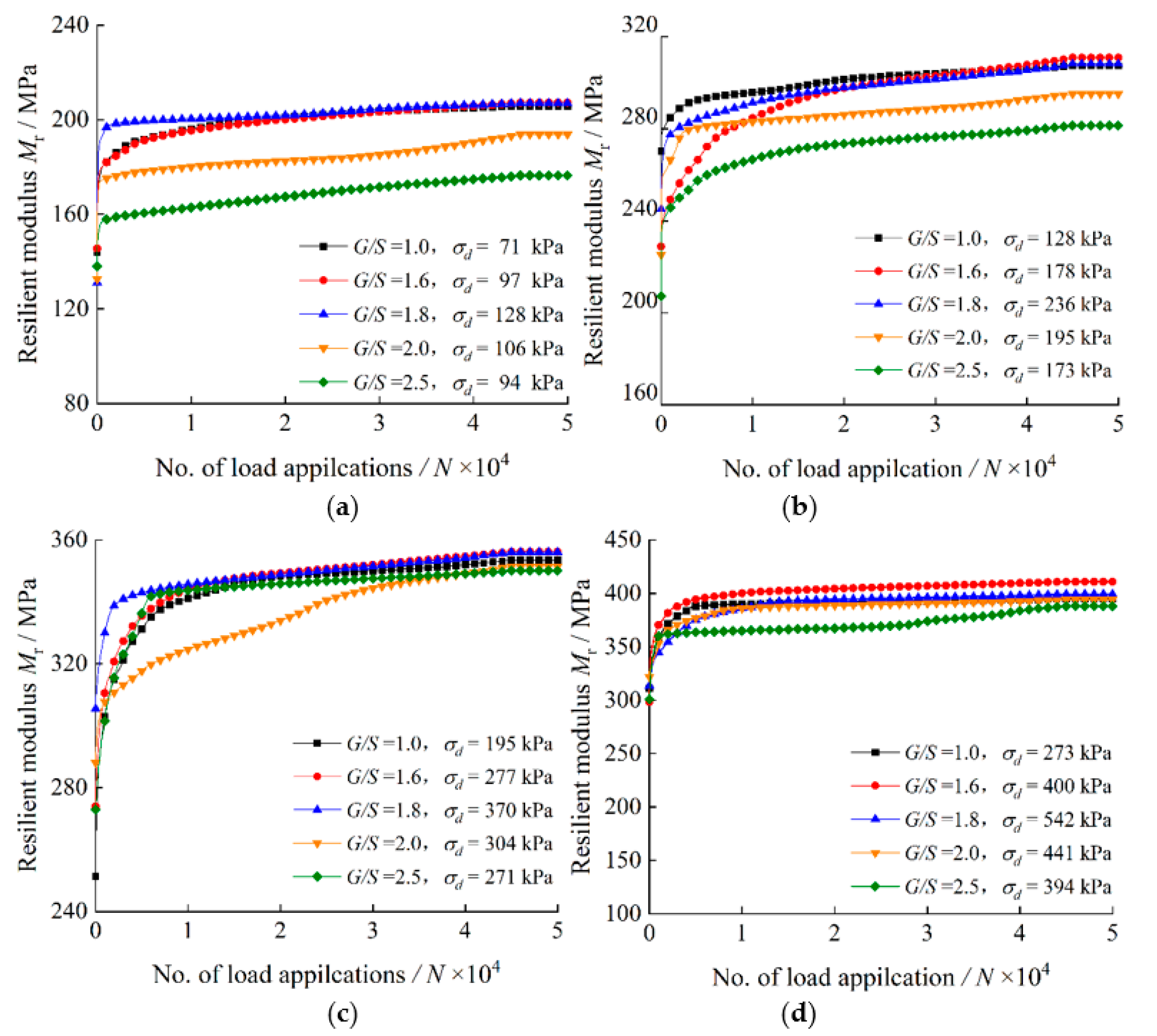

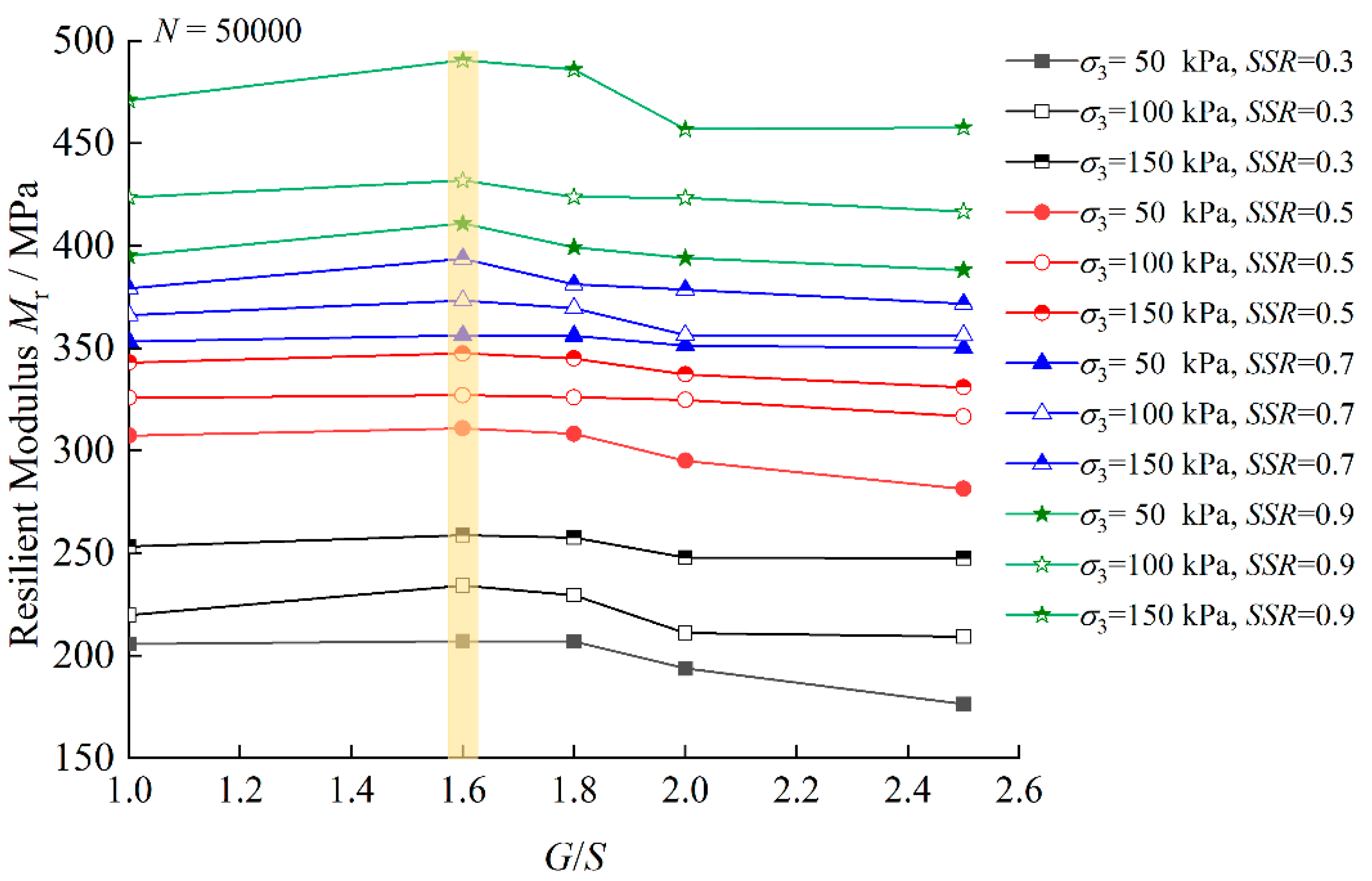

3.2. Resilient Modulus Characteristics

4. Development of Resilient Modulus Prediction Model

4.1. Comparative Assessment of Different Calculation Methods of Representative Mr Values

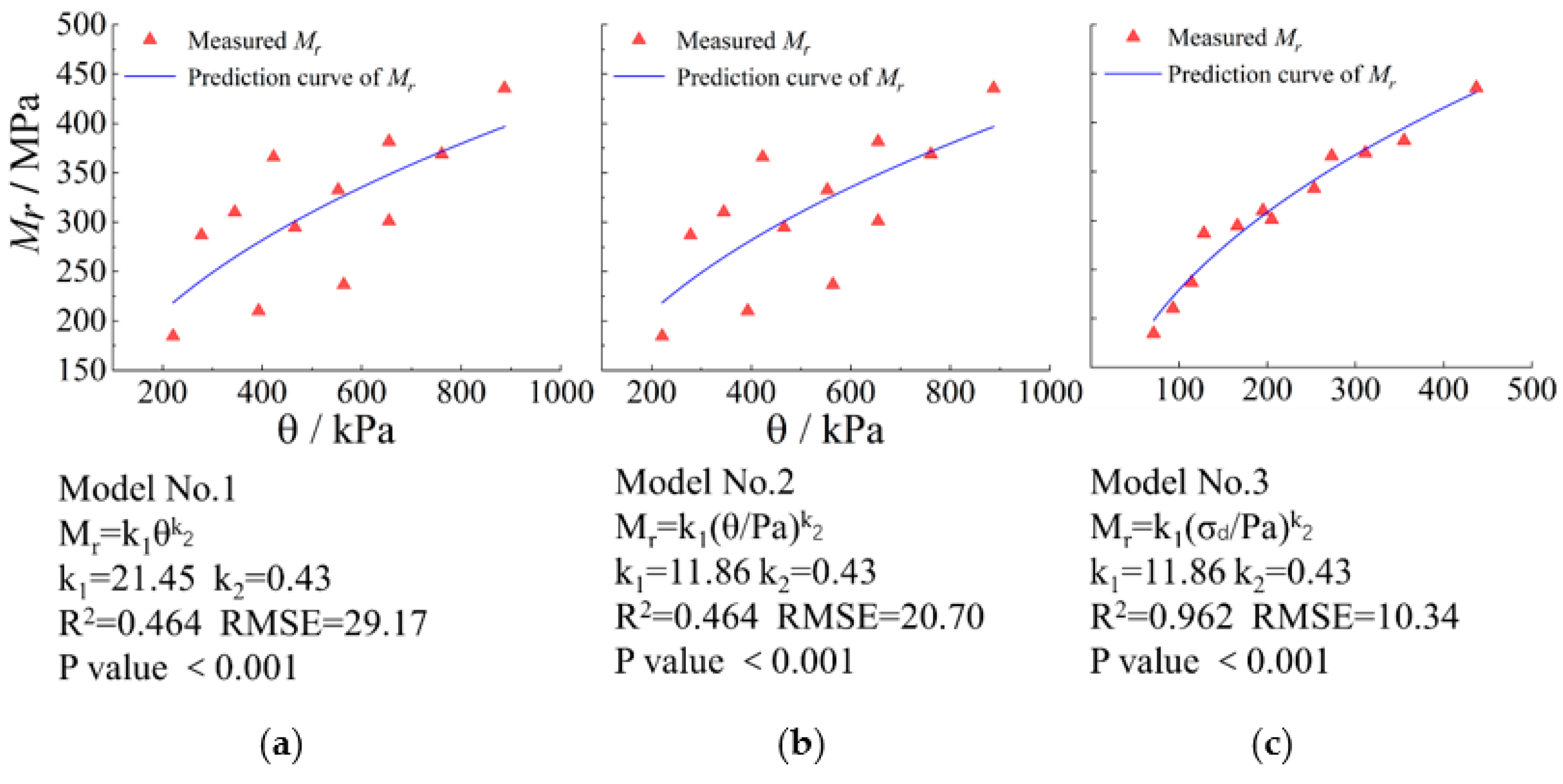

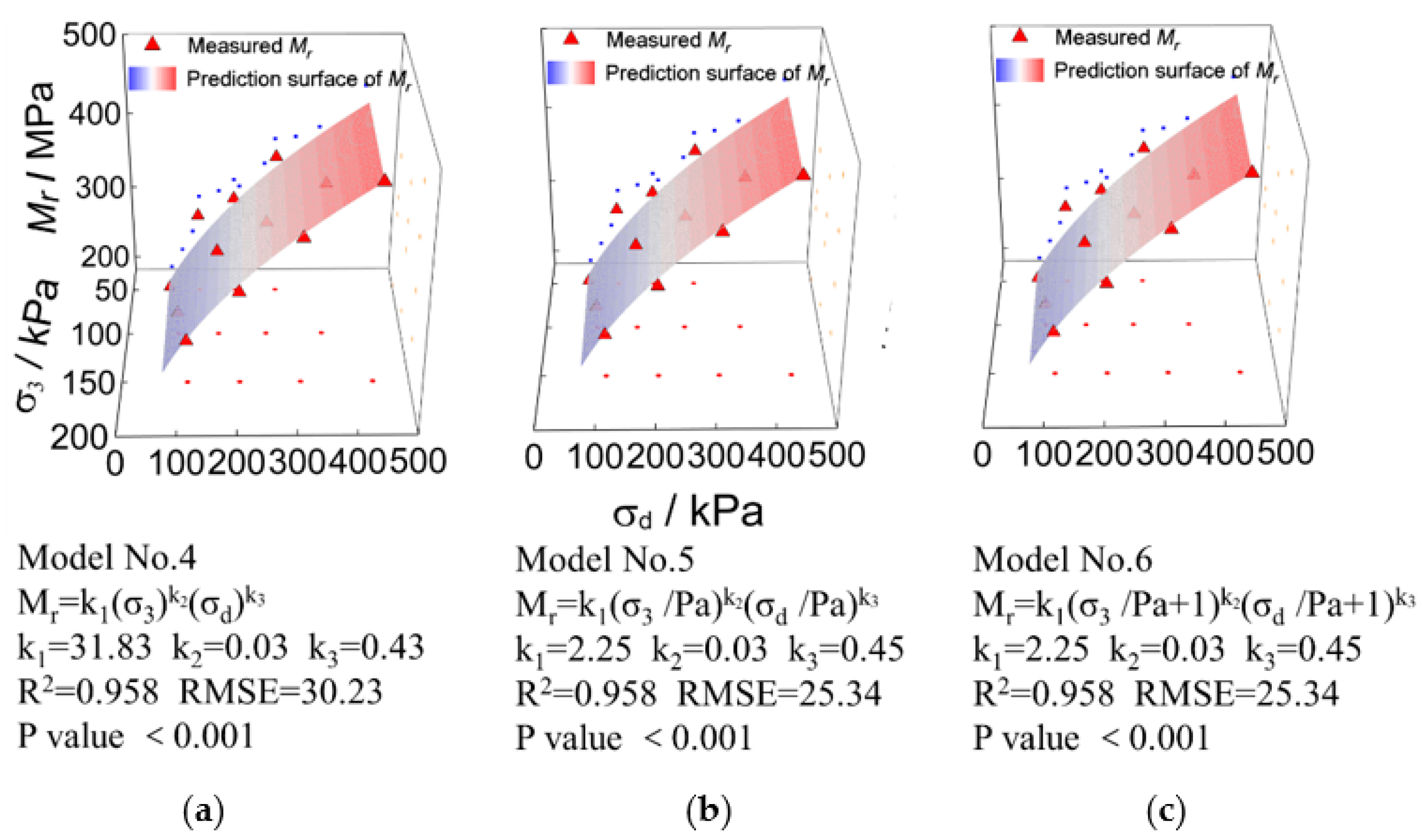

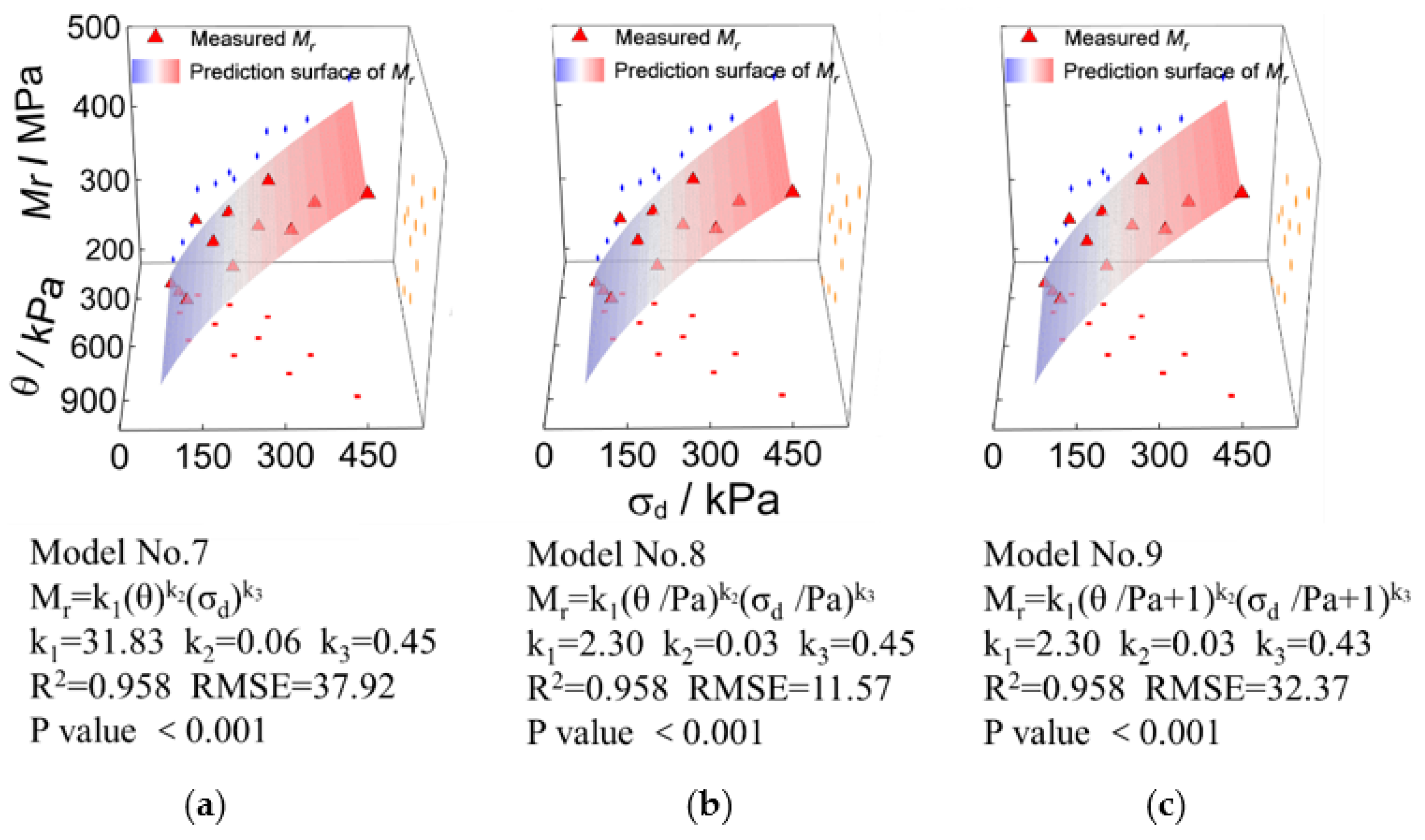

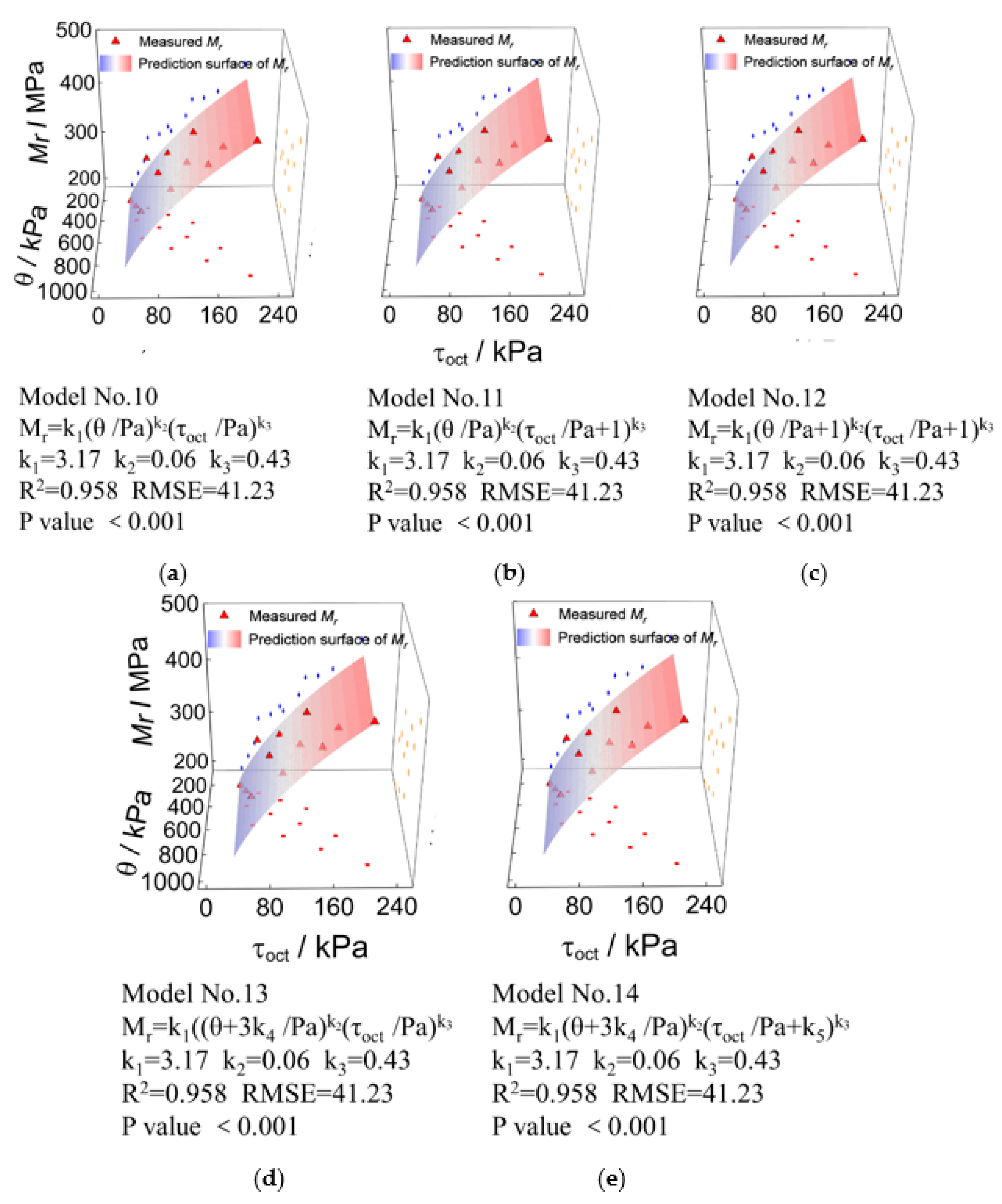

4.2. Comparative Assessment of Existing Classical Mr Prediction Models

4.3. Selection of the Optimal Classical Mr Prediction Model

4.4. Modification of the Optimal Mr Prediction Model

4.5. Parametric Sensitivity Analysis of the Final Optimal Mr Predictive Model

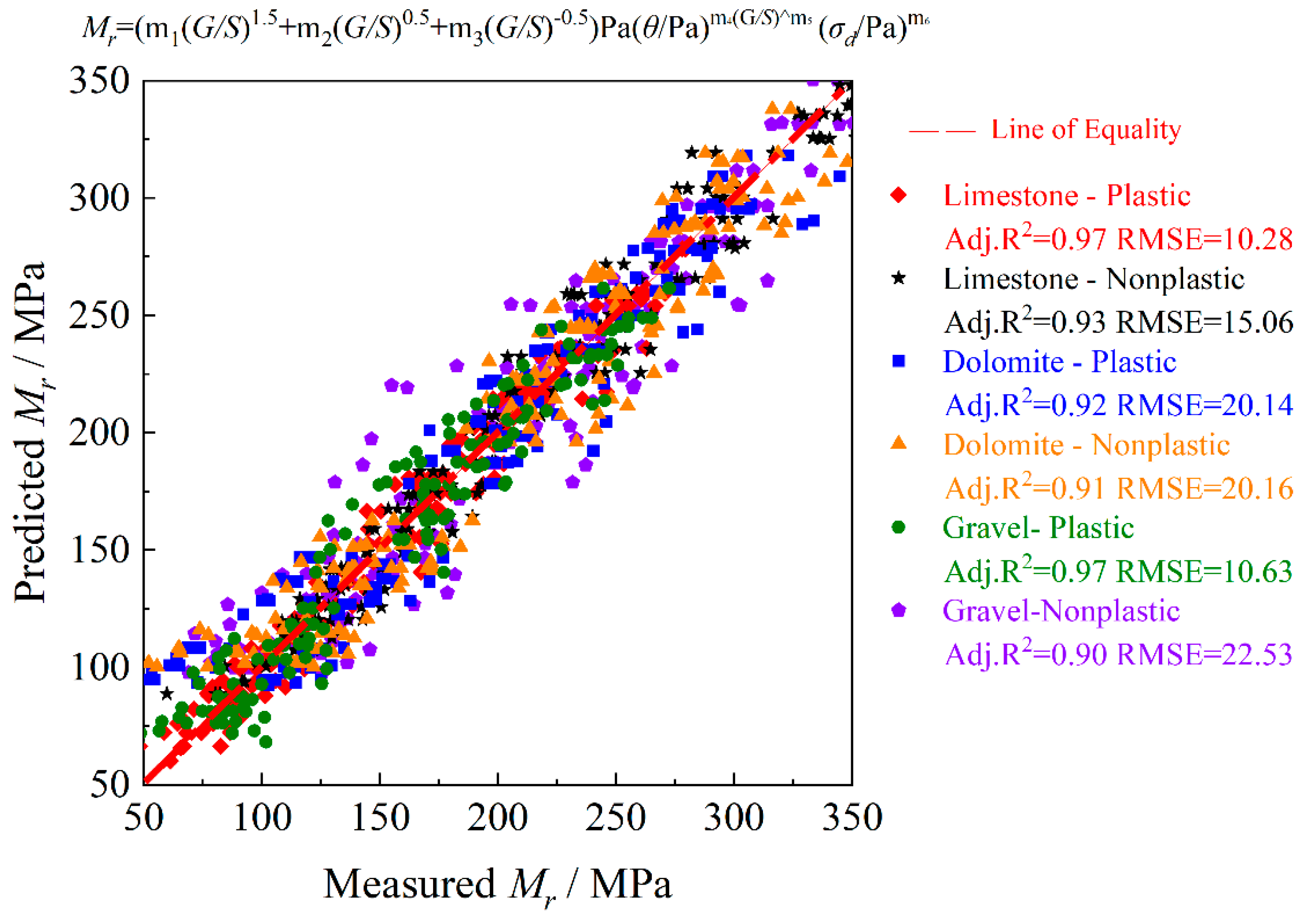

5. Verification of the Developed Resilient Modulus Prediction Model

6. Summary and Conclusions

- (1)

- The Mr values of the TRW-derived UPAB materials studied increase rapidly with increasing number of load applications. Under the same G/S value and confining pressure level, the higher the shear stress ratio (SSR) is, the greater the final Mr values are, and the more significant the effect of gradation (G/S) on Mr is. Under the same SSR level, the increase of confining pressure alleviates the effect of gradation (G/S) on Mr of the TRW-derived UPAB materials studied. There appears to exist an optimal G/S value of around 1.6–1.8 that yields the best resilient modulus behavior of the TRW-derived UPAB materials studied.

- (2)

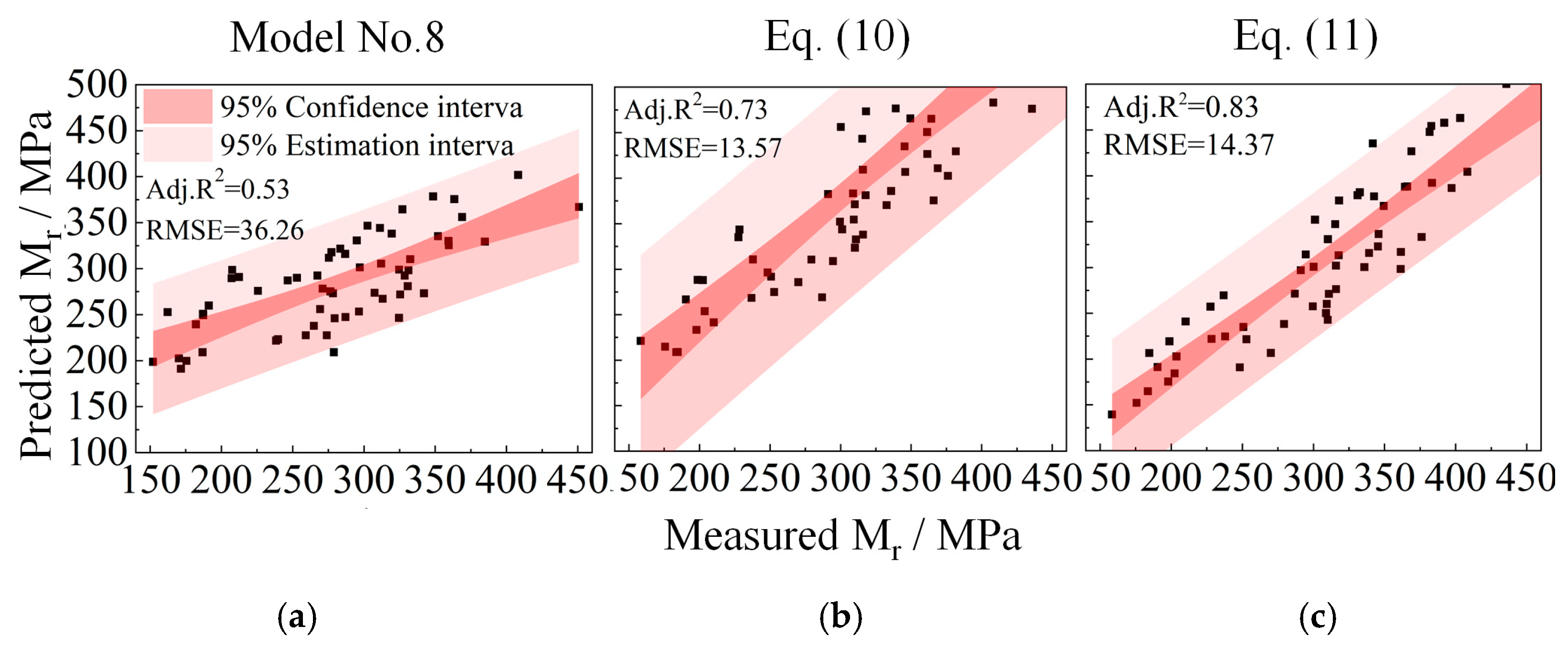

- The addition of standard atmospheric pressure (Pa) and the constant of 1 in the Mr models has little effect on the improvement of prediction accuracy, whereas the inclusion of two additional model coefficients, k4 and k5, is not effective for improving prediction accuracy of the Mr models. Among the Mr prediction models compared, the bivariate Model No. 8 incorporating the first principal stress invariant (θ) and deviatoric stress (σd) possesses the best prediction accuracy.

- (3)

- By comparing and analyzing the existing Mr prediction models, a benchmark prediction model suitable for the TRW-derived UPAB materials studied was selected. The statistical correlations among the fitted model coefficients, the gradation control parameter G/S, and stress state variables were further analyzed, from which the improved Mr prediction model was proposed and verified extensively to be universally applicable.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mokhov, I.I. Anomalous Winters in Regions of Northern Eurasia in Different Phases of the El Niño Phenomena. Dokl. Earth Sci. 2020, 493, 649–653. [Google Scholar] [CrossRef]

- Sonone, R.; Gupte, N. Precursors of the El Niño phenomenon: A climate network analysis. Phys. Rev. E 2021, 103, L040301. [Google Scholar] [CrossRef] [PubMed]

- Qin, M.; Qiu, L.-H.; Tao, R.; Umar, M.; Su, C.-W.; Jiao, W. The inevitable role of El Niño: A fresh insight into the oil market. Econ. Res. -Ekon. Istraživanja 2020, 33, 1943–1962. [Google Scholar] [CrossRef]

- Afonso, M.L.; Dinis-Almeida, M.; Fael, C.S. Permeable pavements–green infrastructures as a flood mitigation measure. In International Symposium on Greener Cities for More Efficient Ecosystem Services in a Climate Changing World; ISHS Acta Horticulturae 1215: Bologna, Italy, 2017; pp. 369–376. [Google Scholar]

- Nguyen, T.H.; Ahn, J. Experimental evaluation of the permanent strains of open-graded aggregate materials. Road Mater. Pavement Des. 2019, 22, 1667–1678. [Google Scholar] [CrossRef]

- Marvin, J.T.; Scott, J.; Van Seters, T.; Bowers, R.; Drake, J.A. Winter Maintenance of Permeable Interlocking Concrete Pavement: Evaluating Opportunities to Reduce Road Salt Pollution and Improve Winter Safety. Transp. Res. Rec. J. Transp. Res. Board 2020, 2675, 174–186. [Google Scholar] [CrossRef]

- Abdullah, M.E.; Zamhari, K.A.; Buhari, R.; Kamaruddin, N.H.M.; Nayan, N.; Hainin, M.R.; Hassan, N.A.; Jaya, R.P.; Yusoff, N.I. A Review on The Exploration of Nanomaterials Application in Pavement Engineering. J. Teknol. 2015, 73. [Google Scholar] [CrossRef]

- Ma, G.; Li, H.; Yang, B.; Zhang, H.; Li, W. Investigation on the deformation behavior of open-graded unbound granular materials for permeable pavement. Constr. Build. Mater. 2020, 260, 119800. [Google Scholar] [CrossRef]

- Koohmishi, M. Hydraulic conductivity and water level in the reservoir layer of porous pavement considering gradation of aggregate and compaction level. Constr. Build. Mater. 2019, 203, 27–44. [Google Scholar] [CrossRef]

- Koohmishi, M.; Shafabakhsh, G. Drainage potential of reservoir course of porous pavement for various particle size distributions of aggregate. Transp. Geotech. 2018, 16, 63–75. [Google Scholar] [CrossRef]

- Lu, G.; Renken, L.; Li, T.; Wang, D.; Li, H.; Oeser, M. Experimental study on the polyurethane-bound pervious mixtures in the application of permeable pavements. Constr. Build. Mater. 2019, 202, 838–850. [Google Scholar] [CrossRef]

- Cooley, L.A.; Prowell, B.D.; Brown, E.R.; Hall, K.; Button, J.; Davis, R. Issues pertaining to the permeability characteristics of coarse-graded superpave mixes. Asph. Paving Technol. Assoc. Asph. Paving Technol.-Proc. Tech. Sess. 2002, 71, 1–29. [Google Scholar]

- Kuang, X.; Sansalone, J.; Ying, G.; Ranieri, V. Pore-structure models of hydraulic conductivity for permeable pavement. J. Hydrol. 2011, 399, 148–157. [Google Scholar] [CrossRef]

- Zhang, H.; Li, H.; Zhang, Y.; Wang, D.; Harvey, J.; Wang, H. Performance enhancement of porous asphalt pavement using red mud as alternative filler. Constr. Build. Mater. 2017, 160, 707–713. [Google Scholar] [CrossRef]

- Mneina, A.; Shalaby, A. Relating gradation parameters to mechanical and drainage performance of unbound granular materials. Transp. Geotech. 2020, 23, 100315. [Google Scholar] [CrossRef]

- Hall, K.D.; Schwartz, C.W. Development of Structural Design Guidelines for Porous Asphalt Pavement. Transp. Res. Rec. J. Transp. Res. Board 2018, 2672, 197–206. [Google Scholar] [CrossRef]

- Rahman, M.S.; Erlingsson, S. Predicting permanent deformation behaviour of unbound granular materials. Int. J. Pavement Eng. 2014, 16, 587–601. [Google Scholar] [CrossRef]

- Zhang, J.; Peng, J.; Liu, W.; Lu, W. Predicting resilient modulus of fine-grained subgrade soils considering relative compaction and matric suction. Road Mater. Pavement Des. 2019, 22, 703–715. [Google Scholar] [CrossRef]

- Zhang, J.; Peng, J.; Zheng, J.; Dai, L.; Yao, Y. Prediction of Resilient Modulus of Compacted Cohesive Soils in South China. Int. J. Géoméch. 2019, 19, 04019068. [Google Scholar] [CrossRef]

- Ping, W.V.; Sheng, B. Developing Correlation Relationship between Modulus of Subgrade Reaction and Resilient Modulus for Florida Subgrade Soils. Transp. Res. Rec. J. Transp. Res. Board 2011, 2232, 95–107. [Google Scholar] [CrossRef]

- Piratheepan, J.; Gnanendran, C.T. Back-Calculation of Resilient Modulus of Lightly Stabilized Granular Base Materials from Cyclic Load Testing Facility. J. Mater. Civ. Eng. 2013, 25, 1068–1076. [Google Scholar] [CrossRef]

- Ping, W.V.; Yang, Z.; Liu, C.; Dietrich, B. Measuring Resilient Modulus of Granular Materials in Flexible Pavements. Transp. Res. Rec. J. Transp. Res. Board 2001, 1778, 81–90. [Google Scholar] [CrossRef]

- Nguyen, B.T.; Mohajerani, A. Resilient modulus of fine-grained soil and a simple testing and calculation method for determining an average resilient modulus value for pavement design. Transp. Geotech. 2016, 7, 59–70. [Google Scholar] [CrossRef]

- Chowdhury, S.M.R.M.; Kassem, E.; Alkuime, H.; Mishra, D.; Bayomy, F.M.S. Summary Resilient Modulus Prediction Model for Unbound Coarse Materials. J. Transp. Eng. Part B Pavements 2021, 147, 04021035. [Google Scholar] [CrossRef]

- Rahman, M.S.; Erlingsson, S. Influence of Post Compaction on the Moisture Sensitive Resilient Modulus of Unbound Granular Materials. Procedia Eng. 2016, 143, 929–936. [Google Scholar] [CrossRef]

- Li, N.; Tian, Y.; Ma, B.; Hu, D. Experimental Investigation of Water-Retaining and Mechanical Behaviors of Unbound Granular Materials under Infiltration. Sustainability 2022, 14, 1174. [Google Scholar] [CrossRef]

- Jaffar, S.T.A.; Abid, M.M.; Khan, S.Z.; Jafri, T.; Rehman, Z.U.; Tariq, M.A.U.R.; Ng, A.W.M. Evaluation of Conventional and Sustainable Modifiers to Improve the Stiffness Behavior of Weak Sub-Grade Soil. Sustainability 2022, 14, 2493. [Google Scholar] [CrossRef]

- Thai, H.N. Effects of Particle Size and Type of Aggregate on Mechanical Properties and Environmental Safety of Unbound Road Base and Subbase Materials: A Literature Review. Int. J. Geomate 2021, 20, 148–157. [Google Scholar] [CrossRef]

- Ekblad, J. Statistical evaluation of resilient models characterizing coarse granular materials. Mater. Struct. 2007, 41, 509–525. [Google Scholar] [CrossRef]

- Barskale, R.D.; Itani, S.Y. Influence of aggregate shape on base behavior. Transp. Res. Rec. 1989, 1227, 173–182. [Google Scholar]

- Li, N.; Wang, H.; Ma, B.; Li, R. Investigation of unbound granular material behavior using precision unbound material analyzer and repeated load triaxial test. Transp. Geotech. 2019, 18, 1–9. [Google Scholar] [CrossRef]

- Smith, W.; Nair, K. Development of Procedures for Characterization of Untreated Granular Base Course and Asphalt-T reated Base Course Materials; Materials Research: Oakland, CA, USA, 1973. [Google Scholar]

- Monismith, C.L.; Seed, F.G.; Mitry, F.G.; Chan, C. Predictions of pavement deflections from laboratory tests. In Proceedings of the Second In-ternational Conference on the Structural Design of Asphalt Pavements, Ann Arbor, MI, USA, 7–11 August 1967. [Google Scholar]

- Lekarp, F.; Isacsson, U.; Dawson, A. State of the Art. I: Resilient Response of Unbound Aggregates. J. Transp. Eng. 2000, 126, 66–75. [Google Scholar] [CrossRef]

- Nguyen, B.T.; Mohajerani, A. Possible simplified method for the determination of the resilient modulus of unbound granular materials. Road Mater. Pavement Des. 2016, 17, 841–858. [Google Scholar] [CrossRef]

- Chanpheng, P.; Sangpetngam, B. Influences of Moisture and Compaction on Resilient Modulus of an Unbound Base Material. In Proceedings of the 18th National Convention on Civil Engineering, Chiang Mai, Thailand, 8–10 May 2013. [Google Scholar]

- Li, N.; Ma, B.; Wang, H.; Tang, J.; Wang, X.; Shao, Z. Influence of loading frequency on mechanical properties of unbound granular materials via repeated load tests. Constr. Build. Mater. 2021, 301, 124098. [Google Scholar] [CrossRef]

- Gu, C.; Zhan, Y.; Wang, J.; Cai, Y.; Cao, Z.; Zhang, Q. Resilient and permanent deformation of unsaturated unbound granular materials under cyclic loading by the large-scale triaxial tests. Acta Geotech. 2020, 15, 3343–3356. [Google Scholar] [CrossRef]

- Allen, J.J.; Thompson, M.R. Resilient response of granular materials subjected to time-dependent lateral stresses. Transp. Res. Rec. 1974, 510, 1–13. [Google Scholar]

- Garg, N.; Thompson, M.R. Triaxial Characterization of Minnesota Road Research Project Granular Materials. Transp. Res. Rec. J. Transp. Res. Board 1997, 1577, 27–36. [Google Scholar] [CrossRef]

- Moossazadeh, J.; Witczak, M.W. Prediction of subgrade moduli for soil that exhibits nonlinear behavior. Transp. Res. Rec. 1981, 810, 9–17. [Google Scholar]

- Seed, H.B.; Chan, C.K.; Lee, C.E. Resilience characteristics of subgrade soils and their relation to fatigue failures in asphalt pavements. In Proceedings of the International Conference on the Structural Design of Asphalt Pavements, Ann Arbor, MI, USA, 20–24 August 1962. [Google Scholar]

- Uzan, J. Characterization of granular material. Transp. Res. Rec. 1985, 1022, 52–59. [Google Scholar]

- Ni, B.; Hopkins, T.; Sun, L.; Beckham, T. Modeling the Resilient Modulus of Soils. In Bearing Capacity of Roads, Railways and Airfields; CRC Press: Lisbon, Portugal, 2002; pp. 1131–1142. [Google Scholar] [CrossRef]

- Ng, K.; Mebrahtom, D.; Ksaibati, K. Characterization of crushed base materials in Wyoming (No. WY-1706F); University of Wyoming: Laramie, WY, USA, 2017. [Google Scholar]

- Hasan, M.; Hasan, A.; Tarefder, R.A. Development of Resilient Modulus Prediction Model for Granular and Noncohesive Soils of New Mexico. Adv. Civ. Eng. Mater. 2019, 8, 400–410. [Google Scholar] [CrossRef]

- Li, L.; Liu, J.; Zhang, X.; Saboundjian, S. Laboratory Investigation of Seasonal Variations in Resilient Modulus of Alaskan Base Course Material. Paving Mater. Pavement Anal. 2010, 3, 270–278. [Google Scholar] [CrossRef]

- Hossain, Z.; Zaman, M.; Doiron, C. Mechanistic Empirical Pavement Design Guide Input Parameters for Unbound Aggregates in Oklahoma. In Proceedings of the IACGE 2013: Challenges and Recent Advances in Geotechnical and Seismic Research and Practices, Chengdu, China, 25–27 October 2013; pp. 578–585. [Google Scholar]

- Haj, E.Y.; Thavathurairaja, J.; Stolte, S.; Sebaaly, P.E.; Piratheepan, M.; Motamed, R.; Center, W.R.S. Resilient modulus prediction models of unbound materials for Nevada (No. P224-14-803); SOLARIS Consortium: Madison, WI, USA, 2018. [Google Scholar]

- Han-Cheng, D.; Lin-Hua, H.; Lian-Heng, Z. Experimental investigation on the resilient response of unbound graded aggregate materials by using large-scale dynamic triaxial tests. Road Mater. Pavement Des. 2018, 21, 434–451. [Google Scholar] [CrossRef]

- Kim, I.T. Permanent Deformation Behavior of Airport Flexible Pavement Base and Subbase Courses. Ph.D. Thesis, University of Illinois at Urbana-Champaign, Champaign, IL, USA, 2005. [Google Scholar]

- Chow, L.C. Permanent Deformation Behavior of Unbound Granular Materials and Rutting Model Development. Master’s Thesis, University of Illinois at Urbana-Champaign, Champaign, IL, USA, 2014. [Google Scholar]

- Xiao, Y. Performance-Based Evaluation of Unbound Aggregates Affecting Mechanistic Response and Performance of Flexible Pavements. Ph.D. Thesis, University of Illinois at Urbana-Champaign, Champaign, IL, USA, 2014. [Google Scholar]

- Technical Guidelines for Construction of Highway Roadbases; China Communications Press Co., Ltd.: Beijing, China, 2015.

- Chow, L.C.; Mishra, D.; Tutumluer, E. Framework for Development of an Improved Unbound Aggregate Base Rutting Model for Mechanistic–Empirical Pavement Design. Transp. Res. Rec. J. Transp. Res. Board 2014, 2401, 11–21. [Google Scholar] [CrossRef]

- Mohajerani, A.; Nguyen, B.T.; Glavacevic, L. Estimation of resilient modulus of unbound granular materials using Clegg impact value and field stress levels. Transp. Geotech. 2016, 7, 115–129. [Google Scholar] [CrossRef]

- Technical Specifications for Construction of Highway Roadbases; China Communications Press Co., Ltd.: Beijing, China, 2019.

- AASHTO T 307-99; Determining the Resilient Modulus of Soils and Aggregate Materials. AASHTO: Washington, DC, USA, 2003.

- Zhou, Z.; Wang, M.; Yu, Q.; Zheng, K.; Xiao, Y.; Chen, X. Mechanical behavior of unbound permeable aggregate base materials studied from large-scale direct shear tests. J. Railw. Sci. Eng. 2019, 16, 2175–2183. [Google Scholar]

- Brown, S.F.; Pell, P.S. An experimental investigation of the stresses, strains and deflection in a layered pavement structure subjected to dynamic loads. In Proceedings of the 2nd International Conference on the Structural Design of Asphalt Pavements, Ann Arbor, MI, USA, 7–11 August 1967; pp. 487–504. [Google Scholar]

- Hicksr, G.; Monismithc, L. Prediction of the resilient response of pavements containing granular layers using nonlinear elastictheory. In Proceedings of the 3rd International Conference on the Structural Design of Asphalt Pavements, Grosvenor House, Park Lane, London, UK, 11–15 September 1972; pp. 410–429. [Google Scholar]

- Pezo, R. A General Method of Reporting Resilient Modulus Tests of Soils-A Pavement Engineer’s Point of View; Paper No: 93082; Transportation Research Board, National Research Council: Washington, DC, USA, 1993. [Google Scholar]

- Raad, L.; Figueroa, J.L. Load Response of Transportation Support Systems. Transp. Eng. J. ASCE 1980, 106, 111–128. [Google Scholar] [CrossRef]

- Boudali, M.; Robert, C. Laboratory determination of base material resilient moduli. In Proceedings of the 5th International Conference on the Bearing Capacity of Road and Airfields; Road Directorate, Danish Road Institute, Trondheim, Norway, 6–8 July 1998; pp. 1235–1245. [Google Scholar]

- Lytton, R.L.; Uzan, J.; Femando, E.G.; Roque, R.; Hiltunen, D.; Stoffels, S.M. Development and Validation of Performance Prediction Models and Specifications for Asphalt Binders and Paving Mixes; Report SHRP A-357, Strategic Highway Research Program, National Research Council: Washington, DC, USA, 1993; pp. 125–138. [Google Scholar]

- Hopkins, T.C.; Beckham, T.L.; Sun, C.; Ni, B. Resilient Modulus of Kentucky Soils; Report No. KTC-01-07/SPR163-95-1F; University of Kentucky: Lexington, KY, USA, 2001. [Google Scholar]

- Tutumluer, E.; Mishra, D.; Butt, A.A. Characterization of Illinois Aggregates for Subgrade Replacement and Subbase; Illinois Center for Transportation: Rantoul, IL, USA, 2009. [Google Scholar]

- Xiao, Y.; Tutumluer, E.; Mishra, D. Performance Evaluations of Unbound Aggregate Permanent Deformation Models for Various Aggregate Physical Properties. Transp. Res. Rec. 2015, 2525, 20–30. [Google Scholar] [CrossRef]

| G/S | Dmax/mm | n | Cu | Cc |

|---|---|---|---|---|

| 1.0 | 26.5 | 0.32 | 270.22 | 3.55 |

| 1.6 | 26.5 | 0.51 | 29.09 | 1.97 |

| 1.8 | 26.5 | 0.56 | 23.64 | 2.08 |

| 2.0 | 26.5 | 0.61 | 18.09 | 1.90 |

| 2.5 | 26.5 | 0.71 | 11.63 | 1.63 |

| G/S | c/kPa | φ/° | Confining Pressure/kPa | SSR | Deviator Stress/kPa | No. of Load Applications (Nmax) |

|---|---|---|---|---|---|---|

| 1.0 | 65.5 | 29.2 | 50 | 0.3/0.5/0.7/0.9 | 71/128/195/273 | 50,000 |

| 100 | 93/166/253/355 | |||||

| 150 | 114/205/311/273 | |||||

| 1.6 | 64.8 | 40.9 | 50 | 97/178/277/400 | ||

| 100 | 136/150/388/560 | |||||

| 150 | 175/321/498/400 | |||||

| 1.8 | 64.3 | 47.9 | 50 | 128/236/370/542 | ||

| 100 | 184/341/535/793 | |||||

| 150 | 241/446/699/542 | |||||

| 2.0 | 64 | 43.6 | 50 | 106/195/304/441 | ||

| 100 | 151/277/432/628 | |||||

| 150 | 196/360/561/441 | |||||

| 2.5 | 48.7 | 45.5 | 50 | 64/173/271/394 | ||

| 100 | 142/261/407/592 | |||||

| 150 | 189/348/543/394 |

| Mr Prediction Model | Fitted Coefficient of Determination (R2) | ||||

|---|---|---|---|---|---|

| No. | Source | Formula | Method I | Method II | Method III |

| 1 | K-θ Model [42,60,61] | 0.46 | 0.43 | 0.42 | |

| 2 | Modification K-θ Model [42,60,61] | 0.46 | 0.43 | 0.42 | |

| 3 | Moossazadeh & Witczak Model [41] | 0.96 | 0.95 | 0.95 | |

| 4 | Pezo Model [62] | 0.96 | 0.96 | 0.95 | |

| 5 | Raad & Figueroa Model [63] | 0.96 | 0.96 | 0.95 | |

| 6 | Ni Model [44] | 0.96 | 0.96 | 0.95 | |

| 7 | Uzan Model [43] | 0.96 | 0.96 | 0.96 | |

| 8 | Octahedral Shear Stress Model [43] | 0.96 | 0.96 | 0.96 | |

| 9 | Modified Ni Model [44] | 0.96 | 0.96 | 0.96 | |

| 10 | Modified Uzan Model [43] | 0.96 | 0.96 | 0.96 | |

| 11 | NCHRP 1-28A Model [64,65] | 0.96 | 0.96 | 0.96 | |

| 12 | Improved Ni Model [44] | 0.96 | 0.96 | 0.96 | |

| 13 | Superpave Performance Model [66] | 0.95 | 0.94 | 0.94 | |

| 14 | Hopkins Model [66] | 0.95 | 0.94 | 0.94 | |

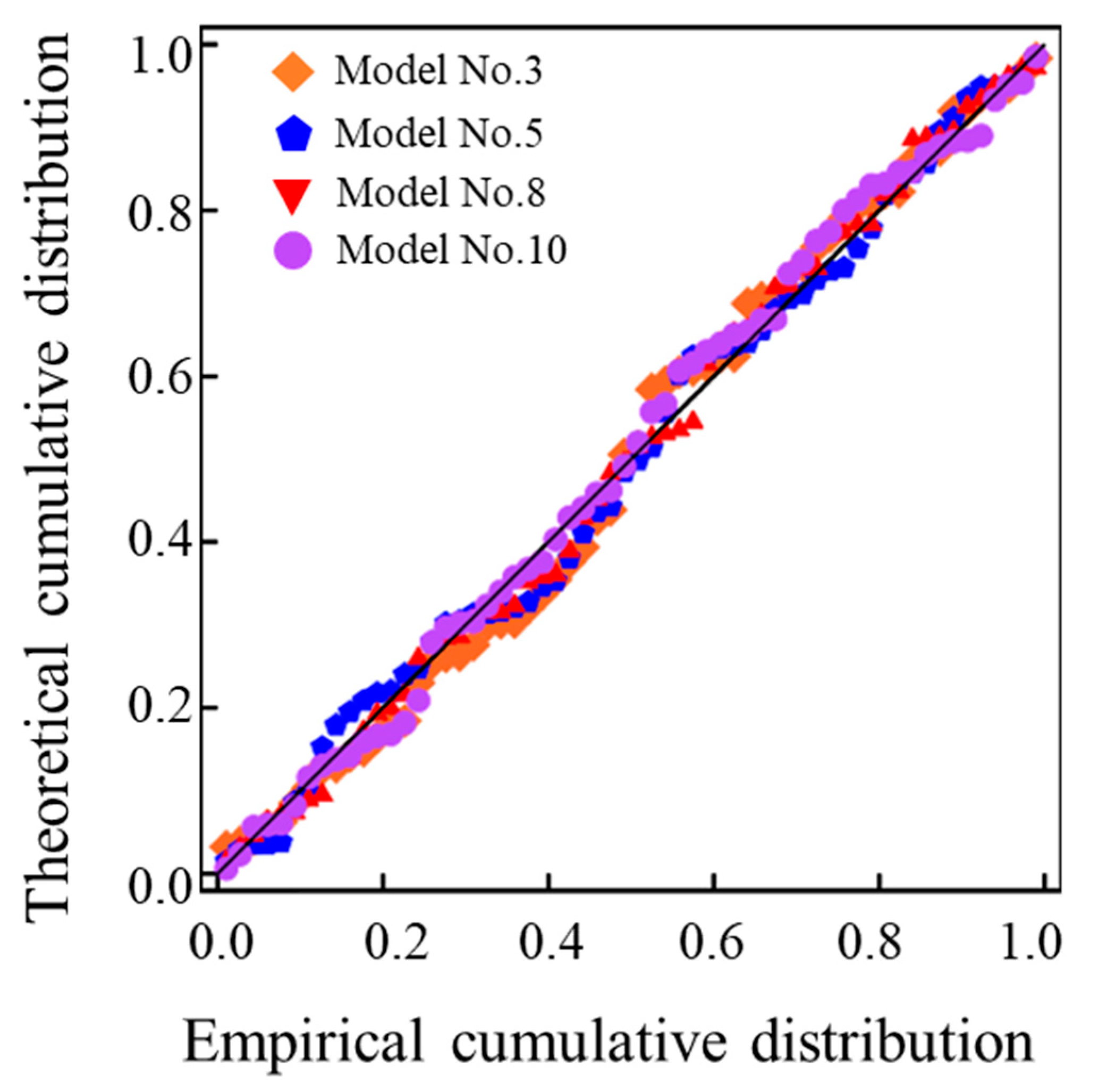

| Statistics | Model No. 3 | Model No. 5 | Model No. 8 | Model No. 10 |

|---|---|---|---|---|

| Residual sum of squares | 23,116.7 | 25,465.61 | 22,296.19 | 25,329.81 |

| Variance | 391.776 | 430.270 | 371.282 | 420.497 |

| Root mean square error | 19.79 | 20.74 | 19.26 | 20.51 |

| Skewness | 0.058 | −0.024 | −0.024 | −0.187 |

| Standard error of skewness | 0.309 | 0.309 | 0.309 | 0.309 |

| Kurtosis | −0.815 | −0.367 | −0.631 | −0.383 |

| Standard error of kurtosis | 0.608 | 0.608 | 0.608 | 0.608 |

| AIC index | 361.23 | 369.04 | 361.07 | 368.72 |

| G/S Value | k1 | k2 | k3 | Adj. R2 |

|---|---|---|---|---|

| 1.0 | 2.29569 | 0.06051 | 0.42957 | 0.95759 |

| 1.6 | 1.89589 | 0.0897 | 0.46408 | 0.95544 |

| 1.8 | 1.82463 | 0.15902 | 0.38588 | 0.85698 |

| 2.0 | 1.947 | 0.12619 | 0.36525 | 0.88606 |

| 2.5 | 1.93914 | 0.14658 | 0.38141 | 0.86677 |

| Unbound Aggregate Materials | Optimal Moisture Content/% | Maximum Dry Density/G·cm3 | G/S | Plasticity Index (PI)/% | |

|---|---|---|---|---|---|

| Limestone with nonplastic fines | L4NP | 10.5 | 2.122 | 1.39 | 0 |

| L8NP | 8.4 | 2.182 | 1.43 | 0 | |

| L12NP | 7.6 | 2.243 | 1.49 | 0 | |

| L16NP | 6.8 | 2.269 | 1.55 | 0 | |

| Limestonewith plastic fines | L4P | 9.3 | 2.165 | 1.39 | 10 |

| L8P | 8 | 2.171 | 1.43 | 8 | |

| L12P | 7.6 | 2.229 | 1.49 | 9 | |

| L16P | 7.1 | 2.270 | 1.55 | 9 | |

| Dolomite with nonplastic fines | D4NP | 9.2 | 2.114 | 1.39 | 0 |

| D8NP | 8.1 | 2.147 | 1.43 | 0 | |

| D12NP | 7.1 | 2.198 | 1.49 | 0 | |

| D16NP | 7.1 | 2.208 | 1.55 | 0 | |

| Dolomite with plastic fines | D4P | 8.0 | 2.149 | 1.39 | 11 |

| D8P | 7.3 | 2.168 | 1.43 | 12 | |

| D12P | 7.1 | 2.194 | 1.49 | 13 | |

| D16P | 6.9 | 2.184 | 1.55 | 14 | |

| Gravel with nonplastic fines | G4NP | 10.6 | 2.118 | 1.39 | 0 |

| G8NP | 8.5 | 2.211 | 1.43 | 0 | |

| L12NP | 6.8 | 2.259 | 1.49 | 0 | |

| G16NP | 6.6 | 2.286 | 1.55 | 0 | |

| Gravel with plastic fines | G4P | 10.4 | 2.157 | 1.39 | 8 |

| G8P | 7.4 | 2.208 | 1.43 | 9 | |

| G12P | 6.6 | 2.242 | 1.49 | 9 | |

| G16P | 6.6 | 2.256 | 1.55 | 9 | |

| Material Type | R2 |

|---|---|

| Limestone with plastic fines | 0.6575 |

| Limestone with nonplastic fines | 0.6098 |

| Dolomite with plastic fines | 0.6218 |

| Dolomite with nonplastic fines | 0.6161 |

| Gravel with plastic fines | 0.5874 |

| Gravel with nonplastic fines | 0.5841 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, M.; Yu, Q.; Xiao, Y.; Li, W. Resilient Modulus Behavior and Prediction Models of Unbound Permeable Aggregate Base Materials Derived from Tunneling Rock Wastes. Materials 2022, 15, 6005. https://doi.org/10.3390/ma15176005

Wang M, Yu Q, Xiao Y, Li W. Resilient Modulus Behavior and Prediction Models of Unbound Permeable Aggregate Base Materials Derived from Tunneling Rock Wastes. Materials. 2022; 15(17):6005. https://doi.org/10.3390/ma15176005

Chicago/Turabian StyleWang, Meng, Qunding Yu, Yuanjie Xiao, and Wenqi Li. 2022. "Resilient Modulus Behavior and Prediction Models of Unbound Permeable Aggregate Base Materials Derived from Tunneling Rock Wastes" Materials 15, no. 17: 6005. https://doi.org/10.3390/ma15176005

APA StyleWang, M., Yu, Q., Xiao, Y., & Li, W. (2022). Resilient Modulus Behavior and Prediction Models of Unbound Permeable Aggregate Base Materials Derived from Tunneling Rock Wastes. Materials, 15(17), 6005. https://doi.org/10.3390/ma15176005