Research on the Evolution of Shield Segment Cracks Based on Acoustic Emission and CMOD

Abstract

:1. Introduction

2. Acoustic Emission Technology and Basic Theory of CMOD

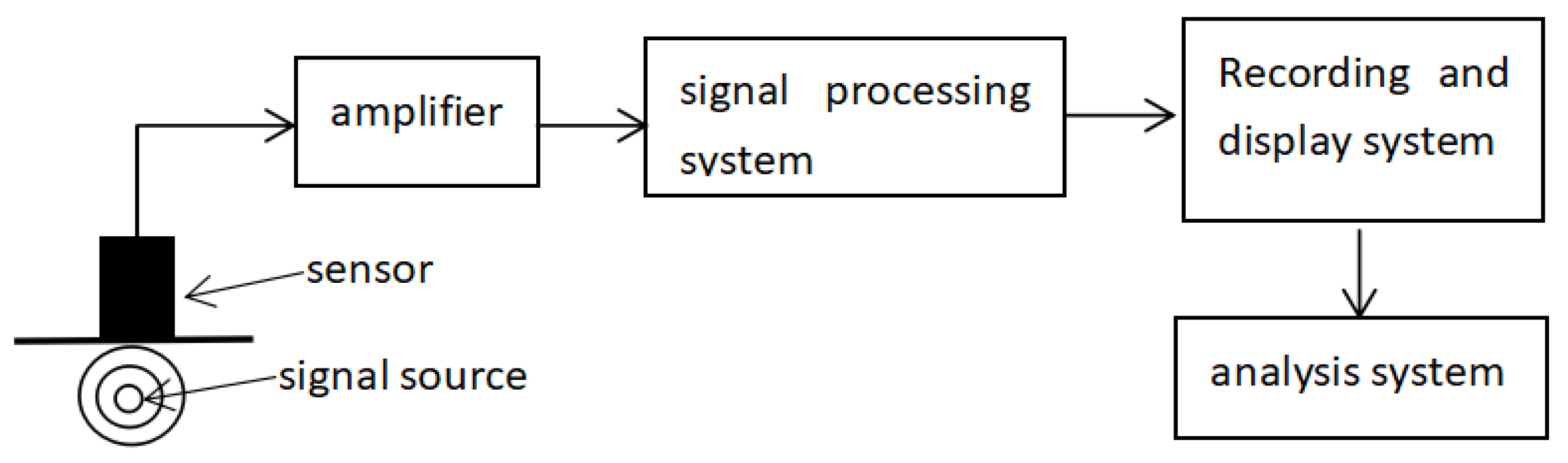

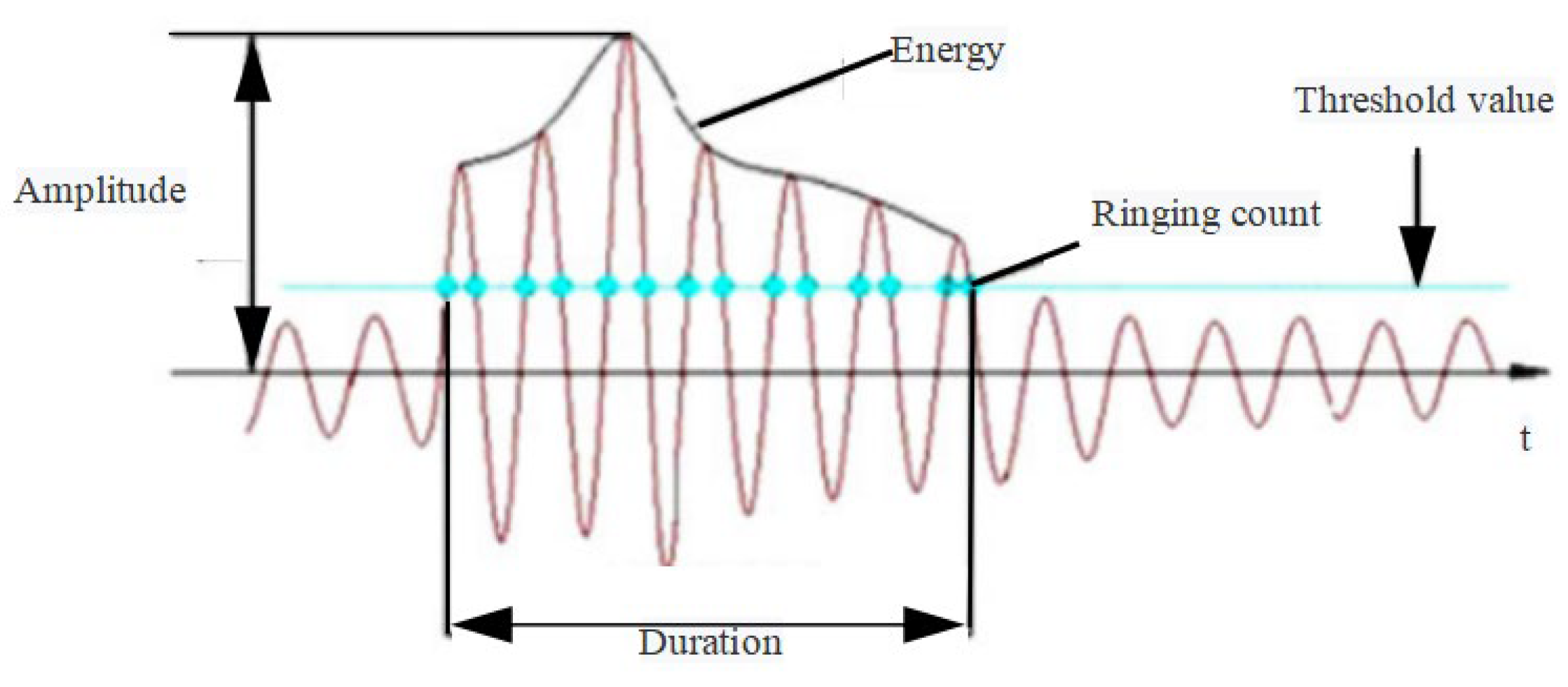

2.1. Basic Theory of Acoustic Emission

2.2. Basic Theory of Acoustic Emission

3. Trial Overview

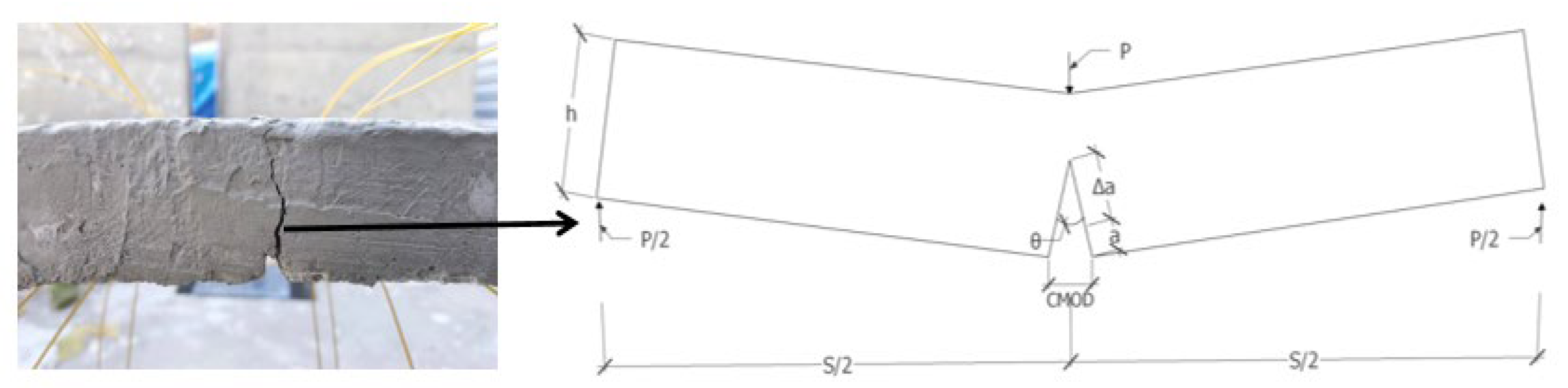

3.1. Specimen Design

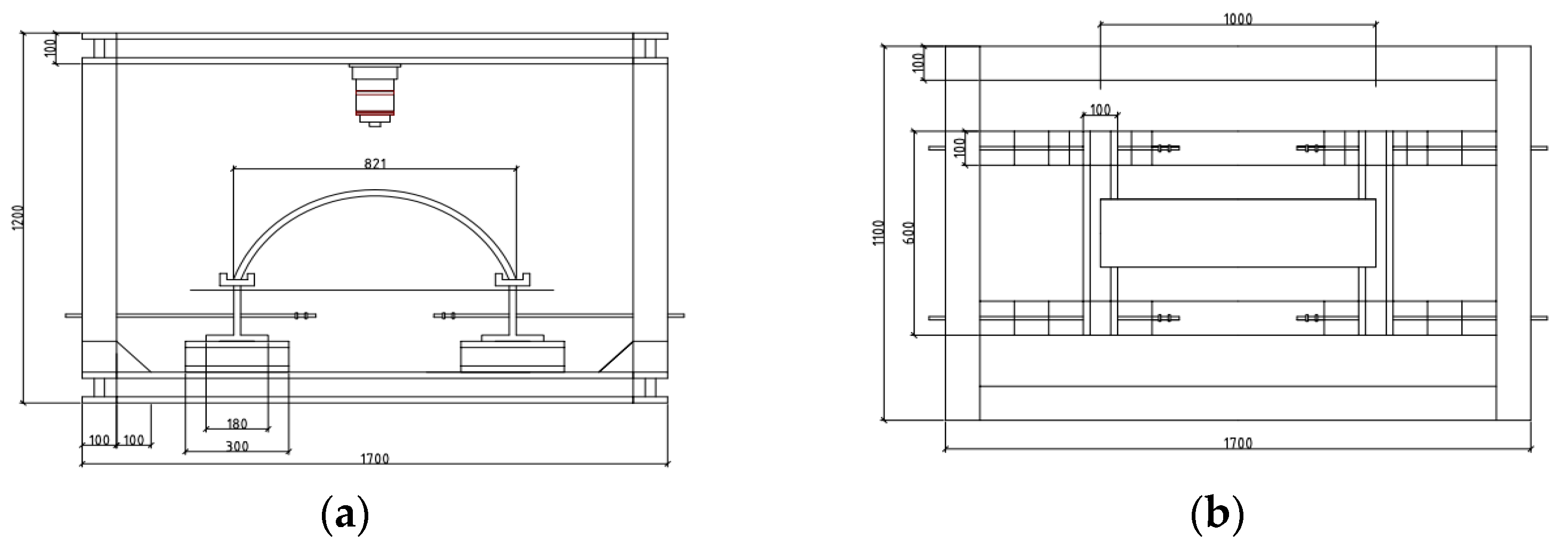

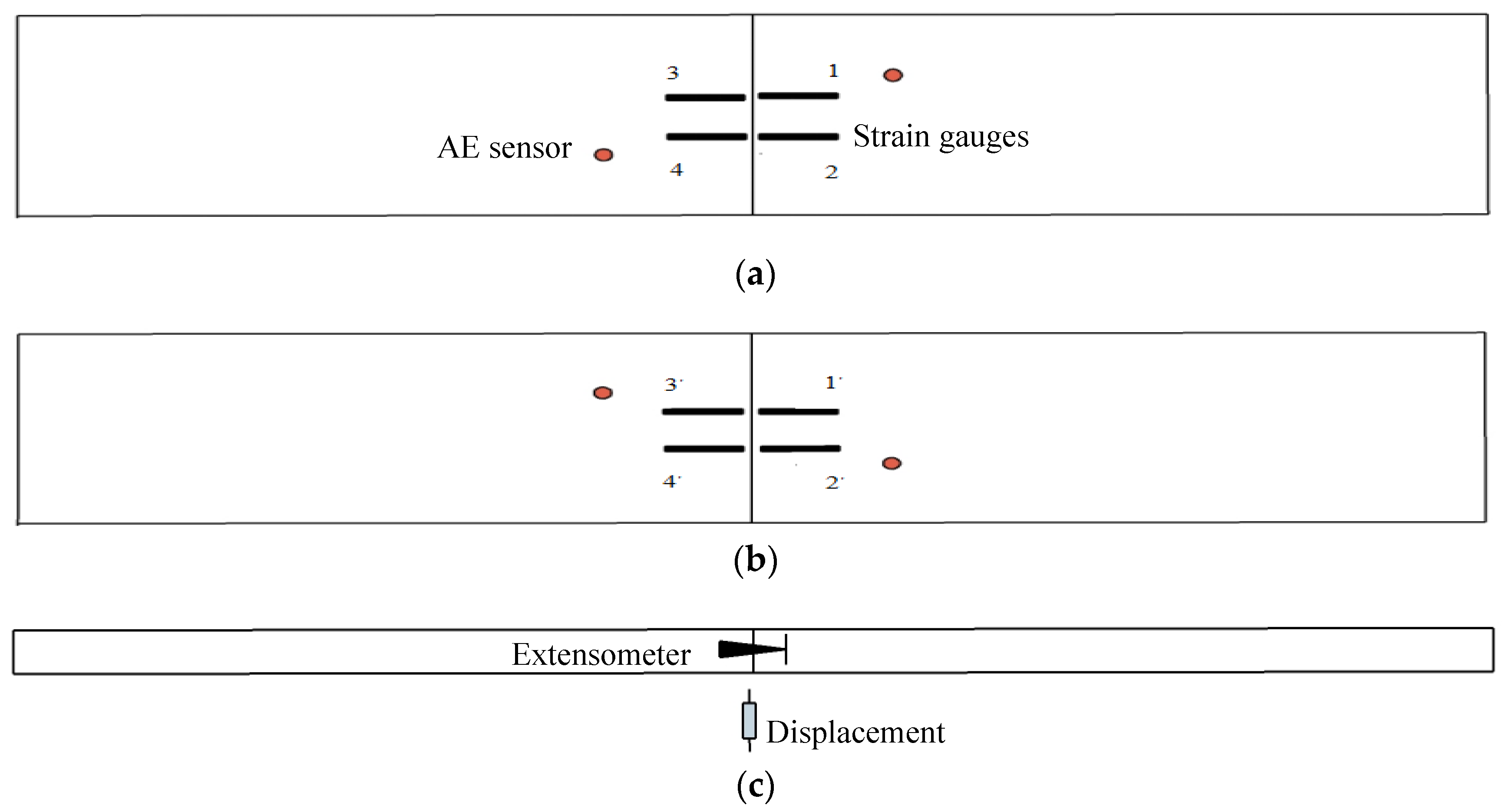

3.2. Loading Method and Measurement Arrangement

4. Test Results and Analysis

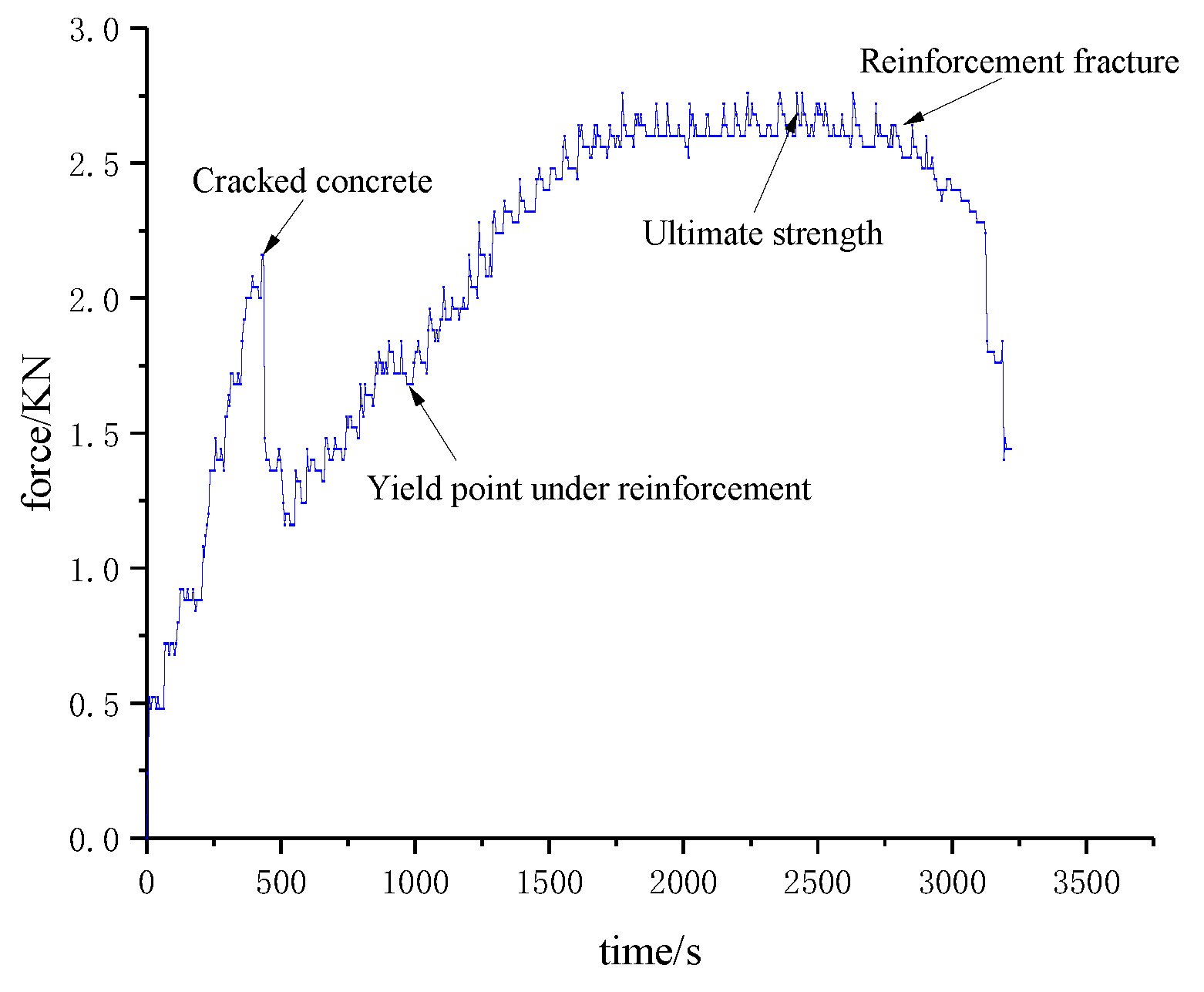

4.1. Crack Failure Process

4.2. Analysis of Microscopic Characteristics of Segment Crack Damage

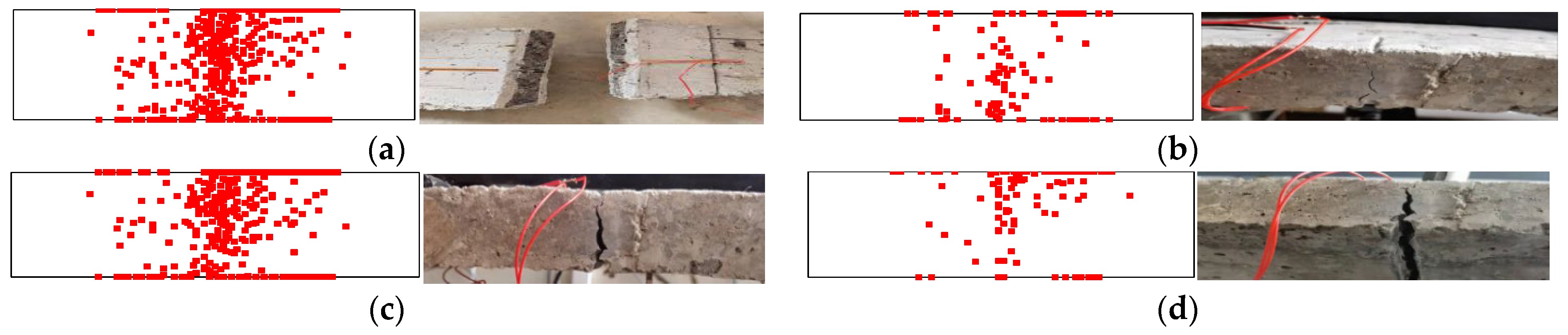

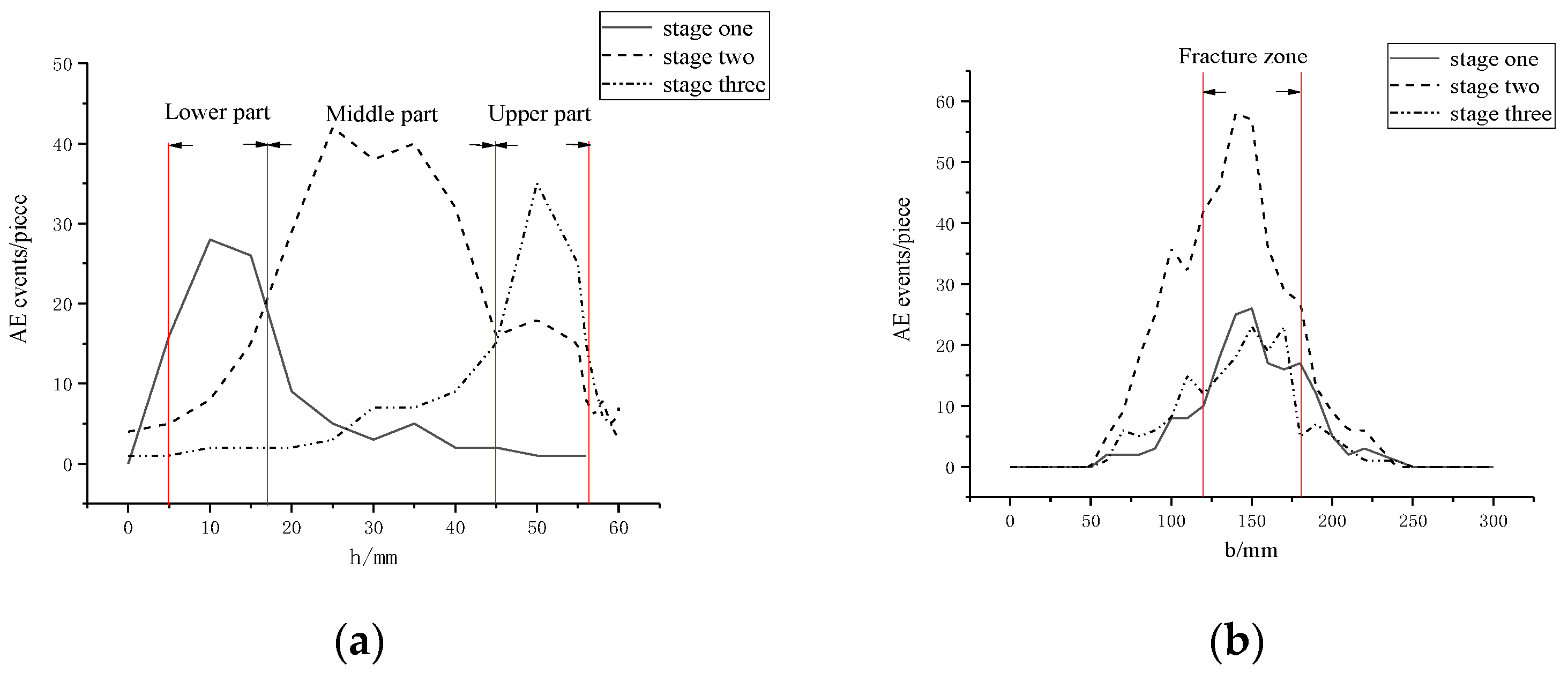

4.3. Analysis of Macroscopic Characteristics of Segment Cracks

5. Segment Cracking Damage Model

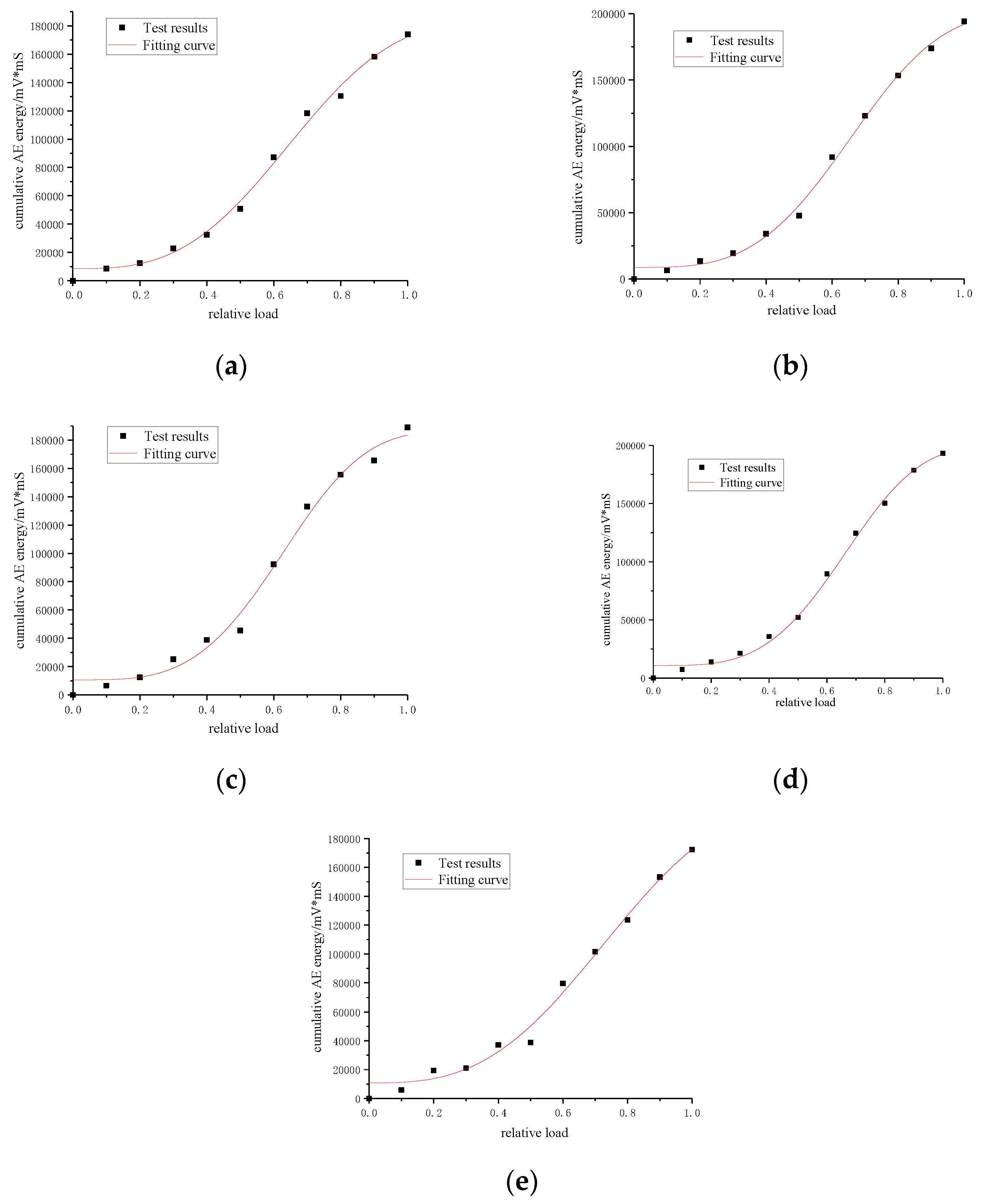

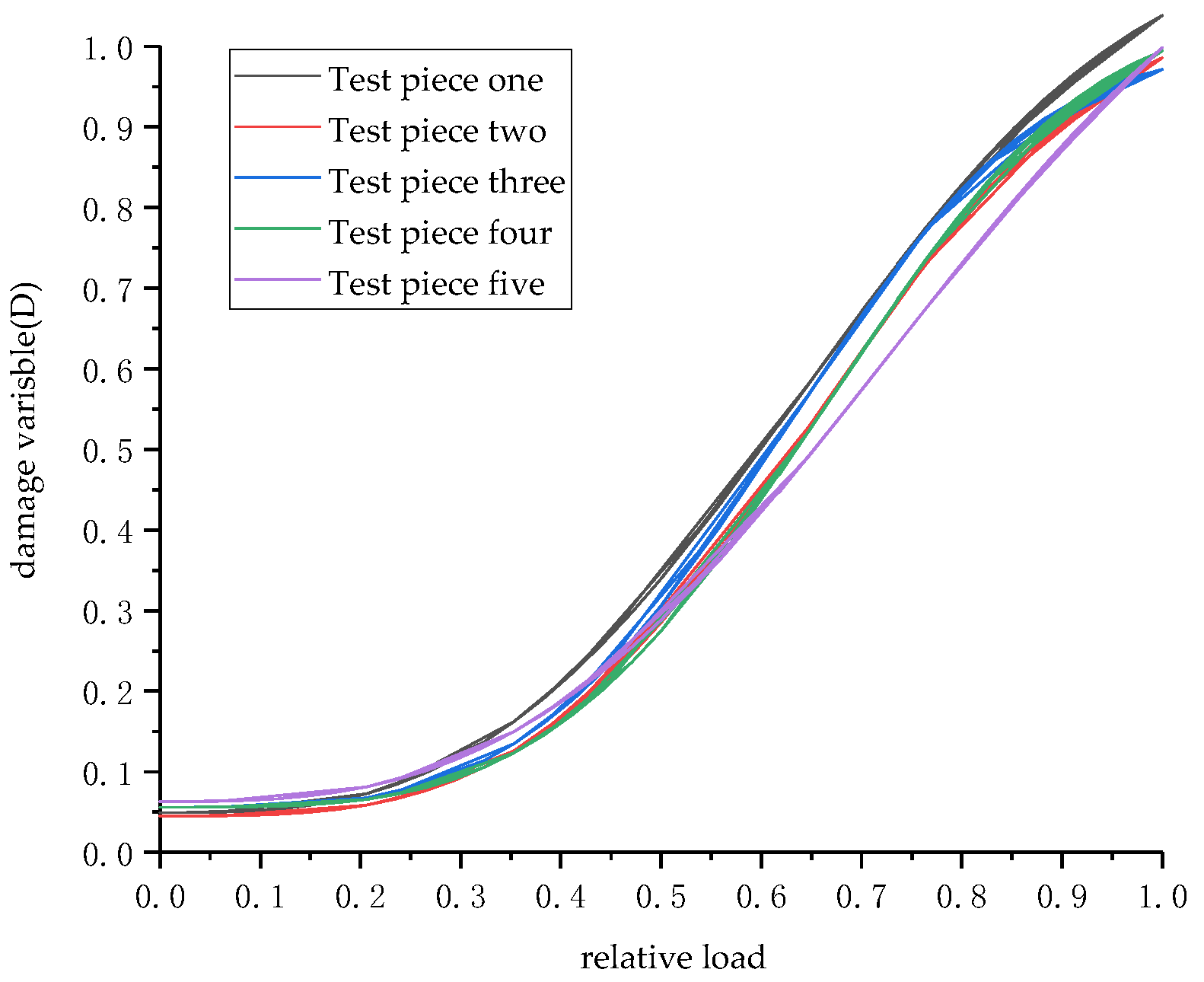

5.1. Damage Model Based on Acoustic Emission

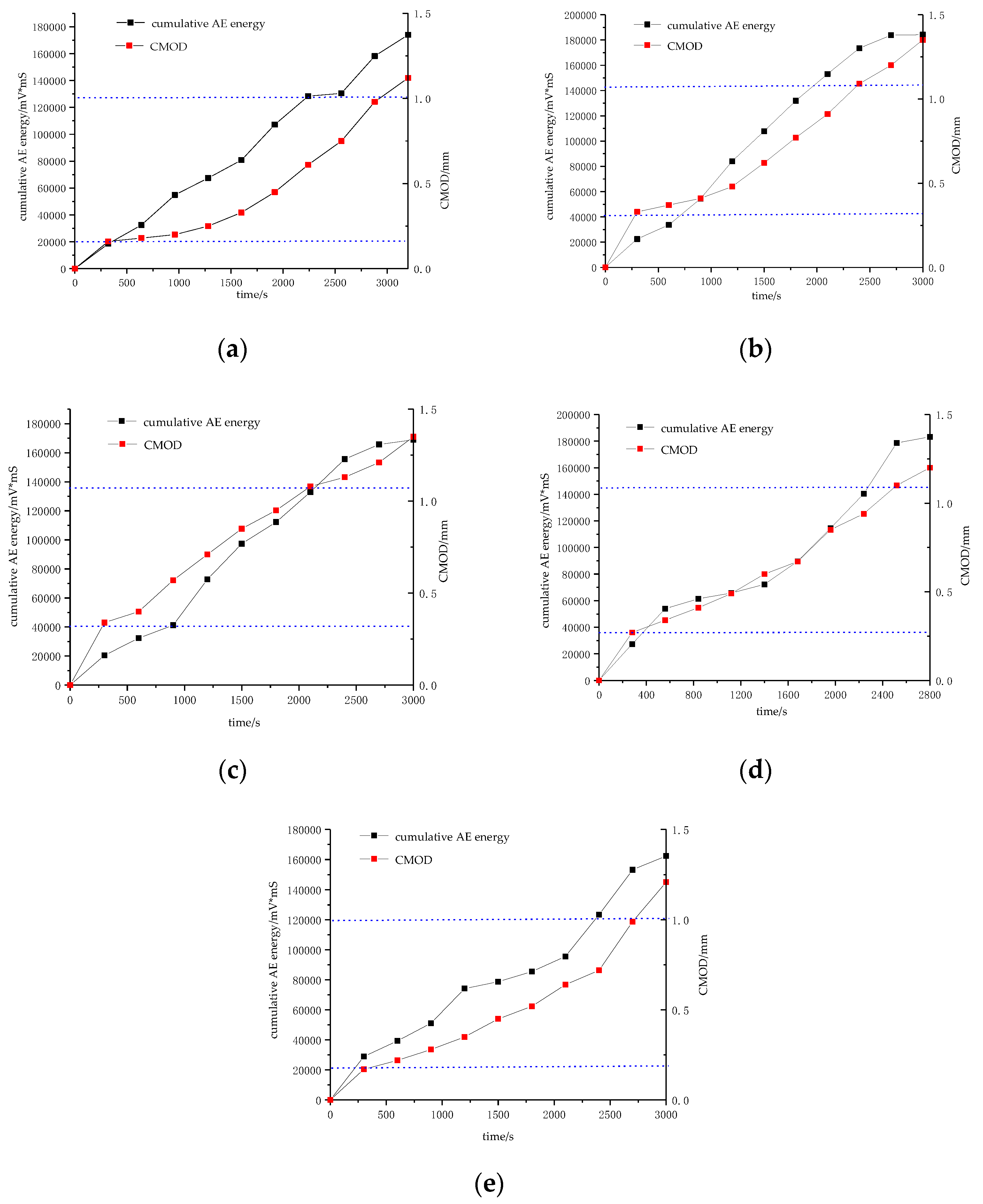

5.2. Correlation between CMOD and Damage Variables

6. Conclusions

- (1)

- Acoustic emission identification results can effectively locate the location of structural damage, and through numerical analysis of data points, the numerical boundary of each stage of fracture damage is defined. The damage is mainly concentrated in the range of 0.1b on both sides of the crack. The yield strengthening stage is an important stage of fracture damage evolution, in which the damage data points account for 76.83% of all the damage data points. The data point exit rate is 0.225 s, and the data point density in the damaged area is 3.219 × 10−4/mm3.

- (2)

- A crack damage evolution model, based on acoustic emission cumulative energy, was established. This can accurately calculate the damage variable of segment cracking failure and evaluate the evolution law of segment cracking damage.

- (3)

- It is proved that the variation trend of CMOD is basically consistent with the variation trend of acoustic emission cumulative energy, and the quantitative relationship between CMOD and segment crack damage degree is established. It provides a feasible method to evaluate segment damage degree based on segment surface disease characteristics.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- He, C.; Feng, K.; Fang, Y. The present situation and prospect of shield tunneling technology. J. Southwest Jiaotong Univ. 2015, 50, 97–109. [Google Scholar]

- Xie, H.P. Damage Mechanics of Rock and Concrete; China University of Mining and Technology Press: Xuzhou, China, 1990; pp. 3–4. [Google Scholar]

- Könke, C. Damage evolution in ductile materials: From micro-to macro-damage. Comput. Mech. 1995, 15, 497–510. [Google Scholar] [CrossRef]

- Tejchman, J.; Bobiński, J. Continuous and Discontinuous Modelling of Fracture in Concrete Using FEM; Springer Publishing Company: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Mandelbrot, B.B.; Passoja, D.E.; Paullay, A.J. Fractal character of fracture surfaces of metals. Nature 1984, 308, 721–722. [Google Scholar] [CrossRef]

- Carpinteri, A.; Spagnoli, A.; Vantadori, S. A multifractal analysis of fatigue crack growth and its application to concrete. Eng. Fract. Mech. 2010, 77, 974–984. [Google Scholar] [CrossRef]

- Lacidogna, G.; Piana, G.; Accornero, F.; Carpinteri, A. Experimental investigation on crack growth in pre-notched concrete beams. Multidiscip. Digit. Publ. Inst. Proc. 2018, 2, 429. [Google Scholar]

- Qin, Z.P.; Tian, Y.; Li, G.; Ma, Y.W.; Liu, L. Fractal Characteristic Study of Bending Behavior of Reinforced Concrete Beams Reinforced with BFRP Cloth. J. Appl. Basic Eng. Sci. 2018, 26, 973–985. [Google Scholar]

- Jiang, S.; Xu, G.; Zhao, T.Y. Fractal characteristics of cracks in the evolution of resistance properties of freeze-thaw damaged concrete beams. Water Resour. Power 2018, 36, 124–127. [Google Scholar]

- Xu, S.L.; Zhang, X.F.; Pu, D. Analysis of the relationship between crack tip opening displacement (CTOD) and crack mouth opening displacement (CMOD) during concrete crack propagation. Eng. Mech. 2011, 28, 64–70. [Google Scholar]

- Yi, Y.Y.; Hu, S.W.; Wang, Y.H. Influence of dead weight on fracture behavior of concrete three-point bending beams. Eng. Mech. 2019, 36, 48–56. [Google Scholar]

- Han, X.Y.; Gao, H.B.; Wu, Z.M.; Ma, P. Experimental study on time-varying fracture of concrete under long-term constant load. J. Hydraul. Eng. 2020, 51, 223–231. [Google Scholar]

- Yu, Q.C.; Chen, H.N.; Wang, D.Q.; Tang, Y.X. Analysis of concrete fracture energy and size effect based on P-CMOD curve. Concrete 2020, 6, 47–52. [Google Scholar]

- Huang, M.; Jiang, L.; Liaw, P.K.; Brooks, C.R.; Seeley, R.; Klarstrom, D.L. Using acoustic emission in fatigue and fracture materials research. JOM 1998, 50, 1–14. [Google Scholar]

- Li, J.W.; Xu, F.; Wang, B.; Gao, Y. Influence of concrete aggregate size on acoustic emission detection. J. Shandong Univ. 2021, 51, 7. [Google Scholar]

- Guo, Q.H.; Yu, B.P.; Li, Z.W.; Zheng, X.S.; Tian, J.B.; Zhu, H.H. Experimental study on correlation between frequency characteristics and strength parameters of concrete acoustic emission signal. J. Cent. South Univ. 2015, 46, 1482–1488. [Google Scholar]

- Duan, L.Q.; Dong, L.; Ma, L.J.; Dai, X.Q.; Wang, B.; Yang, X.P. Experimental study on acoustic emission characteristics of foamed concrete under uniaxial compression. J. China Univ. Min. Technol. 2018, 47, 742–747. [Google Scholar]

- Wang, S.M.; Yu, Q.Y.; Peng, B.; Shen, X.Z. Model experimental study on the effect of cavitation on the stress and failure of shield tunnel. J. Geotech. Eng. 2017, 39, 10. [Google Scholar]

- He, C.; Liu, C.K.; Wang, S.M.; Zhang, Y.B.; Lu, D.Y.; Ma, G.Y. Effect of number of cracks on mechanical properties of shield tunnel segments. China J. Highw. Transp. 2018, 31, 214–223. [Google Scholar]

- Wang, S.M.; Yu, Q.Y.; Peng, B.; Xu, G.W. Analysis of influence of position of cap block on structural mechanical characteristics and failure modes of shield tunnel segment. J. Civ. Eng. 2016, 6, 123–132. [Google Scholar]

- Cao, S.Y.; Wang, S.M.; Liu, C.K.; He, C.; Lu, D.Y.; Ma, G.Y. Influence of fracture location on segment failure mode of shield tunnel. J. Southeast Univ. 2020, 50, 120–128. [Google Scholar]

- China Academy of Building Research. Code for Design of Mix Proportion of Ordinary Concrete; China Construction Industry Press: Beijing, China, 2004. [Google Scholar]

- China Academy of Building Research. Standard for Test Methods for Concrete Structures; GB/T 50152-2012; China Construction Industry Press: Beijing, China, 2012. [Google Scholar]

- Ohtsu, M.; Isoda, T.; Tomoda, Y. Acoustic emission techniques standardized for concrete structure. J. Acoust. Emiss. 2007, 25, 22–32. [Google Scholar]

| Classification | Standard Compressive Strength (fcu, k/MPa) | Elastic Modulus (E/GPa) | Rebar Yield Strength (δs/MPa) | Tensile Strength (σb/MPa) |

|---|---|---|---|---|

| archetype | 50 | 34.5 | 335 | 300 |

| model | 4.6 | 2.63 | 34.12 | 23.9 |

| Segment Fracture Stage | Number of Identification Points (PCS) | Identification Point Out Point Speed (units/s) | Identification Point Unit Volume Density (PCS/mm3) | ||

|---|---|---|---|---|---|

| Acoustic emission test results | Concrete fracture stage in tension zone | elastic stage | 27 | 0.054 | 1.023 × 10−4 |

| Tensile concrete fracture | 101 | 1.010 | 3.826 × 10−4 | ||

| Reinforcement yield strengthening stage | rebar yield | 115 | 0.230 | 1.742 × 10−4 | |

| Tensile limit of reinforcement | 310 | 0.221 | 4.697 × 10−4 | ||

| Reinforcement fracture structure failure stage | Before the rebar breaks | 36 | 0.052 | 1.364 × 10−4 | |

| Structural instability due to reinforcement fracture | 93 | 0.620 | 3.523 × 10−4 | ||

| Specimen | a | b | d | k | R2 |

|---|---|---|---|---|---|

| one | 195,765.61 | 8583.83 | 3.03 | 1.36 | 0.99306 |

| two | 201,933.46 | 8776.07 | 3.41 | 1.37 | 0.99583 |

| three | 187,273.45 | 10,586.52 | 3.63 | 1.45 | 0.98603 |

| four | 200,377.23 | 8724.88 | 3.64 | 1.37 | 0.99261 |

| five | 209,565.19 | 10,855.97 | 2.92 | 1.19 | 0.98741 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Xu, F.; Wang, T.; Shi, S. Research on the Evolution of Shield Segment Cracks Based on Acoustic Emission and CMOD. Materials 2022, 15, 5829. https://doi.org/10.3390/ma15175829

Li J, Xu F, Wang T, Shi S. Research on the Evolution of Shield Segment Cracks Based on Acoustic Emission and CMOD. Materials. 2022; 15(17):5829. https://doi.org/10.3390/ma15175829

Chicago/Turabian StyleLi, Junwei, Fei Xu, Tianmu Wang, and Songtao Shi. 2022. "Research on the Evolution of Shield Segment Cracks Based on Acoustic Emission and CMOD" Materials 15, no. 17: 5829. https://doi.org/10.3390/ma15175829

APA StyleLi, J., Xu, F., Wang, T., & Shi, S. (2022). Research on the Evolution of Shield Segment Cracks Based on Acoustic Emission and CMOD. Materials, 15(17), 5829. https://doi.org/10.3390/ma15175829