Analysis of Stress-Strain State for a Cylindrical Tank Wall Defected Zone

Abstract

1. Introduction

2. Materials and Methods

3. Theory and Calculation of Research

3.1. Experimental Studies of the Stress-Strain State of the Dent Zone in the Tank Wall

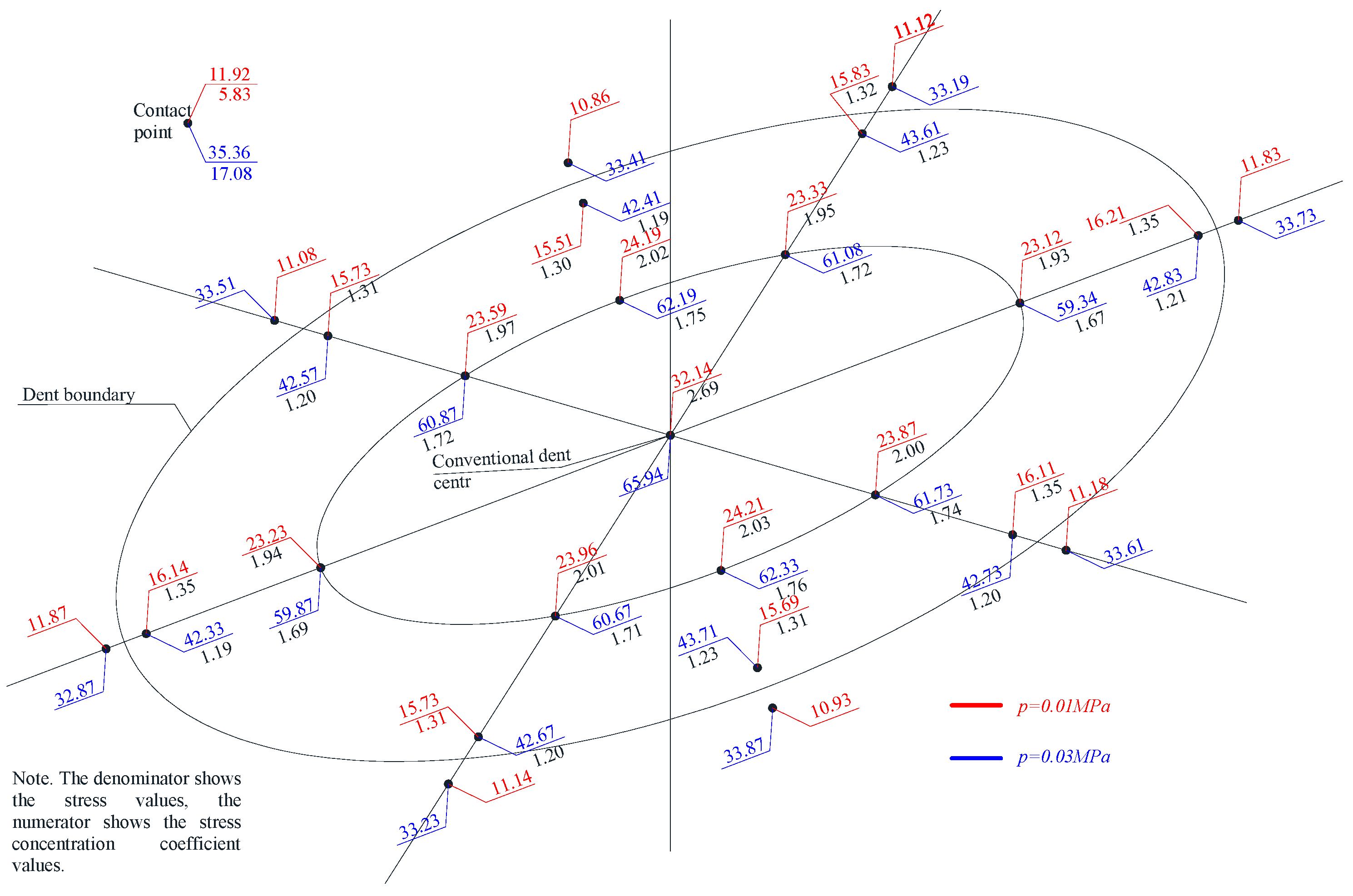

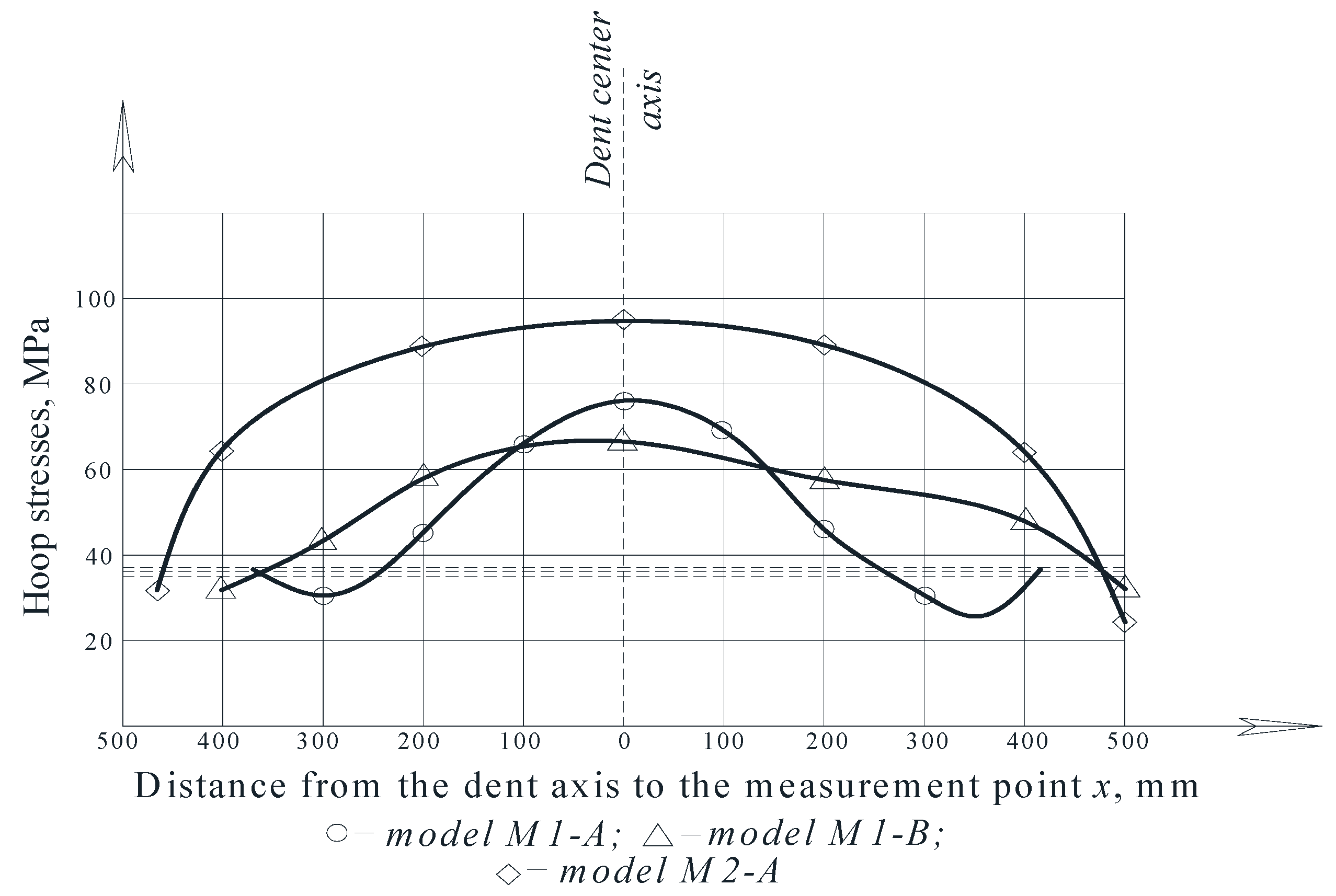

3.1.1. The Nature of the Stress-Strain State of Various Shapes’ Dent Zones

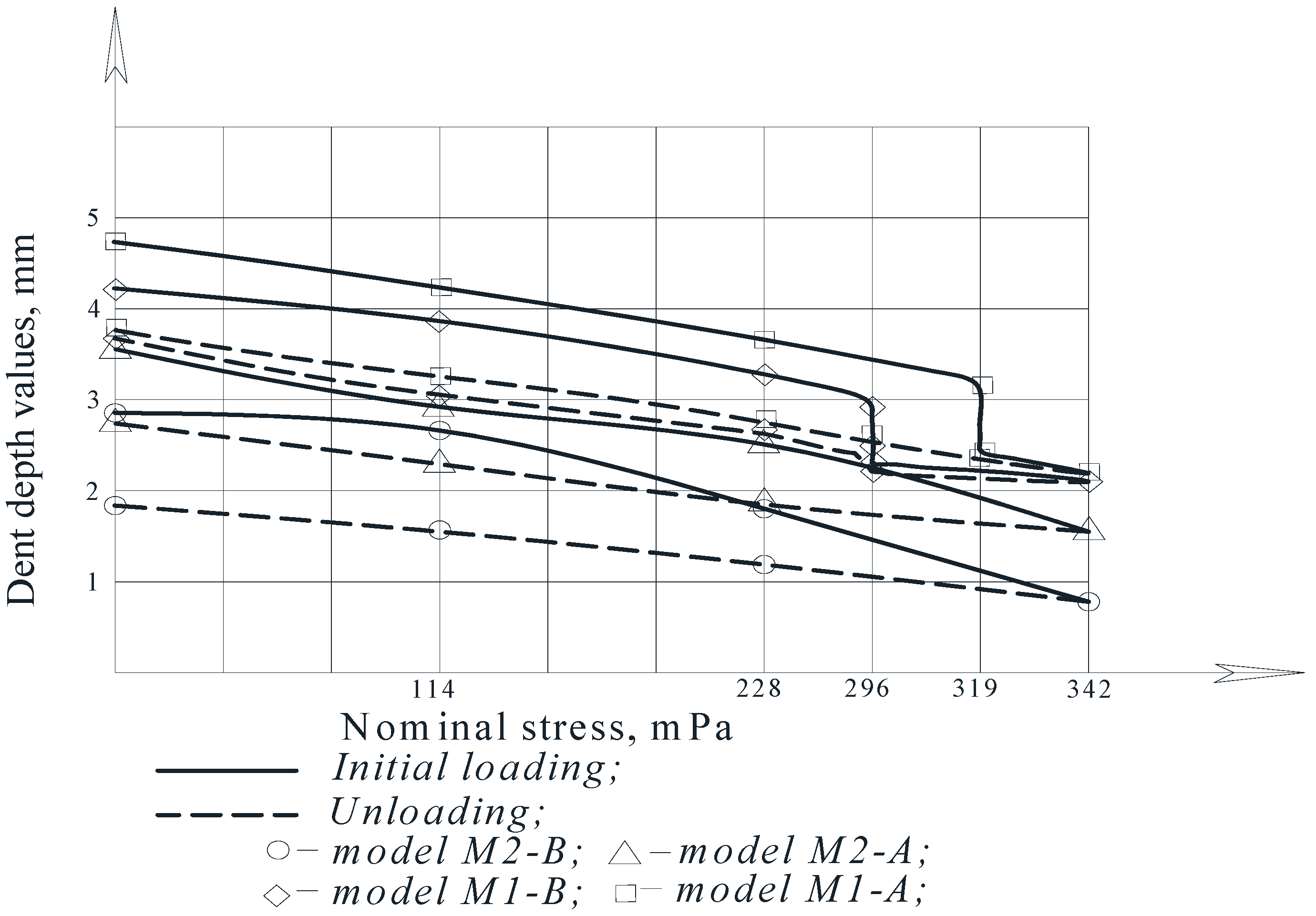

3.1.2. The Nature of the Movements of the Dent Zone in the Model When Loaded with Internal Pressure

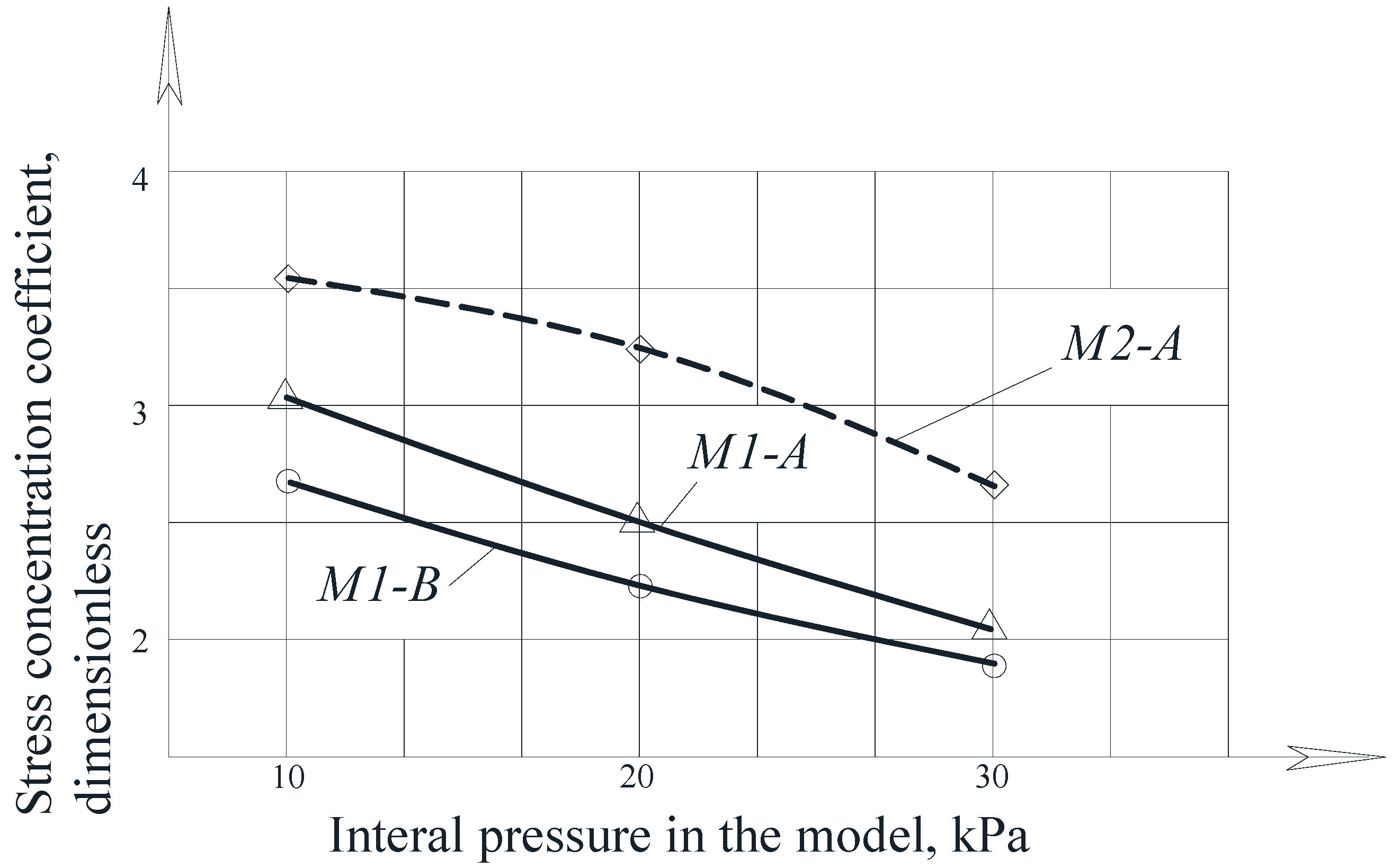

3.1.3. Assessment of the Stress Concentration in the Dent Zone of the Model

3.2. Theoretical Study of Stress Concentration in the Dent Zones in the Tank Wall

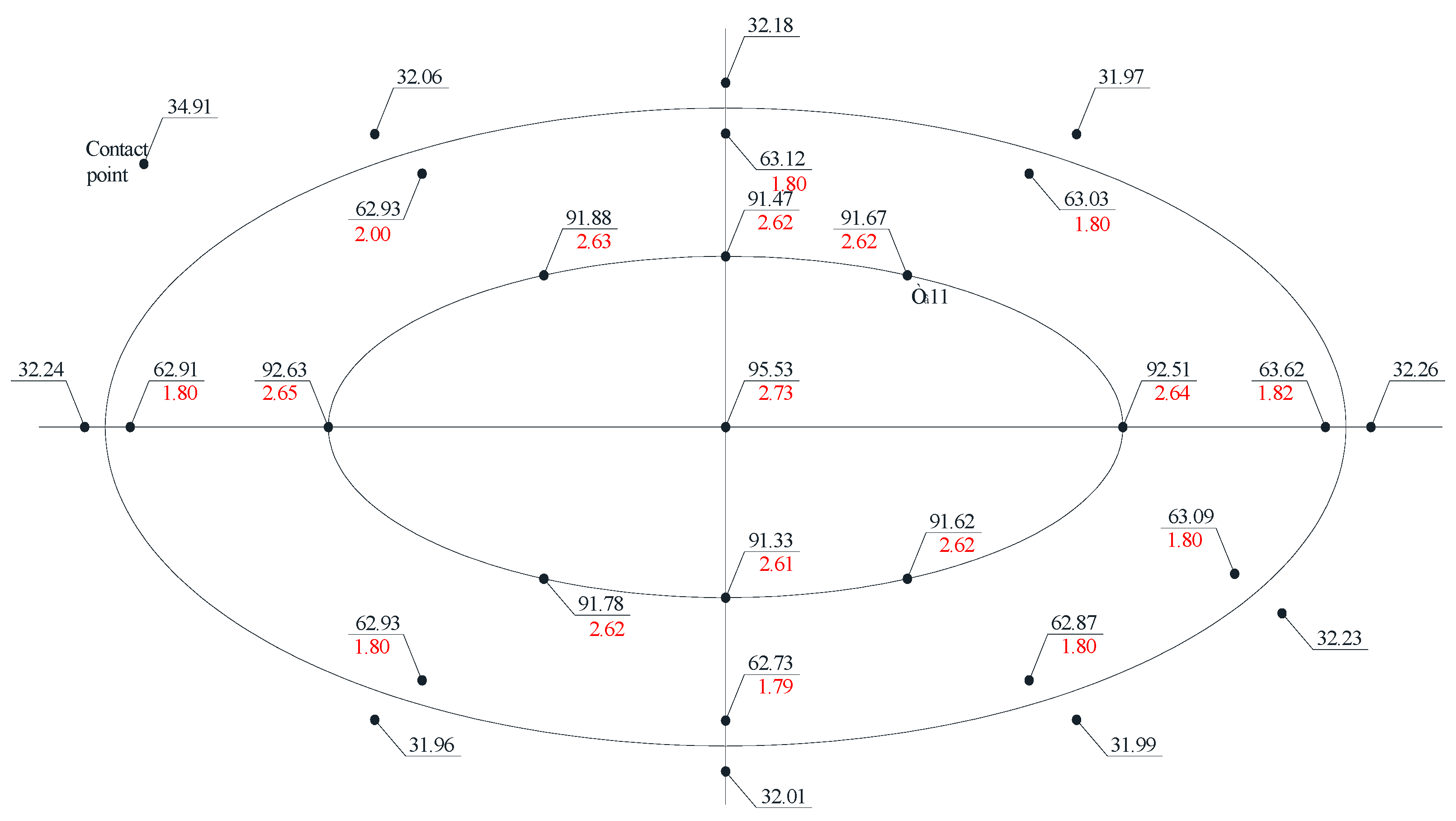

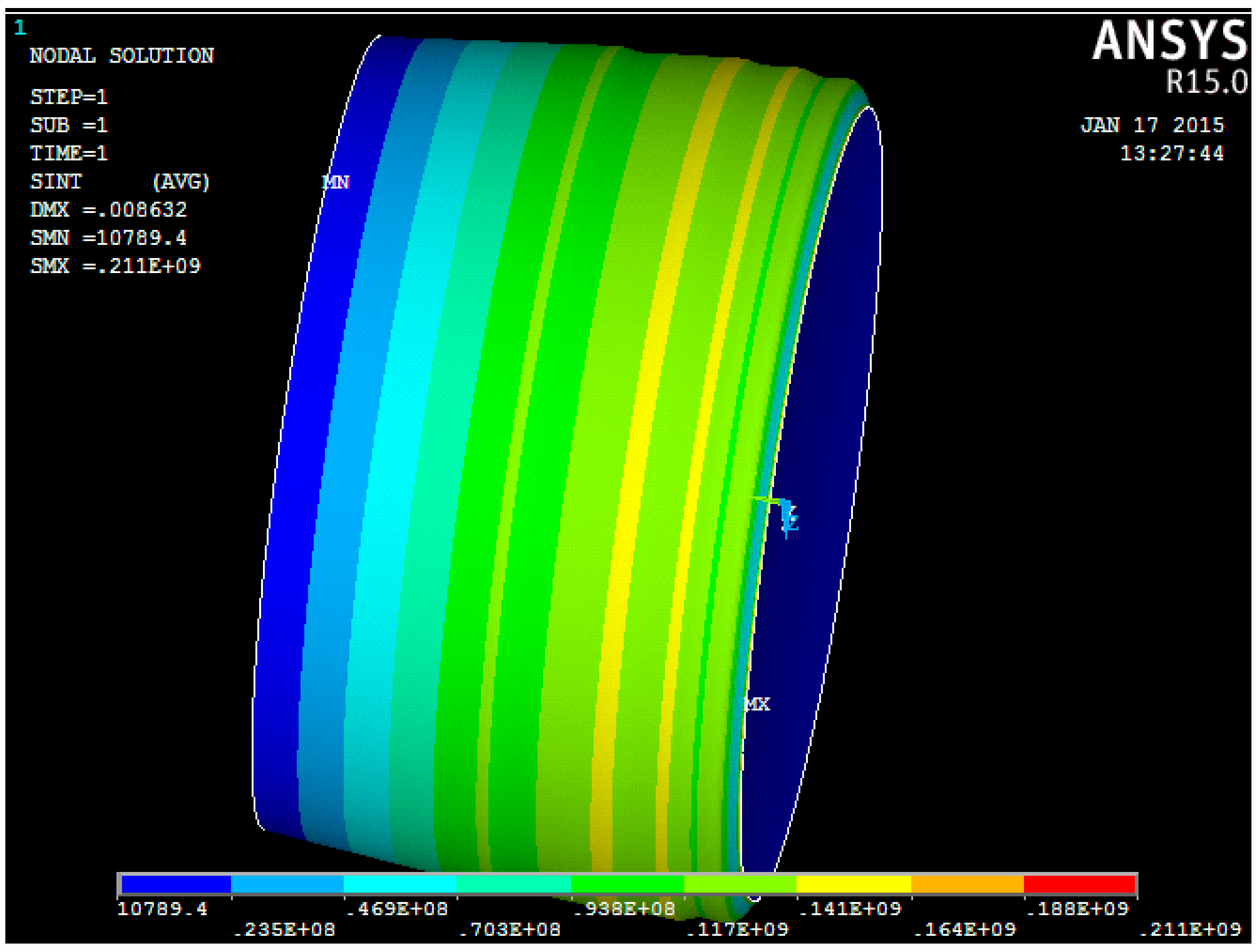

3.2.1. The Order and Verification of the Numerical Simulation Results of the Stress-Strain State of Tanks with Dents in the Wall

3.2.2. Stress-Strain State of the Cylindrical Tank Wall with a Dent

3.2.3. Numerical Studies of Stress Concentration in the Dent Zone in the Tank Wall

3.2.4. Determination of Stress Concentration Coefficients in the Dent Zone

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rakhmatulina, G. Market of Petroleum Products in Kazakhstan within the Framework of the Customs Union: Prospects for Development. Bull. Inst. Econ. Russ. Acad. Sci. 2012, 2, 143–154. Available online: https://cyberleninka.ru/article/n/rynok-nefteproduktov-kazahstana-v-ramkah-tamozhennogo-soyuza-perspektivy-razvitiya. (accessed on 25 July 2022).

- Li, Z.; Song, B.; Li, D. Safety Risk Recognition Method Based on Abnormal Scenarios. Buildings 2022, 12, 562. [Google Scholar] [CrossRef]

- Thongchom, C.; Jearsiripongkul, T.; Refahati, N.; Roudgar Saffari, P.; Roodgar Saffari, P.; Sirimontree, S.; Keawsawasvong, S. Sound. Sound Transmission Loss of a Honeycomb Sandwich Cylindrical Shell with Functionally Graded Porous Layers. Buildings 2022, 12, 151. [Google Scholar] [CrossRef]

- Kou, S.; Zhang, X.; Li, W.; Song, C. Dynamic Response Parameter Analysis of Steel Frame Joints under Blast Loading. Buildings 2022, 12, 433. [Google Scholar] [CrossRef]

- Wang, J.; Kusunoki, K. Study on the Flexural Strength of Interior Thick Wall-Thick Slab Joints Subjected to Lateral Force Using Finite-Element Analysis. Buildings 2022, 12, 535. [Google Scholar] [CrossRef]

- Duissenbekov, B.; Tokmuratov, A.; Zhangabay, N.; Yerimbetov, B.; Aldiyarov, Z. Finite-difference equations of quasi-static motion of the shallow concrete shells in nonlinear setting. Curved Layer. Struct. 2020, 7, 48–55. [Google Scholar] [CrossRef]

- Borodin, K.; Zhangabay, N. Mechanical characteristics, as well as physical-and-chemical properties of the slag-filled concretes, and investigation of the predictive power of the metaheuristic approach. Curved Layer. Struct. 2019, 6, 236–244. [Google Scholar] [CrossRef]

- Shvyrkov, A.; Goryachev, A.; Sorokoumov, P. Statistics of Quasi-Instantaneous Destruction of Oil and Oil Products Storage Tanks. Fire Saf. Build. Struc. Obj. 2007, 6, 48–52. [Google Scholar]

- Utelbaeva, A.B.; Ermakhanov, M.N.; Zhanabai, N.Z.; Utelbaev, B.T.; Mel’deshov, A.A. Hydrogenation of benzene in the presence of ruthenium on a modified montmorillonite support. Russ. J. Phys. Chem. A 2013, 87, 1478–1481. [Google Scholar] [CrossRef]

- Tursunkululy, T.; Zhangabay, N.; Avramov, K.; Chernobryvko, M.; Suleimenov, U.; Utelbayeva, A.; Duissenbekov, B.; Aikozov, Y.; Dauitbek, B.; Abdimanat, Z. Strength analysis of prestressed vertical cylindrical steel oil tanks under operational and dynamic loads. East. Eur. J. Enterp. Technol. 2022, 7, 14–21. [Google Scholar] [CrossRef]

- Suleimenov, U.; Zhangabay, N.; Abshenov, K.; Utelbayeva, A.; Imanaliyev, K.; Mussayeva, S.; Moldagaliyev, A.; Yermakhanov, M.; Raikhanova, G. Estimating the stressed-strained state of the vertical mounting joint of the cylindrical tank wall taking into consideration imperfections. East. Eur. J. Enterp. Technol. 2022, 3, 14–21. [Google Scholar] [CrossRef]

- Lai, E.; Zhao, J.; Li, X.; Hu, K.; Chen, G. Dynamic responses and damage of storage tanks under the coupling effect of blast wave and fragment impact. J. Loss Prev. Process Ind. 2021, 73, 104617. [Google Scholar] [CrossRef]

- Kudabayev, R.; Suleimenov, U.; Ristavletov, R.; Kasimov, I.; Kambarov, M.; Zhangabay, N.; Abshenov, K. Modeling the Thermal Regime of a Room in a Building with a Thermal Energy Storage Envelope. Math. Model. Eng. Probl. 2022, 9, 351–358. [Google Scholar] [CrossRef]

- Zhangabay, N.; Abshenov, K.; Bakhbergen, S.; Zhakash, A.; Moldagaliyev, A. Evaluating the Effectiveness of Energy-Saving Retrofit Strategies for Residential Buildings. Int. Rev. Civ. Eng. 2022, 13, 118–126. [Google Scholar] [CrossRef]

- Zhang, M.; Zheng, F.; Chen, F.; Pan, W.; Mo, S. Propagation probability of domino effect based on analysis of accident chain in storage tank area. J. Loss Prev. Process Ind. 2019, 62, 103962. [Google Scholar] [CrossRef]

- Krentowski, J.; Ziminski, K. Consequences of an incorrect assessment of a structure damaged by explosion. Eng. Fail. Anal. 2019, 101, 135–144. [Google Scholar] [CrossRef]

- Korucuk, F.M.A.; Maali, M.; Kılıç, M.; Aydın, A.C. Experimental analysis of the effect of dent variation on the buckling capacity of thin-walled cylindrical shells. Thin Walled Struct. 2019, 143, 106259. [Google Scholar] [CrossRef]

- Coramik, M.; Ege, Y. Discontinuity inspection in pipelines: A comparison review. Measurement 2017, 111, 359–373. [Google Scholar] [CrossRef]

- Bannikov, R.Y.; Smetannikov, O.Y.; Trufanov, N.A. Method for Calculating the Amplitude of Local Conditional Elastic Stresses on the Section of the Tank Wall with a Shape Defect in the Form of Dents. Bull. Samara State Tech. Univ. Ser. Tech. Sci. 2014, 2, 79–86. Available online: http://vestnik-teh.samgtu.ru/sites/vestnik-teh.samgtu.ru/files/auto/42_4_mashinostroenie_2014.pdf (accessed on 30 July 2022).

- Dmitrieva, A.S.; Lyagova, A.A. Problems of Assessing the Technical Condition of Steel Tanks with the Defect “Dent”. In Science and Youth in the XXI Century, Proceedings of the 2nd All-Russian Scientific and Practical Conference; Omsk State Technical University: Omsk, Russia, 2016; pp. 138–142. Available online: https://www.elibrary.ru/item.asp?id=28085497 (accessed on 25 July 2022).

- Maslak, M.; Pazdanowski, M.; Siudut, J.; Tarsa, K. Corrosion Durability Estimation for Steel Shell of a Tank Used to Store Liquid Fuels. Procedia Eng. 2017, 172, 723–730. [Google Scholar] [CrossRef]

- Kolesov, A.I.; Ageeva, M.A. Residual Resource of Steel Tanks for Chemistry and Petrochemistry that have Worked Out Their Standard Operating Life. Bull. MSCU 2011, 1, 388–391. [Google Scholar]

- Suleimenov, U.; Zhangabay, N.; Utelbayeva, A.; Mohamad, N.; Moldagaliyev, A.; Abshenov, K.; Buganova, S.; Daurbekova, S.; Ibragimova, Z.; Dosmakanbetova, A. Determining the features of oscillations in prestressed pipelines. East. Eur. J. Enterp. Technol. 2021, 6, 85–92. [Google Scholar] [CrossRef]

- Zhang, D.; Yang, L.; Tan, Z.; Xing, S.; Bai, S.; Wei, E.; Tang, X.; Jin, Y. Corrosion behavior of X65 steel at different depths of pitting defects under local flow conditions. Exp. Therm. Fluid Sci. 2020, 124, 110333. [Google Scholar] [CrossRef]

- Davlyatov, M.; Mukhamedov, T.; Igamberdiev, B. Study of work of models of steel cylindrical tanks. Probl. Mod. Sci. Educ. 2018, 128, 21–25. [Google Scholar] [CrossRef]

- Epifanova, E. Determination of Deformations of Steel Vertical Cylindrical Tank with Volume v = 10000 m3 for Oil Using Ground-Based Laser Scanning . Tomsk. Polytech. Univ. 2020, pp. 78–86. Available online: https://cyberleninka.ru (accessed on 30 July 2022).

- Kornev, V. Embrittlement of steel structures at low temperatures and catastrophic failure. Phys. Mesomech. 2018, 2, 45–55. [Google Scholar] [CrossRef]

- Song, Z.; Komvopoulos, K. Contact mechanics analysis of oscillatory sliding of a rigid fractal surface against an elastic-plastic half-space. Philos. Mag. 2014, 94, 3215–3233. [Google Scholar] [CrossRef]

- Hagihara, S.; Tsunori, M.; Ikeda, T.; Miyazaki, N. Application of meshfree method to elastic-plastic fracture mechanics parameter analysis. CMES Comput. Modeling Eng. Sci. 2007, 17, 63–72. [Google Scholar] [CrossRef]

- Sun, J. Hard particle force in a soft fracture. Sci. Rep. 2019, 9, 3065. [Google Scholar] [CrossRef]

- Zhang, Y.M.; Tan, T.K.; Xiao, Z.; Zhang, W.G.; Ariffin, M.Z. Failure Assessment on Offshore Girth Welded Pipelines due to Corrosion Defects. Fatigue Fract. Eng. Mater. Struct. 2016, 39, 453–466. [Google Scholar] [CrossRef]

- Dake, Y.; Sridhar, I.; Zhongmin, X.; Kumar, S.B. Fracture capacity of girth welded pipelines with 3D surface cracks subjected to biaxial loading conditions. Int. J. Press. Vessel. Pip. 2012, 92, 115–126. [Google Scholar] [CrossRef]

- Ainabekov, A.I.; Suleymenov, U.S.; Kambarov, M.A.; Abshenov, K. Experimental Estimation of the Stress State of the Cylindrical Tank Wall Dent Zone. Sci. Edu. South Kazakhstan 2012, 2, 93–97. Available online: https://auezov.edu.kz/rus (accessed on 23 July 2022).

- Ainabekov, A.I.; Suleymenov, U.S.; Kambarov, M.A.; Abshenov, K.; Buganova, S. The evalution of deflected mode of wall hollow zone of standpipe. Mod. Appl. Sci. 2015, 9, 184–191. [Google Scholar] [CrossRef]

- GOST 27069-86; Metal Ferroalloys, Chromium and Manganese. Methods for Determining Carbon. Available online: https://docs.cntd.ru/document/1200008986 (accessed on 25 July 2022).

- GOST 1497-84; Metals. Tensile Test Methods. Available online: https://docs.cntd.ru/document/1200004888 (accessed on 26 July 2022).

- Pitlyuk, D.A. Testing Building Structures on Models; Stroyizdat: Moscow, Russia, 1971; p. 160. Available online: https://rusist.info/book/7804742 (accessed on 25 July 2022).

- Rensky, A.B.; Baranov, D.S. Strain Measurement of Building Structures and Materials; Stroyizdat: Moscow, Russia, 1977; p. 239. Available online: https://e-catalog.nlb.by/Record/BY-NLB-rr29377930000 (accessed on 25 July 2022).

- Zetlab Software. User’s Manual. Part 1 ZTMS, 2nd ed.; 00068-01-34; Zetlab Software: Moscow, Russia, 2017; Available online: https://pandia.ru/text/78/378/488.php (accessed on 25 July 2022).

- Prigorovsky, N.N. Methods and Tools for Determining the Fields of Strains and Stresses: Handbook; Mashinostroenie: Moscow, Russia, 1981; p. 248. Available online: https://lib-bkm.ru/12410 (accessed on 25 July 2022).

- GOST R 50779.21-2004; Statistical Methods. Rules for Determining and Methods for Calculating Statistical Characteristics from Sample Data. Part 1. Normal Distribution. Available online: https://docs.cntd.ru/document/1200035333 (accessed on 25 July 2022).

- Suleimenov, U.; Zhangabay, N.; Utelbayeva, A.; Masrah, A.A.M.; Dosmakanbetova, A.; Abshenov, K.; Buganova, S.; Moldagaliyev, A.; Imanaliyev, K.; Duissenbekov, B. Estimation of the strength of vertical cylindrical liquid storage tanks with dents in the wall. East. Eur. J. Enterp. Technol. 2022, 7, 6–20. [Google Scholar] [CrossRef]

- Ivanov, G.P.; Razbitnoy, S. A Method for Estimating Stresses from Dents on the Wall of Vessels Operating under Pressure. Chem. Oil Eng. 2000, 4, 18–19. Available online: https://www.elibrary.ru/item.asp?id=23060999 (accessed on 25 July 2022).

- Orynyak, I.V.; Shlapak, L.S. Estimation of the Ultimate Pressure of a Pipe with a Dent. Probl. Strength 2001, 5, 101–110. Available online: https://www.studmed.ru/problemy-prochnosti-2001-05-353-_9b66952317e.html (accessed on 26 July 2022).

- Perelygin, O.A.; Serazutdinov, M.N.; Zainullin, R.K.; Fokin, D.A. Study of the Stress-Strain State of Cylindrical Shells with Local Shape Imperfections. Bull. Kazan Technol. Univ. 1999, 1, 58–61. Available online: https://cyberleninka.ru/article/n/raschet-napryazhenno-deformirovannogo-sostoyaniya-sotovogo-polikarbonata (accessed on 26 July 2022).

- Fokin, M.F. Evaluation of Operational Durability of Main Oil Pipelines in the Area of Defects; VNIIOENG: Moscow, Russia, 1986; pp. 51–55. Available online: https://rusist.info/book/5912599 (accessed on 25 July 2022).

- Grigolyuk, E.I. Shell Stability; Grigolyuk, E.I., Kabanov, V.V., Eds.; Nauka: Moscow, Russia, 1978; p. 360. Available online: http://www.rk5.1gb.ru/Knigi/Ust/Grigoluk.pdf (accessed on 25 July 2022).

- Panovko, Y.G. Stability and Oscillations of Elastic Systems: Modern Concepts, Paradoxes and Errors; Nauka: Moscow, Russia, 1987; p. 352. Available online: https://eruditor.io/file/656420/ (accessed on 25 July 2022).

- Likhman, V.V.; Kopysitskaya, N.L.; Muratov, M.V. Stress concentration in tanks with local shape imperfections. Chem Oil Eng. 1992, 6, 22–24. [Google Scholar] [CrossRef]

- Boikov, A.; Payor, V.; Savelev, R.; Kolesnikov, A. Synthetic data generation for steel defect detection and classification using deep learning. Symmetry 2021, 13, 1176. [Google Scholar] [CrossRef]

- Volokitina, I.; Siziakova, E.; Fediuk, R.; Kolesnikov, A. Development of a Thermomechanical Treatment Mode for Stainless-Steel Rings. Materials 2022, 15, 4930. [Google Scholar] [CrossRef]

- Kolesnikov, A.; Fediuk, R.; Kolesnikova, O.; Zhanikulov, N.; Zhakipbayev, B.; Kuraev, R.; Akhmetova, E.; Shal, A. Processing of waste from enrichment with the production of cement clinker and the extraction of zinc. Materials 2022, 15, 324. [Google Scholar] [CrossRef]

- Vasilyeva, N.; Fedorova, E.; Kolesnikov, A. Big Data as a Tool for Building a Predictive Model of Mill Roll Wear. Symmetry 2021, 13, 859. [Google Scholar] [CrossRef]

- Kolesnikov, A.; Fediuk, R.; Amran, M.; Klyuev, S.; Klyuev, A.; Volokitina, I.; Naukenova, A.; Shapalov, S.; Utelbayeva, A.; Kolesnikova, O.; et al. Modeling of Non-Ferrous Metallurgy Waste Disposal with the Production of Iron Silicides and Zinc Distillation. Materials 2022, 15, 2542. [Google Scholar] [CrossRef] [PubMed]

- Zhakipbaev, B.Y.; Zhanikulov, N.N.; Kuraev, R.M.; Shal, A.L. Review of technogenic waste and methods of its processing for the purpose of complex utilization of tailings from the enrichment of non-ferrous metal ores as a component of the raw material mixture in the production of cement clinker. Rasayan J. Chem. 2021, 14, 997–1005. [Google Scholar] [CrossRef]

- Vasilyeva, N.V.; Boikov, A.V.; Erokhina, O.O.; Trifonov, A.Y. Automated digitization of radial charts. J. Min. Inst. 2021, 247, 82–87. [Google Scholar] [CrossRef]

- Kolesnikov, A.S.; Sergeeva, I.V.; Botabaev, N.E.; Al’Zhanova, A.Z.; Ashirbaev, K.A. Thermodynamic simulation of chemical and phase transformations in the system of oxidized manganese ore—Carbon. Izv. Ferr. Metall. 2017, 60, 759–765. [Google Scholar] [CrossRef][Green Version]

- Zhanikulov, N.; Kolesnikov, A.; Taimasov, B.; Zhakipbayev, B.; Shal, A. Influence of industrial waste on the structure of environmentally friendly cement clinker. Kompleks. Ispolz. Miner. Syra (Complex Use Miner. Resour.) 2022, 323, 84–91. [Google Scholar] [CrossRef]

- Volokitin, A.; Naizabekov, A.; Volokitina, I.; Kolesnikov, A. Changes in microstructure and properties of austenitic steel aisi 316 during high-pressure torsion. J. Chem.Technol. Metall. 2022, 57, 809–815. [Google Scholar]

- Volokitina, I.; Kolesnikov, A.; Fediuk, R.; Klyuev, S.; Sabitov, L.; Volokitin, A.; Zhuniskaliyev, T.; Kelamanov, B.; Yessengaliev, D.; Yerzhanov, A.; et al. Study of the Properties of Antifriction Rings under Severe Plastic Deformation. Materials 2022, 15, 2584. [Google Scholar] [CrossRef]

- Kolesnikov, A.S.; Zhanikulov, N.N.; Zhakipbayev, B.Y.; Kolesnikova, O.G.; Kuraev, R.M. Thermodynamic modeling of the synthesis of the main minerals of cement clinker from technogenic raw materials. Kompleks. Ispolz. Miner. Syra. (Complex Use Miner. Resour.) 2021, 3, 24–34. [Google Scholar] [CrossRef]

- Volokitina, I.; Vasilyeva, N.; Fediuk, R.; Kolesnikov, A. Hardening of Bimetallic Wires from Secondary Materials Used in the Construction of Power Lines. Materials 2022, 15, 3975. [Google Scholar] [CrossRef]

- Fediuk, R.S.; Smoliakov, A.K.; Timokhin, R.A.; Batarshin, V.O.; Yevdokimova, Y.G. Using Thermal Power Plants Waste for Building Materials. IOP Conf. Ser. Earth Environ. Sci. 2018, 87, 092010. Available online: https://iopscience.iop.org/article/10.1088/1755-1315/87/9/092010 (accessed on 25 July 2022). [CrossRef]

- Kopysitskaya, L.N.; Likhman, V.V.; Muratov, V.M. Engineering Method for Calculating the Stress-Strain State of Welded Cylindrical Tanks with Edge Withdrawal. Chem Oil Eng. 1989, 10, 15–18. Available online: https://www.dissercat.com/content/opredelenie-ostatochnogo-resursa-bezopasnoi-ekspluatatsii-apparatov-khimicheskikh-proizvodst (accessed on 25 July 2022).

- Makul, N.; Fediuk, R.; Amran, M.; Zeyad, A.M.; Murali, G.; Vatin, N.; Klyuev, S.; Ozbakkaloglu, T.; Vasilev, Y. Use of Recycled Concrete Aggregates in Production of Green Cement-Based Concrete Composites: A Review. Crystals 2021, 11, 232. [Google Scholar] [CrossRef]

- Feodosiev, V.I. On the Calculation of a Buckling Membrane. Ap. Math Mech. 1946, 10, 162–175. Available online: https://pmm.ipmnet.ru/ru/Issues.php?y=2016&n=3&p=291 (accessed on 20 July 2022).

- Zhangabay, N.; Sapargaliyeva, B.; Utelbayeva, A.; Kolesnikov, A.; Aldiyarov, Z.; Dossybekov, S.; Esimov, E.; Duissenbekov, B.; Fediuk, R.; Vatin, N.I.; et al. Experimental Analysis of the Stress State of a Prestressed Cylindrical Shell with Various Structural Parameters. Materials 2022, 15, 4996. [Google Scholar] [CrossRef] [PubMed]

- Lezhnev, S.; Panin, E.; Volokitina, I. Research of combined process “Rolling-pressing” influence on the microstructure and mechanical properties of aluminium. Adv. Mat. Res. 2013, 814, 68–75. [Google Scholar] [CrossRef]

- Fediuk, R.; Timokhin, R.; Mochalov, A.; Otsokov, K.; Lashina, I. Performance properties of high-density impermeable cementitious paste. J. Mat. Civ. Eng. 2019, 31, 04019013. [Google Scholar] [CrossRef]

- Lezhnev, S.; Naizabekov, A.; Panin, E.; Volokitina, I. Influence of combined process “rolling-pressing” on microstructure and mechanical properties of copper. Proc. Engin. 2014, 81, 1499–1505. [Google Scholar]

- Abid, S.R.; Murali, G.; Amran, M.; Vatin, N.; Fediuk, R.; Karelina, M. Evaluation of Mode II Fracture Toughness of Hybrid Fibrous Geopolymer Composites. Materials 2021, 14, 349. [Google Scholar] [CrossRef]

- Kasiman, E.H.; Kueh, A.B.H.; Mohd Yassin, A.Y.; Amin, N.S.; Amran, M.; Fediuk, R.; Kotov, E.V.; Murali, G. Mixed Finite Element Formulation for Navier–Stokes Equations for Magnetic Effects on Biomagnetic Fluid in a Rectangular Channel. Materials 2022, 15, 2865. [Google Scholar] [CrossRef]

- Loganina, V.; Fediuk, R.; Taranov, D.; Amran, Y.H. Estimation of the probability of cracking of facade coatings. In Materials Science Forum; Trans Tech Publications Ltd.: Frienbach, Switzerland, 2021; Volume 1037, pp. 675–683. [Google Scholar]

- Yip, C.C.; Wong, J.Y.; Amran, M.; Fediuk, R.; Vatin, N.I. Reliability Analysis of Reinforced Concrete Structure with Shock Absorber Damper under Pseudo-Dynamic Loads. Materials 2022, 15, 2688. [Google Scholar] [CrossRef] [PubMed]

- Abdullah, M.A.H.; Rashid, R.S.M.; Amran, M.; Hejazii, F.; Azreen, N.M.; Fediuk, R.; Voo, Y.L.; Vatin, N.I.; Idris, M.I. Recent Trends in Advanced Radiation Shielding Concrete for Construction of Facilities: Materials and Properties. Polymers 2022, 14, 2830. [Google Scholar] [CrossRef] [PubMed]

| Model | Model Surface | Dent Shape | Dent Radius, mm | Dent Depth, mm | ||

|---|---|---|---|---|---|---|

| Small | Large | Initial | Steady-State | |||

| M 1 | A | spherical | 252 | - | 4.32 | 3.68 |

| B | elliptical | 185 | 820 | 3.53 | 2.71 | |

| M 2 | A | elliptical | 175 | 830 | 4.86 | 3.73 |

| B | elliptical | 190 | 640 | 2.84 | 1.84 | |

| Design Point Coordinate x, m | Equivalent Stresses, σi, Pa | Hoop Stresses, σθ, Pa |

|---|---|---|

| 1.0728 | 0.14251 × 109 | 0.118 × 108 |

| 1.2516 | 0.13859 × 109 | 0.118 × 108 |

| 2.2052 | 0.15865 × 109 | 0.158 × 108 |

| 2.5032 | 0.15800 × 109 | 0.158 × 108 |

| 3.2184 | 0.19150 × 109 | 0.19 × 108 |

| 3.4568 | 0.19107 × 109 | 0.19 × 108 |

| 3.8144 | 0.19007 × 109 | 0.19 × 108 |

| 4.4104 | 0.18994 × 109 | 0.19 × 108 |

| 4.7680 | 0.18997 × 109 | 0.19 × 108 |

| 5.1256 | 0.19005 × 109 | 0.19 × 108 |

| 5.3640 | 0.18952 × 109 | 0.19 × 108 |

| 6.1984 | 0.24439 × 109 | 0.238 × 108 |

| 6.4368 | 0.23993 × 109 | 0.238 × 108 |

| 6.6752 | 0.23778 × 109 | 0.238 × 108 |

| 8.8208 | 0.23745 × 109 | 0.238 × 108 |

| 10.728 | 0.23745 × 109 | 0.238 × 108 |

| Design Point Coordinate x, m | Equivalent Stresses, σi, Pa | Hoop Stresses, σθ, Pa |

|---|---|---|

| 1.3112 | 0.12294 × 109 | 1.11113 × 108 |

| 1.7880 | 0.14321 × 109 | 1.41493 × 108 |

| 2.5032 | 0.13125 × 109 | 1.31505 × 108 |

| 3.2184 | 0.14962 × 109 | 1.45821 × 108 |

| 4.0528 | 0.13178 × 109 | 1.31838 × 108 |

| 5.1256 | 0.11389 × 109 | 1.13860 × 108 |

| 6.1984 | 0.12359 × 109 | 1.19853 × 108 |

| 7.1520 | 0.99855 × 108 | 9.98776 × 107 |

| 8.3440 | 0.74893 × 108 | 7.49082 × 107 |

| 8.8208 | 0.64907 × 108 | 6.49204 × 107 |

| 9.5360 | 0.49928 × 108 | 4.99388 × 107 |

| Design Point Coordinate x, m | Hoop Stresses, σθ, Pa, According to ANSYS | Hoop Stresses, σθ, Pa, According to [42] |

|---|---|---|

| 4.6098 | 0.116 × 109 | 0.122 × 109 |

| 5.2721 | 0.166 × 109 | 0.114 × 109 |

| 5.1933 | 0.138 × 109 | 0.112 × 109 |

| 5.6411 | 0.121 × 109 | 0.105 × 109 |

| 7.1527 | 0.9825 × 108 | 0.9986 × 108 |

| 8.5363 | 0.697 × 108 | 0.709 × 108 |

| Dimensionless Radius of the Dent ξ | Dimensionless Depth of the Dent ς | The Dent Radius rb, m | The Dent Depth f, m | The Stress Concentration Coefficient, Kσ |

|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 |

| 2 | 4 | 0.3899 | 0.016 | 4.937 |

| 2 | 7 | 0.3899 | 0.028 | 5.3121 |

| 2 | 10 | 0.3899 | 0.04 | 5.406 |

| 2 | 13 | 0.3899 | 0.052 | 5.371 |

| 2 | 15 | 0.3899 | 0.06 | 5.4891 |

| 2 | 18 | 0.3899 | 0.072 | 5.3855 |

| 3 | 4 | 0.585 | 0.016 | 5.672 |

| 3 | 7 | 0.585 | 0.028 | 6.383 |

| 3 | 10 | 0.585 | 0.04 | 6.7322 |

| 3 | 13 | 0.585 | 0.052 | 6.852 |

| 3 | 15 | 0.585 | 0.06 | 6.978 |

| 3 | 18 | 0.585 | 0.072 | 6.906 |

| 4 | 4 | 0.7797 | 0.016 | 6.135 |

| 4 | 7 | 0.7797 | 0.028 | 7.391 |

| 4 | 10 | 0.7797 | 0.04 | 7.405 |

| 4 | 13 | 0.7797 | 0.052 | 7.944 |

| 4 | 15 | 0.7797 | 0.06 | 7.561 |

| 4 | 18 | 0.7797 | 0.072 | 7.714 |

| 5 | 4 | 0.97 | 0.016 | 6.29 |

| 5 | 7 | 0.97 | 0.028 | 8.136 |

| 5 | 10 | 0.97 | 0.04 | 10.02 |

| 5 | 13 | 0.97 | 0.052 | 8.34 |

| 5 | 15 | 0.97 | 0.06 | 8.757 |

| 5 | 18 | 0.97 | 0.072 | 9.0 |

| 6 | 4 | 1.17 | 0.016 | 6.7493 |

| 6 | 7 | 1.17 | 0.028 | 8.4853 |

| 6 | 10 | 1.17 | 0.04 | 10.54 |

| 6 | 13 | 1.17 | 0.052 | 9.204 |

| 6 | 15 | 1.17 | 0.06 | 9.4476 |

| 6 | 18 | 1.17 | 0.072 | 9.598 |

| 7 | 4 | 1.365 | 0.016 | 8.288 |

| 7 | 7 | 1.365 | 0.028 | 8.4469 |

| 7 | 10 | 1.365 | 0.04 | 11.12 |

| 7 | 13 | 1.365 | 0.052 | 10.02 |

| 7 | 15 | 1.365 | 0.06 | 10.09 |

| 7 | 18 | 1.365 | 0.072 | 10.622 |

| 8 | 4 | 1.5595 | 0.016 | 9.6269 |

| 8 | 7 | 1.5595 | 0.028 | 8.4231 |

| 8 | 10 | 1.5595 | 0.04 | 9.849 |

| 8 | 13 | 1.5595 | 0.052 | 10.451 |

| 8 | 15 | 1.5595 | 0.06 | 10.74 |

| 8 | 18 | 1.5595 | 0.072 | 11.013 |

| 9 | 4 | 1.7544 | 0.016 | 10.75 |

| 9 | 7 | 1.7544 | 0.028 | 8.567 |

| 9 | 10 | 1.7544 | 0.04 | 10.30 |

| 9 | 13 | 1.7544 | 0.052 | 11.52 |

| 9 | 15 | 1.7544 | 0.06 | 11.34 |

| 9 | 18 | 1.7544 | 0.072 | 11.799 |

| Dimensionless Radius of the Dent, ξ | Dimensionless Depth of the Dent, ς | The Dent Radius, rb, m | The Dent Depth, f, m | Stress Concentration Coefficient by Numerical Calculation, Kσ | Stress Concentration Coefficient Calculated by the Formula [42], Kσ |

|---|---|---|---|---|---|

| 2 | 4 | 0.3899 | 0.016 | 4.937 | 4.9341 |

| 2 | 7 | 0.3899 | 0.028 | 5.3121 | 5.3268 |

| 2 | 10 | 0.3899 | 0.04 | 5.406 | 5.3736 |

| 2 | 13 | 0.3899 | 0.052 | 5.371 | 5.4142 |

| 2 | 15 | 0.3899 | 0.06 | 5.4891 | 5.4625 |

| 2 | 18 | 0.3899 | 0.072 | 5.3855 | 5.3892 |

| 3 | 4 | 0.585 | 0.016 | 5.672 | 5.6699 |

| 3 | 7 | 0.585 | 0.028 | 6.383 | 6.3939 |

| 3 | 10 | 0.585 | 0.04 | 6.7322 | 6.7083 |

| 3 | 13 | 0.585 | 0.052 | 6.852 | 6.8840 |

| 3 | 15 | 0.585 | 0.06 | 6.978 | 6.9584 |

| 3 | 18 | 0.585 | 0.072 | 6.906 | 6.9088 |

| 4 | 4 | 0.7797 | 0.016 | 6.135 | 6.1521 |

| 4 | 7 | 0.7797 | 0.028 | 7.391 | 7.3004 |

| 4 | 10 | 0.7797 | 0.04 | 7.405 | 7.6036 |

| 4 | 13 | 0.7797 | 0.052 | 7.944 | 7.6784 |

| 4 | 15 | 0.7797 | 0.06 | 7.561 | 7.7231 |

| 4 | 18 | 0.7797 | 0.072 | 7.714 | 7.6898 |

| 5 | 4 | 0.97 | 0.016 | 6.29 | 6.2459 |

| 5 | 7 | 0.97 | 0.028 | 8.136 | 8.3655 |

| 5 | 10 | 0.97 | 0.04 | 10.02 | 9.5133 |

| 5 | 13 | 0.97 | 0.052 | 8.34 | 9.0134 |

| 5 | 15 | 0.97 | 0.06 | 8.757 | 8.3414 |

| 5 | 18 | 0.97 | 0.072 | 9.0 | 9.0566 |

| 6 | 4 | 1.17 | 0.016 | 6.7493 | 6.7114 |

| 6 | 7 | 1.17 | 0.028 | 8.4853 | 8.6836 |

| 6 | 10 | 1.17 | 0.04 | 10.54 | 10.104 |

| 6 | 13 | 1.17 | 0.052 | 9.204 | 9.7865 |

| 6 | 15 | 1.17 | 0.06 | 9.4476 | 9.0918 |

| 6 | 18 | 1.17 | 0.072 | 9.598 | 9.6508 |

| 7 | 4 | 1.365 | 0.016 | 8.288 | 8.2487 |

| 7 | 7 | 1.365 | 0.028 | 8.4469 | 8.6508 |

| 7 | 10 | 1.365 | 0.04 | 11.12 | 10.669 |

| 7 | 13 | 1.365 | 0.052 | 10.02 | 10.618 |

| 7 | 15 | 1.365 | 0.06 | 10.09 | 9.7212 |

| 7 | 18 | 1.365 | 0.072 | 10.622 | 10.672 |

| 8 | 4 | 1.5595 | 0.016 | 9.6269 | 9.6158 |

| 8 | 7 | 1.5595 | 0.028 | 8.4231 | 8.4732 |

| 8 | 10 | 1.5595 | 0.04 | 9.849 | 9.7329 |

| 8 | 13 | 1.5595 | 0.052 | 10.451 | 10.600 |

| 8 | 15 | 1.5595 | 0.06 | 10.74 | 10.643 |

| 8 | 18 | 1.5595 | 0.072 | 11.013 | 11.022 |

| 9 | 4 | 1.7544 | 0.016 | 10.75 | 10.750 |

| 9 | 7 | 1.7544 | 0.028 | 8.567 | 8.5492 |

| 9 | 10 | 1.7544 | 0.04 | 10.30 | 10.332 |

| 9 | 13 | 1.7544 | 0.052 | 11.52 | 11.475 |

| 9 | 15 | 1.7544 | 0.06 | 11.34 | 11.369 |

| 9 | 18 | 1.7544 | 0.072 | 11.799 | 11.799 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhangabay, N.; Sapargaliyeva, B.; Suleimenov, U.; Abshenov, K.; Utelbayeva, A.; Kolesnikov, A.; Baibolov, K.; Fediuk, R.; Arinova, D.; Duissenbekov, B.; et al. Analysis of Stress-Strain State for a Cylindrical Tank Wall Defected Zone. Materials 2022, 15, 5732. https://doi.org/10.3390/ma15165732

Zhangabay N, Sapargaliyeva B, Suleimenov U, Abshenov K, Utelbayeva A, Kolesnikov A, Baibolov K, Fediuk R, Arinova D, Duissenbekov B, et al. Analysis of Stress-Strain State for a Cylindrical Tank Wall Defected Zone. Materials. 2022; 15(16):5732. https://doi.org/10.3390/ma15165732

Chicago/Turabian StyleZhangabay, Nurlan, Bayan Sapargaliyeva, Ulanbator Suleimenov, Khassen Abshenov, Akmaral Utelbayeva, Alexandr Kolesnikov, Kanat Baibolov, Roman Fediuk, Dinara Arinova, Bolat Duissenbekov, and et al. 2022. "Analysis of Stress-Strain State for a Cylindrical Tank Wall Defected Zone" Materials 15, no. 16: 5732. https://doi.org/10.3390/ma15165732

APA StyleZhangabay, N., Sapargaliyeva, B., Suleimenov, U., Abshenov, K., Utelbayeva, A., Kolesnikov, A., Baibolov, K., Fediuk, R., Arinova, D., Duissenbekov, B., Seitkhanov, A., & Amran, M. (2022). Analysis of Stress-Strain State for a Cylindrical Tank Wall Defected Zone. Materials, 15(16), 5732. https://doi.org/10.3390/ma15165732