Assessment of Mechanical Properties for Three-Dimensional Needled Composites: A Geometric Partitioning Strategy Dealing with Mesoscopic Needling Damage

Abstract

:1. Introduction

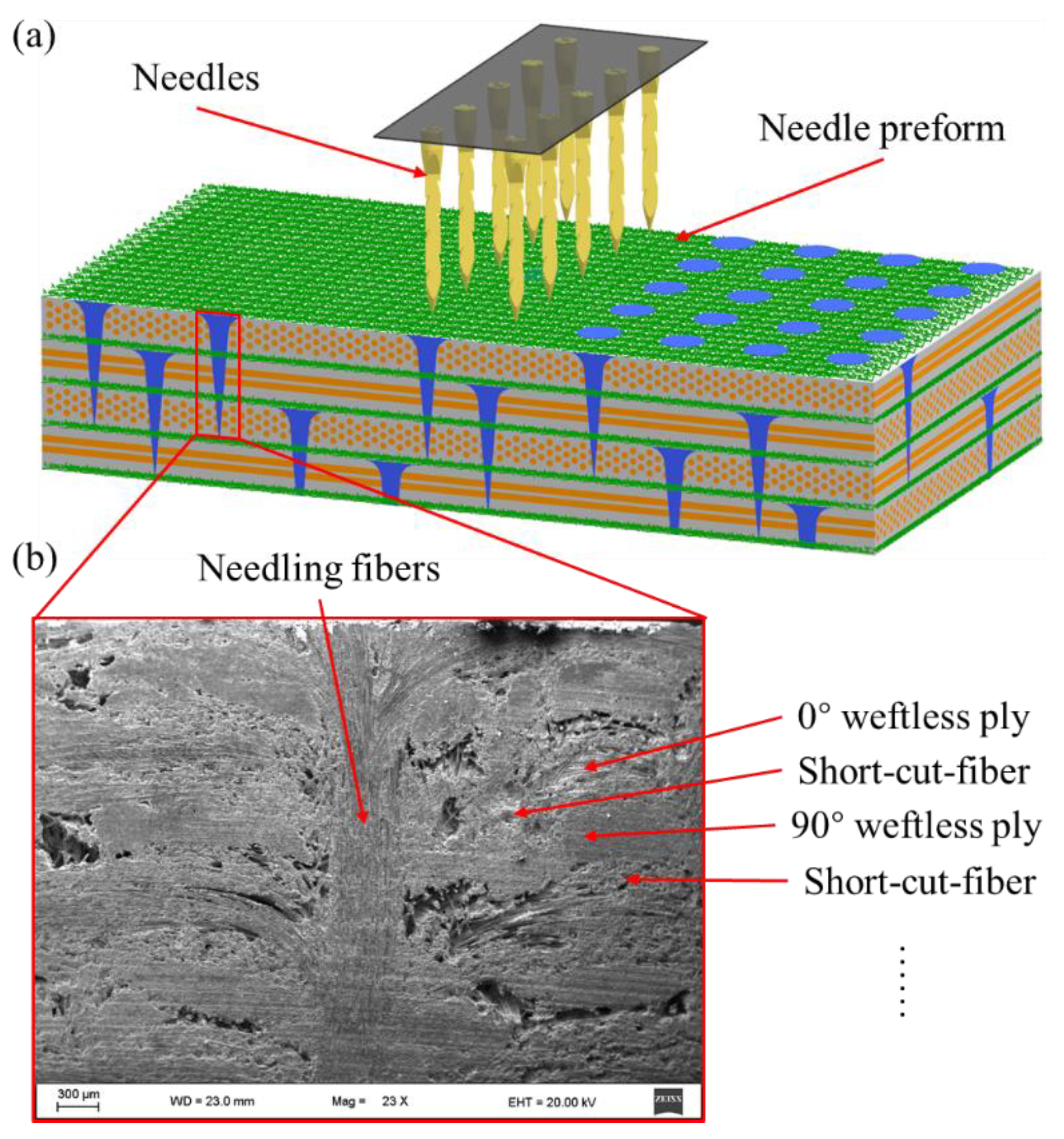

2. Materials

3. Numerical Simulation Theory and Method

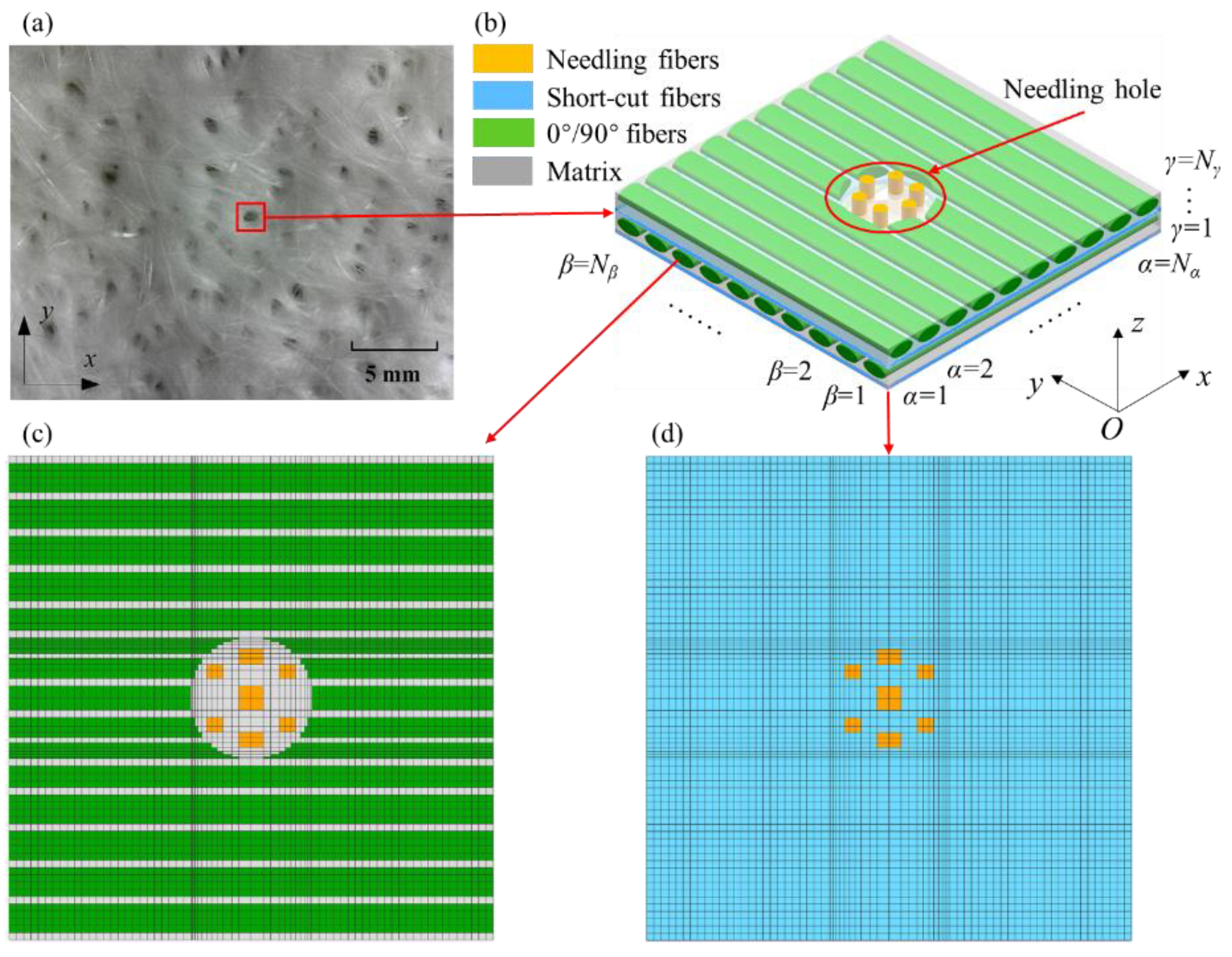

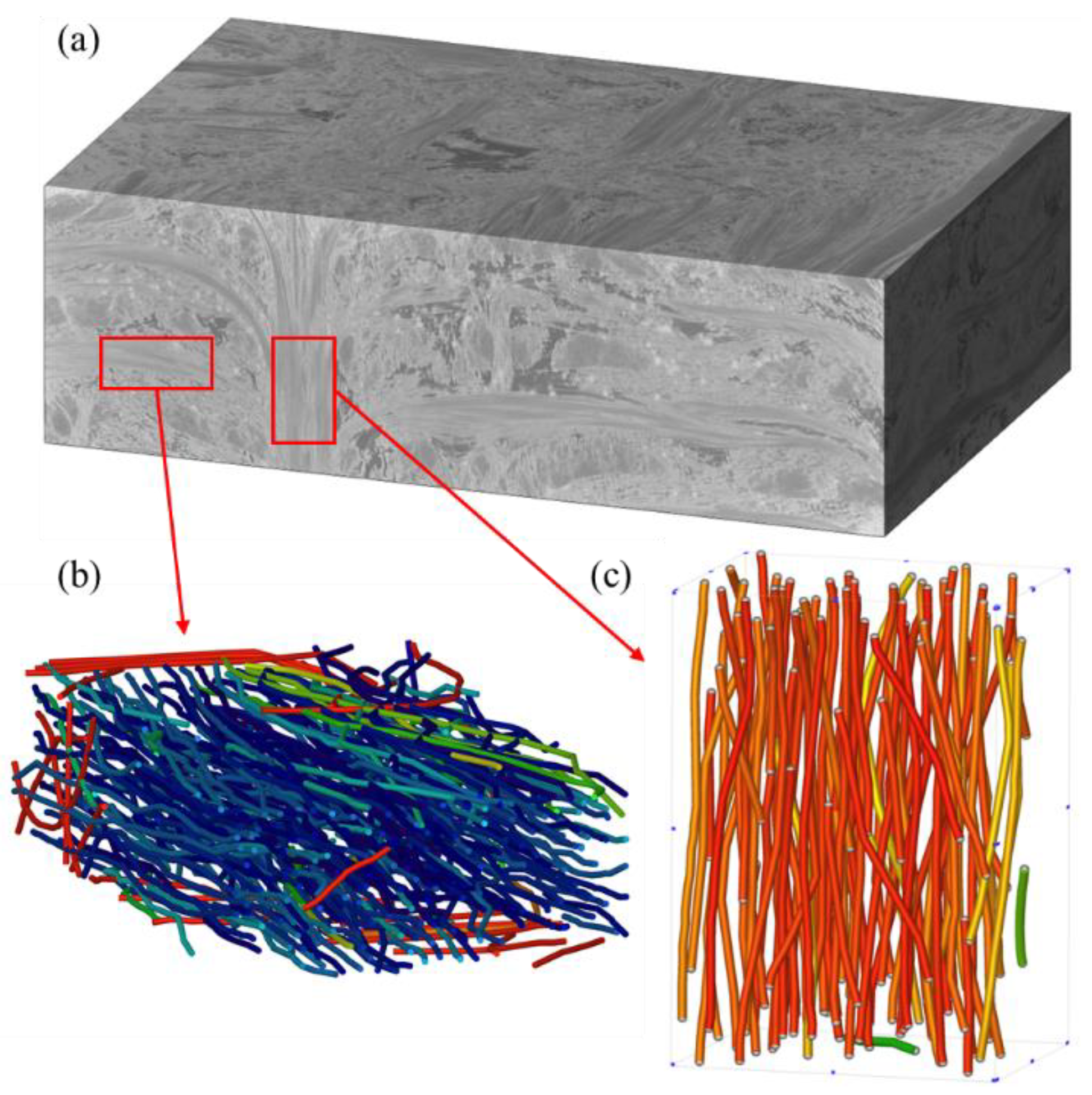

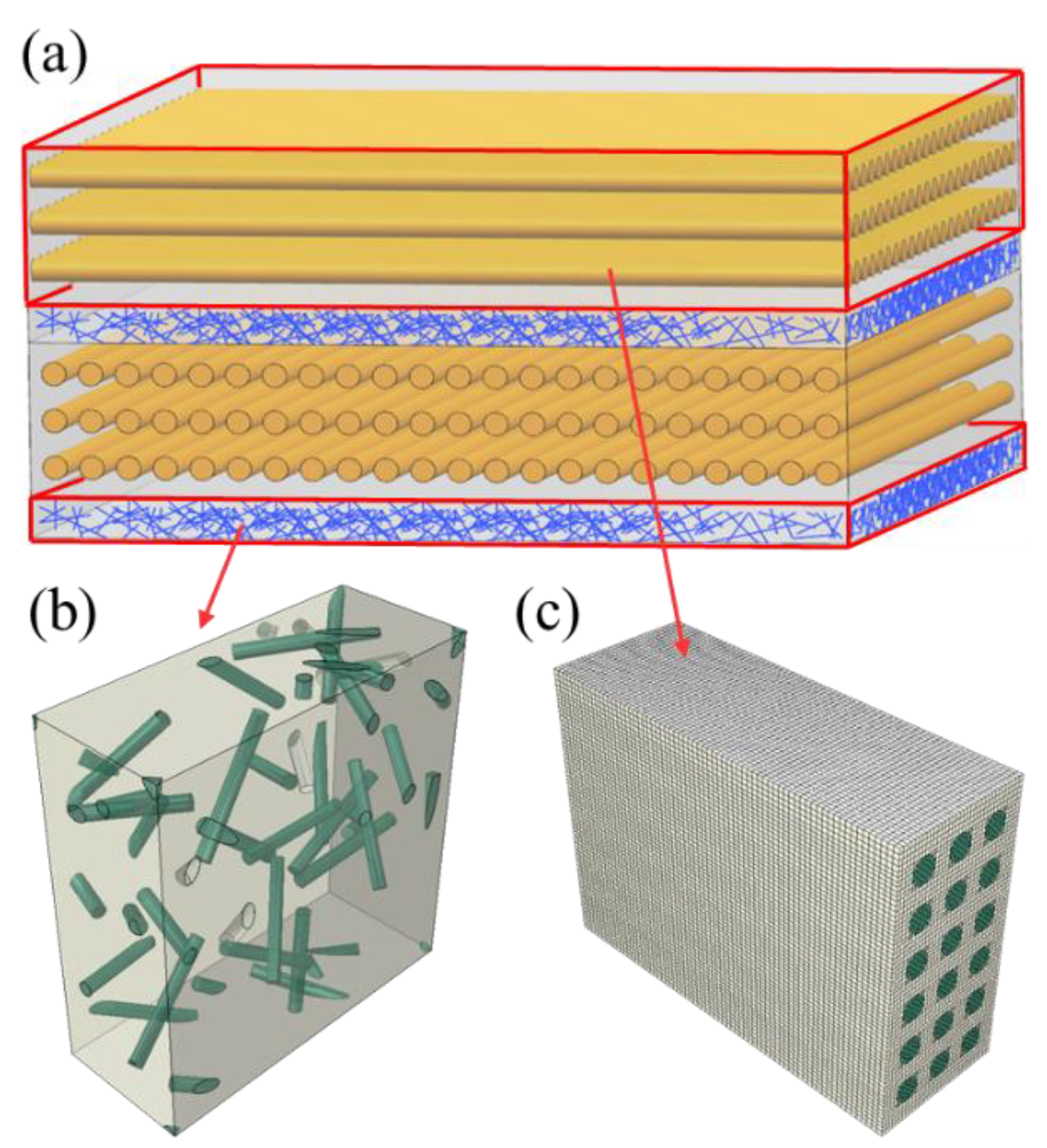

3.1. Mesoscopic Model

3.1.1. Needling Regions Modelling

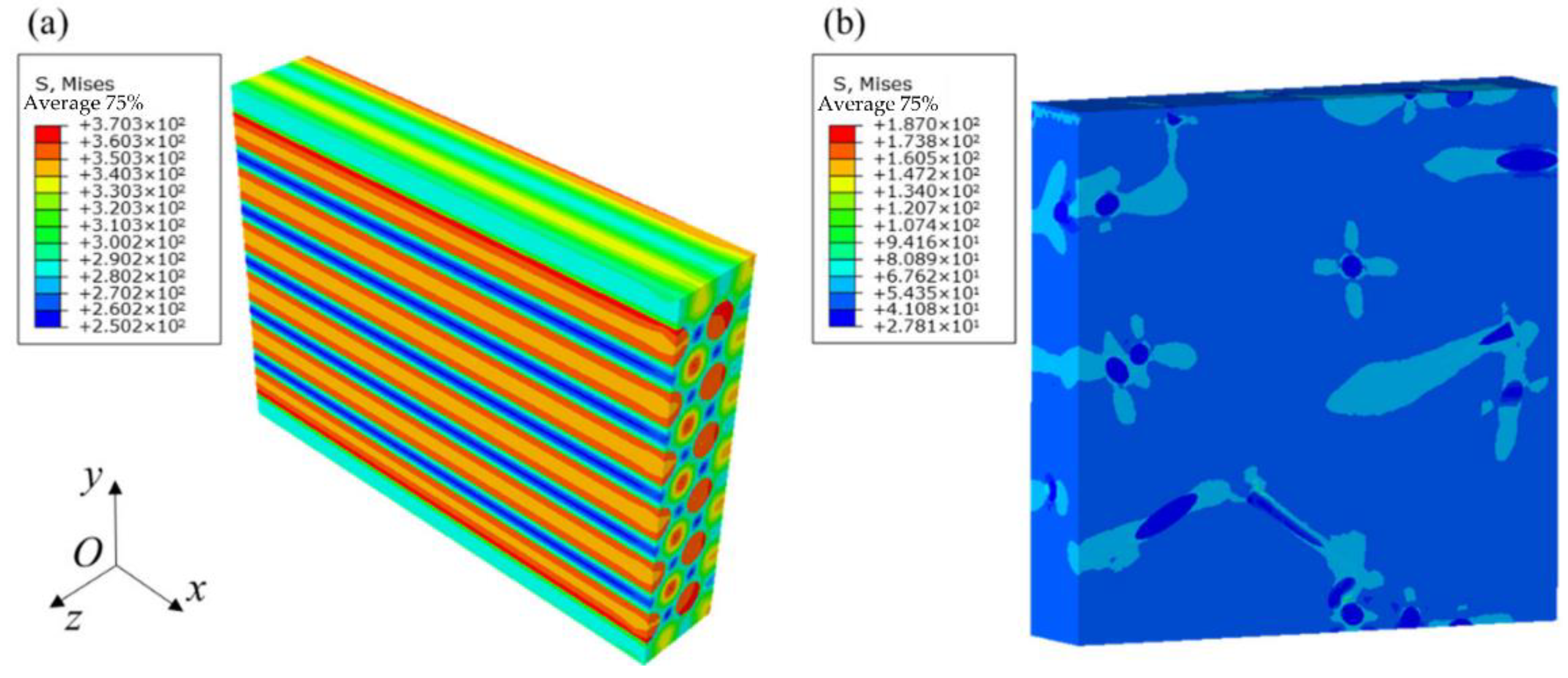

3.1.2. Mesoscopic Damage Characterization

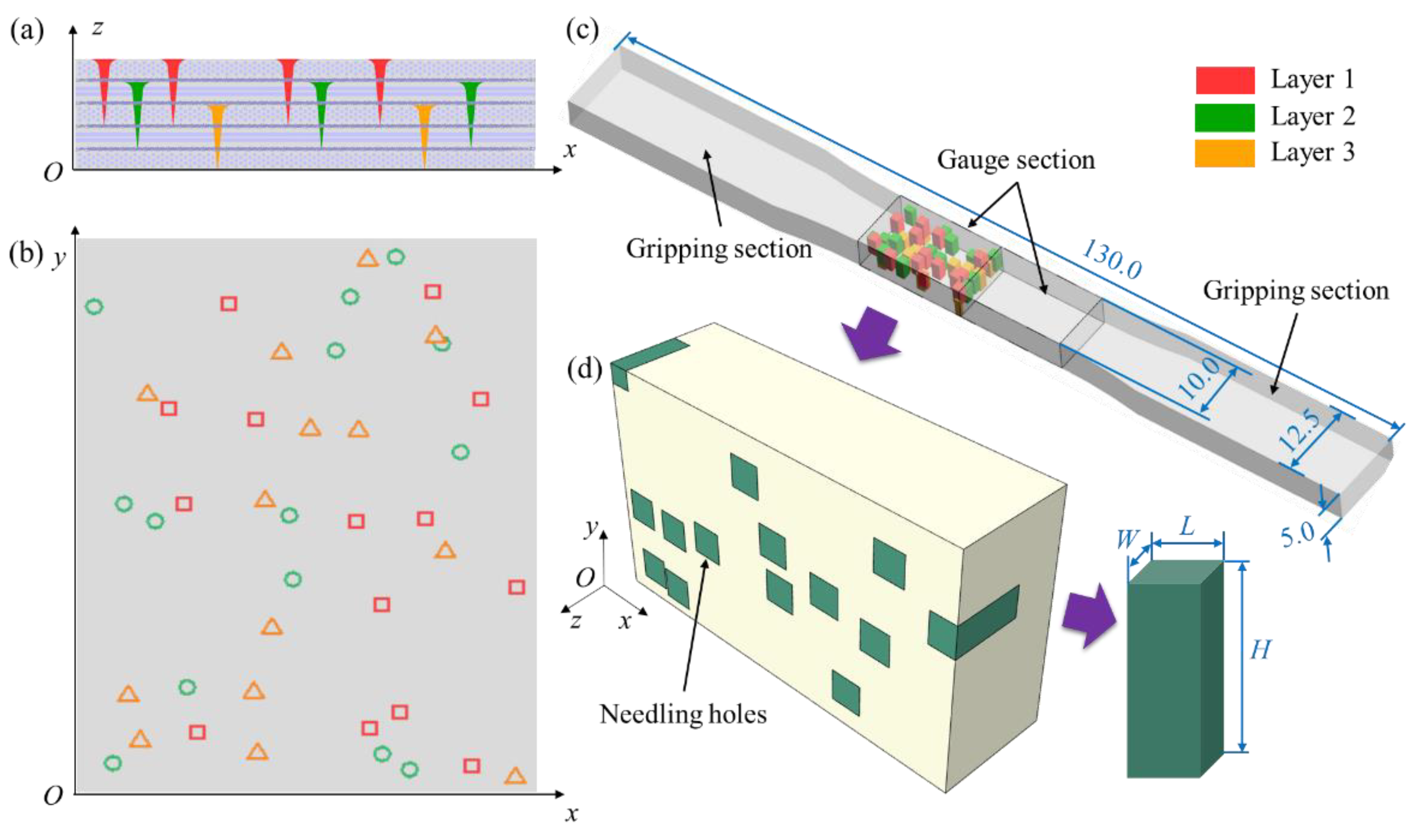

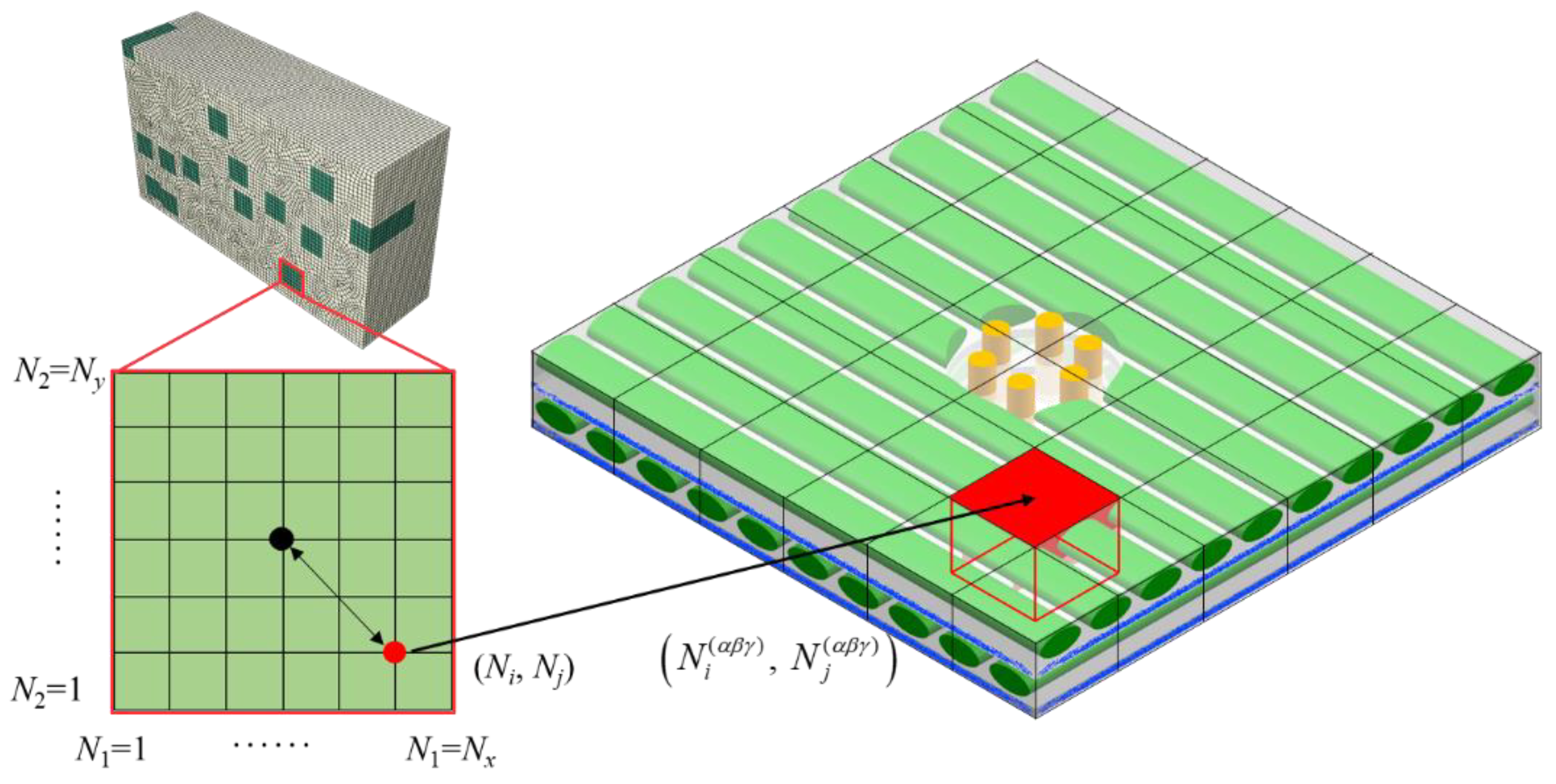

3.2. Macroscopic Model

3.2.1. FE Modelling

3.2.2. CDM Model of Un-Needling Regions

3.3. Multi-Scale Method

- The position sequence number of the integration point (Ni, Nj) is determined by the coordinate relationship with the center point of the needling hole;

- The GMC model is divided into blocks to identify the corresponding local regions (marked as red rectangles in Figure 7) and subcell sequences of macroscopic model integration points;

- The macroscopic field magnitude at (Ni, Nj) is obtained by volume average of the local region.

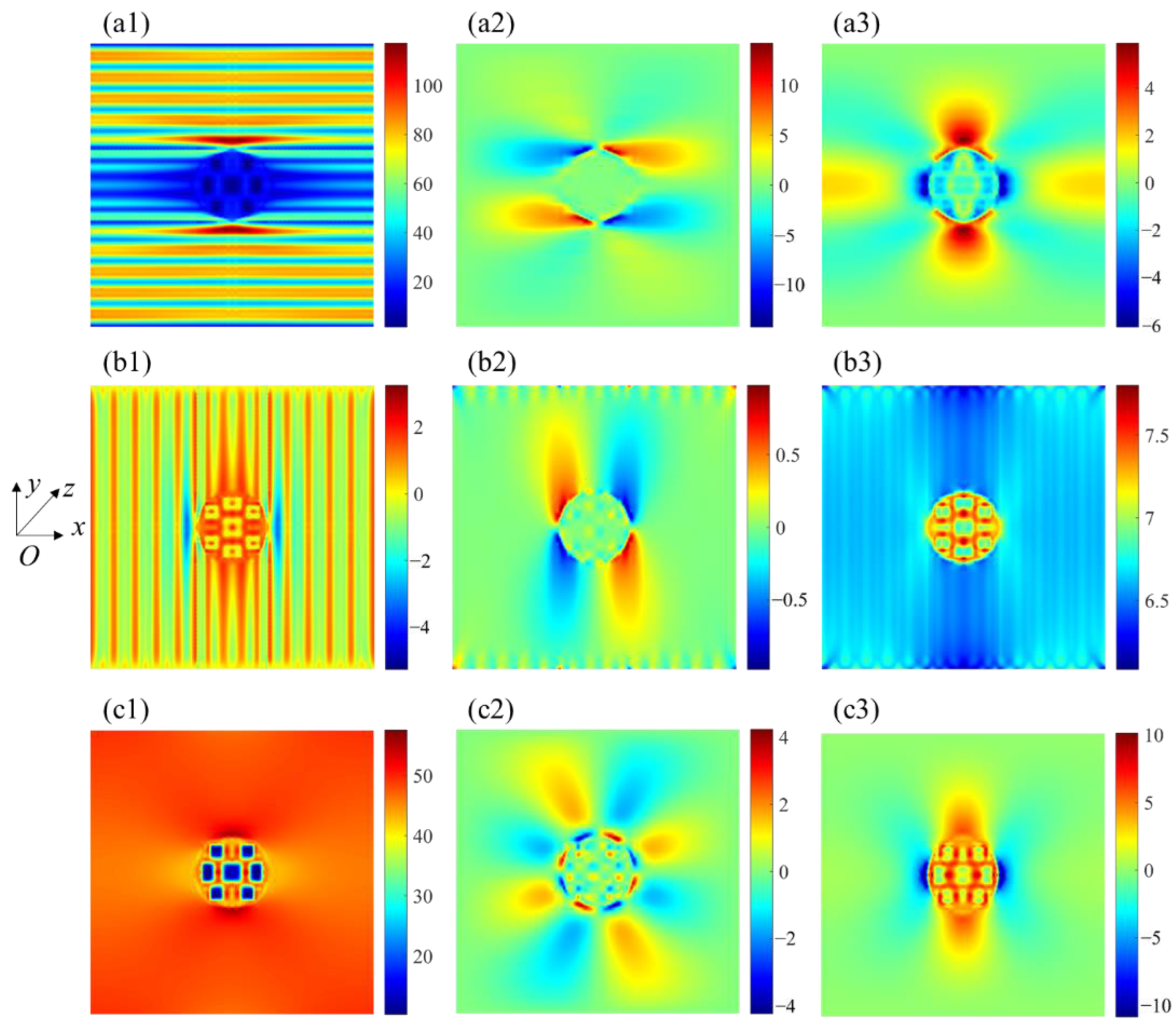

4. Results and Discussions

5. Conclusions

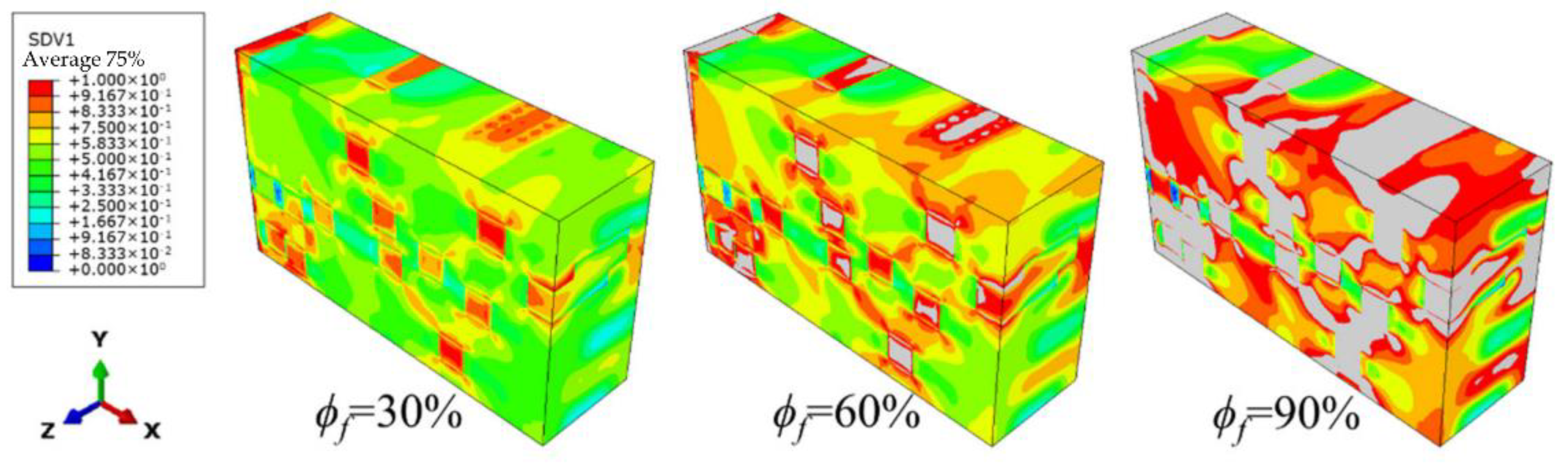

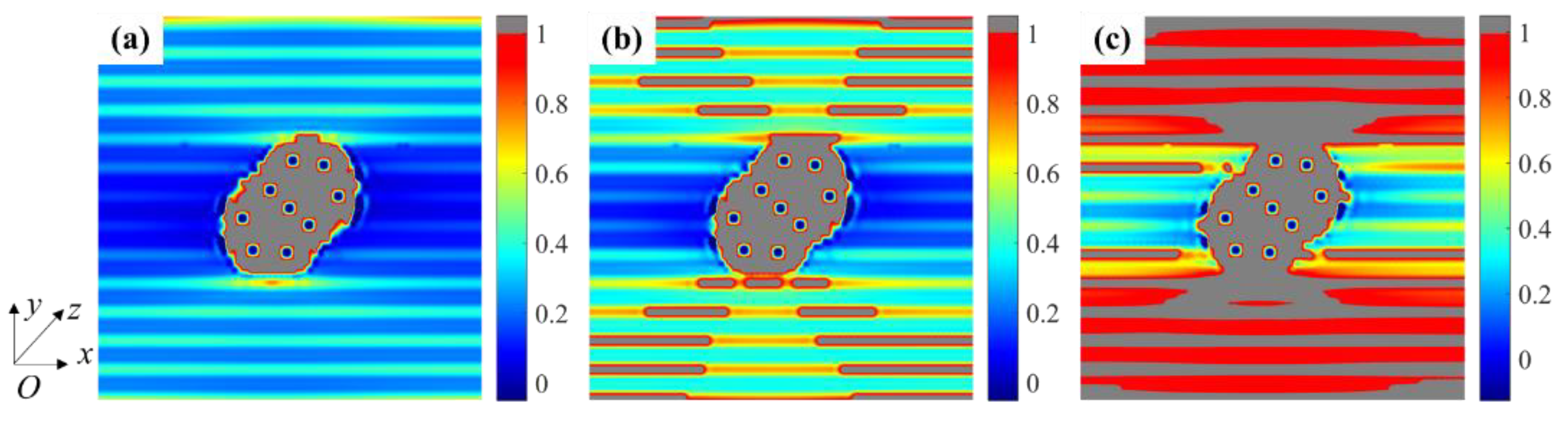

- Based on the μCT tomography tests, the local volume fractions of weftless ply and needling fibers around the needling holes are measured evenly to be 76.2% and 18.7%, respectively. Accordingly, the GMC models of three material phases, i.e., 0°/90° unidirectional fibers and short-cut fibers, are established. The Hashin criterion provides a good description of the failure mechanism in the needling region: stress concentrations firstly appear on both sides of the needling hole perpendicular to the loading direction, followed by the gradual failure of the needling hole and the matrix between the fibers. Eventually, the fibers fracture after the removal of the load transfer medium;

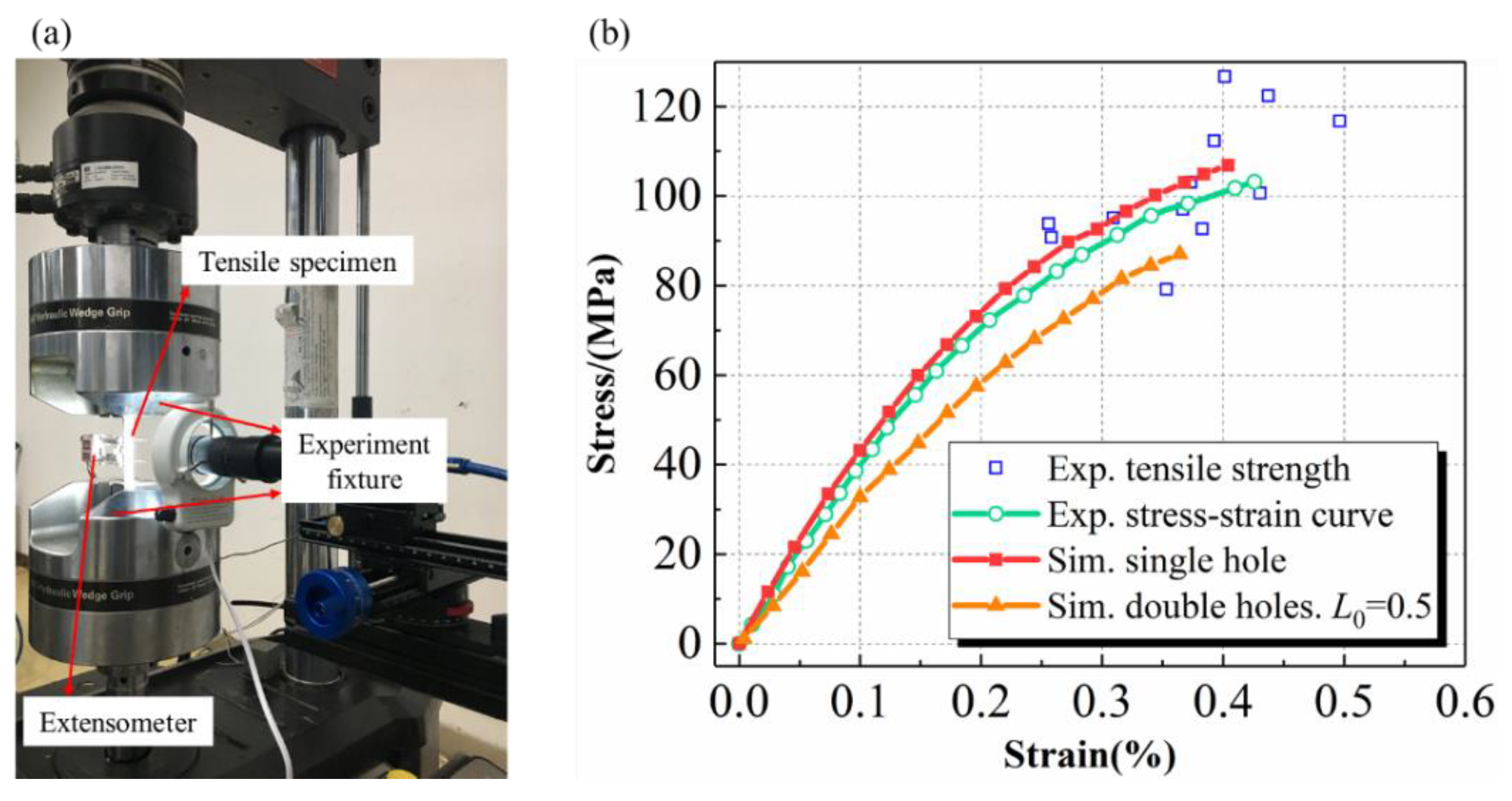

- After conducting the geometric partitioning strategy, the needling regions are described by the multi-scale method, while the un-needling regions are covered through the CDM model. By using the established simulation strategy, the relative errors of the predictions are 2.6% for strength and 4.4% for failure strain in unidirectional tension compared with experimental results. Meanwhile, the proposed approach reveals the damage evolution law in which the initial damage emerges from the stress concentration in the needling region, leading to matrix cracking, fiber fracture, and ultimately structural failure;

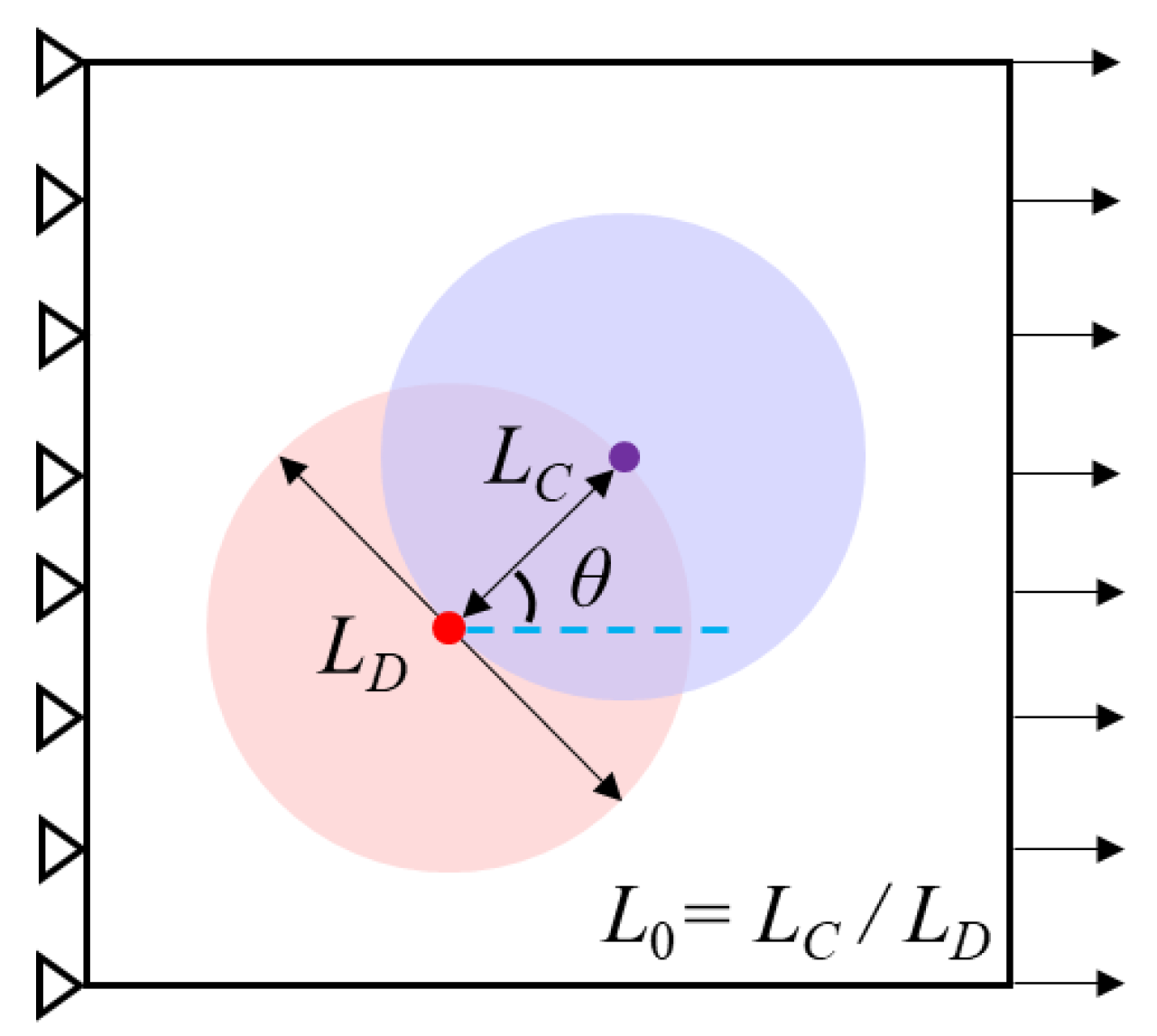

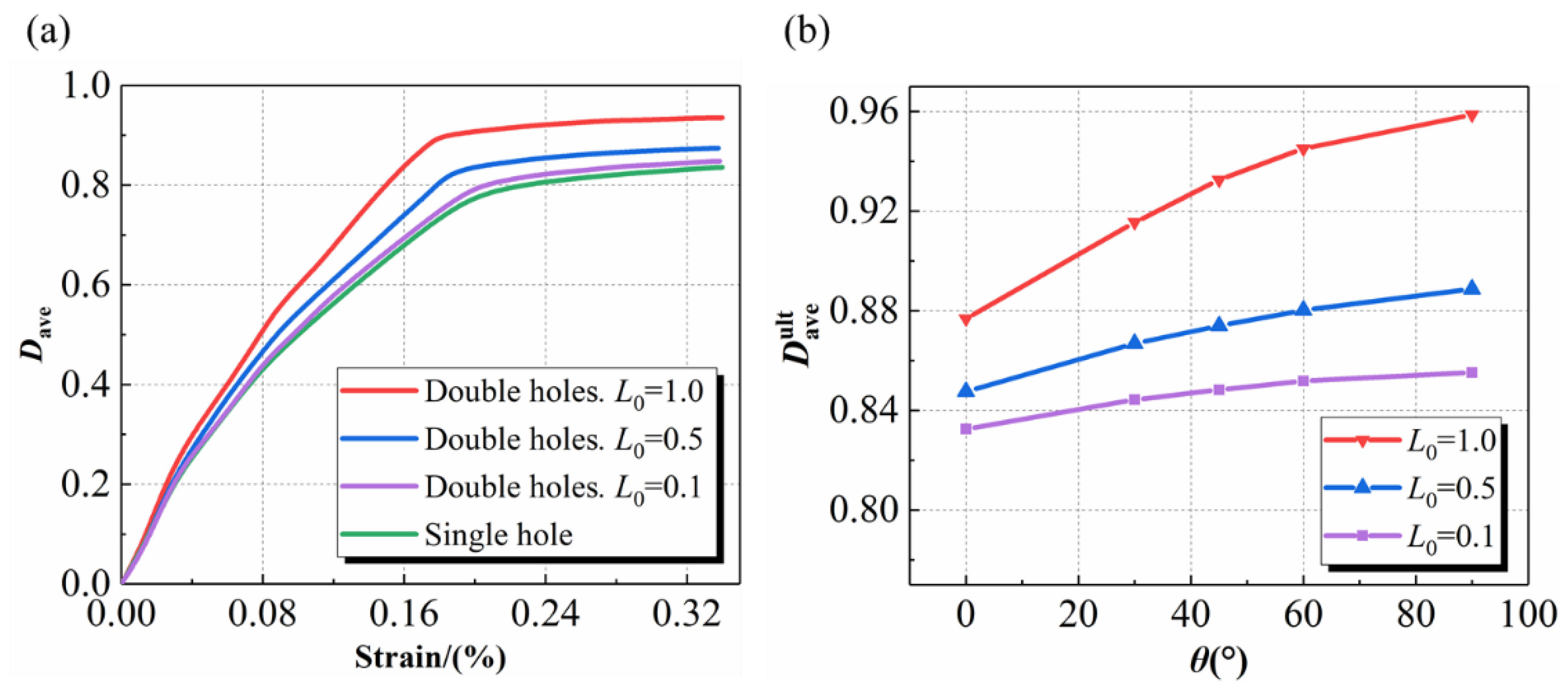

- The damage properties of the repeated needling regions are investigated. The damage mechanism of the repeated needling model is similar to that of the single-hole model, but with an enhanced degree of damage. Results show that the damage accumulation in the repeated needling region is related to the dimensionless overlapping size L0 and loading angle θ. An increase in L0 and θ resulted in a faster rate of damage accumulation. When θ = 45°, the degree of damage to the double hole is at most 20.2% (L0 = 1.0) more than the single hole model. Therefore, we recommend that repeated needling should be avoided as far as possible during the preparation of needled composites.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Udayakumar, A.; Basha, M.R.; Singh, S.; Kumari, S.; Prasad, V.V.B. Carbon fiber reinforced silicon carbide ceramic matrix composites. In Handbook of Advanced Ceramics and Composites: Defense, Security, Aerospace and Energy Applications; Mahajan, Y.R., Johnson, R., Eds.; Springer International Publishing: Cham, Switzerland, 2020; pp. 877–911. [Google Scholar] [CrossRef]

- Du, X.; Li, D.; Wei, Q.; Jiang, L. High temperature bending properties and failure mechanism of 3D needled C/SiC composites up to 2000 °C. J. Eur. Ceram. Soc. 2022, 42, 3036–3043. [Google Scholar] [CrossRef]

- Yao, T.; Chen, X.; Li, J.; Wei, Y.; Ren, Z.; Zheng, H.; He, Y. Experimental and numerical study of interlaminar shear property and failure mechanism of none-felt needled composites. Compos. Struct. 2022, 290, 115507. [Google Scholar] [CrossRef]

- Arteiro, A.; Furtado, C.; Catalanotti, G.; Linde, P.; Camanho, P.P. Thin-ply polymer composite materials: A review. Compos. Part A Appl. Sci. Manuf. 2020, 132, 105777. [Google Scholar] [CrossRef]

- Gao, X.; Yuan, L.; Fu, Y.; Yao, X.; Yang, H. Prediction of mechanical properties on 3D braided composites with void defects. Compos. Part B Eng. 2020, 197, 108164. [Google Scholar] [CrossRef]

- Chen, X.; Chen, L.; Zhang, C.; Song, L.; Zhang, D. Three-dimensional needle-punching for composites—A review. Compos. Part A Appl. Sci. Manuf. 2016, 85, 12–30. [Google Scholar] [CrossRef]

- Qi, Y.; Fang, G.; Wang, Z.; Liang, J.; Meng, S. An improved analytical method for calculating stiffness of 3D needled composites with different needle-punched processes. Compos. Struct. 2020, 237, 111938. [Google Scholar] [CrossRef]

- Zhang, H.; Zhou, C. Tensile strength prediction of needle-punched carbon/carbon composites. J. Reinf. Plast. Compos. 2016, 35, 1490–1512. [Google Scholar] [CrossRef]

- Han, M.; Silberschmidt, V.V. Theoretical Analysis on Needle-Punched Carbon/Carbon Composites. Appl. Compos. Mater. 2019, 26, 805–816. [Google Scholar] [CrossRef]

- Xu, C.; Han, X.; Cheng, G.; Meng, S.; Jin, H. Experimental study of ultra-high temperature interlaminar tensile strengths of 3D-needled C/C composites using the V-shaped notched specimen compression method. Mech. Mater. 2018, 126, 26–35. [Google Scholar] [CrossRef]

- Wan, F.; Liu, R.; Wang, Y.; Cao, Y.; Zhang, C.; Marrow, T.J. In situ observation of compression damage in a 3D needled-punched carbon fiber-silicon carbide ceramic matrix composite. Compos. Struct. 2019, 210, 189–201. [Google Scholar] [CrossRef]

- Song, L.; Zhao, Y.; Chen, L.; Zhu, Y.; Li, J. Three-dimensional finite element models and tensile properties of carbon fiber needled felt reinforced composites. J. Ind. Text. 2020, 50, 293–311. [Google Scholar] [CrossRef]

- Xie, J.; Fang, G.; Chen, Z.; Liang, J. An anisotropic elastoplastic damage constitutive model for 3D needled C/C-SiC composites. Compos. Struct. 2017, 176, 164–177. [Google Scholar] [CrossRef]

- Nagaraj, M.H.; Reiner, J.; Vaziri, R.; Carrera, E.; Petrolo, M. Progressive damage analysis of composite structures using higher-order layer-wise elements. Compos. Part B Eng. 2020, 190, 107921. [Google Scholar] [CrossRef]

- Jung, J.; dos Santos e Lucato, S.L. A CDM-based binary model for the progressive damage prediction of SiC/SiC ceramic matrix composites under tension loading. Int. J. Multiscale Comput. Eng. 2021, 19, 1–15. [Google Scholar] [CrossRef]

- Gao, Y.; Zhang, D.; Li, F.; Zhao, Q.; Zhao, Z.; Chen, Y. Bearing strength and failure behaviour of composite pre-tightened multi-tooth joint. Compos. Struct. 2021, 272, 114208. [Google Scholar] [CrossRef]

- Zhu, H.; Du, X.; Li, D.; Jiang, L. Investigation of parameterized braiding parameters and loading directions on compressive behavior and failure mechanism of 3D four-directional braided composites. Compos. Struct. 2022, 287, 115357. [Google Scholar] [CrossRef]

- Sun, Y.; Hong, C.; Zhang, X.; Han, J.; Qu, Q. Preparation and properties of SiOC ceramic modified carbon fiber needled felt preform composites. Ceram. Int. 2020, 46, 1743–1749. [Google Scholar] [CrossRef]

- Chaboche, J.L.; Maire, J.F. A new micromechanics based CDM model and its application to CMC’s. Aerosp. Sci. Technol. 2002, 6, 131–145. [Google Scholar] [CrossRef]

- Yao, T.; Chen, X.; Li, J.; Wei, Y.; Ren, Z.; Zheng, H. Significantly improve the interlayer and in-plane properties of needled fabrics by novel none-felt needling technology. Compos. Struct. 2021, 274, 114303. [Google Scholar] [CrossRef]

- Liang, X.; Gao, X.; Zhang, H.; Yu, G.; Xie, C.; Zhang, S.; Song, Y. Interlaminar shear behaviors of 2D needled C/SiC composites under compressive and tensile loading. Ceram. Int. 2021, 47, 4954–4962. [Google Scholar] [CrossRef]

- Lu, L.; Fan, W.; Meng, X.; Liu, T.; Han, L.; Zhang, T.; Dong, J.; Yuan, L.; Tian, H. Modal analysis of 3D needled waste cotton fiber/epoxy composites with experimental and numerical methods. Text. Res. J. 2021, 91, 358–372. [Google Scholar] [CrossRef]

- Beyerlein, I.J.; Landis, C.M. Shear-lag model for failure simulations of unidirectional fiber composites including matrix stiffness. Mech. Mater. 1999, 31, 331–350. [Google Scholar] [CrossRef]

- Beyerlein, I.J.; Leigh Phoenix, S. Statistics of fracture for an elastic notched composite lamina containing Weibull fibers—Part I. Features from Monte-Carlo simulation. Eng. Fract. Mech. 1997, 57, 241–265. [Google Scholar] [CrossRef]

- Qi, Y.; Fang, G.; Wang, B.; Meng, S.; Liang, J. Determination of needling process satisfying stiffness requirements of 3D needled composites. Polym. Compos. 2022. [Google Scholar] [CrossRef]

- Xu, H.; Li, L.; Li, G.; Zheng, R.; Yao, X.; Ma, C. In situ characterization of the flexural behavior and failure mechanism of 2D needle-punched carbon/carbon composites by digital image correlation. J. Mater. Sci. 2022, 57, 11077–11091. [Google Scholar] [CrossRef]

- Hou, G.; Shang, D.; Zuo, L.; Qu, L.; Xia, M.; Guo, Y.; Yin, X.; Wu, S. Fatigue crack propagation behavior at a notch for needled C/SiC composite under tension-tension loading. J. Mech. Sci. Technol. 2022, 36, 167–177. [Google Scholar] [CrossRef]

- Aboudi, J. The generalized method of cells and high-fidelity generalized method of cells micromechanical models—A review. Mech. Adv. Mater. Struct. 2004, 11, 329–366. [Google Scholar] [CrossRef]

- Bednarcyk, B.A.; Arnold, S.M.; Aboudi, J.; Pindera, M.-J. Local field effects in titanium matrix composites subject to fiber-matrix debonding. Int. J. Plast. 2004, 20, 1707–1737. [Google Scholar] [CrossRef]

- Massarwa, E.; Aboudi, J.; Haj-Ali, R. A multiscale progressive damage analysis for laminated composite structures using the parametric HFGMC micromechanics. Compos. Struct. 2018, 188, 159–172. [Google Scholar] [CrossRef]

- Shi, J.; Tong, M. Multi-Scale Nonlinear Progressive Damage and Failure Analysis for Open-Hole Composite Laminates. Aerospace 2022, 9, 59. [Google Scholar] [CrossRef]

- Wan, H.; Fan, L.; Jia, J.; Han, Q.; Jamalabadi, M.Y.A. Micromechanical modeling over two length-scales for elastic properties of graphene nanoplatelet/graphite fiber/polyimide composites. Mater. Chem. Phys. 2021, 262, 124255. [Google Scholar] [CrossRef]

- Ge, L.; Li, H.; Zhang, Y.; Zhong, J.; Chen, Y.; Fang, D. Multiscale viscoelastic behavior of 3D braided composites with pore defects. Compos. Sci. Technol. 2022, 217, 109114. [Google Scholar] [CrossRef]

- Tang, S.; Deng, J.; Wang, S.; Liu, W. Fabrication and characterization of C/SiC composites with large thickness, high density and near-stoichiometric matrix by heaterless chemical vapor infiltration. Mater. Sci. Eng. A 2007, 465, 290–294. [Google Scholar] [CrossRef]

- Yu, J.; Zhou, C.; Zhang, H. A micro-image based reconstructed finite element model of needle-punched C/C composite. Compos. Sci. Technol. 2017, 153, 48–61. [Google Scholar] [CrossRef]

- Xie, J.; Liang, J.; Fang, G.; Chen, Z. Effect of needling parameters on the effective properties of 3D needled C/C-SiC composites. Compos. Sci. Technol. 2015, 117, 69–77. [Google Scholar] [CrossRef]

- Xie, J.; Chen, X.; Zhang, Y.; Fang, G.; Chen, L. Experimental and numerical investigation of the needling process for quartz fibers. Compos. Sci. Technol. 2018, 165, 115–123. [Google Scholar] [CrossRef]

- Kari, S.; Berger, H.; Gabbert, U. Numerical evaluation of effective material properties of randomly distributed short cylindrical fibre composites. Comput. Mater. Sci. 2007, 39, 198–204. [Google Scholar] [CrossRef]

- Pan, Y.; Iorga, L.; Pelegri, A.A. Numerical generation of a random chopped fiber composite RVE and its elastic properties. Compos. Sci. Technol. 2008, 68, 2792–2798. [Google Scholar] [CrossRef]

- Shen, X.; Gong, L. RVE model with porosity for 2D woven CVI SiCf/SiC composites. J. Mater. Eng. Perform. 2016, 25, 5138–5144. [Google Scholar] [CrossRef]

- Zhang, L.; Qiu, R.; Cheng, J.; Liu, B. Experimental investigation and multiscale simulation on the bending fatigue of 2D SiCf/SiC composites. Int. J. Fatigue 2021, 144, 106051. [Google Scholar] [CrossRef]

- Hashin, Z. Failure criteria for unidirectional fiber composites. J. Appl. Mech. 1980, 47, 329–334. [Google Scholar] [CrossRef]

- Christensen, R.M. A comprehensive theory of yielding and failure for isotropic materials. J. Eng. Mater. Technol. 2007, 129, 173–181. [Google Scholar] [CrossRef]

- Tao, G.; Xia, Z. Fatigue behavior of an epoxy polymer subjected to cyclic shear loading. Mater. Sci. Eng. A 2008, 486, 38–44. [Google Scholar] [CrossRef]

- Han, J.; Wang, R.; Hu, D.; Liu, X.; Zhang, L.; Guo, X.; Cho, C. Multi-scale analysis and experimental research for turbine guide vanes made of 2D braided SiCf/SiC composites in high-cycle fatigue regime. Int. J. Fatigue 2022, 156, 106697. [Google Scholar] [CrossRef]

- Zhou, Y.; Lu, Z.; Yang, Z. Progressive damage analysis and strength prediction of 2D plain weave composites. Compos. Part B Eng. 2013, 47, 220–229. [Google Scholar] [CrossRef]

- Dupvant, G.; Lions, J.L. Inequalities in Mechanics and Physics; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012; Volume 219. [Google Scholar]

- Gao, X.; Li, L.; Song, Y. A temperature-dependent constitutive model for fiber-reinforced ceramic matrix composites and structural stress analysis. Int. J. Damage Mech. 2013, 23, 507–522. [Google Scholar] [CrossRef]

- Xu, Y.; Zhang, P.; Lu, H.; Zhang, W. Hierarchically modeling the elastic properties of 2D needled carbon/carbon composites. Compos. Struct. 2015, 133, 148–156. [Google Scholar] [CrossRef]

- Alghamdi, A.; Alharthi, H.; Alamoudi, A.; Alharthi, A.; Kensara, A.; Taylor, S. Effect of Needling Parameters and Manufacturing Porosities on the Effective Thermal Conductivity of a 3D Carbon-Carbon Composite. Materials 2019, 12, 3750. [Google Scholar] [CrossRef]

- Tian, W.; Qi, L.; Zhou, J.; Liang, J.; Ma, Y. Representative volume element for composites reinforced by spatially randomly distributed discontinuous fibers and its applications. Compos. Struct. 2015, 131, 366–373. [Google Scholar] [CrossRef]

- Meng, S.; Song, L.; Xu, C.; Wang, W.; Xie, W.; Jin, H. Predicting the effective properties of 3D needled carbon/carbon composites by a hierarchical scheme with a fiber-based representative unit cell. Compos. Struct. 2017, 172, 198–209. [Google Scholar] [CrossRef]

- Kwon, Y.W.; Allen, D.H.; Talreja, R. Multiscale Modeling and Simulation of Composite Materials and Structures; Springer: Berlin/Heidelberg, Germany, 2008; Volume 47. [Google Scholar] [CrossRef]

- Mohan, P.R.K.; Kumar, M.A.; Mohite, P.M. Representative volume element generation and its size determination for discontinuous composites made from chopped prepregs. Compos. Struct. 2020, 252, 112633. [Google Scholar] [CrossRef]

- Simulia, D. Abaqus 6.11 analysis user’s manual. Abaqus 2011, 6, 22. [Google Scholar]

- Adams, J.C.; Brainerd, W.S.; Martin, J.T.; Smith, B.T.; Wagener, J.L. FORTRAN 90 Handbook; McGraw-Hill: New York, NY, USA, 1992; Volume 32. [Google Scholar]

- Xie, J.; Fang, G.; Chen, Z.; Liang, J. Numerical and experimental studies on scattered mechanical properties for 3D needled C/C-SiC composites. Compos. Struct. 2018, 192, 545–554. [Google Scholar] [CrossRef]

| Components | Parameter | Value |

|---|---|---|

| Carbon fiber [36] | Longitudinal modulus (GPa) | 230 |

| Transverse modulus (GPa) | 18.226 | |

| Longitudinal Poisson’s ratio | 0.27 | |

| Transverse Poisson’s ratio | 0.3 | |

| Longitudinal Shear modulus (GPa) | 36.597 | |

| Transverse Shear modulus (GPa) | 7.01 | |

| Fiber volume fraction of weftless plies [25] | 0.24 | |

| Fiber volume fraction of short-cut fibers [25] | 0.045 | |

| Matrix | Elastic modulus (GPa) | 22.607 |

| Poisson’s ratio | 0.218 | |

| Porosity | Pore volume fraction | 0.0985 |

| Ex | Ey | Ez | νxy | νxz | νyz | Gxy | Gxz | Gyz | |

|---|---|---|---|---|---|---|---|---|---|

| Weftless ply | 81.45 | 21.69 | 21.69 | 0.231 | 0.231 | 0.268 | 13.06 | 13.06 | 5.54 |

| short-cut fibers | 20.59 | 20.37 | 19.65 | 0.215 | 0.221 | 0.216 | 7.96 | 7.52 | 6.85 |

| un-needling region | 59.93 | 59.93 | 20.02 | 0.230 | 0.251 | 0.255 | 14.27 | 11.01 | 10.95 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, R.; Liu, Y.; Liu, X.; Hu, D.; Han, J.; Ma, P.; Guo, X. Assessment of Mechanical Properties for Three-Dimensional Needled Composites: A Geometric Partitioning Strategy Dealing with Mesoscopic Needling Damage. Materials 2022, 15, 5659. https://doi.org/10.3390/ma15165659

Wang R, Liu Y, Liu X, Hu D, Han J, Ma P, Guo X. Assessment of Mechanical Properties for Three-Dimensional Needled Composites: A Geometric Partitioning Strategy Dealing with Mesoscopic Needling Damage. Materials. 2022; 15(16):5659. https://doi.org/10.3390/ma15165659

Chicago/Turabian StyleWang, Rongqiao, Yu Liu, Xi Liu, Dianyin Hu, Jiangbo Han, Penghui Ma, and Xiaojun Guo. 2022. "Assessment of Mechanical Properties for Three-Dimensional Needled Composites: A Geometric Partitioning Strategy Dealing with Mesoscopic Needling Damage" Materials 15, no. 16: 5659. https://doi.org/10.3390/ma15165659

APA StyleWang, R., Liu, Y., Liu, X., Hu, D., Han, J., Ma, P., & Guo, X. (2022). Assessment of Mechanical Properties for Three-Dimensional Needled Composites: A Geometric Partitioning Strategy Dealing with Mesoscopic Needling Damage. Materials, 15(16), 5659. https://doi.org/10.3390/ma15165659