Experimental Investigation and Performance Optimization during Machining of Hastelloy C-276 Using Green Lubricants

Abstract

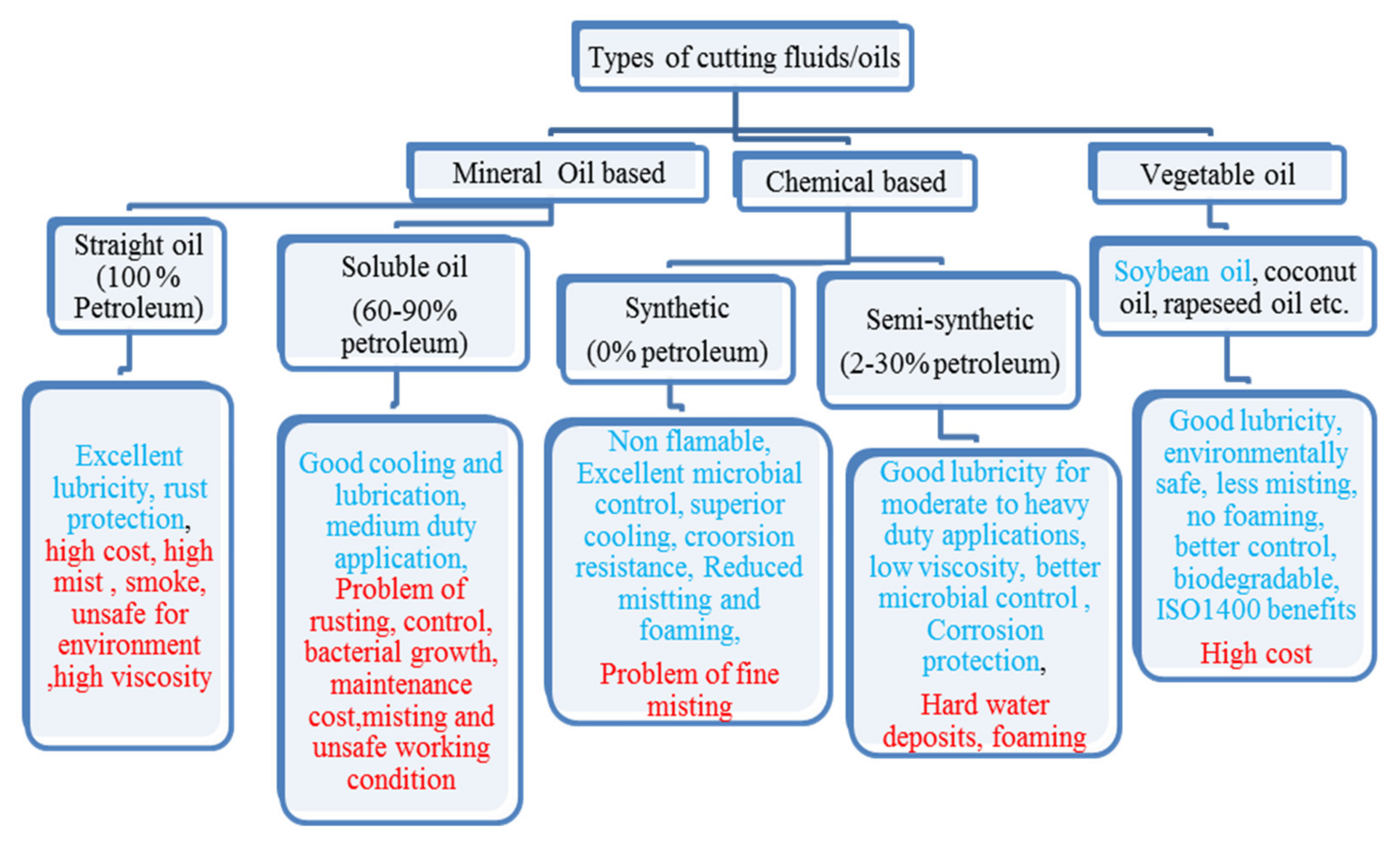

:1. Introduction

1.1. Significance of the Study

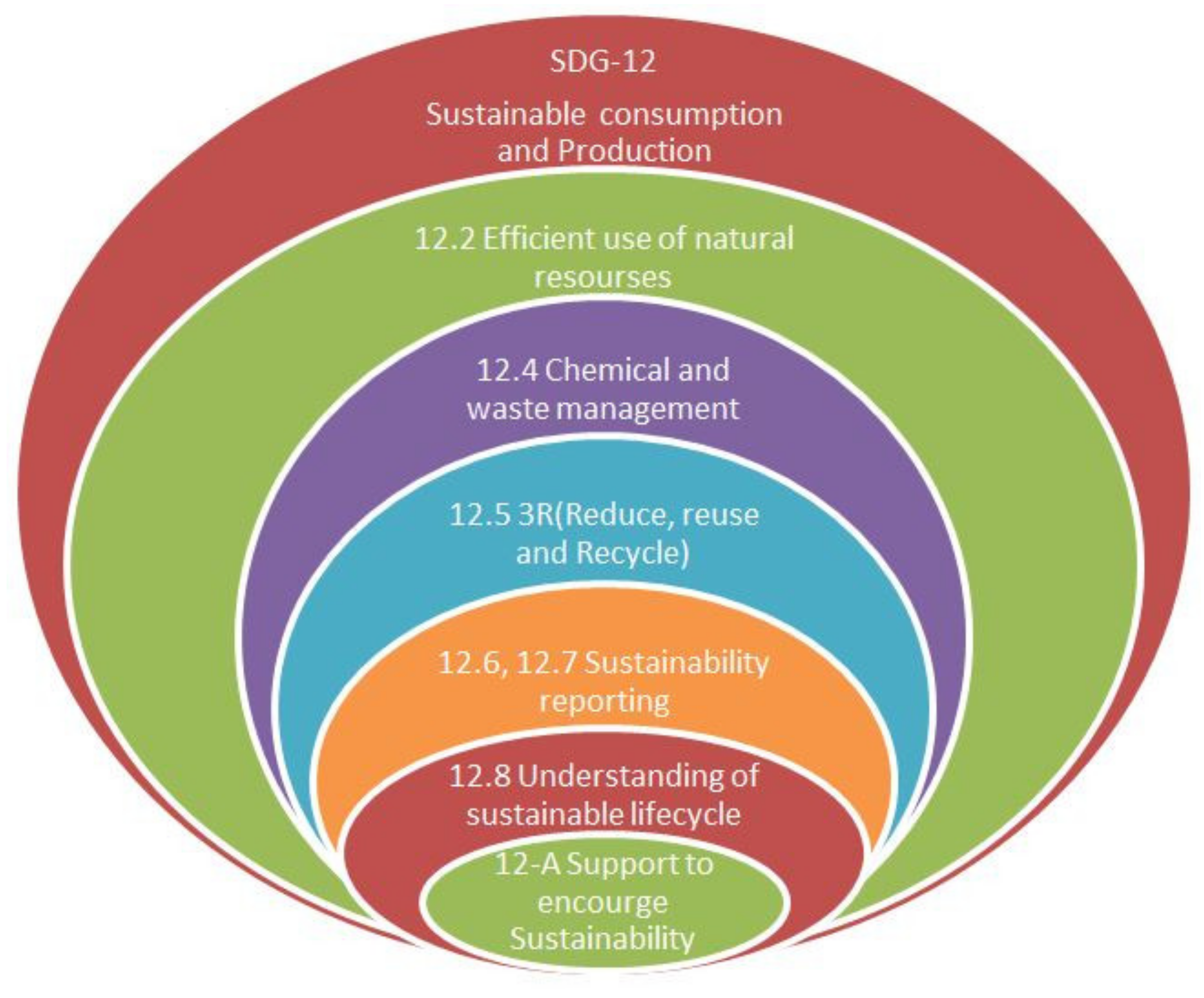

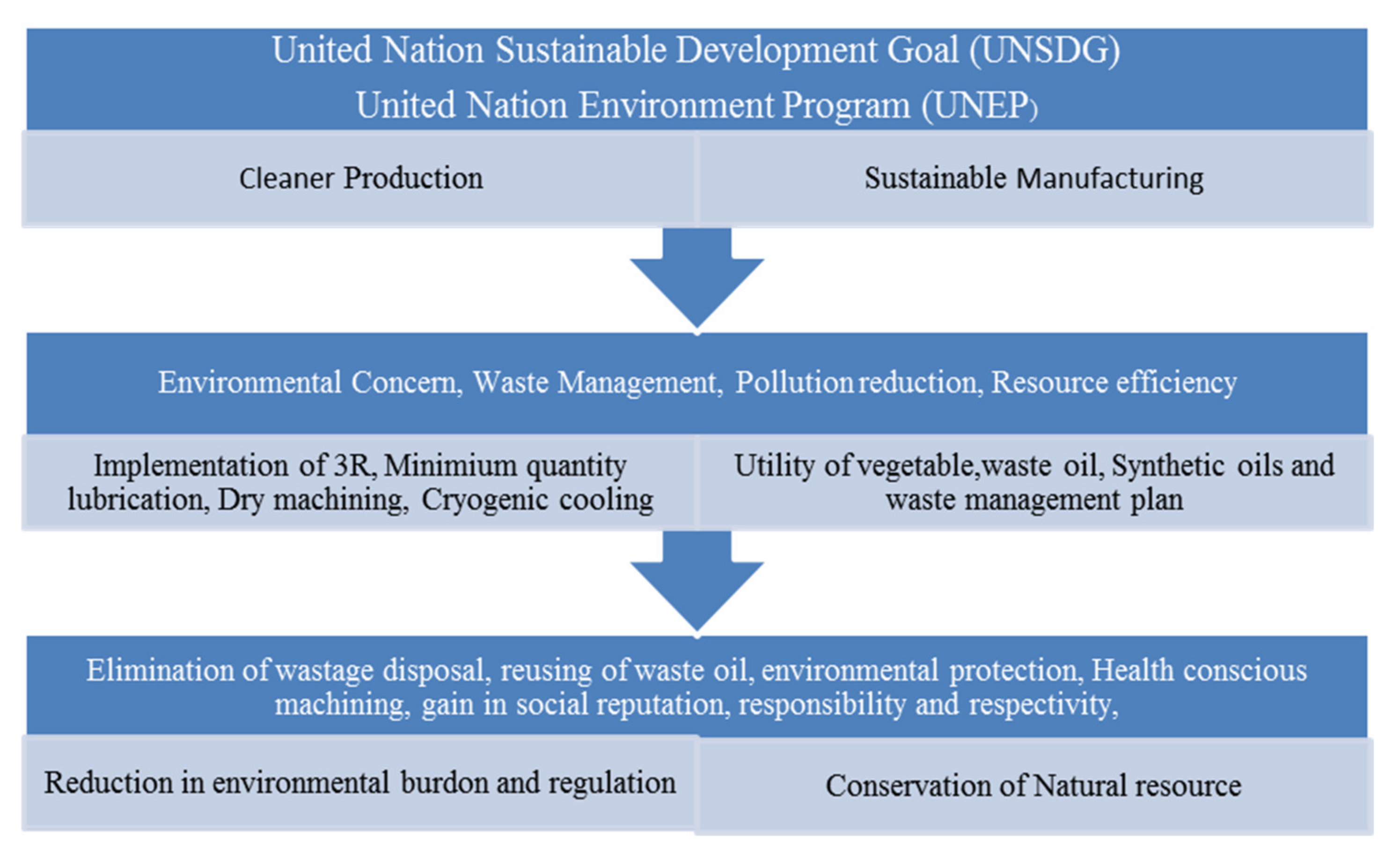

1.1.1. Scope of Sustainable Development Goal (SDG-12)

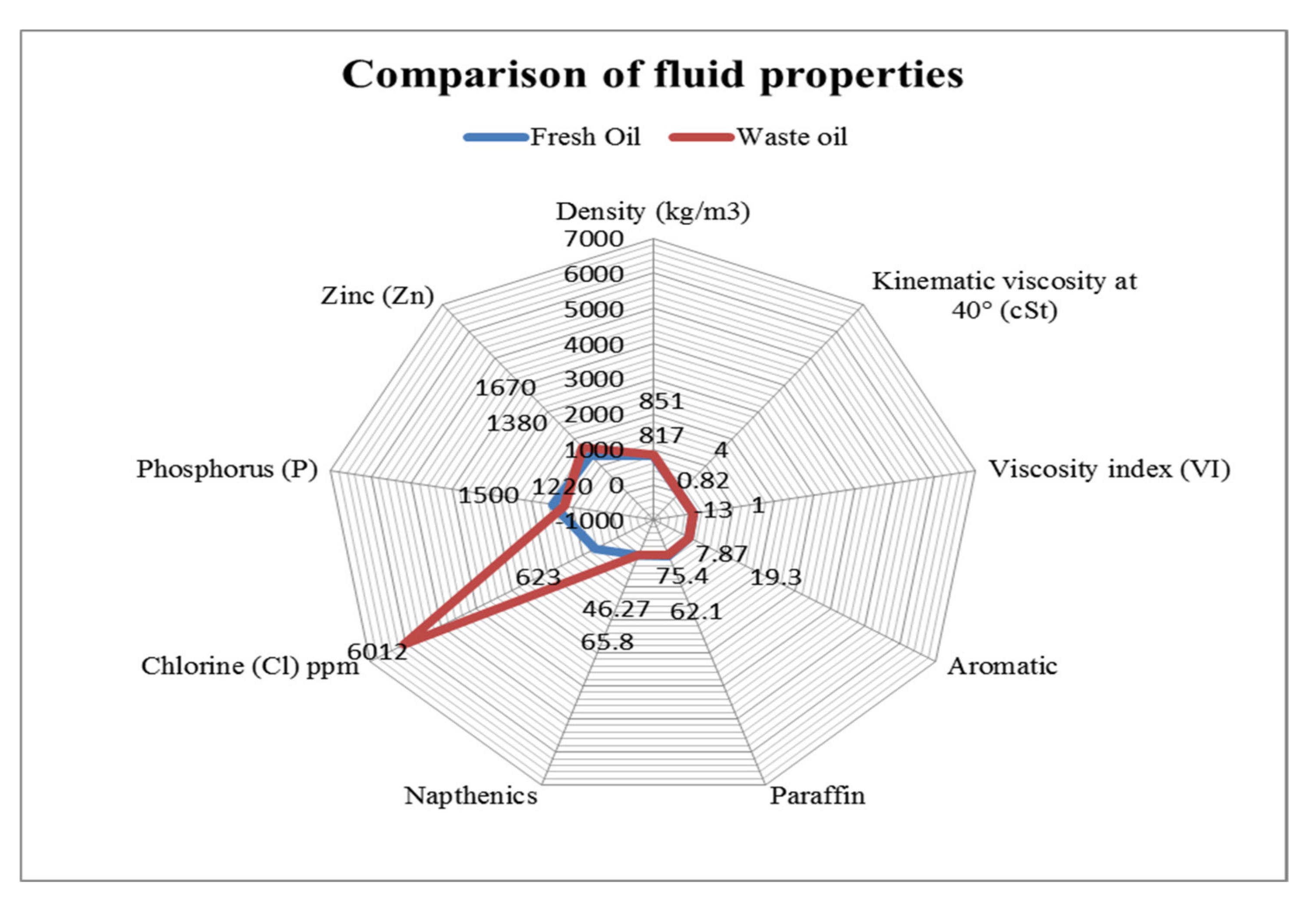

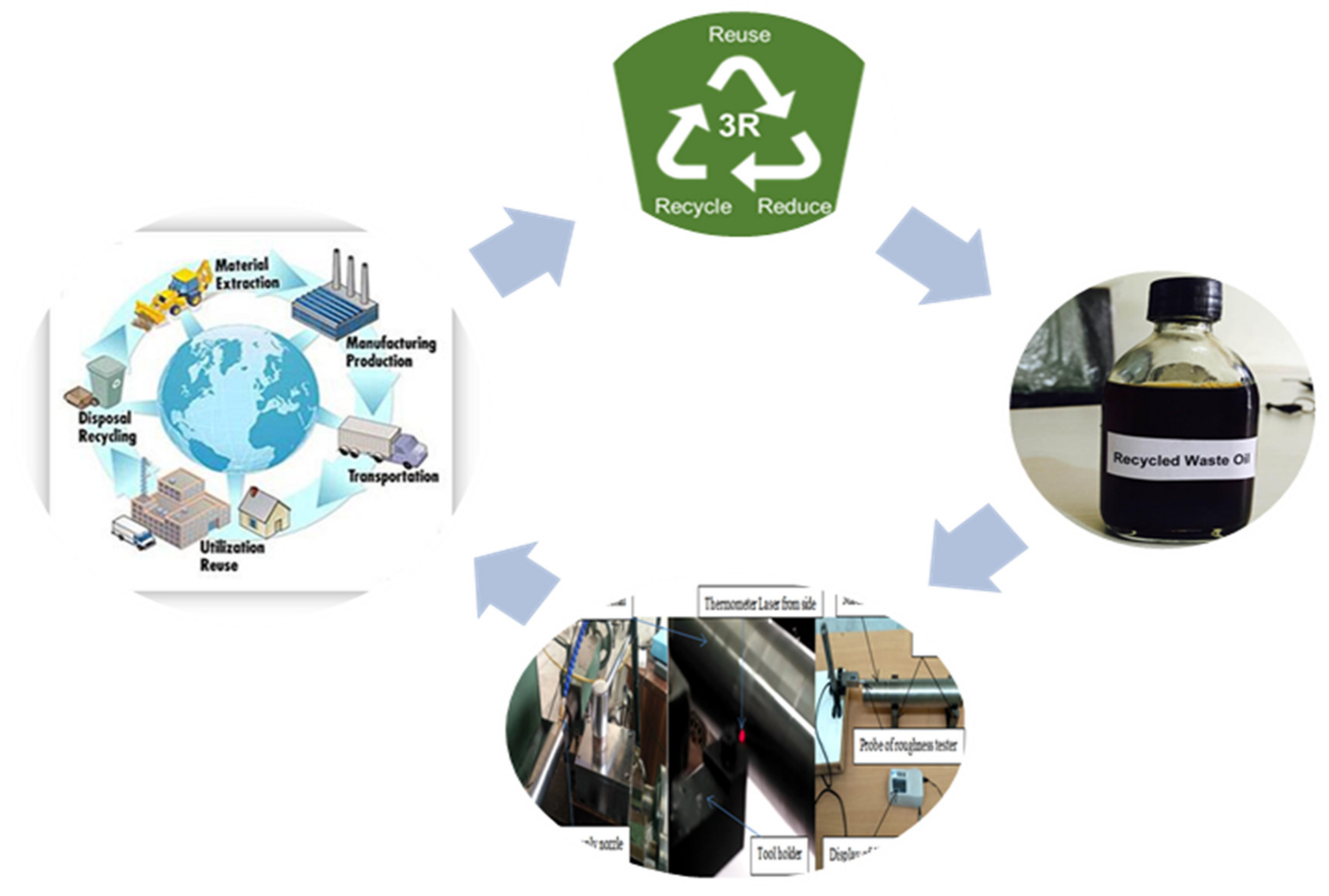

1.1.2. Concept of Wastage Reduction and Its Impacts

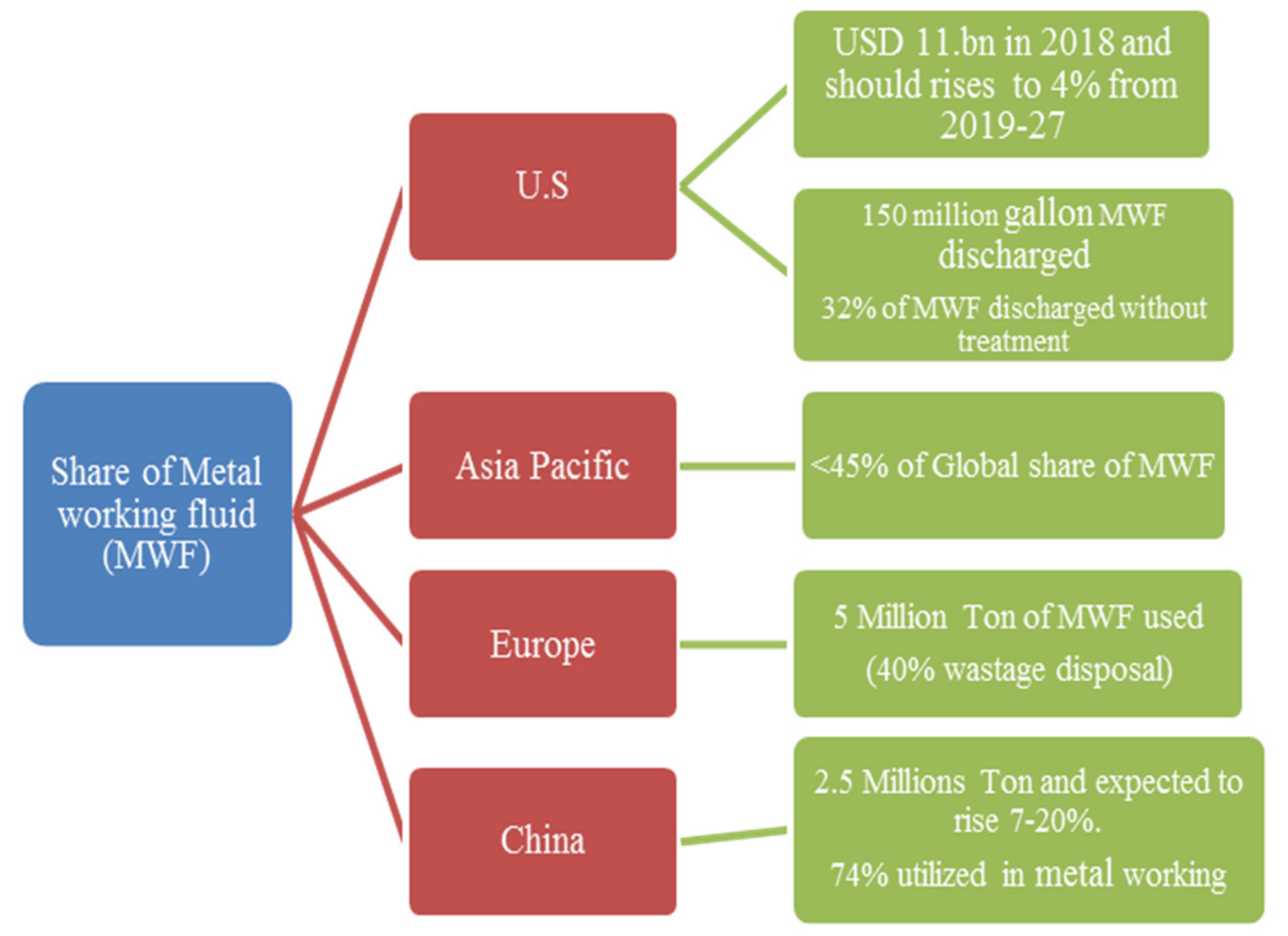

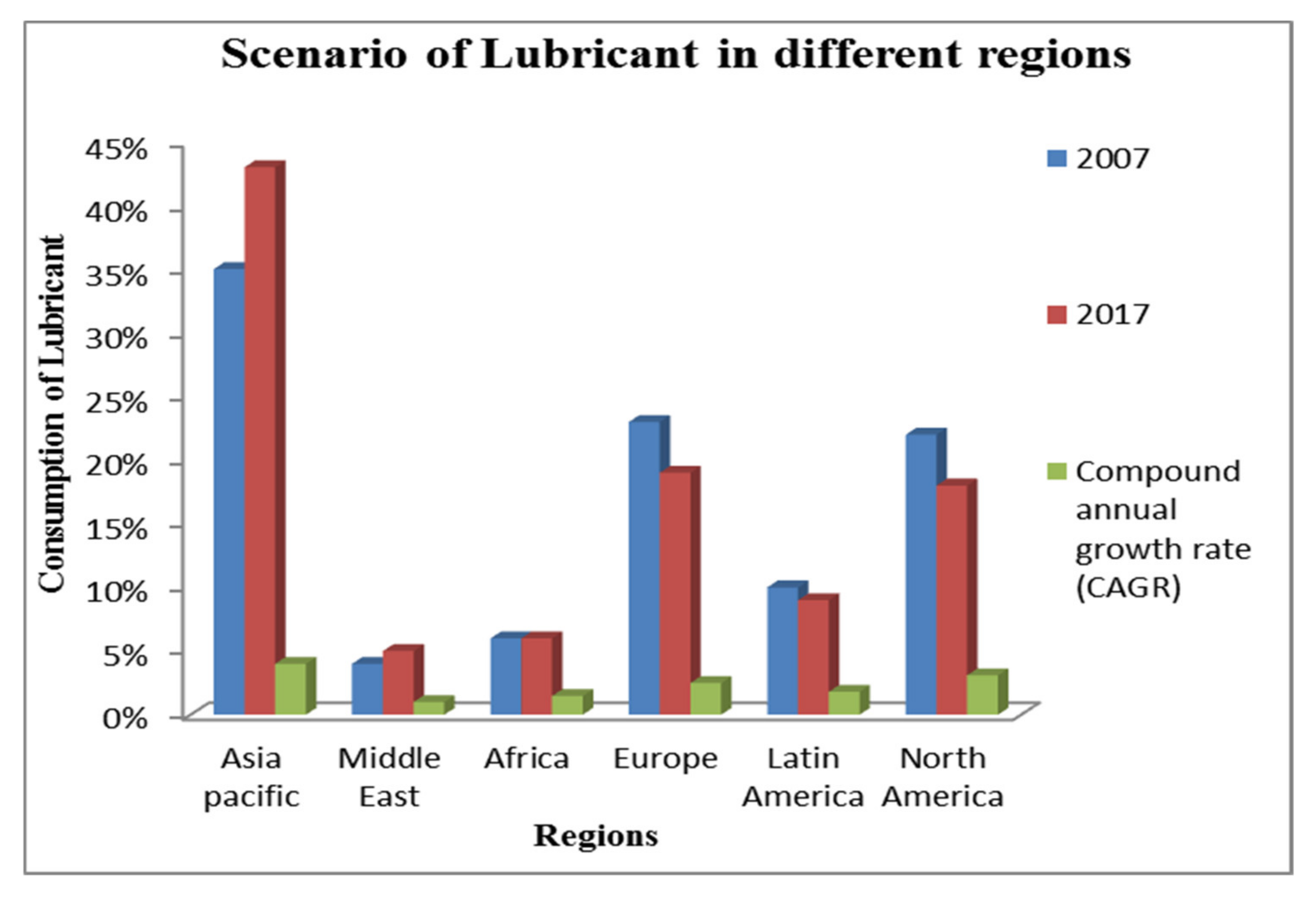

1.1.3. Global Scenario of Lubricant Market

1.1.4. Concept of 3R and Circular Economy

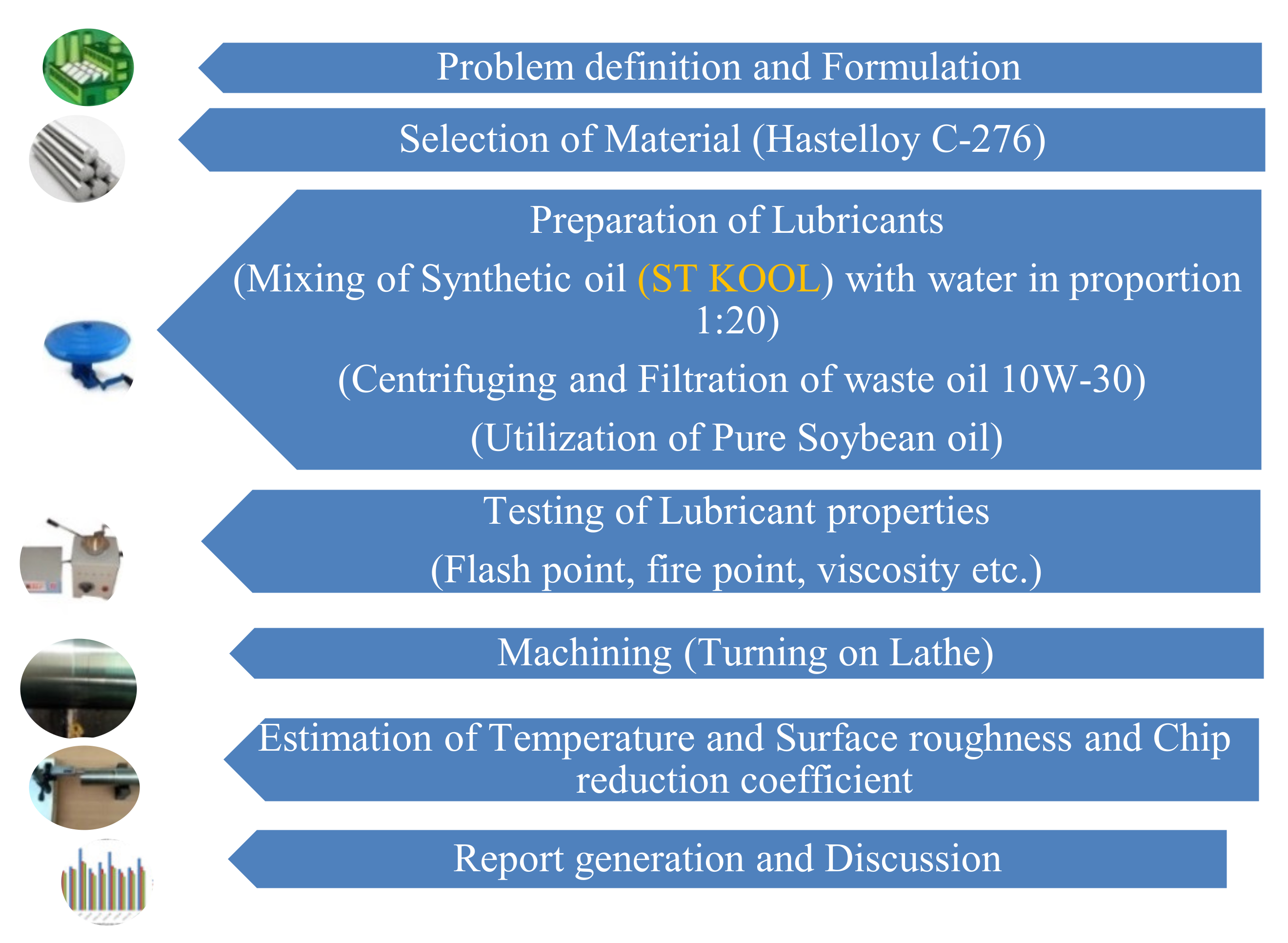

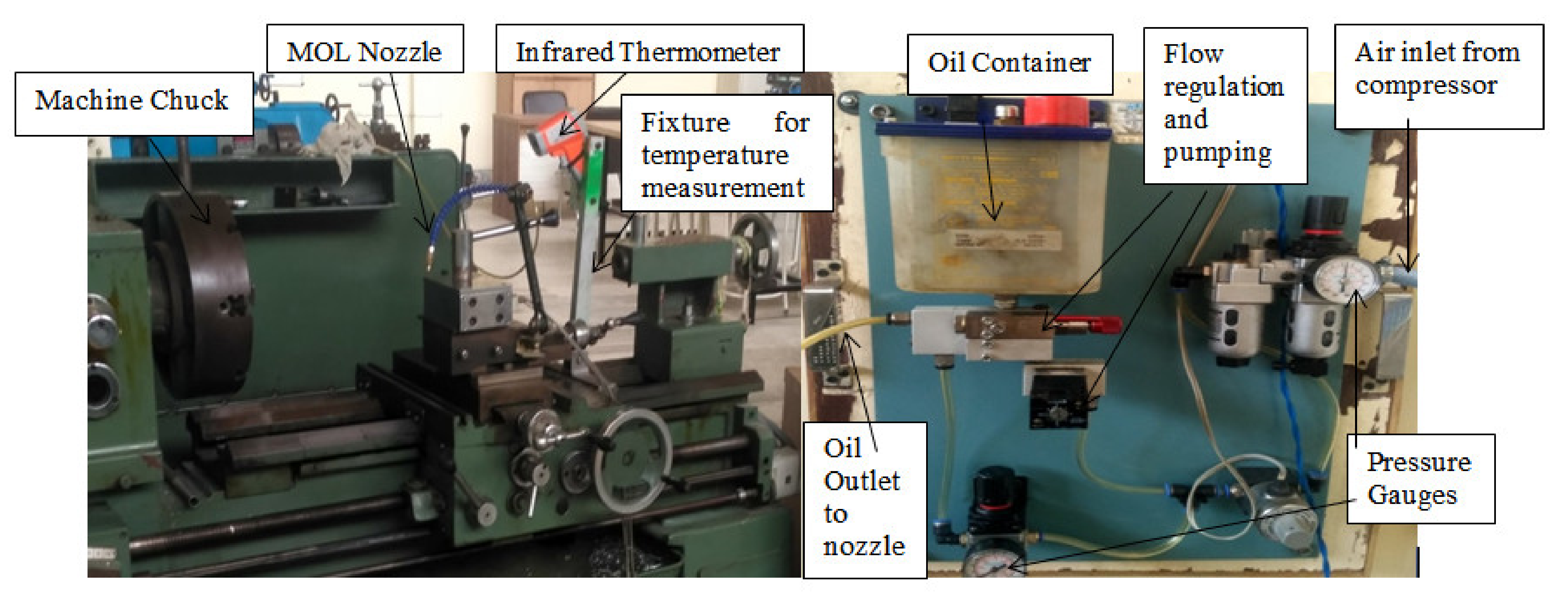

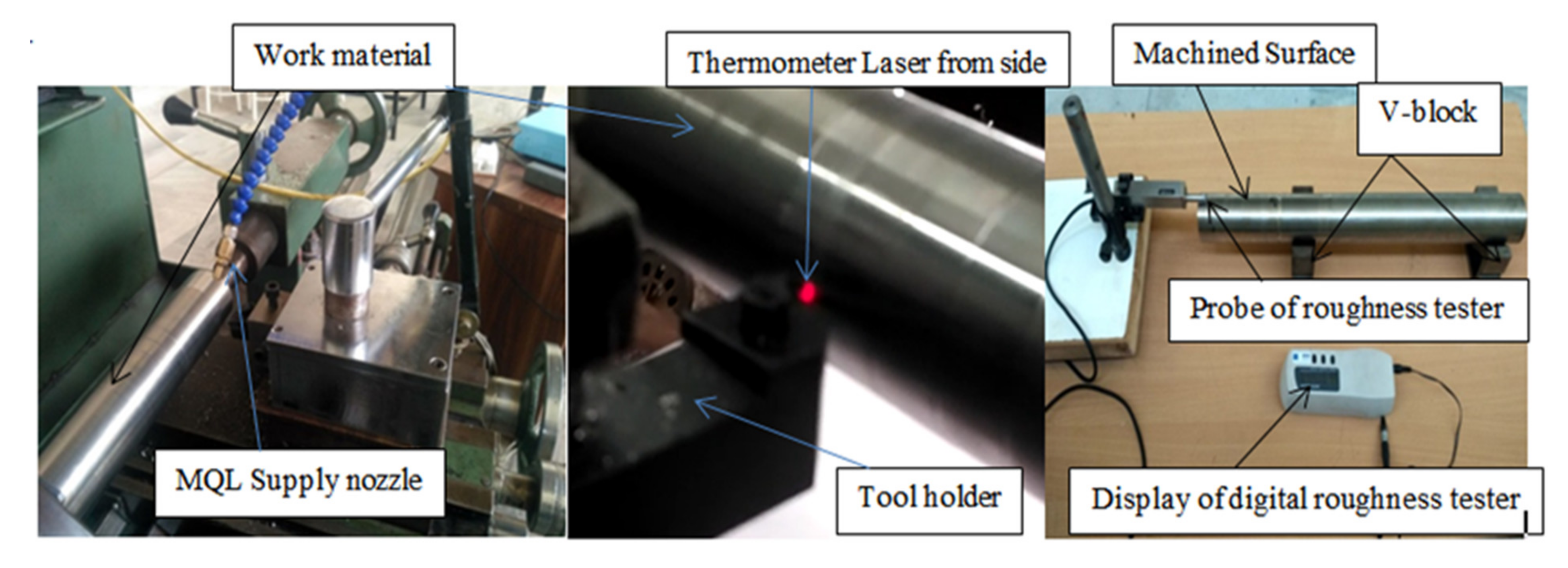

2. Experimental Planning and Methodology

3. Results and Discussions

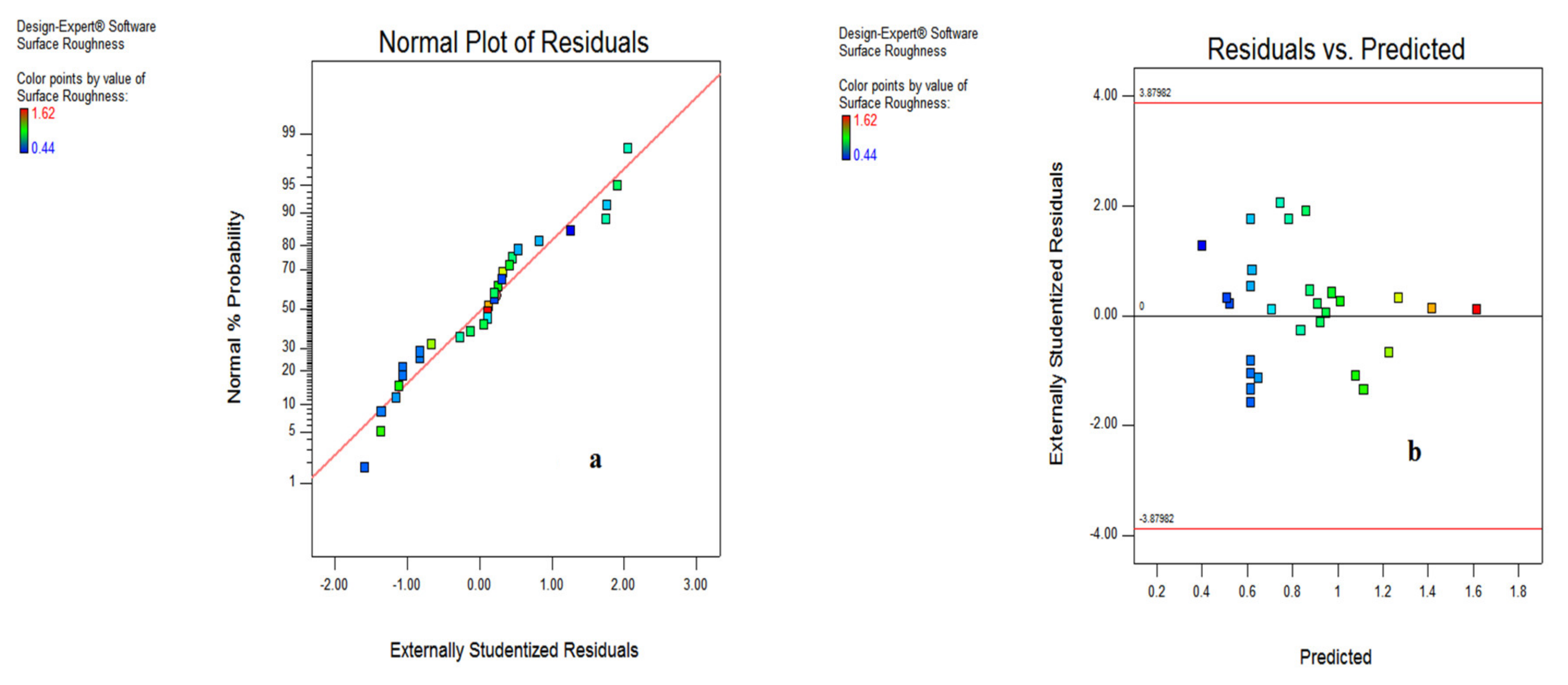

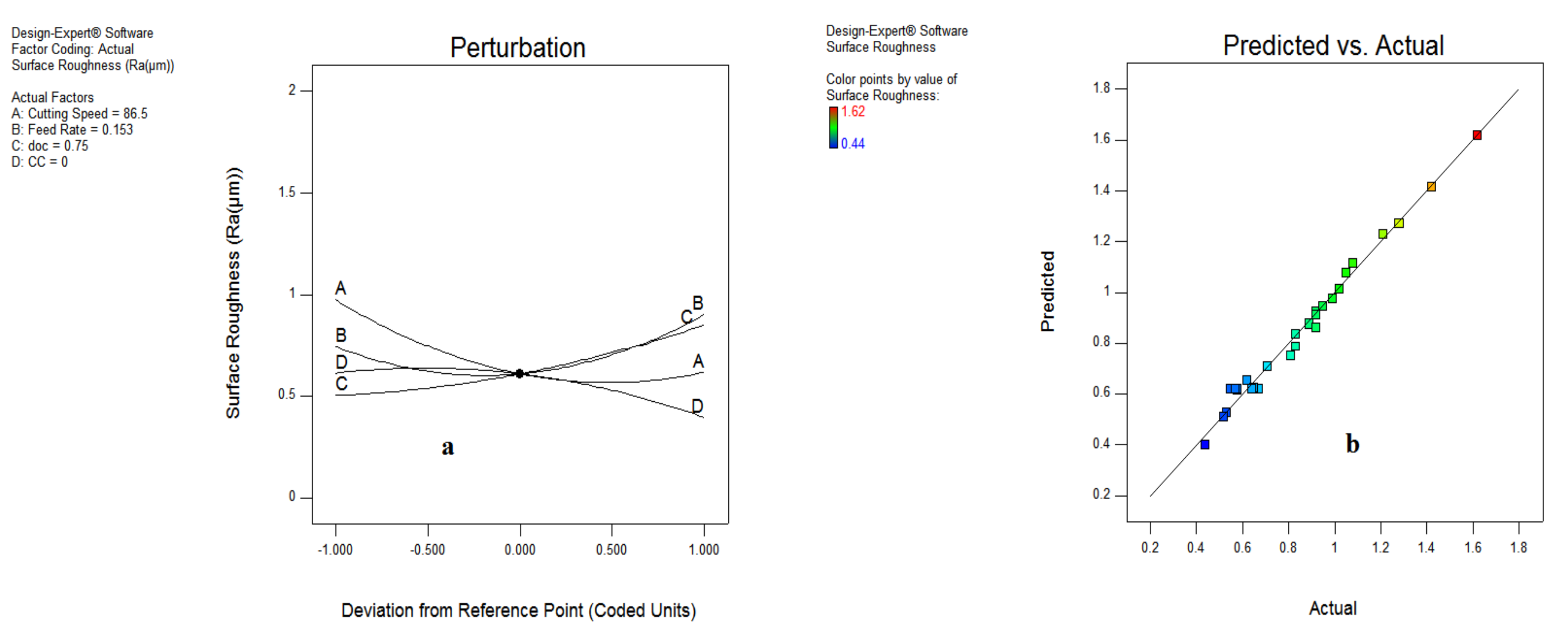

3.1. Analysis of Surface Roughness

3.1.1. Statistical Plots for Surface Roughness

3.1.2. Impact of Input Variable on Surface Roughness

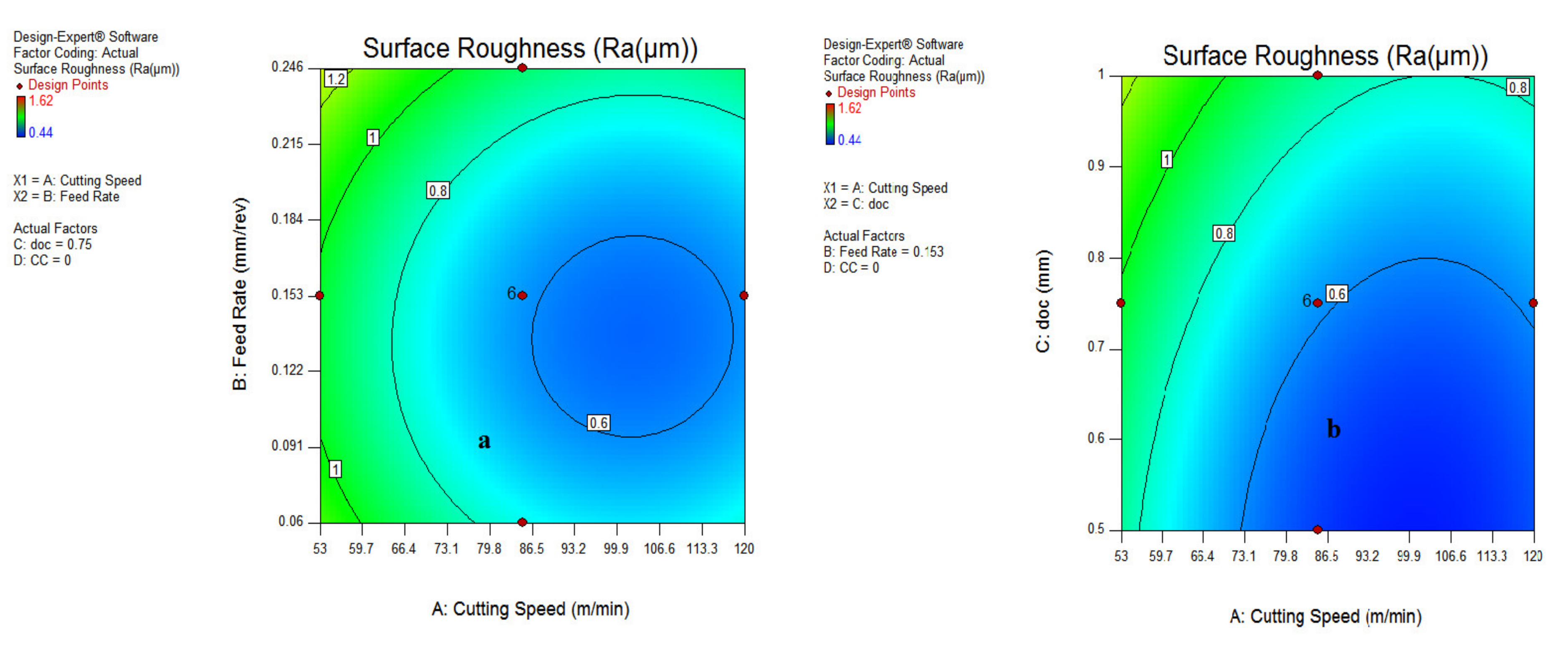

3.1.3. Contour Plot for Surface Roughness

3.2. ANOVA Investigation for Cutting Temperature

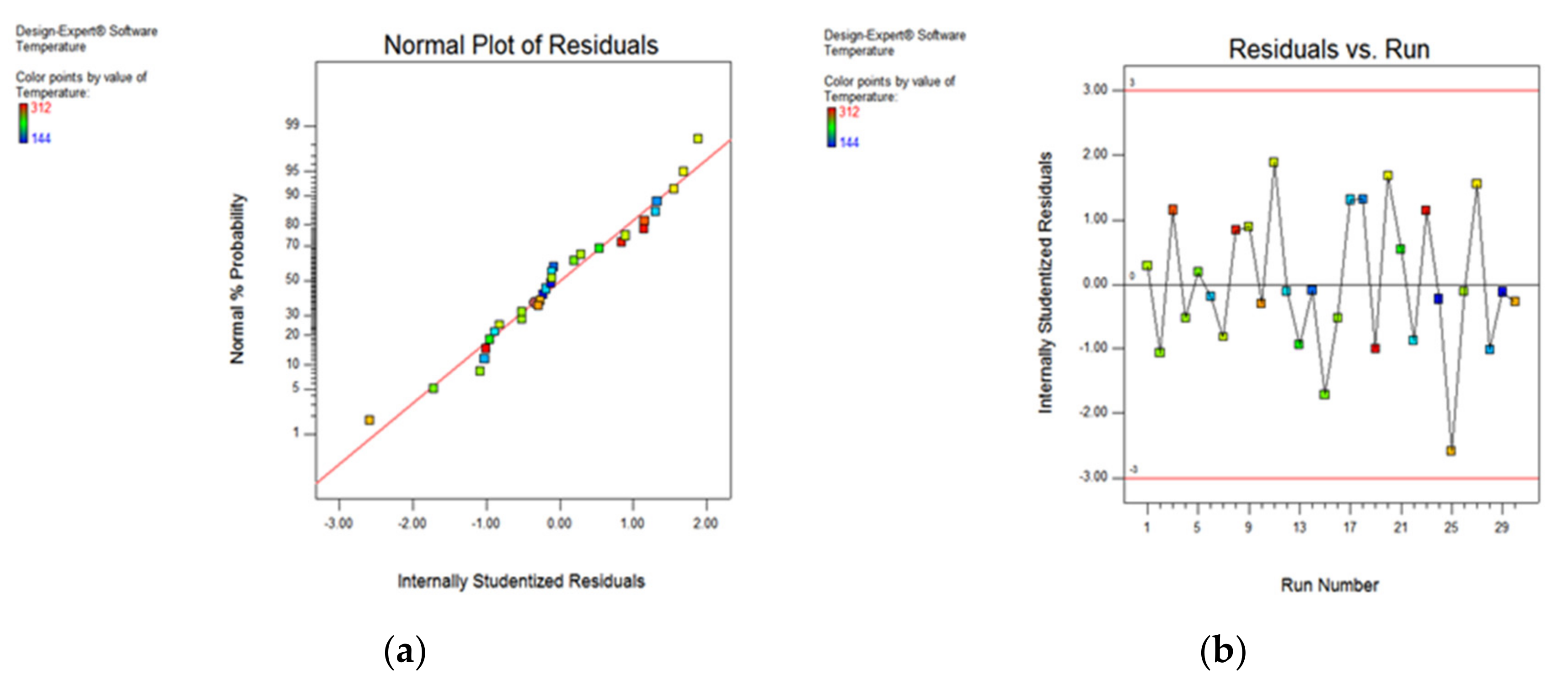

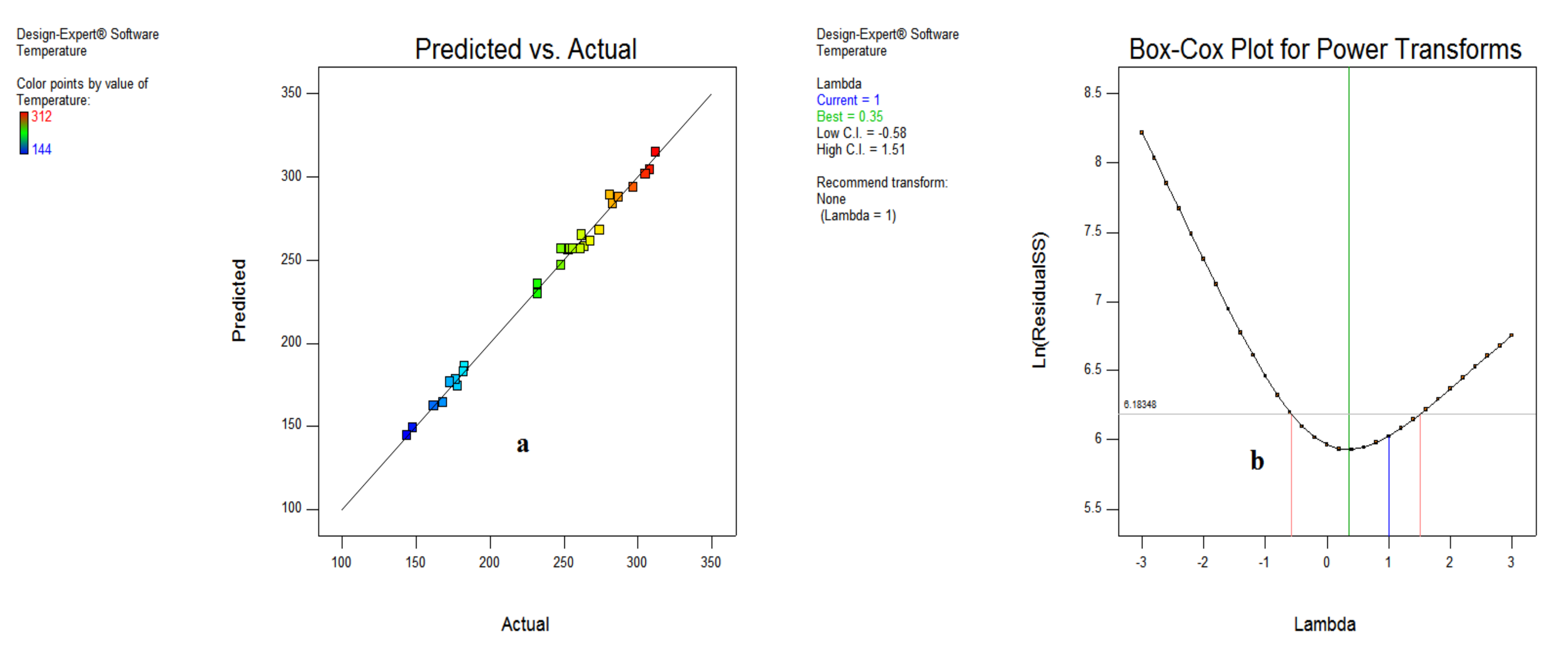

3.2.1. Statistical Plots for Cutting Temperature

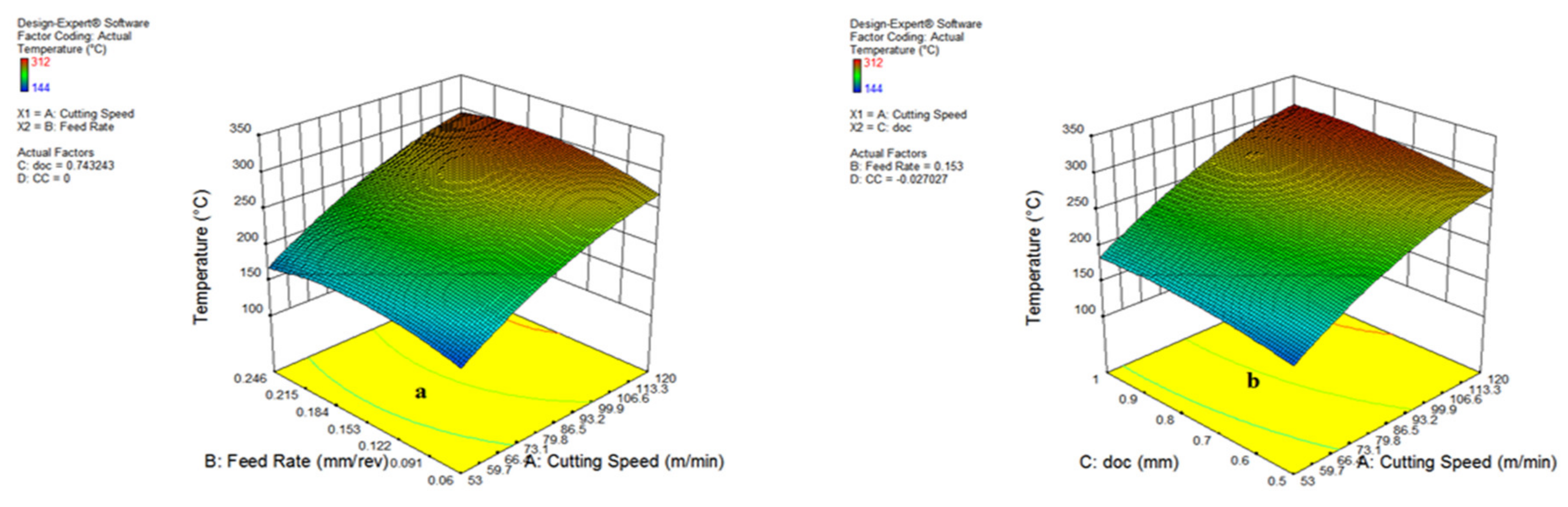

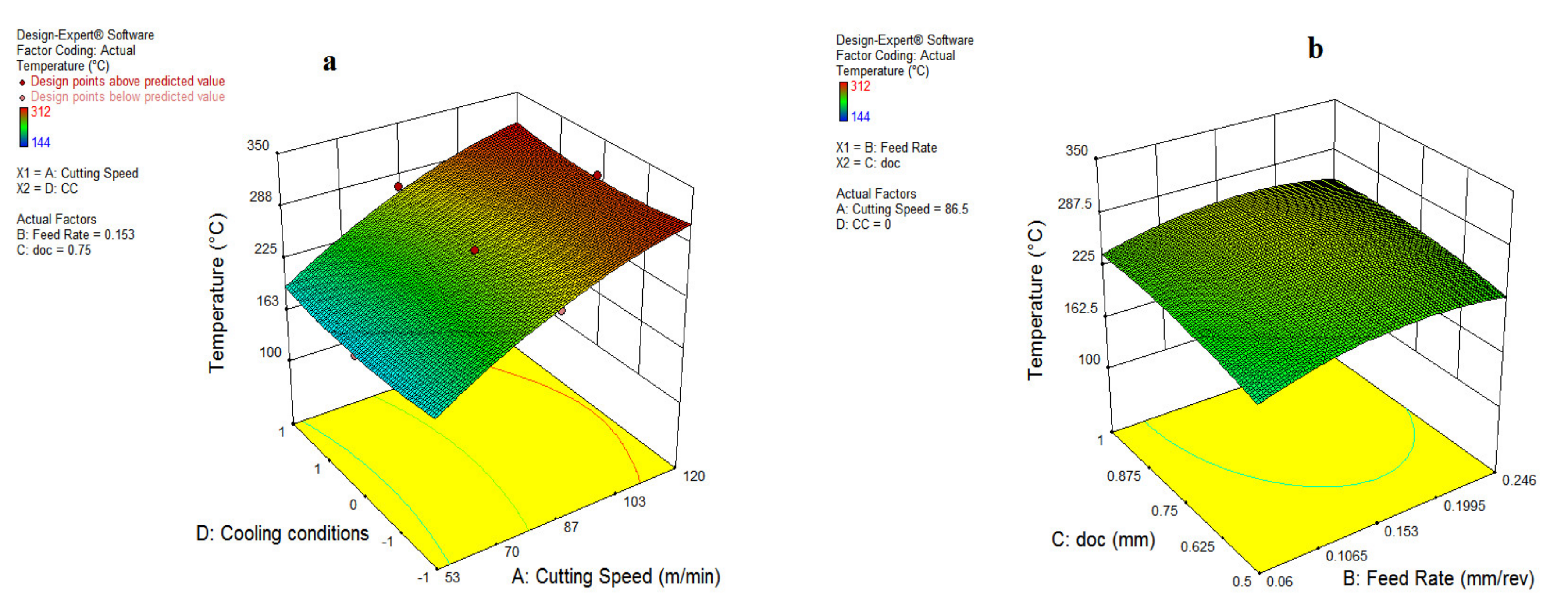

3.2.2. Factor Affecting Cutting Temperature

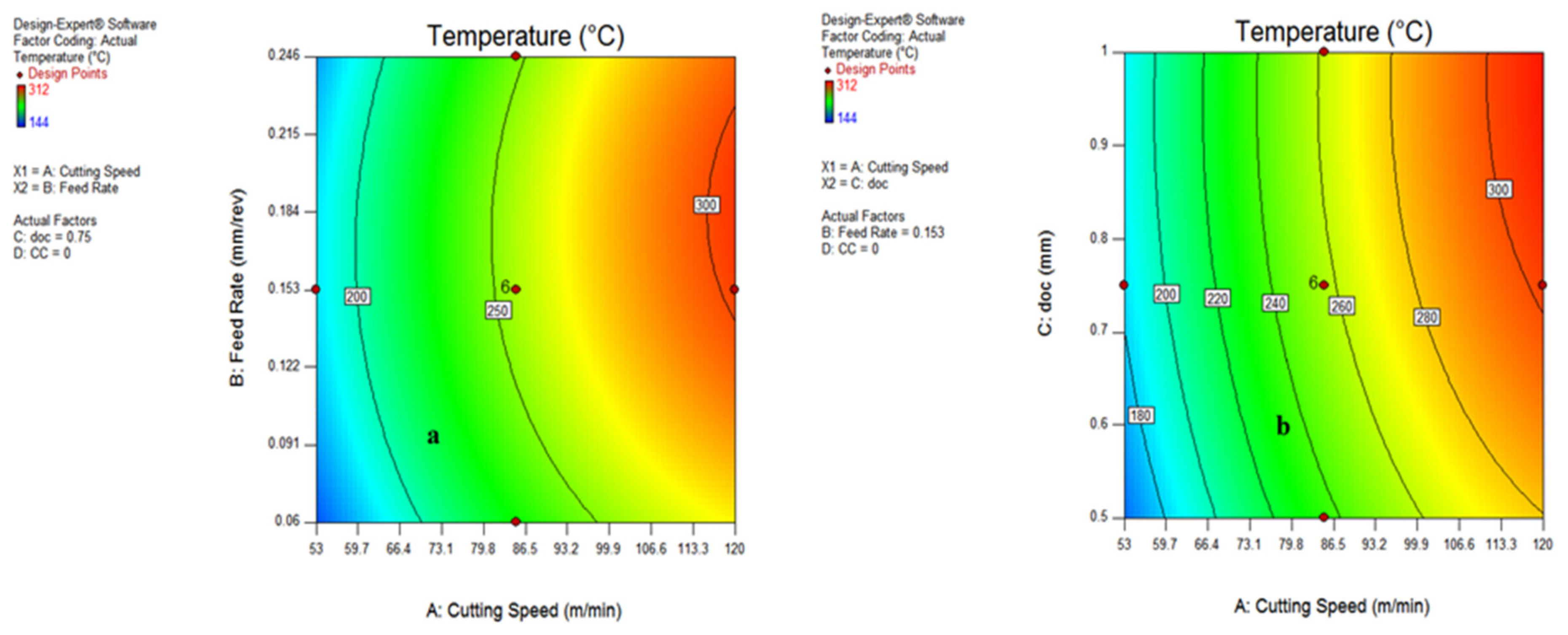

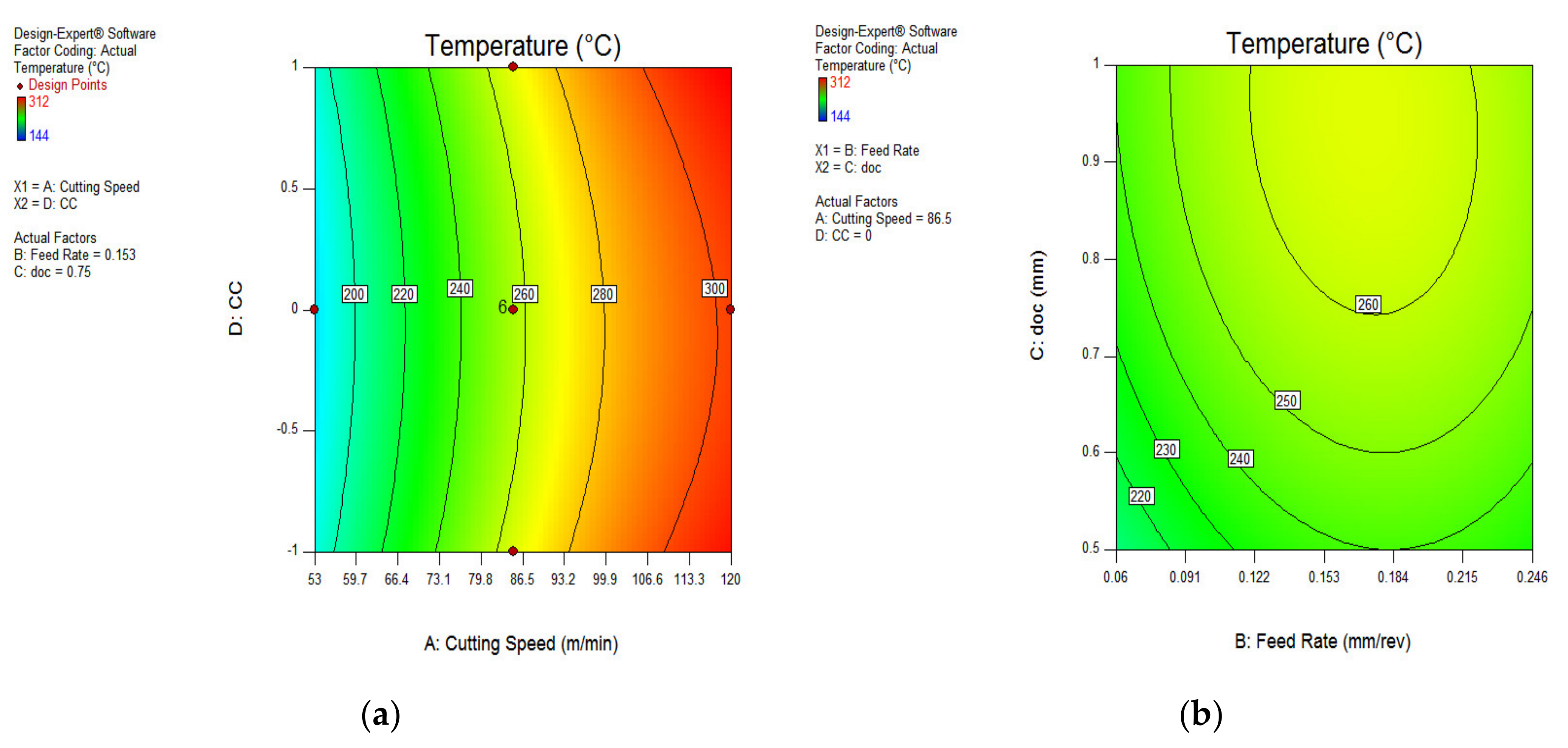

3.2.3. Contour Plot for Temperature

3.3. ANOVA Examination for Chip Reduction Coefficient

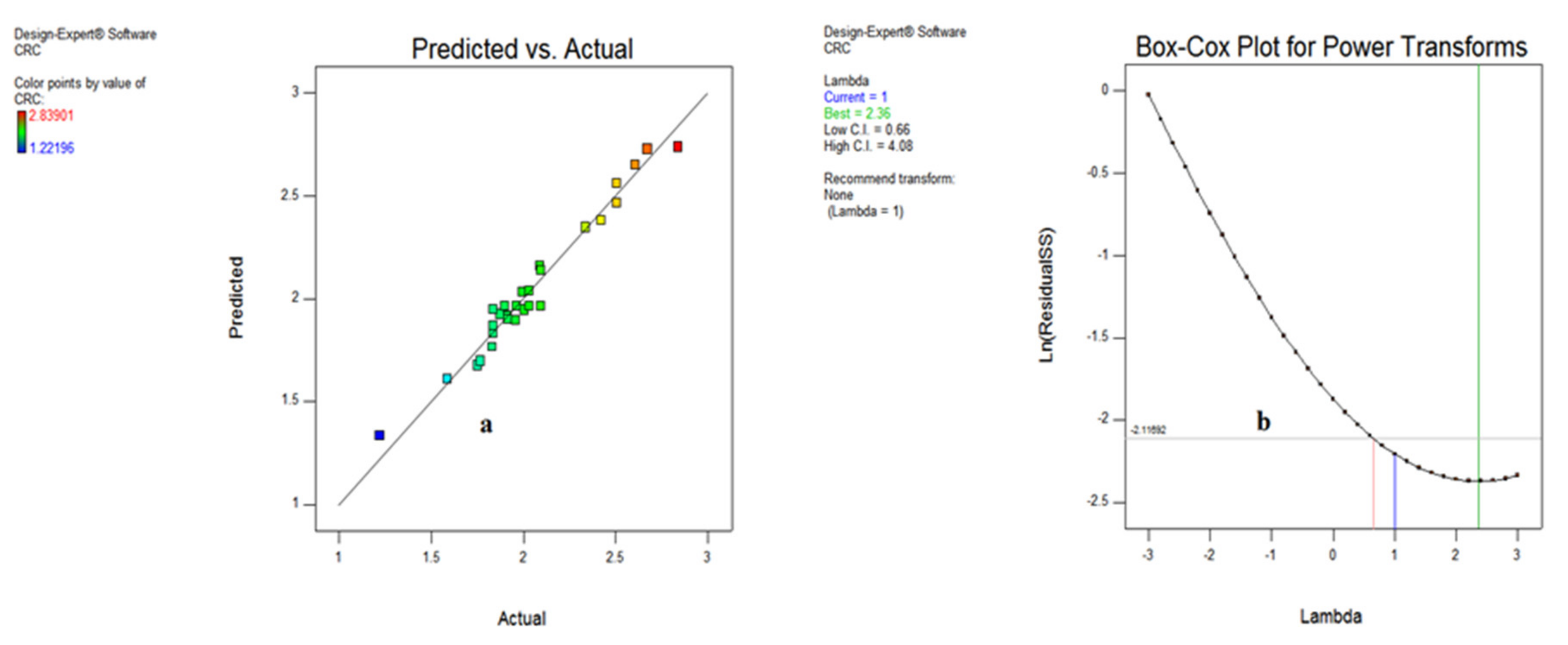

3.3.1. Statistical Plots for Chip Reduction Coefficient (CRC)

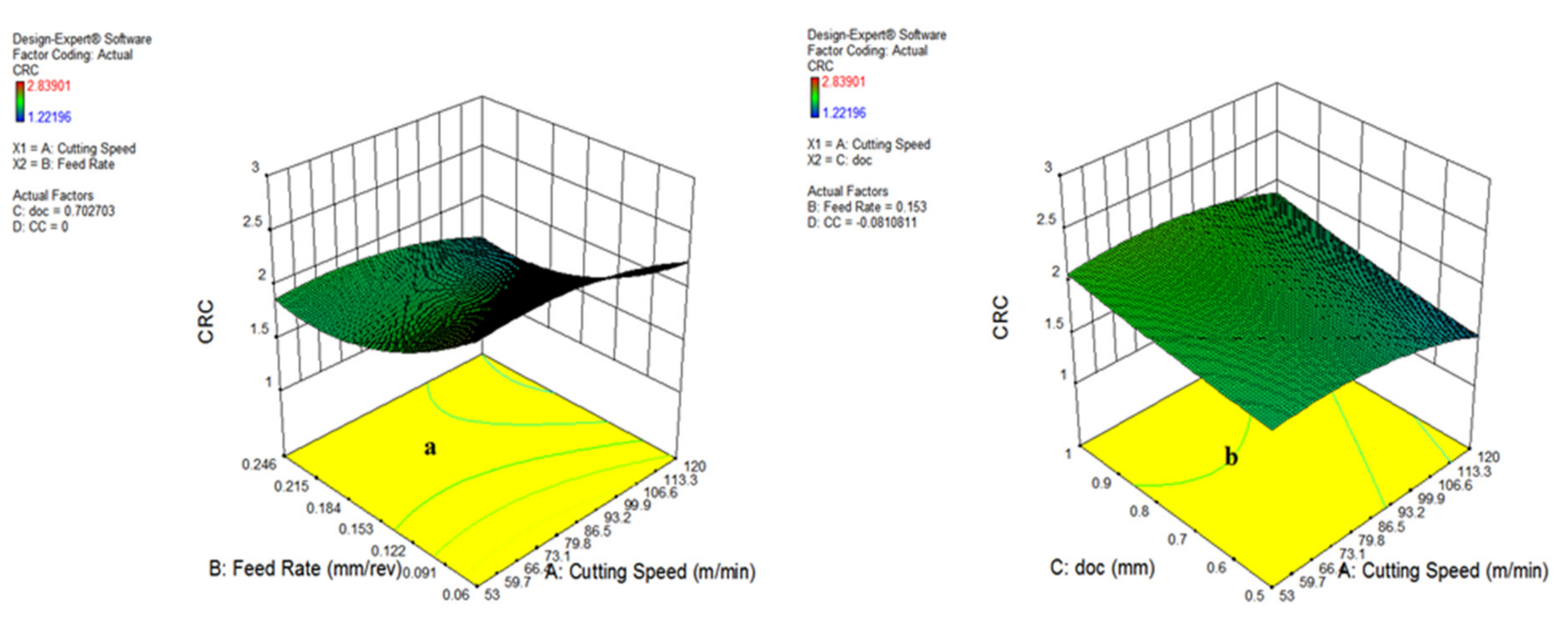

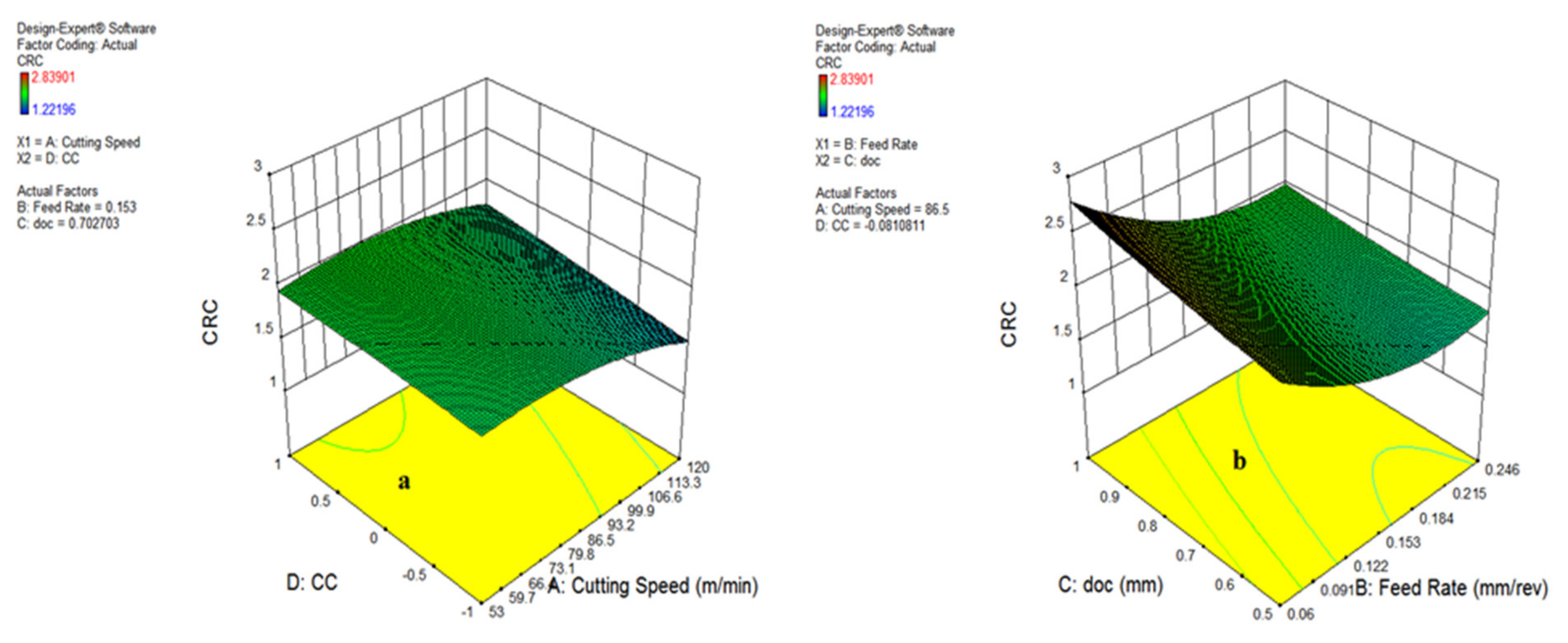

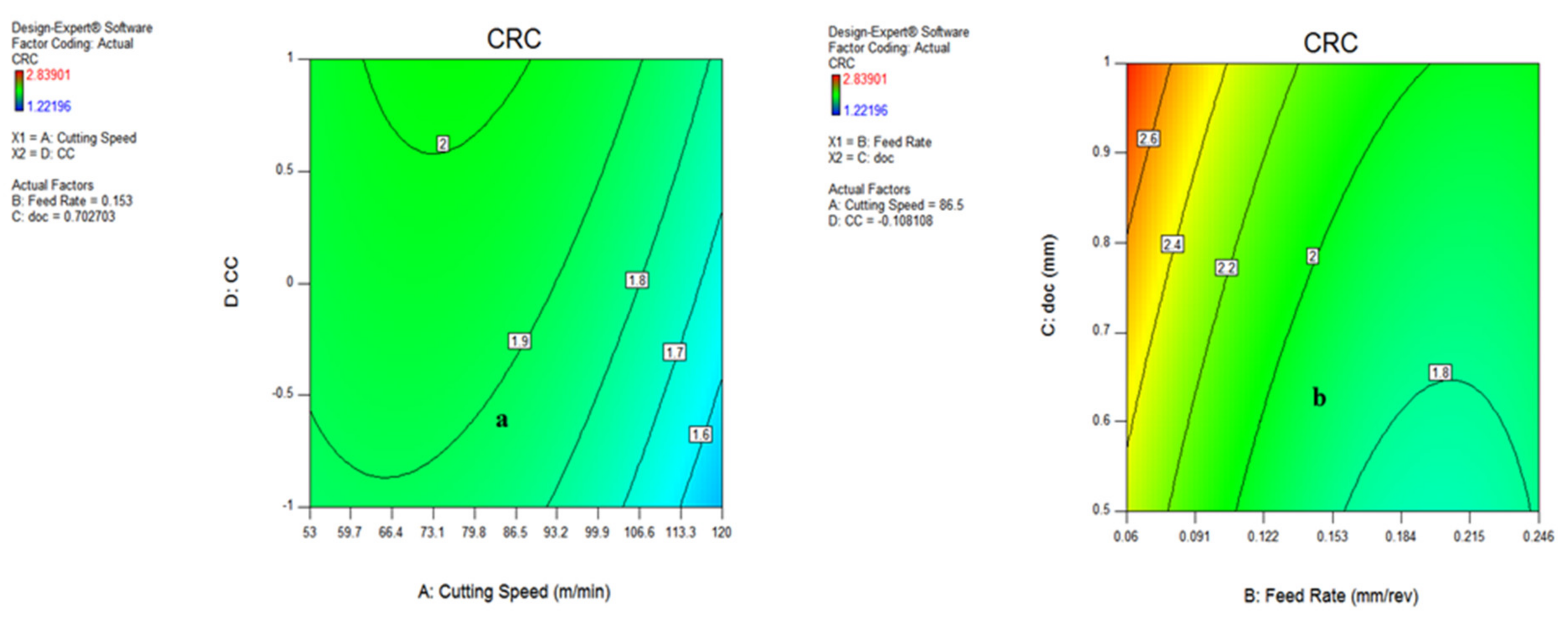

3.3.2. Influence of Process Parameter on Chip Reduction Coefficient (CRC)

3.3.3. Contour Plot for Chip Reduction Coefficient (CRC)

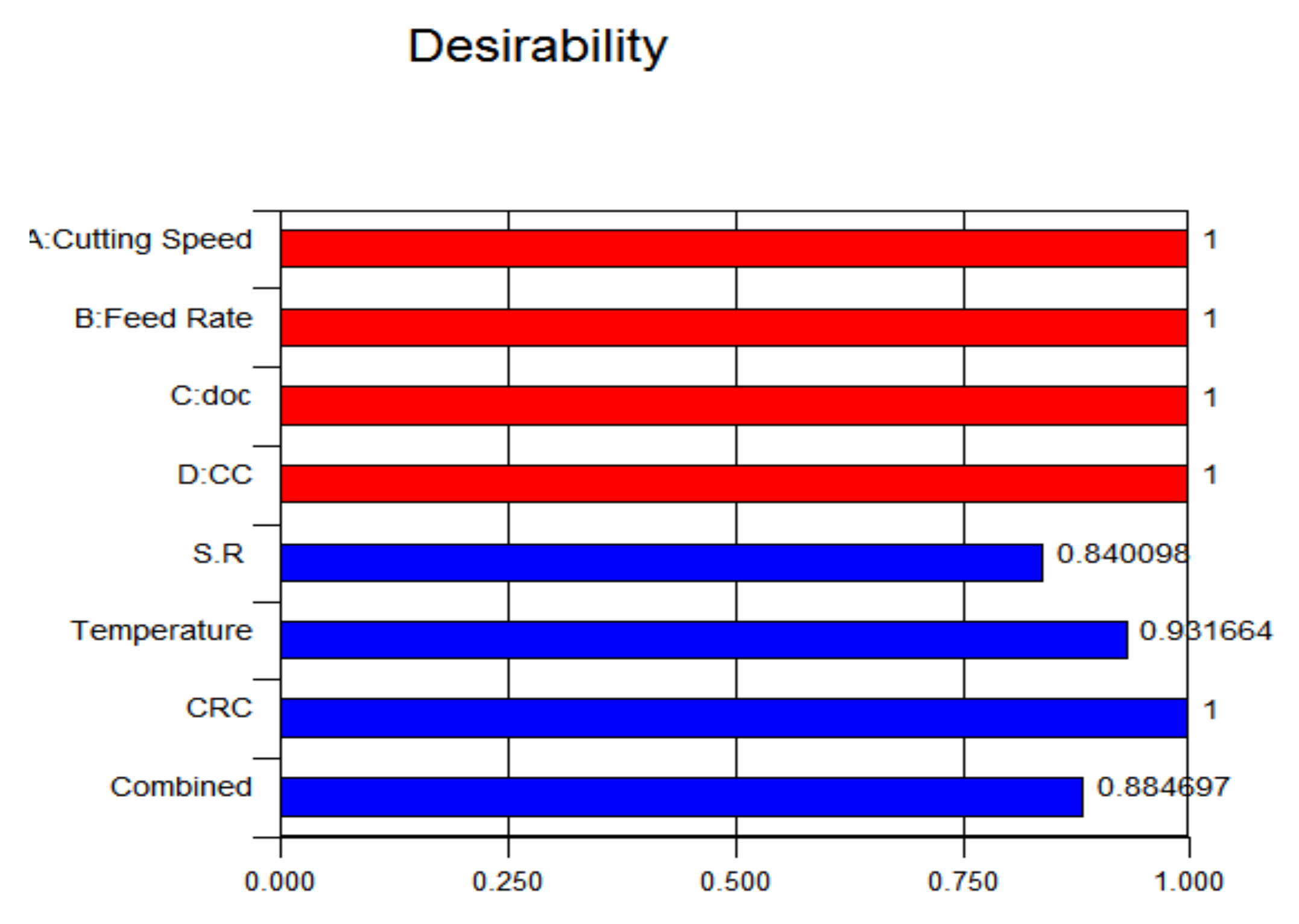

3.4. Evaluation of Desirability

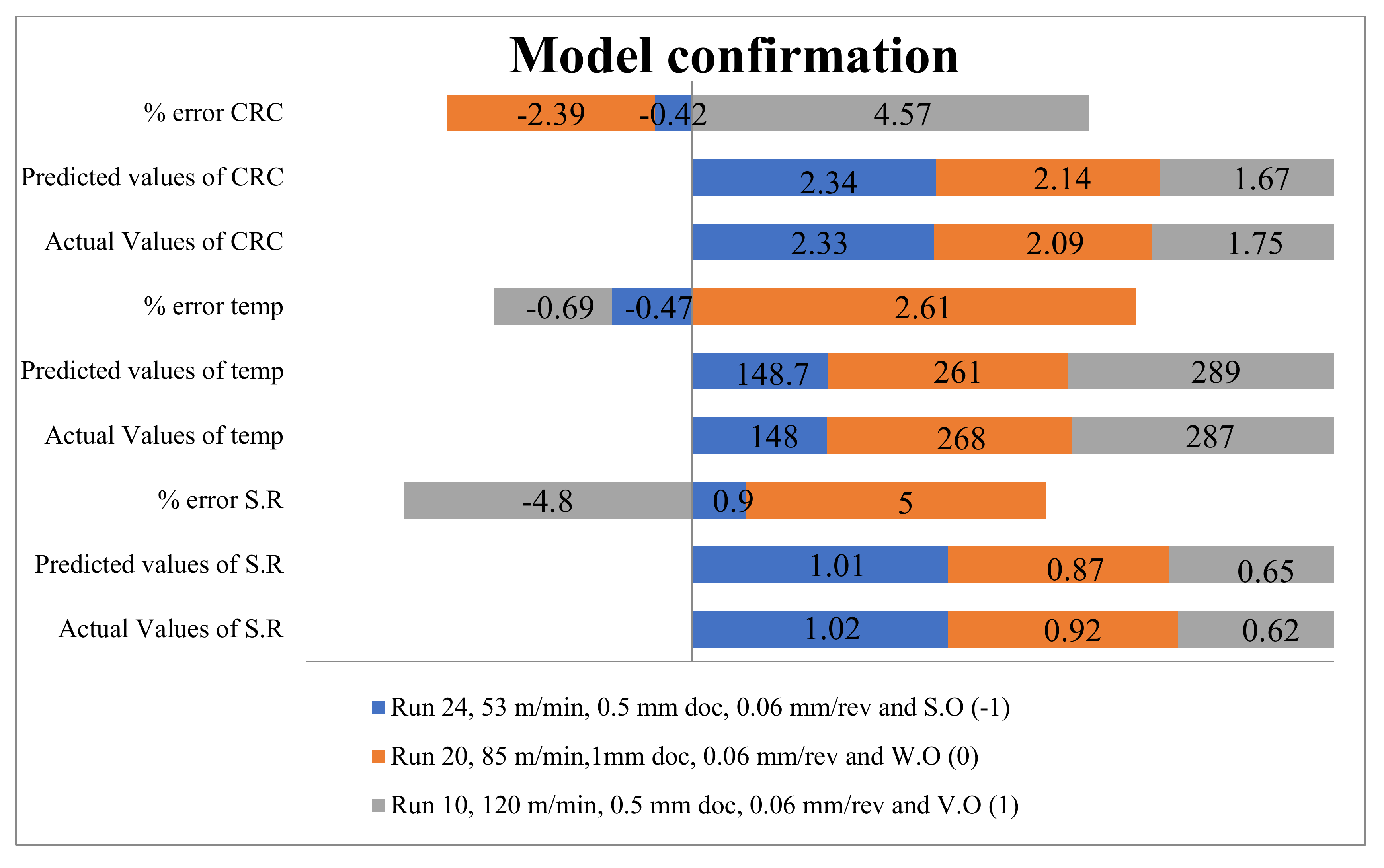

3.5. Confirmation of Model

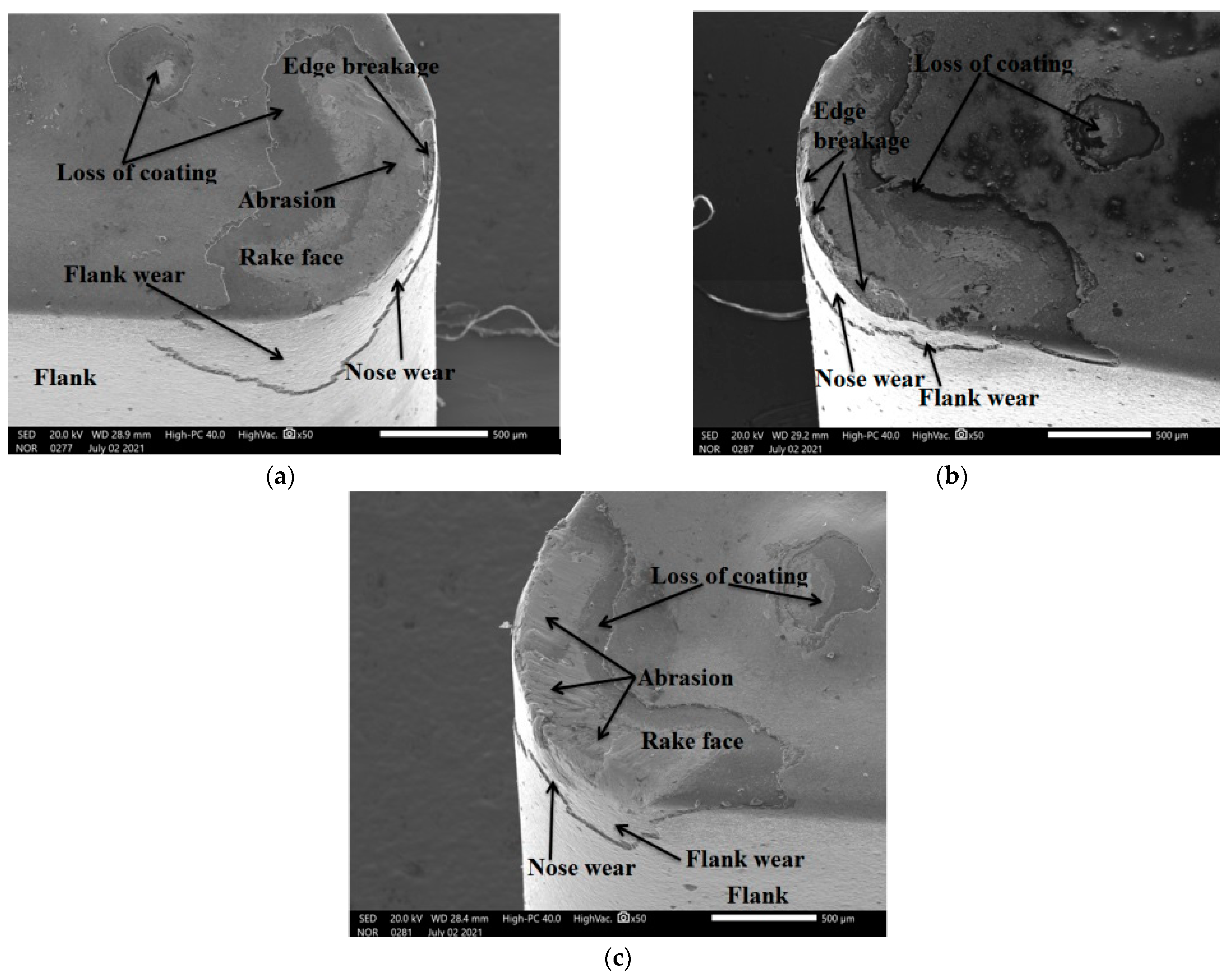

3.6. Analysis of Tool Wear

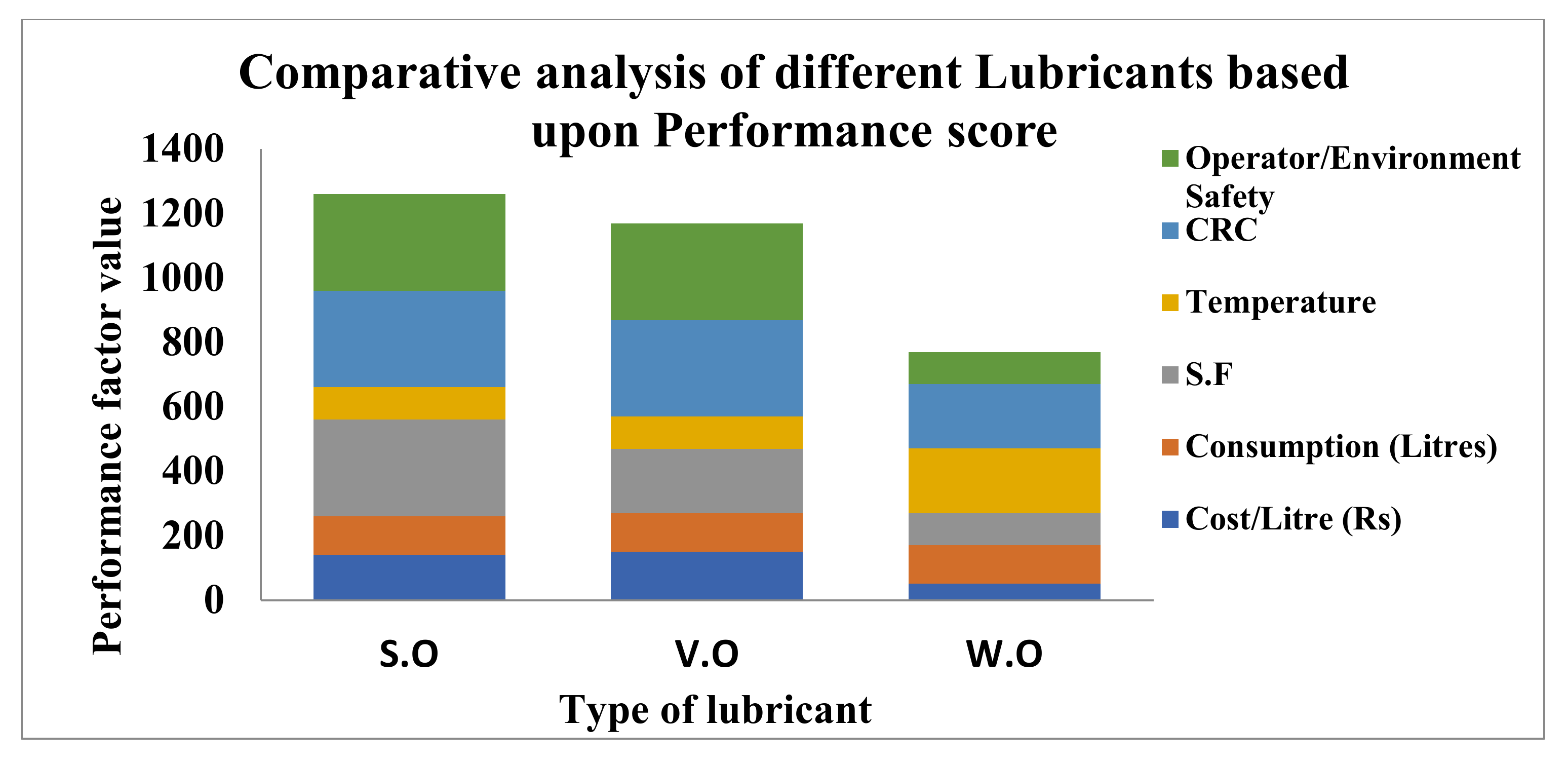

4. Cost Benefits Analysis of MQL with Other Techniques

5. Conclusions

- Machining of Hastelloy C-276 is hard; therefore, the application of an efficient cooling and lubrication system is required to enhance the surface quality, diminish heat generation and minimize CRC at various ranges of input variables.

- Cutting velocity and feed rate has an inverse impact on surface roughness; further, the variation in depth of cut and coolant type alter surface roughness due to the impact of higher heat generation and differential cooling action.

- As per the experimental observations, surface roughness is highly influenced by depth of cut as well as feed rate; however, cutting oils have no major difference for surface finish, which indicates that vegetable oil and waste oil can also be applied for metal machining.

- The SEM micrographs reported a loss of coating, nose and flank wear during all lubrication conditions. Further, tool failure occurred at speed of 120 m/min in S.O as well as V.O, while for W.O the life ended at 85 and 120 m/min.

- The implementation of environmental adaptable lubricants, MQL and circular economy techniques is an approach to achieve the UN sustainable goal (SDG-12). Its overall impact on machining performance, along with the environment, has been listed in Table 10.

- The least temperature was found during the vegetable oil because of its significant lubrication action along with air-assisted jet aimed at the rake face of the cutting insert. Further, tt was been noticed that the waste oil reduced the temperature by a notable amount; despite its good lubrication action. However, a few patterns of smoke were observed during the application of the waste oil.

- Chip reduction coefficient is majorly impacted by cutting speed and feed rate, but not influenced by coolant type due the similar cooling and lubrication obtained in different conditions. However, a lower CRC was observed during vegetable oil cooling compared to other oils.

- With a rise in v and f, the chip reduction coefficient reduces because of a change in uncut chip thickness. However, with the involvement of depth of cut, the CRC reduces up to a certain limit and then start increasing.

- As per ANOVA analysis, the cutting speed majorly influenced the SR, significantly trailed by depth of cut, coolant type and feed rate. Subsequently, identical trends were also recorded for the first two variables, but a non-significance of coolant types was noted during cutting temperature. However, CRC was dominated by feed rate accompanied with depth of cut, cutting speed and coolant type.

- The maximum percentage of error for SR, temperature and CRC was found as 5, 2.61 and 4.57%, respectively, which means that the models are significant.

- The combined desirability of the system is 0.88, which is greater than 0.8, indicating that the set values of the input parameters are within the range of acceptable levels.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Singh, G.; Aggarwal, V.; Singh, S. Experimental investigations into machining performance of Hastelloy C-276 in different cooling environments. Mater. Manuf. Processes 2021, 36, 1789–1799. [Google Scholar] [CrossRef]

- Zheng, G.; Sridharan, K. Corrosion of structural alloys in high-temperature molten fluoride salts for applications in molten salt reactors. JOM-US 2018, 70, 1535–1541. [Google Scholar] [CrossRef] [Green Version]

- Gloria, A.; Montanari, R.; Richetta, M.; Varone, A. Alloys for aeronautic applications: State of the art and perspectives. Metals 2019, 9, 662. [Google Scholar] [CrossRef] [Green Version]

- Rahman, M.S.; Ding, J.; Beheshti, A.; Zhang, X.; Polycarpou, A.A. Elevated temperature tribology of Ni alloys under helium environment for nuclear reactor applications. Tribol. Int. 2018, 123, 372–384. [Google Scholar] [CrossRef]

- M’Saoubi, R.; Axinte, D.; Soo, S.L.; Nobel, C.; Attia, H.; Kappmeyer, G.; Engin, S.; Sim, W.M. High performance cutting of advanced aerospace alloys and composite materials. Proc. CIRP 2015, 64, 557–580. [Google Scholar] [CrossRef]

- Thakur, A.; Gangopadhyay, S. State-of-the-art in surface integrity in machining of nickel-based super alloys. Int. J. Mach. Tool Manuf. 2016, 100, 25–54. [Google Scholar] [CrossRef]

- Razak, N.H.; Rahman, M.M.; Kadirgama, K. Response surface design model to predict surface roughness when machining Hastelloy C-2000 using uncoated carbide insert. IOP Conf. Ser. Mater. Sci. Eng. 2012, 36, 12–22. [Google Scholar] [CrossRef]

- Hegab, H.; Umer, U.; Soliman, M.; Kishawy, H.A. Effects of nano-cutting fluids on tool performance and chip morphology during machining Inconel 718. Int. J. Adv. Manuf. Tech. 2018, 96, 3449–3458. [Google Scholar] [CrossRef]

- Magri, A.; Diniz, A.E.; Suyama, D.-I. Evaluating the use of high-pressure coolant in turning process of Inconel 625 nickel-based alloy. Proceedings of the Institution of Mechanical Engineers, Part B. J. Eng. Manuf. 2018, 232, 1182–1192. [Google Scholar] [CrossRef]

- Dhananchezian, M.; Rajashekar, G.; Narayanan, S.S. Study The effect of cryogenic cooling on machinability characteristics during turning duplex stainless steel. Mater. Today Proc. 2018, 5, 12062–12070. [Google Scholar] [CrossRef]

- Deshpande, Y.V.; Andhare, A.B.; Padole, P.M. How cryogenic techniques help in machining of nickel alloys. A review. Mach. Sci. Technol. 2018, 22, 543–584. [Google Scholar] [CrossRef]

- Shokrani, A.; Dhokia, V.; Muñoz-Escalona, P.; Newman, S.T. State-of-the-art cryogenic machining and processing. Int. J. Comp. Integr. Manuf. 2013, 26, 616–648. [Google Scholar] [CrossRef] [Green Version]

- Behera, B.C.; Alemayehu, H.; Ghosh, S.; Rao, P.V. A comparative study of recent lubri-coolant strategies for turning of Ni-based superalloy. J. Manuf. Process. 2017, 30, 541–552. [Google Scholar] [CrossRef]

- Hribersek, M.; Pusavec, F.; Rech, J.; Kopac, J. Modeling of machined surface characteristics in cryogenic orthogonal turning of inconel 718. Mach. Sci. Technol. 2018, 22, 829–850. [Google Scholar] [CrossRef]

- Parida, A.K. Analysis of chip geometry in hot machining of Inconel 718 alloy. Iran. J. Sci. Technol. Trans. Mech. Eng. 2018, 43, 155–164. [Google Scholar] [CrossRef]

- Thakur, A.; Gangopadhyay, S.; Maity, K.P. Effect of cutting speed and CVD multilayer coating on machinability of Inconel 825. Surf. Eng. 2014, 30, 516–523. [Google Scholar] [CrossRef]

- Ross, K.N.S.; Manimaran, G. Effect of cryogenic coolant on machinability of difficult-to-machine Ni–Cr alloy using PVD-TiAlN coated WC tool. J. Braz. Soc. Mech. Sci. 2019, 41, 44. [Google Scholar] [CrossRef]

- Akhtar, W.; Sun, J.; Sun, P.; Chen, W.; Saleem, Z. Tool wear mechanisms in the machining of Nickel based superalloys: A review. Appl. Mech. Mater. 2014, 9, 106–119. [Google Scholar]

- Rakesh, M.; Datta, S. Effects of cutting speed on chip characteristics and tool wear mechanisms during dry machining of Inconel 718 using uncoated WC tool. Arab. J. Sci. Eng. 2019, 44, 7423–7440. [Google Scholar] [CrossRef]

- Sivaiah, P.; Chakradhar, D. Influence of cryogenic coolant on turning performance characteristics: A comparison with wet machining. Mater. Manuf. Process 2017, 32, 1475–1485. [Google Scholar] [CrossRef]

- Sivaraman, V.; Sankaran, S.; Vijayaraghavan, L. The effect of cutting parameters on cutting force during turning multiphase microalloyed steel. Proc. CIRP 2012, 4, 157–160. [Google Scholar] [CrossRef] [Green Version]

- Dinesh, S.; Senthilkumar, V.; Asokan, P. Experimental studies on the cryogenic machining of biodegradable ZK60 Mg alloy using micro-textured tools. Mater. Manuf. Process 2017, 32, 979–987. [Google Scholar] [CrossRef]

- Sivaiah, P. Experimental investigation and modelling of MQL assisted turning process during machining of 15-5 PH stainless steel using response surface methodology. SN Appl. Sci. 2019, 1, 913. [Google Scholar] [CrossRef] [Green Version]

- Sharma, J.; Sidhu, B.-S. Investigation of effects of dry and near dry machining on AISI D2 steel using vegetable oil. J. Clean. Prod. 2014, 66, 619–623. [Google Scholar] [CrossRef]

- Sivaiah, P.; Chakradhar, D. Effect of cryogenic coolant on turning performance characteristics during machining of 17-4 PH stainless steel: A comparison with MQL, wet, dry machining. CIRP J. Manuf. Sci. Technol. 2018, 21, 86–96. [Google Scholar] [CrossRef]

- Montgomery, D.C. Design and Analysis of Experiments; John and Wiley Sons: Hoboken, NJ, USA, 2001. [Google Scholar]

- Arbizu, I.P.; Perez, C.L. Surface roughness prediction by factorial design of experiments in turning processes. J. Mater. Process. Technol. 2003, 143, 390–397. [Google Scholar] [CrossRef]

- Gupta, M.K.; Sood, P.K.; Sharma, V.S. Machining parameters optimization of titanium alloy using response surface methodology and particle swarm optimization under minimum quantity lubrication environment. Mater. Manuf. Process. 2016, 31, 1671–1682. [Google Scholar] [CrossRef]

- Sivaiah, P.; Chakradhar, D. Analysis and modeling of cryogenic turning operation using response surface methodology. Silicon 2018, 10, 2751–2768. [Google Scholar] [CrossRef]

- Singh, G.; Aggarwal, V.; Singh, S. Critical review on ecological, economical and technological aspects of minimum quantity lubrication towards sustainable machining. J. Clean. Prod. 2020, 271, 122185. [Google Scholar] [CrossRef]

- Xu, K.; Zou, B.; Huang, C.; Yao, Y.; Zhou, H.; Liu, Z. Machinability of Hastelloy C-276 Using Hot-pressed Sintered Ti(C7N3)-based Cermet Cutting Tools. Chin. J. Mech. Eng. 2015, 28, 599–606. [Google Scholar] [CrossRef]

- Gupta, M.K.; Jamil, M.; Wang, X.; Song, Q.; Liu, Z.; Mia, M.; Hegab, H.; Khan, A.M.; Collado, A.G.; Pruncu, C.I. Performance Evaluation of Vegetable Oil-based Nano-Cutting Fluids in Environmentally Friendly Machining of Inconel-800 Alloy. Materials 2019, 12, 2792. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sen, B.; Mia, M.; Krolczyk, G.M.; Mandal, U.K.; Mondal, S.P. Eco-Friendly Cutting Fluids in Minimum Quantity Lubrication Assisted Machining: A Review on the Perception of Sustainable Manufacturing. Int. J. Precis. Eng. Manuf.-Green Technol. 2021, 8, 249–280. [Google Scholar] [CrossRef] [Green Version]

- Singh, S.; Chohan, J.S.; Singh, G. Experimental investigation into machining of hastelloy C-276 during different cooling environments. Mater. Today Proc. 2021, 48, 2214–7853. [Google Scholar] [CrossRef]

- Singh, G.; Singh, S.; Aggarwal, V.; Singh, J.; Grover, N.; Gill, A.S. Ecological aspects of cutting fluids applications in small scale industries of Northern India region. Mater. Today Proc. 2022, 48, 1325–1331. [Google Scholar] [CrossRef]

- Pervaiz, S.; Anwar, S.; Qureshi, I.; Ahmed, N. Recent advances in the machining of titanium alloys using minimum quantity lubrication (MQL) based techniques. Int. J. Precis. Eng. Manuf.-Green Technol. 2019, 6, 133–145. [Google Scholar] [CrossRef]

- Mikolajczyk, T. Modeling of Minimal thickness cutting layer influence on surface roughness in turning. In Applied Mechanics and Materials; Trans Tech Publications Ltd.: Bäch SZ, Switzerland, 2014; Volume 656, pp. 262–269. [Google Scholar]

- Pimenov, D.Y.; Mia, M.; Gupta, M.K.; Machado, A.R.; Tomaz, Í.V.; Sarikaya, M.; Kapłonek, W. Improvement of machinability of Ti and its alloys using cooling-lubrication techniques: A review and future prospect. J. Mater. Res. Technol. 2021, 11, 719–753. [Google Scholar] [CrossRef]

- Yap, T.C. Roles of cryogenic cooling in turning of superalloys, ferrous metals, and viscoelastic polymers. Technologies 2019, 7, 63. [Google Scholar] [CrossRef] [Green Version]

- Yap, T.C.; Sivaraos, C.S.; Lim, C.S.; Leau, J.W. Surface roughness and cutting forces in cryogenic turning of carbon steel. J. Eng. Sci. Technol. 2015, 10, 911–920. [Google Scholar]

- Hong, S.Y.; Ding, Y.; Jeong, J. Experimental evaluation of friction coefficient and liquid nitrogen lubrication effect in cryogenic machining. Mach. Sci. Technol. 2002, 6, 235–250. [Google Scholar] [CrossRef]

- Hong, S.Y. Economical and ecological cryogenic machining. J. Manuf. Sci. Eng. 2001, 123, 331–338. [Google Scholar] [CrossRef]

- Da Silva, L.R.R.; de Souza Ruzzi, R.; Costa, E.S.; Sales, W.F.; Jackson, M.J.; Machado, Á.R. Influence of milling direction in the machinability of Inconel 718 with submicron grain cemented carbide tools. Int. J. Adv. Manuf. Technol. 2019, 105, 1343–1355. [Google Scholar] [CrossRef]

- Abrão, B.S.; Pereira, M.F.; da Silva, L.R.R.; Machado, Á.R.; Gelamo, R.V.; de Freitas, F.M.C.; Mia, M.; da Silva, R.B. Improvements of the MQL Cooling-Lubrication Condition by the Addition of Multilayer Graphene Platelets in Peripheral Grinding of SAE 52100 Steel. Lubricants 2021, 9, 79. [Google Scholar] [CrossRef]

- Clemente, T.E.; Cahoon, E.B. Soybean oil: Genetic approaches for modification of functionality and total content. Plant Physiol. 2009, 151, 1030–1040. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ranjan, P. Hiremath SS. Role of textured tool in improving machining performance: A review. J. Manuf. Process. 2019, 43, 47–73. [Google Scholar] [CrossRef]

- Zhang, P.; Liu, Z.; Du, J.; Su, G.; Zhang, J.; Xu, C. On machinability and surface integrity in subsequent machining of additively-manufactured thick coatings: A review. J. Manuf. Process. 2020, 53, 123–143. [Google Scholar] [CrossRef]

- Shams, O.A.; Pramanik, A.; Chandratilleke, T.T. Thermalassisted machining of titanium alloys. In Advanced Manufacturing Technologies; Springer: Cham, Switzerland, 2017; pp. 49–76. [Google Scholar] [CrossRef]

- Yan, P.; Rong, Y.; Wang, G. The effect of cutting fluids applied in metal cutting process. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2016, 230, 19–37. [Google Scholar] [CrossRef]

- Gupta, M.K.; Song, Q.; Liu, Z.; Sarikaya, M.; Jamil, M.; Mia, M.; Kushvaha, V.; Singla, A.K.; Li, Z. Ecological, economical and technological perspectives based sustainability assessment in hybrid-cooling assisted machining of Ti-6Al-4 V alloy. Sustain. Mater. Technol. 2020, 26, e00218. [Google Scholar] [CrossRef]

- Agrawal, C.; Wadhwa, J.; Pitroda, A.; Pruncu, C.I.; Sarikaya, M.; Khanna, N. Comprehensive analysis of tool wear, tool life, surface roughness, costing and carbon emissions in turning Tie6Ale4V titanium alloy: Cryogenic versus wet machining. Tribol. Int. 2021, 153, 106597. [Google Scholar] [CrossRef]

- Goindi, G.S.; Sarkar, P. Dry machining: A step towards sustainable machining e challenges and future directions. J. Clean. Prod. 2017, 165, 1557-e71. [Google Scholar] [CrossRef]

- Arpa, O.; Yumrutas, R.; Demirbas, A. Production of diesel-like fuel from waste engine oil by pyrolitic distillation. Appl. Energy 2010, 87, 122–127. [Google Scholar] [CrossRef]

- Available online: https://www.mordorintelligence.com/ (accessed on 14 February 2022).

- Sales, W.F.; Diniz, A.E.; Machado, A. Application of cutting fluids in machining processes. J. Braz. Soc. Mech. Sci. 2001, 23, 225–240. [Google Scholar] [CrossRef]

- Klamerus-Iwan, A.; Błonska, E.; Lasota, J.; Kalandyk, A.; Waligorski, P. Influence of oil contamination on physical and biological properties of forest soil after chainsaw use. Water Air Soil Pollut. 2015, 226, 389. [Google Scholar] [CrossRef] [Green Version]

- Pinheiro, C.T.; Quina, M.J.; Gando-Ferreira, L.M. Management of waste lubricant oil in Europe: A circular economy approach. Crit. Rev. Environ. Sci. Technol. 2021, 51, 2015–2050. [Google Scholar] [CrossRef]

- Vwioko, D.E.; Anoliefo, G.O.; Fashemi, S.D. Metal concentration in plant tissues of Ricinus communis L. (Castor oil) grown in soil contaminated with spent lubricating oil. J. Appl. Sci. Environ. Manag. 2006, 10, 127–134. [Google Scholar] [CrossRef] [Green Version]

- Available online: https://www.fuchs.com/de/en/ (accessed on 14 February 2022).

- Available online: https://www.globenewswire.com/ (accessed on 14 February 2022).

- Lugt, P.M. Grease Lubrication in Rolling Bearings; John Wiley & Sons: Hoboken, NJ, USA, 2012. [Google Scholar]

- Speight, J.G.; Exall, D.I. Rerefining of Used Lubricating Oils; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar]

- Mortier, R.M.; Fox, M.F.; Orszulik, S.T. Chemistry and Technology of Lubricants, 3rd ed.; Springer: Dordrecht, The Netherlands, 2010. [Google Scholar]

- Available online: https://www.mordorintelligence.com/industry-reports/asean-lubricants-market/ (accessed on 10 February 2022).

- Yazman, Ş.; Köklü, U.; Urtekin, L.; Morkavuk, S.; Gemi, L. Experimental study on the effects of cold chamber die casting parameters on high-speed drilling machinability of casted AZ91 alloy. J. Manuf. Processes 2020, 57, 136–152. [Google Scholar] [CrossRef]

- Koklu, U.; Morkavuk, S.; Urtekin, L. Effects of the drill flute number on drilling of a casted AZ91 magnesium alloy. Mater. Test. 2019, 61, 260–266. [Google Scholar] [CrossRef]

- Carvalho, D.O.A.; da Silva, L.R.R.; Sopchenski, L.; Jackson, M.J.; Machado, Á.R. Performance evaluation of vegetable-based cutting fluids in turning of AISI 1050 steel. Int. J. Adv. Manuf. Technol. 2019, 103, 1603–1619. [Google Scholar] [CrossRef]

- Rizvi, S.Q.A. A Comprehensive Review of Lubricant Chemistry, Technology, Selection, and Design; ASTM International: West Conshohocken, PA, USA, 2009. [Google Scholar]

- Pinheiro, C.T.; Pais, R.F.; Quina, M.J.; Gando-Ferreira, L.M. Regeneration of waste lubricant oil with distinct properties by extraction-flocculation using green solvents. J. Clean. Prod. 2018, 200, 578–587. [Google Scholar] [CrossRef]

- Pinheiro, C.T.; Ascensão, V.R.; Reis, M.S.; Quina, M.J.; Gando-Ferreira, L.M. A data-driven approach for the study of coagulation phenomena in waste lubricant oils and its relevance in alkaline regeneration treatments. Sci. Total Environ. 2017, 599–600, 2054–2064. [Google Scholar] [CrossRef]

- Bongardt, F.; Willing, A. European ecolabels for biodegradable hydraulic oils, a challenge to base materials producers and formulators. J. Synth. Lubr. 2003, 20, 53–68. [Google Scholar] [CrossRef]

- Batters, N.S. Biodegradable lubricant, what does biodegradable really mean. J. Synth. Lubr. 2005, 22, 3–18. [Google Scholar] [CrossRef]

- Alves, S.M.; Oliveira, J.F.G. Development of new cutting fluid for grinding process adjusting mechanical performance and environmental impact. J. Mater. Process. Technol. 2006, 179, 185–189. [Google Scholar] [CrossRef]

| Element | C | Si | Mn | P | S | Ni | Cr | Mo | V | W | Co | Fe |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Wt% | 0.08 | 0.03 | 0.4 | 0.01 | 0.01 | 57.9 | 15.4 | 16 | 0.05 | 3.7 | 0.3 | 5.5 |

| Hardness | Elongation (%) | Tensile Strength | Yield Strength | |||||||||

| 84 HV | 68 | 106 (ksi) | 47.9 (ksi) | |||||||||

| Properties | Synthetic Oil (ST KOOL) | Vegetable Oil (Soybean Oil) | Waste Motor Oil (10W-30) |

|---|---|---|---|

| Flash point | 230 °C | 240 °C | 120 °C |

| Specific gravity | 0.88 | 0.91 | 0.93 |

| Kinematic viscosity @ 40 °C (cSt) | 32 | 33 | 56 |

| Biodegradability [71,72] | 20–30% | 95% | 10–15% |

| GWP kg of CO2 [73] | 43–48 | 3 | 54 |

| S.N | Element | Details |

|---|---|---|

| 1 | Machine utilized | Centre Lathe (Poland made AFM TUG-40) 5.5 kW |

| 2 | Material used | Hastelloy C-276, (Φ 0.054 m × 0.55 m length) |

| 3 | Cutting tool insert | TNMG160408 |

| 4 | Tool holder | MTJNR2525M16 |

| 5 | Tool angles | −7°, −7°, 7°, 93°, 93°, 0.8 mm |

| 6 | Machining velocity (m/min) | 53, 85 and 120 (m/min) |

| 7 | Coolants | Synthetic Oil, Vegetable oil and waste motor oil (−1, 0, +1) |

| 8 | Feed rate | 0.06, 0.153 and 0.246 mm/rev (−1, 0, +1) |

| 9 | Depth of cut (doc) | 0.5, 0.75 and 1 mm |

| 10 | MQL details | Air pressure 5 bar, flow rate of 90 mL/h |

| 11 | Nozzle distance (mm) | 35 mm at 45° targeted at rake face of insert |

| 12 | Compressor | Ingersoll Rand |

| 13 | Roughness tester | HANDYSURF E-35B, TOKYO SEIMITSU |

| 14 | Heat measurement (°C) | Digital infrared thermometer MTQ580 |

| Standard | Run | Cutting Speed (m/min) | Feed Rate (mm/rev) | doc (mm) | C.C | SR (Ra µm) | Temp (°C) | CRC |

|---|---|---|---|---|---|---|---|---|

| 1 | 24 | 53 | 0.06 | 0.5 | −1 (S.O) | 1.02 | 148 | 2.33 |

| 2 | 11 | 120 | 0.06 | 0.5 | −1 (S.O) | 0.58 | 264 | 2.00 |

| 3 | 14 | 53 | 0.246 | 0.5 | −1 (S.O) | 1.21 | 162 | 1.83 |

| 4 | 30 | 120 | 0.246 | 0.5 | −1 (S.O) | 0.83 | 283 | 1.22 |

| 5 | 17 | 53 | 0.06 | 1 | −1 (S.O) | 1.42 | 178 | 2.67 |

| 6 | 25 | 120 | 0.06 | 1 | −1 (S.O) | 0.92 | 281 | 2.50 |

| 7 | 6 | 53 | 0.246 | 1 | −1 (S.O) | 1.62 | 177 | 1.95 |

| 8 | 23 | 120 | 0.246 | 1 | −1 (S.O) | 1.05 | 308 | 1.58 |

| 9 | 29 | 53 | 0.06 | 0.5 | 1 (W.O) | 0.71 | 144 | 2.42 |

| 10 | 2 | 120 | 0.06 | 0.5 | 1 (W.O) | 0.53 | 253 | 2.08 |

| 11 | 18 | 53 | 0.246 | 0.5 | 1 (W.O) | 0.89 | 168 | 1.87 |

| 12 | 10 | 120 | 0.246 | 0.5 | 1 (W.O) | 0.62 | 287 | 1.75 |

| 13 | 28 | 53 | 0.06 | 1 | 1 (W.O) | 1.08 | 173 | 2.83 |

| 14 | 3 | 120 | 0.06 | 1 | 1(W.O) | 0.83 | 297 | 2.60 |

| 15 | 22 | 85 | 0.246 | 1 | 1 (W.O) | 1.28 | 183 | 1.99 |

| 16 | 19 | 85 | 0.246 | 1 | 1(W.O) | 0.95 | 312 | 1.91 |

| 17 | 12 | 85 | 0.153 | 0.75 | 0 (V.O) | 0.99 | 182 | 1.83 |

| 18 | 8 | 85 | 0.153 | 0.75 | 0 (V.O) | 0.67 | 305 | 1.76 |

| 19 | 21 | 85 | 0.06 | 0.75 | 0 (V.O) | 0.81 | 232 | 2.50 |

| 20 | 5 | 85 | 0.246 | 0.75 | 0 (V.O) | 0.92 | 248 | 1.91 |

| 21 | 13 | 85 | 0.153 | 0.5 | 0 (V.O) | 0.52 | 232 | 1.83 |

| 22 | 20 | 85 | 0.153 | 1 | 0 (V.O) | 0.92 | 268 | 2.09 |

| 23 | 7 | 85 | 0.153 | 0.75 | −1 (S.O) | 0.65 | 262 | 1.83 |

| 24 | 27 | 85 | 0.153 | 0.75 | 1 (W.O) | 0.44 | 274 | 2.03 |

| 25 | 15 | 85 | 0.153 | 0.75 | 0 (V.O) | 0.64 | 248 | 1.96 |

| 26 | 1 | 85 | 0.153 | 0.75 | 0 (V.O) | 0.58 | 258 | 1.89 |

| 27 | 9 | 53 | 0.153 | 0.75 | 0 (V.O) | 0.55 | 261 | 2.03 |

| 28 | 16 | 120 | 0.153 | 0.75 | 0 (V.O) | 0.58 | 254 | 1.96 |

| 29 | 4 | 53 | 0.153 | 0.75 | 0 (V.O) | 0.57 | 254 | 2.09 |

| 30 | 26 | 120 | 0.153 | 0.75 | 0 (V.O) | 0.57 | 256 | 1.96 |

| Analysis of Variance Table for Surface Roughness | ||||||

|---|---|---|---|---|---|---|

| Source | Sum of Squares | df | Mean Square | F-Value | p-Value Prob > F | |

| Model | 2.39474 | 14 | 0.17105 | 81.51888 | 0.00000 | significant |

| A-Cutting Speed | 0.58320 | 1 | 0.58320 | 277.93616 | 0.00000 | |

| B-Feed rate | 0.12005 | 1 | 0.12005 | 57.21234 | 0.00000 | |

| C-doc | 0.55476 | 1 | 0.55476 | 264.38036 | 0.00000 | |

| D-Cooling type | 0.21561 | 1 | 0.21561 | 102.75134 | 0.00000 | |

| AB | 0.00197 | 1 | 0.00203 | 0.96506 | 0.34150 | |

| AC | 0.00912 | 1 | 0.00902 | 4.30105 | 0.05572 | |

| AD | 0.04623 | 1 | 0.04623 | 22.02949 | 0.00029 | |

| BC | 0.00023 | 1 | 0.00023 | 0.10723 | 0.74785 | |

| BD | 0.00203 | 1 | 0.00203 | 0.96506 | 0.34150 | |

| CD | 0.00002 | 1 | 0.00002 | 0.01191 | 0.91453 | |

| A2 | 0.092 | 1 | 0.08386 | 39.96698 | 0.00001 | |

| B2 | 0.12 | 1 | 0.11967 | 57.02984 | 0.00000 | |

| C2 | 0.013 | 1 | 0.01266 | 6.03513 | 0.02669 | |

| D2 | 0.029 | 1 | 0.02861 | 13.63589 | 0.00217 | |

| Residual | 0.03147 | 15 | 0.00210 | |||

| Lack of Fit | 0.027 | 10 | 0.00268 | 2.86030 | 0.12881 | not significant |

| Pure Error | 0.00468 | 5 | 0.00094 | |||

| Cor Total | 2.42622 | 29 | ||||

| Std. Dev. | 0.046 | R2 | 0.9870 | |||

| Mean | 0.83 | Adj R2 | 0.9749 | |||

| C.V. % | 5.51 | Pred R2 | 0.9494 | |||

| PRESS | 0.12 | Adeq Precision | 37.585 | |||

| Analysis of Variance Table for Cutting Temperature | ||||||

|---|---|---|---|---|---|---|

| Source | Sum of Squares | df | Mean Square | F-Value | p-Value Prob > F | |

| Model | 75,053.6 | 14 | 5360.97 | 191.57 | <0.0001 | Significant |

| A-Cutting speed | 64,201.39 | 1 | 64,201.39 | 2294.19 | <0.0001 | |

| B-Feed rate | 1386.89 | 1 | 1386.89 | 49.56 | <0.0001 | |

| C-doc | 3094.22 | 1 | 3094.22 | 110.57 | <0.0001 | |

| D-Cooling type | 43.56 | 1 | 43.56 | 1.56 | 0.2313 | |

| AB | 144 | 1 | 144 | 5.15 | 0.0385 | |

| AC | 30.25 | 1 | 30.25 | 1.08 | 0.315 | |

| AD | 6.25 | 1 | 6.25 | 0.22 | 0.6433 | |

| BC | 100 | 1 | 100 | 3.57 | 0.0782 | |

| BD | 36 | 1 | 36 | 1.29 | 0.2745 | |

| CD | 42.25 | 1 | 42.25 | 1.51 | 0.2381 | |

| A2 | 530.34 | 1 | 530.34 | 18.95 | 0.0006 | |

| B2 | 821.55 | 1 | 821.55 | 29.36 | <0.0001 | |

| C2 | 157.91 | 1 | 157.91 | 5.64 | 0.0313 | |

| D2 | 269.19 | 1 | 269.19 | 9.62 | 0.0073 | |

| Residual | 419.76 | 15 | 27.98 | |||

| Lack of Fit | 330.43 | 10 | 33.04 | 1.85 | 0.2579 | not significant |

| Pure error | 89.33 | 5 | 17.87 | |||

| Cor total | 75,473.37 | 29 | ||||

| Std. dev. | 5.29 | R2 | 0.9944 | |||

| Mean | 238.23 | Adj R2 | 0.9892 | |||

| C.V. % | 2.22 | Pred R2 | 0.9703 | |||

| PRESS | 2240.06 | Adeq Precision | 45.640 | |||

| Analysis of Variance Table for CRC | ||||||

|---|---|---|---|---|---|---|

| Source | Sum of Squares | df | Mean Square | F-Value | p-Value Prob > F | |

| Model | 3.23 | 14 | 0.23 | 31.53 | <0.0001 | significant |

| A-Cutting Speed | 0.30 | 1 | 0.30 | 40.75 | <0.0001 | |

| B-Feed rate | 1.95 | 1 | 1.95 | 267.03 | <0.0001 | |

| C-doc | 0.44 | 1 | 0.44 | 59.97 | <0.0001 | |

| D-MQL type | 0.14 | 1 | 0.14 | 18.71 | 0.0006 | |

| AB | 8.546 × 10−4 | 1 | 8.546 × 10−4 | 0.12 | 0.7373 | |

| AC | 0.019 | 1 | 0.019 | 2.64 | 0.1250 | |

| AD | 0.031 | 1 | 0.031 | 4.24 | 0.0573 | |

| BC | 0.062 | 1 | 0.062 | 8.45 | 0.0108 | |

| BD | 0.016 | 1 | 0.016 | 2.14 | 0.1637 | |

| CD | 6.501 × 10−4 | 1 | 6.501 × 10−4 | 0.089 | 0.7698 | |

| A2 | 0.049 | 1 | 0.049 | 6.64 | 0.0210 | |

| B2 | 0.18 | 1 | 0.18 | 25.05 | 0.0002 | |

| C2 | 1.142 × 10−3 | 1 | 1.142 × 10−3 | 0.16 | 0.6984 | |

| D2 | 3.579 × 10−4 | 1 | 3.579 × 10−4 | 0.049 | 0.8280 | |

| Residual | 0.11 | 15 | 7.318 × 10−3 | |||

| Lack of Fit | 0.087 | 10 | 8.690 × 10−3 | 1.90 | 0.2482 | not significant |

| Pure Error | 0.023 | 5 | 4.575 × 10−3 | |||

| Cor Total | 3.34 | 29 | ||||

| Std. Dev. | 0.086 | R2 | 0.9671 | |||

| Mean | 2.04 | Adj R2 | 0.9365 | |||

| C.V. % | 4.18 | Pred R2 | 0.8115 | |||

| PRESS | 0.63 | Adeq Precision | 23.197 | |||

| S.N | Cutting Speed (m/min) | Feed Rate (mm/rev) | doc (mm) | Cutting Fluids/ Lubricant | Flank Wear VB (µm) |

|---|---|---|---|---|---|

| 1 | 53 | 0.06 | 1 | (S.O) | 195.6 |

| 2 | 85 | 0.153 | 0.75 | (S.O) | 254.9 |

| 3 | 120 | 0.06 | 1 | (S.O) | 367.7 |

| 4 | 53 | 0.153 | 0.75 | (V.O) | 121.4 |

| 5 | 85 | 0.153 | 0.75 | (V.O) | 180.8 |

| 6 | 120 | 0.153 | 0.75 | (V.O) | 332.4 |

| 7 | 53 | 0.06 | 1 | (U.O) | 212.8 |

| 8 | 85 | 0.153 | 0.75 | (U.O) | 417.1 |

| 9 | 120 | 0.06 | 1 | (U.O) | 510.9 |

| S.N | Lubricant/ Coolant | Cooling Methodology | Cost/L (₹ Rs) | Consumption (L/year) | Yearly Cost (₹ INR) | Wastage Disposal Cost | Cost of Water | Total Coolant Cost (₹) | Operator/ Environment Safety | Performance |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | Synthetic oil | MQL | 220 | 225 | 49,500 | Nil | Nil | 49,500 | Excellent | Excellent |

| 2 | Vegetable oil | MQL | 188 | 225 | 42,300 | Nil | Nil | 42,300 | excellent | Good |

| 3 | Waste oil | MQL | 50 | 225 | 11,250 | Nil | Nil | 11,250 | Moderate | Moderate |

| 4 | Mineral oil | MQL | 228 | 260 | 59,280 | Nil | Nil | 59,280 | Good | Moderate |

| 5 | Mineral oil | Flood | 228 | 260 | 59,280 | 54,000 | Yes | 113,280 | Less | Good |

| 6 | Cryogenic cooling | LN2 | 80–120 | 112,320 | 8,985,600 | Nil | Nil | 8,985,600 | Good | Excellent |

| 7 | (LN2 + Vegetable oil) | MQL+ Cryo | 140 (avg) | 375 | 52,500 | Nil | Nil | 52,500 | Good | Excellent |

| 8 | Nil | Dry | Nil | Nil | Nil | Nil | Nil | NA | Good | Poor |

| 9 | Vegetable oil + nano fluid | Hybrid NMQL | 190 ₹ V.O and 4500 ₹ for (100 gm of N.F) | 94 L (V.O), 2.82 kg (N.F) | 17,860 (V.O), 126,900 (N.F) | Nil | Nil | 144,760 | Good | Good |

| S.N | SDG-12 Indices | Description | Implementation in Present Study | Impact |

|---|---|---|---|---|

| 1 | 12.2 | Minimization of natural resource | Utility of vegetable oil/waste oil | Conservation of natural resources |

| 2 | 12.4 | Responsible management of chemical and waste | MQL machining | Reduction in health hazard as well as economic machining |

| 3 | 12.5 | Substantially reduced waste generation | MQL machining using V.O and W.O | Wastage minimization |

| 4 | 12.6 | Practice of Sustainable Production | Low environmental hazards, waste reduction, economic machining, elimination of wastage disposal cost | Better performance index, Sustainable Manufacturing |

| 5 | 12.8 | Understanding of Sustainable Life cycle | Utility of MQL, V.O and W.O | An approach to sustainable machining/ manufacturing |

| 6 | 12-A | Support to developing countries for Sustainable consumption and production | Reduction in wastage disposal, recycling cost and environmental degradation | Conservation of natural resources, cleaner production |

| 7 | 12-C | Bar on wasteful consumption | Non-utilization of petroleum based mineral oil | Conservation of natural resources, cleaner production |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Singh, G.; Aggarwal, V.; Singh, S.; Singh, B.; Sharma, S.; Singh, J.; Li, C.; Ilyas, R.A.; Mohamed, A. Experimental Investigation and Performance Optimization during Machining of Hastelloy C-276 Using Green Lubricants. Materials 2022, 15, 5451. https://doi.org/10.3390/ma15155451

Singh G, Aggarwal V, Singh S, Singh B, Sharma S, Singh J, Li C, Ilyas RA, Mohamed A. Experimental Investigation and Performance Optimization during Machining of Hastelloy C-276 Using Green Lubricants. Materials. 2022; 15(15):5451. https://doi.org/10.3390/ma15155451

Chicago/Turabian StyleSingh, Gurpreet, Vivek Aggarwal, Sehijpal Singh, Balkar Singh, Shubham Sharma, Jujhar Singh, Changhe Li, R.A. Ilyas, and Abdullah Mohamed. 2022. "Experimental Investigation and Performance Optimization during Machining of Hastelloy C-276 Using Green Lubricants" Materials 15, no. 15: 5451. https://doi.org/10.3390/ma15155451

APA StyleSingh, G., Aggarwal, V., Singh, S., Singh, B., Sharma, S., Singh, J., Li, C., Ilyas, R. A., & Mohamed, A. (2022). Experimental Investigation and Performance Optimization during Machining of Hastelloy C-276 Using Green Lubricants. Materials, 15(15), 5451. https://doi.org/10.3390/ma15155451