A Comparative Study of Additive and Subtractive Manufacturing Techniques for a Zirconia Dental Product: An Analysis of the Manufacturing Accuracy and the Bond Strength of Porcelain to Zirconia

Abstract

:1. Introduction

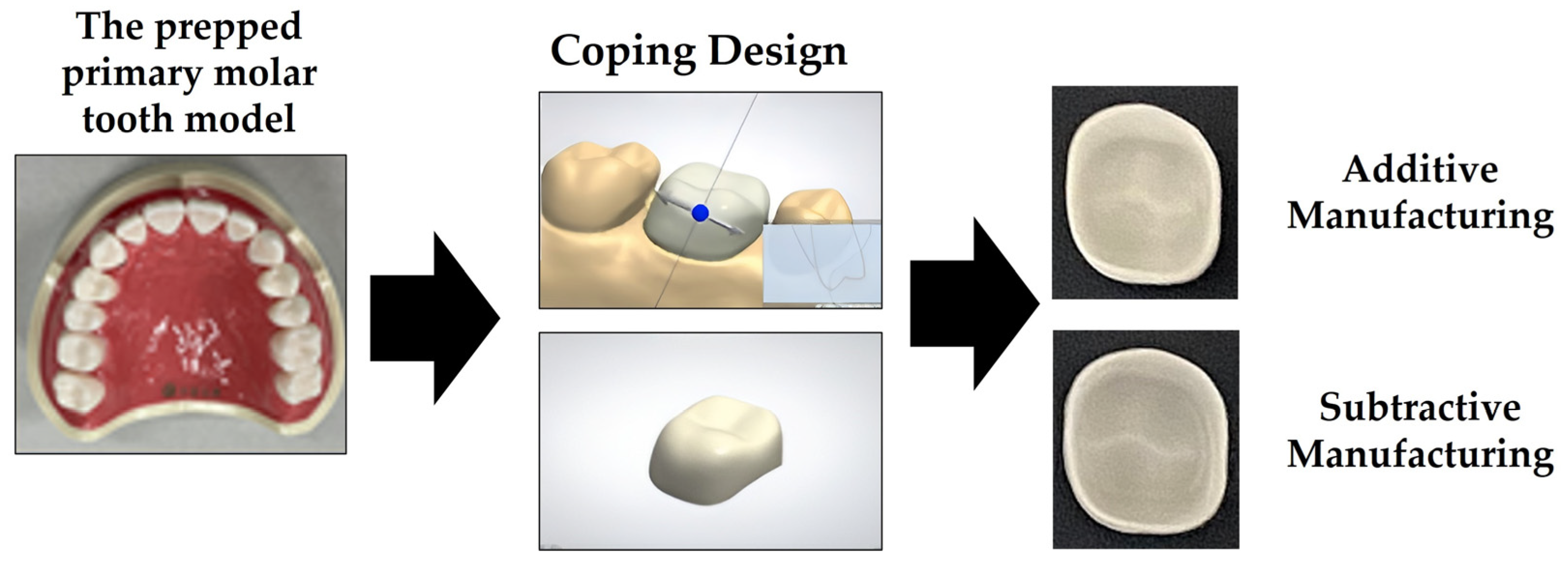

2. Materials and Methods

2.1. Materials

2.2. Accuracy Evaluation of the Internal and Marginal Areas

2.3. Test of the Bond Strength of Veneered Porcelain to Zirconia

2.4. Statistical Analysis

3. Results

3.1. Accuracy Evaluation of the Internal and Marginal Areas

3.2. Bond Strength Test of the Veneered Porcelain with Zirconia

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Duret, F.; Preston, J.D. CAD/CAM imaging in dentistry. Curr. Opin. Dent. 1991, 1, 150–154. [Google Scholar] [PubMed]

- van Noort, R. The future of dental devices is digital. Dent. Mater. 2012, 28, 3–12. [Google Scholar] [CrossRef] [PubMed]

- Beuer, F.; Schweiger, J.; Edelhoff, D. Digital dentistry: An overview of recent developments for CAD/CAM generated restorations. Br. Dent. J. 2008, 204, 505–511. [Google Scholar] [CrossRef] [PubMed]

- Miyazaki, T.; Hotta, Y. CAD/CAM systems available for the fabrication of crown and bridge restorations. Aust. Dent. J. 2011, 56, 97–106. [Google Scholar] [CrossRef]

- Rekow, E.; Erdman, A.; Riley, D.; Klamecki, B. CAD/CAM for dental restorations-some of the curious challenges. IEEE Trans. Biomed. Eng. 1991, 38, 314–318. [Google Scholar] [CrossRef]

- Örtorp, A.; Jönsson, D.; Mouhsen, A.; von Steyern, P.V. The fit of cobalt–chromium three-unit fixed dental prostheses fabricated with four different techniques: A comparative In Vitro study. Dent. Mater. 2011, 27, 356–363. [Google Scholar] [CrossRef]

- Hull, C.W. Apparatus for Production of Three-Dimensional Objects by Stereolithography. U.S. Patent 4575330A, 19 December 1986. [Google Scholar]

- Crump, S.S. Apparatus and Method for Creating Three-Dimensional Objects. U.S. Patent 5121329A, 30 October 1989. [Google Scholar]

- Deckard, C. Method and Apparatus for Producing Parts by Selective Sintering. U.S. Patent US4863538A, 5 September 1989. [Google Scholar]

- Kodama, H. Automatic method for fabricating cubic shapes, as a three-dimensional information disply method. J. IEICE 1981, J64-C, 237–241. [Google Scholar]

- Dawood, A.; Marti, B.M.; Sauret-Jackson, V.; Darwood, A. 3D printing in dentistry. Br. Dent. J. 2015, 219, 521–529. [Google Scholar] [CrossRef]

- Abduo, J.; Lyons, K.; Bennamoun, M. Trends in Computer-Aided Manufacturing in Prosthodontics: A Review of the Available Streams. Int. J. Dent. 2014, 2014, 783948. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Barbin, T.; Velôso, D.V.; Silva, L.D.R.; Borges, G.A.; Presotto, A.G.C.; Barão, V.A.R.; Mesquita, M.F. 3D metal printing in dentistry: An In Vitro biomechanical comparative study of two additive manufacturing technologies for full-arch implant-supported prostheses. J. Mech. Behav. Biomed. Mater. 2020, 108, 103821. [Google Scholar] [CrossRef]

- Meiners, W.; Wissenbach, K.; Gasser, A. Selective Laser Sintering at Melting Temperature. U.S. Patent US6215093B1, 10 April 2001. [Google Scholar]

- Hao, L.; Dadbakhsh, S.; Seaman, O.; Felstead, M. Selective laser melting of a stainless steel and hydroxyapatite composite for load-bearing implant development. J. Mater. Process. Technol. 2009, 209, 5793–5801. [Google Scholar] [CrossRef]

- Mercelis, P.; Kruth, J. Residual stresses in selective laser sintering and selective laser melting. Rapid Prototyp. J. 2006, 12, 254–265. [Google Scholar] [CrossRef]

- Helmer, J.D.; Driskell, T.D. Research on Bioceramics, Symposium on Use of Ceramics as Surgical Implants; Clemson University: Clemson, SC, USA, 1969. [Google Scholar]

- Denry, I.; Kelly, J.R. State of the art of zirconia for dental applications. Dent. Mater. 2008, 24, 299–307. [Google Scholar] [CrossRef]

- Buj-Corral, I.; Vidal, D.; Tejo-Otero, A.; Padilla, J.A.; Xuriguera, E.; Fenollosa-Artés, F. Characterization of 3D Printed Yttria-Stabilized Zirconia Parts for Use in Prostheses. Nanomaterials 2021, 11, 2942. [Google Scholar] [CrossRef] [PubMed]

- Peng, E.; Wei, X.; Garbe, U.; Yu, D.; Edouard, B.; Liu, A.; Ding, J. Robocasting of dense yttria-stabilized zirconia structures. J. Mater. Sci. 2017, 53, 247–273. [Google Scholar] [CrossRef]

- Osman, R.B.; van der Veen, A.J.; Huiberts, D.; Wismeijer, D.; Alharbi, N. 3D-printing zirconia implants; a dream or a reality? An In-Vitro study evaluating the dimensional accuracy, surface topography and mechanical properties of printed zirconia implant and discs. J. Mech. Behav. Biomed. Mater. 2017, 75, 521–528. [Google Scholar] [CrossRef]

- Kohorst, P.; Junghanns, J.; Dittmer, M.P.; Borchers, L.; Stiesch, M. Different CAD/CAM-processing routes for zirconia restorations: Influence on fitting accuracy. Clin. Oral Investig. 2010, 15, 527–536. [Google Scholar] [CrossRef]

- Arezoobakhsh, A.; Shayegh, S.S.; Ghomi, A.J.; Hakimaneh, S.M.R. Comparison of marginal and internal fit of 3-unit zirconia frameworks fabricated with CAD-CAM technology using direct and indirect digital scans. J. Prosthet. Dent. 2019, 123, 105–112. [Google Scholar] [CrossRef] [Green Version]

- Kang, S.-Y.; Yu, J.-M.; Lee, J.-S.; Park, K.-S.; Lee, S.-Y. Evaluation of the milling accuracy of zirconia-reinforced lithium silicate crowns fabricated using the dental medical device system: A three-dimensional analysis. Materials 2020, 13, 4680. [Google Scholar] [CrossRef]

- Jeong, I.-D.; Lee, J.-J.; Jeon, J.-H.; Kim, J.-H.; Kim, H.-Y.; Kim, W.-C. Accuracy of complete-arch model using an intraoral video scanner: An In Vitro study. J. Prosthet. Dent. 2016, 115, 755–759. [Google Scholar] [CrossRef]

- Boitelle, P.; Tapie, L.; Mawussi, B.; Fromentin, O. 3D fitting accuracy evaluation of CAD/CAM copings—Comparison with spacer design settings. Int. J. Comput. Dent. 2016, 19, 27–43. [Google Scholar] [PubMed]

- ISO 9693-2; Dentistry―Compatibility Testing―Part 2: Ceramic-Ceramic Systems. International Standard Organization: Geneva, Switzerland, 2016; pp. 1–9.

- Reich, S.; Wichmann, M.; Nkenke, E.; Proeschel, P. Clinical fit of all-ceramic three-unit fixed partial dentures, generated with three different CAD/CAM systems. Eur. J. Oral Sci. 2005, 113, 174–179. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.-J.; Jo, K.-H.; Lee, K.-B. A comparison of the fidelity of various zirconia-based all-ceramic crowns fabricated with CAD/CAM systems. J. Korean Acad. Prosthodont. 2009, 47, 148–155. [Google Scholar] [CrossRef] [Green Version]

- Huh, J.; Shim, J. The factors caused errors in the production process of CAD/CAM prosthesis based on experience. J. Korean Dent. Assoc. 2014, 52, 332–345. [Google Scholar]

- Kim, M.; Kim, W.; Kang, W. Evaluation of the accuracy of provisional restorative resins fabricated using dental 3D printers. J. Korean Soc. Dent. Hyg. 2019, 19, 1089–1097. [Google Scholar]

- Kim, K.; Kim, J.; Lee, K. The Influence of Microwave Sintering Process on the Adaptation of CAD/CAM Zirconia Core. J. Dent. Rehabil. Appl. Sci. 2009, 25, 95–107. [Google Scholar]

- Song, T.-J.; Yeo, I.-S.; Yang, J.-H. Marginal fit of three-unit zirconia anterior fixed dental prostheses fabricated using CAD/CAM and MAD/MAM system. J. Korean Acad. Prosthodont. 2011, 49, 145–151. [Google Scholar] [CrossRef] [Green Version]

- Shin, M.-S.; Lee, H. Effect of additional firing process after sintering of monolithic zirconia crown on marginal and internal fitness. J. Korean Acad. Prosthodont. 2019, 57, 321–327. [Google Scholar] [CrossRef] [Green Version]

- Nakamoto, T.; Yamaguchi, K. Consideration on the producing of high aspect ratio micro parts using UV sensitive photopolymer. In Proceedings of the MHS’96 Proceedings of the Seventh International Symposium on Micro Machine and Human Science, Nagoya, Japan, 2–4 October 1996; IEEE: Manhattan, NY, USA; pp. 53–58. [Google Scholar]

- He, R.; Liu, W.; Wu, Z.; An, D.; Huang, M.; Wu, H.; Jiang, Q.; Ji, X.; Wu, S.; Xie, Z. Fabrication of complex-shaped zirconia ceramic parts via a DLP-stereolithography-based 3D printing method. Ceram. Int. 2018, 44, 3412–3416. [Google Scholar] [CrossRef]

- Revilla-León, M.; Özcan, M. Additive Manufacturing Technologies Used for 3D Metal Printing in Dentistry. Curr. Oral Health Rep. 2017, 4, 201–208. [Google Scholar] [CrossRef] [Green Version]

- Chen, Z.; Li, Z.; Li, J.; Liu, C.; Lao, C.; Fu, Y.; Liu, C.; Li, Y.; Wang, P.; He, Y. 3D printing of ceramics: A review. J. Eur. Ceram. Soc. 2019, 39, 661–687. [Google Scholar] [CrossRef]

- Pineau, A.; Pardoen, T. Failure of Metals; Elsevier: Amsterdam, The Netherlands, 2007. [Google Scholar]

- O’Brien, W.J. Dental Materials and Their Selection, 2nd ed.; Quintessence Publishing Co.: Batavia, IL, USA, 1997. [Google Scholar]

- Piconi, C.; Maccauro, G. Zirconia as a ceramic biomaterial. Biomaterials 1999, 20, 1–25. [Google Scholar] [CrossRef]

- Wassell, R.W.; Walls, A.W.G.; Steele, J.G. Crowns and extra-coronal restorations: Part 2: Materials selection. Br. Dent. J. 2002, 192, 199–202. [Google Scholar] [CrossRef] [PubMed]

| Group | Model | Manufacturer | Materials | |

|---|---|---|---|---|

| SM 1 | AR | 5X-500L | Arum Co., Daejeon, Korea | Luxen Zirconia 1200 Zr, Dentalmax Co., Seoul, Korea |

| K5 | K5 Impression | vhf camfacture AG, Ammerbuch, Germany | ||

| UP | P52 | UP 3D Co., Shenzhen, China | ||

| AM 2 | AO | INNI-II | AON, Gunpo, Korea | INNI-Cera, AON, Gunpo, Korea |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moon, J.-M.; Jeong, C.-S.; Lee, H.-J.; Bae, J.-M.; Choi, E.-J.; Kim, S.-T.; Park, Y.-B.; Oh, S.-H. A Comparative Study of Additive and Subtractive Manufacturing Techniques for a Zirconia Dental Product: An Analysis of the Manufacturing Accuracy and the Bond Strength of Porcelain to Zirconia. Materials 2022, 15, 5398. https://doi.org/10.3390/ma15155398

Moon J-M, Jeong C-S, Lee H-J, Bae J-M, Choi E-J, Kim S-T, Park Y-B, Oh S-H. A Comparative Study of Additive and Subtractive Manufacturing Techniques for a Zirconia Dental Product: An Analysis of the Manufacturing Accuracy and the Bond Strength of Porcelain to Zirconia. Materials. 2022; 15(15):5398. https://doi.org/10.3390/ma15155398

Chicago/Turabian StyleMoon, Joon-Mo, Chang-Sub Jeong, Hee-Jeong Lee, Ji-Myung Bae, Eun-Joo Choi, Sung-Tae Kim, Young-Bum Park, and Seung-Han Oh. 2022. "A Comparative Study of Additive and Subtractive Manufacturing Techniques for a Zirconia Dental Product: An Analysis of the Manufacturing Accuracy and the Bond Strength of Porcelain to Zirconia" Materials 15, no. 15: 5398. https://doi.org/10.3390/ma15155398

APA StyleMoon, J.-M., Jeong, C.-S., Lee, H.-J., Bae, J.-M., Choi, E.-J., Kim, S.-T., Park, Y.-B., & Oh, S.-H. (2022). A Comparative Study of Additive and Subtractive Manufacturing Techniques for a Zirconia Dental Product: An Analysis of the Manufacturing Accuracy and the Bond Strength of Porcelain to Zirconia. Materials, 15(15), 5398. https://doi.org/10.3390/ma15155398