Microstructure and Mechanical Properties of Metal Foams Fabricated via Melt Foaming and Powder Metallurgy Technique: A Review

Abstract

1. Introduction

2. Types of Metal Foams

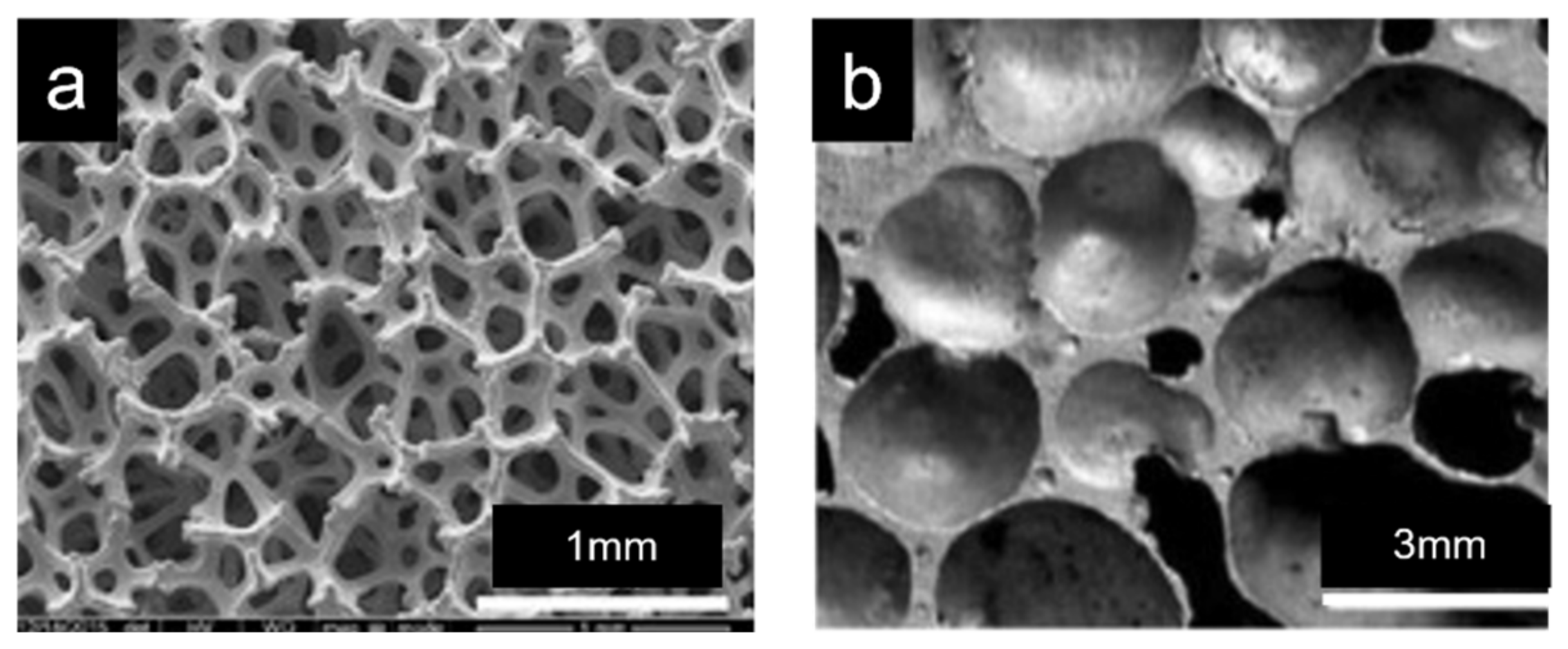

2.1. Open-Cell Foams

2.2. Closed-Cell Foams

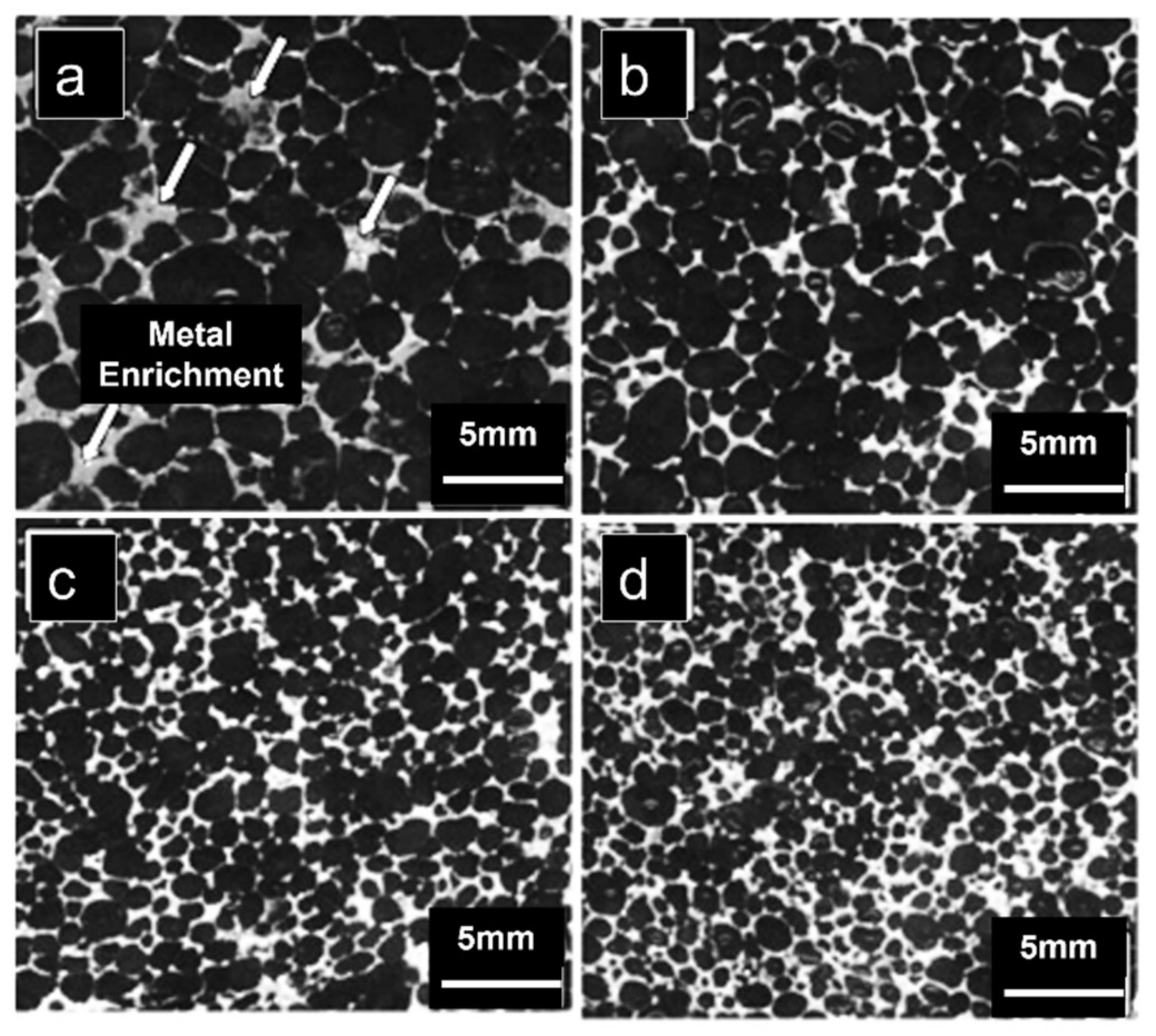

3. Microstructure of Metal Foams

| Manufacturing Techniques | Material | Foaming Agent/Space Holders | Microstructure | Reference |

|---|---|---|---|---|

| Melt foaming | Al matrix, graphene | NaCl, KCl and PMMA |

| [49] |

| Al-Si13-MgX (X = 2.5–15 wt %) alloy | Mg |

| [50] | |

| AlMg50, Ca | TiH2 |

| [48] | |

| A356 foams | CaCO3 |

| [51] | |

| Powder metallurgy | ||||

| Using foaming agent | AlSi10 alloy | TiH2 |

| [52] |

| Mg, Al, Cu, and Zn, yttrium | TiH2 |

| [53] | |

| AlMg4Si8 alloy and multi-walled carbon nanotubes (MWCNT) | TiH2 |

| [54] | |

| Space holder technique | Ti-based Cu alloy | Acrawax |

| [55] |

| Steel (iron, graphite phosphorous) | Urea granules |

| [56] | |

| Aluminium, Graphene | NaCl, KCl, and PMMA |

| [49] | |

| 316L austenitic stainless steel | Urea particles |

| [57] | |

| Al matrix and MWCNT | Urea particles |

| [58] | |

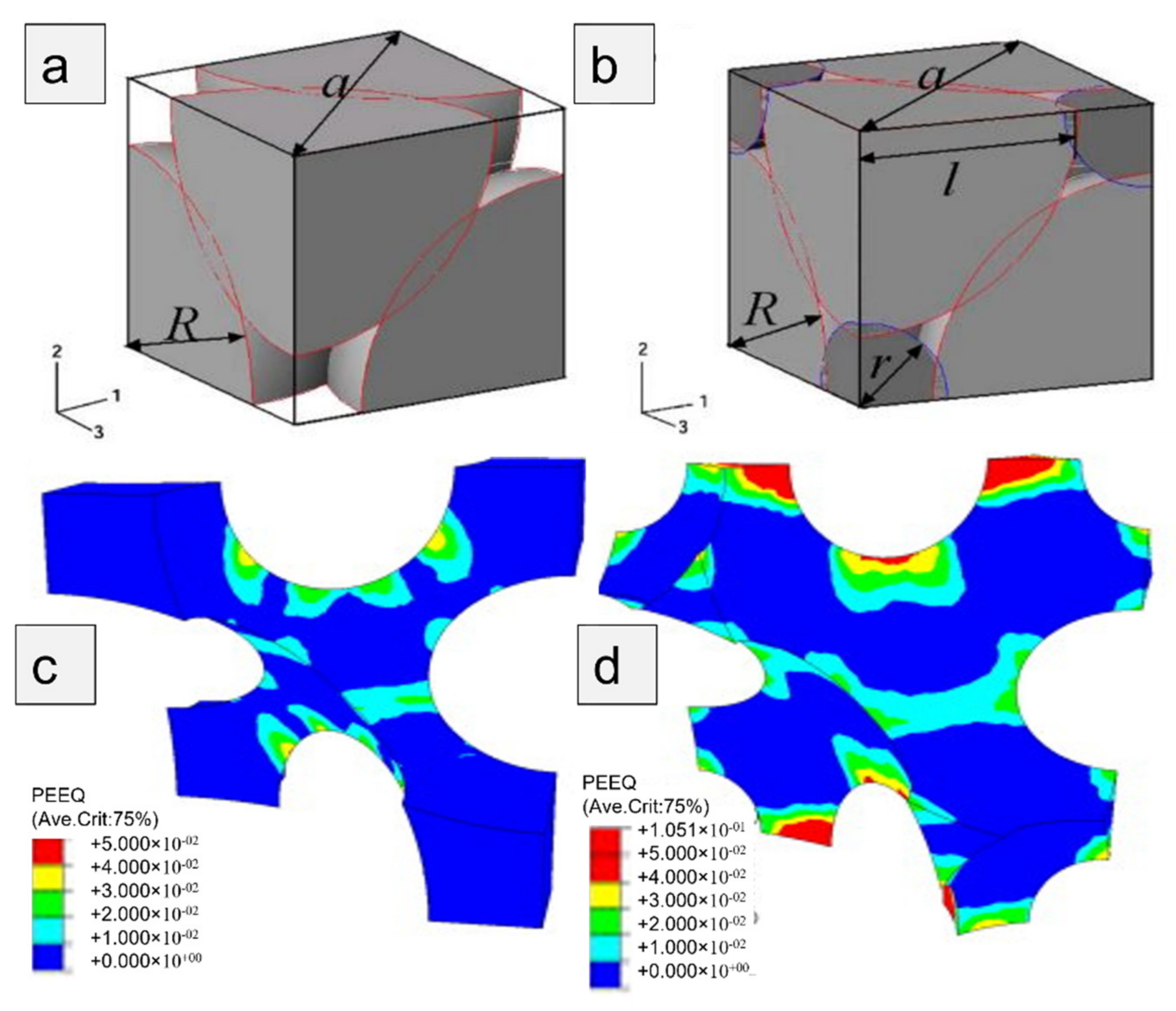

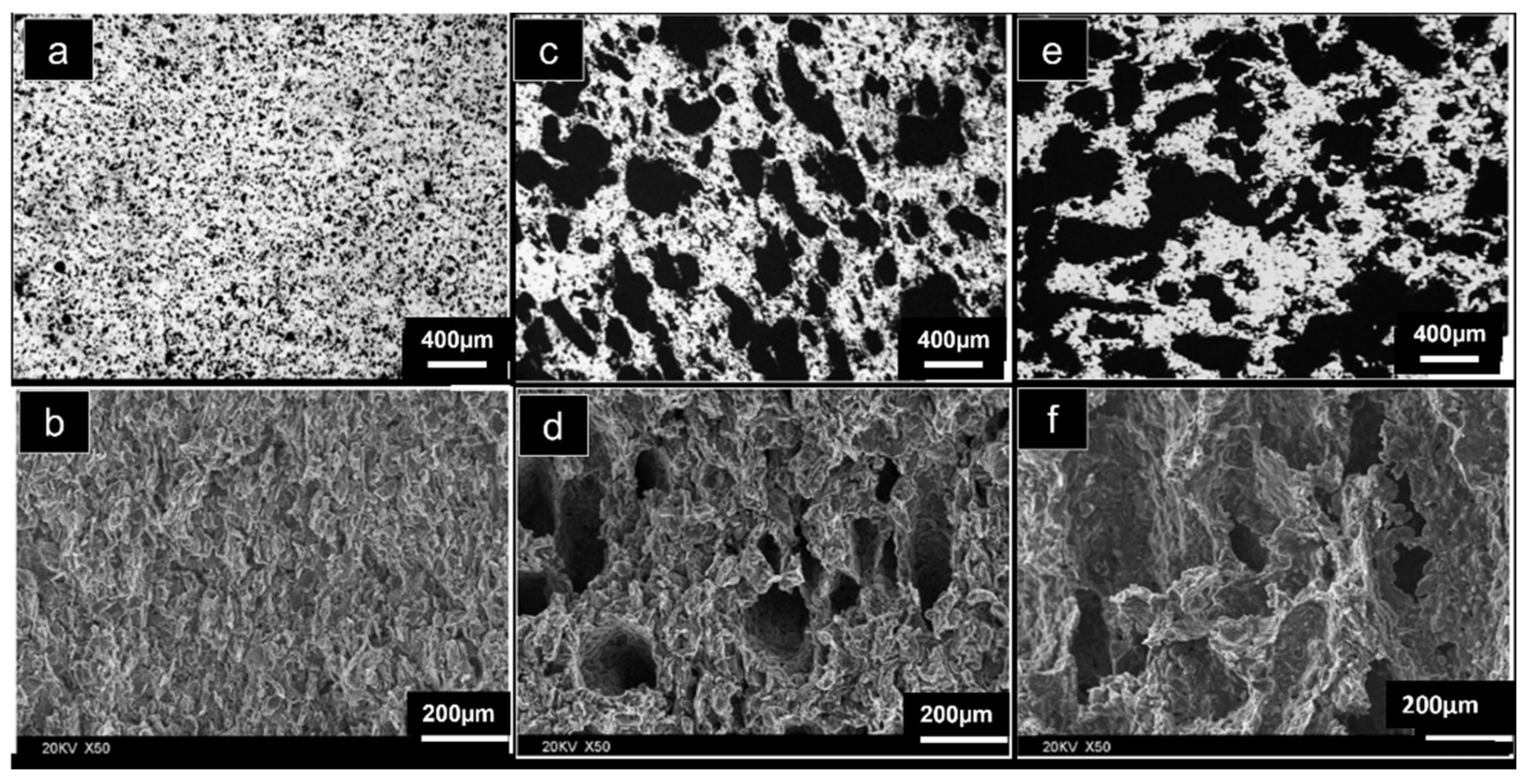

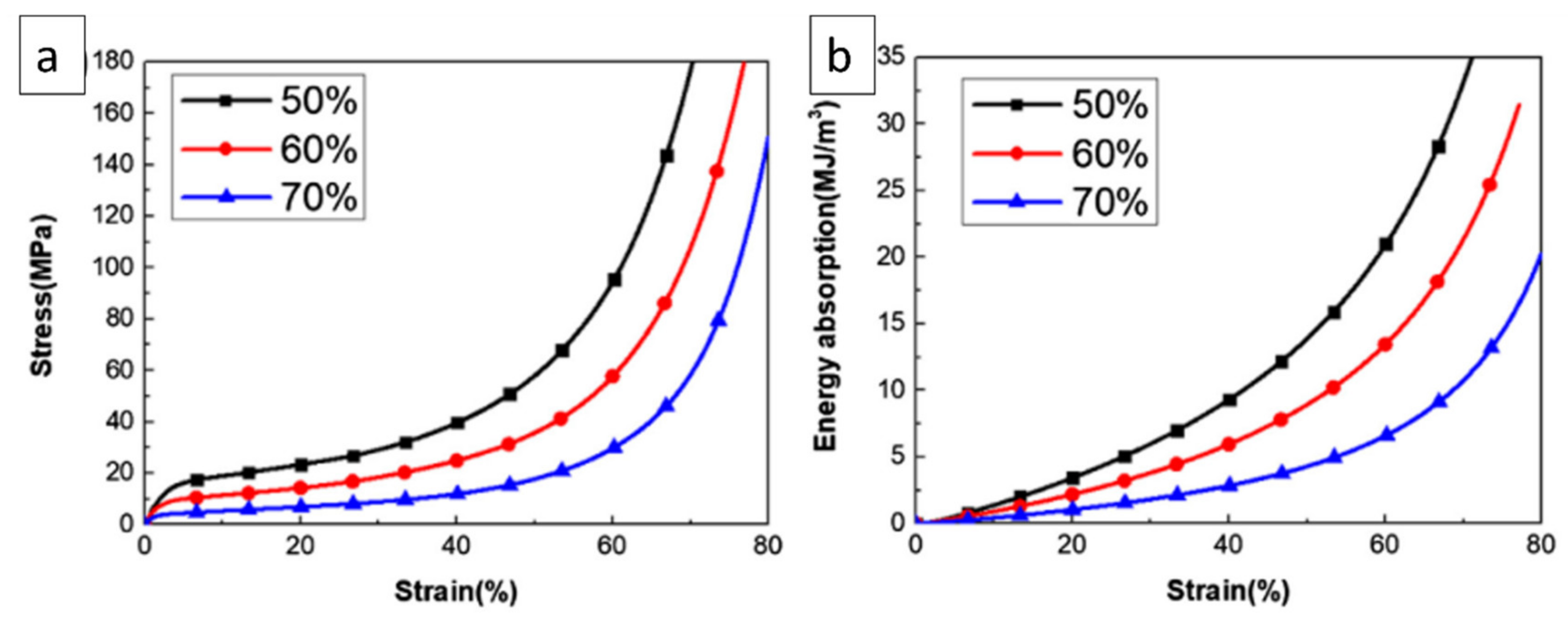

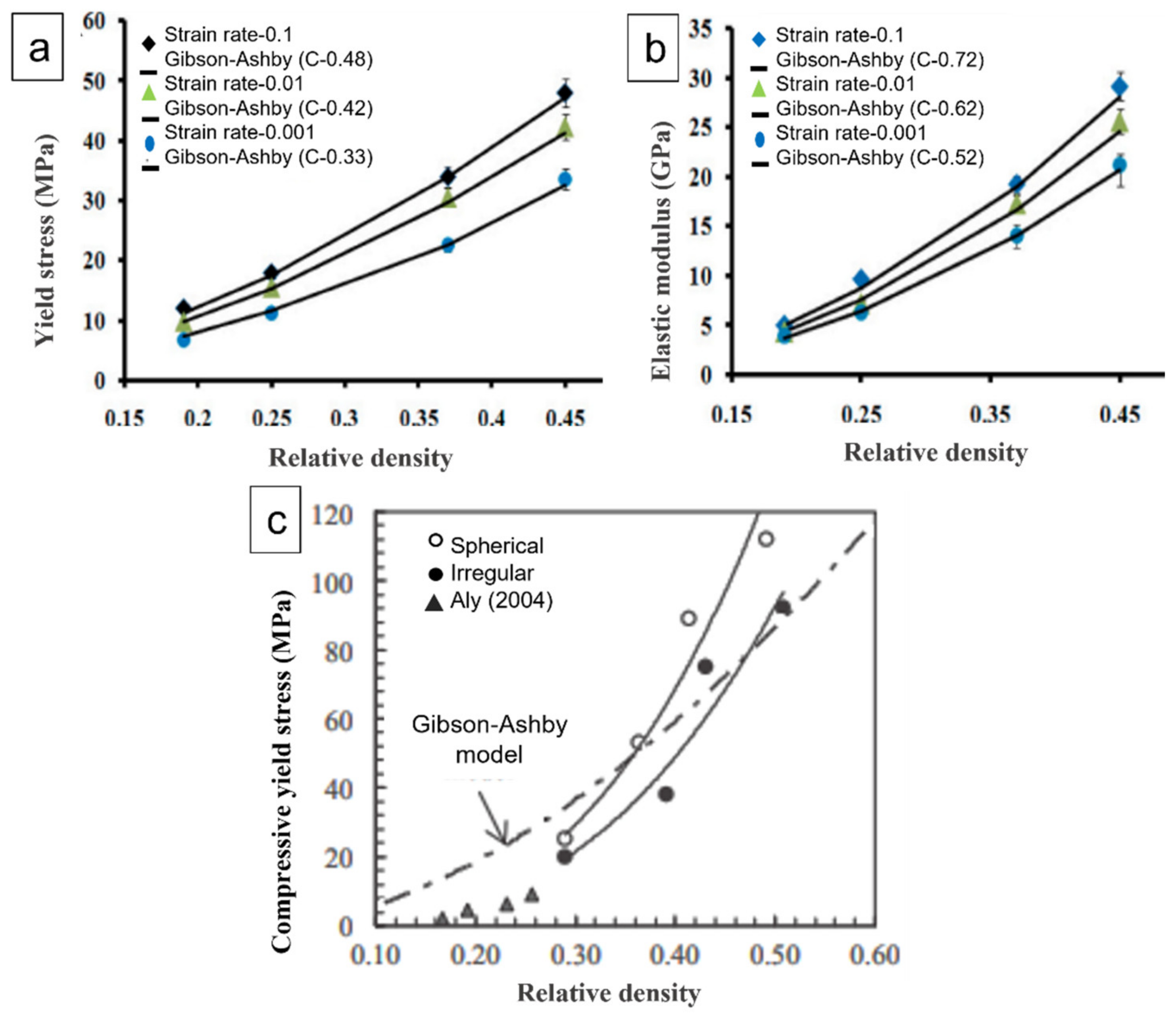

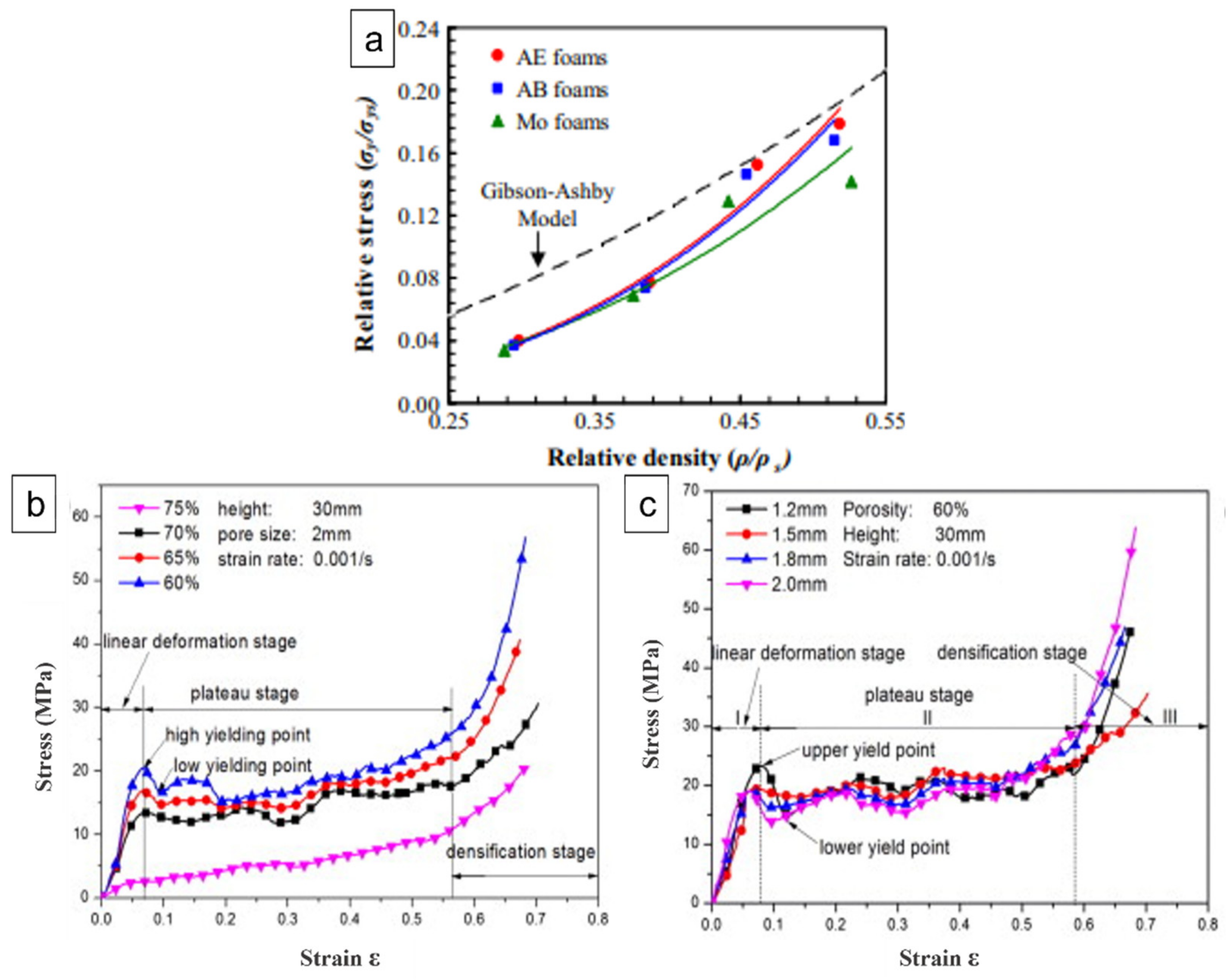

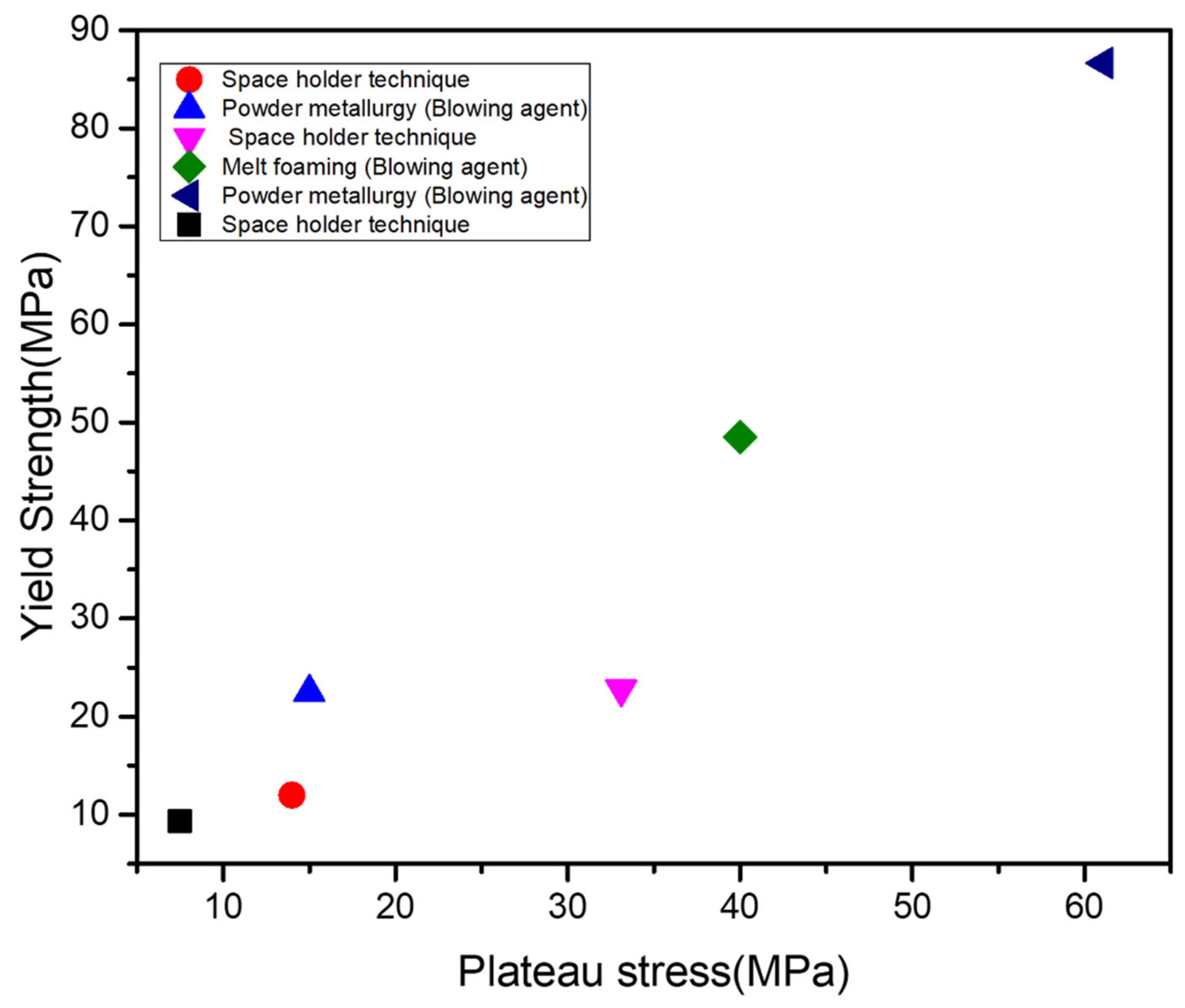

4. Mechanical Properties of Metal Foams

5. Fabrication Techniques of Metal Foams

5.1. Melt Foaming

5.2. Powder Metallurgy Foaming Techniques/Methods

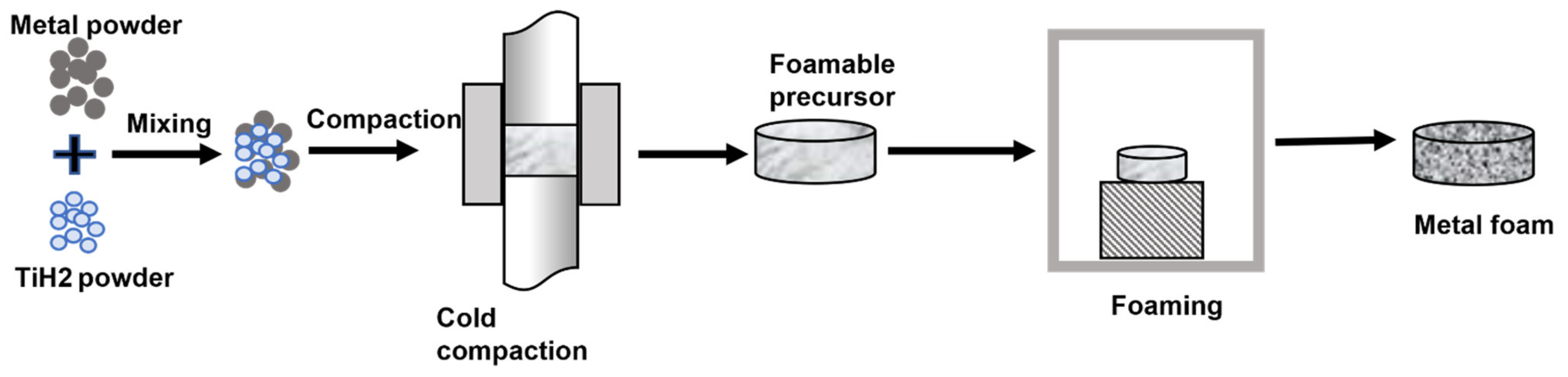

5.2.1. Using Foaming Agent

5.2.2. Space-Holder Technique

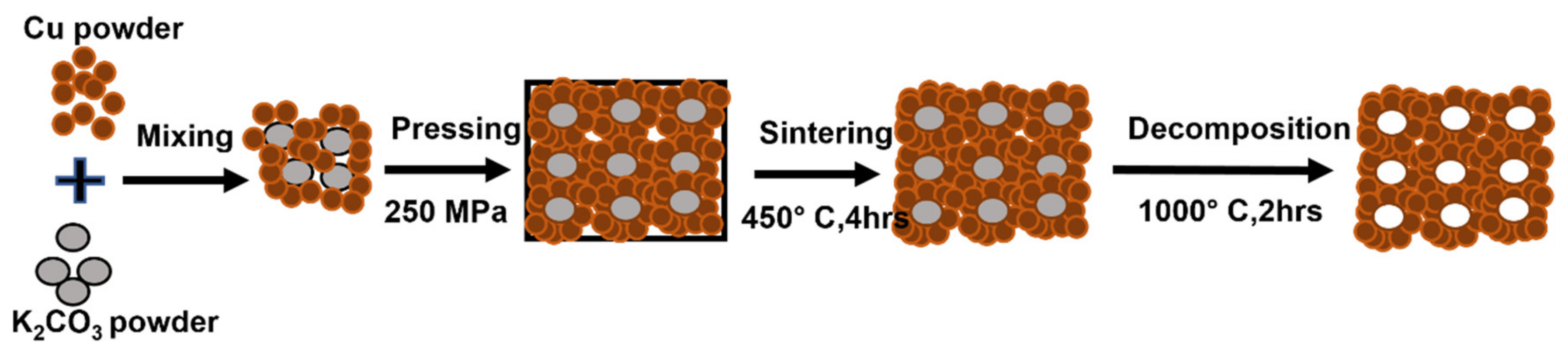

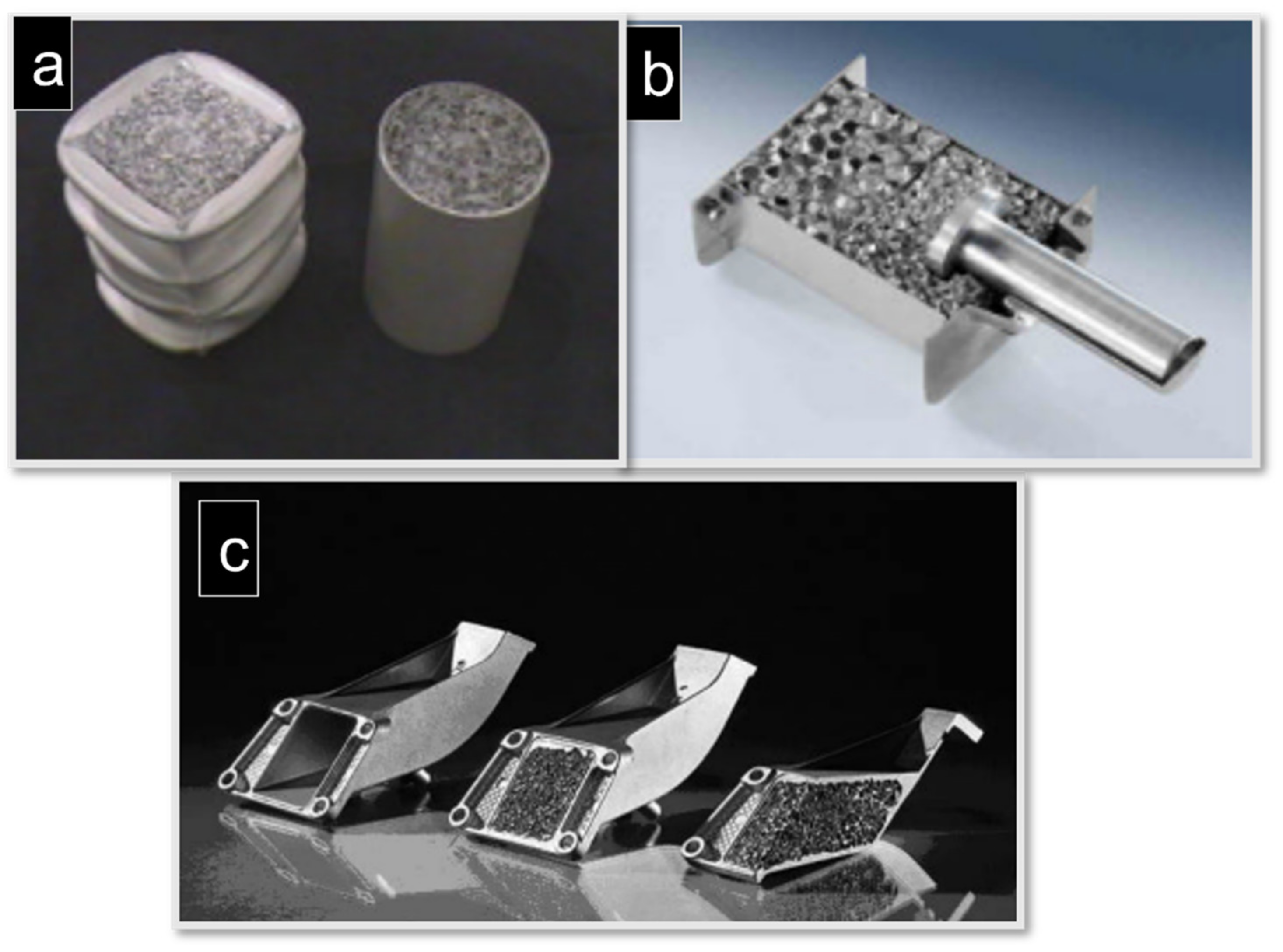

6. Applications of Metal Foams

7. Challenges and Way Forward

8. Summary

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Fleck, N. Metal Foams: A Design Guide; Elsevier: Amsterdam, The Netherlands, 2016; Volume 3069, p. 264. [Google Scholar] [CrossRef]

- Goel, M.D.; Matsagar, V.A.; Marburg, S.; Gupta, A.K. Comparative Performance of Stiffened Sandwich Foam Panels under Impulsive Loading. J. Perform. Constr. Facil. 2013, 27, 540–549. [Google Scholar] [CrossRef]

- Raj, R.E.; Daniel, B.S.S. Aluminum melt foam processing for light-weight structures. Mater. Manuf. Process. 2007, 22, 525–530. [Google Scholar] [CrossRef]

- Banhart, J.; Baumeister, J. Deformation characteristics of metal foams. J. Mater. Sci. 1998, 33, 1431–1440. [Google Scholar] [CrossRef]

- Jeenager, V.K.; Pancholi, V.; Daniel, B.S.S. The effect of aging on energy absorption capability of closed cell aluminum foam. Adv. Mater. Res. 2012, 585, 327–331. [Google Scholar] [CrossRef]

- Ozan, S.; Taskin, M.; Kolukisa, S.; Ozerdem, M.S. Application of ANN in the prediction of the pore concentration of aluminum metal foams manufactured by powder metallurgy methods. Int. J. Adv. Manuf. Technol. 2008, 39, 251–256. [Google Scholar] [CrossRef]

- Jiang, W.; Fan, Z.; Liao, D.; Dong, X.; Zhao, Z. A new shell casting process based on expendable pattern with vacuum and low-pressure casting for aluminum and magnesium alloys. Int. J. Adv. Manuf. Technol. 2010, 51, 25–34. [Google Scholar] [CrossRef]

- Rajak, D.K.; Kumaraswamidhas, L.A.; Das, S. An Energy Absorption Behaviour of Foam Filled Structures. Procedia Mater. Sci. 2014, 5, 164–172. [Google Scholar] [CrossRef]

- Wang, Y.C.; Li, D.Y.; Peng, Y.H.; Zeng, X.Q. Numerical simulation of low pressure die casting of magnesium wheel. Int. J. Adv. Manuf. Technol. 2007, 32, 257–264. [Google Scholar] [CrossRef]

- Lara-Rodriguez, G.A.; Figueroa, I.A.; Suarez, M.A.; Novelo-Peralta, O.; Alfonso, I.; Goodall, R. A replication-casting device for manufacturing open-cell Mg foams. J. Mater. Process. Technol. 2017, 243, 16–22. [Google Scholar] [CrossRef]

- Papadopoulos, D.P.; Omar, H.; Stergioudi, F.; Tsipas, S.A.; Lefakis, H.; Michailidis, N. A novel method for producing Al-foams and evaluation of their compression behavior. J. Porous Mater. 2010, 17, 773–777. [Google Scholar] [CrossRef]

- Paulin, I.; Šuštaršič, B.; Kevorkijan, V.; Škapin, S.D.; Jenko, M. Synthesis of aluminium foams by the powder-metallurgy process: Compacting of precursors. Mater. Tehnol. 2011, 45, 13–19. [Google Scholar]

- Bisht, A.; Gangil, B.; Patel, V.K. Selection of blowing agent for metal foam production: A review. J. Met. Mater. Miner. 2020, 30, 1–10. [Google Scholar] [CrossRef]

- Banhart, J. Manufacture, characterisation and application of cellular metals and metal foams. Prog. Mater. Sci. 2001, 46, 559–632. [Google Scholar] [CrossRef]

- Alavi, R.; Trenggono, A.; Champagne, S.; Hermawan, H. Investigation on mechanical behavior of biodegradable iron foams under different compression test conditions. Metals 2017, 7, 202. [Google Scholar] [CrossRef]

- Davies, G.J.; Zhen, S. Metallic foams: Their production, properties and applications. J. Mater. Sci. 1983, 18, 1899–1911. [Google Scholar] [CrossRef]

- Rajendran, R.; Prem Sai, K.; Chandrasekar, B.; Gokhale, A.; Basu, S. Preliminary investigation of aluminium foam as an energy absorber for nuclear transportation cask. Mater. Des. 2008, 29, 1732–1739. [Google Scholar] [CrossRef]

- Ghafarian, M.; Mohebbi-Kalhori, D.; Sadeghi, J. Analysis of heat transfer in oscillating flow through a channel filled with metal foam using computational fluid dynamics. Int. J. Therm. Sci. 2013, 66, 42–50. [Google Scholar] [CrossRef]

- Kamath, P.M.; Balaji, C.; Venkateshan, S.P. Convection heat transfer from aluminium and copper foams in a vertical channel-An experimental study. Int. J. Therm. Sci. 2013, 64, 1–10. [Google Scholar] [CrossRef]

- Dukhan, N.; Ali, M. Strong wall and transverse size effects on pressure drop of flow through open-cell metal foam. Int. J. Therm. Sci. 2012, 57, 85–91. [Google Scholar] [CrossRef]

- Han, X.H.; Wang, Q.; Park, Y.G.; T’Joen, C.; Sommers, A.; Jacobi, A. A review of metal foam and metal matrix composites for heat exchangers and heat sinks. Heat Transf. Eng. 2012, 33, 991–1009. [Google Scholar] [CrossRef]

- Yang, C.; Nakayama, A.; Liu, W. Heat transfer performance assessment for forced convection in a tube partially filled with a porous medium. Int. J. Therm. Sci. 2012, 54, 98–108. [Google Scholar] [CrossRef]

- Yuan, W.; Tang, Y.; Yang, X.; Wan, Z. Porous metal materials for polymer electrolyte membrane fuel cells-A review. Appl. Energy 2012, 94, 309–329. [Google Scholar] [CrossRef]

- Chen, Z.; Gu, M.; Peng, D. Heat transfer performance analysis of a solar flat-plate collector with an integrated metal foam porous structure filled with paraffin. Appl. Therm. Eng. 2010, 30, 1967–1973. [Google Scholar] [CrossRef]

- Wang, P.; Liu, D.Y.; Xu, C. Numerical study of heat transfer enhancement in the receiver tube of direct steam generation with parabolic trough by inserting metal foams. Appl. Energy 2013, 102, 449–460. [Google Scholar] [CrossRef]

- Liu, Z.; Yao, Y.; Wu, H. Numerical modeling for solid-liquid phase change phenomena in porous media: Shell-and-tube type latent heat thermal energy storage. Appl. Energy 2013, 112, 1222–1232. [Google Scholar] [CrossRef]

- Lafdi, K.; Mesalhy, O.; Shaikh, S. Experimental study on the influence of foam porosity and pore size on the melting of phase change materials. J. Appl. Phys. 2007, 102, 083549. [Google Scholar] [CrossRef]

- Guden, M.; Yüksel, S. SiC-particulate aluminum composite foams produced from powder compacts: Foaming and compression behavior. J. Mater. Sci. 2006, 41, 4075–4084. [Google Scholar] [CrossRef]

- Kennedy, A. Porous Metals and Metal Foams Made from Powders. Powder Metall. 2012, 2, 31–46. [Google Scholar]

- Mondal, D.P.; Goel, M.D.; Das, S. Compressive deformation and energy absorption characteristics of closed cell aluminum-fly ash particle composite foam. Mater. Sci. Eng. A 2009, 507, 102–109. [Google Scholar] [CrossRef]

- Wang, Z.; Shen, J.; Lu, G.; Zhao, L. Compressive behavior of closed-cell aluminum alloy foams at medium strain rates. Mater. Sci. Eng. A 2011, 528, 2326–2330. [Google Scholar] [CrossRef]

- McCullough, K.Y.G.; Fleck, N.A.; Ashby, M.F. Uniaxial stress-strain behaviour of aluminum alloy foams. Acta Mater. 1999, 47, 2323–2330. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, J.; Fang, Q.; Wu, H.; Zhang, Y. Response of closed-cell aluminum foams under static and impact loading: Experimental and mesoscopic numerical analysis. Int. J. Impact Eng. 2017, 110, 382–394. [Google Scholar] [CrossRef]

- Moran, J.L.; Cottrill, A.L.; Benck, J.D.; Liu, P.; Yuan, Z.; Strano, M.S.; Buongiorno, J. Noble-gas-infused neoprene closed-cell foams achieving ultra-low thermal conductivity fabrics. RSC Adv. 2018, 8, 21389–21398. [Google Scholar] [CrossRef]

- Banhart, J.; Ashby, M.F.; Fleck, N.A. Metal foams and porous metal structures. Met. Innov. Technol. 1999, 83, 255–262. [Google Scholar]

- Rajak, D.K.; Kumaraswamidhas, L.A.; Das, S.; Senthil Kumaran, S. Characterization and analysis of compression load behaviour of aluminium alloy foam under the diverse strain rate. J. Alloys Compd. 2016, 656, 218–225. [Google Scholar] [CrossRef]

- Damanik, F.S.; Damanik, M.S.F.; Lange, P.G. Effect of Nickel Coated of Carbon Fiber on Distribution of Carbon Fiber Reinforced Aluminium (AlSi7) Foam Composite by Powder Metallurgy. Int. Conf. Innov. Technol. 2019, 1381, 9–13. [Google Scholar]

- Esmaeelzadeh, S.; Simchi, A.; Lehmhus, D. Effect of ceramic particle addition on the foaming behavior, cell structure and mechanical properties of P/M AlSi7 foam. Mater. Sci. Eng. A 2006, 424, 290–299. [Google Scholar] [CrossRef]

- Daoud, A. Compressive response and energy absorption of foamed A359–Al2O3 particle composites. J. Alloys Compd. 2009, 486, 597–605. [Google Scholar] [CrossRef]

- Kou, D.P.; Li, J.R.; Yu, J.L.; Cheng, H.F. Mechanical behavior of open-cell metallic foams with dual-size cellular structure. Scr. Mater. 2008, 59, 483–486. [Google Scholar] [CrossRef]

- Xu, Z.G.; Fu, J.W.; Luo, T.J.; Yang, Y.S. Effects of cell size on quasi-static compressive properties of Mg alloy foams. Mater. Des. 2012, 34, 40–44. [Google Scholar] [CrossRef]

- Shahzeydi, M.H.; Parvanian, A.M.; Panjepour, M. The distribution and mechanism of pore formation in copper foams fabricated by Lost Carbonate Sintering method. Mater. Charact. 2016, 111, 21–30. [Google Scholar] [CrossRef]

- Golabgir, M.H.; Ebrahimi-Kahrizsangi, R.; Torabi, O.; Saatchi, A. Fabrication of open cell Fe-10%Al foam by space-holder technique. Arch. Metall. Mater. 2014, 59, 41–45. [Google Scholar] [CrossRef]

- Sharma, M.; Modi, O.P.; Kumar, P. Synthesis and characterization of copper foams through a powder metallurgy route using a compressible and lubricant space-holder material. Int. J. Miner. Metall. Mater. 2018, 25, 902–912. [Google Scholar] [CrossRef]

- Li, Q. Effect of porosity and carbon composition on pore microstructure of magnesium/carbon nanotube composite foams. Mater. Des. 2016, 89, 978–987. [Google Scholar] [CrossRef]

- Zhuang, H.; Han, Y.; Feng, A. Preparation, mechanical properties and in vitro biodegradation of porous magnesium scaffolds. Mater. Sci. Eng. C 2008, 28, 1462–1466. [Google Scholar] [CrossRef]

- Wen, C.E.; Yamada, Y.; Shimojima, K.; Chino, Y.; Hosokawa, H.; Mabuchi, M. Compressibility of porous magnesium foam: Dependency on porosity and pore size. Mater. Lett. 2004, 58, 357–360. [Google Scholar] [CrossRef]

- Hu, L.; Li, Y.; Zhou, X.; Yuan, G. Characterization of as-cast microstructure of aluminum foams by melt foaming method. Mater. Lett. 2022, 308, 131112. [Google Scholar] [CrossRef]

- Awad, M.; Hassan, N.M.; Kannan, S. Mechanical properties of melt infiltration and powder metallurgy fabricated aluminum metal matrix composite. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2021, 235, 2093–2107. [Google Scholar] [CrossRef]

- Georgy, K.; Kumar, K.C.H.; Mukherjee, M. Optimization of Mg Blowing Agent Content for Foaming Aluminum. Metall. Mater. Trans. B Process Metall. Mater. Process. Sci. 2022, 53, 1089–1102. [Google Scholar] [CrossRef]

- Ghaleh, M.H.; Ehsani, N.; Baharvandi, H.R. High-Porosity Closed-Cell Aluminum Foams Produced by Melting Method Without Stabilizer Particles. Int. J. Met. 2020, 15, 899–905. [Google Scholar] [CrossRef]

- Linul, E.; Pietras, D.; Sadowski, T.; Marşavina, L.; Rajak, D.K.; Kovacik, J. Crashworthiness performance of lightweight Composite Metallic Foams at high temperatures. Compos. Part A Appl. Sci. Manuf. 2021, 149, 106516. [Google Scholar] [CrossRef]

- Palaniswamy, S.; Arunagiri, K.; Prakash, S. Corrosion behaviour of closed cell magnesium foam with rare earth elements by powder metallurgy process. AIP Conf. Proc. 2020, 2311, 040010. [Google Scholar] [CrossRef]

- Damanik, F.; Lange, G. Uniformly Dispersion of Multi-Walled Carbon Nanotubes in AlMg4Si8 Foam by Powder Metallurgy. In Proceedings of the 3rd Asia Pacific Conference on Research in Industrial and Systems Engineering, Depok, Indonesia, 16–17 June 2020; pp. 230–235. [Google Scholar] [CrossRef]

- Sharma, A.; Mishra, P. Microstructure and mechanical behaviour of Ti-Cu foams synthesized via powder metallurgy technique. Mater. Res. Express 2021, 8, 035402. [Google Scholar] [CrossRef]

- Sazegaran, H. Investigation on Production Parameters of Steel Foam Manufactured Through Powder Metallurgical Space Holder Technique. Met. Mater. Int. 2020, 27, 3371–3384. [Google Scholar] [CrossRef]

- Jain, H.; Mondal, D.P.; Gupta, G.; Kumar, R. Effect of compressive strain rate on the deformation behaviour of austenitic stainless steel foam produced by space holder technique. Mater. Chem. Phys. 2021, 259, 124010. [Google Scholar] [CrossRef]

- Abo Sbia, A.E.S.; Uzun, A. Production of MWCNT-Reinforced Aluminum Foams Via Powder Space-Holder Technique and Investigation of their Mechanical Properties. Trans. Indian Inst. Met. 2022, 75, 1–13. [Google Scholar] [CrossRef]

- Jha, N.; Mondal, D.P.; Dutta Majumdar, J.; Badkul, A.; Jha, A.K.; Khare, A.K. Highly porous open cell Ti-foam using NaCl as temporary space holder through powder metallurgy route. Mater. Des. 2013, 47, 810–819. [Google Scholar] [CrossRef]

- Yang, X.; Hu, Q.; Du, J.; Song, H.; Zou, T.; Sha, J.; He, C.; Zhao, N. Compression fatigue properties of open-cell aluminum foams fabricated by space-holder method. Int. J. Fatigue 2019, 121, 272–280. [Google Scholar] [CrossRef]

- Salehi, A.; Babakhani, A.; Zebarjad, S.M. Microstructural and mechanical properties of Al-SiO2 nanocomposite foams produced by an ultrasonic technique. Mater. Sci. Eng. A 2015, 638, 54–59. [Google Scholar] [CrossRef]

- Jain, H.; Mondal, D.P.; Gupta, G.; Kothari, A.; Kumar, R.; Pandey, A.; Shiva, S. Microstructure and high temperature compressive deformation in lightweight open cell titanium foam. Manuf. Lett. 2021, 27, 67–71. [Google Scholar] [CrossRef]

- Torres-Sanchez, C.; McLaughlin, J.; Bonallo, R. Effect of Pore Size, Morphology and Orientation on the Bulk Stiffness of a Porous Ti35Nb4Sn Alloy. J. Mater. Eng. Perform. 2018, 27, 2899–2909. [Google Scholar] [CrossRef]

- Nieh, T.G.; Higashi, K.; Wadsworth, J. Effect of cell morphology on the compressive properties of open-cell aluminum foams. Mater. Sci. Eng. A 2000, 283, 105–110. [Google Scholar] [CrossRef]

- Kennedy, A.R.; Asavavisitchai, S. Effects of TiB2 particle addition on the expansion, structure and mechanical properties of PM Al foams. Scr. Mater. 2004, 50, 115–119. [Google Scholar] [CrossRef]

- Yang, D.H.; Yang, S.R.; Ma, A.B.; Jiang, J.H. Compression properties of cellular AlCu5Mn alloy foams with wide range of porosity. J. Mater. Sci. 2009, 44, 5552–5556. [Google Scholar] [CrossRef]

- Ipek Nakaş, G.; Dericioglu, A.F.; Bor, Ş. Fatigue behavior of TiNi foams processed by the magnesium space holder technique. J. Mech. Behav. Biomed. Mater. 2011, 4, 2017–2023. [Google Scholar] [CrossRef]

- San Marchi, C.; Mortensen, A. Deformation of open-cell aluminum foam. Acta Mater. 2001, 49, 3959–3969. [Google Scholar] [CrossRef][Green Version]

- Parvanian, A.M.; Panjepour, M. Mechanical behavior improvement of open-pore copper foams synthesized through space holder technique. Mater. Des. 2013, 49, 834–841. [Google Scholar] [CrossRef]

- Wang, Q.Z.; Lu, D.M.; Cui, C.X.; Liang, L.M. Compressive behaviors and energy-absorption properties of an open-celled porous Cu fabricated by replication of NaCl space-holders. J. Mater. Process. Technol. 2011, 211, 363–367. [Google Scholar] [CrossRef]

- Sadighikia, S.; Abdolhosseinzadeh, S.; Asgharzadeh, H. Production of high porosity Zn foams by powder metallurgy method. Powder Metall. 2015, 58, 61–66. [Google Scholar] [CrossRef]

- Bafti, H.; Habibolahzadeh, A. Production of aluminum foam by spherical carbamide space holder technique-processing parameters. Mater. Des. 2010, 31, 4122–4129. [Google Scholar] [CrossRef]

- Kenesei, P.; Kádár, C.; Rajkovits, Z.; Lendvai, J. The influence of cell-size distribution on the plastic deformation in metal foams. Scr. Mater. 2004, 50, 295–300. [Google Scholar] [CrossRef]

- Miyoshi, T.; Hara, S.; Mukai, T.; Higashi, K. Development of a Closed Cell Aluminum Alloy Foam with Enhancement of the Compressive Strength. Mater. Trans. 2001, 42, 2118–2123. [Google Scholar] [CrossRef]

- Yang, D.; Guo, S.; Chen, J.; Qiu, C.; Agbedor, S.O.; Ma, A.; Jiang, J.; Wang, L. Preparation principle and compression properties of cellular Mg–Al–Zn alloy foams fabricated by the gas release reaction powder metallurgy approach. J. Alloys Compd. 2021, 857, 158112. [Google Scholar] [CrossRef]

- Wang, H.; Zhu, D.F.; Wu, Y.; Liu, X.J.; Jiang, S.H.; Nieh, T.G.; Lu, Z.P. New insight into fabrication of shaped Mg–X alloy foams with cellular structure via a gas release reaction powder metallurgy route. J. Iron Steel Res. Int. 2021, 28, 125–132. [Google Scholar] [CrossRef]

- Huang, L.; Wang, H.; Yang, D.; Ye, F.; Lu, Z.P. Effects of scandium additions on mechanical properties of cellular Al-based foams. Intermetallics 2012, 28, 71–76. [Google Scholar] [CrossRef]

- Chethan, A.; Garcia-Moreno, F.; Wanderka, N.; Murty, B.S.; Banhart, J. Influence of oxides on the stability of zinc foam. J. Mater. Sci. 2011, 46, 7806–7814. [Google Scholar] [CrossRef]

- Song, Y.H.; Tane, M.; Ide, T.; Seimiya, Y.; Hur, B.Y.; Nakajima, H. Fabrication of Al-3.7 PCT Si-0.18 PCT MG foam strengthened by aln particle dispersion and its compressive properties. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2010, 41, 2104–2111. [Google Scholar] [CrossRef]

- Suárez, M.A.; Delgado-Pamanes, M.F.; Chávez-Alcalá, J.F.; Cruz-Ramírez, A.; Guadarrama, I.; Figueroa, I.A. Microstructural and mechanical characterization of quasicrystalline Al-Cu-Fe foams. Mater. Today Commun. 2022, 30, 103043. [Google Scholar] [CrossRef]

- Tripathi, O.; Dwivedi, V.K.; Agarwal, M. Microstructural-mechanical co-relation for Al2O3 reinforced aluminum metallic foam processed by compaction and sintering. J. Aust. Ceram. Soc. 2021, 58, 367–377. [Google Scholar] [CrossRef]

- Yang, D.; Chen, J.; Chen, W.; Wang, L.; Wang, H.; Jiang, J.; Ma, A. Fabrication of cellular Zn–Mg alloy foam by gas release reaction via powder metallurgical approach. J. Mater. Sci. Technol. 2017, 33, 1141–1146. [Google Scholar] [CrossRef]

- Farahani, M.R.; Rezaei Ashtiani, H.R.; Elahi, S.H. Effect of Zinc Content on the Mechanical Properties of Closed-Cell Aluminum Foams. Int. J. Met. 2021, 16, 713–722. [Google Scholar] [CrossRef]

- Gibson, L.J.; Ashby, M.F. The Mechanics of Three-Dimensional Cellular Materials. Proc. R. Soc. London A Math. Phys. Sci. 1982, 382, 43–59. [Google Scholar]

- Gibson, L.J.; Editor, G. Cellular Solids; Cambridge University Press: Cambridge, UK, 2021; pp. 270–274. [Google Scholar]

- Ashby, M.F.; Gibson, L.J. Cellular Solids: Structure and Properties; Cambridge University Press: Cambridge, UK, 1997. [Google Scholar]

- Jiang, B.; Zhao, N.Q.; Shi, C.S.; Li, J.J. Processing of open cell aluminum foams with tailored porous morphology. Scr. Mater. 2005, 53, 781–785. [Google Scholar] [CrossRef]

- Bekoz, N.; Oktay, E. Effects of carbamide shape and content on processing and properties of steel foams. J. Mater. Process. Technol. 2012, 212, 2109–2116. [Google Scholar] [CrossRef]

- Aly, M.S.M.A.; Bleck, W. High Temperature Mechanical Properties of Cast as Well as Powder Metallurgical Manufactured Metallic Foams; RWTH Aachen University: Aachen, Germany, 2004. [Google Scholar]

- Bekoz, N.; Oktay, E. The role of pore wall microstructure and micropores on the mechanical properties of Cu-Ni-Mo based steel foams. Mater. Sci. Eng. A 2014, 612, 387–397. [Google Scholar] [CrossRef]

- Xia, X.C.; Chen, X.W.; Zhang, Z.; Chen, X.; Zhao, W.M.; Liao, B.; Hur, B. Effects of porosity and pore size on the compressive properties of closed-cell Mg alloy foam. J. Magnes. Alloys 2013, 1, 330–335. [Google Scholar] [CrossRef]

- Hassanli, F.; Paydar, M.H. Improvement in energy absorption properties of aluminum foams by designing pore-density distribution. J. Mater. Res. Technol. 2021, 14, 609–619. [Google Scholar] [CrossRef]

- Alizadeh, M.; Mirzaei-Aliabadi, M. Compressive properties and energy absorption behavior of Al-Al2O3 composite foam synthesized by space-holder technique. Mater. Des. 2012, 35, 419–424. [Google Scholar] [CrossRef]

- Yang, K.; Yang, X.; Liu, E.; Shi, C.; Ma, L.; He, C.; Li, Q.; Li, J.; Zhao, N. Elevated temperature compressive properties and energy absorption response of in-situ grown CNT- reinforced Al composite foams. Mater. Sci. Eng. A 2017, 690, 294–302. [Google Scholar] [CrossRef]

- Rathore, R.K.; Singh, N.K.; Xavier, J. Epilogue. In Processing and Characterization of Materials; Springer: Berlin/Heidelberg, Germany, 2021; Volume 13, pp. 369–370. [Google Scholar] [CrossRef]

- Banhart, J. Manufacturing routes for metallic foams. Jom 2000, 52, 22–27. [Google Scholar] [CrossRef]

- Jiejun, W.; Chenggong, L.; Dianbin, W.; Manchang, G. Damping and sound absorption properties of particle reinforced Al matrix composite foams. Compos. Sci. Technol. 2003, 63, 569–574. [Google Scholar] [CrossRef]

- Mondal, D.P.; Goel, M.D.; Das, S. Effect of strain rate and relative density on compressive deformation behaviour of closed cell aluminum-fly ash composite foam. Mater. Des. 2009, 30, 1268–1274. [Google Scholar] [CrossRef]

- Deqing, W.; Ziyuan, S. Effect of ceramic particles on cell size and wall thickness of aluminum foam. Mater. Sci. Eng. A 2003, 361, 45–49. [Google Scholar] [CrossRef]

- Malekjafarian, M.; Sadrnezhaad, S.K.; Abravi, M.S.; Golestanipour, M.; Mashhadi, H.A. Manufacturing aluminum foams by melt gas injection process. In Proceedings of the 7th International Conference on Porous Metals and Metallic Foams, Busan, Korea, 18–21 September 2011; pp. 195–202. [Google Scholar]

- Surace, R.; De Filippis, L.; Ludovico, A.; Boghetich, G. Experimental analysis of the effect of control factors on aluminium foam produced by powder metallurgy. Est. J. Eng. 2007, 13, 156–167. [Google Scholar]

- Jeenager, V.K.; Pancholi, V. Influence of cell wall microstructure on the energy absorption capability of aluminium foam. Mater. Des. 2014, 56, 454–459. [Google Scholar] [CrossRef]

- Uzun, A.; Turker, M. The effect of production parameters on the foaming behavior of spherical-shaped aluminum foam. Mater. Res. 2014, 17, 311–315. [Google Scholar] [CrossRef]

- Mukherjee, M.; García-Moreno, F.; Jiménez, C.; Rack, A.; Banhart, J. Microporosity in aluminium foams. Acta Mater. 2017, 131, 156–168. [Google Scholar] [CrossRef]

- Asavavisithchai, S.; Kennedy, A.R. The effect of compaction method on the expansion and stability of aluminium foams. Adv. Eng. Mater. 2006, 8, 810–815. [Google Scholar] [CrossRef]

- Nakamura, T.; Gnyloskurenko, S.V.; Sakamoto, K.; Byakova, A.V.; Ishikawa, R. Development of new foaming agent for metal foam. Mater. Trans. 2002, 43, 1191–1196. [Google Scholar] [CrossRef]

- Amirjan, M.; Bozorg, M. Properties and corrosion behavior of Al based nanocomposite foams produced by the sintering-dissolution process. Int. J. Miner. Metall. Mater. 2018, 25, 94–101. [Google Scholar] [CrossRef]

- Li, D.W.; Jie, L.I.; Tao, L.I.; Ting SU, N.; Zhang, X.M.; Yao, G.C. Preparation and characterization of aluminum foams with ZrH2 as foaming agent. Trans. Nonferrous Met. Soc. China 2011, 21, 346–352. [Google Scholar] [CrossRef]

- Matijasevic, B.; Görke, O.; Schubert, H.; Banhart, J. Zirconium Hydride-A Possible Blowing Agent for Making Aluminium Alloy Foams. Porous Met. Met. Foam. Technol. 2006, 107–110. [Google Scholar]

- Haesche, M.; Lehmhus, D.; Weise, J.; Wichmann, M.; Mocellin, I.C.M. Carbonates as foaming agent in chip-based aluminium foam precursor. J. Mater. Sci. Technol. 2010, 26, 845–850. [Google Scholar] [CrossRef]

- Kevorkijan, V.; Škapin, S.D.; Paulin, I.; Šuštaršič, B.; Jenko, M. Synthesis and characterisation of closed cells aluminium foams containing dolomite powder as foaming agent. Mater. Tehnol. 2010, 44, 363–371. [Google Scholar]

- Sasikumar, S.; Georgy, K.; Mukherjee, M.; Kumar, G.S.V. Production, stability, and properties of in-situ Al–5ZrB2 composite foams. Mater. Sci. Eng. A 2022, 849, 143501. [Google Scholar] [CrossRef]

- Gui, M.C.; Wang, D.B.; Wu, J.J.; Yuan, G.J.; Li, C.G. Deformation and damping behaviors of foamed Al-Si-SiCp composite. Mater. Sci. Eng. A 2000, 286, 282–288. [Google Scholar] [CrossRef]

- Luo, Y.; Yu, S.; Li, W.; Liu, J.; Wei, M. Compressive behavior of SiCp/AlSi9Mg composite foams. J. Alloys Compd. 2008, 460, 294–298. [Google Scholar] [CrossRef]

- Yu, S.; Luo, Y.; Liu, J. Effects of strain rate and SiC particle on the compressive property of SiC p/AlSi 9 Mg composite foams. Mater. Sci. Eng. A 2008, 487, 394–399. [Google Scholar] [CrossRef]

- Orbulov, I.N.; Ginsztler, J. Compressive characteristics of metal matrix syntactic foams. Compos. Part A Appl. Sci. Manuf. 2012, 43, 553–561. [Google Scholar] [CrossRef]

- Yang, D.H.; Hur, B.Y.; He, D.P.; Yang, S.R. Effect of decomposition properties of titanium hydride on the foaming process and pore structures of Al alloy melt foam. Mater. Sci. Eng. A 2007, 445, 415–426. [Google Scholar] [CrossRef]

- Yang, D.H.; Hur, B.Y.; Yang, S.R. Study on fabrication and foaming mechanism of Mg foam using CaCO3 as blowing agent. J. Alloys Compd. 2008, 461, 221–227. [Google Scholar] [CrossRef]

- Erryani, A.; Pramuji, F.; Annur, D.; Amal, M.I.; Kartika, I. Microstructures and Mechanical Study of Mg Alloy Foam Based on Mg-Zn-Ca-CaCO3 System. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: East Java, Indonesia, 2017; Volume 202. [Google Scholar] [CrossRef]

- Tane, M.; Nakajima, H. Fabrication of porous magnesium with directional pores through use of hydrogen thermally decomposed from MgH2 powders during unidirectional solidification. J. Mater. Res. 2008, 23, 849–855. [Google Scholar] [CrossRef]

- Yang, D.; Seo, C.; Hur, B.Y. Mg alloy foam fabrication via melt foaming method. J. Mater. Sci. Technol. 2008, 24, 302–304. [Google Scholar]

- Papadopoulos, D.P.; Konstantinidis, I.C.; Papanastasiou, N.; Skolianos, S.; Lefakis, H.; Tsipas, D.N. Mechanical properties of Al metal foams. Mater. Lett. 2004, 58, 2574–2578. [Google Scholar] [CrossRef]

- Kadoi, K.; Nakae, H. Relationship between foam stabilization and physical properties of particles on aluminum foam production. Mater. Trans. 2011, 52, 1912–1919. [Google Scholar] [CrossRef]

- Mu, Y.; Yao, G.; Liang, L.; Luo, H.; Zu, G. Deformation mechanisms of closed-cell aluminum foam in compression. Scr. Mater. 2010, 63, 629–632. [Google Scholar] [CrossRef]

- Raj, R.E.; Daniel, B.S.S. Structural and compressive property correlation of closed-cell aluminum foam. J. Alloys Compd. 2009, 467, 550–556. [Google Scholar] [CrossRef]

- Yu, S.; Liu, J.; Luo, Y.; Liu, Y. Compressive behavior and damping property of ZA22/SiCp composite foams. Mater. Sci. Eng. A 2007, 457, 325–328. [Google Scholar] [CrossRef]

- Liu, J.; Yu, S.; Zhu, X.; Wei, M.; Luo, Y.; Liu, Y. Correlation between ceramic additions and compressive properties of Zn-22Al matrix composite foams. J. Alloys Compd. 2009, 476, 220–225. [Google Scholar] [CrossRef]

- Amsterdam, E.; De Hosson, J.T.M.; Onck, P.R. Failure mechanisms of closed-cell aluminum foam under monotonic and cyclic loading. Acta Mater. 2006, 54, 4465–4472. [Google Scholar] [CrossRef]

- Markaki, A.E.; Clyne, T.W. The effect of cell wall microstructure on the deformation and fracture of aluminium-based foams. Acta Mater. 2001, 49, 1677–1686. [Google Scholar] [CrossRef]

- Heidari Ghaleh, M.; Ehsani, N.; Baharvandi, H.R. Compressive Properties of A356 Closed-Cell Aluminum Foamed with a CaCO3 Foaming Agent Without Stabilizer Particles. Met. Mater. Int. 2021, 27, 3856–3861. [Google Scholar] [CrossRef]

- Kováčik, J.; Simančík, F. Comparison of zinc and aluminium foam behaviour. Kov. Mater. 2004, 42, 79–90. [Google Scholar]

- Mutlu, I.; Oktay, E. Production and characterisation of Cr-Si-Ni-Mo steel foams. Indian J. Eng. Mater. Sci. 2011, 18, 227–232. [Google Scholar]

- Zhao, N.Q.; Jiang, B.; Du, X.W.; Li, J.J.; Shi, C.S.; Zhao, W.X. Effect of Y2O3 on the mechanical properties of open cell aluminum foams. Mater. Lett. 2006, 60, 1665–1668. [Google Scholar] [CrossRef]

- Hussain, Z.; Suffin, N.S.A. Microstructure and Mechanical Behaviour of Aluminium Foam Produced by Sintering Dissolution Process Using NaCl Space Holder. J. Eng. Sci. 2011, 7, 37–49. [Google Scholar]

- Mohammed, S.H. Manufacturing of Aluminum Foam as a Light Weight Structural Material. Eng. Tech. J. 2016, 34, 697–702. [Google Scholar]

- Despois, J.F.; Marmottant, A.; Salvo, L.; Mortensen, A. Influence of the infiltration pressure on the structure and properties of replicated aluminium foams. Mater. Sci. Eng. A 2007, 462, 68–75. [Google Scholar] [CrossRef]

- Gaillard, C.; Despois, J.F.; Mortensen, A. Processing of NaCI powders of controlled size and shape for the microstructural tailoring of aluminium foams. Mater. Sci. Eng. A 2004, 374, 250–262. [Google Scholar] [CrossRef]

- Sun, D.X.; Zhao, Y.Y. Static and dynamic energy absorption of Al foams produced by the sintering and dissolution process. Metall. Mater. Trans. B Process Metall. Mater. Process. Sci. 2003, 34, 69–74. [Google Scholar] [CrossRef]

- Ertürk, A.T. Production of aluminum glass fiber reinforced foam synthesized by space-holder technique. Acta Phys. Pol. A 2016, 129, 592–595. [Google Scholar] [CrossRef]

- Michailidis, N.; Stergioudi, F.; Tsouknidas, A.; Pavlidou, E. Compressive response of Al-foams produced via a powder sintering process based on a leachable space-holder material. Mater. Sci. Eng. A 2011, 528, 1662–1667. [Google Scholar] [CrossRef]

- Jamal, N.A.; Maizatul, O.; Anuar, H.; Yusof, F.; Nor, Y.A.; Khalid, K.; Zakaria, M.N. Preliminary development of porous aluminum via powder metallurgy technique. Mater. Werkst. 2018, 49, 460–466. [Google Scholar] [CrossRef]

- Tatt, T.K.; Muhamad, N.; Muchtar, A.; Sulong, A.B.; Shia, K.Y. Production of porous stainless steel using the space holder method. Sains Malays. 2021, 50, 507–514. [Google Scholar] [CrossRef]

- Hong, K.; Kádár, C.; Knapek, M.; Drozdenko, D.; Jenei, P.; Kim, M.Y.; Choe, H.; Máthis, K.; Park, H.; Gubicza, J. Comparison of morphology and compressive deformation behavior of copper foams manufactured via freeze-casting and space-holder methods. J. Mater. Res. Technol. 2021, 15, 6855–6865. [Google Scholar] [CrossRef]

- Stanev, L.; Kolev, M.; Drenchev, B.; Drenchev, L. Open-cell metallic porous materials obtained through space holders-Part II: Structure and properties. A review. J. Manuf. Sci. Eng. Trans. ASME 2017, 139, 050802. [Google Scholar] [CrossRef]

- Brothers, A.H.; Scheunemann, R.; DeFouw, J.D.; Dunand, D.C. Processing and structure of open-celled amorphous metal foams. Scr. Mater. 2005, 52, 335–339. [Google Scholar] [CrossRef]

- Abdullah, Z.; Ahmad, S.; Ramli, M. The impact of composition and sintering temperature for stainless steel foams (SS316l) fabricated by space holder method with urea as space holder. Mater. Sci. Forum 2017, 888, 413–417. [Google Scholar] [CrossRef]

- Ozan, S.; Bilhan, S. Effect of fabrication parameters on the pore concentration of the aluminum metal foam, manufactured by powder metallurgy process. Int. J. Adv. Manuf. Technol. 2008, 39, 257–260. [Google Scholar] [CrossRef]

- Čapek, J.; Vojtěch, D. Microstructural and mechanical characteristics of porous iron prepared by powder metallurgy. Mater. Sci. Eng. C 2014, 43, 494–501. [Google Scholar] [CrossRef]

- Čapek, J.; Vojtěch, D.; Oborná, A. Microstructural and mechanical properties of biodegradable iron foam prepared by powder metallurgy. Mater. Des. 2015, 83, 468–482. [Google Scholar] [CrossRef]

- Jiang, B.; Wang, Z.; Zhao, N. Effect of pore size and relative density on the mechanical properties of open cell aluminum foams. Scr. Mater. 2007, 56, 169–172. [Google Scholar] [CrossRef]

- Mohd Razali, R.N.; Abdullah, B.; Ismail, M.H.; Ahmad, U.K.; Idham, M.F.; Rasmli, A. Mechanical properties of aluminium foam by conventional casting combined with NaCL space holder. Appl. Mech. Mater. 2013, 393, 156–160. [Google Scholar] [CrossRef]

- Jamal, N.A.; Tan, A.W.; Yusof, F.; Katsuyoshi, K.; Hisashi, I.; Singh, S.; Anuar, H. Fabrication and compressive properties of low to medium porosity closed-cell porous Aluminum using PMMA space holder technique. Materials 2016, 9, 254. [Google Scholar] [CrossRef]

- Tan, P.P.; Mohamad, H.; Anasyida, A.S. Properties of Porous Magnesium Using Polymethyl Methacrylate (PMMA) as a Space Holder. J. Phys. Conf. Ser. 2018, 1082, 1–6. [Google Scholar] [CrossRef]

- Bi, Y.; Zheng, Y.; Li, Y. Microstructure and mechanical properties of sintered porous magnesium using polymethyl methacrylate as the space holder. Mater. Lett. 2015, 161, 583–586. [Google Scholar] [CrossRef]

- Zhao, Y.Y.; Fung, T.; Zhang, L.P.; Zhang, F.L. Lost carbonate sintering process for manufacturing metal foams. Scr. Mater. 2005, 52, 295–298. [Google Scholar] [CrossRef]

- Parvanian, A.M.; Saadatfar, M.; Panjepour, M.; Kingston, A.; Sheppard, A.P. The effects of manufacturing parameters on geometrical and mechanical properties of copper foams produced by space holder technique. Mater. Des. 2014, 53, 681–690. [Google Scholar] [CrossRef]

- Cuba Ramos, A.I.; Dunand, D.C. Preparation and characterization of directionally freeze-cast copper foams. Metals 2012, 2, 265–273. [Google Scholar] [CrossRef]

- Körner, C.; Berger, F.; Arnold, M.; Stadelmann, C.; Singer, R.F. Influence of processing conditions on morphology of metal foams produced from metal powder. Mater. Sci. Technol. 2000, 16, 781–784. [Google Scholar] [CrossRef]

- Surace, R.; De Filippis, L.A.C.; Ludovico, A.D.; Boghetich, G. Influence of processing parameters on aluminium foam produced by space holder technique. Mater. Des. 2009, 30, 1878–1885. [Google Scholar] [CrossRef]

- Aguirre-Perales, L.Y.; Jung, I.H.; Drew, R.A.L. Foaming behavior of powder metallurgical Al-Sn foams. Acta Mater. 2012, 60, 759–769. [Google Scholar] [CrossRef]

- Mahmutyazicioglu, N.; Albayrak, O.; Ipekoglu, M.; Altintas, S. Effects of alumina (Al2O3) addition on the cell structure and mechanical properties of 6061 foams. J. Mater. Res. 2013, 28, 2509–2519. [Google Scholar] [CrossRef]

- Aguirre-perales, L.Y.; Drew, R.A.L.; Jung, I. The Effect of In Situ Intermetallic Formation on Al-Sn Foaming Behavior. Metall. Mater. Trans. A 2014, 45, 3714–3727. [Google Scholar] [CrossRef]

- Duarte, I.; Banhart, J. A study of aluminium foam formation—Kinetics and microstructure. Acta Mater. 2000, 48, 2349–2362. [Google Scholar] [CrossRef]

- Jee, C.S.Y.; Özgüven, N.; Guo, Z.X.; Evans, J.R.G. Preparation of high porosity metal foams. Metall. Mater. Trans. B Process Metall. Mater. Process. Sci. 2000, 31, 1345–1352. [Google Scholar] [CrossRef]

- Sahu, S.; Mondal, D.P.; Cho, J.U.; Goel, M.D.; Ansari, M.Z. Low-velocity impact characteristics of closed cell AA2014-SiCp composite foam. Compos. Part B Eng. 2019, 160, 394–401. [Google Scholar] [CrossRef]

- Duarte, I.; Ventura, E.; Olhero, S.; Ferreira, J.M.F. An effective approach to reinforced closed-cell Al-alloy foams with multiwalled carbon nanotubes. Carbon 2015, 95, 589–600. [Google Scholar] [CrossRef]

- Schäffler, P.; Hanko, G.; Mitterer, H.; Zach, P. Alulight metal foam products. In Proceedings of the 5th International Conference on Porous Metals and Metallic Foams, Lancaster, PA, USA, 5–7 September 2008; pp. 7–10. [Google Scholar]

- Guo, J.; Du, Z.; Liu, G.; Yang, X.; Li, M.-J. Compression effect of metal foam on melting phase change in a shell-and-tube unit. Appl. Therm. Eng. 2022, 206, 118124. [Google Scholar] [CrossRef]

- Eugénio, S.; Silva, T.M.; Carmezim, M.J.; Duarte, R.G.; Montemor, M.F. Electrodeposition and characterization of nickel-copper metallic foams for application as electrodes for supercapacitors. J. Appl. Electrochem. 2014, 44, 455–465. [Google Scholar] [CrossRef]

- Campana, F.; Pilone, D. Effect of heat treatments on the mechanical behaviour of aluminium alloy foams. Scr. Mater. 2009, 60, 679–682. [Google Scholar] [CrossRef]

- Aghion, E.; Yered, T.; Perez, Y.; Gueta, Y. The prospects of carrying and releasing drugs via biodegradable magnesium foam. Adv. Eng. Mater. 2010, 12, 374–379. [Google Scholar] [CrossRef]

- Duarte, I.M.A.; Banhart, J.; Ferreira, A.J.M.; Santos, M.J.G. Foaming around fastening elements. Mater. Sci. Forum 2006, 514, 712–717. [Google Scholar] [CrossRef]

- Chen, S.; Bourham, M.; Rabiei, A. Applications of Open-cell and Closed-cell Metal Foams for Radiation Shielding. Procedia Mater. Sci. 2014, 4, 293–298. [Google Scholar] [CrossRef]

- Aerospace, E. Duocel® Aluminum Foam–ERG Aerospace. Available online: http://ergaerospace.com/materials/duocel-aluminum-foam/ (accessed on 21 January 2021).

- Oriňák, A.; Oriňáková, R.; Králová, Z.O.; Turoňová, A.M.; Kupková, M.; Hrubovčáková, M.; Radoňák, J.; Džunda, R. Sintered metallic foams for biodegradable bone replacement materials. J. Porous Mater. 2014, 21, 131–140. [Google Scholar] [CrossRef]

- Banhart From fundamental research to applications. Europhys. News 2010, 41, 3.

- Hrubovčáková, M.; Kupková, M.; Džupon, M. Fe and Fe-P Foam for Biodegradable Bone Replacement Material: Morphology, Corrosion Behaviour, and Mechanical Properties. Adv. Mater. Sci. Eng. 2016, 2016, 6257368. [Google Scholar] [CrossRef]

- Filetin, T.; Marić, G.; Kramer, I. Metal foams in shipbuilding. Brodogradnja 2005, 56, 228–237. [Google Scholar]

- Huisseune, H.; De Schampheleire, S.; Ameel, B.; De Paepe, M. Comparison of metal foam heat exchangers to a finned heat exchanger for low Reynolds number applications. Int. J. Heat Mass Transf. 2015, 89, 1–9. [Google Scholar] [CrossRef]

- Banhart, J.; Seeliger, H.-W. Aluminium Foam Sandwich Panels: Manufacture, Metallurgy and Applications. Adv. Eng. Mater. 2008, 10, 793–802. [Google Scholar] [CrossRef]

- Banhart, J. Metal foams—from fundamental research to applications. Front. Des. Mater. 2007, 279, 280–289. [Google Scholar]

- García-Moreno, F. Commercial applications of metal foams: Their properties and production. Materials 2016, 9, 85. [Google Scholar] [CrossRef] [PubMed]

- Banhart, J. Aluminium foams for lighter vehicles. Int. J. Veh. Des. 2005, 37, 114–125. [Google Scholar] [CrossRef]

- Bryant, J.D.; Crowley, M.; Wang, W.; Wilhelmy, D.; Kallivayalil, J. Development of Alcoa aluminum foam products. Porous Met. Met. Foam. 2008, 19–22. [Google Scholar]

- Hanssen, A.G.; Stöbener, K.; Rausch, G.; Langseth, M.; Keller, H. Optimisation of energy absorption of an A-pillar by metal foam insert. Int. J. Crashworthiness 2006, 11, 231–242. [Google Scholar] [CrossRef]

- Walther, G.; Klöden, B.; Büttner, T.; Weissgärber, T.; Kieback, B.; Böhm, A.; Naumann, D.; Soberi, S.; Timberg, L. A new class of high temperature and corrosion resistant nickel-based open-cell foams. Adv. Eng. Mater. 2008, 10, 803–811. [Google Scholar] [CrossRef]

- Torres, Y.; Rodríguez, J.A.; Arias, S.; Echeverry, M.; Robledo, S.; Amigo, V.; Pavón, J.J. Processing, characterization and biological testing of porous titanium obtained by space-holder technique. J. Mater. Sci. 2012, 47, 6565–6576. [Google Scholar] [CrossRef]

| Fabrication Technique (Strain Rate) | Material | Porosity | Plateau Stress (MPa) | Energy Absorption (MJ/m3) | Reference |

|---|---|---|---|---|---|

| Space-holder technique (Strain rate = 0.01/s) | Ti foam | 80 | 12.55 | - | [59] |

| Ti foam | 78 | 15.42 | - | ||

| Ti foam | 76 | 15.84 | - | ||

| Ti foam | 74 | 21.61 | - | ||

| Ti foam | 72.4 | 25.43 | - | ||

| Ti foam | 70 | 27.97 | - | ||

| Ti foam | 66.6 | 30.76 | - | ||

| Space-holder technique (Strain rate = 0.01/s) | Al foam | 50 | 29.5 | 20.9 | [60] |

| Al foam | 60 | 18.8 | 13.5 | ||

| Al foam | 70 | 9.9 | 6.6 | ||

| Melt foaming (Strain rate = 3 × 10−3 s−1) | Al/0.25 wt.% SiO2 | 86 | 0.8 | 13.7 | [61] |

| Al/0.5 wt.% SiO2 | 84 | 1.4 | 46.2 | ||

| Al/0.75 wt.% SiO2 | 91 | 0.4 | 23.0 | ||

| Al/1.0 wt.% SiO2 | 87 | 0.7 | 18.3 | ||

| Space-holder technique (Strain rate = 0.01/s) | Ti foam | 68 | 100 | 120 | [62] |

| Ti foam | 57 | 180 | 160 | ||

| Ti foam | 46 | 260 | 220 |

| Foam Material | Foaming Agent | Fabrication Technique | Mechanical Properties | References |

|---|---|---|---|---|

| Al (ALPORAS) | TiH2 | Melt foaming |

| [73] |

| Al alloy | TiH2 | Melt foaming |

| [74] |

| Mg–Al, Mg–Zn and Mg–Cu foams | CaCO3 | Powder metallurgy |

| [76] |

| Al/ scandium | TiH2 | Melt foaming |

| [77] |

| Al/TiB2 | TiH2 | Powder metallurgy |

| [65] |

| Zn foam | TiH2 | Powder metallurgy |

| [78] |

| Al/3.7% Si/0.18% Mg | TiH2 | Melt foaming |

| [79] |

| Al63Cu28Fe9 alloy | - | Melt foaming |

| [80] |

| Al/Al2O3 | - | Powder metallurgy |

| [81] |

| Zn–Mg alloy foam | CaCO3 | Powder metallurgy |

| [82] |

| Al/Zn foams | CaCO3 | Melt foaming |

| [83] |

| Mg/Al/Zn foams | CaCO3 | Powder metallurgy |

| [75] |

| Processing Technique | Foam Type | Material | Space Holder/Blowing Agent | Reference |

|---|---|---|---|---|

| Space-holder technique | Closed cell | Al | Space holder (Carbamide) | [92] |

| Space-holder technique | Open cell | Al-Al2O3 | Space holder (Carbamide) | [93] |

| Powder metallurgy (blowing agent) | Closed cell | Al | Blowing agent (Dolomite) | [11] |

| Space-holder technique | Closed cell | Al-CNT | Space holder (Carbamide) | [94] |

| Melt foaming | Closed cell | AlMnCu | Blowing agent (TiH2) | [66] |

| Powder metallurgy (blowing agent) | Closed cell | AA7075/SiC | Foaming agent (CaCO3) | [95] |

| Foam Material | Foam Type | Foaming Agents | Reference |

|---|---|---|---|

| Al | Closed cell | TiH2 | [122] |

| Al/SiC | Closed cell | TiH2 | [123] |

| Al/Ca | Closed cell | TiH2 | [124] |

| Al 6061/Cu | Closed cell | TiH2 | [125] |

| ZA22/SiC | Closed cell | CaCO3 | [126] |

| Zn/22Al/SiC | Closed cell | CaCO3 | [127] |

| Al alloy (ALPORAS) | Closed cell | TiH2 | [128] |

| Al (ALPORAS) | Closed cell | TiH2 | [129] |

| Al/Si/Mg | Closed cell | CaCO3 | [130] |

| Foam Material | Foaming Agent/Space Holders | Fabrication Technique | Reference |

|---|---|---|---|

| Cu | Potassium carbonate | Space-holder method | [155] |

| Cu | Potassium carbonate | Space-holder method | [156] |

| Cu/CuO | Oxide | Powder metallurgy | [157] |

| AlSi10Mg | TiH2 | Powder metallurgy | [158] |

| Al/Mg | NaCl | Space-holder method | [159] |

| Al/Y2O3 | NaCl | Space-holder method | [133] |

| Al/SiC | TiH2 | Powder metallurgy | [28] |

| Al–Sn foams | TiH2 | Powder metallurgy | [160] |

| Al 6061-Al2O3 | TiH2 | Powder metallurgy | [161] |

| Al-Sn (Co, Mg, Mn, Ni, and Ti) | TiH2 | Powder metallurgy | [162] |

| Al6061 and AlSi7 alloys | TiH2 | Powder metallurgy | [163] |

| Fe/Titanium (Ti) | CO2 | Powder metallurgy | [164] |

| AA2014-SiC | Calcium hydride | Liquid metallurgy | [165] |

| Al/MWCNTs | TiH2 | Powder metallurgy | [166] |

| Fabrication Techniques | Advantages | Disadvantages |

|---|---|---|

| Melt foaming |

|

|

| Powder metallurgy |

|

|

| Foams | Applications | Reference |

|---|---|---|

| Mg foams | Bone implants | [46] |

| Metallic foam | Heat exchanger | [168] |

| Ni-Cu | Electrodes for super capacitors | [169] |

| Al7075 and 6061 alloy | Crash boxes | [170] |

| Drug delivery | [171] | |

| Al alloy (AlSi12 or 6061) | Foaming around fastening elements | [172] |

| A356/steel | Radiation shielding | [173] |

| Al-foam (Duocel®) | Military-medium tactical vehicles | [174] |

| Fe/Mg/CNT foam | Bone implant | [175] |

| Al foam | Crash box for Valeo’s front-end module systems | [176] |

| Fe/P foam | Bone replacement | [177] |

| Al foam | Ship structure | [178] |

| Cu foam | Heat exchangers | [179] |

| Alulight | Tail lifts, Alimex panel | [180] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Parveez, B.; Jamal, N.A.; Anuar, H.; Ahmad, Y.; Aabid, A.; Baig, M. Microstructure and Mechanical Properties of Metal Foams Fabricated via Melt Foaming and Powder Metallurgy Technique: A Review. Materials 2022, 15, 5302. https://doi.org/10.3390/ma15155302

Parveez B, Jamal NA, Anuar H, Ahmad Y, Aabid A, Baig M. Microstructure and Mechanical Properties of Metal Foams Fabricated via Melt Foaming and Powder Metallurgy Technique: A Review. Materials. 2022; 15(15):5302. https://doi.org/10.3390/ma15155302

Chicago/Turabian StyleParveez, Bisma, Nur Ayuni Jamal, Hazleen Anuar, Yusilawati Ahmad, Abdul Aabid, and Muneer Baig. 2022. "Microstructure and Mechanical Properties of Metal Foams Fabricated via Melt Foaming and Powder Metallurgy Technique: A Review" Materials 15, no. 15: 5302. https://doi.org/10.3390/ma15155302

APA StyleParveez, B., Jamal, N. A., Anuar, H., Ahmad, Y., Aabid, A., & Baig, M. (2022). Microstructure and Mechanical Properties of Metal Foams Fabricated via Melt Foaming and Powder Metallurgy Technique: A Review. Materials, 15(15), 5302. https://doi.org/10.3390/ma15155302