Thermal and Mechanical Variation Analysis on Multi-Layer Thin Wall during Continuous Laser Deposition, Continuous Pulsed Laser Deposition, and Interval Pulsed Laser Deposition

Abstract

:1. Introduction

2. Finite Element Model Methodology

2.1. DLD Model

2.2. Thermal Model of Multi-Layer Deposition

2.2.1. Laser Beam

2.2.2. Thermal Model Boundary Conditions

2.3. Mechanical Model of Multi-Layer Deposition

2.3.1. Material Model

2.3.2. Mechanical Model Boundary Conditions

2.4. Model Description

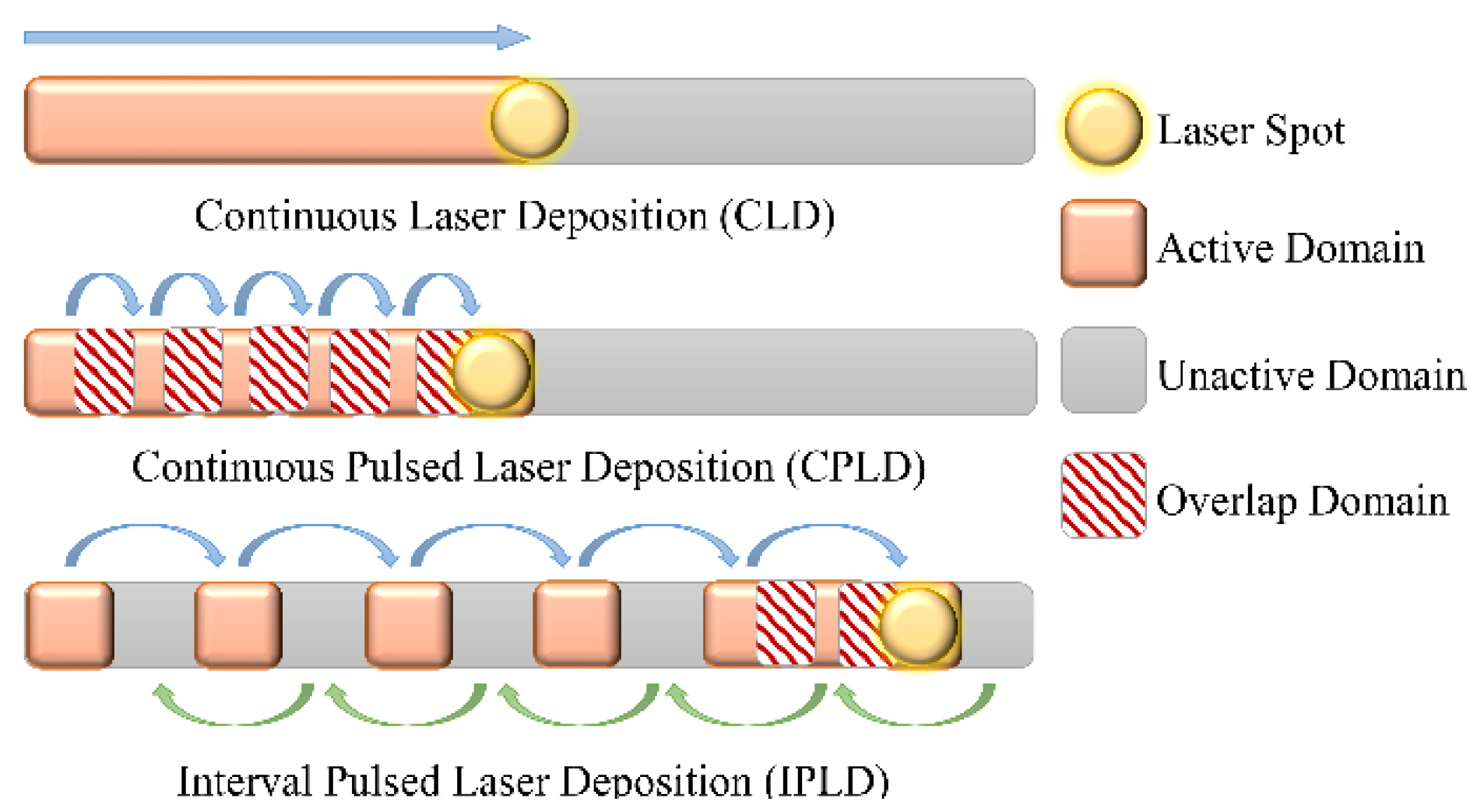

2.4.1. DLD Parameters and Scanning Pattern Illustration

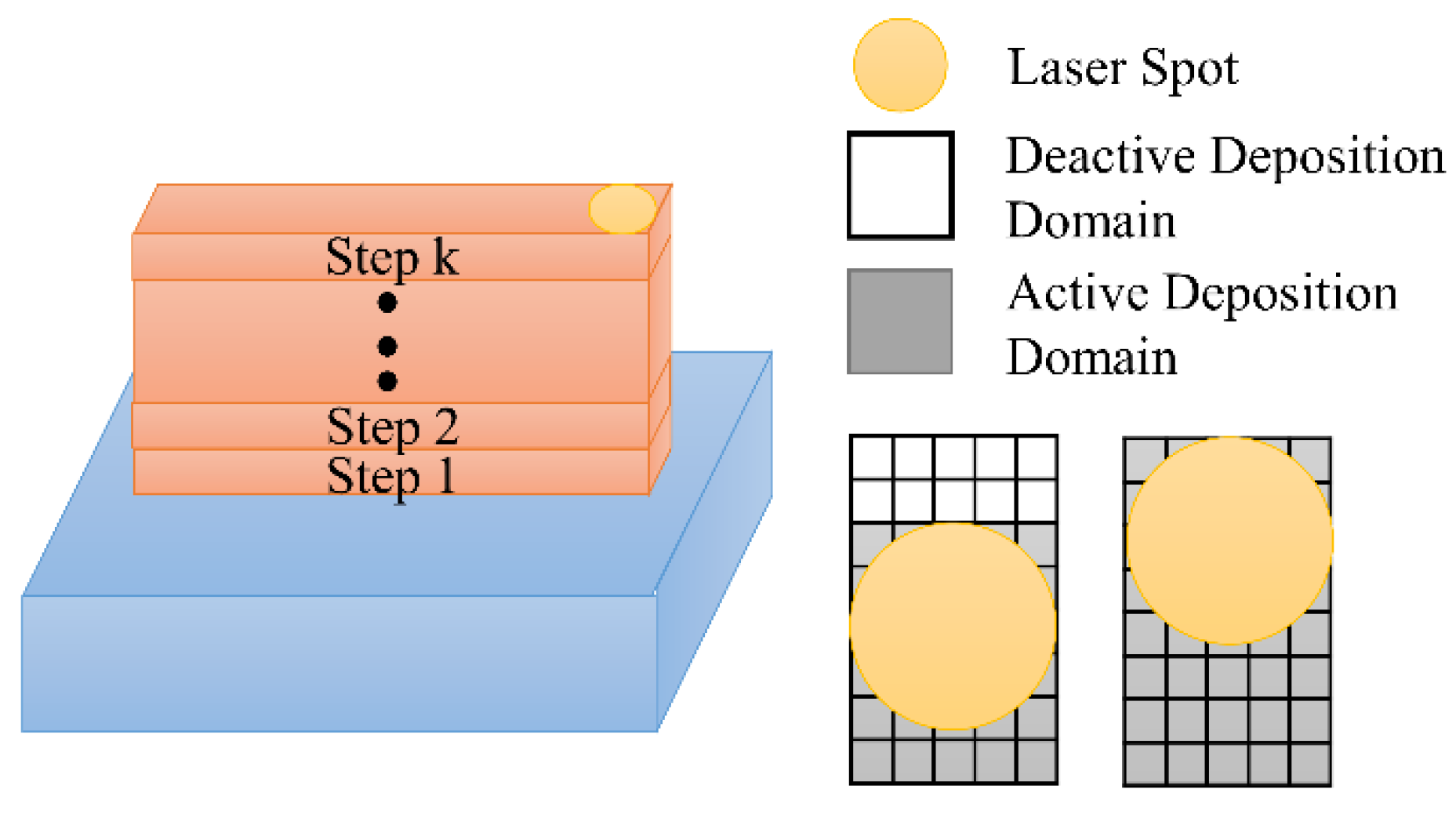

2.4.2. Element Activating Process Illustration

2.4.3. DLD Simulation Model Architecture

3. Validation

3.1. DLD Experimental Setup

3.2. Temperature Measurement

3.3. Residual Stress Measurement

4. Results and Discussion

4.1. Thermal Results

4.2. Residual Stress Results

4.3. Discussion

5. Conclusions

- The temperature results obtained from the proposed model show reasonable agreement with the experimental data collected from thermocouples (results of three measuring points show errors within 10%, while the maximum error at the beginning and end of the experiment is close to 20%).

- At the end of each layer, the temperature fields show that two PLD processes cool faster than the CLD process. This indicates that the pulse interval reduces the accumulation of heat in the deposition layers.

- The proposed IPLD process shows more homogeneous residual stress distribution, which is attributed to lower intensity changes in the temperature field and the thermal stress effect.

- With the increase in the number of layers, the maximum temperature of the three processes increases gradually, and the CLD process temperature shows the fastest growth. Due to heat conduction, the temperature in the middle area of each layer is higher than that on both sides. At the beginning of deposition, the cooling rate of the IPLD process is the highest, but the values of the three processes decrease gradually with the deposition process.

Author Contributions

Funding

Conflicts of Interest

References

- Thompson, S.M.; Bian, L.; Shamsaei, N.; Yadollahi, A. An overview of Direct Laser Deposition for additive manufacturing; Part I: Transport phenomena, modeling and diagnostics. Addit. Manuf. 2015, 8, 36–62. [Google Scholar] [CrossRef]

- Yan, J.; Battiato, I.; Fadel, G.M. Planning the process parameters for the direct metal deposition of functionally graded parts based on mathematical models. J. Manuf. Process. 2018, 31, 56–71. [Google Scholar] [CrossRef]

- Ren, K.; Chew, Y.; Fuh, J.Y.H.; Zhang, Y.F.; Bi, G.J. Thermo-mechanical analyses for optimized path planning in laser aided additive manufacturing processes. Mater. Des. 2019, 162, 80–93. [Google Scholar] [CrossRef]

- Gao, J.; Wu, C.; Hao, Y.; Xu, X.; Guo, L. Numerical simulation and experimental investigation on three-dimensional modelling of single-track geometry and temperature evolution by laser cladding. Opt. Laser Technol. 2020, 129, 106287. [Google Scholar] [CrossRef]

- Kovalev, O.; Bedenko, D.; Zaitsev, A. Development and application of laser cladding modeling technique: From coaxial powder feeding to surface deposition and bead formation. Appl. Math. Model. 2018, 57, 339–359. [Google Scholar] [CrossRef]

- Arrizubieta, J.I.; Lamikiz, A.; Klocke, F.; Martínez, S.; Arntz, K.; Ukar, E. Evaluation of the relevance of melt pool dynamics in Laser Material Deposition process modeling. Int. J. Heat Mass Transf. 2017, 115, 80–91. [Google Scholar] [CrossRef]

- Sawant, M.S.; Jain, N.; Nikam, S.H. Theoretical modeling and finite element simulation of dilution in micro-plasma transferred arc additive manufacturing of metallic materials. Int. J. Mech. Sci. 2019, 164, 105166. [Google Scholar] [CrossRef]

- Zhan, X.; Lin, X.; Gao, Z.; Qi, C.; Zhou, J.; Gu, D. Modeling and simulation of the columnar-to-equiaxed transition during laser melting deposition of Invar alloy. J. Alloys Compd. 2018, 755, 123–134. [Google Scholar] [CrossRef]

- Xie, H.; Yang, K.; Li, F.; Sun, C.; Yu, Z. Investigation on the Laves phase formation during laser cladding of IN718 alloy by CA-FE. J. Manuf. Process. 2020, 52, 132–144. [Google Scholar] [CrossRef]

- Du, L.; Gu, D.; Dai, D.; Shi, Q.; Ma, C.; Xia, M. Relation of thermal behavior and microstructure evolution during multi-track laser melting deposition of Ni-based material. Opt. Laser Technol. 2018, 108, 207–217. [Google Scholar] [CrossRef]

- Chen, Y.; Guo, Y.; Xu, M.; Ma, C.; Zhang, Q.; Wang, L.; Yao, J.; Li, Z. Study on the element segregation and Laves phase formation in the laser metal deposited IN718 superalloy by flat top laser and gaussian distribution laser. Mater. Sci. Eng. A 2019, 754, 339–347. [Google Scholar] [CrossRef]

- Yan, L.; Zhang, Y.; Liou, F. A conceptual design of residual stress reduction with multiple shape laser beams in direct laser deposition. Finite Elem. Anal. Des. 2018, 144, 30–37. [Google Scholar] [CrossRef]

- Walker, T.; Bennett, C.; Lee, T.; Clare, A. A validated analytical-numerical modelling strategy to predict residual stresses in single-track laser deposited IN718. Int. J. Mech. Sci. 2019, 151, 609–621. [Google Scholar] [CrossRef]

- Nikam, S.H.; Jain, N.K. Three-dimensional thermal analysis of multi-layer metallic deposition by micro-plasma transferred arc process using finite element simulation. J. Mater. Process. Technol. 2017, 249, 264–273. [Google Scholar] [CrossRef]

- Liu, H.; Du, X.; Guo, H.; Liu, J.; Chen, P.; Yang, H.; Hao, J. Finite element analysis of effects of dynamic preheating on thermal behavior of multi-track and multi-layer laser cladding. Optik 2021, 228, 166194. [Google Scholar] [CrossRef]

- Zhang, J.; Liou, F.; Seufzer, W.; Taminger, K. A coupled finite element cellular automaton model to predict thermal history and grain morphology of Ti-6Al-4V during direct metal deposition (DMD). Addit. Manuf. 2016, 11, 32–39. [Google Scholar] [CrossRef]

- Bailey, N.S.; Katinas, C.; Shin, Y.C. Laser direct deposition of AISI H13 tool steel powder with numerical modeling of solid phase transformation, hardness, and residual stresses. J. Mater. Process. Technol. 2017, 247, 223–233. [Google Scholar] [CrossRef]

- Ci, S.; Liang, J.; Li, J.; Wang, H.; Zhou, Y.; Sun, X.; Ding, Y. Microstructure and stress-rupture property of DD32 nickel-based single crystal superalloy fabricated by additive manufacturing. J. Alloys Compd. 2021, 854, 157180. [Google Scholar] [CrossRef]

- Kumar, S.P.; Elangovan, S.; Mohanraj, R.; Narayanan, V.S. Significance of continuous wave and pulsed wave laser in direct metal deposition. Mater. Today Proc. 2021, 46, 8086–8096. [Google Scholar] [CrossRef]

- Li, S.; Xiao, H.; Liu, K.; Xiao, W.; Li, Y.; Han, X.; Mazumder, J.; Song, L. Melt-pool motion, temperature variation and dendritic morphology of Inconel 718 during pulsed-and continuous-wave laser additive manufacturing: A comparative study. Mater. Des. 2017, 119, 351–360. [Google Scholar] [CrossRef]

- Han, X.; da Zhang, C.; Li, C.; Yu, Z.B.; Zhang, B. Study on a multifield coupling mechanism and a numerical simulation method of a pulsed laser deposition process from a disk laser. Appl. Phys. A 2021, 127, 17. [Google Scholar] [CrossRef]

- Ci, S.; Liang, J.; Li, J.; Wang, H.; Zhou, Y.; Sun, X.; Zhang, H.; Ding, Y.; Zhou, X. Prediction of Primary Dendrite Arm Spacing in Pulsed Laser Surface Melted Single Crystal Superalloy. Acta Metall. Sin. Engl. Lett. 2021, 34, 485–494. [Google Scholar] [CrossRef]

- Bayat, M.; Dong, W.; Thorborg, J.; To, A.C.; Hattel, J.H. A review of multi-scale and multi-physics simulations of metal additive manufacturing processes with focus on modeling strategies. Addit. Manuf. 2021, 47, 102278. [Google Scholar] [CrossRef]

- Singh, P.; Singari, R.M.; Mishra, R. A review of study on modeling and simulation of additive manufacturing processes. Mater. Today Proc. 2021, 56, 3594–3603. [Google Scholar] [CrossRef]

- Kumar, S.; Roy, S.; Paul, C.; Nath, A. Three-dimensional conduction heat transfer model for laser cladding process. Numer. Heat Transf. Part B Fundam. 2008, 53, 271–287. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, J. Finite element simulation and experimental validation of distortion and cracking failure phenomena in direct metal laser sintering fabricated component. Addit. Manuf. 2017, 16, 49–57. [Google Scholar] [CrossRef] [Green Version]

- Mills, K.C. Recommended Values of Thermophysical Properties for Selected Commercial Alloys; Woodhead Publishing: Philadelphia, PA, USA, 2002. [Google Scholar]

- Davis, J.R. Handbook-Nickel, Cobalt, and Their Alloys; ASM International Materials Park OH: Almere, The Netherlands, 2000. [Google Scholar]

- Romano, J.; Ladani, L.; Sadowski, M. Laser additive melting and solidification of Inconel 718: Finite element simulation and experiment. JOM 2016, 68, 967–977. [Google Scholar] [CrossRef]

- Promoppatum, P.; Uthaisangsuk, V. Part scale estimation of residual stress development in laser powder bed fusion additive manufacturing of Inconel 718. Finite Elem. Anal. Des. 2021, 189, 103528. [Google Scholar] [CrossRef]

- Heigel, J.; Michaleris, P.; Reutzel, E.W. Thermo-mechanical model development and validation of directed energy deposition additive manufacturing of Ti–6Al–4V. Addit. Manuf. 2015, 5, 9–19. [Google Scholar] [CrossRef]

- Xia, Z.; Xu, J.; Shi, J.; Shi, T.; Sun, C.; Qiu, D. Microstructure evolution and mechanical properties of reduced activation steel manufactured through laser directed energy deposition. Addit. Manuf. 2020, 33, 101114. [Google Scholar] [CrossRef]

- Nie, Z.; Wang, G.; McGuffin-Cawley, J.D.; Narayanan, B.; Zhang, S.; Schwam, D.; Kottman, M.; Rong, Y.K. Experimental study and modeling of H13 steel deposition using laser hot-wire additive manufacturing. J. Mater. Process. Technol. 2016, 235, 171–186. [Google Scholar] [CrossRef]

- Fang, J.; Li, S.; Dong, S.; Wang, Y.; Huang, H.; Jiang, Y.; Liu, B. Effects of phase transition temperature and preheating on residual stress in multi-pass & multi-layer laser metal deposition. J. Alloys Compd. 2019, 792, 928–937. [Google Scholar]

| Deposition Parameters | Value |

|---|---|

| Laser power P | 1800 W |

| Laser scanning speed v | 0.005 m/s |

| Laser turn-on time ton | 0.25 s |

| Laser turn-off time toff | 0.25 s |

| Laser absorptivity η | 0.12 |

| Laser beam radius r | 0.001 m |

| Powder feeding rate | 10 g/min |

| Powder type | Inconel 718 |

| Initial temperature | 298 K |

| Temperature (K) | Density (kg/m3) | Emissivity | Thermal Conductivity (W/mK) | Specific Heat Capacity (J/kgK) | Thermal Linear Expansion |

|---|---|---|---|---|---|

| 298 | 8190 | 0.539 | 8.9 | 435 | 12.8 |

| 373 | 8160 | 0.533 | 10.8 | 455 | 13.2 |

| 473 | 8118 | 0.533 | 12.9 | 479 | 13.6 |

| 573 | 8079 | 0.534 | 15.2 | 497 | 13.9 |

| 673 | 8040 | 0.534 | 17.4 | 515 | 14.1 |

| 773 | 8001 | 0.535 | 18.7 | 527 | 14.4 |

| 873 | 7962 | 0.535 | 20.8 | 558 | 14.9 |

| 973 | 7925 | 0.536 | 21.9 | 568 | 15.5 |

| 1073 | 7884 | 0.536 | 26.9 | 680 | 16.3 |

| 1173 | 7845 | 0.537 | 25.8 | 640 | 17.5 |

| 1273 | 7806 | 0.537 | 26.7 | 620 | 19.2 |

| 1373 | 7767 | 0.538 | 28.3 | 640 | 21.9 |

| Temperature (K) | Modulus of Elasticity (GPa) | Poisson’s Ratio | Yield Stress (MPa) |

|---|---|---|---|

| 294 | 208 | 0.3 | 1117 |

| 366 | 205 | 0.3 | 1117 |

| 477 | 202 | 0.3 | 1112 |

| 589 | 194 | 0.3 | 1110 |

| 700 | 186 | 0.3 | 1080 |

| 811 | 179 | 0.3 | 1070 |

| 922 | 172 | 0.3 | 1030 |

| 1033 | 162 | 0.3 | 758 |

| 1144 | 127 | 0.3 | 592 |

| 1227 | 17.8 | 0.3 | 468 |

| 1533 | 2.08 | 0.3 | 11.7 |

| Process Classifier | Maximum Temperature (K) | Temperature Difference between Center and Edge (K) | Maximum Bottom Residual Stress (MPa) | Residual Stress Difference between Center and Edge (MPa) | Deposition Time (s) |

|---|---|---|---|---|---|

| CLD | 2696 | 109.5 | 419 | 147.5 | 200 |

| CPLD | 2468 | 71.5 | 378 | 116 | 365 |

| IPLD | 2284 | 68 | 324 | 38 | 365 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, L.; Kong, X.; Liang, J.; Li, J.; Sun, C.; Jin, Z.; Jiao, Z. Thermal and Mechanical Variation Analysis on Multi-Layer Thin Wall during Continuous Laser Deposition, Continuous Pulsed Laser Deposition, and Interval Pulsed Laser Deposition. Materials 2022, 15, 5157. https://doi.org/10.3390/ma15155157

Ma L, Kong X, Liang J, Li J, Sun C, Jin Z, Jiao Z. Thermal and Mechanical Variation Analysis on Multi-Layer Thin Wall during Continuous Laser Deposition, Continuous Pulsed Laser Deposition, and Interval Pulsed Laser Deposition. Materials. 2022; 15(15):5157. https://doi.org/10.3390/ma15155157

Chicago/Turabian StyleMa, Liang, Xiangwei Kong, Jingjing Liang, Jinguo Li, Cong Sun, Zhibo Jin, and Zhidong Jiao. 2022. "Thermal and Mechanical Variation Analysis on Multi-Layer Thin Wall during Continuous Laser Deposition, Continuous Pulsed Laser Deposition, and Interval Pulsed Laser Deposition" Materials 15, no. 15: 5157. https://doi.org/10.3390/ma15155157

APA StyleMa, L., Kong, X., Liang, J., Li, J., Sun, C., Jin, Z., & Jiao, Z. (2022). Thermal and Mechanical Variation Analysis on Multi-Layer Thin Wall during Continuous Laser Deposition, Continuous Pulsed Laser Deposition, and Interval Pulsed Laser Deposition. Materials, 15(15), 5157. https://doi.org/10.3390/ma15155157