The Strange Case of the Nuragic Offerers Bronze Statuettes: A Multi-Analytical Study

Abstract

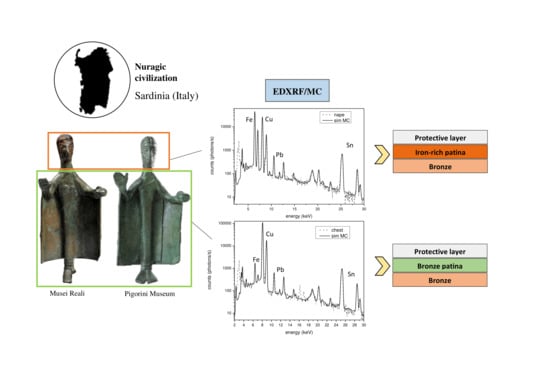

:1. Introduction

2. Materials and Methods

2.1. X-ray Fluorescence

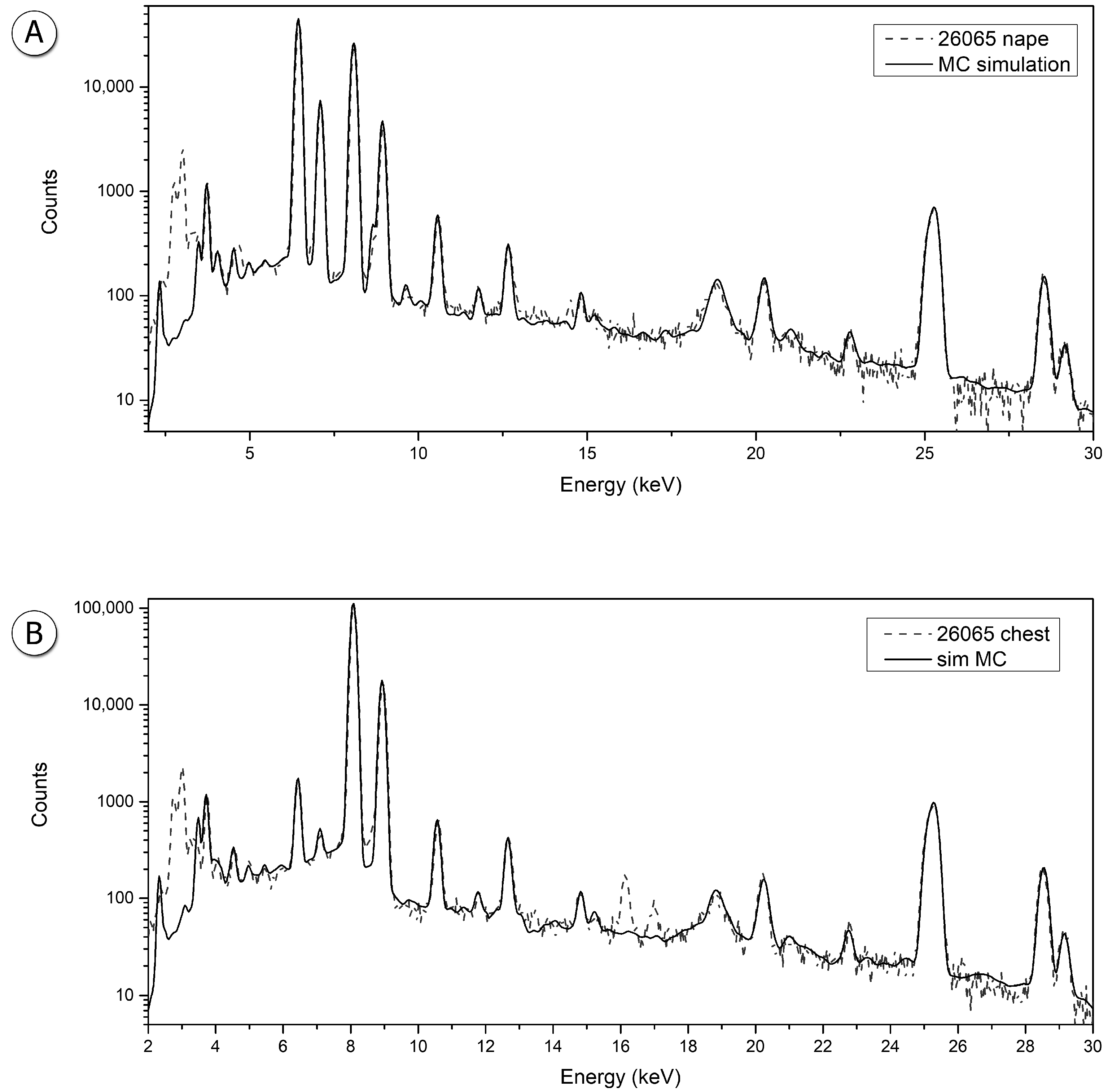

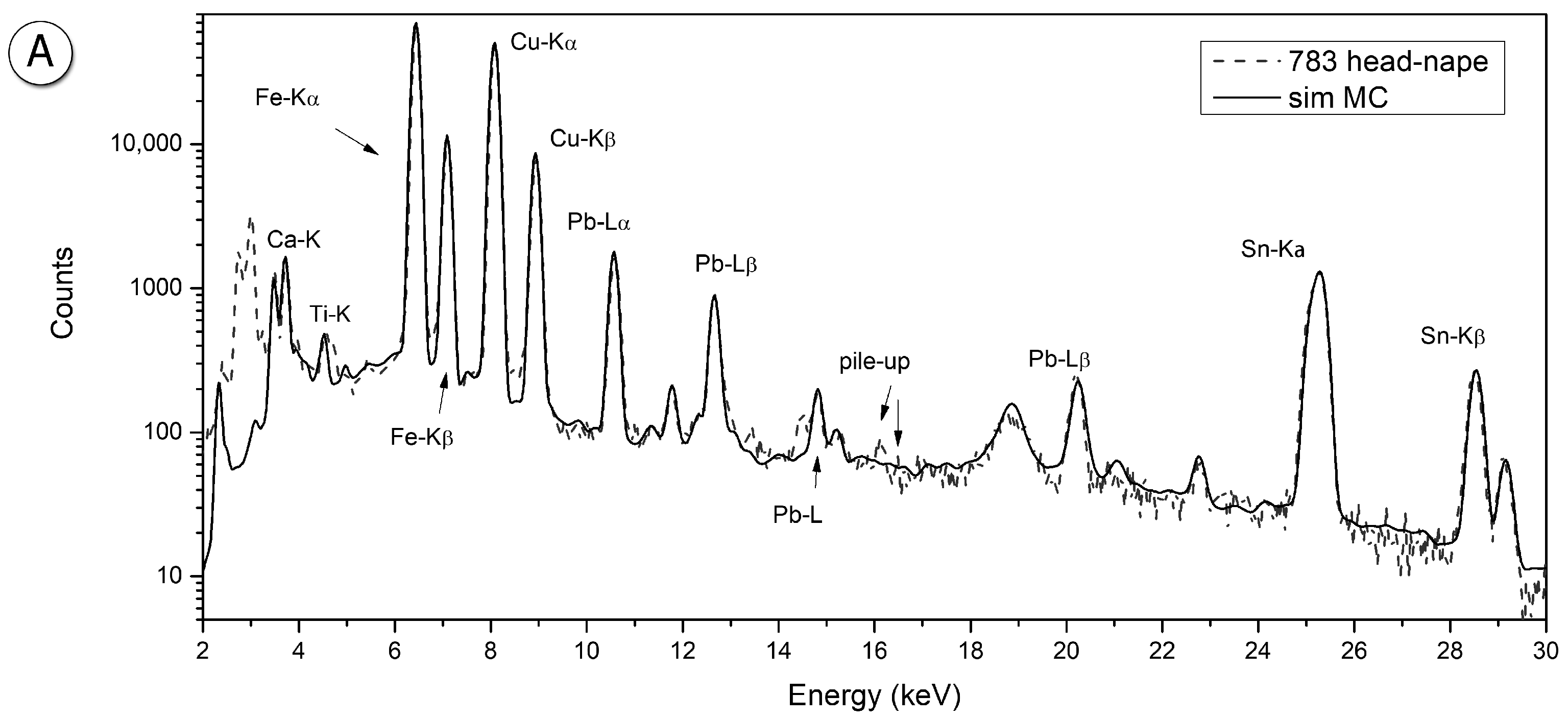

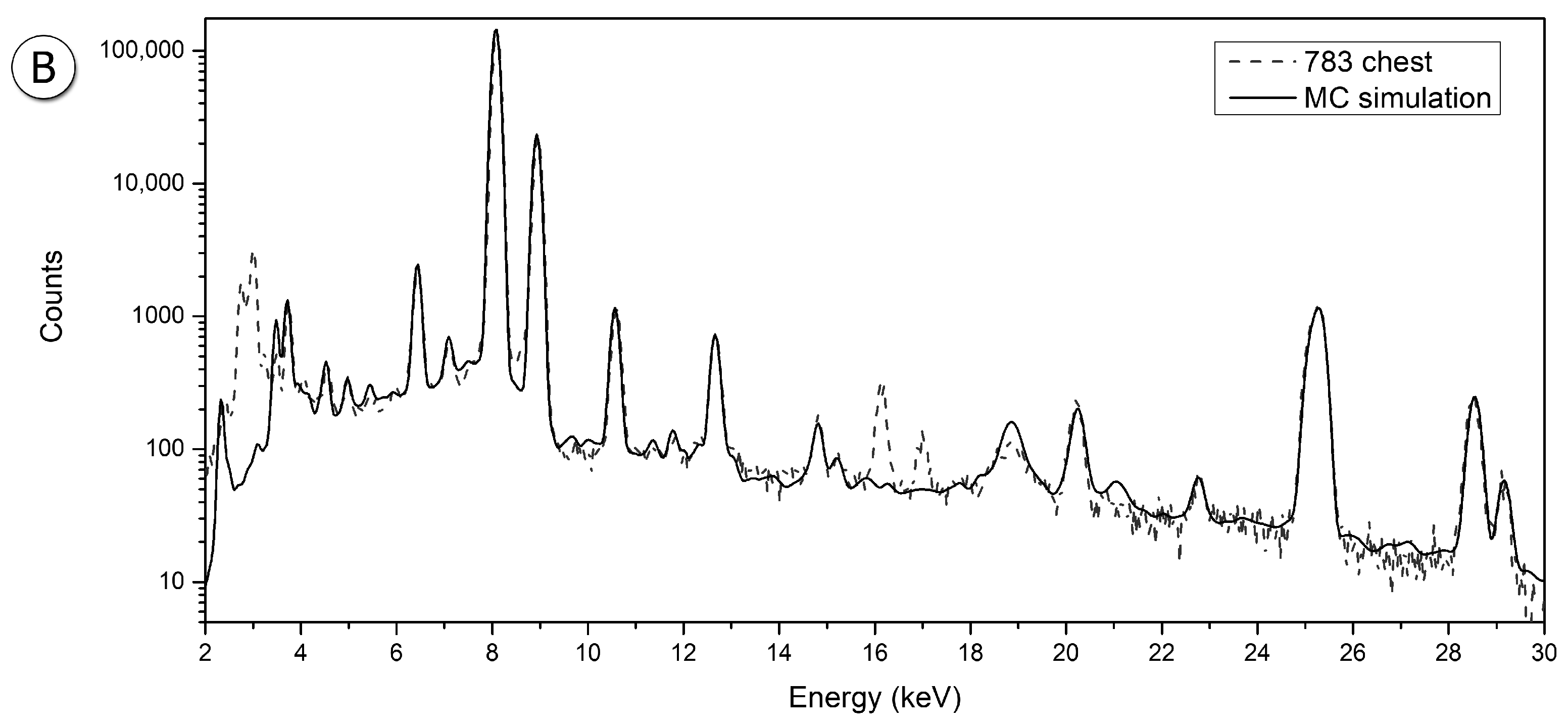

2.2. Monte Carlo Simulations

2.3. Quantification Protocol

3. Results and Discussion

4. Discussion and Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Moravetti, A.; Alba, E.; Foddai, L. La Sardegna Nuragica: Storia e Materiali; Carlo Delfino: Sassari, Italy, 2014. [Google Scholar]

- Atzeni, C. Aspects of Ancient Metallurgy. In Archaeometallurgy in Sardinia from the Origin to the Beginning of Early Iron Age; Lo Schiavo, F., Giumlia-Mair, A., Sanna, U., Valera, R., Eds.; Edition M. Mergoil: Montagnac, France, 2005. [Google Scholar]

- Begemann, F.; Schmitt-Strecker, S.; Pernicka, E.; Schiavo, F.L. Chemical composition and lead isotopy of copper and bronze from Nuragic Sardinia. Eur. J. Archaeol. 2001, 4, 43–85. [Google Scholar] [CrossRef]

- Lo Schiavo, F.; Giardino, C. Ripostigli Sardi Algheresi Della Tarda età Nuragica. Nuove Ricerche Archeometallurgiche; Bagatto Libri: Rome, Italy, 2007. [Google Scholar]

- Porcaro, M.; Depalmas, A.; Lins, S.; Bulla, C.; Pischedda, M.; Brunetti, A. Nuragic working tools characterization with corrosion layer determinations. Materials 2022, in press. [Google Scholar] [CrossRef] [PubMed]

- Depalmas, A.; Cataldo, M.; Grazzi, F.; Scherillo, A.; Fedrigo, A.; Kockelmann, W.; di Gennaro, F.; Canu, A.; Brunetti, A. Neutron-based techniques for archaeometry: Characterization of a Sardinian boat model. Archaeol. Anthropol. Sci. 2021, 13, 101. [Google Scholar] [CrossRef]

- Brunetti, A.; Grazzi, F.; Scherillo, A.; Minoja, M.E.; Salis, G.; Orrù, S.; Depalmas, A. Non-destructive microstructural characterization of a bronze boat model from Vetulonia. Archaeol. Anthropol. Sci. 2019, 11, 3041–3046. [Google Scholar] [CrossRef]

- Grazzi, F.; Brunetti, A.; Scherillo, A.; Minoja, M.E.; Salis, G.; Orrù, S.; Depalmas, A. Non-destructive compositional and microstructural characterization of Sardinian Bronze Age swords through Neutron Diffraction. Mater. Charact. 2018, 144, 387–392. [Google Scholar] [CrossRef]

- Moreno-Suárez, A.; Ager, F.; Rodríquez-Segovia, C.; Gómez-Morón, A.; Chaves, F.; Scrivano, S.; Gómez-Tubío, B.; Pliego, R.; Respaldiza, M. Feasibility of different cleaning methods for silver-copper alloys by X-ray fluorescence: Application to ancient Greek silver coins. Spectrochim. Acta Part B At. Spectrosc. 2016, 116, 85–91. [Google Scholar] [CrossRef]

- Robbiola, L.; Blengino, J.M.; Fiaud, C. Morphology and mechanisms of formation of natural patinas on archaeological Cu–Sn alloys. Corros. Sci. 1998, 40, 2083–2111. [Google Scholar] [CrossRef]

- Hughes, M.J.; Northover, J.P.; Staniaszek, B.E.P. Problems in the analysis of leaded bronze alloys in ancient artefacts. Oxf. J. Archaeol. 1982, 1, 359–364. [Google Scholar] [CrossRef]

- Vincze, L.; Janssen, K.; Adams, F. A general Monte Carlo simulation of energy-dispersive X-ray fluorescence spectrometers—I: Unpolarized radiation, homogeneous samples. Spectrochim. Acta Part B At. Spectrosc. 1993, 48, 553–573. [Google Scholar] [CrossRef]

- Golosio, B.; Schoonjans, T.; Brunetti, A.; Oliva, P.; Masala, G.L. Monte Carlo simulation of X-ray imaging and spectroscopy experiments using quadric geometry and variance reduction techniques. Comput. Phys. Commun. 2014, 185, 1044–1052. [Google Scholar] [CrossRef] [Green Version]

- Brunetti, A.; Sanchez del Rio, M.; Golosio, B.; Simionovici, A.; Somogyi, A. A library for X-ray–matter interaction cross sections for X-ray fluorescence applications. Spectrochim. Acta Part B At. Spectrosc. 2004, 59, 1725–1731. [Google Scholar] [CrossRef]

- Schoonjans, T.; Brunetti, A.; Golosio, B.; Sanchez del Rio, M.; Solé, V.A.; Ferrero, C.; Vincze, L. The xraylib library for X-ray–matter interactions. Recent developments. Spectrochim. Acta Part B At. Spectrosc. 2011, 66, 776–784. [Google Scholar] [CrossRef]

- Bottaini, C.E.; Brunetti, A.; Montero-Ruiz, I.; Valera, A.; Candeias, A.; Ao, J.M. Use of Monte Carlo Simulation as a Tool for the Nondestructive Energy Dispersive X-ray Fluorescence (ED-XRF) Spectroscopy Analysis of Archaeological Copper-Based Artifacts from the Chalcolithic Site of Perdigões, Southern Portugal. Appl. Spectrosc. 2018, 72, 17–27. [Google Scholar] [CrossRef] [PubMed]

- Brunetti, A.; Golosio, B.; Schoonjans, T.; Oliva, P. Use of Monte Carlo simulations for cultural heritage X-ray fluorescence analysis. Spectrochim. Acta Part B At. Spectrosc. 2015, 108, 15–20. [Google Scholar] [CrossRef]

- Cesareo, R.; Brunetti, A.; D’Oriano, R.; Canu, A.; Demontis, G.M.; Celauro, A. A Roman bronze statuette with gilded silver mask from Sardinia: An EDXRF study. Appl. Phys. A 2013, 113, 905–910. [Google Scholar] [CrossRef]

- Brunetti, A.; Depalmas, A.; di Gennaro, F.; Serges, A.; Schiavon, N. X-ray fluorescence spectroscopy and Monte Carlo characterization of a unique nuragic artifact (Sardinia, Italy). Spectrochim. Acta Part B At. Spectrosc. 2016, 121, 18–21. [Google Scholar] [CrossRef]

- Scott, D.A. Metallography and Microstructure of Ancient and Historic Metals; The J. Paul Getty Trust: Marina del Rey, CA, USA, 1991. [Google Scholar]

- Ingo, G.M.; de Caro, T.; Riccucci, C.; Angelini, E.; Grassini, S.; Balbi, S.; Bernardini, P.; Salvi, D.; Bousselmi, L.; Çilingiroglu, A.; et al. Large scale investigation of chemical composition, structure and corrosion mechanism of bronze archeological artefacts from Mediterranean basin. Appl. Phys. A 2006, 83, 513–520. [Google Scholar] [CrossRef]

- Figueiredo, E.; Valério, P.; Araújo, M.; Senna-Martinez, J. Micro-EDXRF surface analyses of a bronze spear head: Lead content in metal and corrosion layers. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2007, 580, 725–727. [Google Scholar] [CrossRef]

- Klein, S.; Hauptmann, A. Iron Age Leaded Tin Bronzes from Khirbet Edh-Dharih, Jordan. J. Archaeol. Sci. 1999, 26, 1075–1082. [Google Scholar] [CrossRef]

- Westner, K.J.; Kemmers, F.; Klein, S. A novel combined approach for compositional and Pb isotope data of (leaded) copper-based alloys: Bronze coinage in Magna Graecia and Rome (5th to 2nd centuries BCE). J. Archaeol. Sci. 2020, 121, 105204. [Google Scholar] [CrossRef]

| Inventory Number | Area | Copper (Cu %) | Tin (Sn %) | Lead (Pb %) |

|---|---|---|---|---|

| 26065 | Head | 86.8 | 8.3 | 4.5 |

| Body | 86.5 | 8.6 | 4.7 | |

| 783 | Head | 91.0 | 7.1 | 1.7 |

| Body | 90.6 | 7.1 | 2.2 |

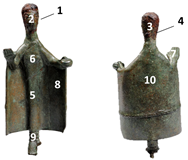

| Sample | Measurement Points | Iron (Fe %) | Graphic Representation |

|---|---|---|---|

| 26065 | (a) Right side neck | 15.0 |  |

| (b) Neck | 19.7 | ||

| (c) Nape | 26.3 | ||

| (d) Cloak | 0.8 | ||

| (e) Inner cloak on the left | 0.7 | ||

| (f) Center back | 1.0 | ||

| (g) Chest | 0.8 | ||

| (h) Right hand | 0.7 | ||

| (i) Ankles | 1.3 | ||

| 783 | (1) Head left | 20.0 |  |

| (2) Nose | 22.0 | ||

| (3) Nape | 31.3 | ||

| (4) Right side neck | 10.5 | ||

| (5) Bust - belt | 0.6 | ||

| (6) Chest | 0.8 | ||

| (7) Right hand back | 0.9 | ||

| (8) Inner cloak on the left | 1.0 | ||

| (9) Ankles | 1.0 | ||

| (10) Back | 0.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Brunetti, A.; Porcaro, M.; Lins, S.; di Gennaro, F.; Anzalone, R.M.; Mineo, M.; Depalmas, A. The Strange Case of the Nuragic Offerers Bronze Statuettes: A Multi-Analytical Study. Materials 2022, 15, 4174. https://doi.org/10.3390/ma15124174

Brunetti A, Porcaro M, Lins S, di Gennaro F, Anzalone RM, Mineo M, Depalmas A. The Strange Case of the Nuragic Offerers Bronze Statuettes: A Multi-Analytical Study. Materials. 2022; 15(12):4174. https://doi.org/10.3390/ma15124174

Chicago/Turabian StyleBrunetti, Antonio, Marta Porcaro, Sergio Lins, Francesco di Gennaro, Rosario Maria Anzalone, Mario Mineo, and Anna Depalmas. 2022. "The Strange Case of the Nuragic Offerers Bronze Statuettes: A Multi-Analytical Study" Materials 15, no. 12: 4174. https://doi.org/10.3390/ma15124174

APA StyleBrunetti, A., Porcaro, M., Lins, S., di Gennaro, F., Anzalone, R. M., Mineo, M., & Depalmas, A. (2022). The Strange Case of the Nuragic Offerers Bronze Statuettes: A Multi-Analytical Study. Materials, 15(12), 4174. https://doi.org/10.3390/ma15124174