Unraveling the Phase Stability and Physical Property of Modulated Martensite in Ni2Mn1.5In0.5 Alloys by First-Principles Calculations

Abstract

:1. Introduction

2. Computational Methods

3. Results and Discussion

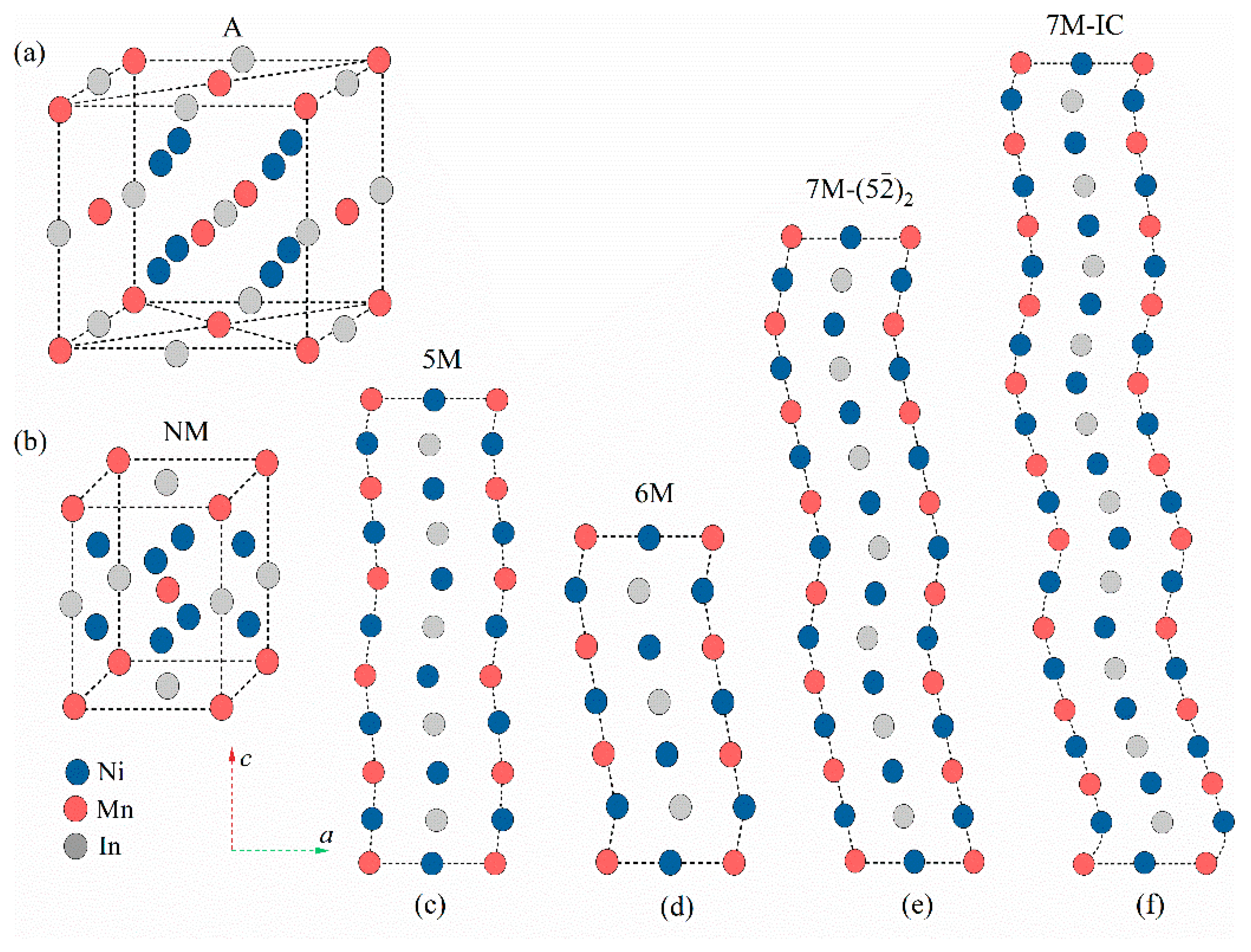

3.1. Structural Parameters of Possible Phases

| Structure | Lattice Parameter | |||||

|---|---|---|---|---|---|---|

| a (Å) | b (Å) | c (Å) | β (Å) | V | ||

| A | FM | 5.95, 5.962 a, 5.95 b | 90 | 52.57 | ||

| FIM | 5.93, 5.94 a | 90 | 52.15 | |||

| 5M | FM | 4.21 | 5.91 | 21.05 | 90.17 | 52.42 |

| FIM | 4.41 | 5.49 | 21.30 | 89.03 | 51.64 | |

| 6M | FM | 4.26 | 5.82 | 12.71 | 91.40 | 52.51 |

| FIM | 4.41 | 5.47 | 12.89 | 94.07 | 51.70 | |

| Exp. c | 4.66 | 5.40 | 12.80 | 95.24 | 53.49 | |

| Exp. d | 4.42 | 5.48 | 12.99 | 94.19 | ||

| )2 | FM | 4.23 | 5.88 | 29.55 | 92.01 | 52.44 |

| FIM | 4.37 | 5.55 | 30.05 | 95.45 | 51.78 | |

| 7M–IC | FM | 4.24 | 5.87 | 42.28 | 91.14 | 52.63 |

| FIM | 4.39 | 5.52 | 43.12 | 94.89 | 52.02 | |

| Exp. e | 4.37 | 5.69 | 30.21 | 93.67 | ||

| Exp. e | 4.35 | 5.73 | 30.38 | 93.24 | ||

| NM | FM | 4.21 | 5.95 | 90 | 52.64 | |

| FIM | 3.87 | 6.89 | 90 | 51.49 | ||

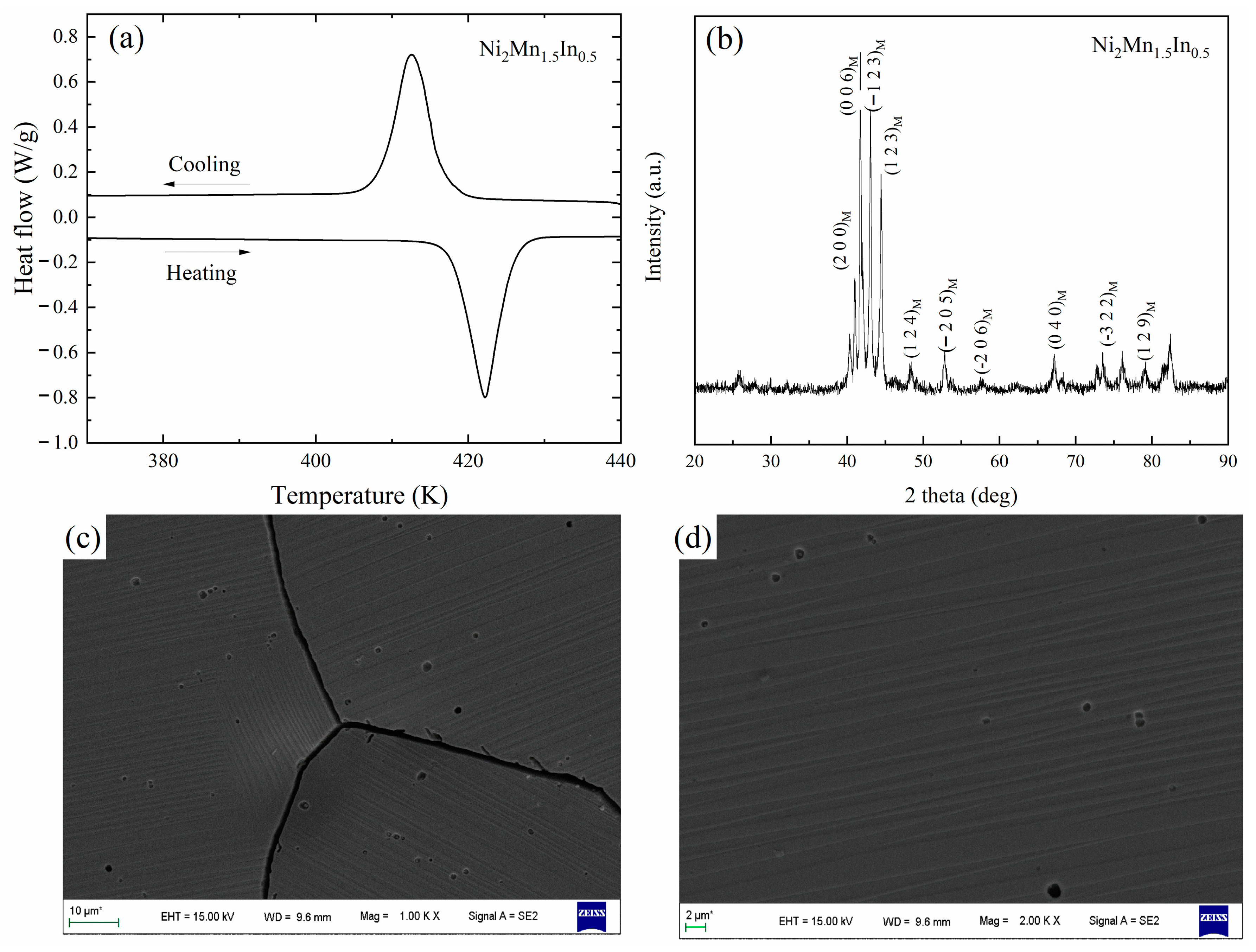

3.2. Phase Stability of Possible Phases

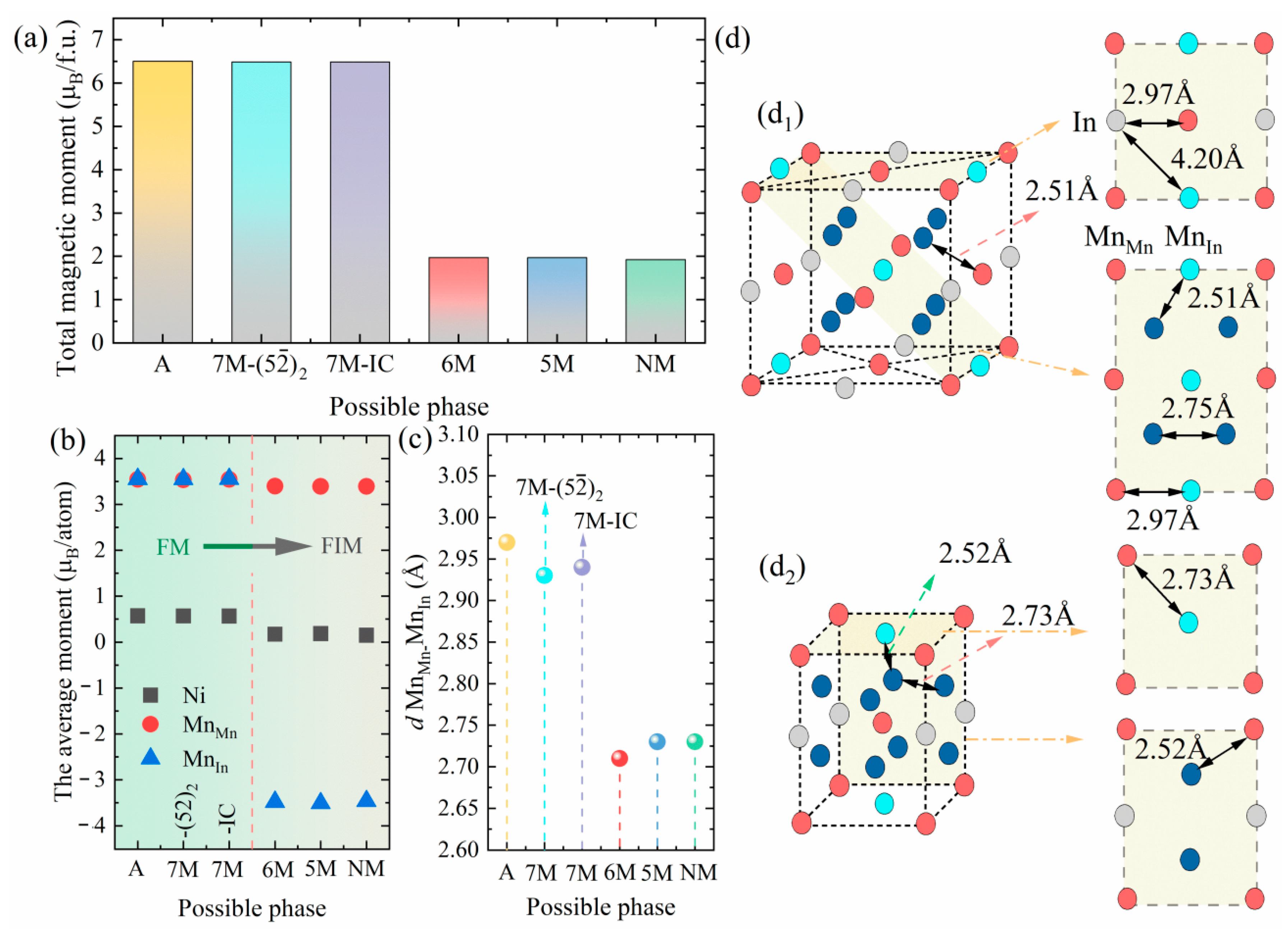

3.3. Total/Atomic Magnetic Moment

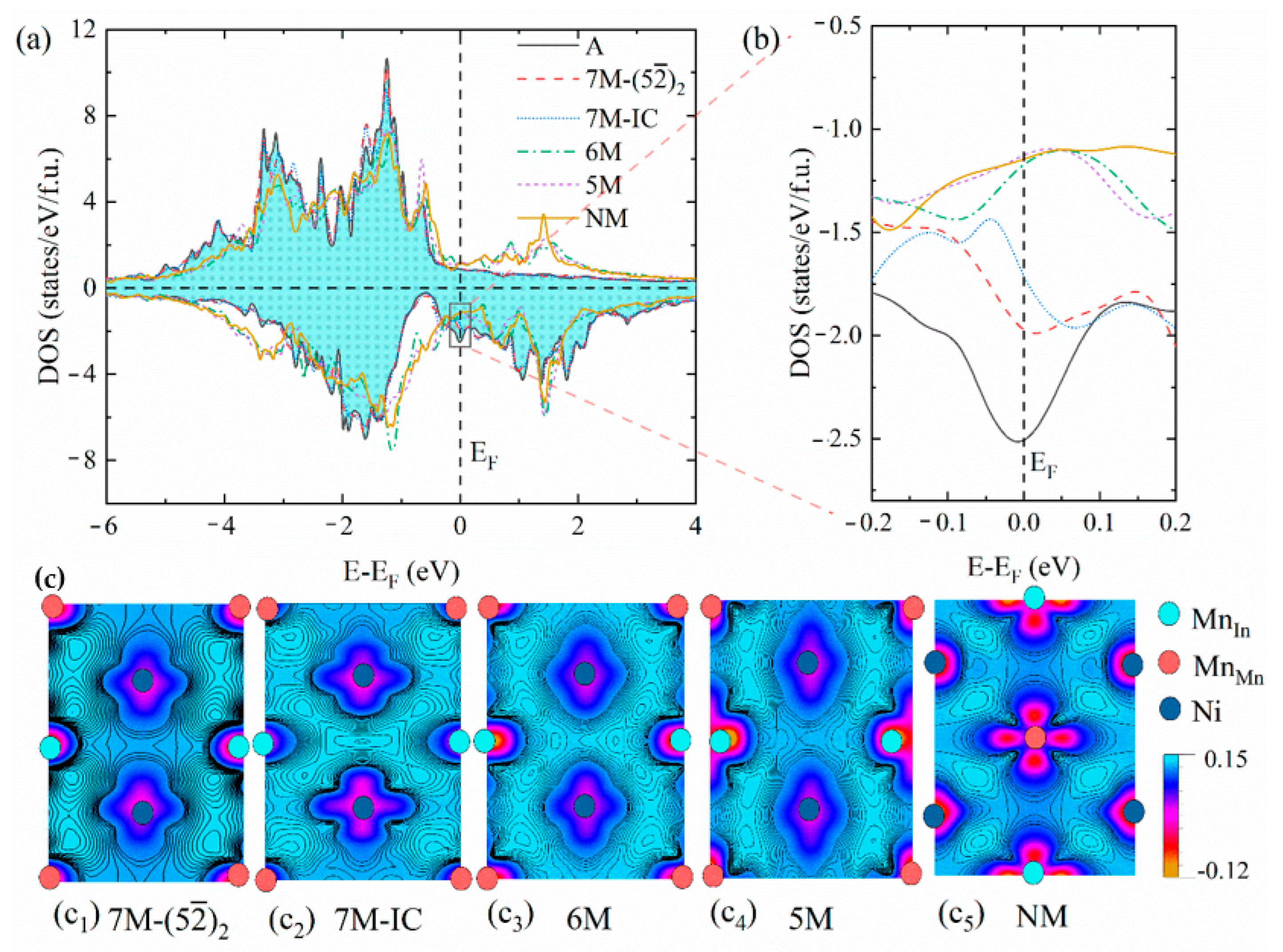

3.4. Electronic Structure

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sozinov, A.; Likhachev, A.; Lanska, N.; Ullakko, K. Giant magnetic-field-induced strain in NiMnGa seven-layered martensitic phase. Appl. Phys. Lett. 2002, 80, 1746–1748. [Google Scholar] [CrossRef]

- Chmielus, M.; Zhang, X.; Witherspoon, C.; Dunand, D.; Müllner, P. Giant magnetic-field-induced strains in polycrystalline Ni-Mn-Ga foams. Nat. Mater. 2009, 8, 863–866. [Google Scholar] [CrossRef]

- Ullakko, K.; Huang, J.; Kantner, C.; Ohandley, R.; Kokorin, V. Large magnetic-field-induced strains in Ni2MnGa single crystals. Appl. Phys. Lett. 1996, 69, 1966–1968. [Google Scholar] [CrossRef]

- Yang, J.; Li, Z.; Yang, B.; Yan, H.; Cong, D.; Zhao, X.; Zuo, L. Effects of Co and Si co-doping on magnetostructural transformation and magnetocaloric effect in Ni-Mn-Sn based alloys. J. Alloys Comp. 2022, 892, 162190. [Google Scholar] [CrossRef]

- Pfeuffer, L.; Lemke, J.; Shayanfar, N.; Riegg, S.; Koch, D.; Taubel, A.; Scheibel, F.; Kani, N.A.; Adabifiroozjaei, E.; Molina-Luna, L.; et al. Microstructure engineering of metamagnetic Ni-Mn-based Heusler compounds by Fe-doping: A roadmap towards excellent cyclic stability combined with large elastocaloric and magnetocaloric effects. Acta Mater. 2021, 221, 117390. [Google Scholar] [CrossRef]

- Heczko, O.; Sozinov, A.; Ullakko, K. Giant field-induced reversible strain in magnetic shape memory NiMnGa alloy. IEEE Trans. Magn. 2000, 36, 3266–3268. [Google Scholar] [CrossRef]

- Murray, S.J.; Marioni, M.; Allen, S.M.; O’Handley, R.C.; Lograsso, T.A. 6% magnetic-field-induced strain by twin-boundary motion in ferromagnetic Ni-Mn-Ga. Appl. Phys. Lett. 2000, 77, 886–888. [Google Scholar] [CrossRef] [Green Version]

- Sozinov, A.; Lanska, N.; Soroka, A.; Zou, W. 12% magnetic field-induced strain in Ni-Mn-Ga-based non-modulated martensite. Appl. Phys. Lett. 2013, 102, 021902. [Google Scholar] [CrossRef]

- Yan, H.L.; Liu, H.X.; Zhao, Y.; Jia, N.; Bai, J.; Yang, B.; Li, Z.B.; Zhang, Y.D.; Esling, C.; Zhao, X.; et al. Impact of B alloying on ductility and phase transition in the Ni–Mn-based magnetic shape memory alloys: Insights from first-principles calculation. J. Mater. Sci. Technol. 2021, 74, 27–34. [Google Scholar] [CrossRef]

- Yan, H.L.; Huang, X.M.; Esling, C. Recent Progress in Crystallographic Characterization, Magnetoresponsive and Elastocaloric Effects of Ni-Mn-In-Based Heusler Alloys—A Review. Front. Mater. 2022, 85, 812984. [Google Scholar] [CrossRef]

- Akır, A.C.; Righi, L.; Albertini, F.; Acet, M.; Farle, M.; Akturk, S. Extended investigation of intermartensitic transitions in Ni-Mn-Ga magnetic shape memory alloys: A detailed phase diagram determination. J. Appl. Phys. 2013, 114, 183912. [Google Scholar]

- Singh, S.; Petricek, V.; Rajput, P.; Hill, A.H.; Suard, E.; Barman, S.R.; Pandey, D. High-resolution synchrotron x-ray powder diffraction study of the incommensurate modulation in the martensite phase of Ni2MnGa: Evidence for nearly 7M modulation and phason broadening. Phys. Rev. B 2014, 90, 014109. [Google Scholar] [CrossRef] [Green Version]

- Wang, H.; Li, D.; Zhang, G.; Li, Z.; Yang, B.; Yan, H.; Cong, D.; Esling, C.; Zhao, X.; Zuo, L. Highly sensitive elastocaloric response in a directionally solidified Ni50Mn33In15. 5Cu1. 5 alloy with strong <001> A preferred orientation. Intermetallics 2022, 140, 107379. [Google Scholar] [CrossRef]

- Martynov, V.V.; Kokorin, V.V. The crystal structure of thermally-and stress-induced martensites in Ni2MnGa single crystals. J. Phys. III 1992, 2, 739–749. [Google Scholar] [CrossRef] [Green Version]

- Otsuka, K.; Ohba, T.; Tokonami, M.; Wayman, C.M. New description of long period stacking order structures of martensites in β phase alloys. Scr. Metall. Mater. 1993, 29, 1359–1364. [Google Scholar] [CrossRef]

- Brown, P.J.; Crangle, J.; Kanomata, T.; Matsmuoto, M.; Neumann, K.U.; Ouladdiaf, B.; Ziebeck, K.R.A. The crystal structure and phase transitions of the magnetic shape memory compound Ni2MnGa. J. Phys. Condens. Matter 2002, 14, 10159–10171. [Google Scholar] [CrossRef]

- Mariager, S.; Huber, T.; Ingold, G. The incommensurate modulations of stoichiometric Ni2MnGa. Acta Mater. 2014, 66, 192–198. [Google Scholar] [CrossRef]

- Righi, L.; Albertini, F.; Calestani, G.; Pareti, L.; Paoluzi, A.; Ritter, C.; Algarabel, P.A.; Morellon, L.; Ricardo Ibarra, M. Incommensurate modulated structure of the ferromagnetic shape-memory Ni2MnGa martensite. J. Solid State Chem. 2006, 179, 3525–3533. [Google Scholar] [CrossRef]

- Righi, L.; Albertini, F.; Pareti, L.; Paoluzi, A.; Calestani, G. Commensurate and incommensurate “5M” modulated crystal structures in Ni-Mn-Ga martensitic phases. Acta Mater. 2007, 55, 5237–5245. [Google Scholar] [CrossRef]

- Glavatskyy, I.; Glavatska, N.; Urubkov, I.; Hoffman, J.U.; Bourdarot, F. Crystal and magnetic structure temperature evolution in Ni-Mn-Ga magnetic shape memory martensite. Mater. Sci. Eng. A 2008, 481-482, 298–301. [Google Scholar] [CrossRef]

- Gruner, M.E.; Fahler, S.; Entel, P. Magnetoelastic coupling and the formation of adaptive martensite in magnetic shape memory alloys. Phys. Status Solodi B 2014, 251, 2067–2079. [Google Scholar] [CrossRef]

- Zayak, A.T.; Entel, P.; Enkovaara, J.; Ayuela, A.; Nieminen, R.M. First-principles investigations of homogeneous lattice-distortive strain and shuffles in Ni2MnGa. J. Phys. Condens. Matter 2003, 15, 159–164. [Google Scholar] [CrossRef]

- Righi, L.; Albertini, F.; Villa, E.; Paoluzi, A.; Calestani, G.; Chernenko, V.; Besseghini, S.; Ritter, C.; Passaretti, F. Crystal structure of 7M modulated Ni-Mn-Ga martensitic phase. Acta Mater. 2008, 56, 4529–4535. [Google Scholar] [CrossRef]

- Kaufmann, S.; Rößler, U.K.; Heczko, O.; Wuttig, M.; Buschbeck, J.; Schultz, L.; Fähler, S. Adaptive Modulations of Martensites. Phys. Rev. Lett. 2010, 104, 145702. [Google Scholar] [CrossRef] [Green Version]

- Li, Z.B.; Zhang, Y.D.; Esling, C.; Zhao, X.; Zuo, L. Twin relationships of 5M modulated martensite in Ni-Mn-Ga alloy. Acta Mater. 2011, 59, 3390–3397. [Google Scholar] [CrossRef]

- Li, Z.B.; Zhang, Y.D.; Esling, C.; Zhao, X.; Zuo, L. Determination of the orientation relationship between austenite and incommensurate 7M modulated martensite in Ni-Mn-Ga alloys. Acta Mater. 2011, 59, 2762–2772. [Google Scholar] [CrossRef]

- Xu, N.; Raulot, J.M.; Li, Z.B.; Zhang, Y.D.; Bai, J.; Peng, W.; Meng, X.Y.; Zhao, X.; Zuo, L.; Esling, C. Composition dependent phase stability of Ni-Mn-Ga alloys studied by ab initio calculations. J. Alloys Comp. 2014, 614, 126–130. [Google Scholar] [CrossRef]

- Bai, J.; Wang, J.L.; Shi, S.F.; Raulot, J.M.; Zhang, Y.D.; Esling, C.; Zhao, X.; Zuo, L. Complete martensitic transformation sequence and magnetic properties of non-stoichiometric Ni2Mn1.2Ga0.8 alloy by first-principles calculations. J. Magn. Magn. Mater. 2019, 473, 360–364. [Google Scholar] [CrossRef]

- Liang, X.Z.; Bai, J.; Gu, J.L.; Wang, J.L.; Yan, H.L.; Zhang, Y.D.; Esling, C.; Zhao, X.; Zuo, L. Ab initio-based investigation of phase transition path and magnetism of Ni-Mn-In alloys with excess Ni or Mn. Acta Mater. 2020, 195, 109–122. [Google Scholar] [CrossRef]

- Liang, X.Z.; Bai, J.; Gu, J.L.; Yan, H.L.; Zhang, Y.D.; Esling, C.; Zhao, X.; Zuo, L. Probing martensitic transformation, kinetics, elastic and magnetic properties of Ni2-xMn1.5In0.5Cox alloys. J. Mater. Sci. Technol. 2020, 44, 31–41. [Google Scholar] [CrossRef]

- Krenke, T.; Acet, M.; Wassermann, E.F.; Moya, X.; Manosa, L.; Planes, A. Ferromagnetism in the austenitic and martensitic states of Ni-Mn-In alloys. Phys. Rev. B 2006, 73, 174413. [Google Scholar] [CrossRef] [Green Version]

- Hernando, B.; Llamazares, J.L.S.; Santos, J.D.; Sanchez, M.L.; Escoda, L.; Sunol, J.J.; Varga, R.; Garcia, C.; Gonzalez, J. Grain oriented NiMnSn and NiMnIn Heusler alloys ribbons produced by melt spinning: Martensitic transformation and magnetic properties. J. Magn. Magn. Mater. 2009, 321, 763–768. [Google Scholar] [CrossRef]

- Yan, H.L.; Zhang, Y.D.; Xu, N.; Senyshyn, A.; Brokmeier, H.G.; Esling, C.; Zhao, X.; Zuo, L. Crystal structure determination of incommensurate modulated martensite in Ni-Mn-In Heusler alloys. Acta Mater. 2015, 88, 375–388. [Google Scholar] [CrossRef]

- Kresse, G.; Joubert, D. From ultrasoft pseudopotentials to the projector augmented-wave method. Phys. Rev. B 1999, 59, 1758–1775. [Google Scholar] [CrossRef]

- Blochl, P.E. Projector augmented-wave method. Phys. Rev. B Condens. Matter 1994, 50, 17953–17979. [Google Scholar] [CrossRef] [Green Version]

- Perdew, J.P.; Burke, K.; Ernzerhof, M. Generalized gradient approximation made simple. Phys. Rev. Lett. 1996, 77, 3865–3868. [Google Scholar] [CrossRef] [Green Version]

- Monkhorst, H.J.; Pack, J.D. Special points for Brillouin-zone integrations. Phys. Rev. B 1976, 13, 5188–5192. [Google Scholar] [CrossRef]

- Li, C.M.; Luo, H.B.; Hu, Q.M.; Yang, R.; Johansson, B.; Vitos, L. Role of magnetic and atomic ordering in the martensitic transformation of Ni-Mn-In from a first-principles study. Phys. Rev. B 2012, 86, 214205. [Google Scholar] [CrossRef]

- He, W.Q.; Huang, H.B.; Liu, Z.H.; Ma, X.Q. First-principles investigation of magnetic properties and metamagnetic transition of NiCoMnZ (Z = In, Sn, Sb) Heusler alloys. Intermetallics 2017, 90, 140–146. [Google Scholar] [CrossRef]

- Li, C.M.; Luo, H.B.; Hu, Q.M.; Yang, R.; Johansson, B.; Vitos, L. First-principles investigation of the composition dependent properties of Ni2+xMn1-xGa shape-memory alloys. Phys. Rev. B 2010, 82, 024201. [Google Scholar] [CrossRef]

- Wang, C.H. Crystal Structure, Martensitic Transformation and Microstructure in Ni-Mn-In Meta-Magnetic Shape Memory Alloys. Master’s Thesis, Northeastern University, Shenyang, China, 2015. [Google Scholar]

- Feng, Y. Martensitic Transformation Behavior and Structure and Properties of Ni-Mn-In Based Alloys. Ph.D. Thesis, Harbin Institute of Technology, Harbin, China, 2009. [Google Scholar]

- Xu, N.; Raulot, J.M.; Li, Z.B.; Bai, J.; Zhang, Y.D.; Zhao, X.; Zuo, L.; Esling, C. Oscillation of the magnetic moment in modulated martensites in Ni2MnGa studied by ab initio calculations. Appl. Phys. Lett. 2012, 100, 084106. [Google Scholar] [CrossRef]

- Straka, L.; Drahokoupil, J.; Vertat, P.; Kopecek, J.; Zeleny, M.; Seiner, H.; Heczko, O. Orthorhombic intermediate phase originating from {110} nanotwinning in Ni50.0Mn28.7Ga21.3 modulated martensite. Acta. Mater. 2017, 132, 335–344. [Google Scholar] [CrossRef]

- Straka, L.; Drahokoupil, J.; Vertat, P.; Zeleny, M.; Kopecek, J.; Sozinov, A.; Heczko, O. Low temperature a/b nanotwins in Ni50Mn25+xGa25-x Heusler alloys. Sci. Rep. 2018, 8, 11943. [Google Scholar] [CrossRef] [PubMed]

- Vertat, P.; Seiner, H.; Straka, L.; Klicpera, M.; Sozinov, A.; Fabelo, O.; Heczko, O. Hysteretic structural changes within five-layered modulated 10M martensite o fNi–Mn–Ga (–Fe). J. Phys. Condens. Matter 2021, 33, 265404. [Google Scholar] [CrossRef]

- Dutta, B.; Cakir, A.; Giacobbe, C.; Al-Zubi, A.; Hickel, T.; Acet, M.; Neugebauer, J. Ab initio prediction of martensitic and intermartensitic phase boundaries in Ni-Mn-Ga. Phys. Rev. Lett. 2016, 116, 025503. [Google Scholar] [CrossRef]

- Marcos, J.; Planes, A.; Mañosa, L.; Casanova, F.; Batlle, X.; Labarta, A.; Martínez, B. Magnetic field induced entropy change and magnetoelasticity in Ni-Mn-Ga alloys. Phys. Rev. B 2002, 66, 224413. [Google Scholar] [CrossRef] [Green Version]

- Wu, Z.; Liu, Z.; Yang, H.; Liu, Y.; Wu, G. Effect of Co addition on martensitic phase transformation and magnetic properties of Mn50Ni40-xIn10Cox polycrystalline alloys. Intermetallics 2011, 19, 1839–1848. [Google Scholar] [CrossRef]

- Kundu, A.; Gruner, M.E.; Siewert, M.; Hucht, A.; Entel, P.; Ghosh, S. Interplay of phase sequence and electronic structure in the modulated martensites of Mn2NiGa from first-principles calculations. Phys. Rev. B 2017, 96, 064107. [Google Scholar] [CrossRef] [Green Version]

- Ghosh, S.; Ghosh, S. Role of composition, site ordering, and magnetic structure for the structural stability of off-stoichiometric Ni2MnSb alloys with excess Ni and Mn. Phys. Rev. B 2019, 99, 064112. [Google Scholar] [CrossRef]

- Kundu, A.; Ghosh, S. Site occupancy, composition and magnetic structure dependencies of martensitic transformation in Mn2Ni1+xSn1-x. J. Phys. Condens. Matter 2018, 30, 015401. [Google Scholar] [CrossRef] [Green Version]

- Liang, X.Z.; Jiang, X.J.; Gu, J.L.; Bai, J.; Guan, Z.Z.; Li, Z.Z.; Yan, H.L.; Zhang, Y.D.; Esling, C.; Zhao, X.; et al. 5M and 7M martensitic stability and associated physical properties in Ni50Mn35In15 alloy: First-principles calculations and experimental verification. Scr. Mater. 2021, 204, 114140. [Google Scholar] [CrossRef]

- Barman, S.R.; Banik, S.; Chakrabarti, A. Structural and electronic properties of Ni2MnGa. Phys. Rev. B 2005, 72, 184410. [Google Scholar] [CrossRef]

- Liang, Z.; Li, Q.; Sun, K.; Luo, H.J. Martensitic transition and magnetic structure in Zn-doped Heusler alloy Mn2NiGa: A theoretical approach. Phys. Chem. Solids 2019, 134, 127–132. [Google Scholar] [CrossRef]

- Zelený, M.; Sozinov, A.; Straka, L.; Björkman, T.; Nieminen, R.M. First-principles study of Co- and Cu-doped along the tetragonal deformation path. Phys. Rev. B 2014, 89, 184103. [Google Scholar] [CrossRef] [Green Version]

- Li, Z.B. Study on Crystallographic Features of Ni-Mn-Ga Ferromagnetic Shape Memory Alloys. Ph.D. Thesis, Paul-Verlaine University of Metz, Metz, France, Northeastern University, Shenyang, China, 2011. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liang, X.-Z.; Bai, J.; Guan, Z.-Q.; Zhang, Y.; Gu, J.-L.; Zhang, Y.-D.; Esling, C.; Zhao, X.; Zuo, L. Unraveling the Phase Stability and Physical Property of Modulated Martensite in Ni2Mn1.5In0.5 Alloys by First-Principles Calculations. Materials 2022, 15, 4032. https://doi.org/10.3390/ma15114032

Liang X-Z, Bai J, Guan Z-Q, Zhang Y, Gu J-L, Zhang Y-D, Esling C, Zhao X, Zuo L. Unraveling the Phase Stability and Physical Property of Modulated Martensite in Ni2Mn1.5In0.5 Alloys by First-Principles Calculations. Materials. 2022; 15(11):4032. https://doi.org/10.3390/ma15114032

Chicago/Turabian StyleLiang, Xin-Zeng, Jing Bai, Zi-Qi Guan, Yu Zhang, Jiang-Long Gu, Yu-Dong Zhang, Claude Esling, Xiang Zhao, and Liang Zuo. 2022. "Unraveling the Phase Stability and Physical Property of Modulated Martensite in Ni2Mn1.5In0.5 Alloys by First-Principles Calculations" Materials 15, no. 11: 4032. https://doi.org/10.3390/ma15114032

APA StyleLiang, X.-Z., Bai, J., Guan, Z.-Q., Zhang, Y., Gu, J.-L., Zhang, Y.-D., Esling, C., Zhao, X., & Zuo, L. (2022). Unraveling the Phase Stability and Physical Property of Modulated Martensite in Ni2Mn1.5In0.5 Alloys by First-Principles Calculations. Materials, 15(11), 4032. https://doi.org/10.3390/ma15114032