Magnetic and Magnetostrictive Behaviors of Laves-Phase Rare-Earth—Transition-Metal Compounds Tb1−xDyxCo1.95

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Crystal Structure Characterization

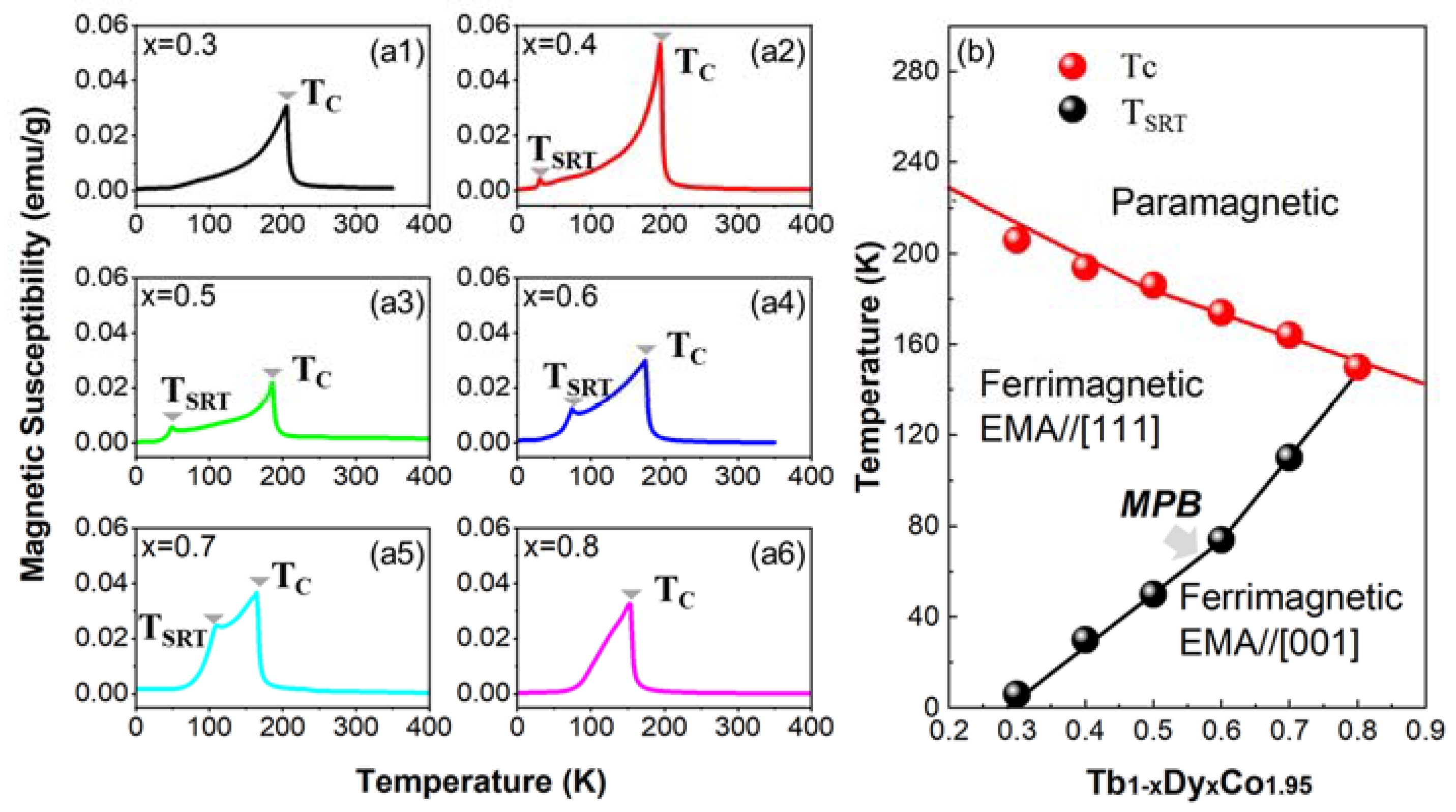

3.2. Temperature Spectrum of Magnetic Susceptibility and Magnetic Phase Diagram

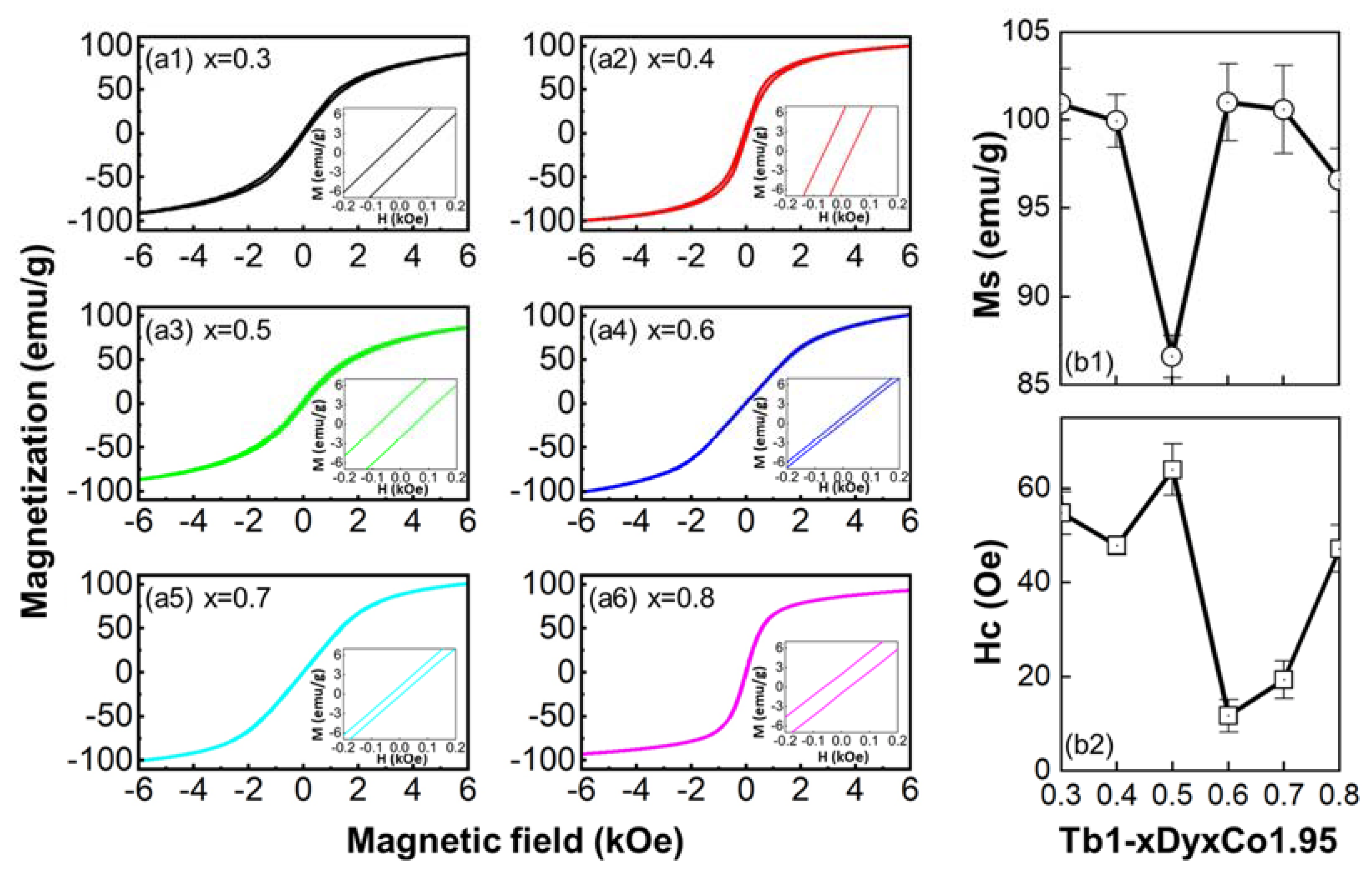

3.3. M-H Hysteresis Loops

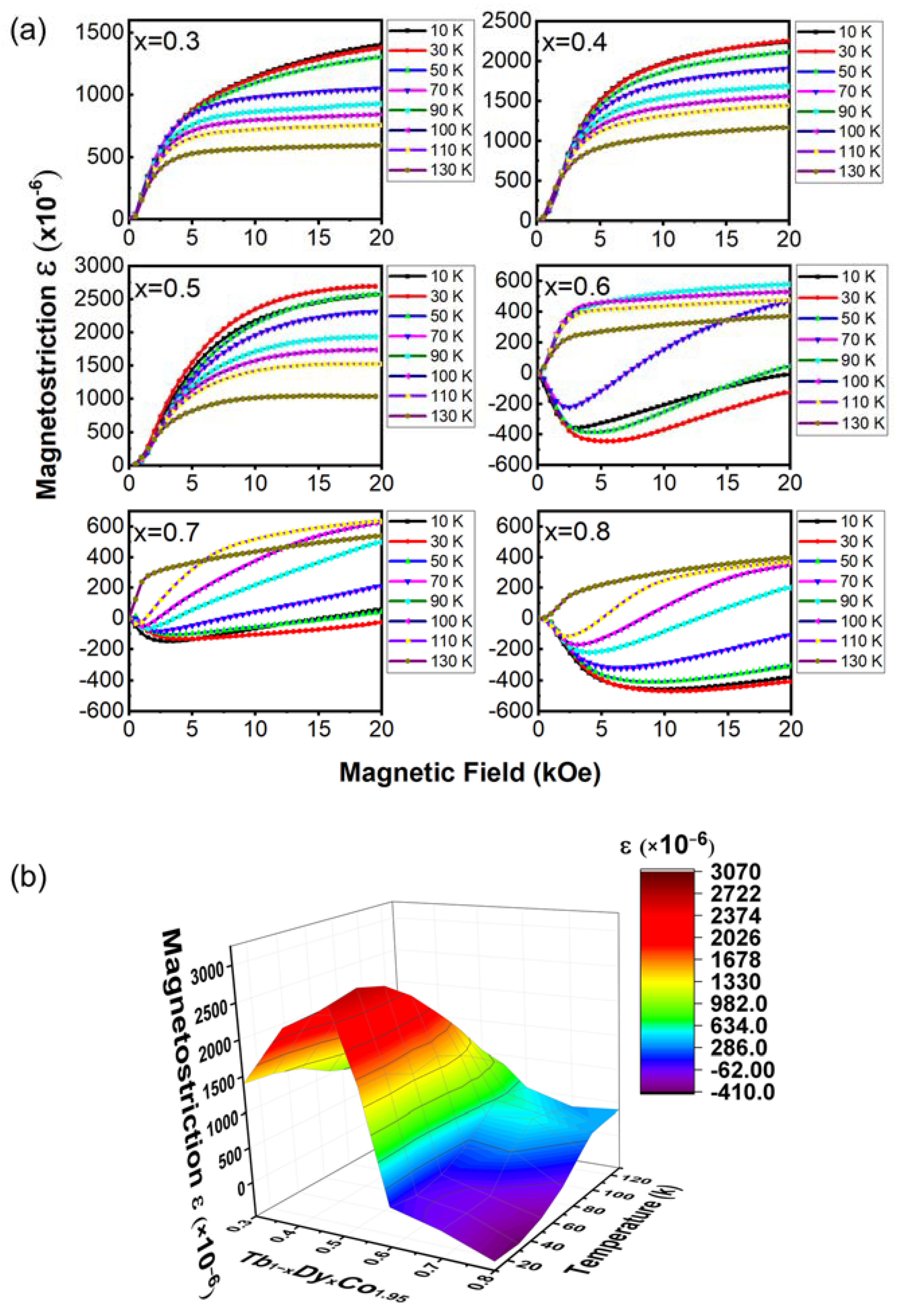

3.4. Composition- and Temperature-Dependent Magnetostriction

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- O’Handley, R.C. Modern Magnetic Materials: Principles and Applications; John Wiley & Sons, Inc.: New York, NY, USA, 1999. [Google Scholar]

- Duc, N.H.; Brommer, P.E. Formation of 3d-Moments and Spin Fluctuations in the Rare Earth—Transition Metal Intermetallics. In Advanced Magnetism and Magnetic Materials; Duc, N.H., Ed.; Vietnam National University Press: Hanoi, Vietnam, 2014; pp. 97–270. [Google Scholar]

- Lee, E.W.; Pourarian, F. Magnetoelastic properties of (Rare-Earth)–Co2 compounds. II. The anisotropic magnetostriction. Phys. Status Solidi (A) 1976, 34, 383–390. [Google Scholar] [CrossRef]

- Clark, A.E.; Belson, H.S. Giant Room-Temperature Magnetostrictions in TbFe2 and DyFe2. Phys. Rev. B 1972, 5, 3642–3644. [Google Scholar] [CrossRef]

- Yang, S.; Bao, H.; Zhou, C.; Wang, Y.; Ren, X.; Matsushita, Y.; Katsuya, Y.; Tanaka, M.; Kobayashi, K.; Song, X.; et al. Large Magnetostriction from Morphotropic Phase Boundary in Ferromagnets. Phys. Rev. Lett. 2010, 104, 197201. [Google Scholar] [CrossRef] [PubMed]

- Bergstrom, R., Jr.; Wuttig, M.; Cullen, J.; Zavalij, P.; Briber, R.; Dennis, C.; Garlea, V.O.; Laver, M. Morphotropic Phase Boundaries in Ferromagnets: Tb1−xDyxFe2 Alloys. Phys. Rev. Lett. 2013, 111, 017203. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Murtaza, A.; Yang, S.; Zhou, C.; Chang, T.; Chen, K.; Tian, F.; Song, X.; Suchomel, M.R.; Ren, Y. Anomalous magnetoelastic behaviour near morphotropic phase boundary in ferromagnetic Tb1−xNdxCo2 system. Appl. Phys. Lett. 2016, 109, 052904. [Google Scholar] [CrossRef]

- Adil, M.; Yang, S.; Mi, M.; Zhou, C.; Wang, J.; Zhang, R.; Liao, X.; Wang, Y.; Ren, X.; Song, X.; et al. Morphotropic phase boundary and magnetoelastic behaviour in ferromagnetic Tb1−xGdxFe2 system. Appl. Phys. Lett. 2015, 106, 132403. [Google Scholar] [CrossRef] [Green Version]

- Zhou, C.; Ren, S.; Bao, H.; Yang, S.; Yao, Y.; Ji, Y.; Ren, X.; Matsushita, Y.; Katsuya, Y.; Tanaka, M.; et al. Inverse effect of morphotropic phase boundary on the magnetostriction of ferromagnetic Tb1−xGdxCo2. Phys. Rev. B 2014, 89, 100101. [Google Scholar] [CrossRef]

- Zhao, H.; Ji, Y.; Ma, T.; Fang, M.; Hao, Y.; Yang, T.; Zhou, C.; Yang, S.; Ren, X. Exceptional combination of large magnetostriction, low hysteresis and wide working temperature range in (1−x)TbFe2−xDyCo2 alloys. Acta Mater. 2021, 220, 117308. [Google Scholar] [CrossRef]

- Hu, J.; Lin, K.; Cao, Y.; Yu, C.; Li, W.; Huang, R.; Fischer, H.E.; Kato, K.; Song, Y.; Chen, J.; et al. Adjustable Magnetic Phase Transition Inducing Unusual Zero Thermal Expansion in Cubic RCo2-Based Intermetallic Compounds (R = Rare Earth). Inorg. Chem. 2019, 58, 5401–5405. [Google Scholar] [CrossRef]

- Song, Y.; Chen, J.; Liu, X.; Wang, C.; Zhang, J.; Liu, H.; Zhu, H.; Hu, L.; Lin, K.; Zhang, S.; et al. Zero Thermal Expansion in Magnetic and Metallic Tb(Co,Fe)2 Intermetallic Compounds. J. Am. Chem. Soc. 2018, 140, 602–605. [Google Scholar] [CrossRef]

- Halder, M.; Yusuf, S.M.; Mukadam, M.D.; Shashikala, K. Magnetocaloric effect and critical behavior near the paramagnetic to ferrimagnetic phase transition temperature in TbCo2−xFex. Phys. Rev. B 2010, 81, 174402. [Google Scholar] [CrossRef] [Green Version]

- Zhou, C.; Bao, H.; Matsushita, Y.; Chang, T.; Chen, K.; Zhang, Y.; Tian, F.; Zuo, W.; Song, X.; Yang, S.; et al. Thermal Expansion and Magnetostriction of Laves-Phase Alloys: Fingerprints of Ferrimagnetic Phase Transitions. Materials 2019, 12, 1755. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hirosawa, S.; Nakamura, Y. 59Co NMR Study of Spin Orientation in Pseudobinary Tb1−xDyxCo2. J. Phys. Soc. Jpn. 1982, 51, 1162–1165. [Google Scholar] [CrossRef]

- Gu, K.; Li, J.; Ao, W.; Jian, Y.; Tang, J. The magnetocaloric effect in (Dy,Tb)Co2 alloys. J. Alloys Compd. 2007, 441, 39–42. [Google Scholar] [CrossRef]

- Zhuang, Y.; Xiang, C.H.; Kaiwen, Z.H.; Kefeng, L.I.; Chunhua, M.A. Phase structure and magnetocaloric effect of (Tb1−xDyx)Co2 alloys. J. Rare Earths 2008, 26, 749–752. [Google Scholar] [CrossRef]

- Zhang, D.; Ma, X.; Yang, S.; Song, X. Role of the electronic structure in the morphotropic phase boundary of TbxDy1−xCo2 studied by first-principle calculation. J. Alloys Compd. 2016, 689, 1083–1087. [Google Scholar] [CrossRef] [Green Version]

- Palit, M.; Pandian, S.; Chattopadhyay, K. Phase relationships and magnetic properties of TbxDy1−xFe1.95 alloys. J. Alloys Compd. 2012, 541, 297–304. [Google Scholar] [CrossRef]

- Ma, T.; Zhang, C.; Zhang, P.; Yan, M. Effect of magnetic annealing on magnetostrictive performance of a <110> oriented crystal Tb0.3Dy0.7Fe1.95. J. Magn. Magn. Mater. 2010, 322, 1889–1893. [Google Scholar] [CrossRef]

- Arout Chelvane, J.; Palit, M.; Basumatary, H.; Pandian, S.; Chandrasekaran, V. Structural, magnetic and Mössbauer studies on magnetostrictive Ho1−xTbxFe1.95 [x = 0–1]. Phys. B Condens. Matter 2009, 404, 1432–1436. [Google Scholar] [CrossRef]

- Liu, X.; Lin, K.; Gao, Q.; Zhu, H.; Li, Q.; Cao, Y.; Liu, Z.; You, L.; Chen, J.; Ren, Y.; et al. Structure and Phase Transformation in the Giant Magnetostriction Laves-Phase SmFe2. Inorg. Chem. 2018, 57, 689–694. [Google Scholar] [CrossRef]

- Murtaza, A.; Zuo, W.; Yaseen, M.; Ghani, A.; Saeed, A.; Hao, C.; Mi, J.; Li, Y.; Chang, T.; Wang, L.; et al. Magnetocaloric effect in the vicinity of the magnetic phase transition in NdCo2−xFex compounds. Phys. Rev. B 2020, 101, 214427. [Google Scholar] [CrossRef]

- Murtaza, A.; Li, Y.; Mi, J.; Zuo, W.; Ghani, A.; Dai, Z.; Yao, K.; Hao, C.; Yaseen, M.; Saeed, A.; et al. Spin configuration, magnetic and magnetostrictive properties of Tb0.27Dy0.73−xNdxFe2 compounds. Mater. Chem. Phys. 2020, 249, 122951. [Google Scholar] [CrossRef]

- Murtaza, A.; Yang, S.; Khan, M.T.; Ghani, A.; Zhou, C.; Song, X. Temperature dependent magnetization and coercivity in morphotropic phase boundary involved ferromagnetic Tb1−xGdxFe2 system. Mater. Chem. Phys. 2018, 217, 278–284. [Google Scholar] [CrossRef]

- Chang, T.Y.; Zhou, C.; Mi, J.; Chen, K.; Tian, F.; Chen, Y.S.; Wang, S.G.; Ren, Y.; Brown, D.E.; Song, X.; et al. Crystal structures and phase relationships in magnetostrictive Tb1−xDyxCo2 system. J. Phys.-Condens. Matter 2020, 32, 135802. [Google Scholar] [CrossRef]

- Yang, S.; Ren, X. Noncubic crystallographic symmetry of a cubic ferromagnet: Simultaneous structural change at the ferromagnetic transition. Phys. Rev. B 2008, 77, 014407. [Google Scholar] [CrossRef] [Green Version]

- Ouyang, Z.W.; Wang, F.; Hang, Q.; Liu, W.; Liu, G.; Lynn, J.; Liang, J.; Rao, G. Temperature dependent neutron powder diffraction study of the Laves phase compound TbCo2. J. Alloys Compd. 2005, 390, 21–25. [Google Scholar] [CrossRef]

- Stein, F.; Leineweber, A. Laves phases: A review of their functional and structural applications and an improved fundamental understanding of stability and properties. J. Mater. Sci. 2021, 56, 5321–5427. [Google Scholar]

- Atzmony, U.; Dublon, G. Directions of easy magnetization in Laves RCo2 compounds. Phys. B+C 1977, 86–88, 167–168. [Google Scholar] [CrossRef]

- Horner, H.; Varma, C.M. Nature of Spin-Reorientation Transitions. Phys. Rev. Lett. 1968, 20, 845–846. [Google Scholar] [CrossRef]

- Atzmony, U.; Dariel, M.P.; Bauminger, E.R.; Lebenbaum, D.; Nowik, I.; Ofer, S. Spin-Orientation Diagrams and Magnetic Anisotropy of Rare-Earth-Iron Ternary Cubic Laves Compounds. Phys. Rev. B 1973, 7, 4220–4232. [Google Scholar] [CrossRef]

- Duc, N.H. Effects of the 3d—5d Hybridization on the 4f—3d Coupling in the Rare Earth—Transition Metal Compounds. Phys. Status Solidi (B) 1993, 175, K63–K66. [Google Scholar] [CrossRef]

- Liu, J.-J.; Ren, W.J.; Li, D.; Sun, N.K.; Zhao, X.G.; Li, J.; Zhang, Z.D. Magnetic transitions and magnetostrictive properties of TbxDy1−x(Fe0.8Co0.2)2 (0.20 < x < 0.40). Phys. Rev. B 2007, 75, 064429. [Google Scholar]

- Chikazumi, S.; Chikazumi, S.; Graham, C.D. Physics of Ferromagnetism, 2nd ed.; Oxford University Press: Oxford, UK, 1997; p. 503. [Google Scholar]

- Atzmony, U.; Dariel, M.P.; Bauminger, E.R.; Lebenbaum, D.; Nowik, I.; Ofer, S. Magnetic anisotropy and spin rotations in cubic lave compounds, anisotropy and spin rotations in cubic lave compounds. Phys. Rev. Lett. 1972, 28, 244. [Google Scholar] [CrossRef]

- Hu, C.-C.; Yang, T.N.; Huang, H.B.; Hu, J.M.; Wang, J.J.; Shi, Y.G.; Shi, D.N.; Chen, L.Q. Phase-field simulation of domain structures and magnetostrictive response in Tb1−xDyxFe2 alloys near morphotropic phase boundary. Appl. Phys. Lett. 2016, 108, 141908. [Google Scholar] [CrossRef]

- Ma, T.; Liu, X.; Pan, X.; Li, X.; Jiang, Y.; Yan, M.; Li, H.; Fang, M.; Ren, X. Local rhombohedral symmetry in Tb0.3Dy0.7Fe2 near the morphotropic phase boundary. Appl. Phys. Lett. 2014, 105, 192407. [Google Scholar] [CrossRef]

- Clark, A.; Crowder, D. High temperature magnetostriction of TbFe2 and Tb.27Dy.73Fe2. IEEE Trans. Magn. 1985, 21, 1945–1947. [Google Scholar] [CrossRef]

- Deng, C.G.; Ye, L.; He, C.; Xu, G.; Zhai, Q.; Luo, H.; Liu, Y.; Bell, A.J. Reporting Excellent Transverse Piezoelectric and Electro-Optic Effects in Transparent Rhombohedral PMN-PT Single Crystal by Engineered Domains. Adv. Mater. 2021, 33, 2103013. [Google Scholar] [CrossRef] [PubMed]

| Composition | MS (emu/g) | HC (Oe) | ε (ppm) at 110 K | Figure of Merit ׀ε׀/HC (Oe−1·106) | Reference |

|---|---|---|---|---|---|

| Tb0.6Dy0.4Co1.95 | 99.9 | 47.9 | 1441 | 30.1 | The present study |

| Tb0.5Dy0.5Co1.95 | 86.6 | 64 | 1523 | 23.8 | The present study |

| Tb0.4Dy0.6Co1.95 | 101.1 | 11.7 | 475 | 40.6 | The present study |

| Tb0.3Dy0.7Co1.95 | 100.6 | 19.4 | 635 | 32.7 | The present study |

| Tb0.6Dy0.4Co2 | 115 | 102 | 1410 | 13.8 | Ref. [5] |

| Tb0.3Dy0.7Co2 | 105.5 | 15.6 | 828 | 53.1 | Ref. [5] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, C.; Li, K.; Chen, Y.; Dai, Z.; Wang, Y.; Wang, L.; Matsushita, Y.; Zhang, Y.; Zuo, W.; Tian, F.; et al. Magnetic and Magnetostrictive Behaviors of Laves-Phase Rare-Earth—Transition-Metal Compounds Tb1−xDyxCo1.95. Materials 2022, 15, 3884. https://doi.org/10.3390/ma15113884

Zhou C, Li K, Chen Y, Dai Z, Wang Y, Wang L, Matsushita Y, Zhang Y, Zuo W, Tian F, et al. Magnetic and Magnetostrictive Behaviors of Laves-Phase Rare-Earth—Transition-Metal Compounds Tb1−xDyxCo1.95. Materials. 2022; 15(11):3884. https://doi.org/10.3390/ma15113884

Chicago/Turabian StyleZhou, Chao, Kaili Li, Yuanliang Chen, Zhiyong Dai, Yu Wang, Liqun Wang, Yoshitaka Matsushita, Yin Zhang, Wenliang Zuo, Fanghua Tian, and et al. 2022. "Magnetic and Magnetostrictive Behaviors of Laves-Phase Rare-Earth—Transition-Metal Compounds Tb1−xDyxCo1.95" Materials 15, no. 11: 3884. https://doi.org/10.3390/ma15113884

APA StyleZhou, C., Li, K., Chen, Y., Dai, Z., Wang, Y., Wang, L., Matsushita, Y., Zhang, Y., Zuo, W., Tian, F., Murtaza, A., & Yang, S. (2022). Magnetic and Magnetostrictive Behaviors of Laves-Phase Rare-Earth—Transition-Metal Compounds Tb1−xDyxCo1.95. Materials, 15(11), 3884. https://doi.org/10.3390/ma15113884