Barrier Diamond-like Carbon Coatings on Polydimethylsiloxane Substrate

Abstract

:1. Introduction

2. Materials and Methods

2.1. Manufacturing of PDMS Substrates

2.2. Apparatus and Modification Parameters

2.3. Contact Angle Measurement

2.4. Atomic Force Microscopy AFM

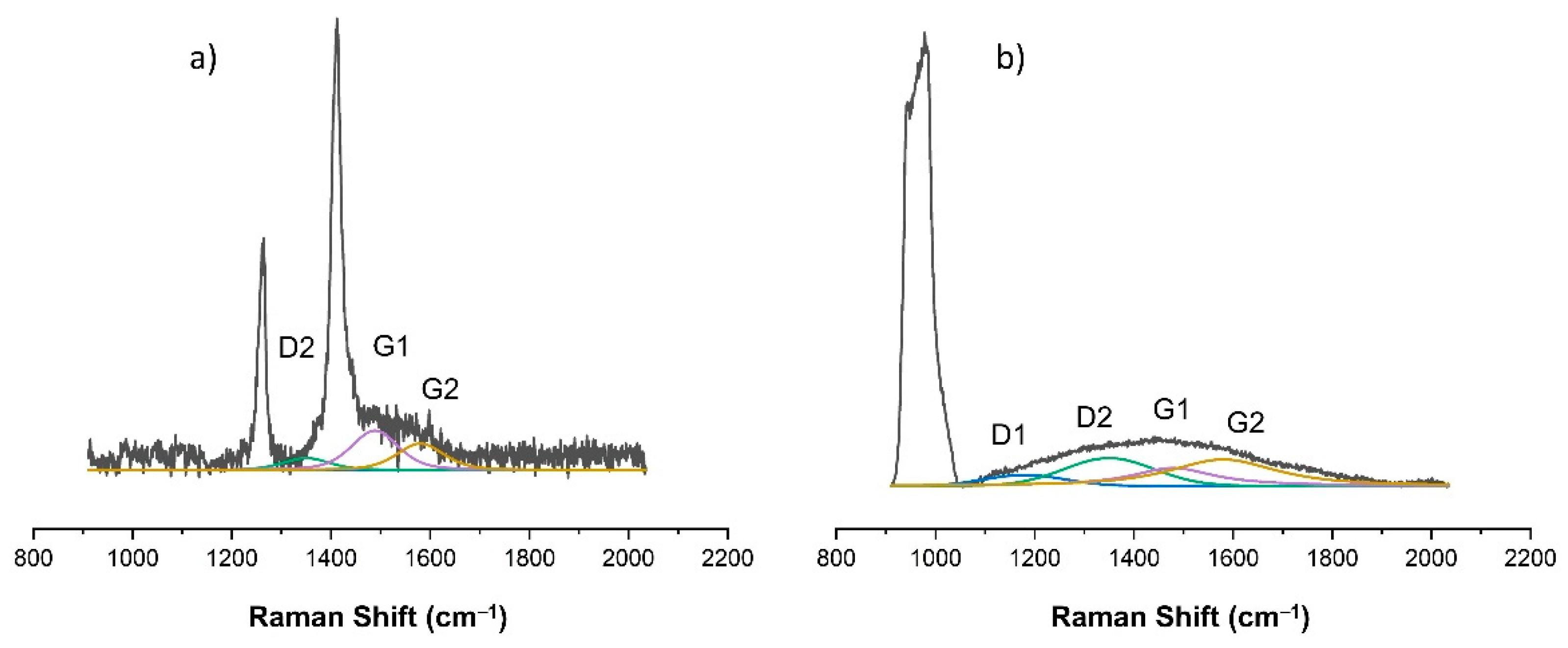

2.5. Raman Spectroscopy

2.6. Thickness Analysis

3. Results and Discussion

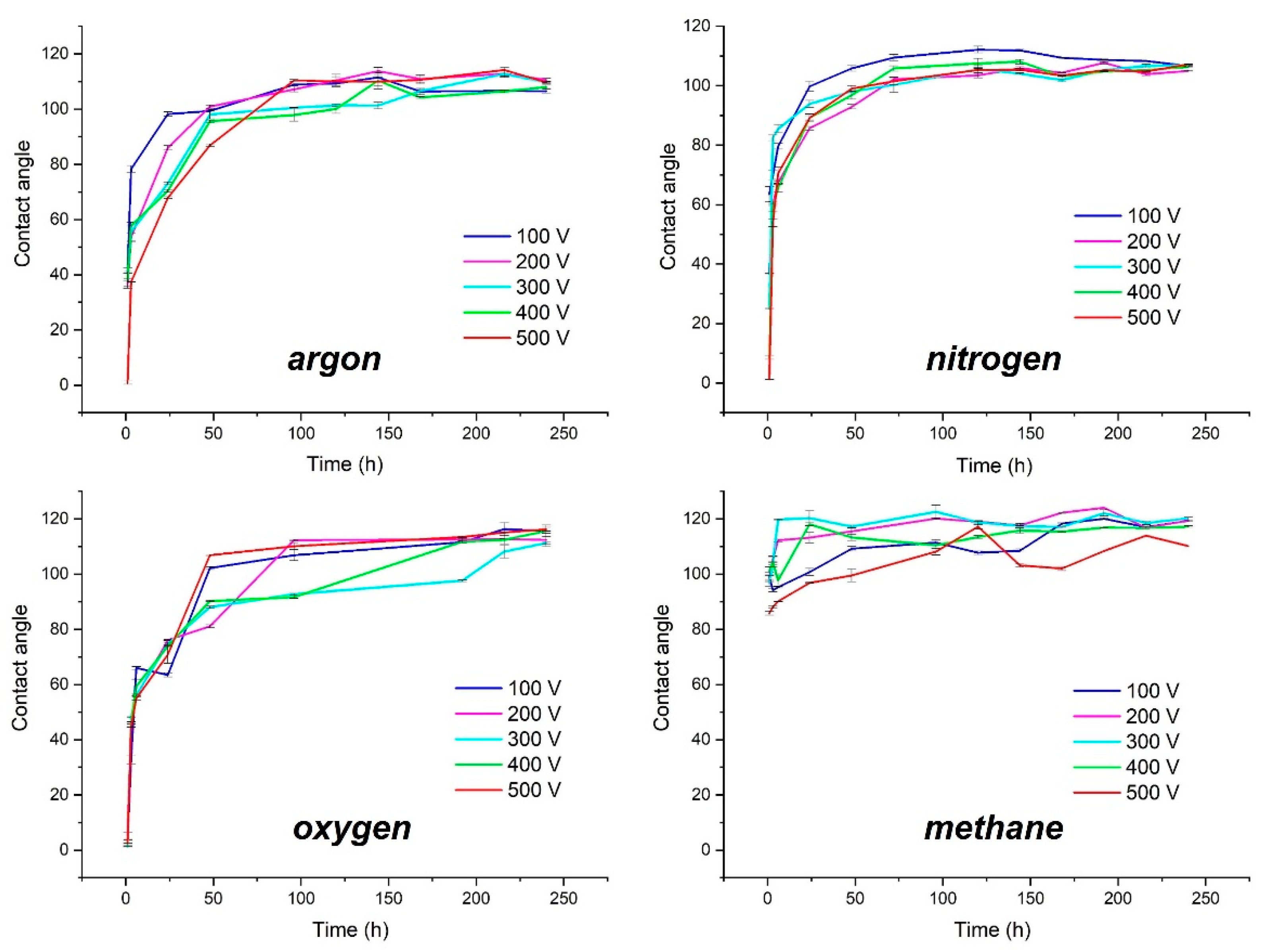

3.1. Changes in Contact Angles over Time of the Modified PDMS Substrates

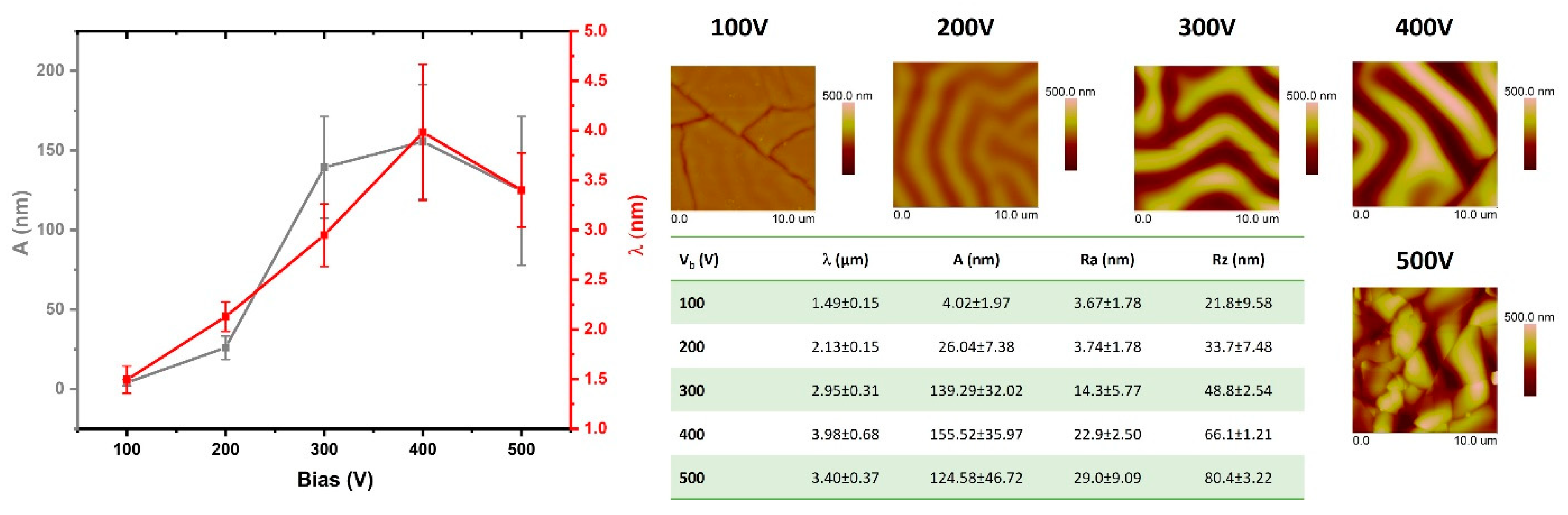

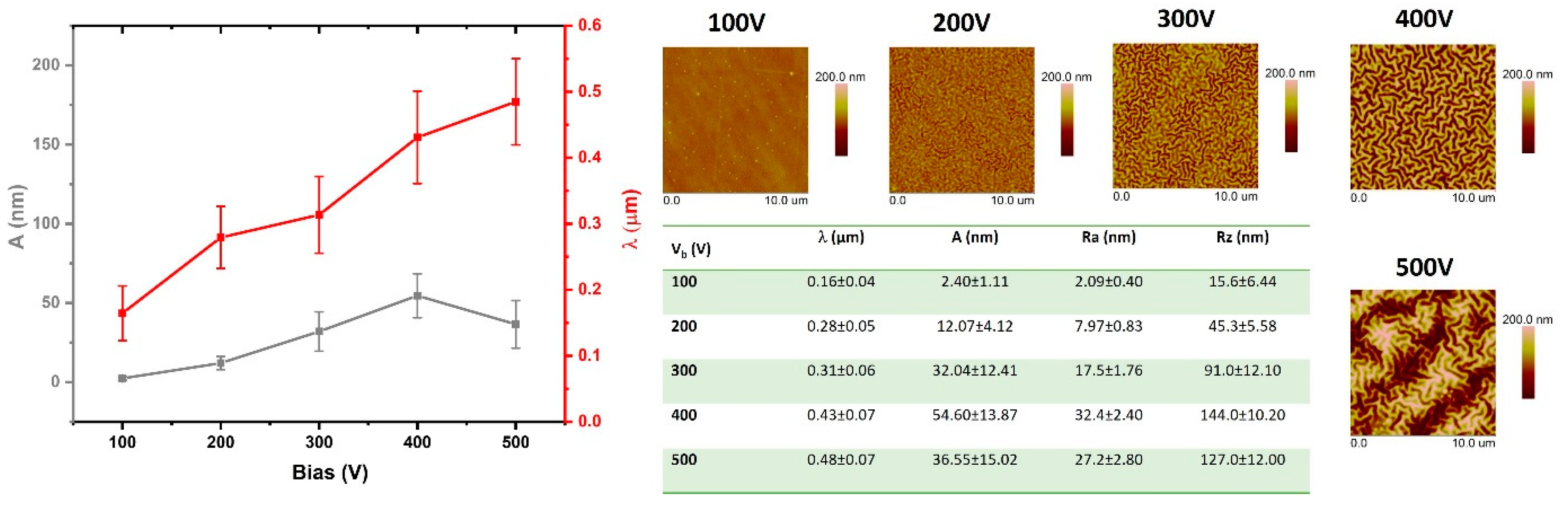

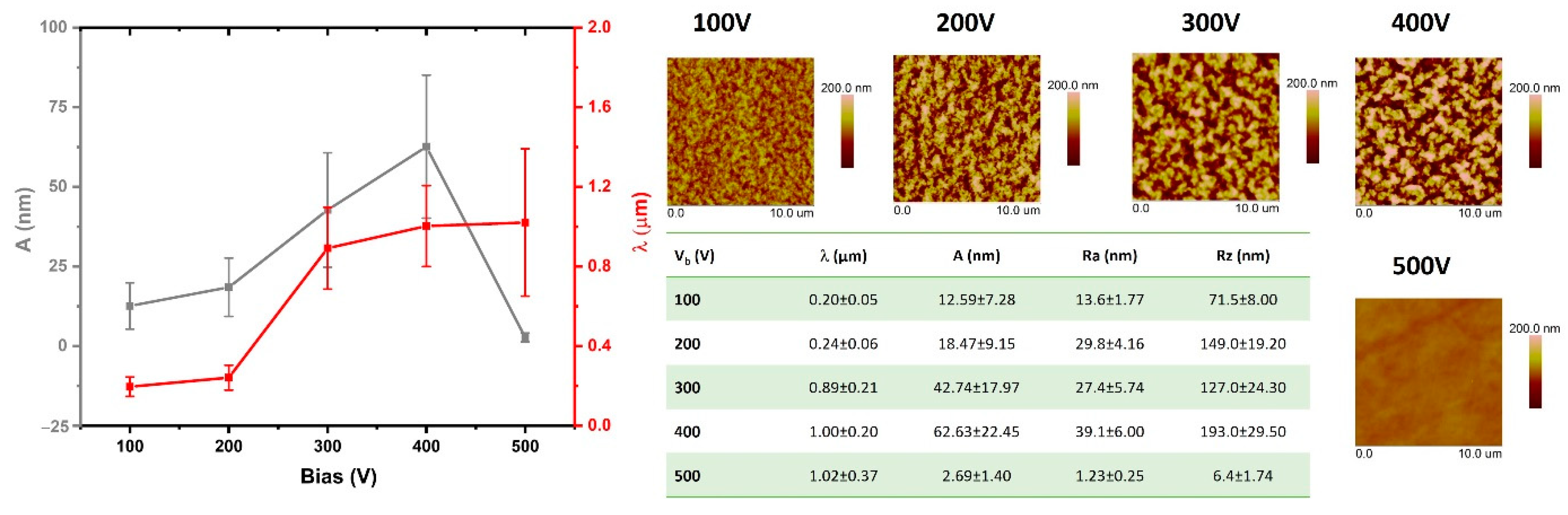

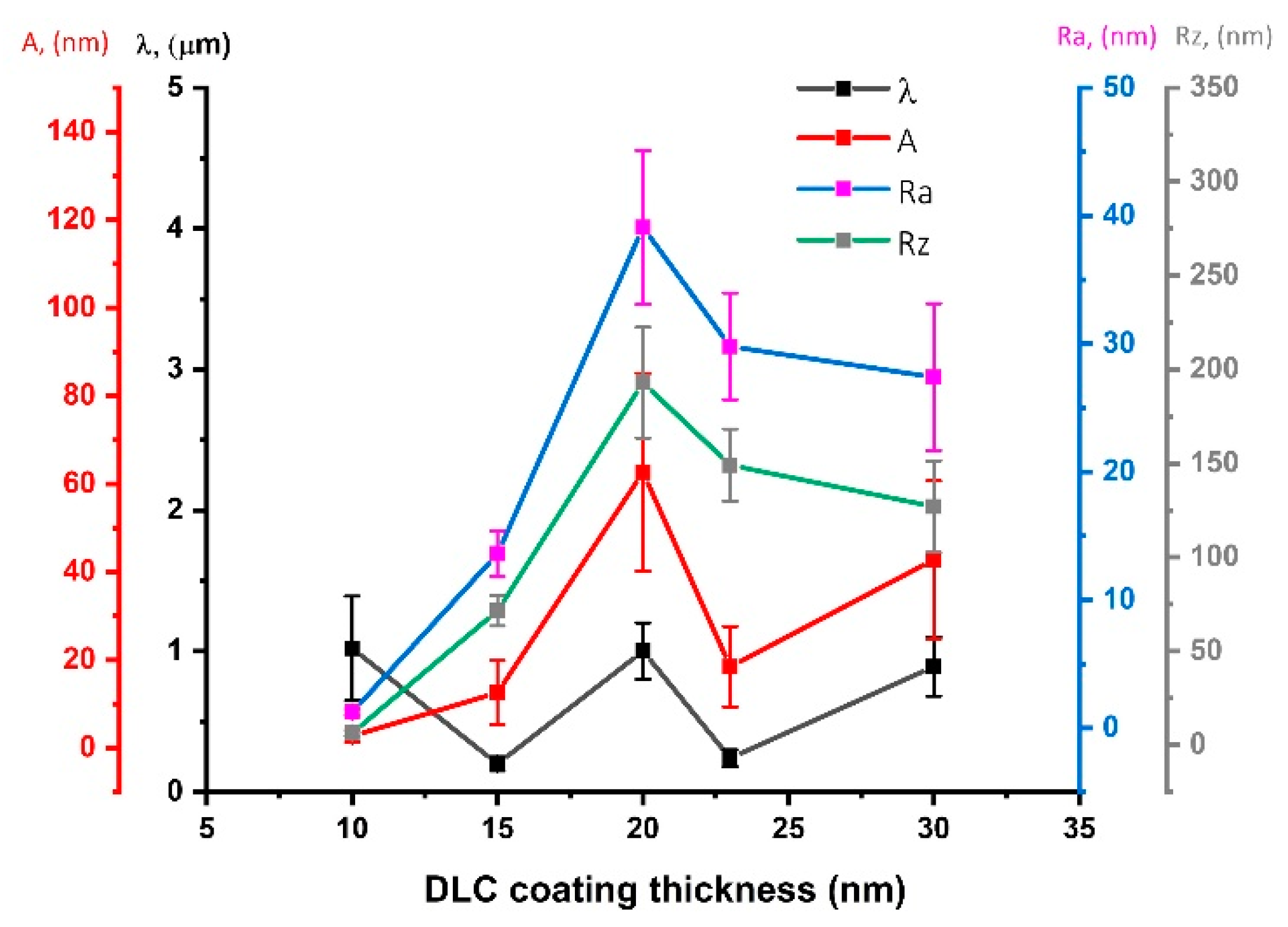

3.2. Geometrical Structure Analysis of the Modified PDMS Surfaces

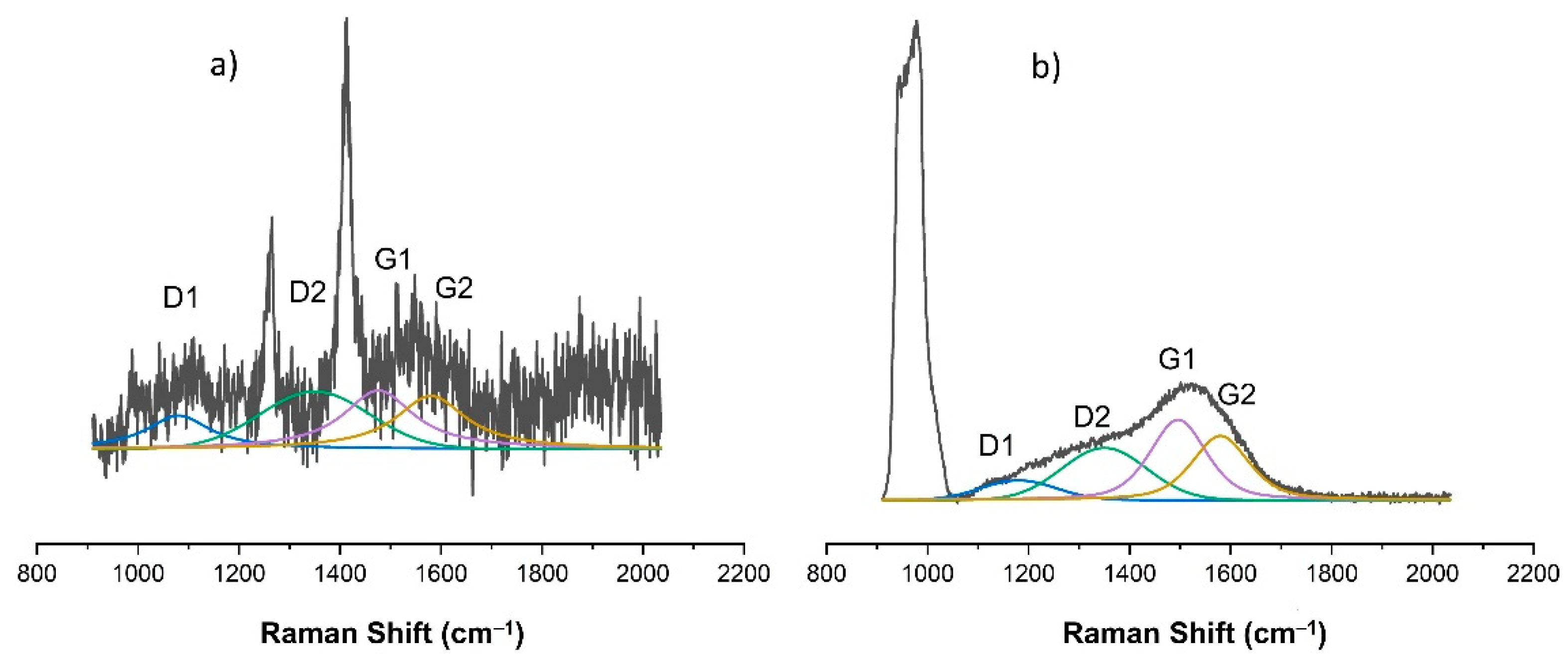

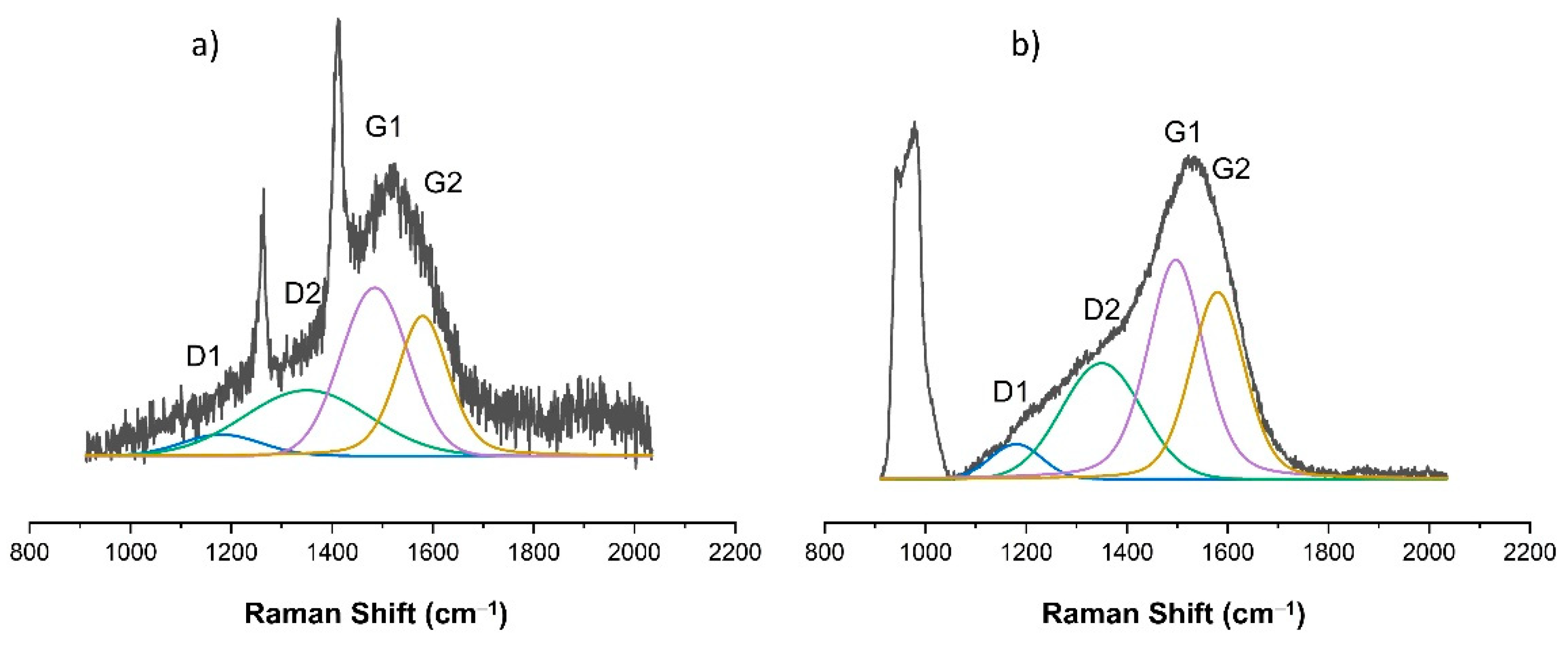

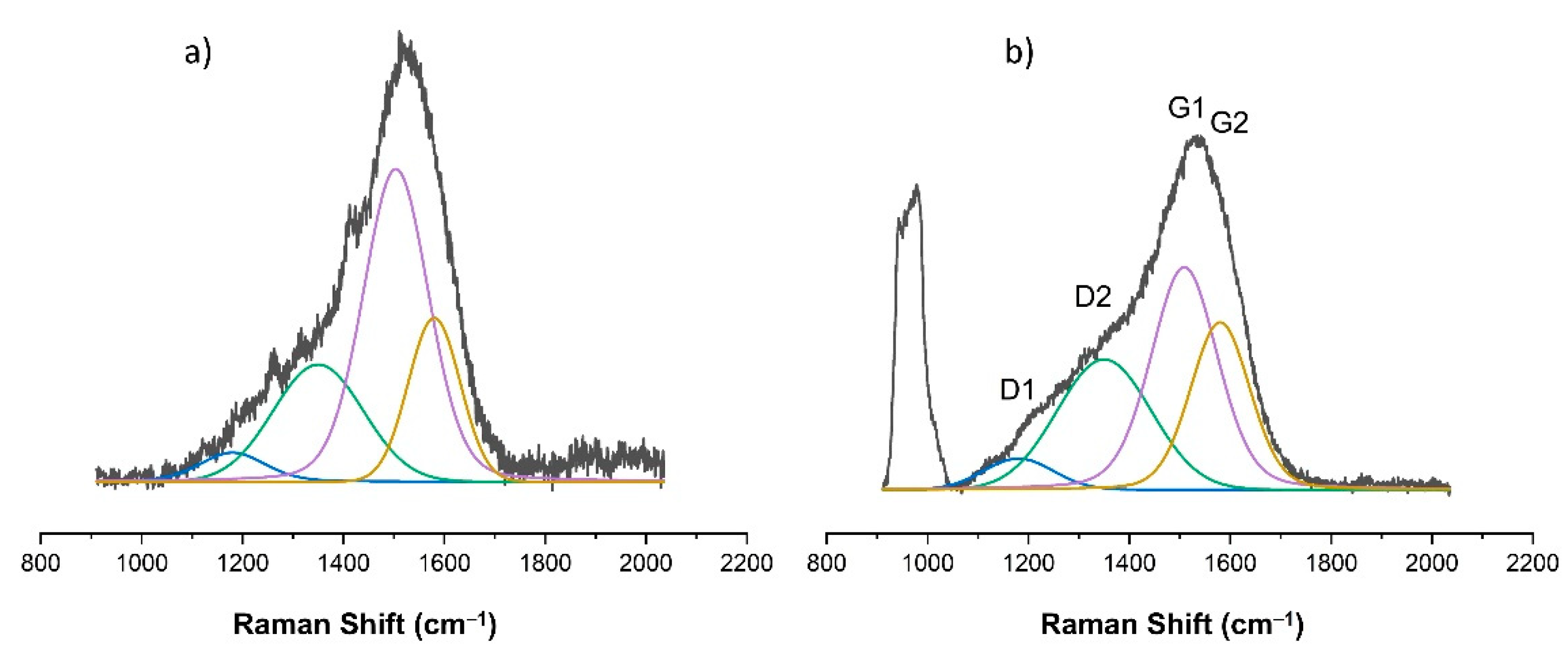

3.3. Chemical Structure Analysis of the Modified PDMS Substrates

3.4. Determination of Thickness of DLC Coatings in the PDMS Substrates

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, Z.; Lou, Y.; Zheng, F.; Zhang, N.; Yin, C.; Li, J.; He, C.; Peng, X.; Huang, Z.; Fang, P. Study on surface structure of plasma-treated polydimethylsiloxane (PDMS) elastomer by slow positron beam. Surf. Interface Anal. 2018, 50, 819–826. [Google Scholar] [CrossRef]

- Wolf, M.P.; Salieb-Beugelaar, G.B.; Hunziker, P. PDMS with designer functionalities-Properties, modifications strategies, and applications. Prog. Polym. Sci. 2018, 83, 97–134. [Google Scholar] [CrossRef]

- Zahid, A.; Dai, B.; Hong, R.; Zhang, D. Optical properties study of silicone polymer PDMS substrate surfaces modified by plasma treatment. Mater. Res. Express 2017, 4, 105301. [Google Scholar] [CrossRef] [Green Version]

- Ban, M.; Tobe, S.; Takeuchi, L. Effects of diamond-like carbon thin film and wrinkle microstructure on cell proliferation. Diam. Relat. Mater. 2018, 90, 194–201. [Google Scholar] [CrossRef]

- Cheng, X.; Meng, B.; Chen, X.; Han, M.; Chen, H.; Su, Z.; Shi, M.; Zhang, H. Single-step fluorocarbon plasma treatment-induced wrinkle structure for high-performance triboelectric nanogenerator. Small 2016, 12, 229–236. [Google Scholar] [CrossRef]

- Gokaltun, A.; Yarmush, M.L.; Asatekin, A.; Usta, O.B. Recent advances in nonbiofouling PDMS surface modification strategies applicable to microfluidic technology. Technology (Singap. World Sci.) 2017, 5, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Qi, L.; Ruck, C.; Spychalski, G.; King, B.; Wu, B.; Zhao, Y. Writing wrinkles on poly(dimethylsiloxane) (PDMS) by surface oxidation with a CO2 laser engraver. ACS Appl. Mater. Interfaces 2018, 10, 4295–4304. [Google Scholar] [CrossRef]

- Leigh, B.L.; Cheng, E.; Xu, L.; Derk, A.; Hansen, M.R.; Guymon, C.A. Antifouling photograftable zwitterionic coatings on PDMS substrates. Langmuir 2019, 35, 1100–1110. [Google Scholar] [CrossRef]

- Wang, Q.; Sun, G.; Tong, Q.; Yang, W.; Hao, W. Fluorine-free superhydrophobic coatings from polydimethylsiloxane for sustainable chemical engineering: Preparation methods and applications. Chem. Eng. J. 2021, 426, 130829. [Google Scholar] [CrossRef]

- Ban, M.; Hagiwara, T.; Masumoto, Y. Partial formation of linear concavo-convex microstructure onto microwells by diamond-like carbon thin film deposition. Diam. Relat. Mater. 2017, 74, 138–144. [Google Scholar] [CrossRef]

- Glatz, B.A.; Fery, A. The influence of plasma treatment on the elasticity of the in situ oxidized gradient layer in PDMS: Towards crack-free wrinkling. Soft Matter 2019, 15, 65. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lee, D.; Yang, S. Surface modification of PDMS by atmospheric-pressure plasma-enhanced chemical vapor deposition and analysis of long-lasting surface hydrophilicity. Sens. Actuat. B Chem. 2012, 162, 425–434. [Google Scholar] [CrossRef]

- Kaczorowski, W.; Szymański, W.; Batory, D.; Niedzielski, P. Effect of plasma treatment on the surface properties of polydimethylsiloxane. J. Appl. Polym. Sci. 2015, 132, 41635. [Google Scholar] [CrossRef]

- Ma, L.; He, L.; Ni, Y. Tunable hierarchical wrinkling: From models to applications. J. Appl. Phys. 2020, 127, 111101. [Google Scholar] [CrossRef]

- Zhou, Q.; Kuhn, P.T.; Huisman, T.; Nieboer, E.; van Zwol, C.; van Kooten, T.; van Rijn, P. Directional nanotopographic gradients: A high-throughput screening platform for cell contact guidance. Sci. Rep. 2015, 5, 16240. [Google Scholar] [CrossRef] [Green Version]

- Mortazavi, M.; Nosonovsky, M. A model for diffusion-driven hydrophobic recovery in plasma treated polymers. Appl. Surf. Sci. 2012, 258, 6876–6883. [Google Scholar] [CrossRef]

- Kim, J.; Chaudhury, M.K.; Owen, M.J.; Orbeck, T. The mechanisms of hydrophobic recovery of polydimethylsiloxane elastomers exposed to partial electrical discharges. J. Colloid Interface Sci. 2001, 244, 200–207. [Google Scholar] [CrossRef] [Green Version]

- Bacharouche, J.; Haidara, H.; Kunemann, P.; Vallat, M.F.; Roucoules, V. Singularities in hydrophobic recovery of plasma treated polydimethylsiloxane surfaces under non-contaminant atmosphere. Sens. Actuator A Phys. 2013, 197, 25–29. [Google Scholar] [CrossRef]

- Vandenbossche, M.; Hegemann, D. Recent approaches to reduce aging phenomena in oxygen- and nitrogen-containing plasma polymer films: An overview. Curr. Opin. Solid State Mater. Sci. 2018, 22, 26–38. [Google Scholar] [CrossRef]

- Pascual, M.; Kerdraon, M.; Rezard, Q.; Jullien, M.C.; Champougny, L. Wettability patterning in microfluidic devices using thermally-enhanced hydrophobic recovery of PDMS. Soft Matter 2019, 15, 9253. [Google Scholar] [CrossRef] [Green Version]

- Kaczorowski, W.; Batory, B.; Szymański, W.; Kaźmierczak, T.; Kotela, I.; Niedzielski, P. Frictional behavior of polyurethane modified by carbon coatings synthesized in dual-frequency plasma. Tribol. T. 2016, 59, 530–537. [Google Scholar] [CrossRef]

- Kaczorowski, W.; Batory, B.; Szymański, W.; Niedzielski, P. Evaluation of the surface properties of PEEK substrate after two-step plasma modification: Etching and deposition of DLC coatings. Surf. Coat. Technol. 2015, 333, 92–98. [Google Scholar] [CrossRef]

- Kaczorowski, W.; Batory, D.; Jakubowski, W.; Szymański, W.; Komorowski, P.; Walkowiak, B.; Sanak, M.; Niedzielski, P. Physicochemical and Biological Investigation of Different Structures of Carbon Coatings Deposited onto Polyurethane. Braz. Arch. Biol. Technol. 2016, 59, e16150305. [Google Scholar] [CrossRef] [Green Version]

- Grill, A. Diamond-like carbon coatings as biocompatible materials—An overview. Diam. Relat. Mater. 2003, 12, 166–170. [Google Scholar] [CrossRef]

- Sui, J.H.; Cai, W. Effect of diamond-like carbon (DLC) on the properties of the NiTi alloys. Diam. Relat. Mater. 2006, 15, 1720–1726. [Google Scholar] [CrossRef]

- Alam, M.S.; Mukherjee, N.; Ahmed, S.F. Electron field emission property of nanostructure wrinkle thin film induced by amorphous diamond like carbon. Mater. Today Proc. 2018, 5, 2082–2088. [Google Scholar] [CrossRef]

- Teixeira, F.S.; Araujo, W.W.R.; Gushiken, N.K.; Cattani, M.; Salvadori, M.C. On the influence of PDMS (polydimethylsiloxane) substrate surface energy in wrinkling of DLC (diamond-like carbon) thin films. J. Appl. Phys. 2017, 122, 135308. [Google Scholar] [CrossRef]

- Ferreira, S.; Piedade, A.P. Influence of extracellular mimicked hierarchical nano-micro-topography on the bacteria/abiotic interface. Polymers 2020, 12, 828. [Google Scholar] [CrossRef] [Green Version]

- Li, S.J.; Wu, K.; Yuan, H.Z.; Zhang, J.Y.; Liu, G.; Sun, J. Formation of wrinkled patterns in metal films deposited on elastic substrates: Tunability and wettability. Surf. Coat. Technol. 2019, 362, 35–43. [Google Scholar] [CrossRef]

- Wang, Y.; Xiao, J. Programmable, reversible and repeatable wrinkling of shape memory polymer thin films on elastomeric substrates for smart adhesion. Soft Matter 2017, 13, 5317. [Google Scholar] [CrossRef]

- Lee, W.K.; Engel, C.J.; Huntington, M.D.; Hu, J.; Odom, T.W. Controlled three-dimensional hierarchical structuring by memory-based, sequential wrinkling. Nano Lett. 2015, 15, 5624–5629. [Google Scholar] [CrossRef] [PubMed]

- Vandeparre, H.; Leodpoldes, J.; Poulard, C.; Desprez, S.; Derue, G.; Gay, C.; Damman, P. Slippery or sticky boundary conditions: Control of wrinkling in metal-capped thin polymer films by selective adhesion to substrates. Phys. Rev. Lett. 2007, 99, 188302. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.S.; Hong, H.; Park, S.J.; Lee, S.J.; Kim, D.S. A simple fabrication process for stepwise gradient wrinkle pattern with spatially-controlled wavelength based on sequential oxygen plasma treatment. Microelectron. Eng. 2017, 176, 101–105. [Google Scholar] [CrossRef]

- Kaczorowski, W.; Gajewski, K.; Szymanski, W.; Batory, D.; Wojciechowska, A.; Swiatek, L.; Gotszalk, T.; Niedzielski, P. Evaluation of mechanical properties of carbon coatings synthesised in radio frequency plasma on PDMS. Surf. Coat. Technol. 2018, 333, 220–228. [Google Scholar] [CrossRef]

- Tai, F.C.; Lee, S.C.; Chen, J.; Wei, C.; Chang, S.H. multipeak fitting analysis of raman spectra on DLCH film. J. Raman Spectrosc. 2009, 40, 1055–1059. [Google Scholar] [CrossRef]

- Kaczorowski, W.; Świątek, H.; Łuczak, K.; Głuszek, M.; Cłapa, M. Impact of plasma pre-treatment on the tribological properties of DLC coatings on PDMS substrates. Materials 2021, 14, 433. [Google Scholar] [CrossRef]

- Nagashima, S.; Hasebe, T.; Tsuya, D.; Horikosh, T.; Ochiai, M.; Tanigawa, S.; Koide, Y.; Hotta, A.; Suzuki, T. Controlled formation of wrinkled diamond-like carbon (DLC) film on grooved poly(dimethylsiloxane) substrate. Diam. Relat. Mater. 2012, 22, 48–51. [Google Scholar] [CrossRef]

- Bociaga, D.; Kaminska, M.; Sobczyk-Guzenda, A.; Jastrzebski, K.; Swiatek, L.; Olejnik, A. Surface properties and biological behaviour of Si-DLC coatings fabricated by a multi-target DC–RF magnetron sputtering method for medical applications. Diam. Relat. Mater. 2016, 67, 41–50. [Google Scholar] [CrossRef]

- Ogwu, A.A.; Okpalugo, T.I.T.; Ali, N.; Maguire, P.D.; McLaughlin, J.A.D. Endothelial cell growth on silicon modified hydrogenated amorphous carbon thin films. J. Biomed. Mater. Res. B 2008, 85B, 105–113. [Google Scholar] [CrossRef]

- Okpalugo, T.I.T.; Ogwu, A.A.; Maguire, P.D.; McLaughlin, J.A.D. Platelet adhesion on silicon modified hydrogenated amorphous carbon films. Biomaterials 2004, 25, 239–245. [Google Scholar] [CrossRef]

- Paul, R.; Das, S.N.; Dalui, S.; Gayen, R.N.; Roy, R.K.; Bhar, R.; Pal, A.K. Synthesis of DLC films with different sp2/sp3 ratios and their hydrophobic behaviour. J. Phys. D Appl. Phys. 2008, 41, 055309. [Google Scholar] [CrossRef]

- Salvadori, M.C.; Araújo, W.W.R.; Teixeira, F.S.; Cattani, M.; Pasquarelli, A.; Oks, E.M.; Brown, I.G. Termination of diamond surfaces with hydrogen, oxygen and fluorine using a small, simple plasma gun. Diam. Relat. Mater. 2010, 19, 324–328. [Google Scholar] [CrossRef]

- Artemenko, A.; Ižák, T.; Marton, M.; Ukraintsev, E.; Stuchlík, J.; Hruška, K.; Vojs, M.; Kromka, A. Stability of the surface termination of nanocrystalline diamond and diamond-like carbon films exposed to open air conditions. Diam. Relat. Mater. 2019, 100, 107562. [Google Scholar] [CrossRef]

- Sasaki, Y.; Osanai, H.; Ohtani, Y.; Murono, Y.; Sato, M.; Kobayashi, Y.; Enta, Y.; Suzuki, Y.; Nakazawa, H. Influence of hydrogen gas flow ratio on the properties of silicon- and nitrogen-doped diamond-like carbon films by plasma-enhanced chemical vapor deposition. Diam. Relat. Mater. 2022, 123, 108878. [Google Scholar] [CrossRef]

- Gu, B.; Ko, D.; Jo, S.; Hyun, D.C.; Oh, H.J.; Kim, J. Effect of low-pressure plasma treatment parameters on wrinkle features. Materials 2020, 13, 3852. [Google Scholar] [CrossRef]

- Miao, L.; Cheng, X.; Chen, H.; Song, Y.; Guo, H.; Zhang, J.; Chen, X.; Zhang, H. Fabrication of controlled hierarchical wrinkle structures on polydimethylsiloxane via one-step C4F8 plasma treatment. J. Micromech. Microeng. 2018, 28, 015007. [Google Scholar] [CrossRef]

- Xu, H.; Shi, T.; Liao, G.; Xia, Q. Controlling nested wrinkle morphology through the boundary effect on narrow-band thin films. Front. Mech. Eng. 2019, 14, 235–240. [Google Scholar] [CrossRef]

- Rahmawan, Y.; Moon, M.W.; Kim, K.S.; Lee, K.R.; Suh, K.Y. Wrinkled, dual-scale structures of diamond-like carbon (DLC) for superhydrophobicity. Langmuir 2010, 26, 484–491. [Google Scholar] [CrossRef]

- Bae, S.C.; Lee, H.; Lin, Z.; Granick, S. Chemical imaging in a surface forces apparatus: Confocal raman spectroscopy of confined poly(dimethylsiloxane). Langmuir 2005, 21, 5685–5688. [Google Scholar] [CrossRef]

- Tomar, B.S.; Shahin, A.; Tirumkudulu, M.S. Cracking in drying films of polymer solutions. Soft Matter 2020, 16, 3476. [Google Scholar] [CrossRef]

- Ahmed, S.F.; Nagashima, S.; Lee, J.Y.; Lee, K.R.; Kim, K.S.; Moon, M.W. Self-assembled folding of a biaxially compressed film on a compliant substrate. Carbon 2014, 76, 105–112. [Google Scholar] [CrossRef]

- Ahmed, S.F.; Nho, G.H.; Lee, K.R.; Vaziri, A.; Moon, M.W. High aspect ratio wrinkles on a soft polymer. Soft Matter 2010, 6, 5709–5714. [Google Scholar] [CrossRef]

- Foong, Y.M.; Hsieh, J.; Li, X.; Chua, D.H.C. The study on the effect of erbium on diamond-like carbon deposited by pulsed laser deposition technique. J. Appl. Phys. 2009, 106, 064904. [Google Scholar] [CrossRef]

- Batory, D.; Jedrzejczak, A.; Kaczorowski, W.; Kolodziejczyk, L.; Burnat, B. The effect of Si incorporation on the corrosion resistance of a-C:H:SiOx coatings. Diam. Relat. Mater. 2016, 67, 1–7. [Google Scholar] [CrossRef]

- Kaźmierczak, T.; Niedzielski, P.; Kaczorowski, W. The influence of plasma-assisted production and milling processes of DLC flakes on their size, composition and chemical structure. Materials 2020, 13, 1209. [Google Scholar] [CrossRef] [Green Version]

- Thirumalai, S.; Hausberger, A.; Lackner, J.M.; Waldhauser, M.; Schwartz, T. Effect of the type of elastomeric substrate on the microstructural, surface and tribological characteristics of diamond-like carbon (DLC) coatings. Surf. Coat. Technol. 2016, 302, 244–254. [Google Scholar] [CrossRef]

- Sheeja, D.; Tay, B.K.; Shi, X.; Lau, S.P.; Daniel, C.; Krishnan, S.M.; Nung, L.N. Mechanical and tribological characterization of diamond-like carbon coatings on orthopedic materials. Diam. Relat. Mater. 2001, 10, 1043–1048. [Google Scholar] [CrossRef]

- Borowicz, P.; Latek, M.; Rzodkiewicz, W.; Łaszcz, A.; Czerwinski, A.; Ratajczak, J. Deep-ultraviolet Raman investigation of silicon oxide: Thin film on silicon substrate versus bulk material. Adv. Nat. Sci. Nanosci. Nanotechnol. 2012, 3, 045003. [Google Scholar] [CrossRef]

| Gas | Gas Flow (sccm) | Pressure (Pa) | Bias Vb (V) | Power P (W) | Time (s) |

|---|---|---|---|---|---|

| Ar | 60 | 29 | 100 | 92 | 60 |

| 200 | 140 | ||||

| 300 | 280 | ||||

| 400 | 460 | ||||

| 500 | 690 | ||||

| N2 | 27 | 100 | 84 | ||

| 200 | 136 | ||||

| 300 | 250 | ||||

| 400 | 420 | ||||

| 500 | 570 | ||||

| O2 | 30 | 100 | 82 | ||

| 200 | 125 | ||||

| 300 | 220 | ||||

| 400 | 350 | ||||

| 500 | 550 | ||||

| CH4 | 33 | 100 | 80 | ||

| 200 | 120 | ||||

| 300 | 210 | ||||

| 400 | 340 | ||||

| 500 | 540 |

| Bias (V) | ID/IG | |

|---|---|---|

| Silicon | PDMS | |

| 100 | 0.59 | 0.8 |

| 200 | 0.54 | 0.5 |

| 300 | 0.53 | 0.41 |

| 400 | 0.52 | 0.45 |

| 500 | 0.56 | 0.50 |

| Negative Self-Bias [V] | |||||

|---|---|---|---|---|---|

| 100 | 200 | 300 | 400 | 500 | |

| Average thickness of DLC coating on silicon substrates [nm] | 15 ± 5 | 23 ± 4 | 30 ± 6 | 20 ± 3 | 10 ± 3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kaczorowski, W.; Batory, D.; Szymański, W.; Lauk, K.; Stolarczyk, J. Barrier Diamond-like Carbon Coatings on Polydimethylsiloxane Substrate. Materials 2022, 15, 3883. https://doi.org/10.3390/ma15113883

Kaczorowski W, Batory D, Szymański W, Lauk K, Stolarczyk J. Barrier Diamond-like Carbon Coatings on Polydimethylsiloxane Substrate. Materials. 2022; 15(11):3883. https://doi.org/10.3390/ma15113883

Chicago/Turabian StyleKaczorowski, Witold, Damian Batory, Witold Szymański, Klaudia Lauk, and Jakub Stolarczyk. 2022. "Barrier Diamond-like Carbon Coatings on Polydimethylsiloxane Substrate" Materials 15, no. 11: 3883. https://doi.org/10.3390/ma15113883

APA StyleKaczorowski, W., Batory, D., Szymański, W., Lauk, K., & Stolarczyk, J. (2022). Barrier Diamond-like Carbon Coatings on Polydimethylsiloxane Substrate. Materials, 15(11), 3883. https://doi.org/10.3390/ma15113883