Towards Interband Cascade lasers on InP Substrate

Abstract

:1. Introduction

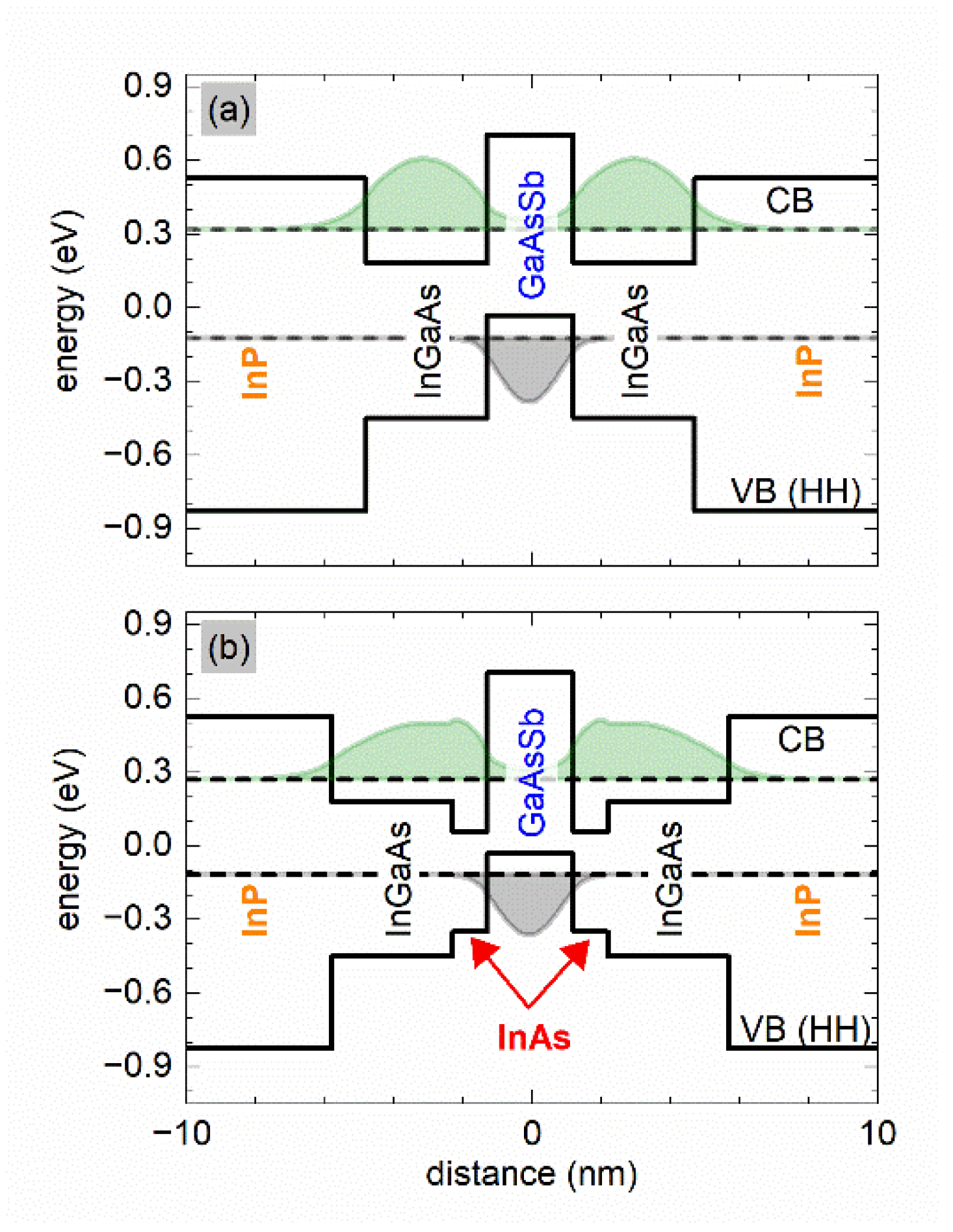

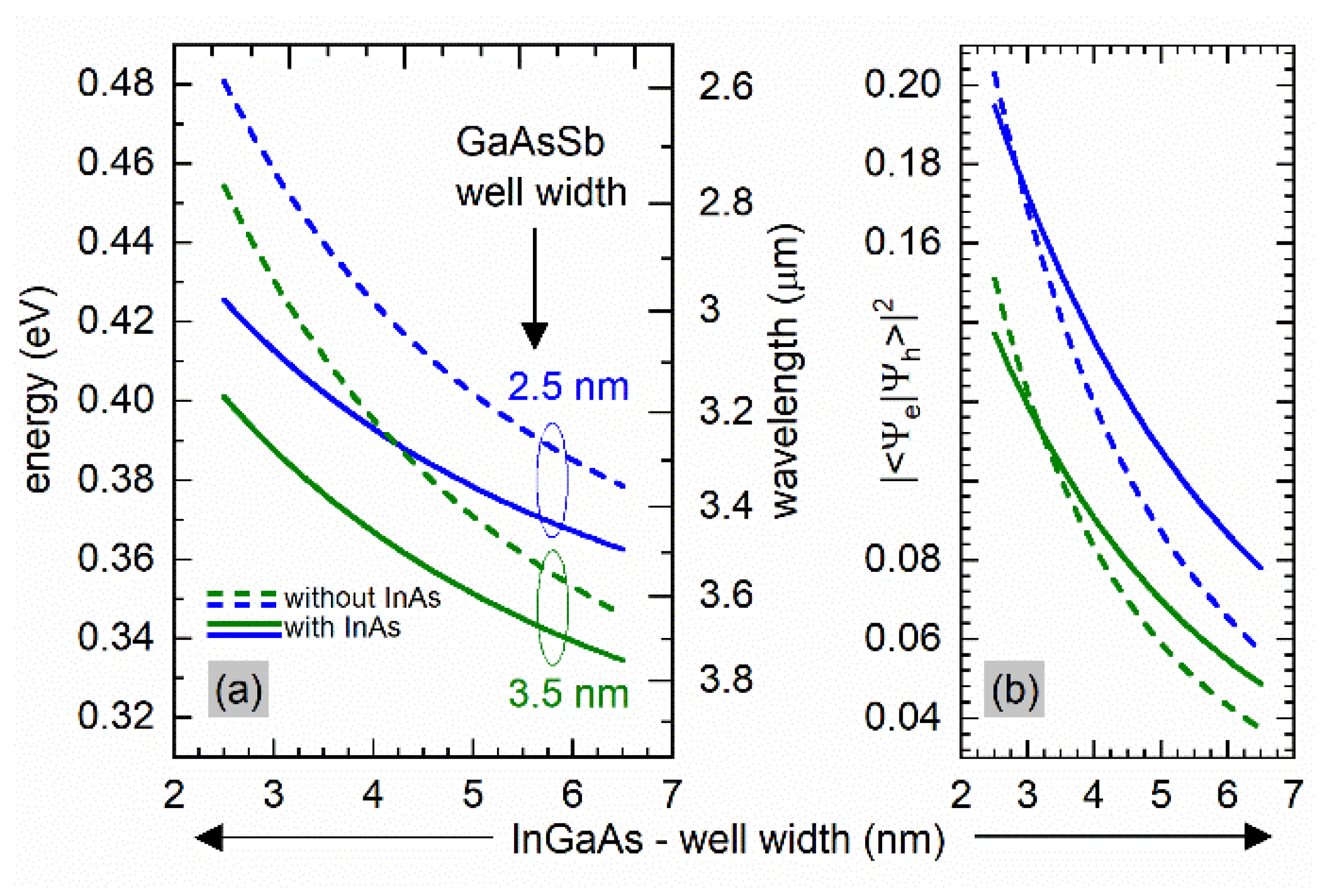

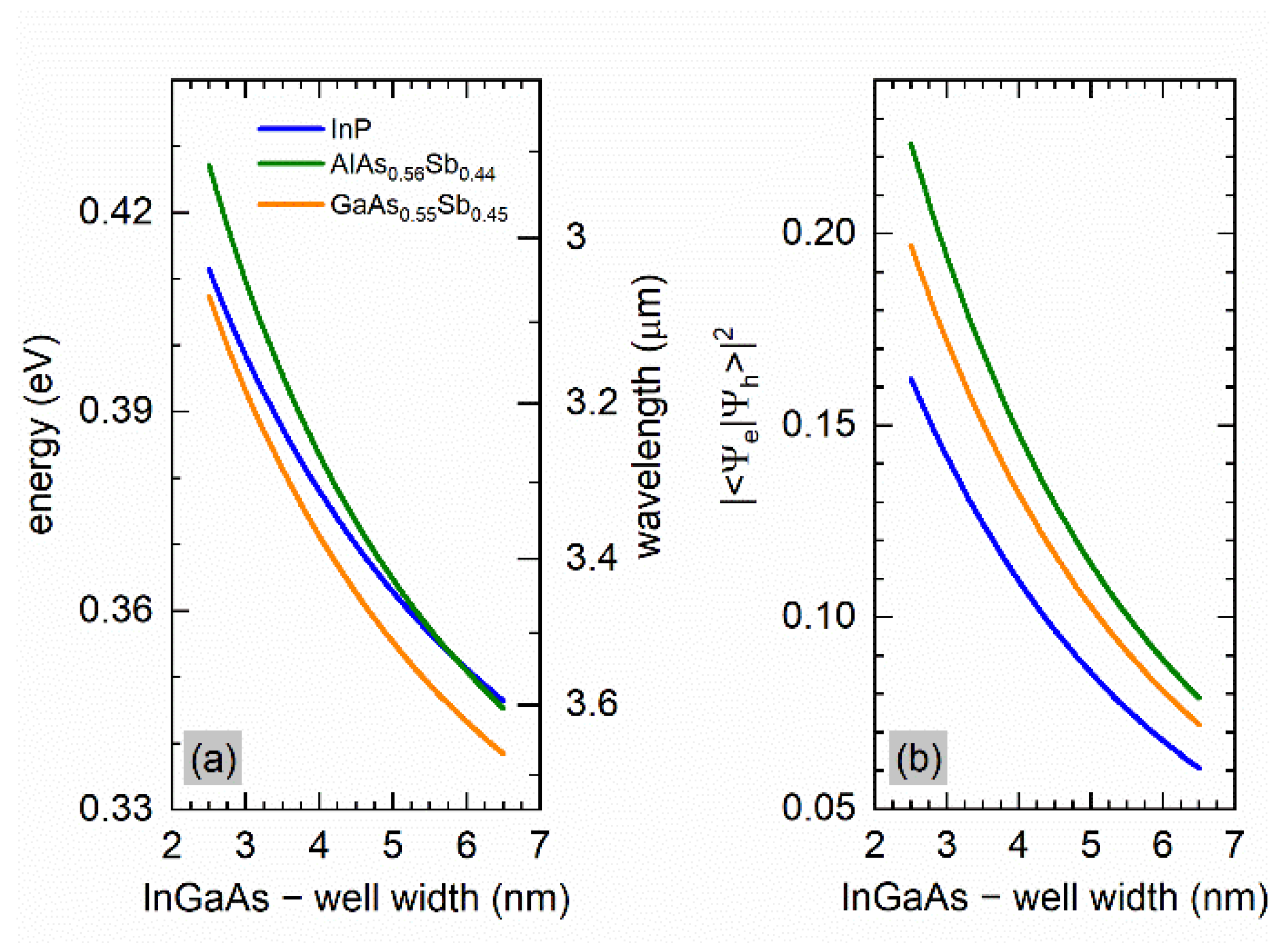

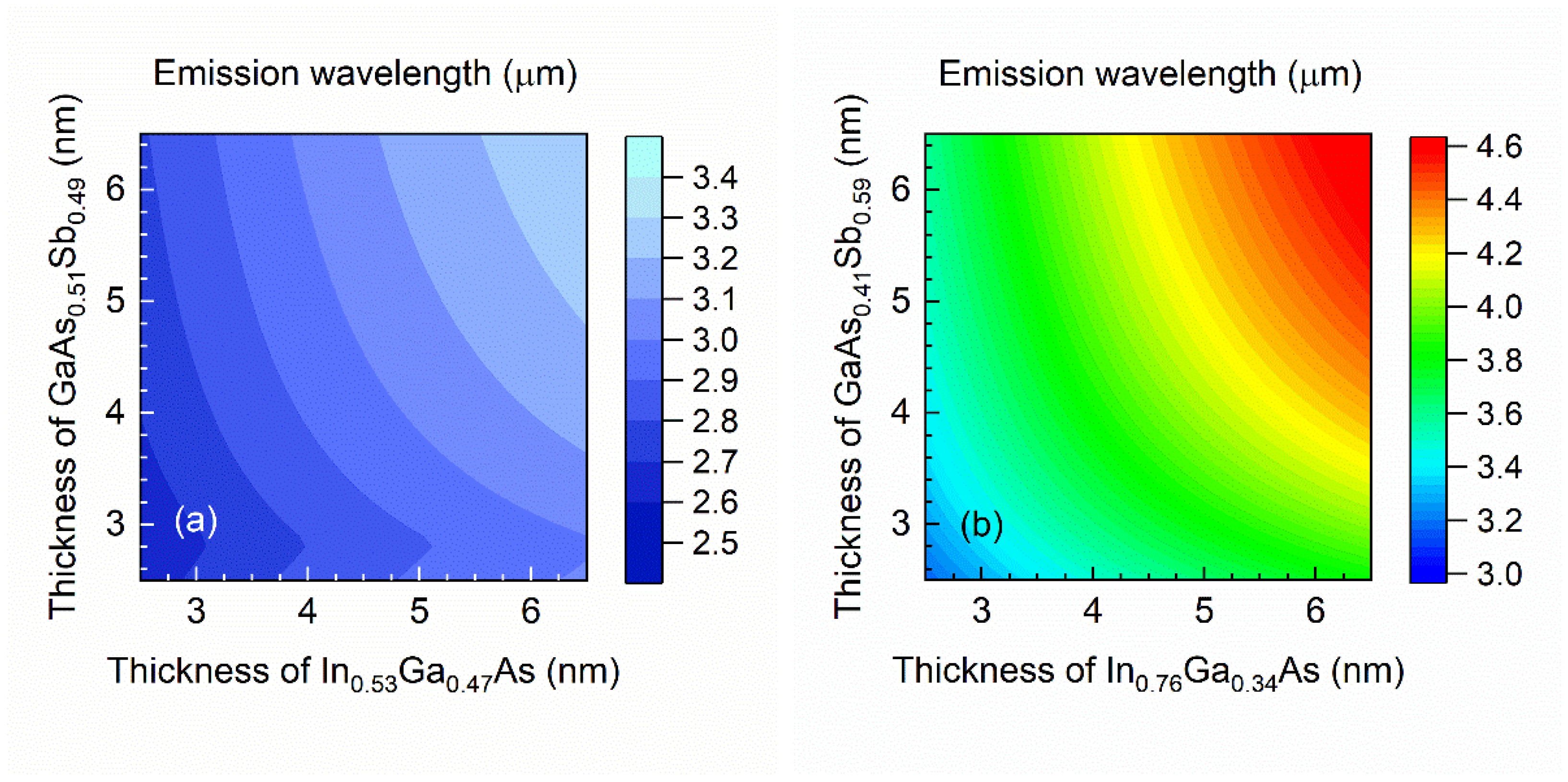

2. Materials and Methods

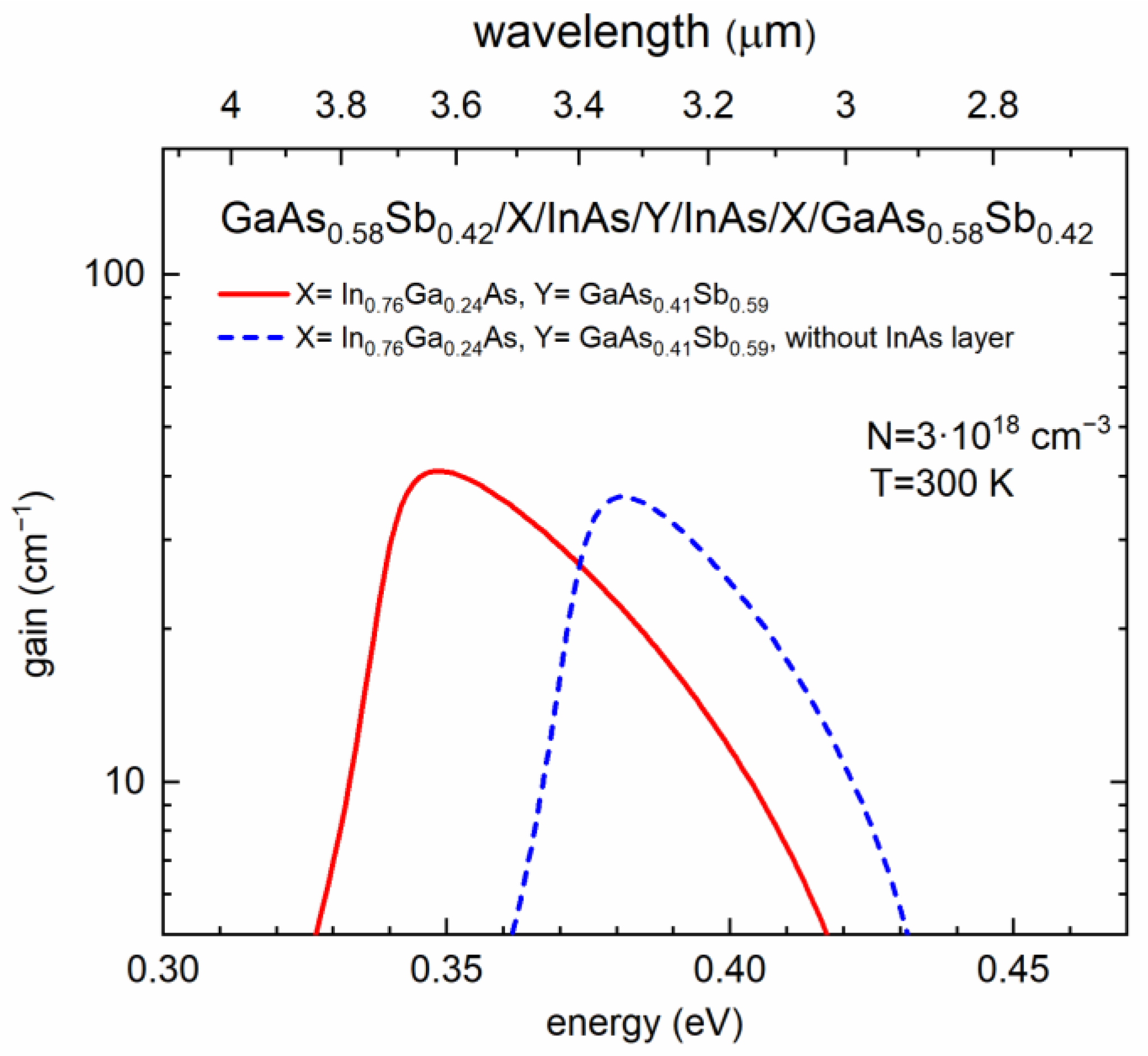

3. Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yang, R.Q. Infrared laser based on intersubband transitions in quantum wells. Superlattices Microstruct. 1995, 17, 77. [Google Scholar] [CrossRef]

- Meyer, J.R.; Bewley, W.W.; Canedy, C.L.; Kim, C.S.; Kim, M.; Merritt, C.D.; Vurgaftman, I. The Interband Cascade Laser. Photonics 2020, 7, 75. [Google Scholar] [CrossRef]

- Bauer, A.; Rößner, K.; Lehnhardt, T.; Kamp, M.; Höfling, S.; Worschech, L.; Forchel, A. Mid-infrared semiconductor hetero-structure lasers for gas sensing applications. Semicond. Sci. Technol. 2011, 26, 014032. [Google Scholar] [CrossRef]

- Vurgaftman, I.; Weih, R.; Kamp, M.; Meyer, J.R.; Canedy, C.L.; Kim, C.S.; Kim, M.; Bewley, W.W.; Merritt, C.D.; Abell, J.; et al. Interband cascade lasers. J. Phys. D Appl. Phys. 2015, 48, 123001. [Google Scholar] [CrossRef]

- Motyka, M.; Ryczko, K.; Sęk, G.; Janiak, F.; Misiewicz, J.; Bauer, A.; Höfling, S.; Forchel, A. Type II quantum wells on GaSb substrate designed for laser-based gas sensing applications in a broad range of mid infrared. Opt. Mater. 2012, 34, 1107. [Google Scholar] [CrossRef]

- Dallner, M.; Hau, F.; Höfling, S.; Kamp, M. InAs-based interband-cascade-lasers emitting around 7 μm with threshold cur-rent densities below 1 kA/cm2 at room temperature. Appl. Phys. Lett. 2015, 106, 041108. [Google Scholar] [CrossRef] [Green Version]

- Kim, C.; Bewley, W.; Merritt, C.; Canedy, C.; Warren, M.; Vurgaftman, I.; Meyer, J.; Kim, M. Improved mid-infrared interband cascade light emitting devices. Opt. Eng. 2017, 57, 011002. [Google Scholar] [CrossRef]

- Scheuermann, J.; Weih, R.; Edlinger, M.; Nähle, L.; Fischer, M.; Koeth, J.; Kamp, M.; Höfling, S. Single-mode interband cascade lasers emitting below 2.8 μm. Appl. Phys. Lett. 2015, 106, 161103. [Google Scholar] [CrossRef] [Green Version]

- Weih, R.; Kamp, M.; Höfling, S. Interband cascade lasers with room temperature threshold current densities below 100 A/cm2. Appl. Phys. Lett. 2013, 102, 231123. [Google Scholar] [CrossRef] [Green Version]

- Bewley, W.; Canedy, C.; Kim, C.; Kim, M.; Merritt, C.; Abell, J.; Vurgaftman, I.; Meyer, J. Continuous-wave interband cascade lasers operating above room temperature at λ = 4.7 − 5.6 μm. Opt. Express 2012, 20, 3235. [Google Scholar] [CrossRef] [PubMed]

- Janiak, F.; Motyka, M.; Sęk, G.; Dyksik, M.; Ryczko, K.; Misiewicz, J.; Weih, R.; Höfling, S.; Kamp, M.; Patriarche, G. Effect of arsenic on the optical properties of GaSb-based type II quantum wells with quaternary GaInAsSb layers. J. Appl. Phys. 2013, 114, 223510. [Google Scholar] [CrossRef]

- Vurgaftman, I.; Bewley, W.W.; Canedy, C.L.; Kim, C.S.; Kim, M.; Merritt, C.D.; Abell, J.; Meyer, J.R. Interband cascade lasers with low threshold powers and high output powers. IEEE J. Sel. Top. Quantum Electron. 2013, 19, 1200210. [Google Scholar] [CrossRef]

- Dong, L.; Tittel, F.K.; Li, C.; Sanchez, N.P.; Wu, H.; Zheng, C.; Yu, Y.; Sampaolo, A.; Griffin, R.J. Compact TDLAS based sensor design using interband cascade lasers for mid-IR trace gas sensing. Optics Express 2016, 24, A528. [Google Scholar] [CrossRef]

- Kluczynski, P. Multi-laser in-situ analyzer for real time control of DESOX and DENOX processes in a waste incinerator plant. In Proceedings of the Annual ISA Analysis Division Symposium, Galveston, TX, USA, 6–8 May 2019; Volume 534, p. 12. [Google Scholar]

- Scheuermann, J.; Kluczynski, P.; Siembab, K.; Straszewski, M.; Kaczmarek, J.; Weih, R.; Fischer, M.; Koeth, J.; Schade, A.; Höfling, S. Interband Cascade Laser Arrays for Simultaneous and Selective Analysis of C1–C5 Hydrocarbons in Petrochemical Industry. Appl. Spectrosc. 2021, 75, 336–342. [Google Scholar] [CrossRef] [PubMed]

- Fang, B.; Yang, N.; Zhao, W.; Wang, C.; Zhang, W.; Song, W.; Venables, D.S.; Chen, W. Improved spherical mirror multi-pass-cell-based interband cascade laser spectrometer for detecting ambient formaldehyde at parts per trillion by volume levels. Appl. Opt. 2019, 58, 8743. [Google Scholar] [CrossRef] [PubMed]

- Rena, W.; Luo, L.; Tittel, F.K. Sensitive detection of formaldehyde using an interband cascade laser near 3.6 μm. Sens. Actuators 2015, B 221, 1062. [Google Scholar] [CrossRef]

- Wysocki, G.; Bakhirkin, Y.; So, S.; Tittel, F.K.; Hill, C.; Yang, R.Q.; Fraser, M.P. Dual interband cascade laser based trace-gas sensor for environmental monitoring. Appl. Opt. 2007, 46, 8202. [Google Scholar] [CrossRef] [Green Version]

- Ghorbani, R.; Schmidt, F.M. ICL-based TDLAS sensor for real-time breath gas analysis of carbon monoxide isotopes. Opt. Express 2017, 25, 12743–12752. [Google Scholar] [CrossRef]

- Höfling, S.; Weih, R.; Bauer, A.; Kamp, M.; Forchel, A. Room temperature continuous wave interband cascade lasers for gas sensing. Proc. SPIE 2012, 8432, 84320N1–84320N8. [Google Scholar] [CrossRef]

- Lundqvist, S.; Kluczyński, P.; Weih, R.; von Edlinger, M.; Nähle, L.; Fischer, M.; Bauer, A.; Höfling, S.; Koeth, J. Sensing of formaldehyde using a distributed feedback interband cascade laser emitting around 3493 nm. Appl. Opt. 2012, 51, 6009–6013. [Google Scholar] [CrossRef]

- Soibel, A.; Wright, M.W.; Farr, W.H.; Keo, S.A.; Hill, C.J.; Yang, R.Q.; Liu, H.C. Midinfrared Interband Cascade Laser for Free Space Optical Communication. IEEE Photonics Technol. Lett. 2010, 22, 121–123. [Google Scholar] [CrossRef]

- Mikołajczyk, J.; Weih, R.; Motyka, M. Optical Wireless Link Operated at the Wavelength of 4.0 µm with Commercially Available Interband Cascade Laser. Sensors 2021, 21, 4102. [Google Scholar] [CrossRef]

- Goldenstein, C.S.; Spearrin, R.M.; Jeries, J.B.; Hanson, R.K. Infrared laser-absorption sensing for combustion gases. Prog. Energy Combust. Sci. 2016, 60, 132–176. [Google Scholar] [CrossRef] [Green Version]

- Ejzak, G.A.; Dickason, J.; Marks, J.A.; Nabha, K.; McGee, R.T.; Waite, N.A.; Benedict, J.T.; Hernandez, M.A.; Provence, S.R.; Norton, D.T., Jr.; et al. 512 × 512, 100 Hz mid-wave infrared LED microdisplay system. J. Disp. Technol. 2016, 12, 1139–1144. [Google Scholar] [CrossRef]

- Fuchs, F.; Hugger, S.; Jarvis, J.; Yang, Q.K.; Ostendorf, R.; Schilling, C.; Bronner, W.; Driad, R.; Aidam, R.; Wagner, J. Imaging stando trace detection of explosives using IR-laser based backscattering. Proc. SPIE 2016, 9836, 983621. [Google Scholar] [CrossRef]

- Hill, C.J.; Yang, R.Q. Interband cascade lasers grown on GaAs substrates lasing at 4 microns. Appl. Phys. Lett. 2004, 85, 3014. [Google Scholar] [CrossRef]

- Vurgaftman, I.; Meyer, J.R.; Tansu, N.; Mawst, L.J. InP-based dilute-nitride mid-infrared type-II “W” quantum-well lasers. J. Appl. Phys. 2004, 96, 4653–4655. [Google Scholar] [CrossRef] [Green Version]

- Chang, C.H.; Li, Z.-L.; Pan, C.-H.; Lu, H.-T.; Lee, C.-P.; Lin, S.-D. Room-temperature mid-infrared “M”-type GaAsSb/InGaAs quantum well lasers on InP substrate. J. Appl. Phys. 2014, 115, 063104. [Google Scholar] [CrossRef] [Green Version]

- Sprengel, S.; Andrejew, A.; Federer, F.; Veerabathran, G.K.; Boehm, G.; Amann, M.-C. Continuous wave vertical cavity surface emitting lasers at 2.5 μm with InP-based type-II quantum wells. Appl. Phys. Lett. 2015, 106, 151102. [Google Scholar] [CrossRef]

- Gu, Y.; Zhanga, Y.G.; Ma, Y.J.; Zhou, L.; Chen, X.Y.; Xi, S.P.; Du, B. InP-based type-I quantum well lasers up to 2.9 μm at 230 K in pulsed mode on a metamorphic buffer. Appl. Phys. Lett. 2015, 106, 121102. [Google Scholar] [CrossRef]

- Sprengel, S.; Grasse, C.; Wiecha, P.; Andrejew, A.; Gruendl, T.; Boehm, G.; Meyer, R.; Amann, M.-C. InP-Based Type-II Quantum-Well Lasers and LEDs. IEEE J. Sel. Top. Quantum Electron. 2013, 19, 1900909. [Google Scholar] [CrossRef]

- Huang, J.Y.T.; Mawst, L.J.; Kuech, T.F.; Song, X.; Babcock, S.E.; Kim, C.S.; Vurgaftman, I.; Meyer, J.R.; Holmes, A.L., Jr. Design and characterization of strained InGaAs/GaAsSb type-II ’W’ quantum wells on InP substrates for mid-IR emission. J. Phys. D Appl. Phys. 2009, 42, 025108. [Google Scholar] [CrossRef]

- Sprengel, S.; Grasse, C.; Vizbaras, K.; Gruendl, T.; Amann, M.C. Up to 3 um light emission on InP substrate using GaInAs/GaAsSb type-II quantum wells. Appl. Phys. Lett. 2011, 99, 221109. [Google Scholar] [CrossRef]

- Gladysiewicz, M.; Kudrawiec, R.; Wartak, M.S. Electronic Band Structure and Material Gain of Dilute Nitride Quantum Wells Grown on InP Substrate. IEEE J. Quantum Electron. 2015, 51, 7100212. [Google Scholar] [CrossRef]

- Chen, B. Active Region Design and Gain Characteristics of InP-Based Dilute Bismide Type-II Quantum Wells for Mid-IR Lasers. IEEE Trans. Electron. Devices 2017, 64, 1606–1611. [Google Scholar] [CrossRef]

- Broderick, C.A.; Xiong, W.; Sweeney, S.J.; O’Reilly, E.P.; Rorison, J.M. Theory and design of InxGa1−xAs1−yBiy mid-infrared semiconductor lasers: Type-I quantum wells for emission beyond 3 μm on InP substrates. Semicond. Sci. Technol. 2018, 33, 094007. [Google Scholar] [CrossRef] [Green Version]

- Ryczko, K.; Sȩk, G.; Misiewicz, J. Eight-band k·p modeling of InAs/InGaAsSb type-II W-design quantum well structures for interband cascade lasers emitting in a broad range of mid infrared. J. Appl. Phys. 2013, 114, 223519. [Google Scholar] [CrossRef]

- Tan, I.H.; Snider, G.L.; Chang, L.D.; Hu, E.L. A self consistent solution of Schrödinger–Poisson equations using a nonuni-form mesh. J. Appl. Phys. 1990, 68, 4071. [Google Scholar] [CrossRef] [Green Version]

- LAPACK Users’ Guide (Third ed.). Available online: http://www.netlib.org/lapack/ (accessed on 10 September 2021).

- Ryczko, K.; Zielińska, A.; Sęk, G. Interband Cascade Active Region with Ultra-Broad Gain in the Mid-Infrared Range. Materials 2021, 14, 1112. [Google Scholar] [CrossRef] [PubMed]

- Jadczak, J.; Kubisa, M.; Ryczko, K.; Bryja, L.; Potemski, M. High magnetic field spin splitting of excitons in asymmetric GaAs quantum wells. Phys. Rev. B 2012, 86, 245401. [Google Scholar] [CrossRef]

- Vurgaftman, I.; Meyer, J.R.; Ram-Mohan, L.R. Band parameters for III–V compound semiconductors and their alloys. J. Appl. Phys. 2001, 89, 5815. [Google Scholar] [CrossRef] [Green Version]

- Chuang, S.L. Physics of Optoelectronic Devices, Wiley Series in Pure and Applied Optics; John Wiley & Sons: New York, NY, USA, 1995; Chapter 9. [Google Scholar]

- Hoffman, C.A.; Meyer, J.R.; Youngdale, E.R.; Bartoli, F.J.; Miles, R.H. Interface roughness scattering in semiconducting and semimetallic InAs-Ga1−xInxSb superlattices. Appl. Phys. Lett. 1993, 63, 2210. [Google Scholar] [CrossRef]

- Ryczko, K.; Sęk, G.; Misiewicz, J. Novel design of type-II quantum wells for mid-infrared emission with tensile-strained GaAsSb layer for confinement of holes. Appl. Phys. Express 2015, 8, 121201. [Google Scholar] [CrossRef]

- Ryczko, K.; Sęk, G. Towards unstrained interband cascade lasers. Appl. Phys. Express 2018, 11, 012703. [Google Scholar] [CrossRef]

| Active Region | Emission Wavelength (μm) | Comments | References |

|---|---|---|---|

| “M”-type GaAsSb/InGaAs quantum-well | 2.4–2.5 | Room temperature PL at 2.5 μm and optically pumped lasing at 2.41 μm | [29] |

| W-shaped type II InGaAs/GaAsSb QWs | ∼2.5 | VCSEL device | [30] |

| Type I InAs/InGaAs/InAlAs QWs | ∼2.9 | Low-temperature lasing in pulsed mode; growth on In0.8Al0.2As metamorphic buffer | [31] |

| GaInAs/GaAsSb type-II quantum wells | 2.6–3.9 | Electrically pumped lasing in pulsed mode at 2.6 μm; spontaneous emission up to 3.9 μm | [32] |

| InGaAs/GaAsSb type-II ‘W-design’ quantum wells | > 2.0 | Room temperature PL at ∼2.1 µm; up to ∼2.5 µm from calculations | [33] |

| GaInAs/GaAsSb type-II quantum wells | 2.4–3.0 | Room temperature PL data | [34] |

| Type II W-shaped InAsN/GaAsSb/InAsN/GaInP QW | ∼3.8 | Only theoretical modelling data | [28] |

| Type I QWs: GaInNAs/InP; GaNAsSb/InP; GaNPSb/InP | up to 3.6 | Theoretical modelling of the gain | [35] |

| InGaAs/GaAsSbBi type II quantum wells | up to 3.26 | Theoretical modelling of the gain | [36] |

| InGaAs/GaAsSbBi type I quantum wells | >3.0 | Theoretical modelling | [37] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ryczko, K.; Andrzejewski, J.; Sęk, G. Towards Interband Cascade lasers on InP Substrate. Materials 2022, 15, 60. https://doi.org/10.3390/ma15010060

Ryczko K, Andrzejewski J, Sęk G. Towards Interband Cascade lasers on InP Substrate. Materials. 2022; 15(1):60. https://doi.org/10.3390/ma15010060

Chicago/Turabian StyleRyczko, Krzysztof, Janusz Andrzejewski, and Grzegorz Sęk. 2022. "Towards Interband Cascade lasers on InP Substrate" Materials 15, no. 1: 60. https://doi.org/10.3390/ma15010060

APA StyleRyczko, K., Andrzejewski, J., & Sęk, G. (2022). Towards Interband Cascade lasers on InP Substrate. Materials, 15(1), 60. https://doi.org/10.3390/ma15010060