Characterisation of Wood Particles Used in the Particleboard Production as a Function of Their Moisture Content

Abstract

1. Introduction

2. Materials and Methods

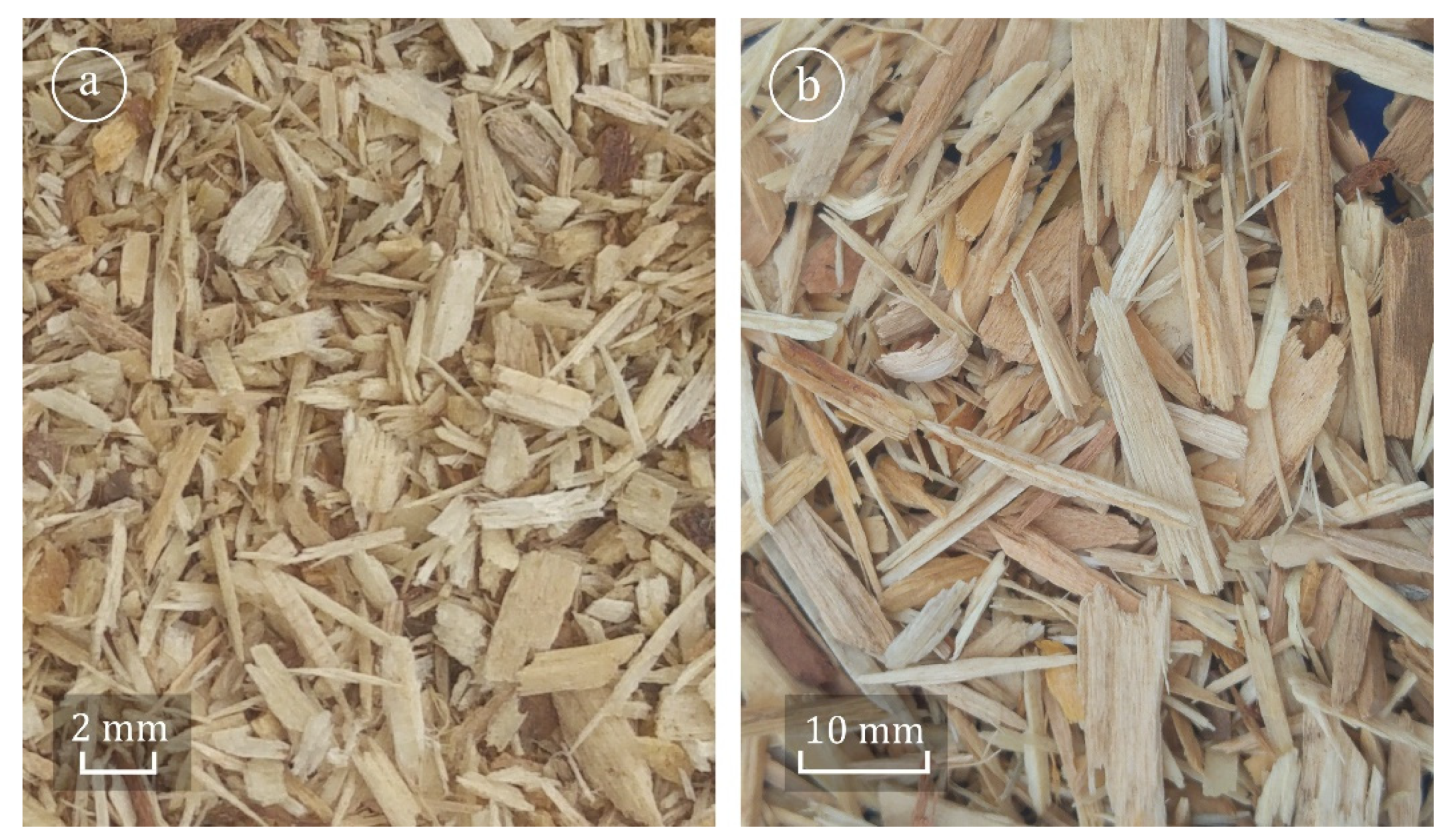

2.1. Materials

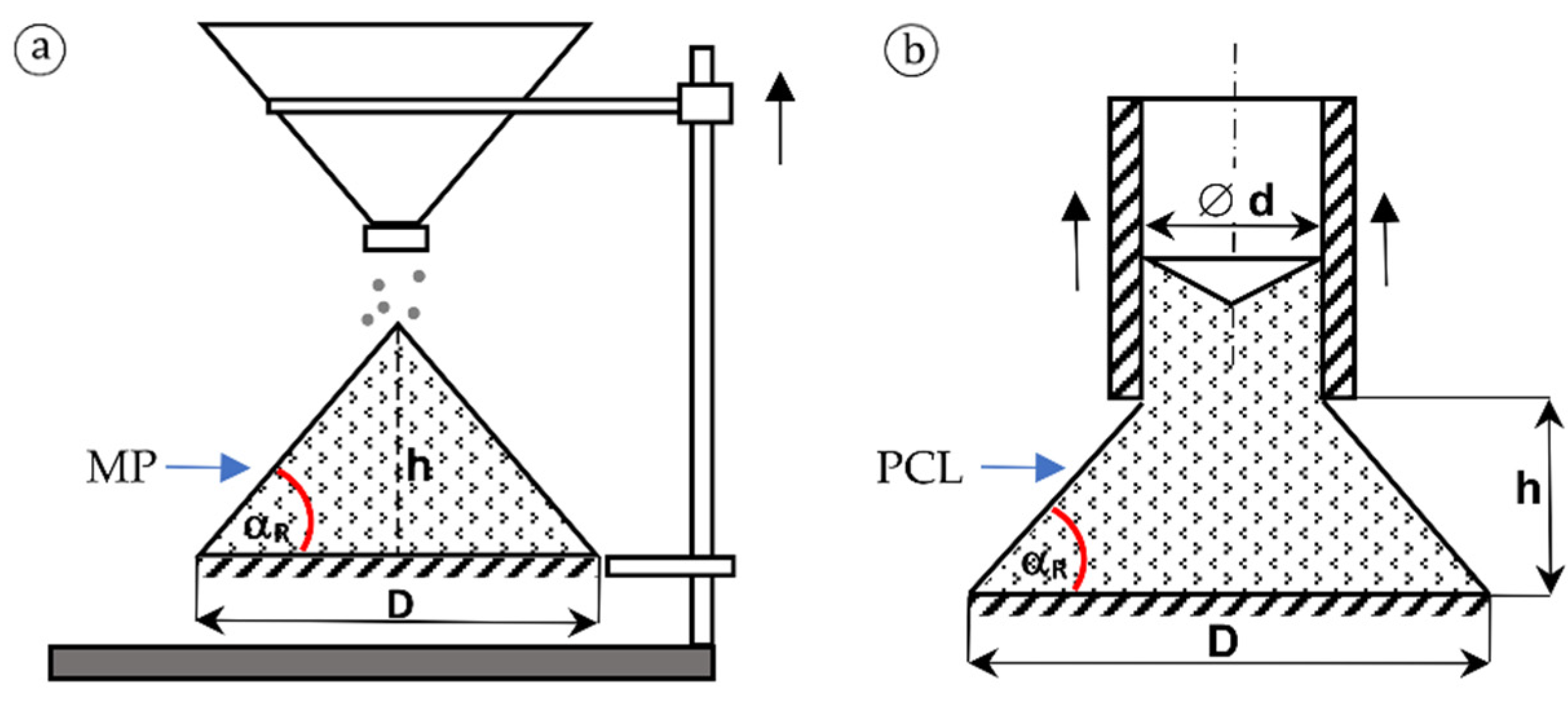

2.2. Poured Bulk Density and Tapped Bulk Density of Wood Particles

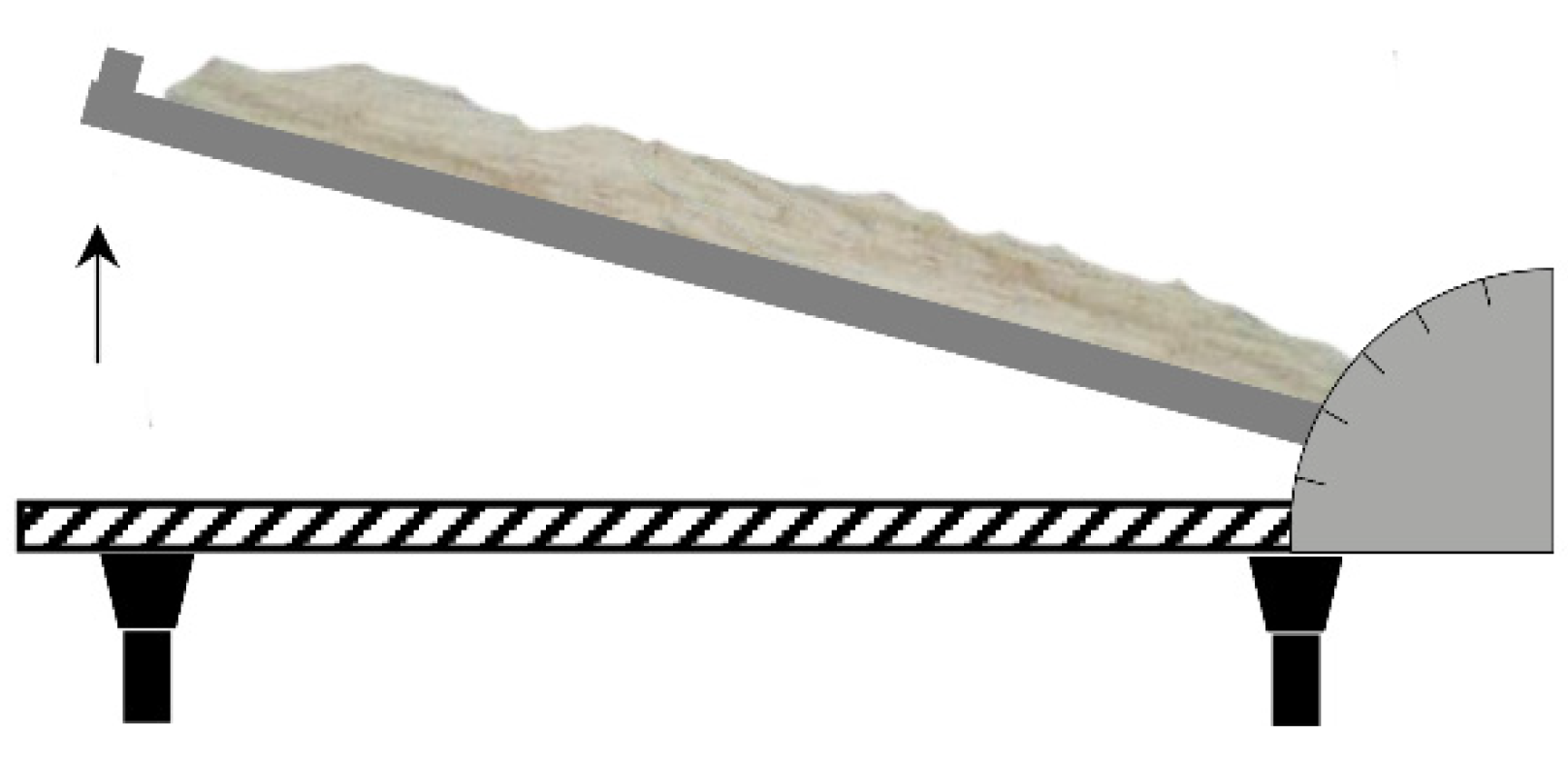

2.3. Angle of Repose and Slippery Angle of Repose of Wood Particles

2.4. Statistical Analysis

3. Results

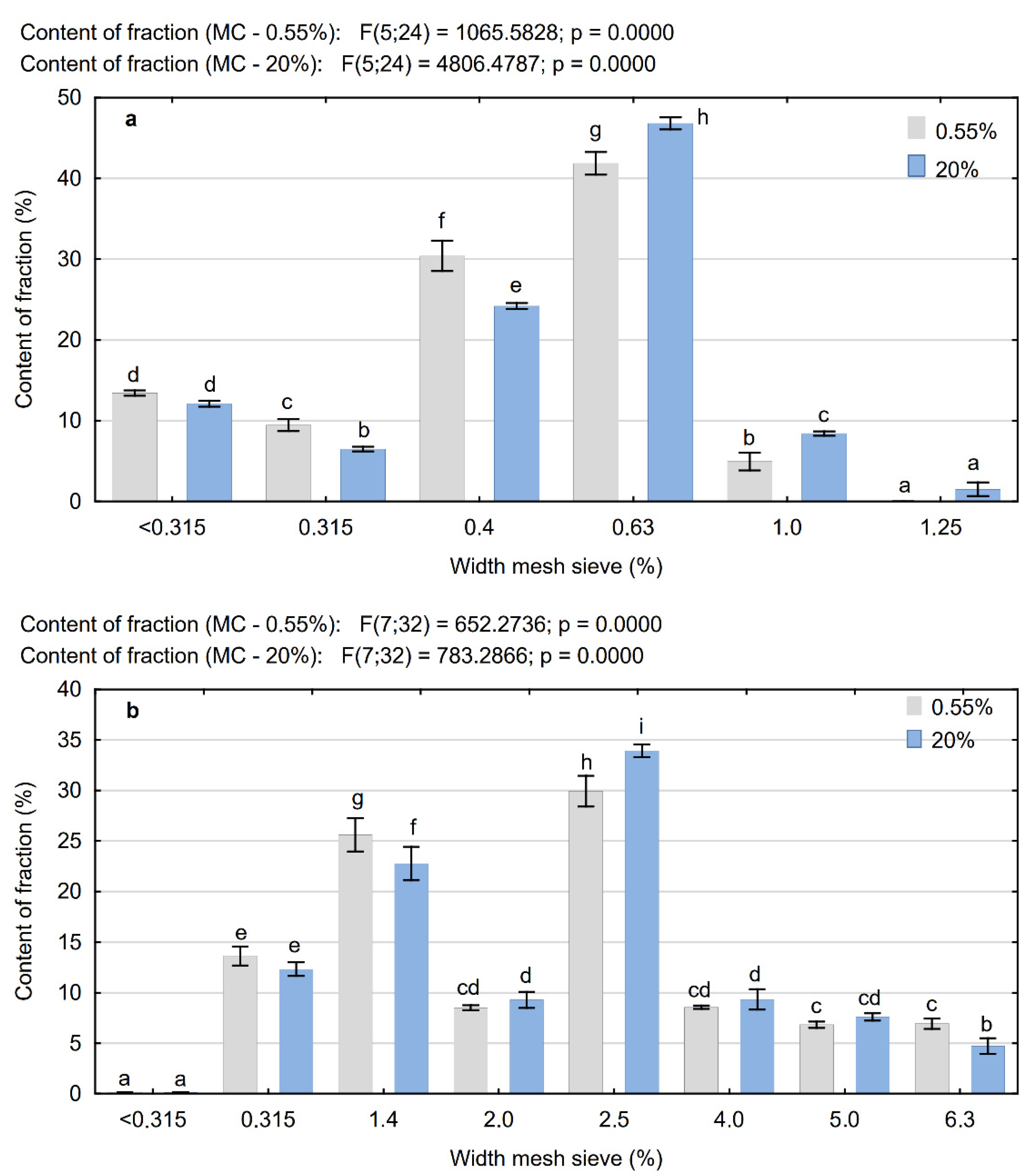

3.1. Fractional Composition of Wood Particles

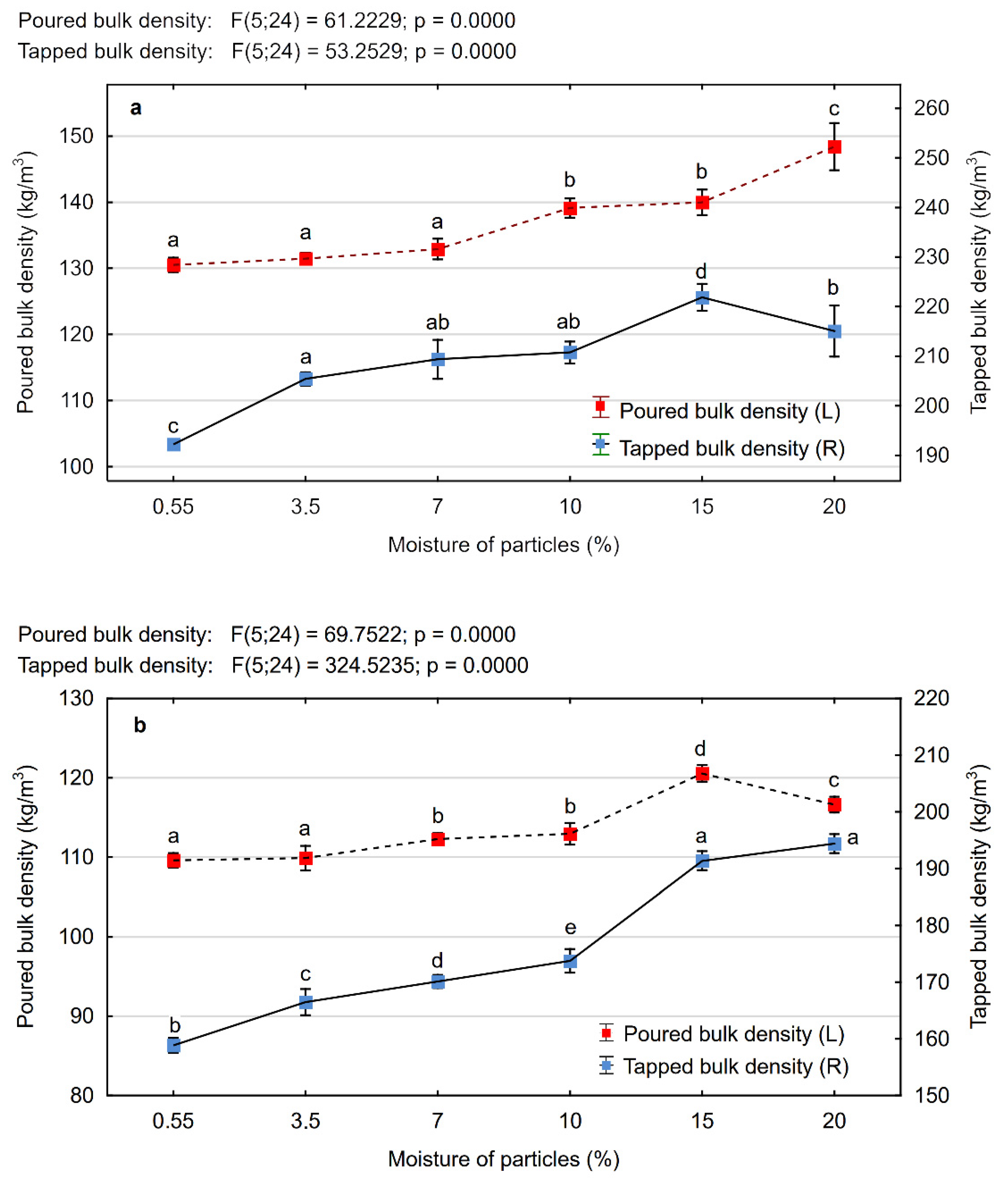

3.2. Poured Bulk Density and Tapped Bulk Density of Wood Particles

3.3. Compression Ratio

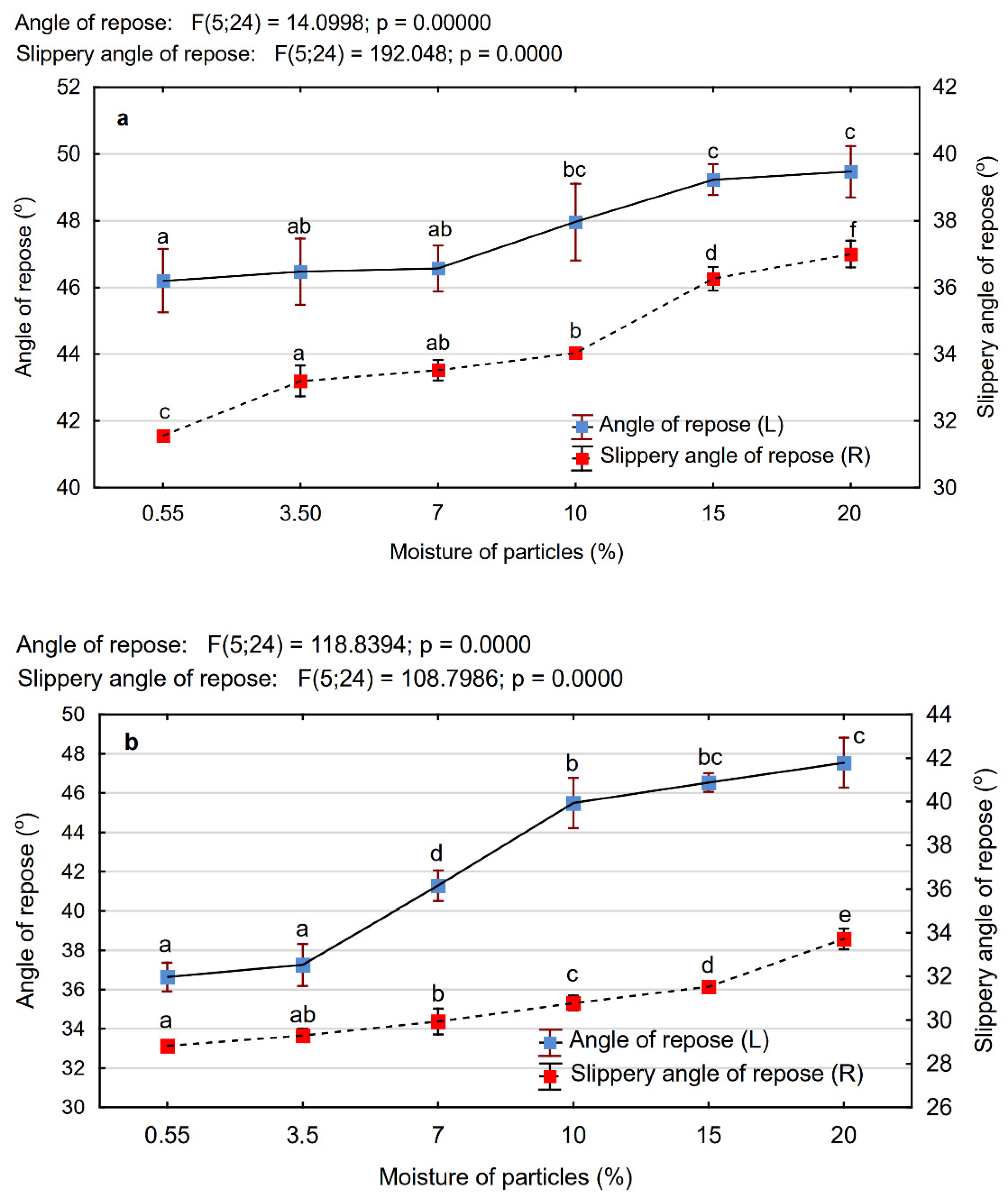

3.4. Angle of Repose and Slippery Angle of Repose of Wood Particles

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Pędzik, M.; Janiszewska, D.; Rogoziński, T. Alternative Lignocellulosic Raw Materials in Particleboard Production: A Review. Ind. Crops Prod. 2021, 174, 114162. [Google Scholar] [CrossRef]

- Wang, B.; Li, D.; Wang, L.; Huang, Z.; Zhang, L.; Chen, X.D.; Mao, Z. Effect of Moisture Content on the Physical Properties of Fibered Flaxseed. Int. J. Food Eng. 2007, 5. [Google Scholar] [CrossRef]

- Cosereanu, C.N.; Brenci, L.-M.N.G.; Zeleniuc, O.I.; Fotin, A.N. Effect of Particle Size and Geometry on the Performance of Single-Layer and Three-Layer Particleboard Made from Sunflower Seed Husks. BioResources 2015, 10, 1127–1136. [Google Scholar] [CrossRef]

- Dukarska, D.; Czarnecki, R.; Dziurka, D.; Mirski, R. Construction Particleboards Made from Rapeseed Straw Glued with Hybrid PMDI/PF Resin. Eur. J. Wood Prod. 2017, 75, 175–184. [Google Scholar] [CrossRef]

- Benthien, J.T.; Ohlmeyer, M.; Schneider, M.; Stehle, T. Experimental Determination of the Compression Resistance of Differently Shaped Wood Particles as Influencing Parameter on Wood-Reduced Particleboard Manufacturing. Eur. J. Wood Prod. 2018, 76, 937–945. [Google Scholar] [CrossRef]

- Istek, A.; Aydin, U.; Özlüsoylu, I. The Effect of Chip Size on the Particleboard Properties. In Proceedings of the International Congress on Engineering and Life Science (ICELIS), Kastamouno, Turkey, 26–29 April 2018; pp. 26–29. [Google Scholar]

- Istek, A.; Aydin, U.; Ozlusoylu, I. The Effect of Mat Layers Moisture Content on Some Properties of Particleboard. Drv. Ind. 2019, 70, 221–228. [Google Scholar] [CrossRef]

- Benthien, J.T.; Ohlmeyer, M. Effects of Flat-Shaped Face Layer Particles and Core Layer Particles of Intentionally Greater Thickness on the Properties of Wood-Reduced Particleboard. Fibers 2020, 8, 46. [Google Scholar] [CrossRef]

- Barbu, M.C.; Montecuccoli, Z.; Förg, J.; Barbeck, U.; Klímek, P.; Petutschnigg, A.; Tudor, E.M. Potential of Brewer’s Spent Grain as a Potential Replacement of Wood in PMDI, UF or MUF Bonded Particleboard. Polymers 2021, 13, 319. [Google Scholar] [CrossRef] [PubMed]

- Dukarska, D.; Pędzik, M.; Rogozińska, W.; Rogoziński, T.; Czarnecki, R. Characteristics of Straw Particles of Selected Grain Species Purposed for the Production of Lignocellulose Particleboards. Part. Sci. Technol. 2021, 39, 213–222. [Google Scholar] [CrossRef]

- Kristak, L.; Ruziak, I.; Tudor, E.M.; Barbu, M.C.; Kain, G.; Reh, R. Thermophysical Properties of Larch Bark Composite Panels. Polymers 2021, 13, 2287. [Google Scholar] [CrossRef]

- Tudor, E.M.; Kristak, L.; Barbu, M.C.; Gergeľ, T.; Němec, M.; Kain, G.; Réh, R. Acoustic Properties of Larch Bark Panels. Forests 2021, 12, 887. [Google Scholar] [CrossRef]

- Korai, H.; Ling, N.; Osada, T.; Yasuda, O.; Sumida, A. Development of an Air-Injection Press for Preventing Blowout of Particleboard I: Effects of an Air-Injection Press on Board Properties. J. Wood Sci. 2011, 57, 401–407. [Google Scholar] [CrossRef]

- Sarı, B.; Nemli, G.; Ayrilmis, N.; Baharoğlu, M.; Bardak, S. The Influences of Drying Temperature of Wood Particles on the Quality Properties of Particleboard Composite. Dry. Technol. 2013, 31, 17–23. [Google Scholar] [CrossRef]

- Park, Y.; Chang, Y.-S.; Park, J.-H.; Yang, S.-Y.; Chung, H.; Jang, S.-K.; Choi, I.-G.; Yeo, H. Energy Efficiency of Fluidized Bed Drying for Wood Particles. J. Korean Wood Sci. Technol. 2016, 44, 821–827. [Google Scholar] [CrossRef]

- Pizzi, A.; Mittal, K.L. Urea-Formaldehyde Adhesives. In Handbook of Adhesive Technology; Marcel Dekker: New York, NY, USA, 2003. [Google Scholar]

- Dorieh, A.; Mahmoodi, N.O.; Mamaghani, M.; Pizzi, A.; Zeydi, M.M. New Insight into the Use of Latent Catalysts for the Synthesis of Urea Formaldehyde Adhesives and the Mechanical Properties of Medium Density Fiberboards Bonded with Them. Eur. Polym. J. 2019, 112, 195–205. [Google Scholar] [CrossRef]

- Li, X.; Cai, Z.; Winandy, J.E.; Basta, A.H. Selected Properties of Particleboard Panels Manufactured from Rice Straws of Different Geometries. Bioresour. Technol. 2010, 101, 4662–4666. [Google Scholar] [CrossRef] [PubMed]

- Korai, H.; Saotome, H. Blowout Conditions and Properties of Isocyanate Resin Bonded Particleboard Manufactured from High-Moisture Particles Using an Air-Injection Press. J. Wood Sci. 2013, 59, 42–49. [Google Scholar] [CrossRef]

- Bekhta, P.; Noshchenko, G.; Réh, R.; Kristak, L.; Sedliačik, J.; Antov, P.; Mirski, R.; Savov, V. Properties of Eco-Friendly Particleboards Bonded with Lignosulfonate-Urea-Formaldehyde Adhesives and PMDI as a Crosslinker. Materials 2021, 14, 4875. [Google Scholar] [CrossRef]

- Jiang, J.; Lu, X. Improving Characteristics of Melamine–Urea–Formaldehyde Resin by Addition of Blocked Polyurethane Prepolymer. Eur. J. Wood Wood Prod. 2017, 75, 185–191. [Google Scholar] [CrossRef]

- European Committee for Standardization. EN 312. Particleboards. Specifications; European Committee for Standardization: Brussels, Belgium, 2003. [Google Scholar]

- Rofii, M.N.; Yamamoto, N.; Ueda, S.; Kojima, Y.; Suzuki, S. The Temperature Behaviour inside the Mat of Wood-Based Panel during Hot Pressing under Various Manufacturing Conditions. J. Wood Sci. 2014, 60, 414–420. [Google Scholar] [CrossRef][Green Version]

- Cai, Z.; Muehl, J.H.; Winandy, J.E. Effects of Panel Density and Mat Moisture Content on Processing Medium Density Fiberboard. For. Prod. J. 2006, 56, 20–25. [Google Scholar]

- Dai, C.; Wang, S. Press Control for Optimized Wood Composite Processing and Properties. In Proc. Fundamentals of Composite Processing; Gen. Tech. Rept. FPL-GTR-149; Winandy, J., Kamke, F.A., Eds.; USDA Forest Serv., Forest Products Lab.: Madison, WI, USA, 2004; pp. 54–64. [Google Scholar]

- Murayama, K.; Kukita, K.; Kobori, H.; Kojima, Y.; Suzuki, S.; Miyamoto, K. Effect of Face-Layer Moisture Content and Face–Core–Face Ratio of Mats on the Temperature and Vapor Pressure Behavior during Hot-Pressing of Wood-Based Panel Manufacturing. J. Wood Sci. 2021, 67, 42. [Google Scholar] [CrossRef]

- Rogozinski, T.; Dolny, S. Influence of Moisture Content on the Apparent Densities of Dust from Sanding of Alder Wood. Trieskové a Beztrieskové Obrábanie Dreva 2004, 4, 205–208. [Google Scholar]

- Dolny, S.; Rogoziński, T. Influence of Moisture Content on the Physical and Aerodynamic Properties of Dusts from Working of Particleboards. Ann. Wars. Univ. Life Sci.–SGGW For. Wood Technol. 2010, 71, 138–141. [Google Scholar]

- Kalman, H.; Portnikov, D. Analyzing Bulk Density and Void Fraction: B. Effect of Moisture Content and Compression Pressure. Powder Technol. 2021, 381, 285–297. [Google Scholar] [CrossRef]

- Tannous, K.; Lam, P.S.; Sokhansanj, S.; Grace, J.R. Physical Properties for Flow Characterization of Ground Biomass from Douglas Fir Wood. Part. Sci. Technol. 2013, 31, 291–300. [Google Scholar] [CrossRef]

- Rezaei, H.; Lim, C.J.; Lau, A.; Sokhansanj, S. Size, Shape and Flow Characterization of Ground Wood Chip and Ground Wood Pellet Particles. Powder Technol. 2016, 301, 737–746. [Google Scholar] [CrossRef]

- Polski Komitet Normalizacji i Miar. PN-74 Z-04002.07. Ochrona Czystości Powietrza. Badanie Fizycznych Właściwości Pyłów. Oznaczanie Kąta Nasypu Pyłu; Polski Komitet Normalizacji i Miar: Warszawa, Polska, 1974. [Google Scholar]

- Трoфимoв, С.П. Цехoвые системы аспирации и пневмoтранспoрта измельченных древесных oтхoдoв; Белoрусский гoсударственный технoлoгический университет: Минск, Беларусь, 2010; ISBN 978-985-434-929-9. [Google Scholar]

- Grubecki, I. Airflow versus Pressure Drop for a Mixture of Bulk Wood Chips and Bark at Different Moisture Contents. Biosyst. Eng. 2015, 139, 100–110. [Google Scholar] [CrossRef]

- Lam, P.S.; Sokhansanj, S.; Bi, X.; Lim, C.J.; Naimi, L.J.; Hoque, M.; Mani, S.; Womac, A.R.; Narayan, S.; Ye, X.P. Bulk Density of Wet and Dry Wheat Straw and Switchgrass Particles. Appl. Eng. Agric. 2008, 24, 351–358. [Google Scholar] [CrossRef]

- Wu, M.R.; Schott, D.; Lodewijks, G. Physical Properties of Solid Biomass. Biomass Bioenergy 2011, 35, 2093–2105. [Google Scholar] [CrossRef]

- Eisenbies, M.H.; Volk, T.A.; Therasme, O.; Hallen, K. Three Bulk Density Measurement Methods Provide Different Results for Commercial Scale Harvests of Willow Biomass Chips. Biomass Bioenergy 2019, 124, 64–73. [Google Scholar] [CrossRef]

- Santalla, E.; Mascheroni, R. Note: Physical Properties of High Oleic Sunflower Seeds. Food Sci. Technol. Int. 2003, 9, 435–442. [Google Scholar] [CrossRef]

- Aviara, N.A.; Oluwole, F.A.; Haque, M.A. Effect of Moisture Content on Some Physical Properties of Sheanut [Butyrospernum Paradoxum]. Int. Agrophysics 2005, 19, 193–198. [Google Scholar]

- Aviara, N.A.; Power, P.P.; Abbas, T. Moisture-Dependent Physical Properties of Moringa Oleifera Seed Relevant in Bulk Handling and Mechanical Processing. Ind. Crops Prod. 2013, 42, 96–104. [Google Scholar] [CrossRef]

- Littlefield, B.; Fasina, O.O.; Shaw, J.; Adhikari, S.; Via, B. Physical and Flow Properties of Pecan Shells—Particle Size and Moisture Effects. Powder Technol. 2011, 212, 173–180. [Google Scholar] [CrossRef]

- Mani, S.; Tabil, L.G.; Sokhansanj, S. Grinding Performance and Physical Properties of Wheat and Barley Straws, Corn Stover and Switchgrass. Biomass Bioenergy 2004, 27, 339–352. [Google Scholar] [CrossRef]

- McGlinchey, D. (Ed.) Characterisation of Bulk Solids; Blackwell Publishing Ltd.: Oxford, UK, 2005; ISBN 978-1-4443-0545-6. [Google Scholar]

| Parameter | Value |

|---|---|

| Average dimensions (mm): | |

| length (l) | 19.1 * ± 6.2 ** |

| width (w) | 3.2 ± 1.0 |

| thickness (h) | 1.38 ± 0.4 |

| Shape factors: | |

| ) | 13.84 |

| flatness (ψ) | 2.32 |

| width coefficient (m) | 6.23 |

| Effect | F | P |

|---|---|---|

| Moisture content range: 0.55–7% | ||

| Type of particles | F (1; 482.9) = 623.94 | 0.000 |

| Particle moisture content | F (2; 17.79) = 22.99 | 0.000 |

| Type of particles × particle moisture content | F (2; 14.01) = 18.11 | 0.000 |

| Moisture content range: 10–20% | ||

| Type of particles | F (1; 41.89) = 44.85 | 0.001 |

| Particle moisture content | F (2; 8.13) = 8.71 | 0.00 |

| Type of particles × particle moisture content | F (2; 0.4) = 0.43 | 0.65 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dukarska, D.; Rogoziński, T.; Antov, P.; Kristak, L.; Kmieciak, J. Characterisation of Wood Particles Used in the Particleboard Production as a Function of Their Moisture Content. Materials 2022, 15, 48. https://doi.org/10.3390/ma15010048

Dukarska D, Rogoziński T, Antov P, Kristak L, Kmieciak J. Characterisation of Wood Particles Used in the Particleboard Production as a Function of Their Moisture Content. Materials. 2022; 15(1):48. https://doi.org/10.3390/ma15010048

Chicago/Turabian StyleDukarska, Dorota, Tomasz Rogoziński, Petar Antov, Lubos Kristak, and Jakub Kmieciak. 2022. "Characterisation of Wood Particles Used in the Particleboard Production as a Function of Their Moisture Content" Materials 15, no. 1: 48. https://doi.org/10.3390/ma15010048

APA StyleDukarska, D., Rogoziński, T., Antov, P., Kristak, L., & Kmieciak, J. (2022). Characterisation of Wood Particles Used in the Particleboard Production as a Function of Their Moisture Content. Materials, 15(1), 48. https://doi.org/10.3390/ma15010048