The influence of starch impregnation on selected properties of honeycomb panels turned out not to be obvious. Therefore, this part of the work decided to present only the observed quantitative differences. In the other part of the study, a detailed statistical analysis was prepared to show the qualitative relationships and the impact of all selected variable factors on the properties of the tested honeycomb panels.

3.1. Effect of Impregnation on the Panel’s Strength

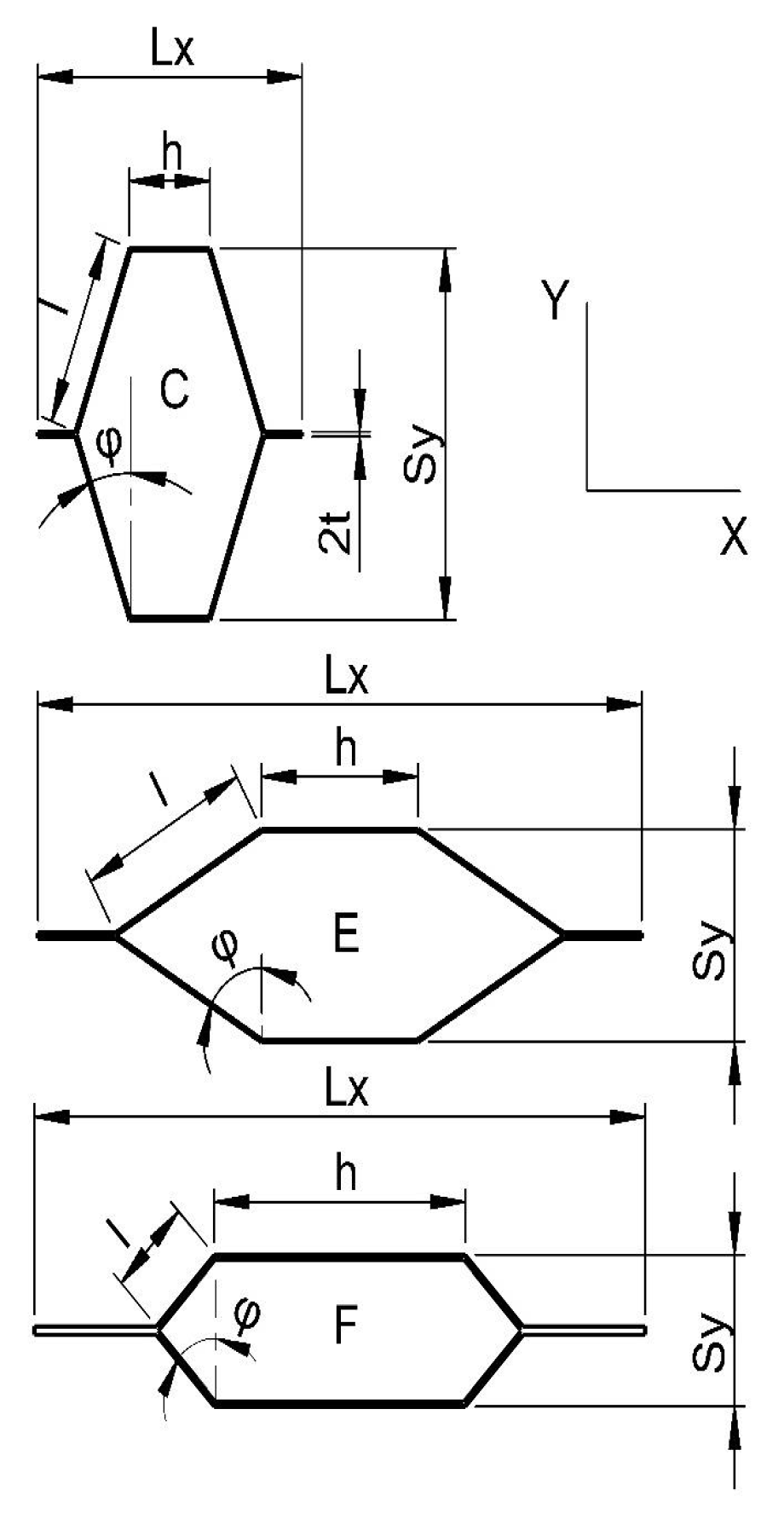

Figure 6,

Figure 7 and

Figure 8 illustrate the effects of starch impregnation, type of material, the direction of orthotropy, and climatic conditions on the

of honeycomb panel with a core of different cells (C,E,F). The summary shows that the highest

(15.3 MPa) was observed among the beams with starch impregnated F-cells for the X orthotropy direction in dry conditions (FSH25XD). Conversely, the lowest

(0.9 MPa) occurred in the case of beams with non-impregnated E-type cells for the Y orthotropy direction in tropical conditions (ENH25YW).

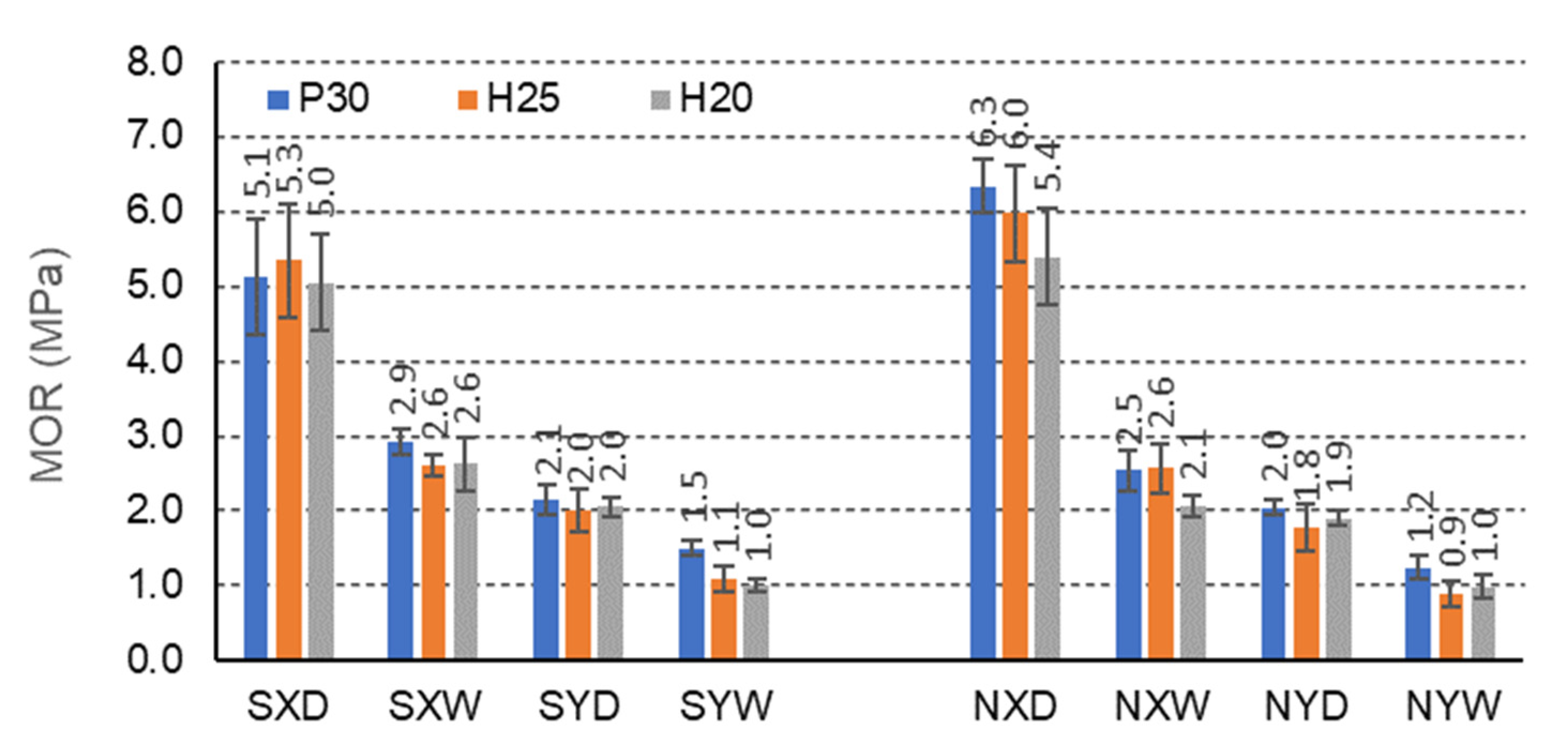

In the group of beams with C-cells, under all climatic conditions D, W, the starch impregnation improves the

of the beams for each case of the facing used and the orthotropy direction (

Figure 6). Only CNP30XD beams with P30 facings in dry conditions and the X orthotropy direction show higher strength (5.0 MPa) than the corresponding CSP30XD beams impregnated with starch (4.5 MPa). It should be noted here that the increase in

for beams with impregnated cores compared to beams with non-impregnated cores is from 2.3 to 46.7%. For beams with P30, H25, and H20 facings, in dry conditions D and for the direction of orthotropy X, the bending strength increases by 2.3%, 4.5%, and −11.1%, respectively, and in tropical conditions W by 33.3%, 31% and 20.8, respectively. Note that a negative value indicates the opposite tendency to increase—i.e., decrease. For beams with the same facings P30, H25 and H20, in dry conditions D, and for the direction of orthotropy Y, the bending strength increases by 30.4%, 28.6%, and 34.0%, respectively, and in tropical conditions W by 46.7%, 44.8%, and 40.0%, respectively. It is also significant that for C-type cells, there was no clear difference in the strength of the beams in the X and Y orthotropy directions greater by −7.0%, 4.5%, and −4.4% in relation to the strength in the Y direction, and in tropical conditions W by 11.1%, 0.0%, and −4.2%, respectively. For non-impregnated beams, these relationships are significantly different. For beams with P30, H25, and H20 facings, in dry conditions D, the bending strength in the direction of X orthotropy is respectively higher by 23.8%, 28.6%, and 38.0% concerning the strength in the Y direction and tropical conditions W, respectively 11.1%, 20.0%, and 21.1%. Thus, the effect of impregnation on the strength of beams with C-cells is visible, but also on the change of this strength depending on the direction of orthotropy. After impregnation, the influence of the direction of orthotropy on the strength of the beams decreased significantly.

For beams with E-cells, the effect of impregnation is not so pronounced (

Figure 7). Beams with P30 facing, not impregnated, in dry conditions D, and the orthotropy direction X (6.3 MPa) show the highest bending strength. In dry conditions D, impregnation with starch significantly reduces the

of beams with P30, H25, H20 facings, for the X orthotropy direction, compared to analogous non-impregnated beams by 23.5%, 13.2%, 8.0%, respectively. In tropical conditions, W increases this strength by 13.8%, 0.0%, and 19.2%, respectively. For beams with the same facings P30, H25 and H20, in dry conditions D, and for the direction of orthotropy Y, the bending strength increases by 4.8%, 10.0%, and 5.0%, respectively, and in tropical conditions W, by 20.0%, 18.2%, and 0.0%, respectively. It is also noticeable that clear differences in the strength of the beams in the X and Y orthotropy directions were observed for E-type cells, by 58.8%, 62.3% and 60.0% of the strength in the Y direction, and in tropical conditions by 48.3%, 57.7% and 61.5%, respectively. For non-impregnated beams, these relationships are very similar. For beams with P30, H25, and H20 facings, in dry conditions D, the bending strength in the direction of X orthotropy is, respectively, 68.3%, 70.0%, and 64.8% greater concerning the strength in the Y direction, and in tropical conditions W, respectively 52.0%, 65.4%, and 52.4%. Moreover, in this case, the influence of impregnation on the strength of beams with E-cells is visible. The presented results also illustrate the effect of large and slightly changing orthotropy of the tested beams. It can be assumed that the effect of impregnation on the change of orthotropic properties of the panel is significant.

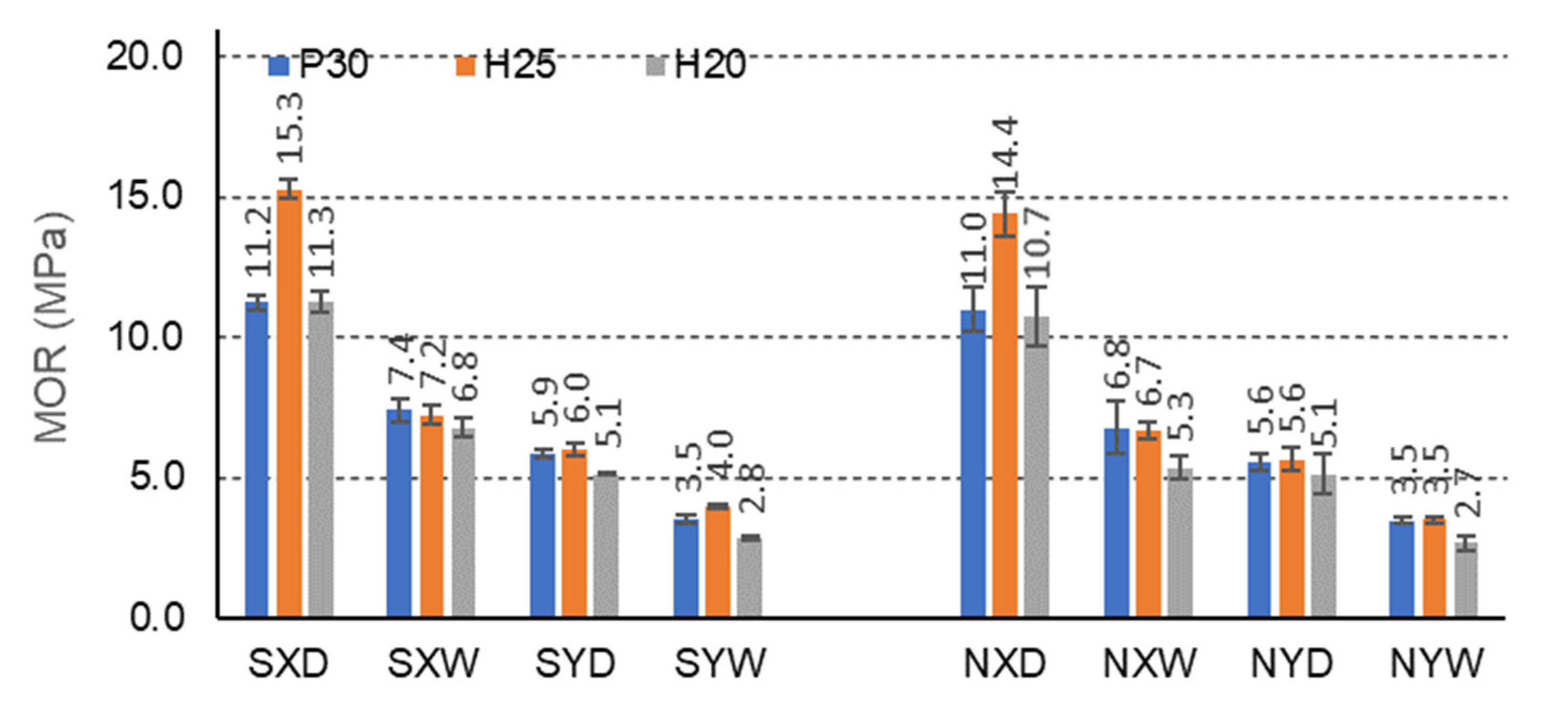

The F-cell beams also show marked strength differences due to the impregnation of the paper (

Figure 8). Beams with H25 facing, impregnated, in dry conditions D, and for the orthotropy direction X (15.3 MPa) show the highest bending strength. Beams with H25 facing, not impregnated, in dry conditions D achieve slightly lower strength for the same direction of orthotropy (14.4 MPa). In dry conditions D, impregnation with starch slightly improves

of beams with P30, H25, H20 facings, for the X orthotropy direction, compared to non-impregnated beams by 1.8%, 5.9%, 5.3%, respectively, and in tropical conditions by 8.1%, respectively, 6.9% and 22.1%. Beams with the same facings P30, H25, and H20, in dry conditions D, and for the orthotropy direction Y show greater bending strength by 5.1%, 6.7%, and 0.0%, respectively, and in tropical conditions W by 0.0%, 12.5%, and 3.6%, respectively. As in the case of beams with E-cells, clear differences in the strength of the beams in the X and Y orthotropy directions were observed: 47.3%, 60.8%, and 54.9% of the strength in the Y direction, and in tropical conditions by 52.7%, 44.4%, and 58.8%, respectively. The relations are very similar also for non-impregnated beams. When using P30, H25, and H20 facing, in dry conditions D, the bending strength of the beams in the direction of X orthotropy is greater by 49.1%, 61.1%, and 52.3%, respectively, concerning the strength in the Y direction, and in tropical conditions W, by 48.5%, 47.8%, and 49.1%, respectively. Therefore, it can be concluded that also in this case, the effect of impregnation on the strength of beams with F-cells is visible. Moreover, the test results illustrate the effect of large and slightly changing orthotropy of the tested beams. Hence, it should be concluded that the effect of impregnation on the change of orthotropic properties of the plate with F-cells is significant.

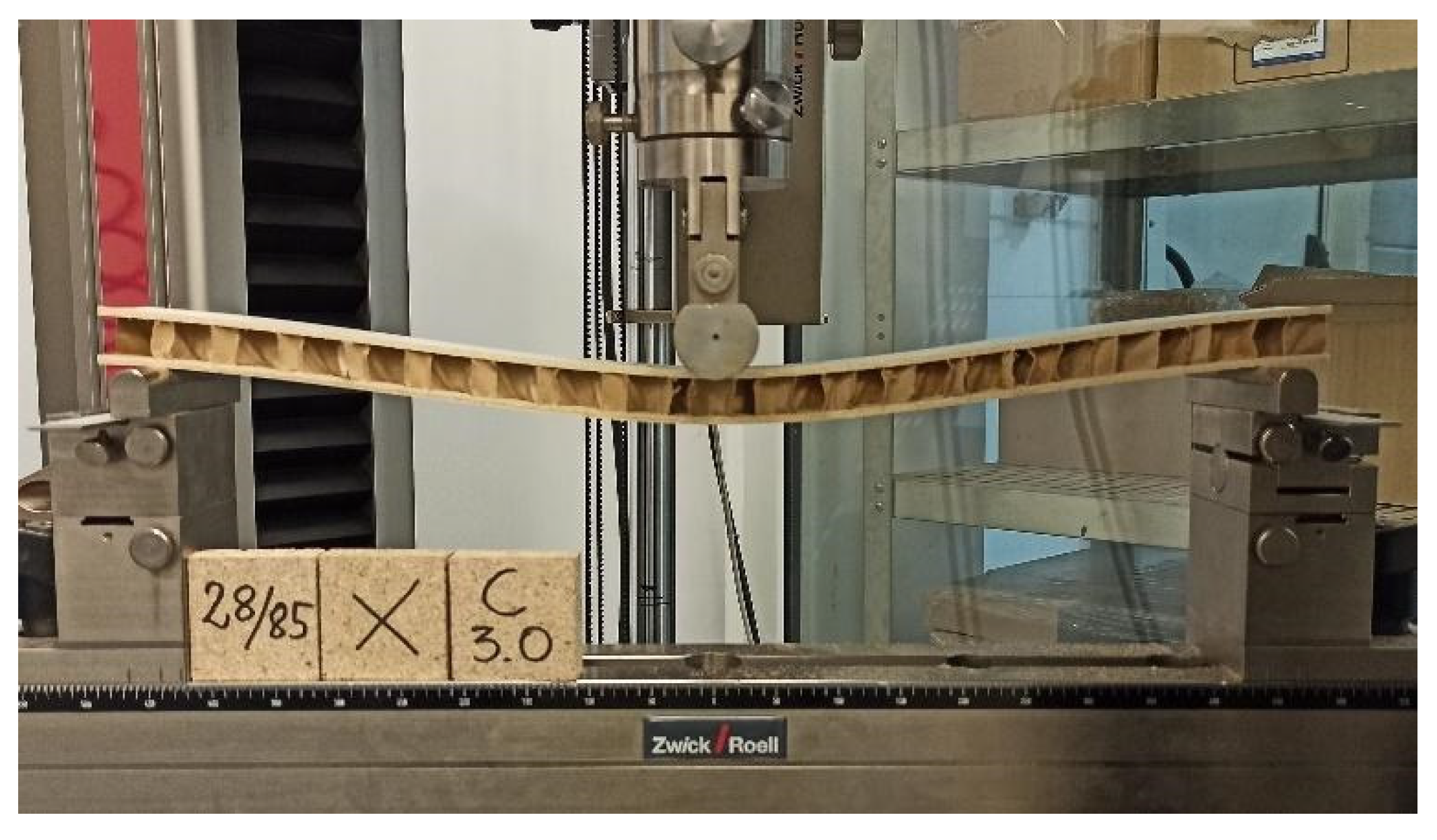

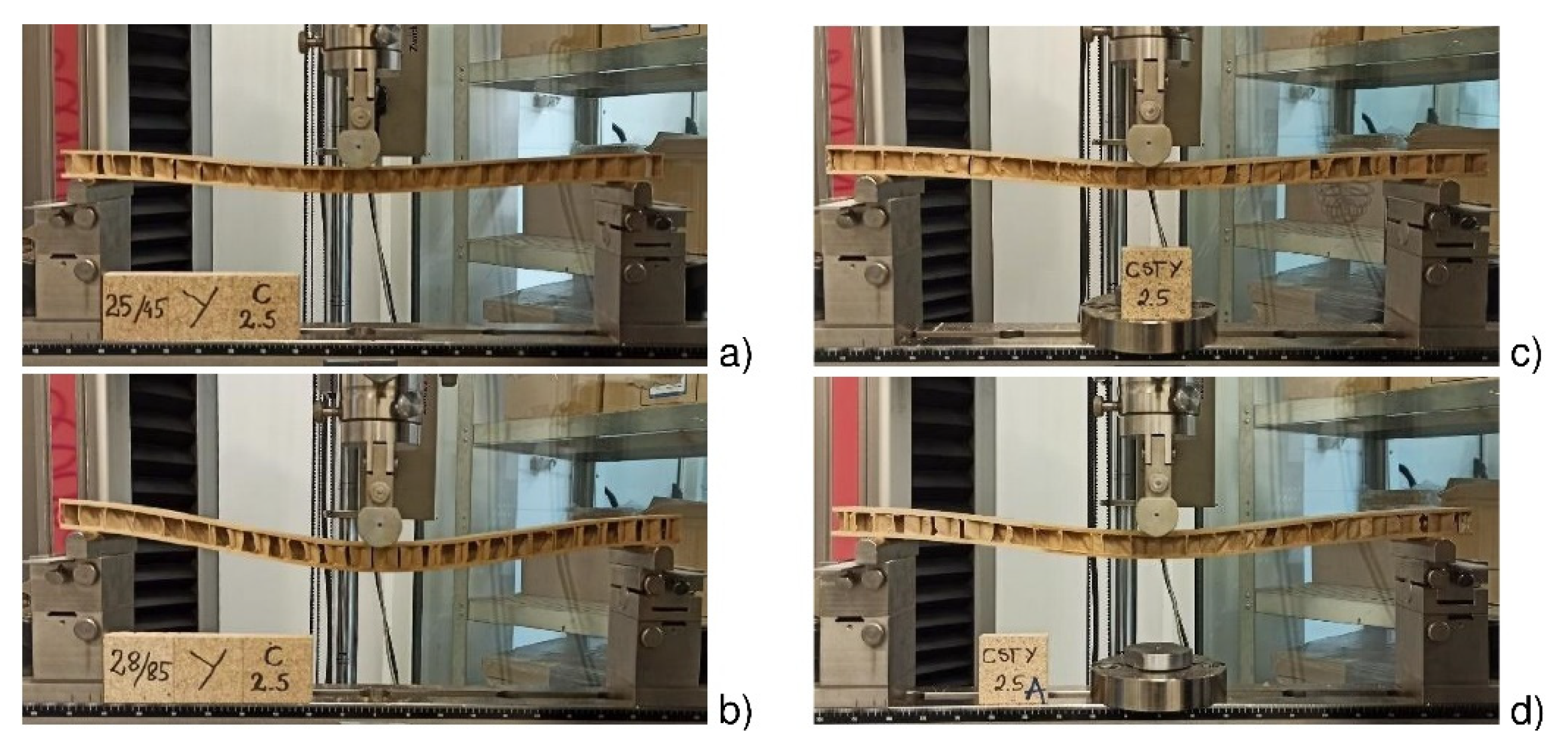

Figure 9 shows deflections of a beam with C-type cells, H25 facings, before and after impregnation (N, S), examined in the direction of the

Y-axis in the conditions of dry D and tropical W climate. Under tropical conditions (T = 28 °C/H = 85%,

Figure 9b), the beam deflection is much higher compared to beams loaded under dry climate conditions (T = 25 °C/H = 45%,

Figure 9a). On the other hand, the beams reduce deflections in dry and tropical conditions after impregnating starch, respectively (

Figure 9c,d).

3.2. Effect of Impregnation on the Panel’s Stiffness

As shown above, impregnating the core paper with a 10% aqueous acetylated starch water repellant improves the strength of the three-layer furniture panel and its stiffness. This is illustrated in the figures below (

Figure 10,

Figure 11 and

Figure 12). The average increase in the modulus of linear elasticity

for all tested beam combinations is approximately 7%.

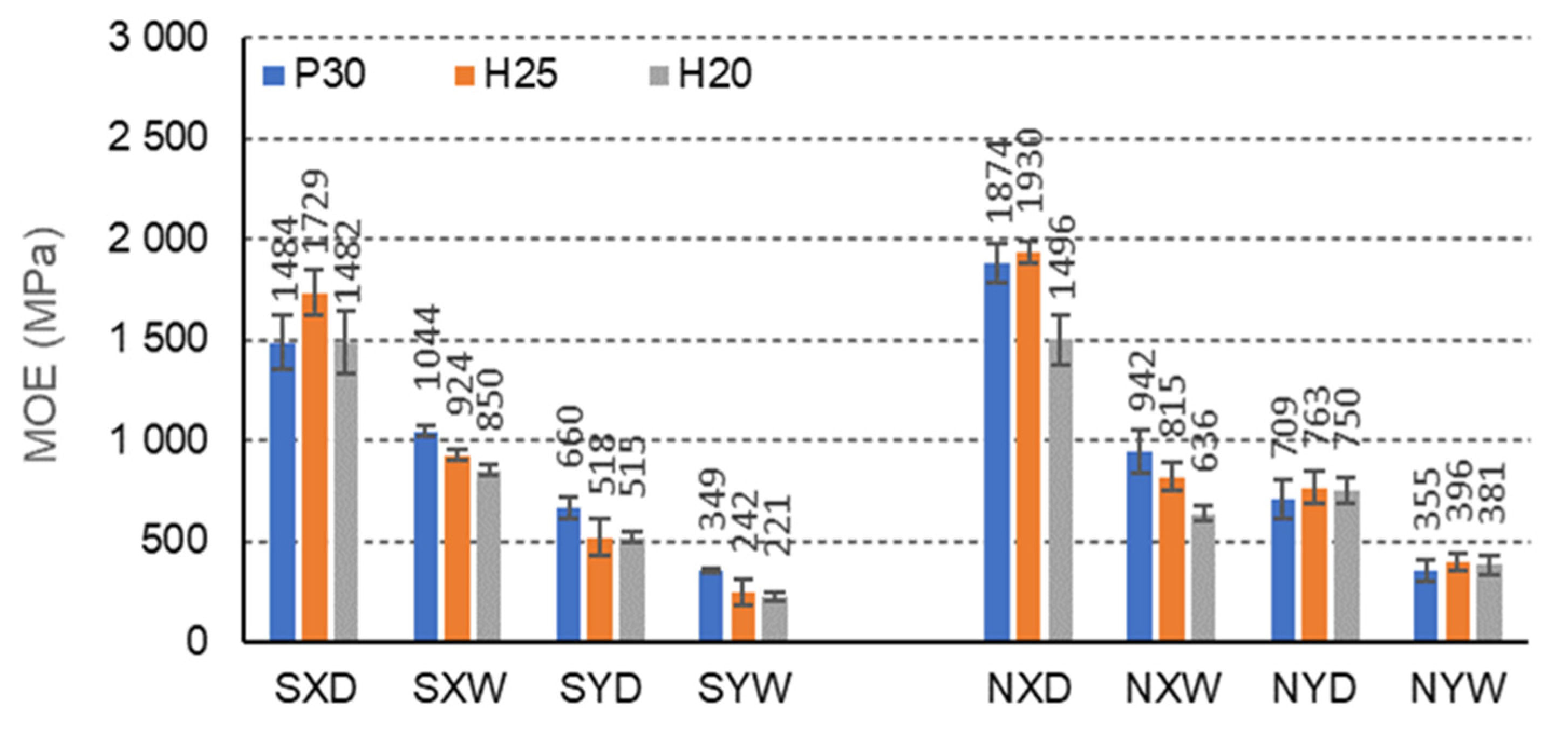

For C-cell beams, under all climatic conditions, starch impregnation improves the MOE for each case of a facing used and the direction of orthotropy (

Figure 10). Only CNH25XD beams with H25 facing in dry conditions and for the X orthotropy direction show a greater modulus of elasticity (1733 MPa) compared to the corresponding beams (CSH25XD) impregnated with starch (1649 MPa). It should be noted that for beams with P30, H25, and H20 facings, in dry conditions D, and for the orthotropy direction X, the

increases by 12.0%, −5.1%, and 14.6%, respectively, and in tropical conditions W, respectively by 23.9%, 23.2%, and 15.2%. For beams with the same facings P30, H25 and H20, in dry conditions D, and for the direction of orthotropy Y, the

increases by 9.9%, 15.1%, and 32.1%, respectively, and in tropical conditions W by 22.6%, 40.5%, and 37.7%. It is also characteristic that, as in the case of strength changes, no significant difference in linear elasticity modules was observed in the X and Y orthotropy directions for C-type cells. In the orthotropy direction, X is 3.2%, 8.6%, and 10.6% lower concerning the

in the Y direction, and in tropical conditions, W is lower by −4.2%, 18.8%, and 19.3%, respectively. Note that a negative value indicates the opposite tendency to decrease, i.e., increase. For non-impregnated beams, these relationships are significantly different. For beams with P30, H25, and H20 facing, in dry conditions D, the

in the X orthotropy direction is respectively greater by −5.7%, 12.3%, and 12.1% concerning the

in the Y direction, and in tropical conditions W, by 2.6%, 8.0%, and 12.4%, respectively. Thus, the influence of impregnation on the modulus of elasticity of beams with C-cells is visible, but also on the change of this property depending on the direction of orthotropy. After impregnation, the influence of the orthotropy direction on the

of the beams changed and diversified. The impregnation of the paper resulted in a weakening of the modulus of linear elasticity of the beams in the direction of the

X-axis in favor of increasing the MOE in the direction of the

Y-axis. Although the differences are insignificant, they persuade the orthotropic properties of the honeycomb panels.

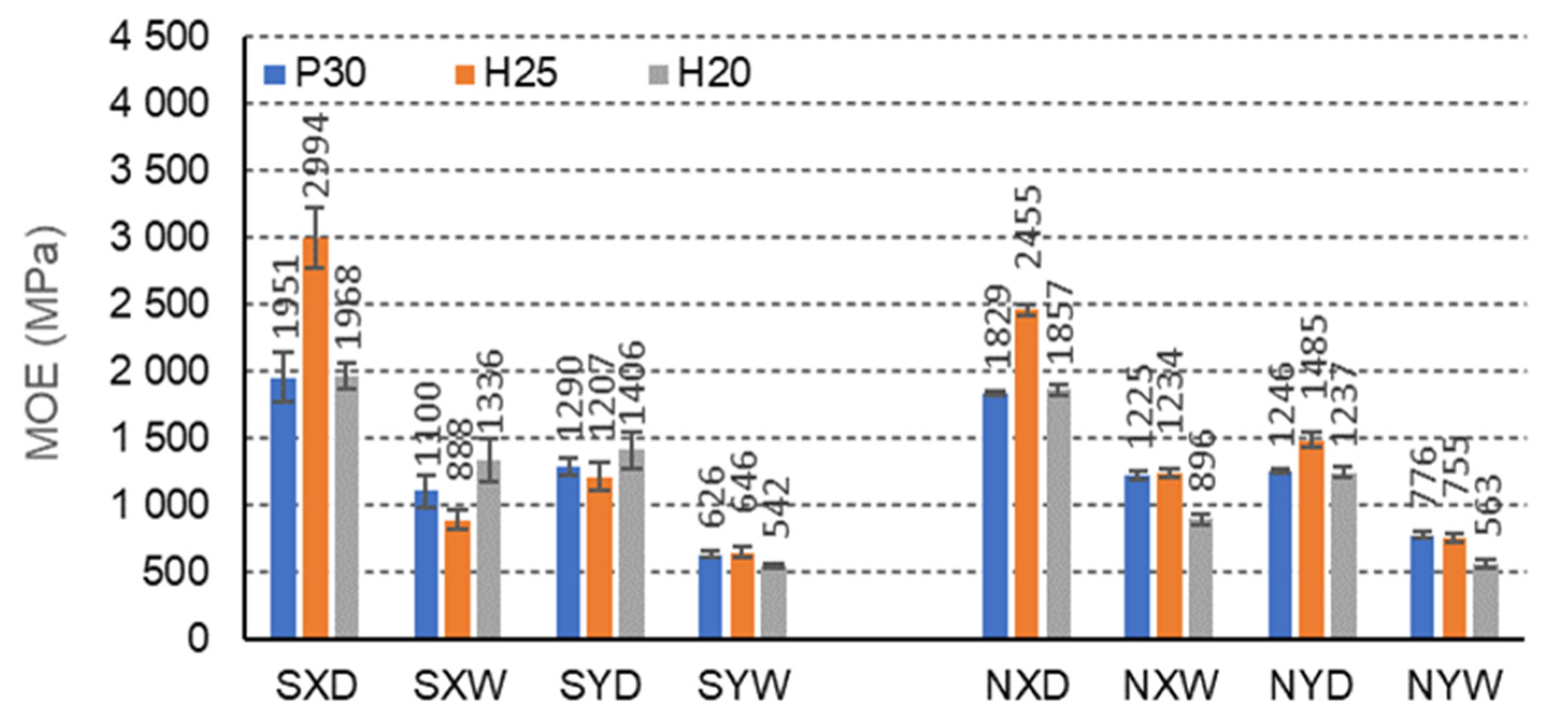

In the case of beams with E-cells, the effect of impregnation on the modulus of elasticity is also pronounced (

Figure 11). The highest

is shown for beams with H25 facing, not impregnated, in dry conditions D, and orthotropy direction X (1930 MPa). In dry conditions D, impregnation with starch significantly reduces the

of beams with P30, H25, H20 facings for the X orthotropy direction, compared to analogous non-impregnated beams, by 26.2%, 11.7%, 0.9%, respectively. In tropical conditions, W increases this property by 9.7%, 11.7%, and 25.3%, respectively. For beams with the same facings P30, H25 and H20, in dry conditions D, and for the Y orthotropy direction,

also decreases by 7.4%, 47.6%, and 45.4%, respectively, and in tropical conditions W, by 2.0%, 63.6%, and 72.7%. It is also noticeable that clear differences in the modulus of elasticity of the beams in the X and Y orthotropy directions were observed for E-type cells, 55.5%, 70.1%, and 65.2% concerning the

in the Y direction, and in tropical conditions by 66.6%, 78.3%, and 74.1%, respectively. For non-impregnated beams, these relationships are very similar. For beams with P30, H25, and H20 facings, in dry conditions D, the modulus of elasticity in the X orthotropy direction is respectively higher by 62.1%, 60.5%, and 49.9% concerning the

in the Y direction, and in tropical conditions W, by respectively, 62.3% 51.4%, and 40.2%. In this case, a clear influence of impregnation on the modulus of elasticity of beams with E-cells is visible. The presented results also illustrate the effect of large and changing orthotropy of the tested beams. The changes result both from the use of starch as an impregnating agent and the slender shape of the cells. It is clear that in the case of an elongated E-cell with long free walls (

= 13 mm), impregnation weakens the elastic properties of the core in the direction of the X and Y axes, but at the same time reduces the difference between the modulus of elasticity in these directions.

The F-cell beams also show significant strength differences due to the impregnation of the paper (

Figure 12). FSH25XD beams show the highest modulus of elasticity with H25 facing, impregnated, in dry conditions D, and for the orthotropy direction X (2994 MPa). FNH25XD beams achieve much lower

with H25 facing, not impregnated, in dry conditions D, and for the same direction of orthotropy (2455 MPa). In dry conditions D, impregnation with starch improves the

of beams with P30, H25, H20 facings for the X orthotropy direction, compared to non-impregnated beams by 6.2%, 18.0%, 5.4%, respectively, and in tropical conditions W, by respectively −11.3% 12.5%, and 32.9%. Beams with the same facings P30, H25, and H20, in dry conditions D, and for the direction of orthotropy Y also show a higher

by 12.0%, −23.0%, and 12.0%, respectively, and in tropical conditions W, lower

by respectively, 24.0%, 17.1%, and 3.9%. There were also visible differences in the modulus of elasticity of the beams in the X and Y orthotropy directions to

in the Y direction, and tropical conditions W, by 43.1%, 54.3%, and 59.5%, respectively. The relationships are also similar for non-impregnated beams. When using P30, H25, and H20 facing, in dry D conditions, the

of the beams in the X direction is higher by 31.9%, 39.5%, and 33.4%, respectively, concerning the

in the Y direction, and in tropical conditions W, by 36.6%, respectively, 38.8% and 37.3%. Therefore, it can be concluded that in this case, the effect of the impregnation on the strength of the beams with F-cells is visible. The changes result both from the use of starch as an impregnating agent and the slender shape of the cells. There is a regularity that in the case of an elongated F cell with short free walls (

= 6.3 mm), the impregnation strengthens the elastic properties of the core in the direction of the

X-axis. On the other hand, in the direction of the

Y-axis, the paper’s impregnation contributed to the reduction of the linear elasticity modulus.

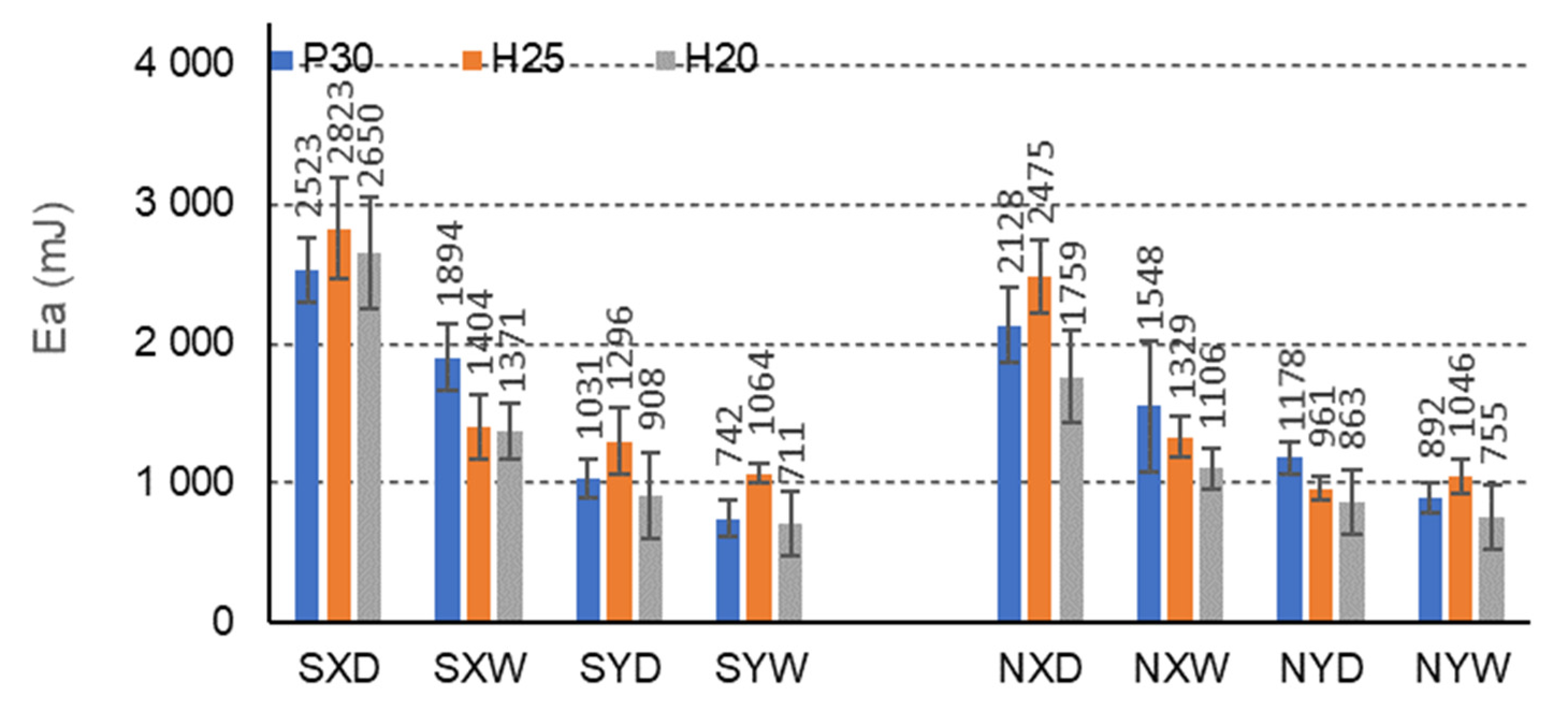

3.3. Effect of Impregnation on the Energy Absorption

The more energy the composite can absorb, the more effective it is to protect the protected charge. The research (

Figure 13,

Figure 14 and

Figure 15) shows that the FNH25XD and FSH25XD beams have the highest energy absorption capacity before and after impregnation

= 2474 mJ i

= 2823 mJ, respectively.

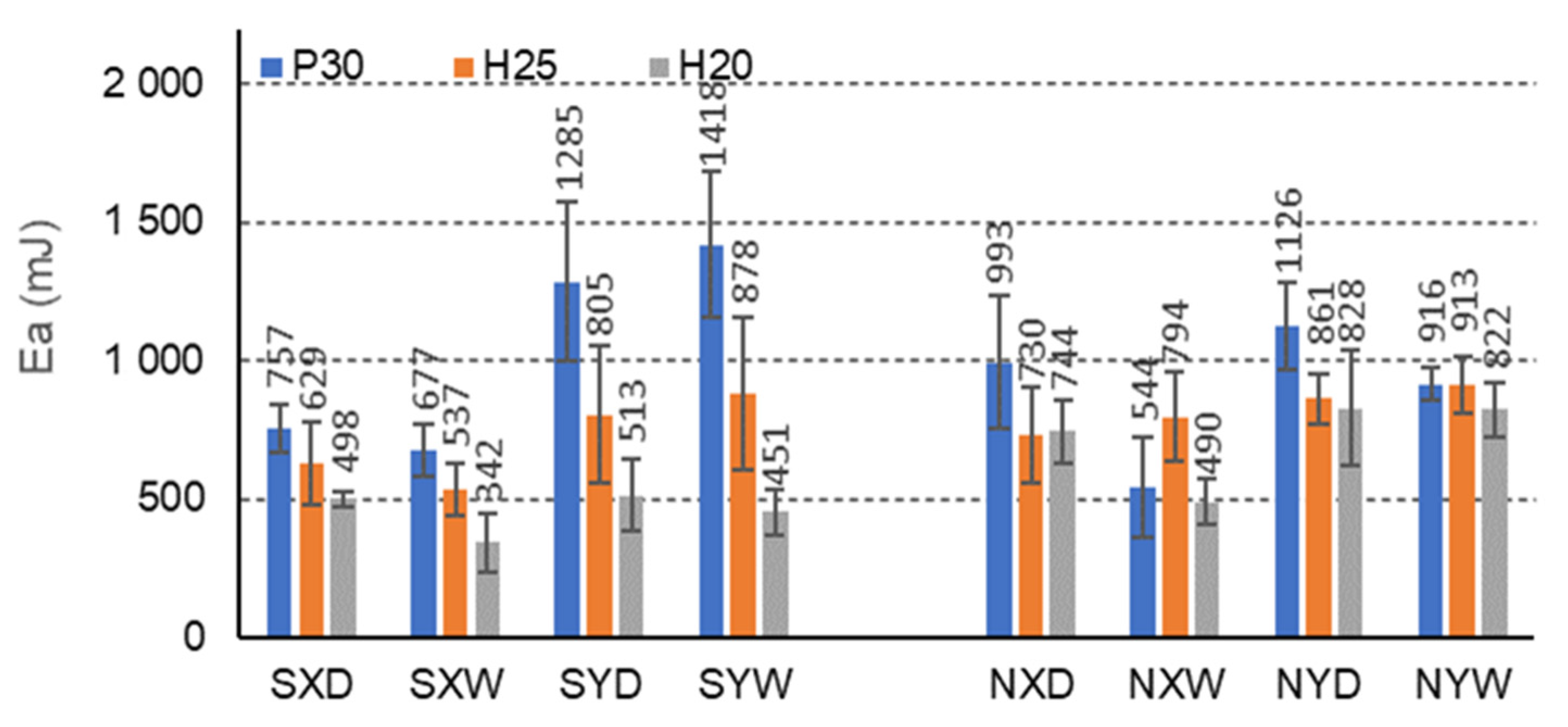

For beams with C-cells, under all climatic conditions, impregnation with starch significantly reduces the amount of energy absorbed for the case of a facing used and the direction of orthotropy (

Figure 13). It should be noted that for beams with P30, H25, and H20 facings, in dry conditions D, and for the orthotropy direction X, the amount of absorbed energy decreases by 31.2%, 16.1%, and 49.4%, respectively, and in tropical conditions W, by −19.5%, 47.7%, and 43.3%. For beams with the same facings P30, H25, and H20, in dry conditions D, and for the direction of orthotropy Y, the amount of energy absorbed also decreases by −12.3%, 6.8%, and 61.4%, respectively, and in tropical conditions W, by −35.5, 3.9% and 82.3%, respectively. However, clear differences in the amount of absorbed energy were observed dependent on the X and Y orthotropy directions, 3.0% concerning the amount of energy absorbed in the Y direction, and in tropical conditions W, respectively 109.8%, 63.5%, and 31.9% lower. For non-impregnated beams, these relationships are significantly more favorable. For beams with P30, H25, and H20 facings, in dry conditions D, the amount of absorbed energy in the X direction is respectively lower by 13.4%, 17.8%, and 11.3% about the amount of energy absorbed in the Y direction, and in tropical conditions W, by 68.2%, 15.0%, and 67.8%, respectively. Thus, the effect of impregnation on the reduction in the amount of absorbed energy of beams with C-type cells is visible, but also on the change of this property depending on the direction of orthotropy. The impregnation of the paper caused a reduction in the ability to absorb energy in the X and Y directions. The differences illustrated are significant and convincing to the honeycomb panels’ orthotropic properties in terms of energy absorption.

In the case of beams with E-cells, the effect of impregnation on the amount of energy absorbed is presented in

Figure 14. The greatest amount of absorbed energy is shown by beams with P30 facing, not impregnated, in dry conditions D, and for the orthotropy direction X (1019 mJ). In dry conditions D, impregnation with starch significantly reduces the amount of absorbed energy for beams with P30, H25, H20 facings, for the X orthotropy direction, compared to analogous non-impregnated beams by 3.3%, 12.2%, 26.4%, respectively. This property also reduces by 16.5%, 12.8%, and 3.2% in tropical conditions, respectively. For beams with the same facings P30, H25 and H20, in dry conditions D, and for the direction of orthotropy Y, the amount of energy absorbed increases by 13.3%, 37.3%, and 24.2%, respectively, and in tropical conditions W, by 26.1%, 49.8%, and 15.6%. It is also noticeable that for E-type cells, clear differences were observed in the amount of energy absorbed for the beams in the X and Y orthotropy directions; it is, respectively, 2.8%, 11.6%, and 54.1% lower concerning the amount of energy absorbed in the Y direction, and tropical conditions by 60.5%, 40.4%, and 69.9%, respectively. These relationships are different for non-impregnated beams. For beams with P30, H25, and H20 facings, in dry conditions D, the amount of absorbed energy in the X direction is 18.4%, 37.6%, and 7.6% greater, respectively, concerning the amount of energy absorbed in the Y direction, and in tropical conditions W, by −1.8%, 37.6% and −48.2%, respectively. In this case, a variable influence of impregnation on the amount of absorbed energy is visible for beams with E-cells. The changes result both from the use of starch as an impregnating agent and the slender shape of the cells. The regularity is drawn that in the case of an elongated E cell with long free walls (

= 13 mm), the impregnation weakens the core’s ability to absorb energy in the

X-axis direction and increases this ability in the Y direction.

F-cell beams also show marked differences in the amount of energy absorbed due to the impregnation of the paper (

Figure 15). The highest amount of absorbed energy is shown by FSH25XD beams with H25 facing, impregnated, in dry conditions D, and for the orthotropy direction X (2822 mJ). A much smaller amount of absorbed energy is achieved by FNH25XD beams with H25 facing, not impregnated, in dry conditions D, and for the same direction of orthotropy (2475 mJ). In dry conditions D, impregnation with starch improves the amount of absorbed energy for beams with P30, H25, H20 facings, for the X orthotropy direction, about non-impregnated beams by 15.7%, 12.3%, 33.7%, respectively, and in tropical conditions by W, respectively, by 18.3%, 5.4%, and 19.3%. Beams with the same facing P30, H25, and H20, in dry conditions D, and for the orthotropy Y direction, show a reduction in the amount of absorbed energy by 14.3%, –26.0%, and −4.9%, respectively, and in tropical conditions W, a lower amount of absorbed energy by 20.2%, −1.7% and 6.2%, respectively. There were also clear differences in the energy absorbed for the beams in the X and Y orthotropy directions: 65.8% concerning the amount of energy absorbed in the Y direction, and tropical conditions by 60.9%, 24.2%, and 48.2%, respectively. The relationships are also similar for non-impregnated beams. When using P30, H25, and H20 facing, in dry conditions D, the amount of absorbed energy for the beams in the X orthotropy direction is, respectively, 44.7%, 61.2%, and 50.9% greater than the amount of energy absorbed in the Y direction, and in tropical conditions W, by 42.4%, 21.2% and 31.8%, respectively. Therefore, it can be concluded that in this case, impregnation’s effect on the amount of absorbed energy is visible for beams with F-cells. The changes result both from the use of starch as an impregnating agent and also from the slender shape of the cells with short free walls (

= 6.3 mm). The impregnation increases the amount of absorbed energy, especially in the direction of the

X-axis. On the other hand, in the direction of the

Y-axis, the impregnation of the paper tended to reduce the amount of absorbed energy.

The observations listed above are generally consistent with the current state of knowledge. For example, Pohl [

11] showed in his work that an adequately selected impregnating agent increases the strength (

) and stiffness (

) of light boards with a paper core. On the other hand, the climatic conditions with high air humidity have been repeatedly quoted in the literature [

53,

54,

58] as having a destructive effect on the mechanical properties of furniture boards. Furthermore, the influence of the geometry, wall thickness, and the orientation of the core cells on the stiffness and strength of lightweight three-layer panels is also known as meaningful [

42,

68,

78].

3.4. Statistical Analysis

In order to determine the influence of impregnation and other variable factors on the mechanical properties of the modeled furniture panels, a statistical analysis was performed using the Statistica 13.3 program (StatSoft Polska Sp. z oo, Kraków, Poland).

The statistical model included five factors (starch impregnation, cell type (C, E, F), facing type (H20, H25, P30), climate condition (D, W), orthotropy direction (X, Y)) and three features (

,

and

). Because panels with a paper honeycomb core are characterized by strong orthotropy manifested by significant differences in

,

and

values for the X and Y directions, the data for statistical analysis was divided into two groups. The first group consisted of factors (starch impregnation, cell type, facing type, and climate condition) and three features (

,

and

) for the direction of X orthotropy as well as appropriate factors and features for the direction of Y orthotropy. On this basis, an analysis of the correlation of the analyzed features in individual experiments was prepared. The correlation coefficients presented in

Table 4 show that the features (

,

and

) for the X and Y orthotropy directions, respectively, are strongly correlated with each other. Because all the determined correlation coefficients (

) are statistically significant (

p < 0.05), it was concluded that the further application of the multiple features model to assess the significance of the influence of individual factors on these features could be burdened with some “redundancy”. In this situation, it was justified to use a transformation that would allow us to analyze the influence of all factors differentiating the experiment’s results on all features simultaneously but avoiding their mutual strong linear correlation. For this purpose, principal components analysis was used [

79,

80], in which three features of

,

and

were transformed into three principal components (1), (2), (3), which are their linear combinations (

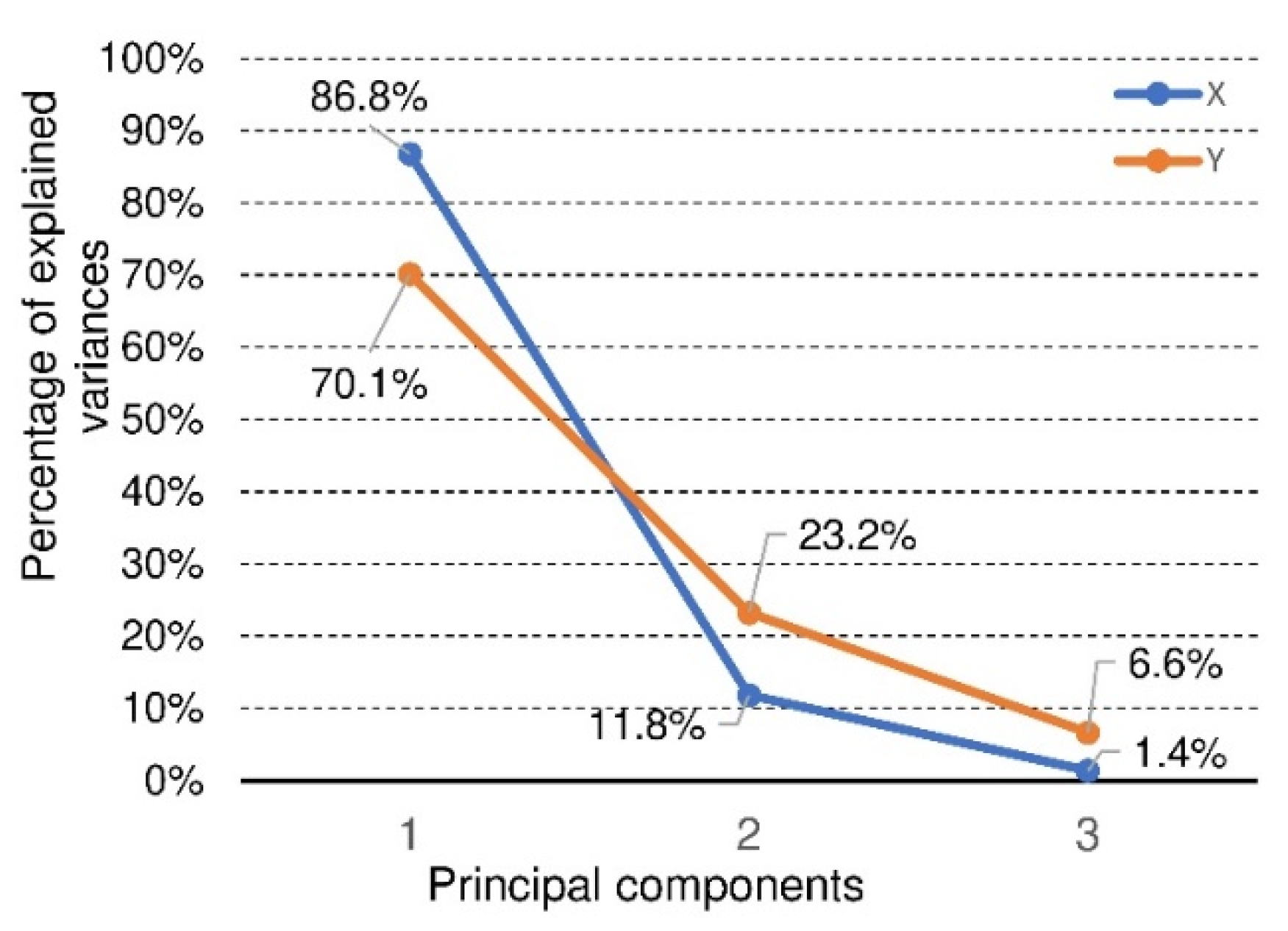

Figure 16).

Figure 16 shows that for further analysis of the significance of the influence of selected factors on three features (

,

and

) for the direction of X orthotropy, only the first principal component (1) should be left because it explains about 87% of the entire variability in the model. Moreover, in the first component (1), the individual features (

,

and

) are proportionally represented. In the case of the features from the experiment for the direction of the Y orthotropy, the first two principal components (1), (2) should be taken into account because together they explain more than 93% of the entire variability of the model. The contribution of individual features to the main components is presented in

Table 5. It is worth noting that in the experiment for the direction of the Y orthotropy in the second principal component (2), the feature

plays a fundamental role.

Taking into account the above considerations, the tests of the hypotheses about the significance of differences in mean values for the first principal component (1) in the experiment for the direction of orthotropy X (one-way and multivariate ANOVA) and the significance of differences in mean values for the first and second principal components (1), (2) were started, in the experiment for the direction of orthotropy Y (univariate MANOVA).

Table 6 shows that the influence of individual factors on the selected main components (1) and (1), (2) for the directions of orthotropy X and Y, respectively, is statistically significant (

p < 0.05). The HSD Tukey test was performed on this basis, which indicated statistically significant differences in the results for selected variable factors (

Table 7 and

Table 8).

Table 7 shows that similar mean values of the principal component (1) are obtained for the X orthotropy direction. Therefore,

is obtained for E and C cells, and statistically different for an F cell. These differences are clearly visible when comparing

Figure 6,

Figure 7,

Figure 8,

Figure 9,

Figure 10,

Figure 11,

Figure 12,

Figure 13,

Figure 14 and

Figure 15. For example, the average

value for CSP30XD, ESP30XD, FSP30XD is 4.3 MPa, 5.1 MPa and 11.2 MPa, respectively. Thus, it can be seen that the mean

values for boards with E and C cells are similar, and the differences are statistically insignificant. On the other hand, for the F-type cells, the obtained values are statistically different, which also positively and statistically significantly increases both

and

. At the same time, it can be seen that each type of cell significantly affects the amount of energy

absorbed by the panels.

Further analysis of

Table 7 leads to the following observations. Similar mean values of the principal component (1) were obtained for facing type H25 and P30, and statistically different for facing type H20. As an example, we can give the average

values for CSP30XW, CSH25XW, CSH20XW, which are equal to 2.7 MPa, 2.9 MPa and 2.4 MPa, respectively, and for ESP30XW, ESH25XW, ESH20XW or FSP30XW, FSH25XW, FSH20XW boards, respectively 2.9 MPa, 2.6 MPa, and 2.6 MPa, 7.4 MPa, 7.2 MPa and 6.8 MPa. Thus, it can be seen that the average

values for panels with H25 and P30 facings are similar, and the differences are statistically insignificant. Moreover, these facings have a positive effect on increasing both

and

compared to the H20 type facings because in this case, the average values of the principal component (1) are statistically different and lower. The comparison of

Figure 13,

Figure 14 and

Figure 15 also shows that

for panels with H25 facing has higher values than panels with P30 and H20 facing.

Table 7 also shows a statistically significant difference in the mean values of the principal component (1) obtained for tropical climatic conditions (W). A similar regularity applies to the lack of impregnation of the core cells with starch (Y). Because, in both cases, the differences are clearly visible in

Figure 6,

Figure 7,

Figure 8,

Figure 9,

Figure 10,

Figure 11,

Figure 12,

Figure 13,

Figure 14 and

Figure 15, it can only be concluded that under dry conditions (D), the

values for the cellular plates reach the highest values, similar to the impregnation of paper with starch (S). The beneficial effect of impregnation (S) on the

of the tested boards is visible based on the results of tests in dry (D) and tropical (W) conditions. For example, the average

value for CSP30XD, ESP30XD, FSP30XD boards is 4.3 MPa, 5.1 MPa, and 11.2 MPa, respectively, and for the boards without impregnation (N), CNP30XD, ENP30XD, FNP30XD, respectively, are 4.2 MPa, 6.3 MPa, and 11.0 MPa. On the other hand, the average

value for CSP30XW, ESP30XW, FSP30XW boards is equal to 2.7 MPa, 2.9 MPa, 7.4 MPa, respectively, and for CNP30XW, ENP30XW, FNP30XW boards, 1.8 MPa, 2.5 MPa, and 6.8 MPa, respectively. It can also be seen that the impregnation (Y) of the core cells causes variations in the amount of energy absorbed. Comparison of

Figure 13,

Figure 14 and

Figure 15 shows that

for plates with non-impregnated cells has higher values compared to boards with impregnated cells.

Table 8 shows the statistical significance for the model in a multidirectional classification, therefore taking into account many factors and their interactions. Of course, the values of the first principal component (1) were tested here. It is clear from this table that all factors and their interactions are statistically significant (

p < 0.05).

Table 9 shows that for the direction of the Y orthotropy, different mean values of the principal components (1), (2) were obtained, thus

and the linearly correlated

for the selected cell types. For example, the average

value for CSP30YD, ESP30YD, FSP30YD is 4.6 MPa, 2.1 MPa, and 5.9 MPa, respectively. The

value for the same panels is 1472 MPa, 660 MPa, and 1290 MPa, respectively, and the

value is 1285 mJ, 1959 mJ, and 1031 mJ, respectively. Thus, it can be seen that the average values of

,

,

for the plates are different and statistically significant.

Moreover, the analysis of

Table 9 leads to further observations that similar mean values of component (1) were obtained for facing type H25 and P30 and statistically different for facing type H20. As an example, we can give the average

values for CSP30YW, CSH25YW, CSH20YW which are equal to 3.0 MPa, 2.9 MPa, and 2.5 MPa, respectively, and for ESP30YW, ESH25YW, ESH20YW or FSP30YW, FSH25YW, FSH20YW boards, respectively, 1.5 MPa, 1.1 MPa, 1.0 MPa, 3.5 MPa, 4.0 MPa and 2.8 MPa. Different mean values of the component (2) were obtained for the same facings. For example, for the CSP30YW, CSH25YW, CSH20YW, the

is 907 MPa, 1026 MPa, and 828 MPa, respectively, and for the ESP30YW, ESH25YW, ESH20YW or FSP30YW, FSH25YW, FSH20YW plates, it is 349 MPa, 242 MPa, 221 MPa, 626 MPa, 646 MPa, and 542 MPa, respectively. Thus, it can be seen that the average

values for panels with H25 and P30 facings are similar, and the differences are statistically insignificant. In addition, these facings have a positive effect on increasing both

and

compared to H20 facings. The comparison of

Figure 13 and

Figure 14 also shows that

for panels with P30 facing has higher values than panels with H25 and H20 facings.

Table 9 also shows a statistically significant difference in the mean values of the main component (1) obtained for dry climatic conditions (D). A similar pattern applies to the impregnation of core cells with starch (Y). Because, in both cases, the differences are clearly visible in

Figure 6,

Figure 7,

Figure 8,

Figure 9,

Figure 10,

Figure 11,

Figure 12,

Figure 13,

Figure 14 and

Figure 15, it can only be concluded that under dry conditions (D), the

and

values for the honeycomb boards reach the highest values, similar to the impregnation of paper with starch (S). The beneficial effect of impregnation (S) on the

and

of the tested boards is visible on the basis of the results of tests in dry (D) and tropical (W) conditions. For example, the average

value for the CSP30YD, ESP30YD, FSP30YD boards is 4.6 MPa, 2.1 MPa and 5.9 MPa, respectively, and for the boards without impregnation (N), CNP30YD, ENP30YD, FNP30YD, respectively, are 3.2 MPa, 2.0 MPa, and 5.5 MPa. On the other hand, the average

value for the CSP30YW, ESP30YW, FSPand FSP30YW boards equals 3.0 MPa, 1.5 MPa, and 3.5 MPa, respectively, and for CNP30YW, ENP30YW, FNP30YW boards, respectively, 1.6 MPa, 1.2 MPa and 3.5 MPa. The

value for the same CSP30YW, ESP30YW, FSP30YW and CNP30YW, ENP30YW, FNP30YW panels is equal to 907 MPa, 349 MPa, 626 MPa, 701 MPa, 355 MPa and 776 MPa, respectively. The comparison of

Figure 13 and

Figure 14 also shows that

for panels with cells impregnated with P30 facings has higher values compared to panels with cells not impregnated with starch.

In order to be able to assess the statistical significance of the factor interactions, only the value of the main component was taken into account in the multidirectional analysis (1).

Table 10 shows the statistical significance for the model in the multidirectional classification for the value of only the component (1). It was decided so because, for component (1), we still maintain as much as 70% of the model’s variability (

Figure 16). This table shows that only the interactions of Conditions*Starch, Core*Facing*Conditions, Core*Conditions*Starch, Core*Facing*Conditions*Starch are not statistically significant.