An Overview of Nano Multilayers as Model Systems for Developing Nanoscale Microstructures

Abstract

1. Introduction

2. Materials and Methods

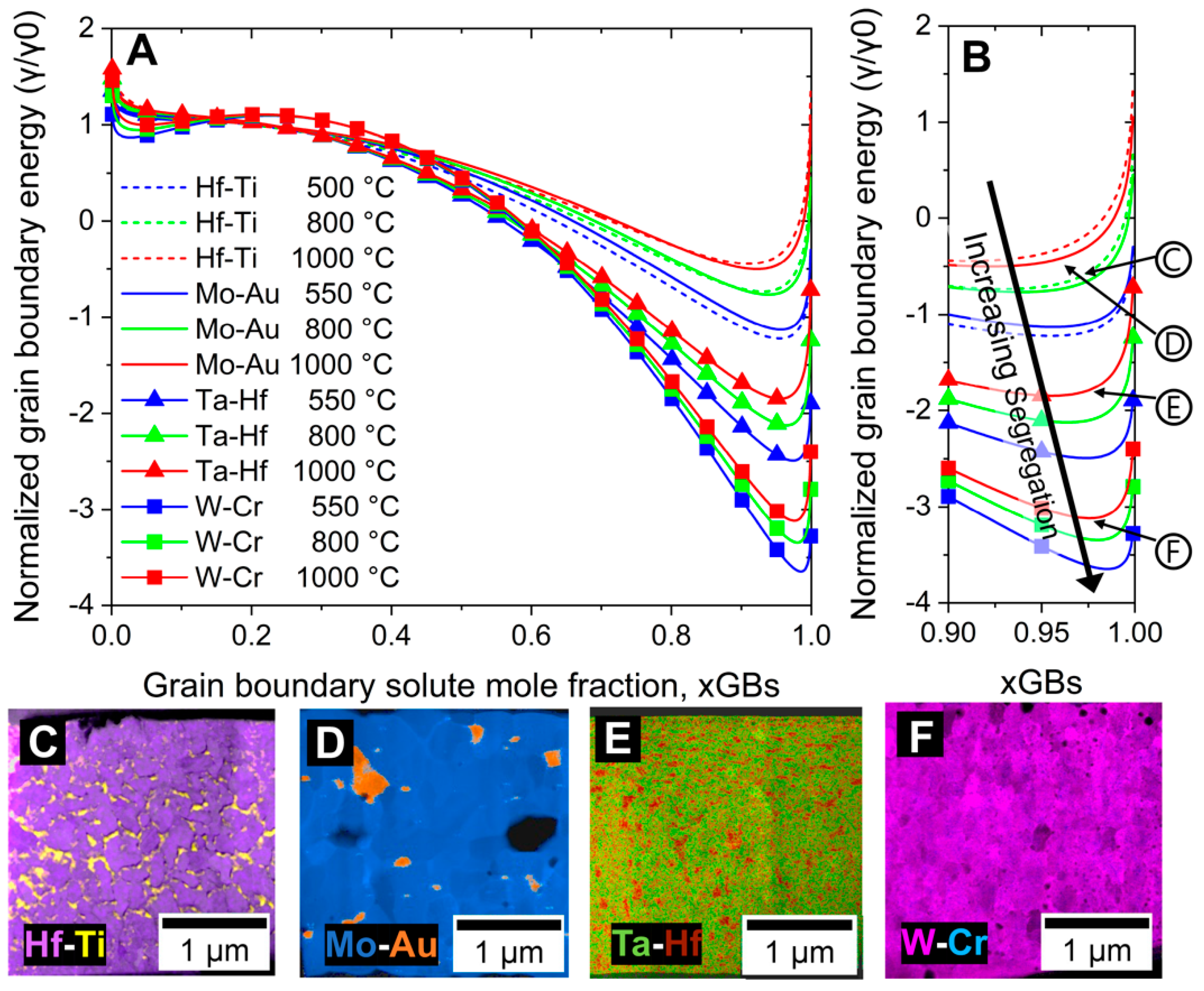

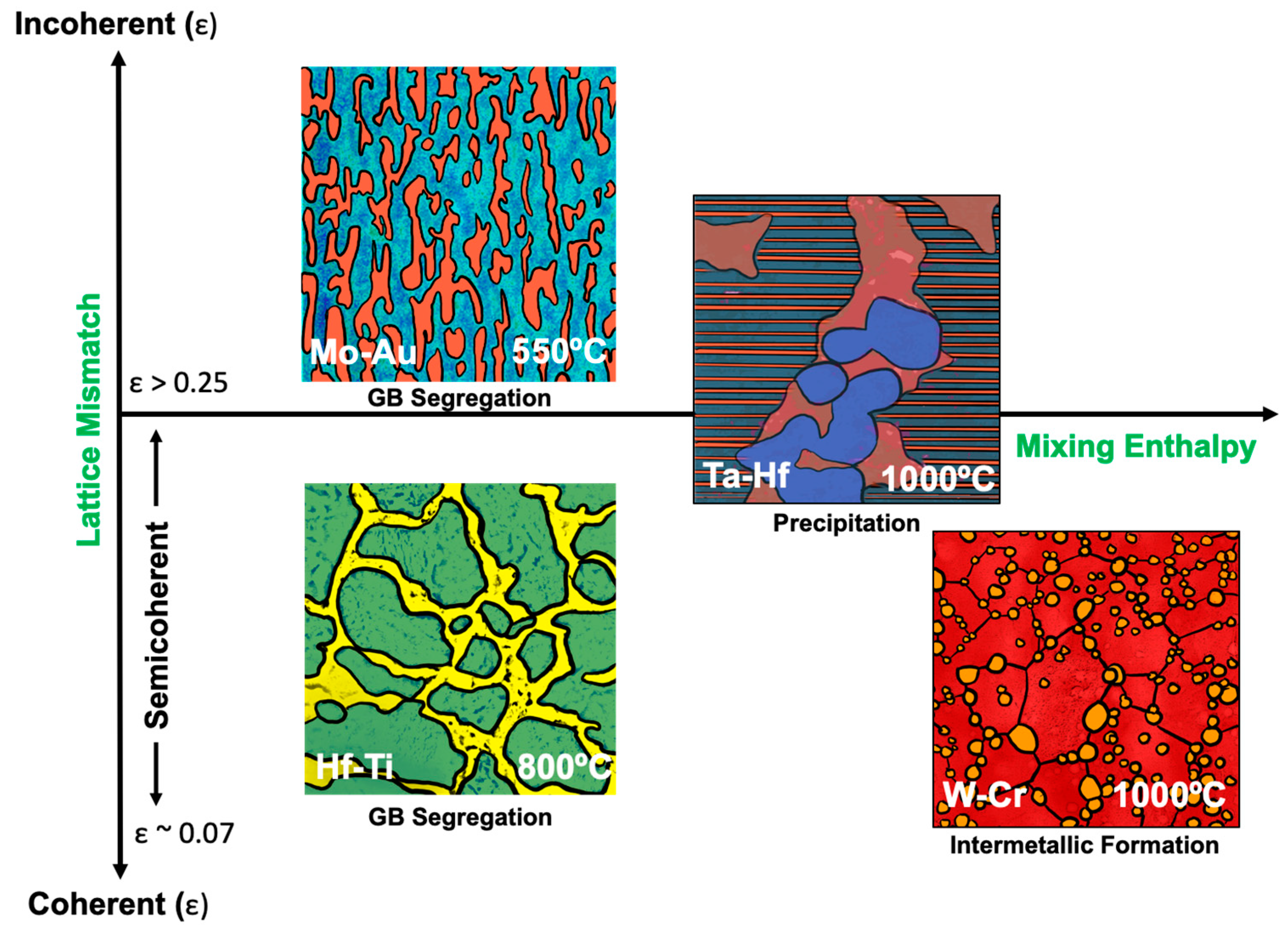

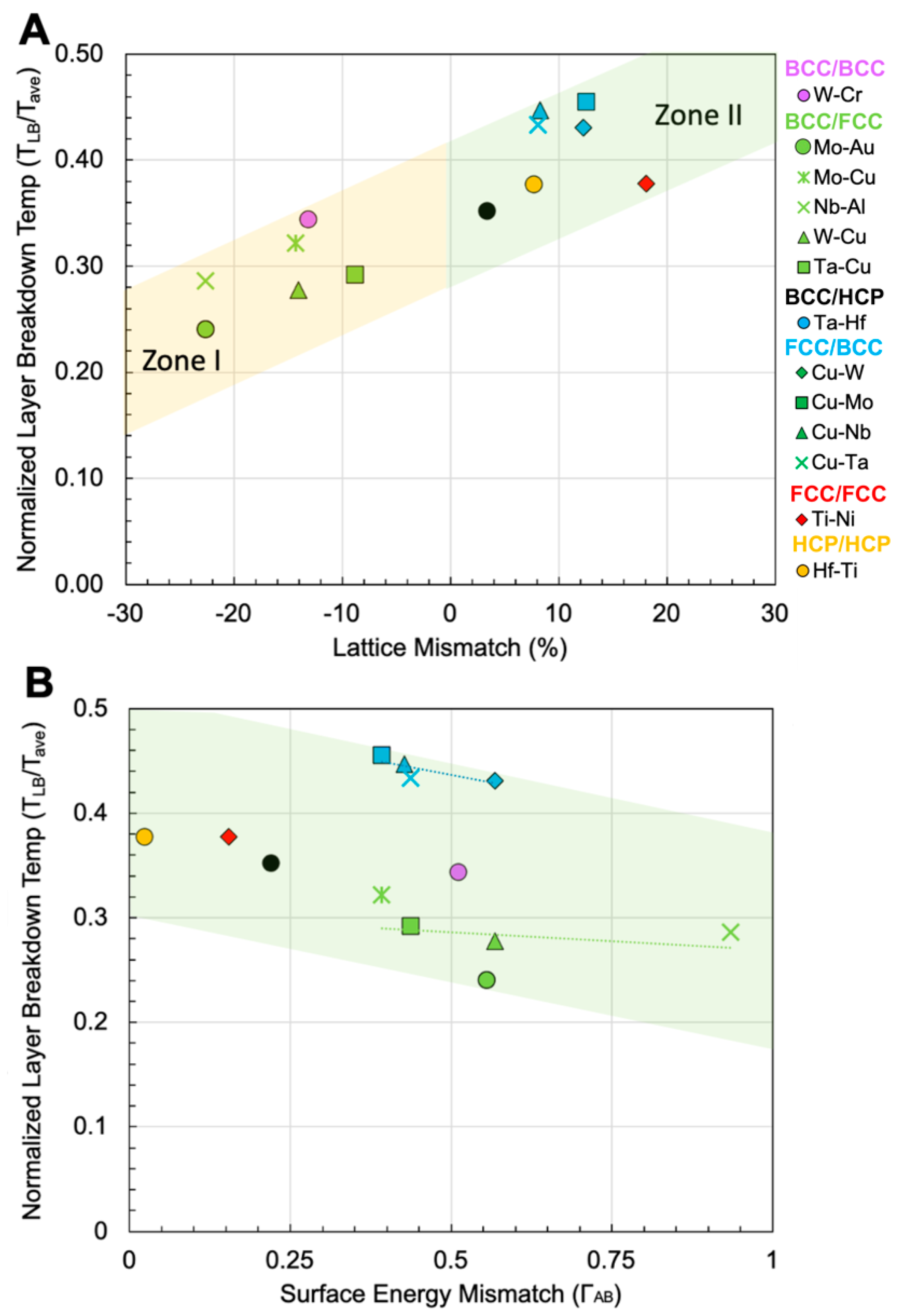

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Misra, A.; Demkowicz, M.J.; Zhang, X.; Hoagland, R.G. The radiation damage tolerance of ultra-high strength nanolayered composites. JOM 2007, 59, 62–65. [Google Scholar] [CrossRef]

- Misra, A.; Hirth, J.P.; Hoagland, R.G. Length-scale-dependent deformation mechanisms in incoherent metallic multilayered composites. Acta Mater. 2005, 53, 4817–4824. [Google Scholar] [CrossRef]

- Gleiter, H. Nanocrystalline materials. In Advanced Structural and Functional Materials; Springer: Berlin/Heidelberg, Germany, 1991; pp. 1–37. [Google Scholar]

- Gleiter, H. Nanostructured materials: Basic concepts and microstructure. Acta Mater. 2000, 48, 1–29. [Google Scholar] [CrossRef]

- Weissmüller, J. Alloy effects in nanostructures. Nanostructured Mater. 1993, 3, 261–272. [Google Scholar] [CrossRef]

- Fecht, H.; Hellstern, E.; Fu, Z.; Johnson, W. Nanocrystalline metals prepared by high-energy ball milling. Metall. Trans. A 1990, 21, 2333–2337. [Google Scholar] [CrossRef]

- Birringer, R. Nanocrystalline materials. Mater. Sci. Eng. A 1989, 117, 33–43. [Google Scholar] [CrossRef]

- Beyerlein, I.J.; Mara, N.A.; Wang, J.; Carpenter, J.S.; Zheng, S.J.; Han, W.Z.; Zhang, R.F.; Kang, K.; Nizolek, T.; Pollock, T.M. Structure-Property-Functionality of Bimetal Interfaces. JOM 2012, 64, 1192–1207. [Google Scholar] [CrossRef]

- Shahabi, H.S.; Manesh, H.D. Micro-structural evaluation of Cu/Nb nano-layered composites produced by repeated press and rolling process. J. Alloy. Compd. 2009, 482, 526–534. [Google Scholar] [CrossRef]

- Holzschuh, H. Deposition of Ti–B–N (single and multilayer) and Zr–B–N coatings by chemical vapor deposition techniques on cutting tools. Thin Solid Film. 2004, 469, 92–98. [Google Scholar] [CrossRef]

- Keller, S.; Heikman, S.; Ben-Yaacov, I.; Shen, L.; DenBaars, S.; Mishra, U. Indium-surfactant-assisted growth of high-mobility AlN/GaN multilayer structures by metalorganic chemical vapor deposition. Appl. Phys. Lett. 2001, 79, 3449–3451. [Google Scholar] [CrossRef]

- Shu, B.P.; Liu, L.; Deng, Y.D.; Zhong, C.; Wu, Y.T.; Shen, B.; Hu, W.B. An investigation of grain boundary diffusion and segregation of Ni in Cu in an electrodeposited Cu/Ni micro-multilayer system. Mater. Lett. 2012, 89, 223–225. [Google Scholar] [CrossRef]

- Ross, C.A. Electrodeposited multilayer thin-films. Annu. Rev. Mater. Sci. 1994, 24, 159–188. [Google Scholar] [CrossRef]

- Vyas, A.; Shen, Y.; Zhou, Z.; Li, K. Nano-structured CrN/CNx multilayer films deposited by magnetron sputtering. Compos. Sci. Technol. 2008, 68, 2922–2929. [Google Scholar] [CrossRef]

- Mara, N.; Sergueeva, A.; Misra, A.; Mukherjee, A. Structure and high-temperature mechanical behavior relationship in nano-scaled multilayered materials. Scr. Mater. 2004, 50, 803–806. [Google Scholar] [CrossRef]

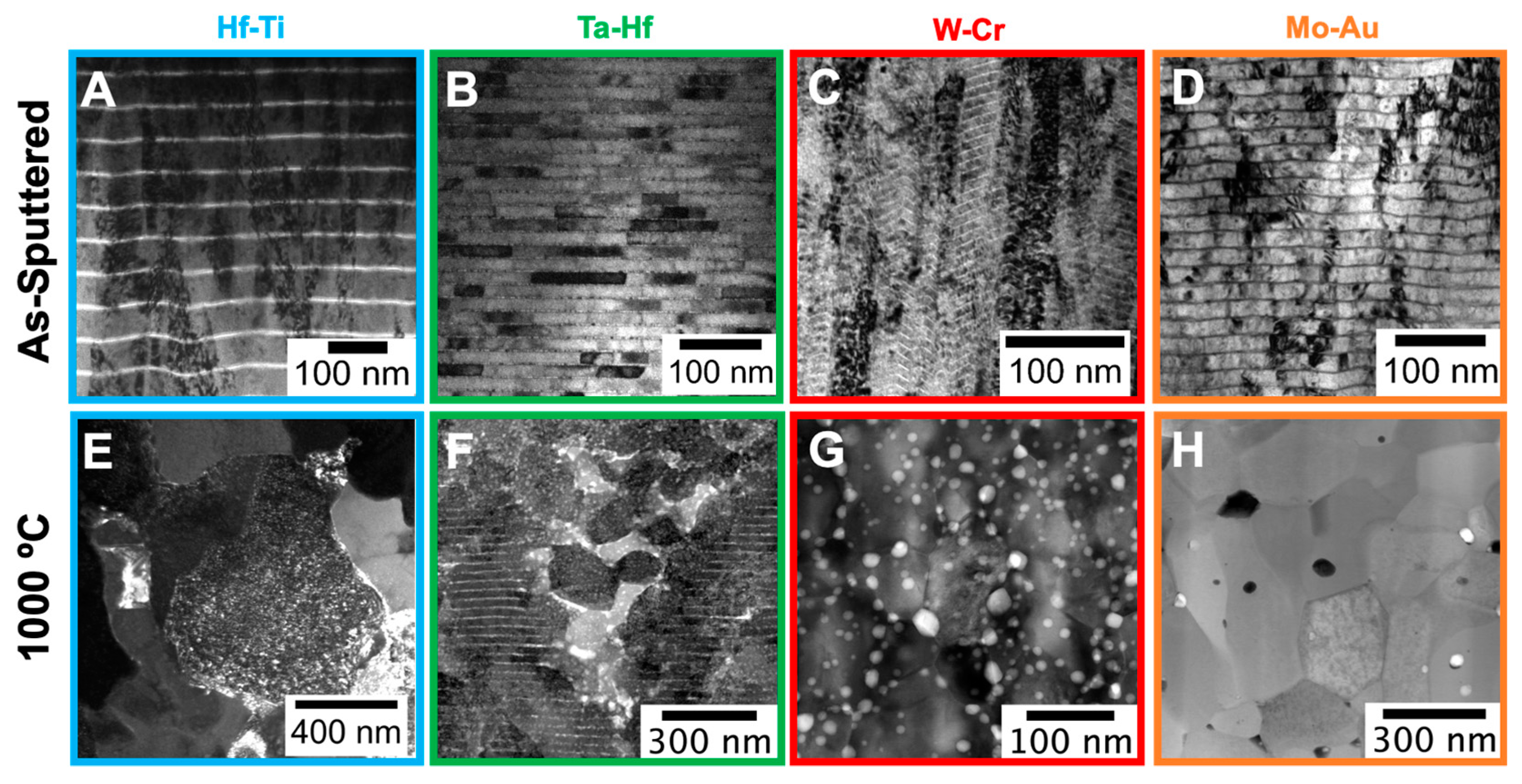

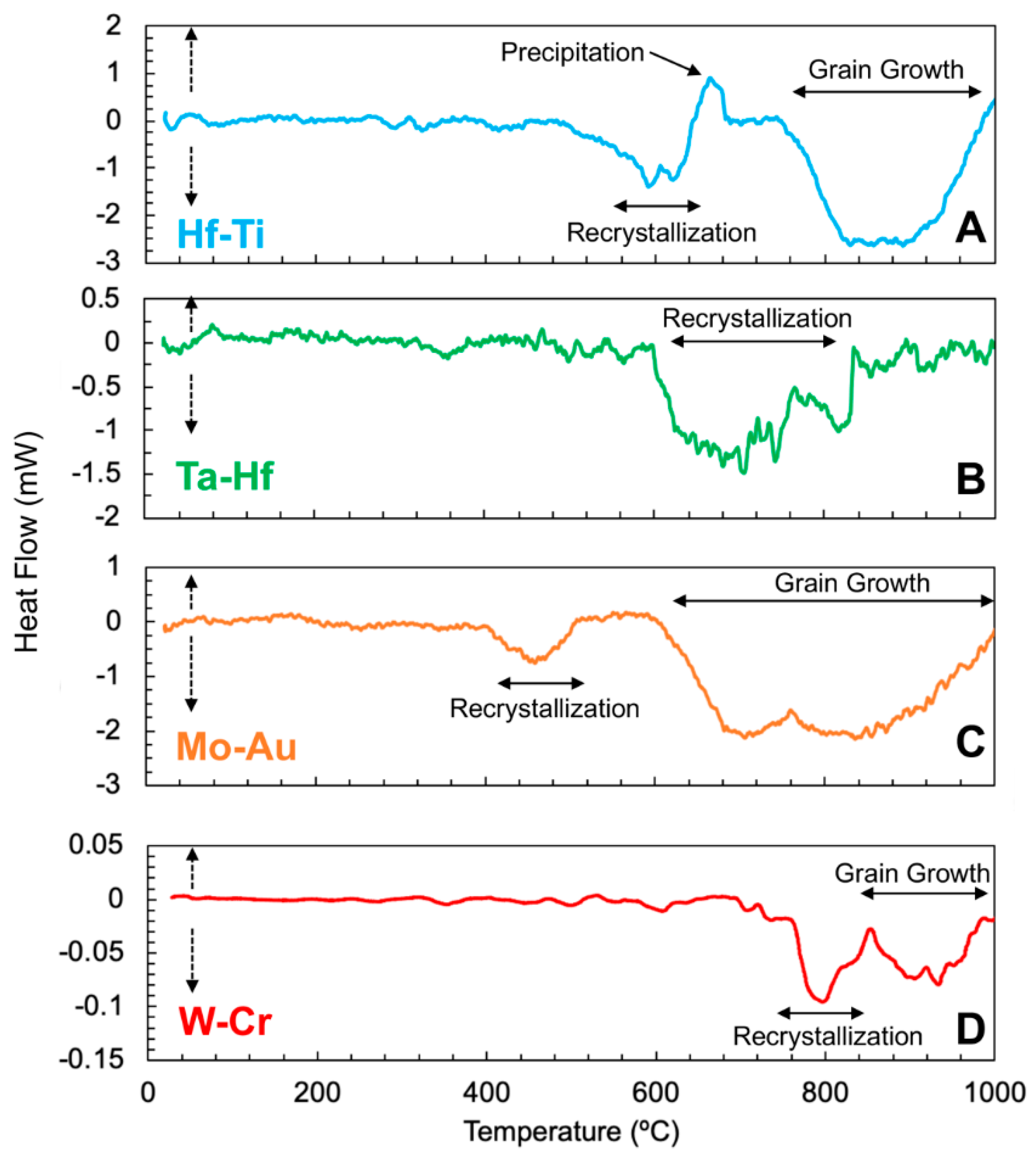

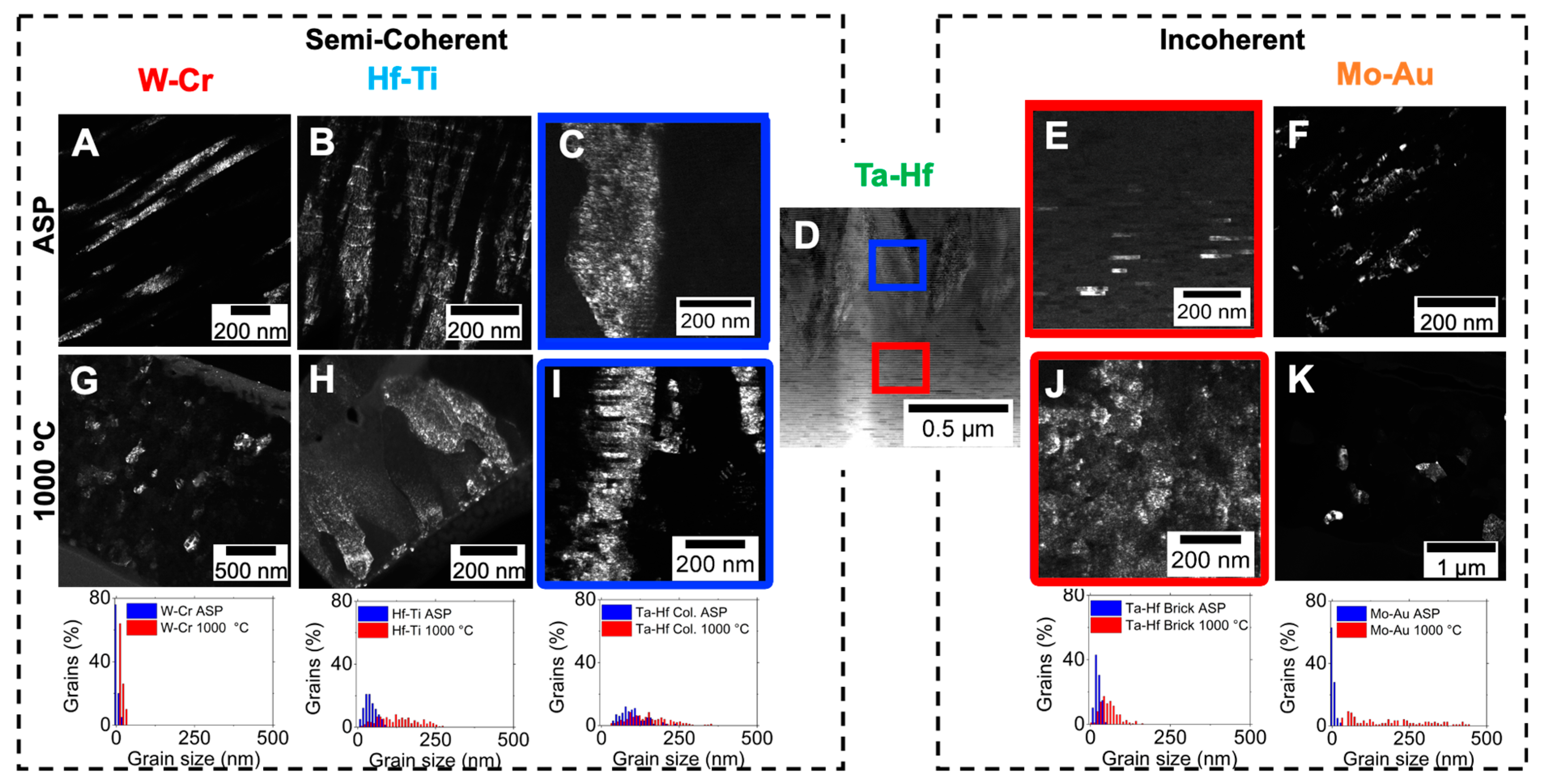

- Polyakov, M.N.; Chookajorn, T.; Mecklenburg, M.; Schuh, C.A.; Hodge, A.M. Sputtered Hf–Ti nanostructures: A segregation and high-temperature stability study. Acta Mater. 2016, 108, 8–16. [Google Scholar] [CrossRef]

- Bahena, J.A.; Riano, J.S.; Chellali, M.R.; Boll, T.; Hodge, A.M. Thermally activated microstructural evolution of sputtered nanostructured Mo–Au. Materialia 2018, 4, 157–165. [Google Scholar] [CrossRef]

- Riano, J.S.; Hodge, A.M. Exploring the microstructural evolution of Hf-Ti: From nanometallic multilayers to nanostructures. Scr. Mater. 2018, 142, 55–60. [Google Scholar] [CrossRef]

- Riano, J.S.; Hodge, A.M. Exploring the thermal stability of a bimodal nanoscale multilayered system. Scr. Mater. 2019, 166, 19–23. [Google Scholar] [CrossRef]

- Riano, J.S.; Hodge, A.M. Phase transformations in the W–Cr system at the nanoscale. Materialia 2018, 2, 190–195. [Google Scholar] [CrossRef]

- Bobeth, M.; Ullrich, A.; Pompe, W. Destratification mechanisms in coherent multilayers. In Journal of Metastable and Nanocrystalline Materials; Trans Tech Publications Ltd.: Freienbach, Switzerland, 2004; p. 153. [Google Scholar]

- Misra, A.; Hoagland, R. Effects of elevated temperature annealing on the structure and hardness of copper/niobium nanolayered films. J. Mater. Res. 2005, 20, 2046–2054. [Google Scholar] [CrossRef]

- Ma, Y.; Wei, M.; Sun, C.; Cao, Z.; Meng, X. Length scale effect on the thermal stability of nanoscale Cu/Ag multilayers. Mater. Sci. Eng. A 2017, 686, 142–149. [Google Scholar] [CrossRef]

- Wan, H.; Shen, Y.; Wang, J.; Shen, Z.; Jin, X. A predictive model for microstructure evolution in metallic multilayers with immiscible constituents. Acta Mater. 2012, 60, 6869–6881. [Google Scholar] [CrossRef]

- Christian, J.W. The Theory of Transformations in Metals and Alloys; Newnes: Oxford, UK, 2002. [Google Scholar]

- Zeng, L.; Gao, R.; Fang, Q.; Wang, X.; Xie, Z.; Miao, S.; Hao, T.; Zhang, T. High strength and thermal stability of bulk Cu/Ta nanolamellar multilayers fabricated by cross accumulative roll bonding. Acta Mater. 2016, 110, 341–351. [Google Scholar] [CrossRef]

- Carpenter, J.; Zheng, S.; Zhang, R.; Vogel, S.; Beyerlein, I.; Mara, N. Thermal stability of Cu–Nb nanolamellar composites fabricated via accumulative roll bonding. Philos. Mag. 2013, 93, 718–735. [Google Scholar] [CrossRef]

- Moszner, F.; Cancellieri, C.; Chiodi, M.; Yoon, S.; Ariosa, D.; Janczak-Rusch, J.; Jeurgens, L. Thermal stability of Cu/W nano-multilayers. Acta Mater. 2016, 107, 345–353. [Google Scholar] [CrossRef]

- Darling, K.A.; Tschopp, M.A.; VanLeeuwen, B.K.; Atwater, M.A.; Liu, Z.K. Mitigating grain growth in binary nanocrystalline alloys through solute selection based on thermodynamic stability maps. Comput. Mater. Sci. 2014, 84, 255–266. [Google Scholar] [CrossRef]

- Murdoch, H.A.; Schuh, C.A. Estimation of grain boundary segregation enthalpy and its role in stable nanocrystalline alloy design. J. Mater. Res. 2013, 28, 2154–2163. [Google Scholar] [CrossRef]

- Murdoch, H.A.; Schuh, C.A. Stability of binary nanocrystalline alloys against grain growth and phase separation. Acta Mater. 2013, 61, 2121–2132. [Google Scholar] [CrossRef]

- Chookajorn, T.; Schuh, C.A. Thermodynamics of stable nanocrystalline alloys: A Monte Carlo analysis. Phys. Rev. B 2014, 89, 064102. [Google Scholar] [CrossRef]

- Chookajorn, T.; Murdoch, H.A.; Schuh, C.A. Design of stable nanocrystalline alloys. Science 2012, 337, 951–954. [Google Scholar] [CrossRef] [PubMed]

- Darling, K.; VanLeeuwen, B.; Koch, C.; Scattergood, R. Thermal stability of nanocrystalline Fe–Zr alloys. Mater. Sci. Eng. A 2010, 527, 3572–3580. [Google Scholar] [CrossRef]

- Klement, U.; Erb, U.; El-Sherik, A.; Aust, K. Thermal stability of nanocrystalline Ni. Mater. Sci. Eng. A 1995, 203, 177–186. [Google Scholar] [CrossRef]

- Peng, H.; Gong, M.; Chen, Y.; Liu, F. Thermal stability of nanocrystalline materials: Thermodynamics and kinetics. Int. Mater. Rev. 2017, 62, 303–333. [Google Scholar] [CrossRef]

- Clark, B.G.; Hattar, K.; Marshall, M.T.; Chookajorn, T.; Boyce, B.L.; Schuh, C.A. Thermal stability comparison of nanocrystalline Fe-based binary alloy pairs. Jom 2016, 68, 1625–1633. [Google Scholar] [CrossRef]

- Humphreys, F.J.; Hatherly, M. Recrystallization and Related Annealing Phenomena; Elsevier: Amsterdam, The Netherlands, 2012. [Google Scholar]

- Kaur, I.; Mishin, Y.; Gust, W. Fundamentals of Grain and Interphase Boundary Diffusion; John Wiley: Hoboken, NJ, USA, 1995. [Google Scholar]

- Howe, J.M.; Howe, J.M. Interfaces in Materials: Atomic Structure, Thermodynamics and Kinetics of Solid-Vapor, Solid-Liquid and Solid-Solid Interfaces; Wiley-Interscience: Hoboken, NJ, USA, 1997. [Google Scholar]

- Bauer, E.; van der Merwe, J.H. Structure and growth of crystalline superlattices: From monolayer to superlattice. Phys. Rev. B 1986, 33, 3657. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Q.; Xie, J.; Wang, F.; Huang, P.; Xu, K.; Lu, T. The mechanical behavior of nanoscale metallic multilayers: A survey. Acta Mech. Sin. 2015, 31, 319–337. [Google Scholar] [CrossRef]

- Cardarelli, F. Materials Handbook: A Concise Desktop Reference; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2008. [Google Scholar]

- Vitos, L.; Ruban, A.; Skriver, H.L.; Kollár, J. The surface energy of metals. Surf. Sci. 1998, 411, 186–202. [Google Scholar] [CrossRef]

- Wynblatt, P.; Ku, R.C. Surface energy and solute strain energy effects in surface segregation. Surf. Sci. 1977, 65, 511–531. [Google Scholar] [CrossRef]

- Wynblatt, P.; Chatain, D. Anisotropy of segregation at grain boundaries and surfaces. Metall. Mater. Trans. A 2006, 37, 2595–2620. [Google Scholar] [CrossRef]

- Matson, T.P.; Schuh, C.A. Atomistic assessment of solute-solute interactions during grain boundary segregation. Nanomaterials 2021, 11, 2360. [Google Scholar] [CrossRef]

- Wagih, M.; Schuh, C.A. Spectrum of grain boundary segregation energies in a polycrystal. Acta Mater. 2019, 181, 228–237. [Google Scholar] [CrossRef]

- Abdeljawad, F.; Lu, P.; Argibay, N.; Clark, B.G.; Boyce, B.L.; Foiles, S.M. Grain boundary segregation in immiscible nanocrystalline alloys. Acta Mater. 2017, 126, 528–539. [Google Scholar] [CrossRef]

- Naidu, S.N.; Sriramamurthy, A.; Rao, P.R. The Cr−W (Chromium−Tungsten) system. Bull. Alloy. Phase Diagr. 1984, 5, 289–292. [Google Scholar] [CrossRef]

- Zhang, L.; Gao, R.; Hou, J.; Zhao, B.; Sun, M.; Hao, T.; Xie, Z.; Liu, R.; Wang, X.; Fang, Q. Study on thermal stability and irradiation response of copper/iron nano-multilayer composite fabricated by cross accumulative roll bonding. J. Nucl. Mater. 2021, 543, 152548. [Google Scholar] [CrossRef]

- Druzhinin, A.; Ariosa, D.; Siol, S.; Ott, N.; Straumal, B.; Janczak-Rusch, J.; Jeurgens, L.; Cancellieri, C. Effect of the individual layer thickness on the transformation of Cu/W nano-multilayers into nanocomposites. Materialia 2019, 7, 100400. [Google Scholar] [CrossRef]

- Cancellieri, C.; Moszner, F.; Chiodi, M.; Yoon, S.; Janczak-Rusch, J.; Jeurgens, L. The effect of thermal treatment on the stress state and evolving microstructure of Cu/W nano-multilayers. J. App. Phys. 2016, 120, 195107. [Google Scholar] [CrossRef]

- Bhattacharya, P.; Ishihara, K.; Chattopadhyay, K. FeAl multilayers by sputtering: Heat treatment and the phase evolution. Mater. Sci. Eng. A 2001, 304, 250–254. [Google Scholar] [CrossRef]

- Cho, H.; Kim, H.; Miyazaki, S. Alloying process of sputter-deposited Ti/Ni multilayer thin films. Mater. Sci. Eng. A 2006, 438, 699–702. [Google Scholar] [CrossRef]

- Ramos, A.; Cavaleiro, A.; Vieira, M.; Morgiel, J.; Safran, G. Thermal stability of nanoscale metallic multilayers. Thin Solid Film. 2014, 571, 268–274. [Google Scholar] [CrossRef]

- Ramos, A.; Vieira, M.; Morgiel, J.; Grzonka, J.; Simões, S.; Vieira, M. Production of intermetallic compounds from Ti/Al and Ni/Al multilayer thin films—A comparative study. J. Alloys Compd. 2009, 484, 335–340. [Google Scholar] [CrossRef]

- Cavaleiro, A.; Santos, R.; Ramos, A.; Vieira, M. In-situ thermal evolution of Ni/Ti multilayer thin films. Intermetallics 2014, 51, 11–17. [Google Scholar] [CrossRef]

- Seifert, M.; Lattner, E.; Menzel, S.B.; Oswald, S.; Gemming, T. Phase formation and high-temperature stability of very thin co-sputtered Ti-Al and multilayered Ti/Al films on thermally oxidized si substrates. Materials 2020, 13, 2039. [Google Scholar] [CrossRef]

- Misra, A.; Hoagland, R.; Kung, H. Thermal stability of self-supported nanolayered Cu/Nb films. Philos. Mag. 2004, 84, 1021–1028. [Google Scholar] [CrossRef]

- Lewis, A.; Josell, D.; Weihs, T.P. Stability in thin film multilayers and microlaminates: The role of free energy, structure, and orientation at interfaces and grain boundaries. Scr. Mater. 2003, 48, 1079–1085. [Google Scholar] [CrossRef]

- Knoedler, H.L.; Lucas, G.; Levi, C. Morphological stability of copper-silver multilayer thin films at elevated temperatures. Metall. Mater. Trans. A 2003, 34, 1043–1054. [Google Scholar] [CrossRef]

- Srinivasan, D.; Sanyal, S.; Corderman, R.; Subramanian, P. Thermally stable nanomultilayer films of Cu/Mo. Metall. Mater. Trans. A 2006, 37, 995–1003. [Google Scholar] [CrossRef]

- Shewmon, P. Diffusion in Solids; Springer: Berlin/Heidelberg, Germany, 2016. [Google Scholar]

- Shi, J.; Cao, Z.; Liu, Y.; Zhao, Z. Size dependent alloying and plastic deformation behaviors of Ti/Ni nano-multilayers. J. Alloys Compd. 2017, 727, 691–695. [Google Scholar] [CrossRef]

- Im, Y.; Johnson, P.; McKnelly, L., Jr.; Morris, J., Jr. Nb3Al formation in sputter-deposited Nb/Al multilayer samples. J. Less Common Met. 1988, 139, 87–95. [Google Scholar] [CrossRef][Green Version]

- Troche, P.; Hoffmann, J.; Heinemann, K.; Hartung, F.; Schmitz, G.; Freyhardt, H.C.; Rudolph, D.; Thieme, J.; Guttmann, P. Thermally driven shape instabilities of Nb/Cu multilayer structures: Instability of Nb/Cu multilayers. Thin Solid Film. 1999, 353, 33–39. [Google Scholar] [CrossRef]

- Zhang, Y.; Fu, L.; Zhu, J.; Yang, W.; Li, D.; Zhou, L. Thermal stability of co-sputtered TaCu amorphous nano-multilayers. Thin Solid Film. 2021, 732, 138766. [Google Scholar] [CrossRef]

- Lee, H.-J.; Kwon, K.-W.; Ryu, C.; Sinclair, R. Thermal stability of a Cu/Ta multilayer: An intriguing interfacial reaction. Acta Mater. 1999, 47, 3965–3975. [Google Scholar] [CrossRef]

- Massalski, T.; Laughlin, D.; Soffa, W. The nature and role of incoherent interphase interfaces in diffusional solid-solid phase transformations. Metall. Mater. Trans. A 2006, 37, 825–831. [Google Scholar] [CrossRef]

- Porter, D.A.; Easterling, K.E. Phase Transformations in Metals and Alloys (Revised Reprint); CRC Press: Boca Raton, FL, USA, 2009. [Google Scholar]

- Donaldson, O.K.; Hattar, K.; Kaub, T.; Thompson, G.B.; Trelewicz, J.R. Solute stabilization of nanocrystalline tungsten against abnormal grain growth. J. Mater. Res. 2018, 33, 68–80. [Google Scholar] [CrossRef]

- Balbus, G.H.; Kappacher, J.; Sprouster, D.J.; Wang, F.; Shin, J.; Eggeler, Y.M.; Rupert, T.J.; Trelewicz, J.R.; Kiener, D.; Maier-Kiener, V. Disordered interfaces enable high temperature thermal stability and strength in a nanocrystalline aluminum alloy. Acta Mater. 2021, 215, 116973. [Google Scholar] [CrossRef]

- Lu, P.; Abdeljawad, F.; Rodriguez, M.; Chandross, M.; Adams, D.; Boyce, B.; Clark, B.; Argibay, N. On the thermal stability and grain boundary segregation in nanocrystalline PtAu alloys. Materialia 2019, 6, 100298. [Google Scholar] [CrossRef]

| Alloy System | Global Composition | Alloy Layer Composition | Layer Thicknesses | Total Film Thickness (µm) | Layers |

|---|---|---|---|---|---|

| Hf-Ti | 20.1 at.% Ti | 9.7 at.% Ti | 40 bilayers: 5.3 nm Ti/48.1 nm Hf-Ti | 2.1 | hcp/hcp |

| Ta-Hf | 22.4 at.% Hf | 14.6 at.% Hf | 127 bilayers: 1.7 nm Hf/14.0 nm Ta-Hf | 2.0 | bcc/hcp |

| W-Cr | 33.1 at.% Cr | 12.4 at.% Cr | 247 bilayers: 1.5 nm Cr/6.3 nm W-Cr | 2.0 | bcc/bcc |

| Mo-Au | 21.3 at.% Au | 11.0 at.% Au | 107 bilayers: 2.5 nm Au/17.3 nm Mo-Au | 2.0 | bcc/fcc |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Appleget, C.D.; Riano, J.S.; Hodge, A.M. An Overview of Nano Multilayers as Model Systems for Developing Nanoscale Microstructures. Materials 2022, 15, 382. https://doi.org/10.3390/ma15010382

Appleget CD, Riano JS, Hodge AM. An Overview of Nano Multilayers as Model Systems for Developing Nanoscale Microstructures. Materials. 2022; 15(1):382. https://doi.org/10.3390/ma15010382

Chicago/Turabian StyleAppleget, Chelsea D., Juan Sebastian Riano, and Andrea M. Hodge. 2022. "An Overview of Nano Multilayers as Model Systems for Developing Nanoscale Microstructures" Materials 15, no. 1: 382. https://doi.org/10.3390/ma15010382

APA StyleAppleget, C. D., Riano, J. S., & Hodge, A. M. (2022). An Overview of Nano Multilayers as Model Systems for Developing Nanoscale Microstructures. Materials, 15(1), 382. https://doi.org/10.3390/ma15010382