Durability of Mortars with Fly Ash Subject to Freezing and Thawing Cycles and Sulfate Attack

Abstract

:1. Introduction

2. Research Scope

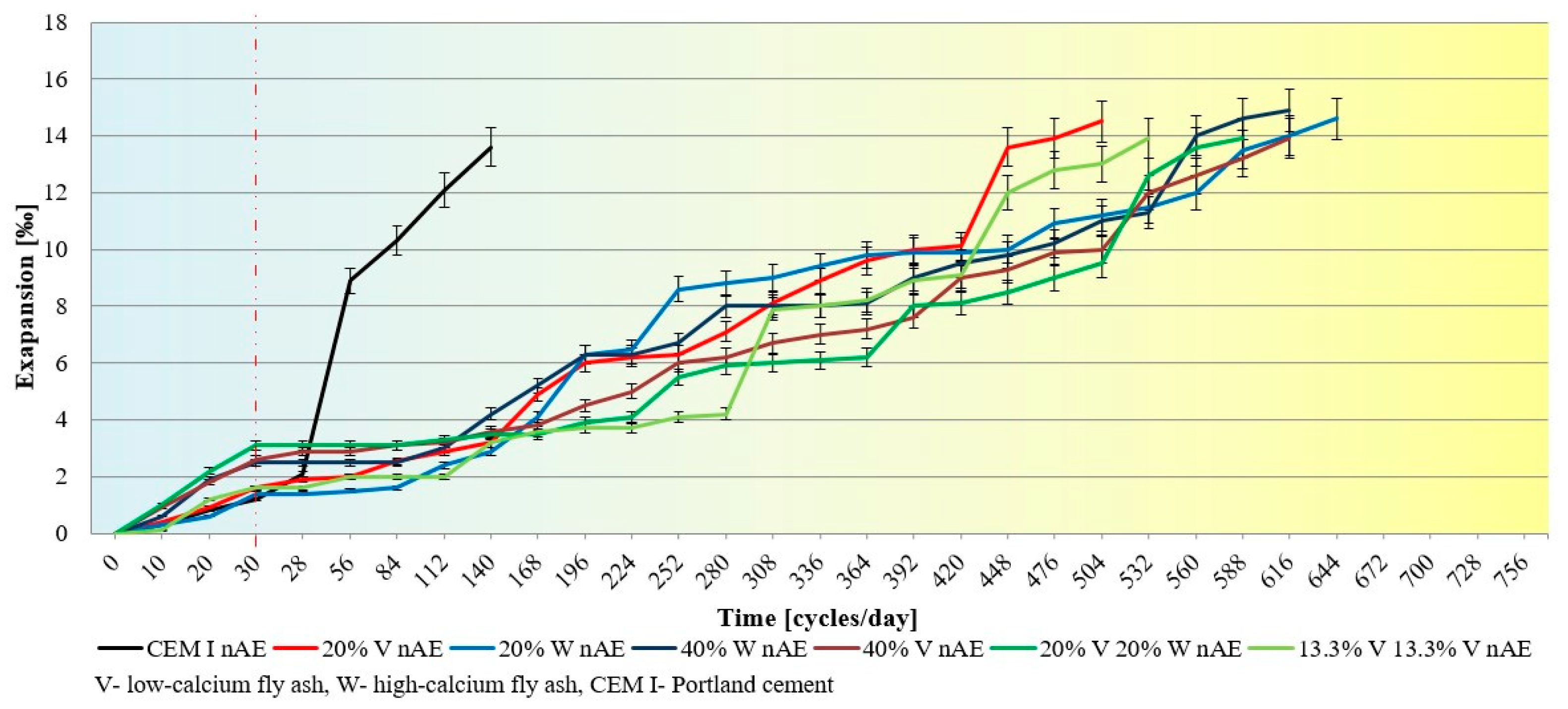

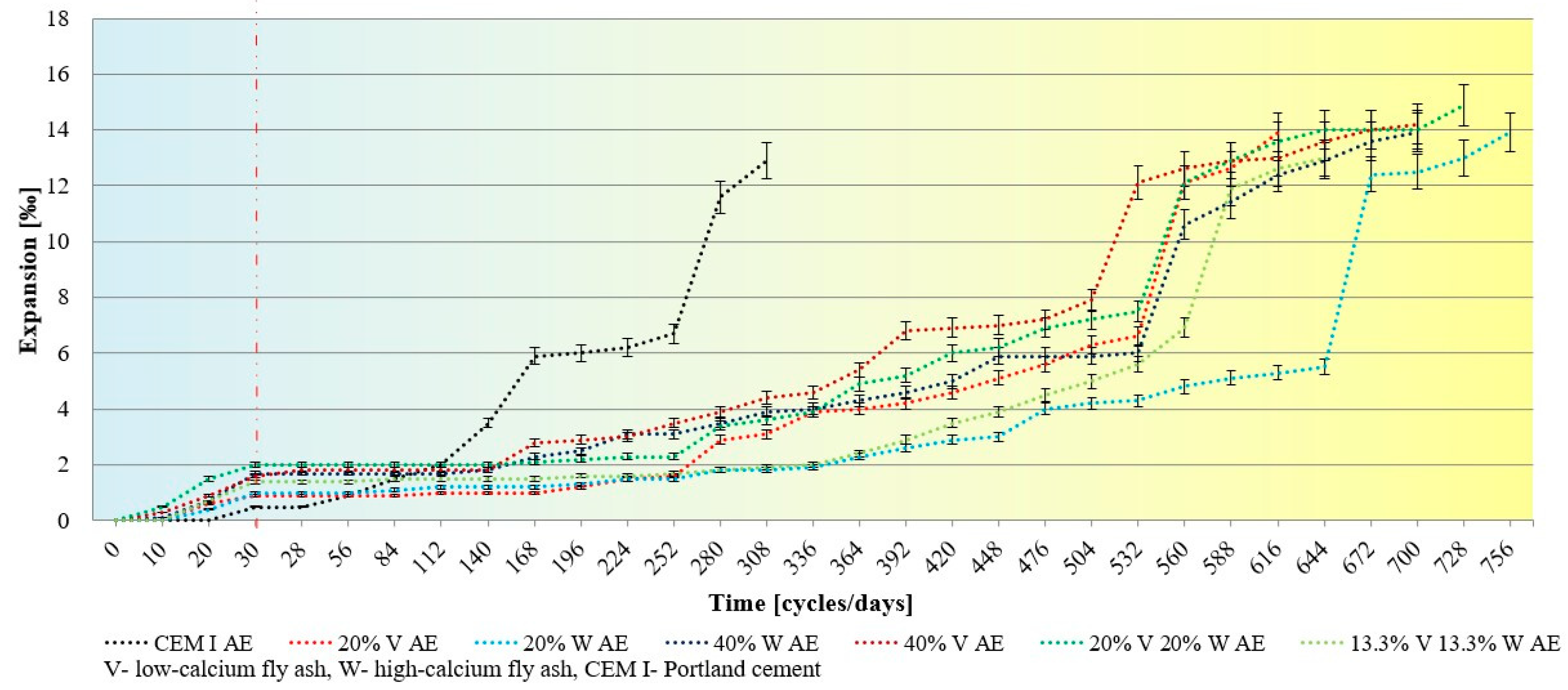

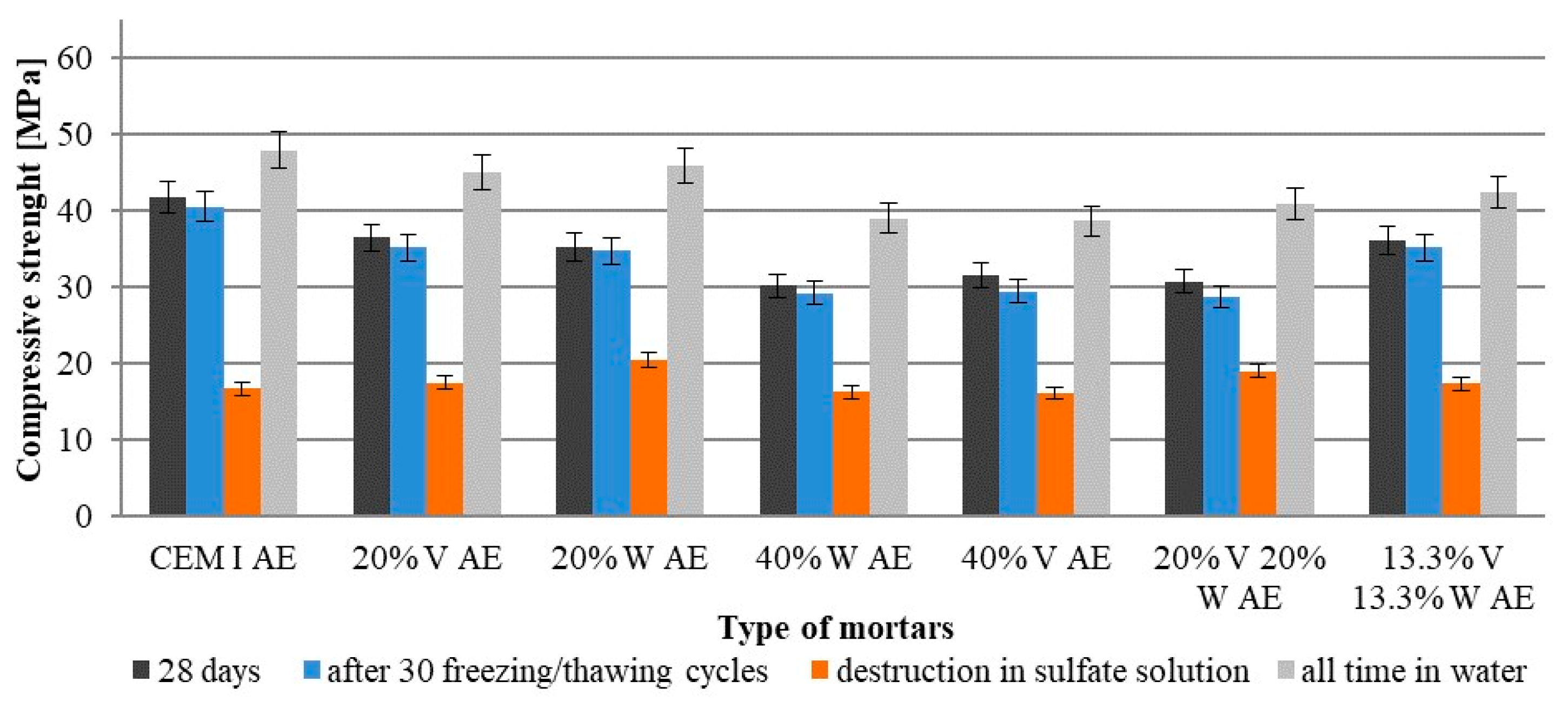

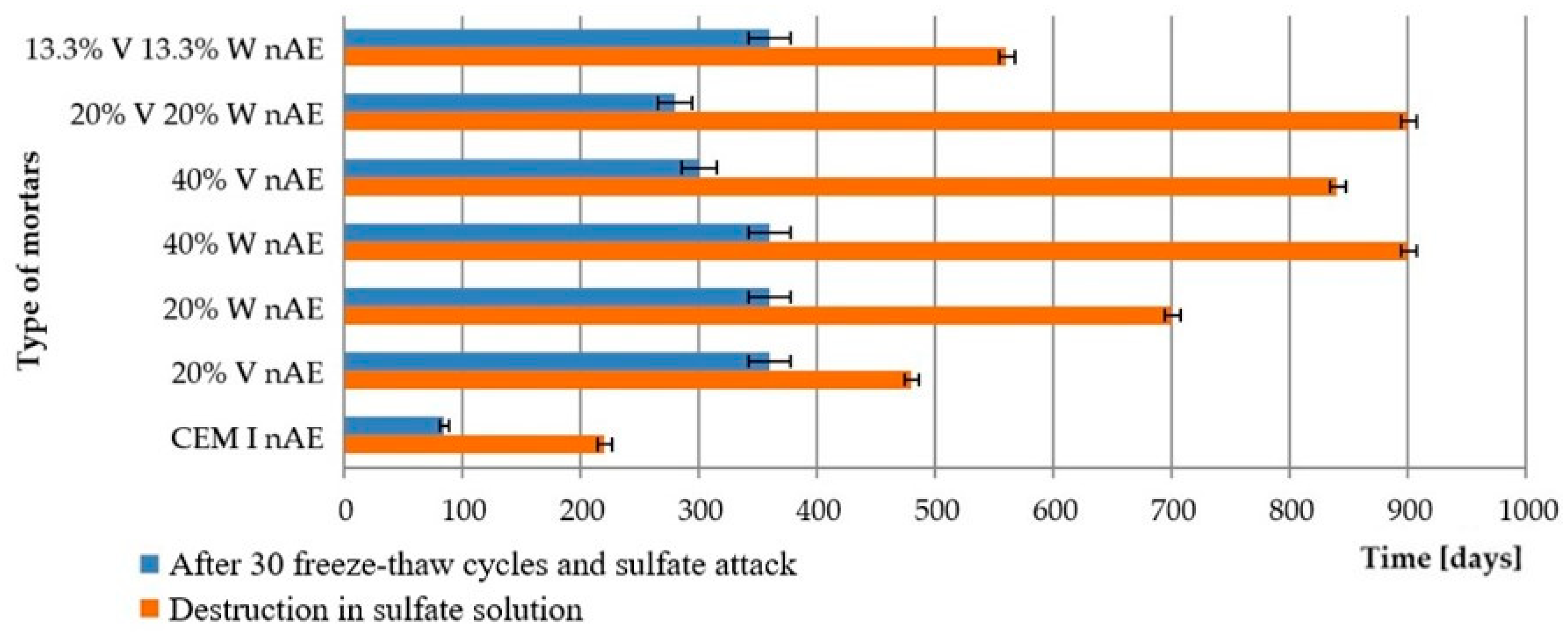

3. Materials and Methods

3.1. Portland Cement

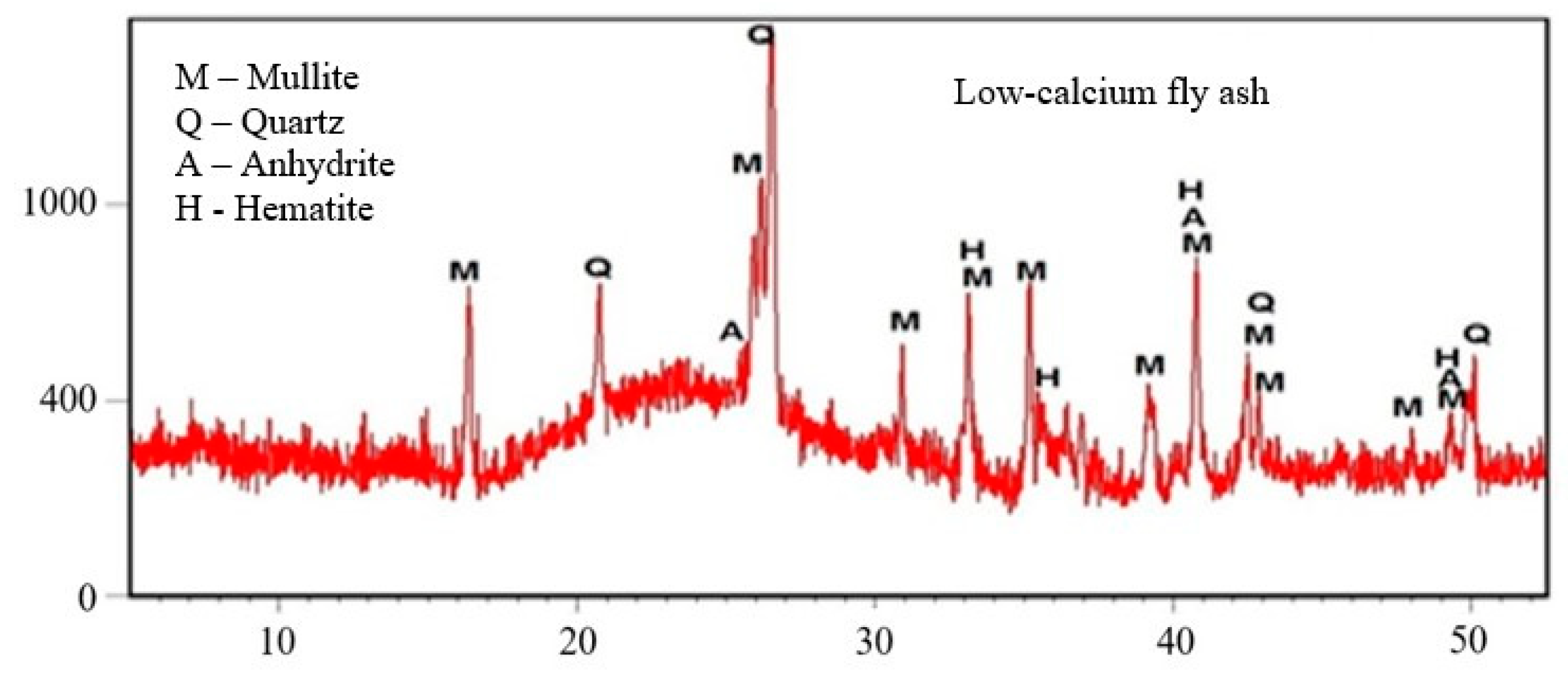

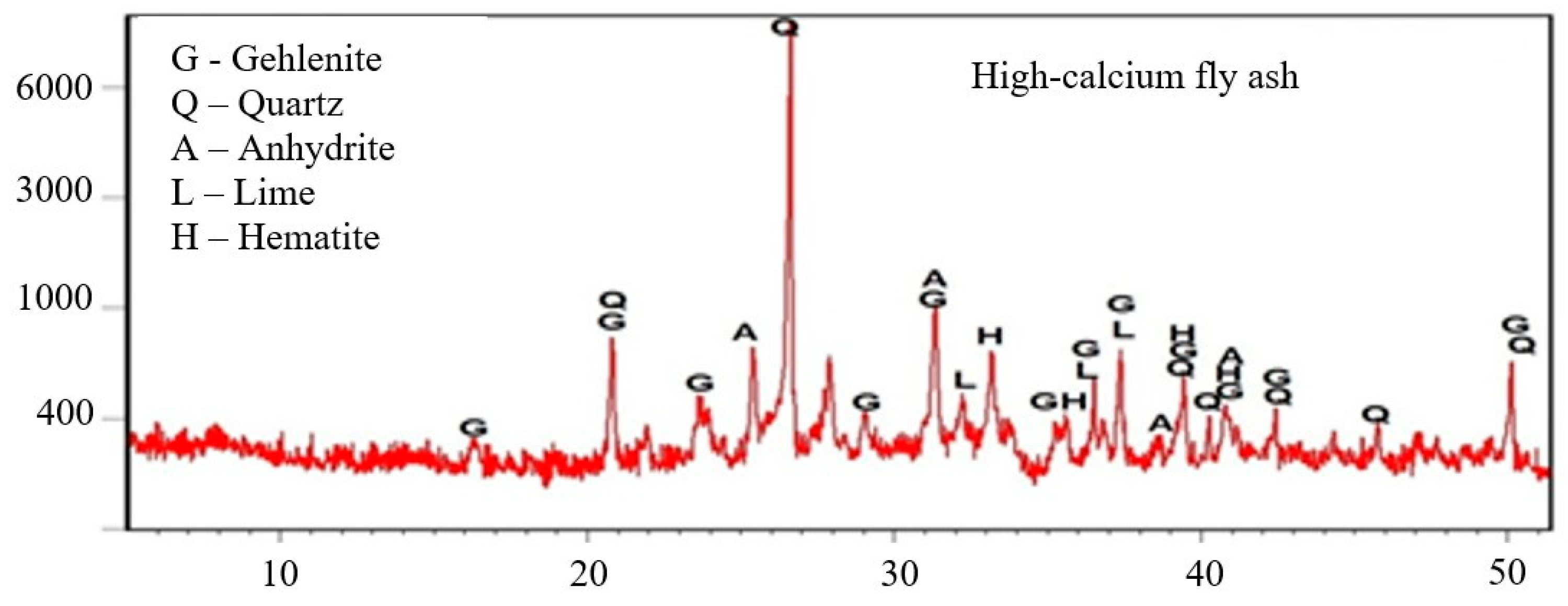

3.2. Low- and High-Calcium Fly Ash

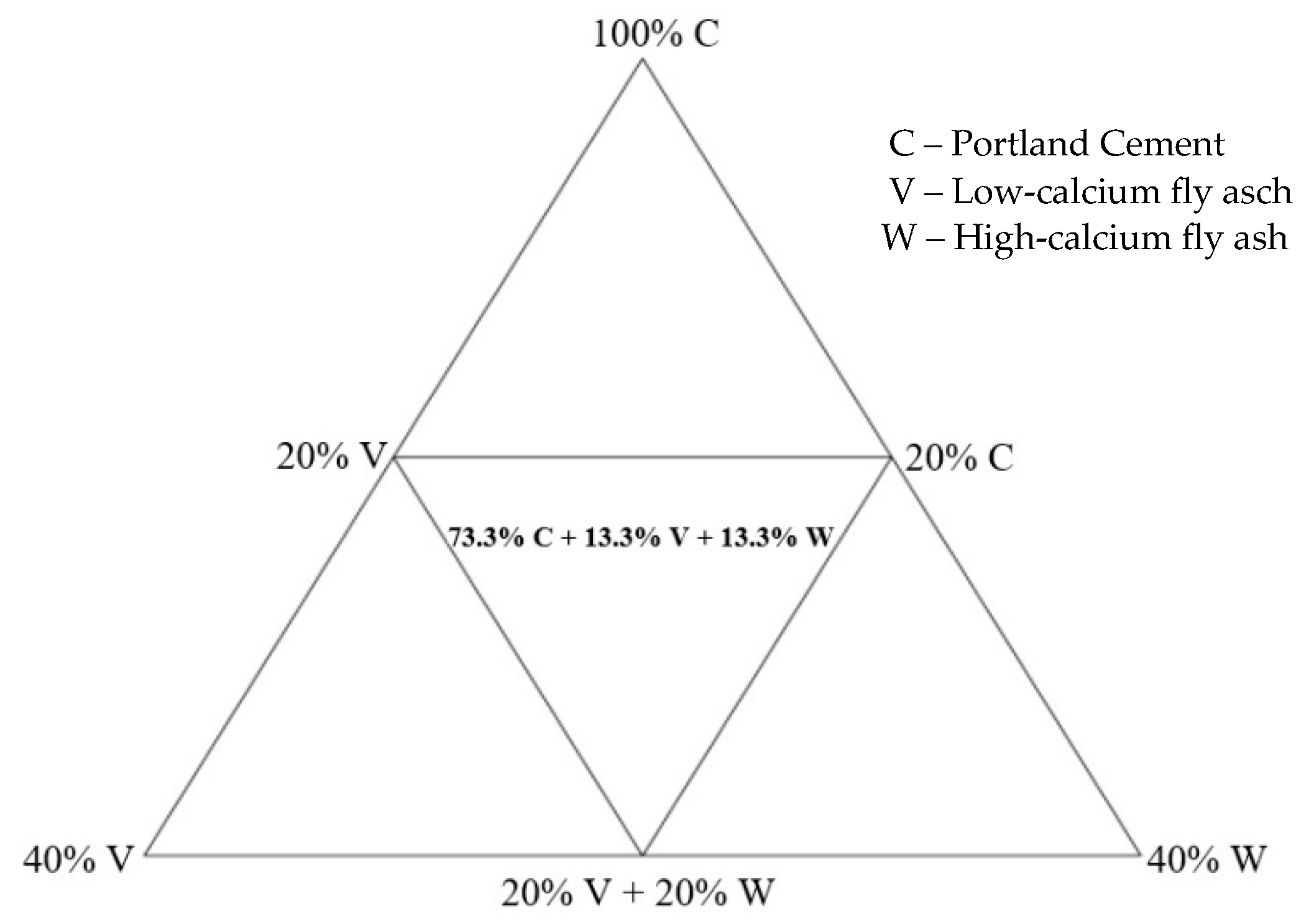

3.3. Composition of Mortars

3.4. Compressive Strength

3.5. Linear Strains Measurement

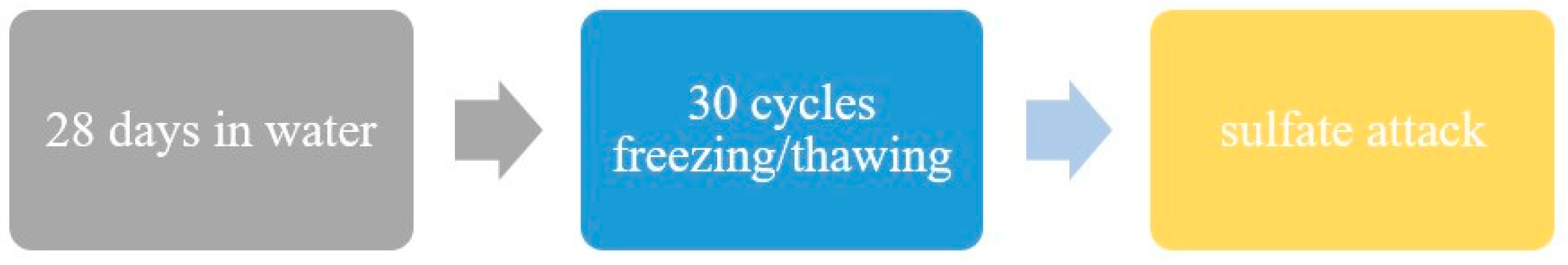

3.6. The Resistance of Freezing and Thawing Cycles

3.7. X-ray Diffraction

3.8. Scanning Electron Microscopy (SEM-EDS)

3.9. The Air Content in Fresh Mortar

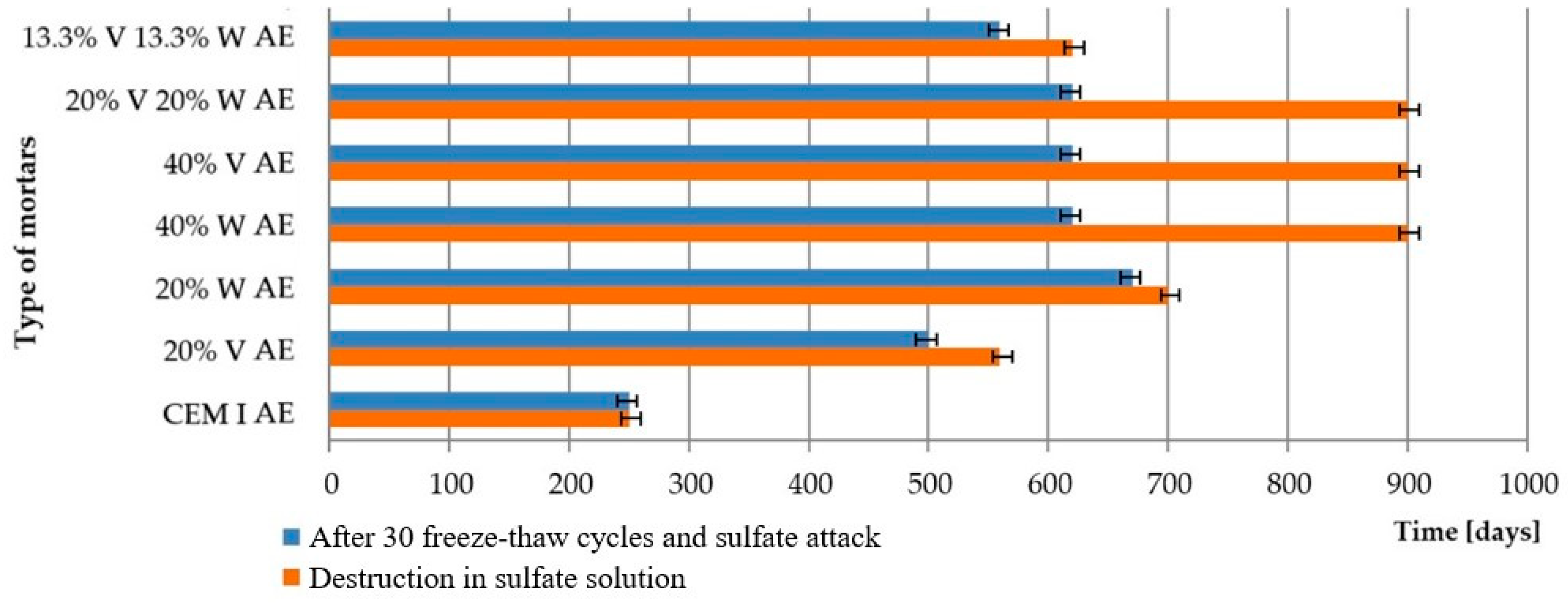

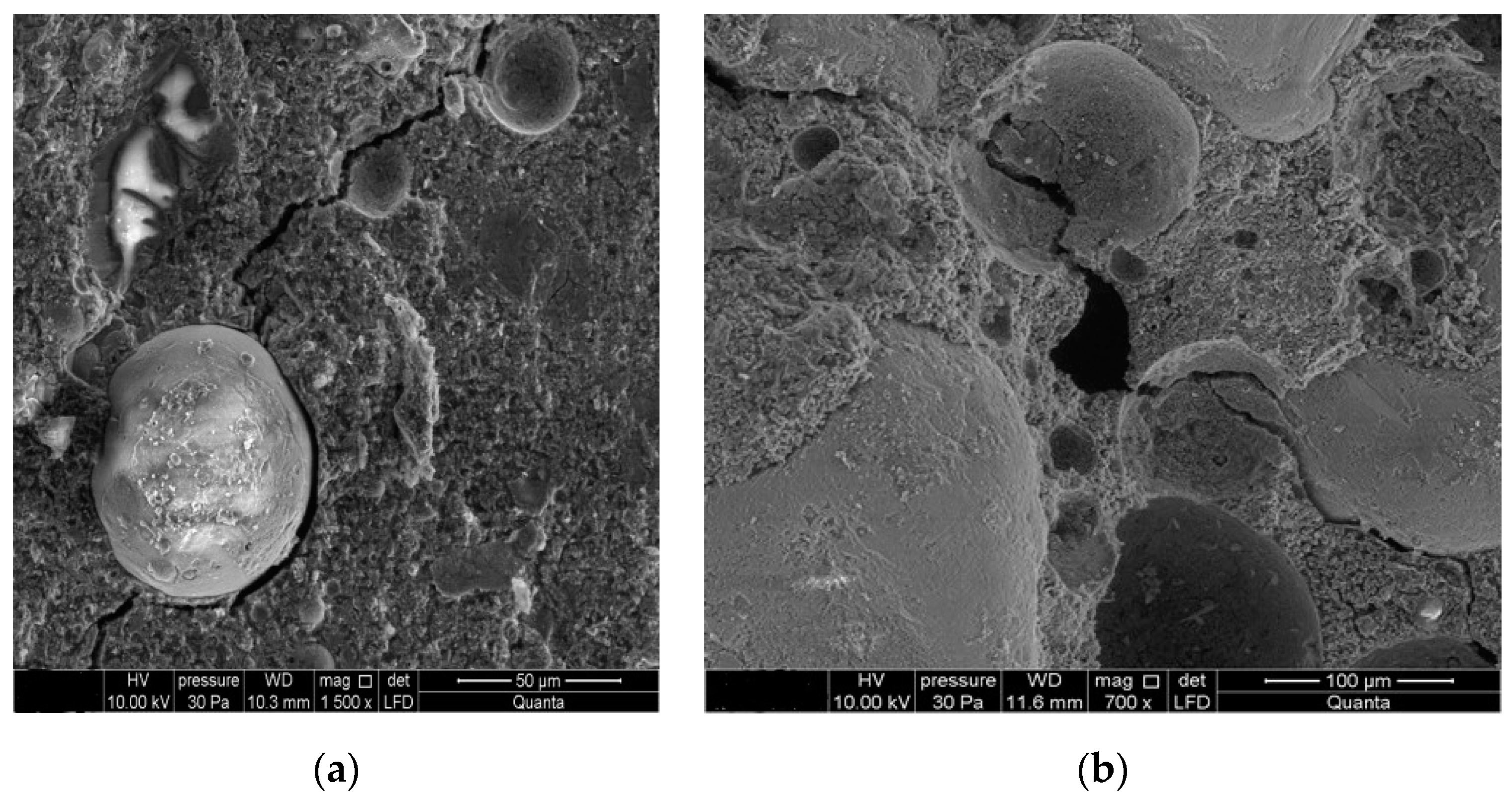

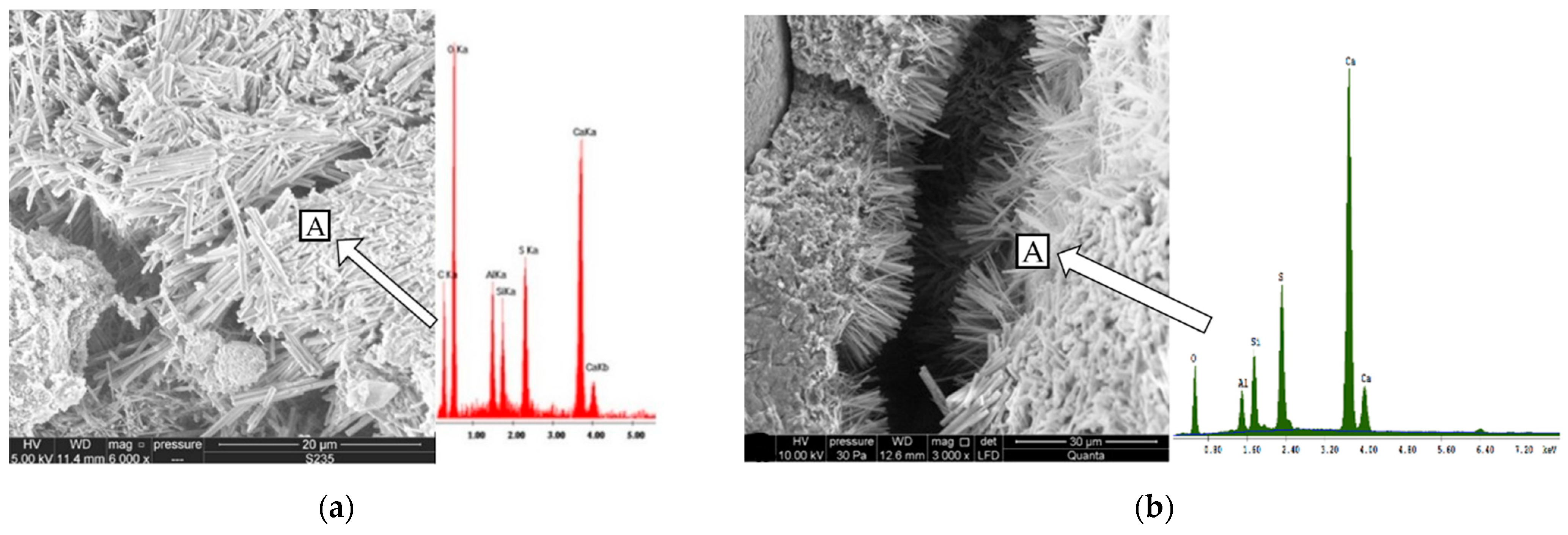

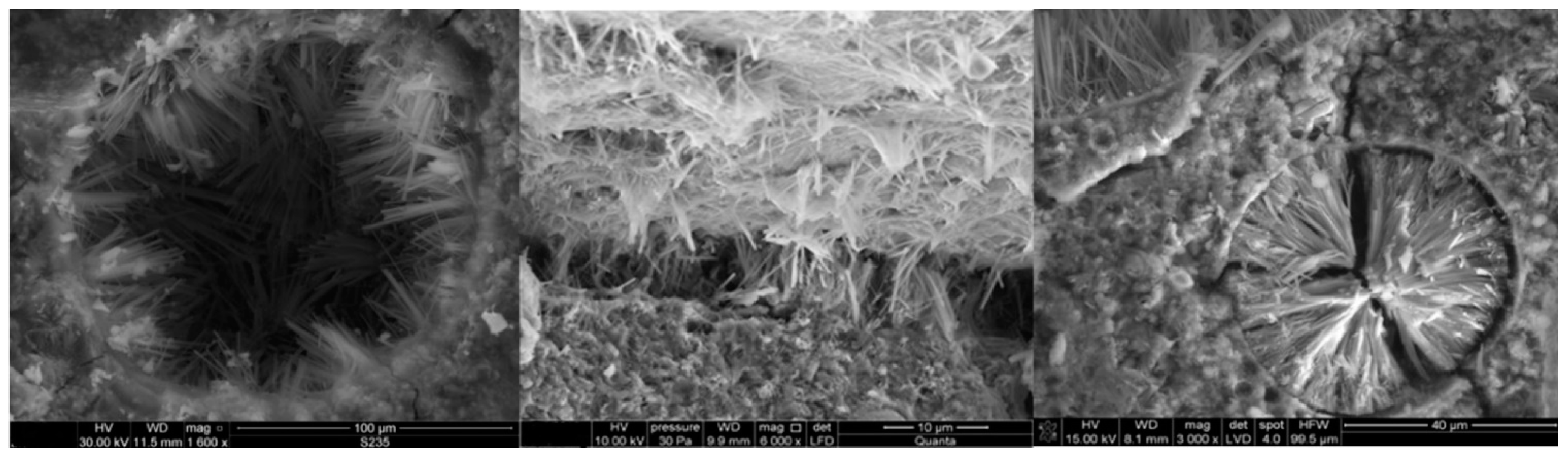

4. Results

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Dandan, S.; Changfu, H.; Zhenjie, C.; Kai, W.; Lihai, Z. Reliability assessment of concrete under external sulfate attack. Case Stud. Constr. Mater. 2021, 15, e00690. [Google Scholar]

- Kasaniy, M.; Edward, M.; Moffatt, G. Efficiency of natural pozzolans, ground glasses and coal bottom ashes in mitigating sulfate attack and alkali-silica reaction. Cem. Concr. Res. 2021, 149, 106551. [Google Scholar] [CrossRef]

- Mehta, P.K. Scientific basic for determination the sulfate resistance of blended cement. In Symposium on Fly Ash and Coal Conversion By-Products: Characterization Utilization and Disposal IV; Materials Research Society: Warrendale, PA, USA, 1987; pp. 145–152. [Google Scholar]

- Giergiczny, Z. Rola Popiołów Lotnych Wapiennych i Krzemionkowych w Kształtowaniu Właściwości Spoiw Budowlanych i Tworzyw Cementowych; Monografia Politechnika Krakowska: Kraków, Poland, 2006. [Google Scholar]

- Meng, W.; Yunsheng, Z.; Yongsheng, J.; Guojian, L. No AccessEffects of fly ash on Portland limestone cement under sulfate attack at low temperature. Mag. Concr. Res. 2020, 72, 134–148. [Google Scholar]

- Prusinski, J.R.; Carrasquillo, R.L. Using Medium- to High-Volume Fly Ash Blended Cements to Improve the Sulfate Resistance of High-Lime Fly Ash Concrete. ACI Spec. Publ. 1995, 153, 43–66. [Google Scholar]

- Siddique, R. Performance characteristics of high-volume Class F fly ash concrete. Cem. Concr. Res. 2004, 34, 487–493. [Google Scholar] [CrossRef]

- Manjur, M.; Christopher, A.; ShearerbAbuNaser, R. Improving the sulfate attack resistance of concrete by using supplementary cementitious materials (SCMs): A review. Constr. Build. Mater. 2021, 281, 122628. [Google Scholar]

- Mehta, P.K. High-Performance, High-Volume Fly Ash Concrete for Sustainable Development; University of California: Berkeley, CA, USA, 2005. [Google Scholar]

- Wong, H.; Pappas, A.; Zimmerman, R.; Buenfeld, N. Effect of entrained air voids on the microstructure and mass transport properties of concrete. Cem. Concr. Res. 2011, 41, 1067–1077. [Google Scholar] [CrossRef] [Green Version]

- Santhanam, M.; Cohen, M.D.; Olek, J. Mechanism of sulfate attack: A fresh look: Part 1: Summary of experimental results. Cem. Concr. Res. 2002, 32, 915–921. [Google Scholar] [CrossRef]

- Santhanam, M.; Cohen, M.D.; Olek, J. Sulfate attack research—Whither now? Cem. Concr. Res. 2001, 31, 845–851. [Google Scholar] [CrossRef]

- Neville, A. The confused world of sulfate attack on concrete. Cem. Concr. Res. 2004, 34, 1275–1296. [Google Scholar] [CrossRef]

- Miao, C.; Mu, R.; Tian, Q.; Sun, W. Effect of sulfate solution on the frost resistance of concrete with and without steel fiber reinforcement. Cem. Concr. Res. 2002, 32, 31–34. [Google Scholar] [CrossRef]

- Yang, J.; Wang, P.; Li, H.; Yang, X. Sulfate attack resistance of air-entrained silica fume concrete under dry-wet cycle condition. J. Wuhan Univ. Technol. Sci. Ed. 2016, 31, 857–864. [Google Scholar] [CrossRef]

- Lei, J.; Niu, D.; Yuan, L.; Fei, Q. Durability of concrete under sulfate attack ex-posed to freeze–thaw cycles. Cold Reg. Sci. Technol. 2015, 112, 112–117. [Google Scholar]

- Yang, H.; Shen, X.; Rao, M.; Li, X.; Wang, X. Influence of Alternation of Sulfate Attack and Freeze-Thaw on Microstructure of Concrete. Adv. Build. Technol. Constr. Mater. 2015, 2015, 859069. [Google Scholar] [CrossRef] [Green Version]

- Wei, T.; Fangfang, G. Damage and Degradation of Concrete under Coupling Action of Freeze-Thaw Cycle and Sulfate Attack. Adv. Mater. Sci. Eng. 2020, 2020, 8032849. [Google Scholar]

- Ditao, N.; Lei, J.; Qiannan, F. Deterioration mechanism of sulfate attack on concrete under freeze-thaw cycles. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2013, 28, 1172–1176. [Google Scholar]

- Wang, D.; Zhou, X.; Meng, Y.; Chen, Z. Durability of concrete containing fly ash and silica fume against combined freezing-thawing and sulfate attack. Constr. Build. Mater. 2017, 147, 398–406. [Google Scholar] [CrossRef]

- PN-EN 1008:2004; Mixing Water for Concrete-Specification for Sampling, Testing and Assessing the Suitability of Water, Including Water Recovered from Processes in the Concrete Industry, as Mixing Water for Concrete. Comite Europeen de Normalisation: Warsaw, Poland, 2004.

- PN-EN 1015:2020; Methods of Test for Mortar for Masonry-Part 1: Determination of Particle Size Distribution (by Sieve Analysis). Comite Europeen de Normalisation: Warsaw, Poland, 2020.

- PN-EN 197:2007 + A1:2005/A3:2007; Cement-Part 1: Composition, Specifications and Conformity Criteria for Common Cements. Comite Europeen de Normalisation: Warsaw, Poland, 2007.

- PN-EN 206:2014-04; Concrete-Specification, Performance, Production and Conformity. Comite Europeen de Normalisation: Warsaw, Poland, 2014.

- Jiang, L.; Malhotra, V. Reduction in water demand of non-air-entrained concrete incorporating large volumes of fly ash. Cem. Concr. Res. 2000, 30, 1785–1789. [Google Scholar] [CrossRef]

- Glinicki, M.A. Właściwe i Patologiczne Napowietrzanie Betonu; Budownictwo-Technologie-Architektura: Krakow, Poland, 2004. [Google Scholar]

- Glinicki, M.A.; Zieliński, M. Rozmieszczenie Porów Powietrznych w Betonie z Dodatkiem Fluidalnego Popiołu Lotnego; Cement Wapno Beton: Kraków, Poland, 2007. [Google Scholar]

- Glinicki, M.A.; Zieliński, M. Air void system in concrete containing circulating fluidized bed combustion fly ash. Mater. Struct. 2008, 41, 681–687. [Google Scholar] [CrossRef]

- Zhang, D.S. Air entrainment in fresh concrete with PFA. Cem. Concr. Compos. 1996, 18, 409–416. [Google Scholar] [CrossRef]

- Rusin, Z. Technologia Betonów Mrozoodpornych; Polski Cement: Krakow, Poland, 2002. [Google Scholar]

- Rønning, T.F. Freeze-Thaw Resistance of Concrete, Effect of: Curing Conditions, Moisture Exchange and Materials. Ph.D. Thesis, Division of Structural Engineering, Concrete Section, The Norwegian Institute of Technology, Trondheim, Norway, 2001. [Google Scholar]

- Müller, C.; Severins, K. Durability of concrete made with cements containing fly ash. In Concrete Technology Reports 2007–2009; Federal Ministry for Economic Affairs and Technology: Düsseldorf, Germany, 2010; Volume 31, pp. 7–17. [Google Scholar]

- Knutsson, A. Freeze/Thaw Durability of Concrete with Fly Ash. Master’s Thesis, Chalmers University of Technology, Göteborg, Sweden, 2010. [Google Scholar]

- Karakurt, C.; Yıldırım, B. Freeze-thaw resistance of normal and high strength concrete produced with fly ash and silica fume. Adv. Mater. Sci. Eng. 2015, 2015, 830984. [Google Scholar] [CrossRef] [Green Version]

- Xir, W. Air Entrainment and Variation of Air Void System in Fresh Concrete; State University Doctor of Philosophy: Ames, IA, USA, 2018. [Google Scholar]

- Whiting, D.A.; Nagi, M.A. Manual on Control of Air Content in Concrete; EB116; PCA: Skokie, IL, USA, 1998. [Google Scholar]

- Shon, C.S.; Abdigaliyev, A.; Bagitova, S.; Chung, C.W.; Kim, D. Determination of air-void system and modified frost resistance number for freeze-thaw resistance evaluation of ternary blended concrete made of ordinary Portland cement/silica fume/class F fly ash. Cold Reg. Sci. Technol. 2018, 155, 127–136. [Google Scholar] [CrossRef]

- Glinicki, M.A.; Zieliński, M. Frost salt scaling resistance of concrete containing CFBC fly ash. Mater. Struct. 2009, 42, 993–1002. [Google Scholar] [CrossRef]

- Pigeon, M.; Marchand, J.; Pleau, R. Frost resistant concrete. Constr. Build. Mater. 1996, 10, 339–348. [Google Scholar] [CrossRef]

- Wang, C.Q.; Tan, K.F.; Dai, C.B.; Wang, P.X.; Li, S.N. Effects of Air Entraining Agent on Properties of Fly Ash-based Drymixed Mortar. China Concr. Cem. Prod. 2014, 4. [Google Scholar]

- Gebler, S.H.; Klieger, P. Effect of fly ash on the durability of air-entrained concrete. Spec. Publ. 1986, 91, 483–520. [Google Scholar]

- Huai-Shuai, S.; Ting-Hua, Y. Freeze-Thaw Durability of Air-Entrained Concrete. Sci. World J. 2013, 2013, 650791. [Google Scholar]

- Ley, M.T.; Chancey, R.; Juenger, M.C.; Folliard, K.J. The physical and chemical characteristics of the shell of air-entrained bubbles in cement paste. Cem. Concr. Res. 2009, 39, 417–425. [Google Scholar] [CrossRef]

| Cement | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 | Cl− | Na2Oeq |

|---|---|---|---|---|---|---|---|---|

| CEM I | 20.6 | 5.75 | 3.4 | 65.8 | 1.5 | 2.5 | 0.014 | 0.77 |

| Cement | C3S | C2S | C3A | C4AF |

|---|---|---|---|---|

| CEM I | 63.2 | 8.2 | 6.3 | 9.9 |

| Fly Ash | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 | Cl− | Na2O | K2O |

|---|---|---|---|---|---|---|---|---|---|

| Low- calcium | 50.5 | 26.1 | 7.4 | 4.5 | 2.9 | 0.5 | 0.01 | - | - |

| High- calcium | 45.2 | 20.8 | 4.6 | 20.6 | 1.5 | 3.0 | 0.014 | 0.23 | 0.19 |

| Mortars Composition [%] | Cement, C [g] | Low-Calcium Fly Ash, V [g] | High-Calcium Fly Ash, W [g] |

|---|---|---|---|

| CEM I = 100% C | 500 | 0 | 0 |

| 20% V = 80% C + 20% V | 400 | 100 | 0 |

| 40% V = 60% C + 40% V | 300 | 200 | 0 |

| 20% W = 80% C + 20% W | 400 | 0 | 100 |

| 40% W = 60% C + 40% W | 300 | 0 | 200 |

| 20% V 20% W = 60% C + 20% V + 20% W | 300 | 100 | 100 |

| 13.3% V 13.3% W = 73.3% C 13.3% V 13.3% W | 370 | 65 | 65 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jaworska-Wędzińska, M.; Jasińska, I. Durability of Mortars with Fly Ash Subject to Freezing and Thawing Cycles and Sulfate Attack. Materials 2022, 15, 220. https://doi.org/10.3390/ma15010220

Jaworska-Wędzińska M, Jasińska I. Durability of Mortars with Fly Ash Subject to Freezing and Thawing Cycles and Sulfate Attack. Materials. 2022; 15(1):220. https://doi.org/10.3390/ma15010220

Chicago/Turabian StyleJaworska-Wędzińska, Monika, and Iga Jasińska. 2022. "Durability of Mortars with Fly Ash Subject to Freezing and Thawing Cycles and Sulfate Attack" Materials 15, no. 1: 220. https://doi.org/10.3390/ma15010220

APA StyleJaworska-Wędzińska, M., & Jasińska, I. (2022). Durability of Mortars with Fly Ash Subject to Freezing and Thawing Cycles and Sulfate Attack. Materials, 15(1), 220. https://doi.org/10.3390/ma15010220