Laser Remelting Process Simulation and Optimization for Additive Manufacturing of Nickel-Based Super Alloys

Abstract

:1. Introduction

2. Numerical Modeling Approach

2.1. Model Domain

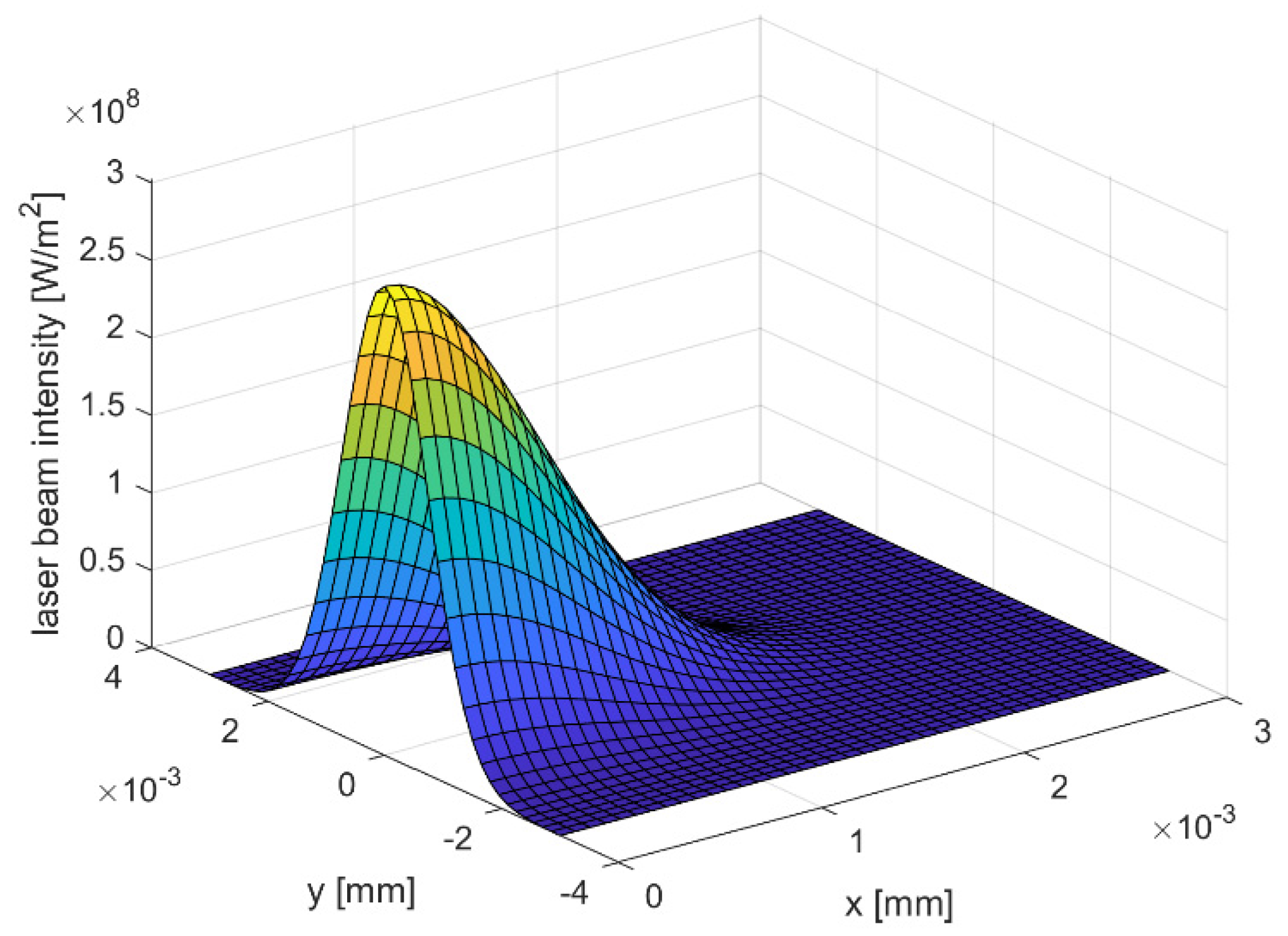

2.2. Heat Source Definition

2.3. Heat Conduction Model

2.4. Fluid Flow Model

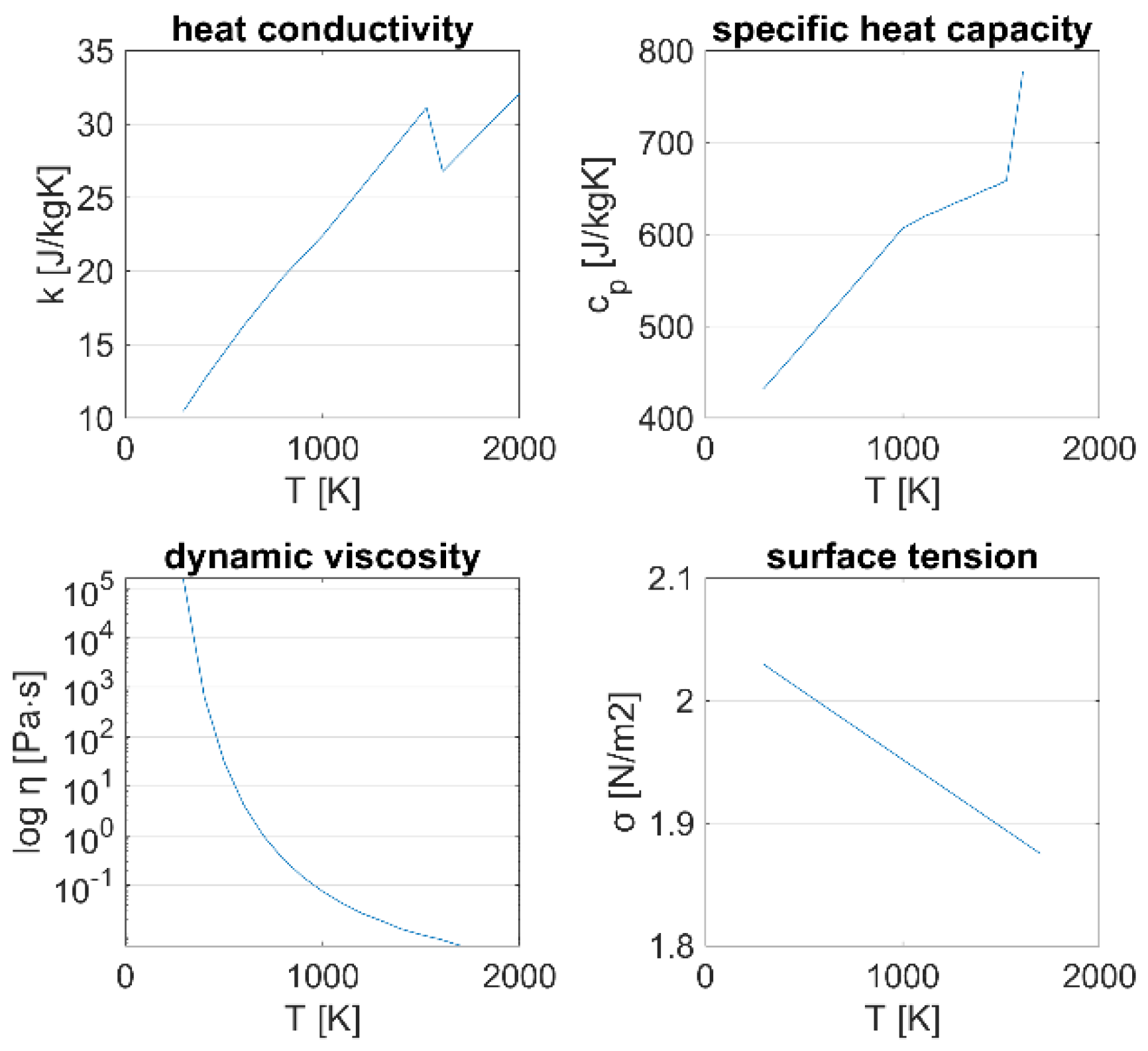

2.5. Material Properties

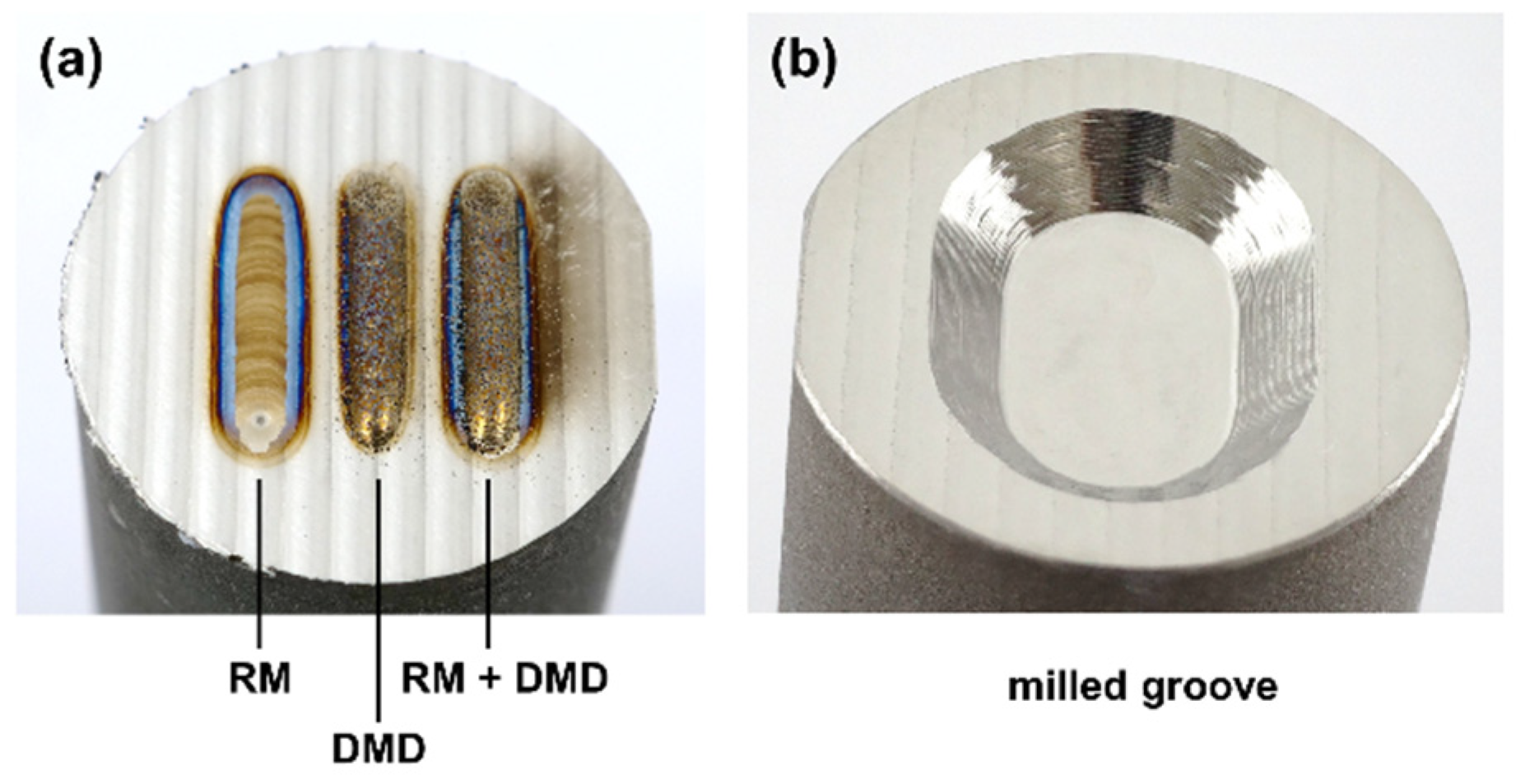

3. Experimental Procedure

4. Results and Discussion

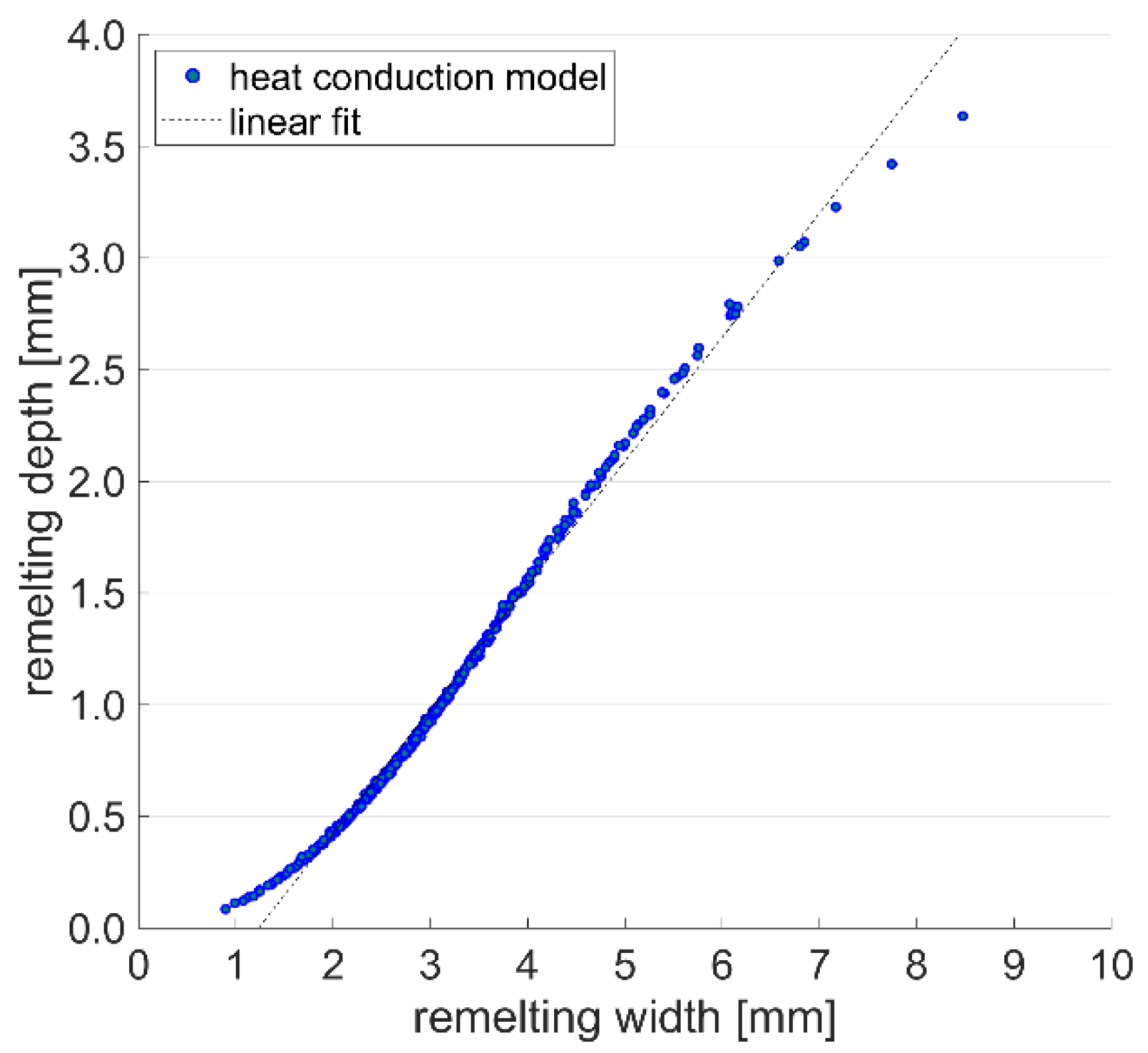

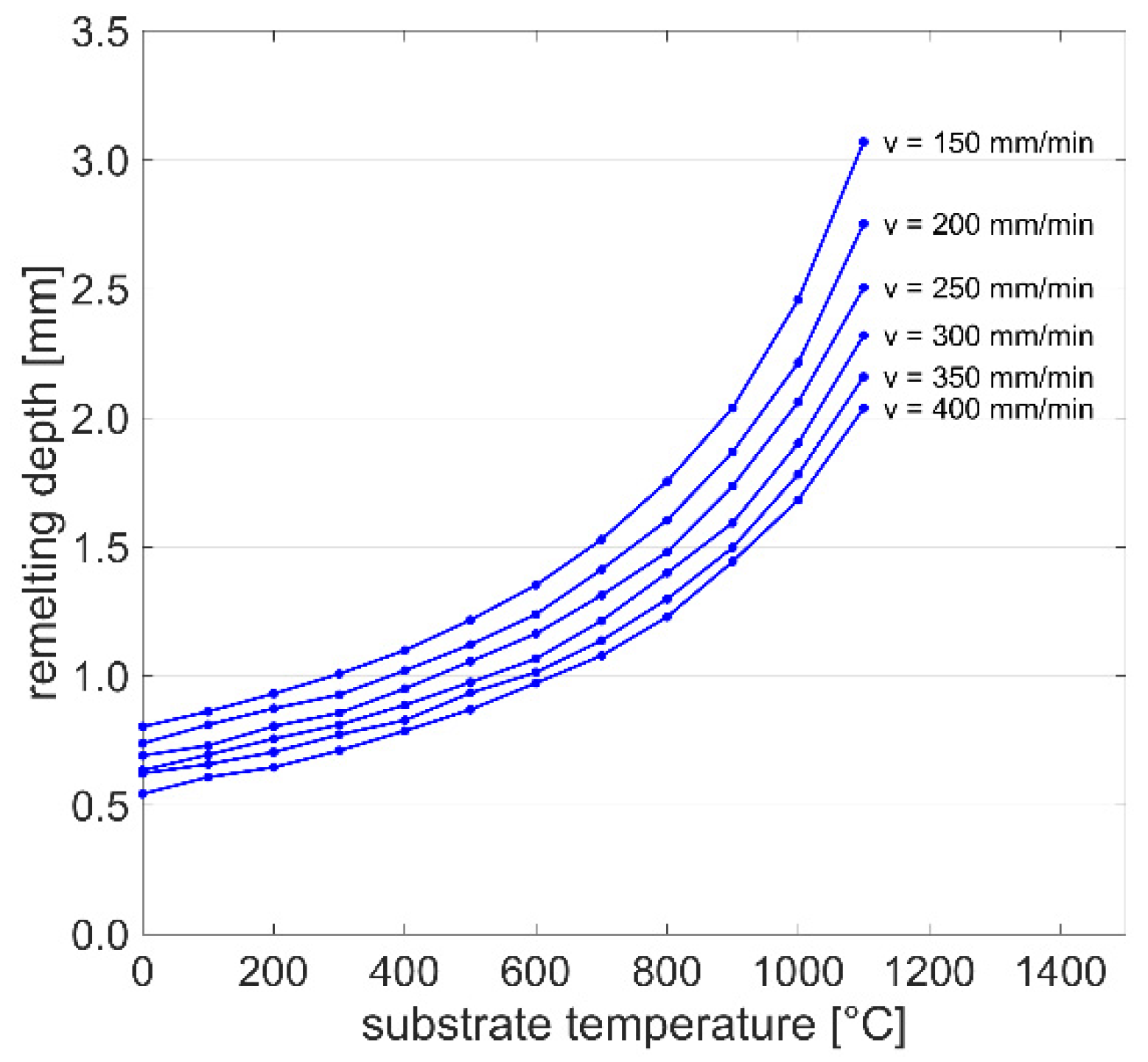

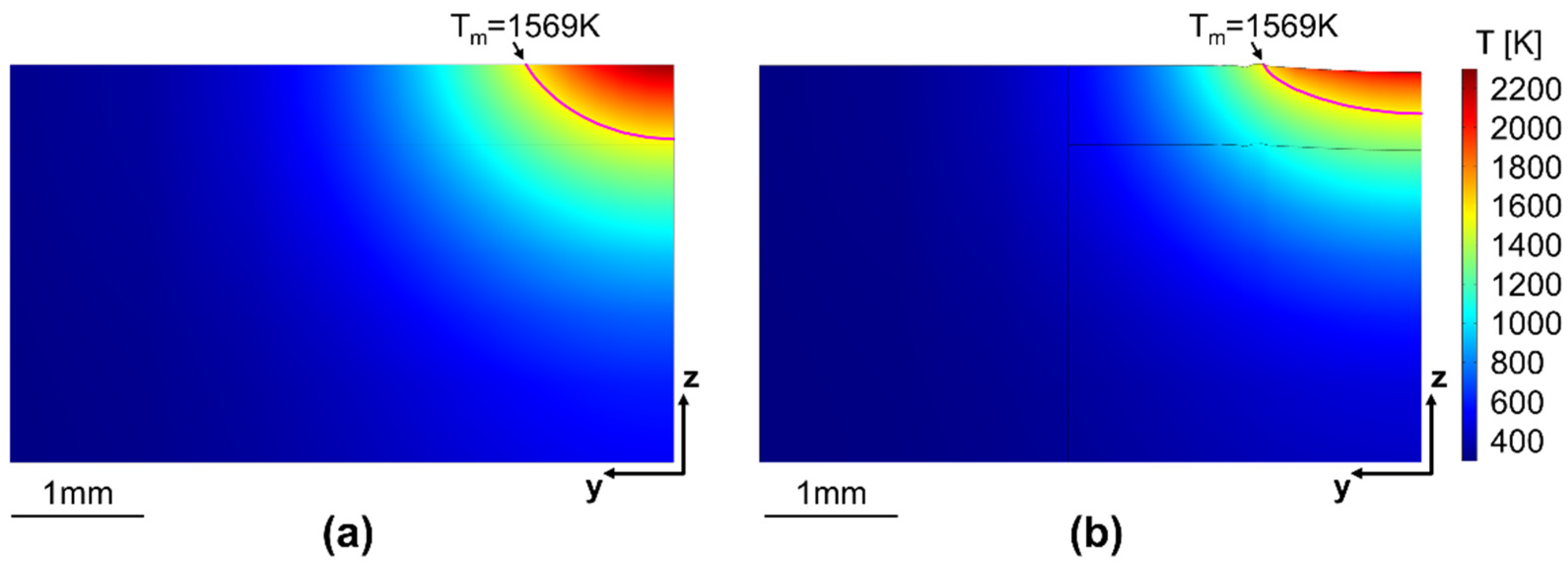

4.1. Simulation Results

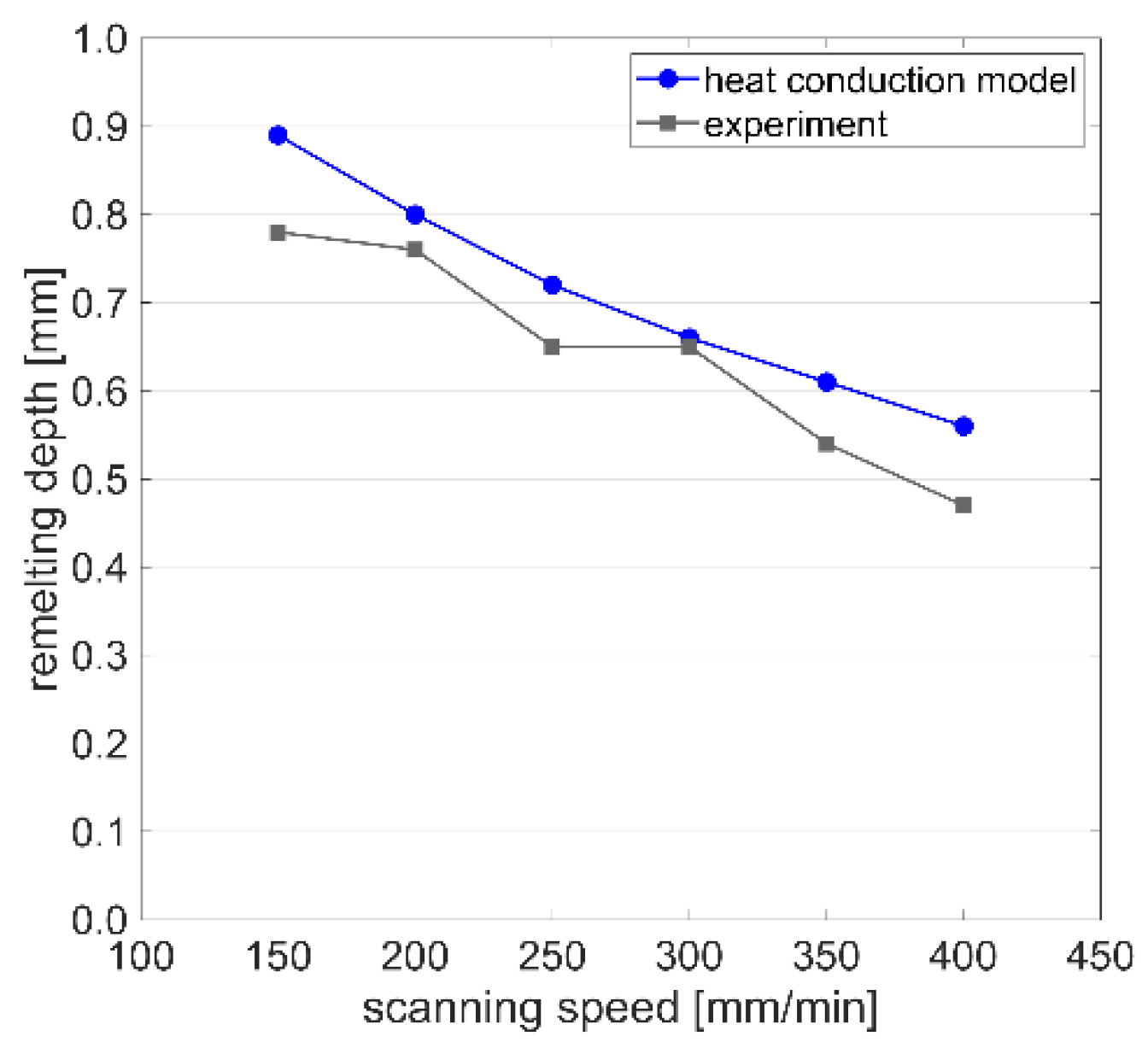

4.2. Single Track Validation

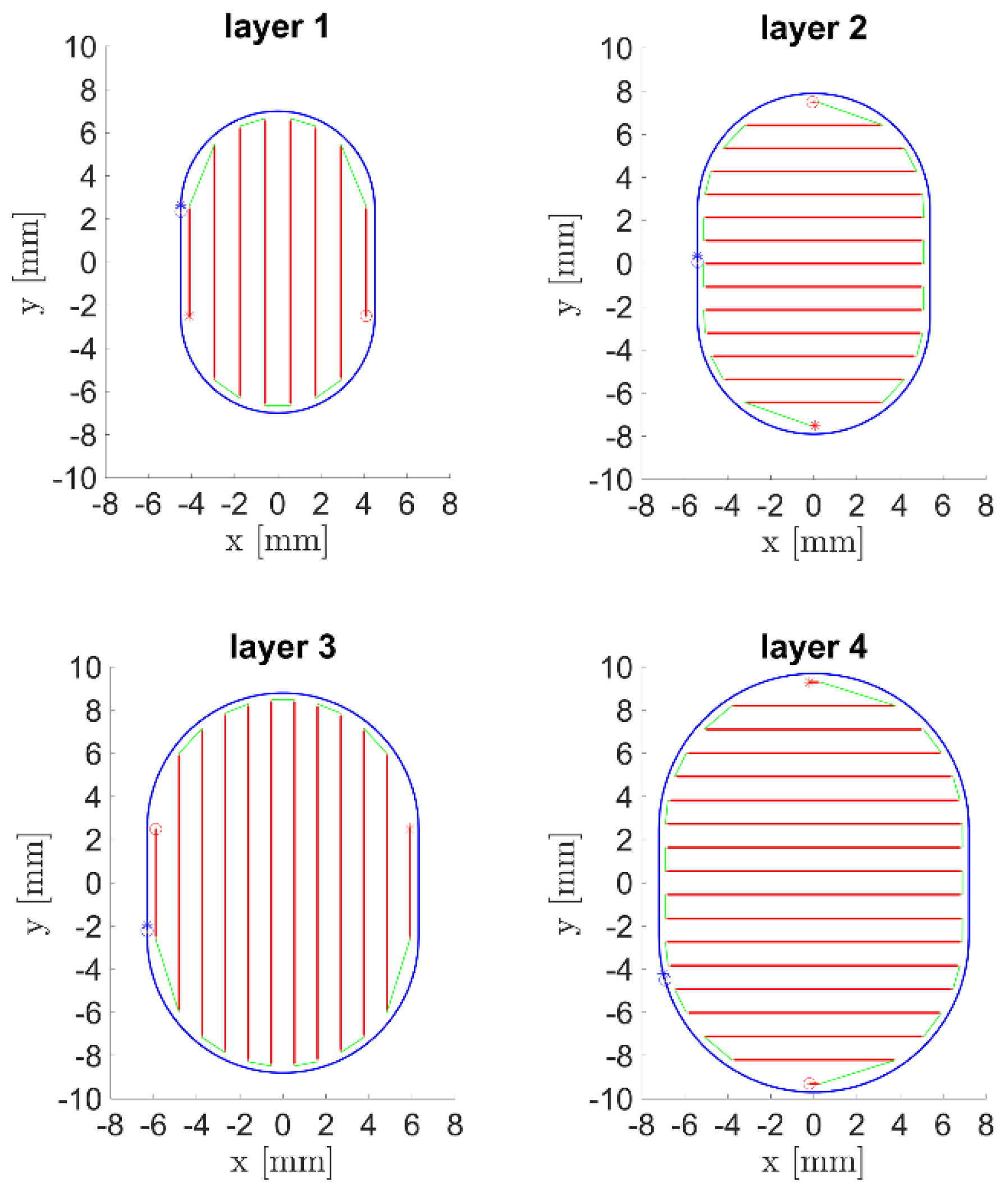

4.3. Groove Repair Process Optimization

5. Conclusions

- The neglection of fluid flow in the numerical simulation reduces the computing time from 16 h to less than one minute.

- The simplified heat conduction model is useful for quantifying the effects of the main laser remelting processing parameters.

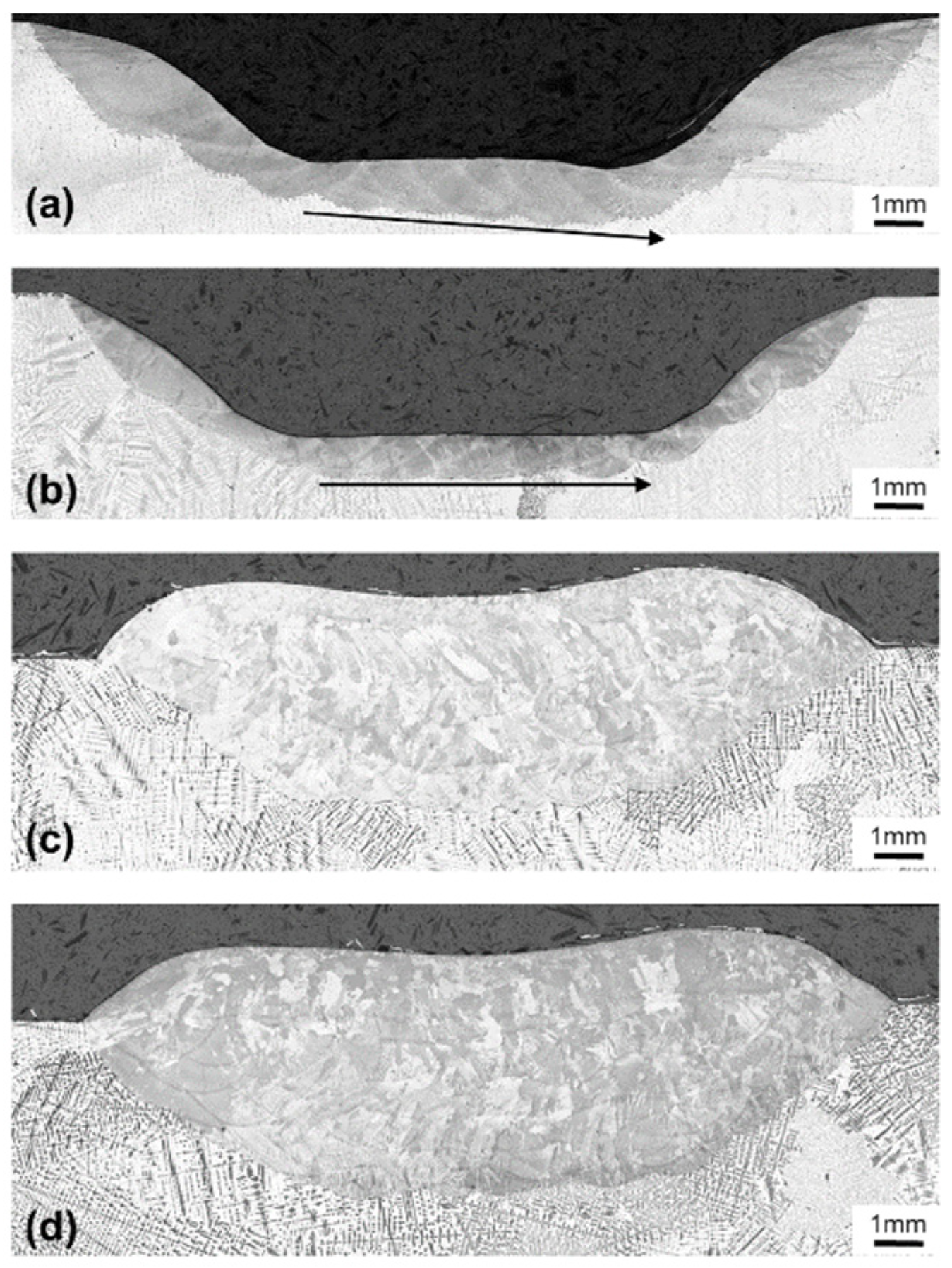

- Single remelting track experiments with varying scanning speeds confirm the high physical accuracy of both the heat conduction model and the fluid flow model. The fluid flow model showed the highest geometrical accuracy, while the heat conduction model slightly overestimated the remelting depth and underestimated the width.

- Single tracks fabricated by DMD with and without prior remelting show that the remelting step leads to more uniform substrate bonding.

- The application of laser remelting within a process chain for part repair confirms increased bonding quality. Furthermore, the remelting process is expected to be suitable for defect prevention in metal AM part fabrication and repair.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, S.; Yu, H.; Wang, Y.; Zhang, X.; Li, J.; Chen, S.; Liu, C. Cracking, Microstructure and Tribological Properties of Laser Formed and Remelted K417G Ni-Based Superalloy. Coatings 2019, 9, 71. [Google Scholar] [CrossRef] [Green Version]

- Liu, B.; Li, B.-Q.; Li, Z. Selective laser remelting of an additive layer manufacturing process on AlSi10Mg. Results Phys. 2019, 12, 982–988. [Google Scholar] [CrossRef]

- Yang, X.; Liu, J.; Cui, X.; Jin, G.; Liu, Z.; Chen, Y.; Feng, X. Effect of remelting on microstructure and magnetic properties of Fe-Co-based alloys produced by laser additive manufacturing. J. Phys. Chem. Solids 2019, 130, 210–216. [Google Scholar] [CrossRef]

- Liu, D.; Lippold, J.C.; Li, J.; Rohklin, S.R.; Vollbrecht, J.; Grylls, R. Laser Engineered Net Shape (LENS) Technology for the Repair of Ni-Base Superalloy Turbine Components. Metall. Mater. Trans. A 2014, 45, 4454–4469. [Google Scholar] [CrossRef]

- Guo, Z.; Wang, L.; Wang, C.; Ding, X.; Liu, J. Heat Transfer, Molten Pool Flow Micro-Simulation, and Experimental Research on Molybdenum Alloys Fabricated via Selective Laser Melting. Materials 2021, 14, 75. [Google Scholar] [CrossRef] [PubMed]

- Mukin, D.; Valdaytseva, E.; Turichin, G. Analytical Solution of the Non-Stationary Heat Conduction Problem in Thin-Walled Products during the Additive Manufacturing Process. Materials 2021, 14, 4049. [Google Scholar] [CrossRef] [PubMed]

- Dalaee, M.T.; Gloor, L.; Leinenbach, C.; Wegener, K. Experimental and numerical study of the influence of induction heating process on build rates Induction Heating-assisted laser Direct Metal Deposition (IH-DMD). Surf. Coat. Technol. 2020, 384, 125275. [Google Scholar] [CrossRef]

- Knapp, G.L.; Mukherjee, T.; Zuback, J.S.; Wei, H.L.; Palmer, T.A.; De, A.; DebRoy, T. Building blocks for a digital twin of additive manufacturing. Acta Mater. 2017, 135, 390–399. [Google Scholar] [CrossRef]

- Wei, H.L.; Mukherjee, T.; Zhang, W.; Zuback, J.S.; Knapp, G.L.; De, A.; DebRoy, T. Mechanistic models for additive manufacturing of metallic components. Prog. Mater. Sci. 2020, 116, 100703. [Google Scholar] [CrossRef]

- Wirth, F.; Eisenbarth, D.; Wegener, K. Absorptivity Measurements and Heat Source Modeling to Simulate Laser Cladding. Phys. Proc. 2016, 83, 1424–1434. [Google Scholar] [CrossRef] [Green Version]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive manufacturing of metallic components—Process, structure and properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Pottlacher, G.; Hosaeus, H.; Kaschnitz, E.; Seifter, A. Thermophysical properties of solid and liquid Inconel 718 Alloy. Scand. J. Metall. 2002, 31, 161–168. [Google Scholar] [CrossRef]

- Hosaeus, H.; Seifter, A.; Kaschnitz, E.; Pottlacher, G. Thermophysical properties of solid and liquid Inconel 718. High Temp. High Press. 2001, 33, 405–410. [Google Scholar] [CrossRef]

- Overfelt, R.; Matlock, C.; Wells, M. Viscosity of superalloy 718 by the oscillating vessel technique. Metall. Mater. Trans. B 1996, 27, 698–701. [Google Scholar] [CrossRef]

- Wirth, F. Process Understanding, Modeling and Predictive Simulation of Laser Cladding. Doctoral Thesis, ETH Zurich, Zürich, Switzerland, 2019. [Google Scholar] [CrossRef]

- Anderson, M.; Patwa, R.; Shin, Y. Laser-Assisted Machining of Inconel 718 with an Economic Analysis. Int. J. Mach. Tools Manuf. 2006, 46, 1879–1891. [Google Scholar] [CrossRef]

- Mills, K.; Su, Y. Review of surface tension data for metallic elements and alloys: Part 1—Pure metals. Int. Mater. Rev. 2006, 51, 329–351. [Google Scholar] [CrossRef]

- Eisenbarth, D. Buildup Strategies for Additive Manufacturing by Direct Metal Deposition. Ph.D. Thesis, ETH Zurich, Zürich, Switzerland, 2020. [Google Scholar] [CrossRef]

- Turichin, G.A.; Valdaytseva, E.A.; Stankevich, S.L.; Udin, I.N. Computer Simulation of Hydrodynamic and Thermal Processes in DLD Technology. Materials 2021, 14, 4141. [Google Scholar] [CrossRef]

- Afrasiabi, M.; Lüthi, C.; Bambach, M.; Wegener, K. Multi-Resolution SPH Simulation of a Laser Powder Bed Fusion Additive Manufacturing Process. Appl. Sci. 2021, 11, 2962. [Google Scholar] [CrossRef]

- Eisenbarth, D.; Soffel, F.; Wegener, K. Geometry-Based Process Adaption to Fabricate Parts with Varying Wall Thickness by Direct Metal Deposition. In Proceedings of the 1st International Conference on Progress in Digital and Physical Manufacturing (ProDMP’19), Leiria, Portugal, 2–4 October 2019; pp. 125–130. [Google Scholar] [CrossRef]

- Le, T.-N.; Lo, Y.-L. Effects of sulfur concentration and Marangoni convection on melt-pool formation in transition mode of selective laser melting process. Mater. Des. 2019, 179, 107866. [Google Scholar] [CrossRef]

- Eisenbarth, D.; Borges Esteves, P.M.; Wirth, F.; Wegener, K. Spatial powder flow measurement and efficiency prediction for laser direct metal deposition. Surf. Coat. Technol. 2019, 362, 397–408. [Google Scholar] [CrossRef]

- Higashi, M.; Yoshimi, K. Electron beam surface melting of MoSiBTiC alloys: Effect of preheating on cracking behavior and microstructure evolution. Mater. Des. 2021, 209, 110010. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhang, J.; Zhuang, Y.; Lu, J.; Yao, J. Hot Corrosion and Mechanical Performance of Repaired Inconel 718 Components via Laser Additive Manufacturing. Materials 2020, 13, 2128. [Google Scholar] [CrossRef]

- Soffel, F.; Eisenbarth, D.; Hosseini, E.; Wegener, K. Interface strength and mechanical properties of Inconel 718 processed sequentially by casting, milling, and direct metal deposition. J. Mater. Process. Technol. 2021, 291, 117021. [Google Scholar] [CrossRef]

| Property | Symbol | Value | Source |

|---|---|---|---|

| Density | ρ | 8190 kg/m3 | [12] |

| Solidus temperature | Ts | 1528 K | [12] |

| Liquidus temperature | Tl | 1610 K | [12] |

| Melting enthalpy | hm | 227,000 J/kg | [12] |

| Coefficient of thermal expansion | β | 6.473 × 10−5 K−1 | [12] |

| Work piece absorptivity | αwp | 0.3 | [16] |

| Parameter | Symbol | Unit | Values |

|---|---|---|---|

| Laser power | P | W | 550, 700, 850, 1000, 1150 |

| Scanning speed | v | mm/min | 150, 200, 250, 300, 350, 400 |

| Substrate temperature | T | °C | 0–1100 in steps of 100 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Soffel, F.; Lin, Y.; Keller, D.; Egorov, S.; Wegener, K. Laser Remelting Process Simulation and Optimization for Additive Manufacturing of Nickel-Based Super Alloys. Materials 2022, 15, 177. https://doi.org/10.3390/ma15010177

Soffel F, Lin Y, Keller D, Egorov S, Wegener K. Laser Remelting Process Simulation and Optimization for Additive Manufacturing of Nickel-Based Super Alloys. Materials. 2022; 15(1):177. https://doi.org/10.3390/ma15010177

Chicago/Turabian StyleSoffel, Fabian, Yunong Lin, Dominik Keller, Sergei Egorov, and Konrad Wegener. 2022. "Laser Remelting Process Simulation and Optimization for Additive Manufacturing of Nickel-Based Super Alloys" Materials 15, no. 1: 177. https://doi.org/10.3390/ma15010177

APA StyleSoffel, F., Lin, Y., Keller, D., Egorov, S., & Wegener, K. (2022). Laser Remelting Process Simulation and Optimization for Additive Manufacturing of Nickel-Based Super Alloys. Materials, 15(1), 177. https://doi.org/10.3390/ma15010177