Mechanical and Electrical Performance of Flexible Polymer Film Designed for a Textile Electrically-Conductive Path

Abstract

1. Introduction

2. Materials and Methods

2.1. Test Materials

2.1.1. Components

- Polymer: ethylene-octene copolymer (EOR)—without a team crosslinking agent, trade name: ENGAGE 8150, the degree of crystallinity: 27%, viscosity acc. to Mooney’s scale (ML(1 + 4) 1210C): 16, producer: The Dow Chemical Company (Midland, MI, USA);

- Electroconductive fillers: (1) electroconductive soot/carbon black (PRINTEX) with a particle size: (10–210) nm (symbol used: PRINTEX); (2) Silver flakes (Silver flakes AX20L) with a particle size: 2.5 µm in average (symbol used: Ag);

- Ionic liquids—manufacturer: Sigma Aldrich (St. Louis, MO, USA): (1) hydrophobic-hexafluorophosphate, 1-hexyl-3-methylimidazolium [hmim][PF6], (symbol used: [hmim][PF6]); (2) hydrophilic-hexafluorophosphate, 1-butyl-3-methylimidazolium [bmim][PF6], (symbol used: [bmim][PF6]); (3) hydrophilic-chloride, 1-butyl-3-methylimidazolium [bmim][Cl] (symbol used: [bmim][Cl]).

- Textile materials: three variants of the substrates specified in Table 1 were considered, where variants A and B relate to the same laminate but are differently oriented during the vulcanization process (see Section 2.1.3).

2.1.2. The Compositions of Prepared Polymer Films for Vulcanization with Textile Materials

- in the first series, the polymers containing electrically-conductive carbon black,

- in the second series of polymers with the addition of the silver particles.

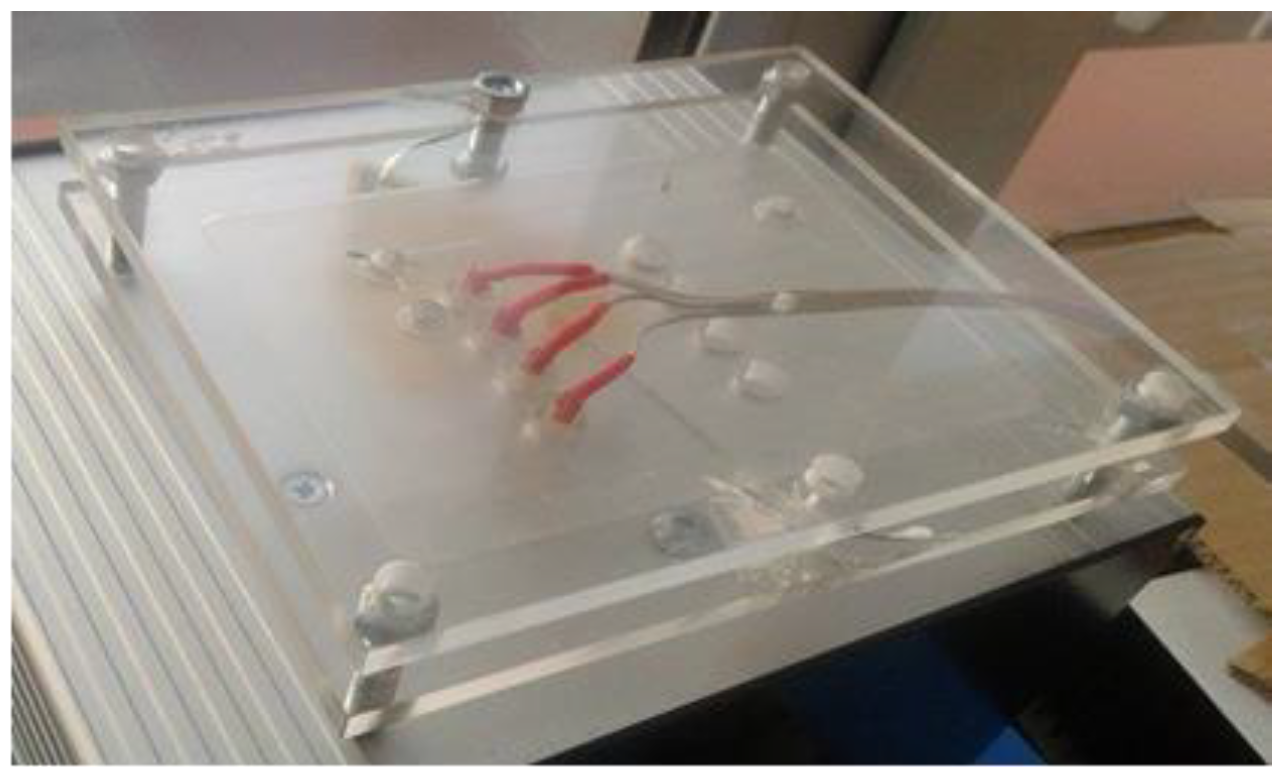

2.1.3. Technology of Preparation of Electroconductive Polymers, Polymer Films and Vulcanizates

- the volume of the chamber: V = 80 cm3;

- the measuring range torque: 0–200 Nm;

- the ratio of rotating impellers: 2:3;

- the heating medium: paraffin oil;

- the sample mass: 70–80 g;

- the temperature: 60 °C;

- the mixing time: 10 min.

- the length of the cylinders: L = 450 mm;

- the diameter of the cylinders: D = 200 mm;

- the width of the gap between the cylinders: 1.5–3.0 mm;

- the rotational speed of the front roller: Vp = 16 rot./min;

- the friction: 1.0–1.2;

- the average temperature of the cylinders: 30 °C;

- the screw diameter: 19 mm;

- the screw length: 190 mm;

- the ratio of screw length to its diameter (L/D): 10;

- the maximum torque: 150 Nm;

- the maximum operating temperature: 300 °C;

- the maximum pressure by weight: 700 bar;

- the production capacity (0.5–5) kg/h.

- the temperature of the heating plates: 160 °C;

- the pressure between the plates (in the form)—(100–130) Bar;

- the time in the form: 30 min.

2.2. Test Methodology

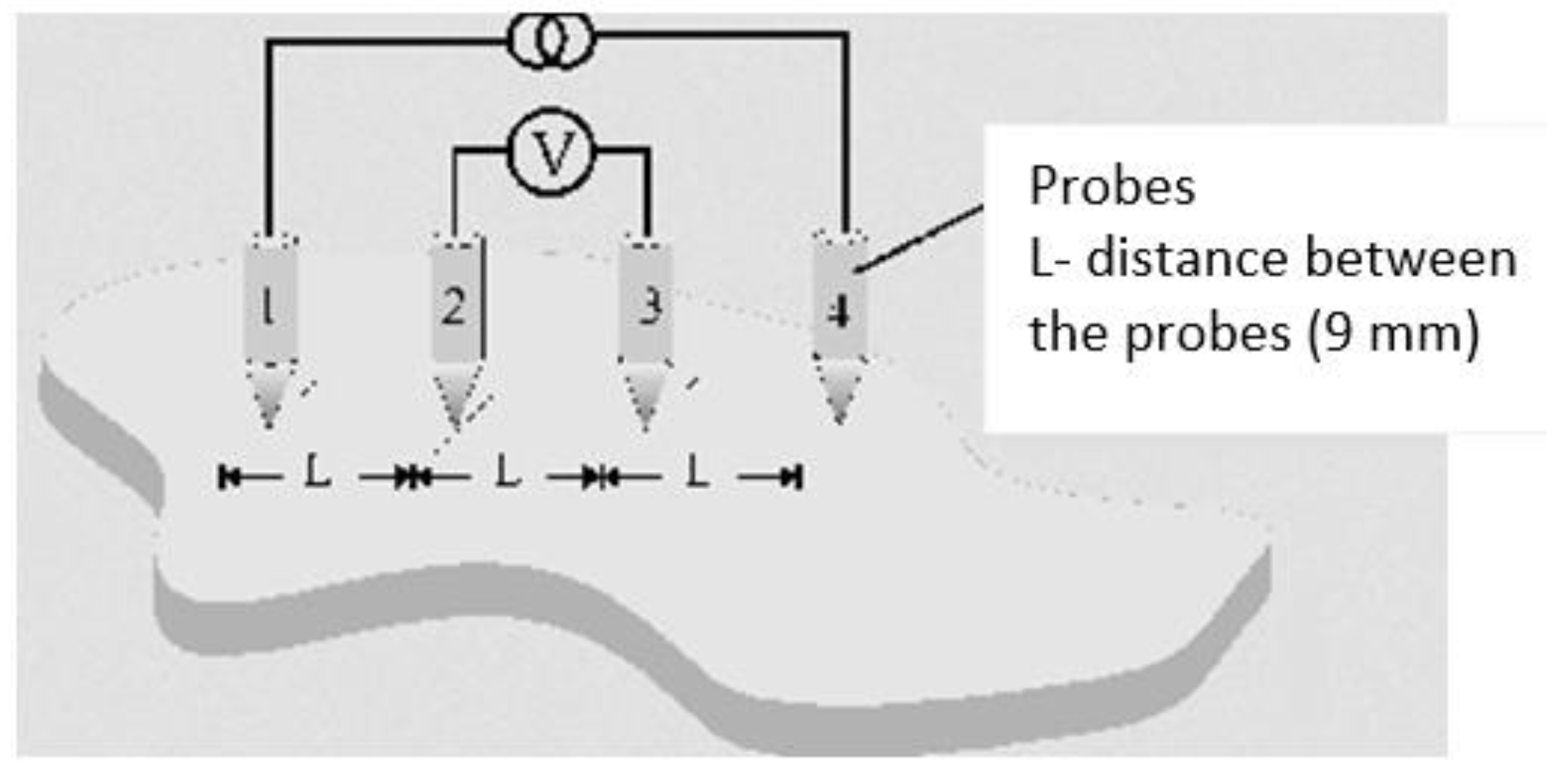

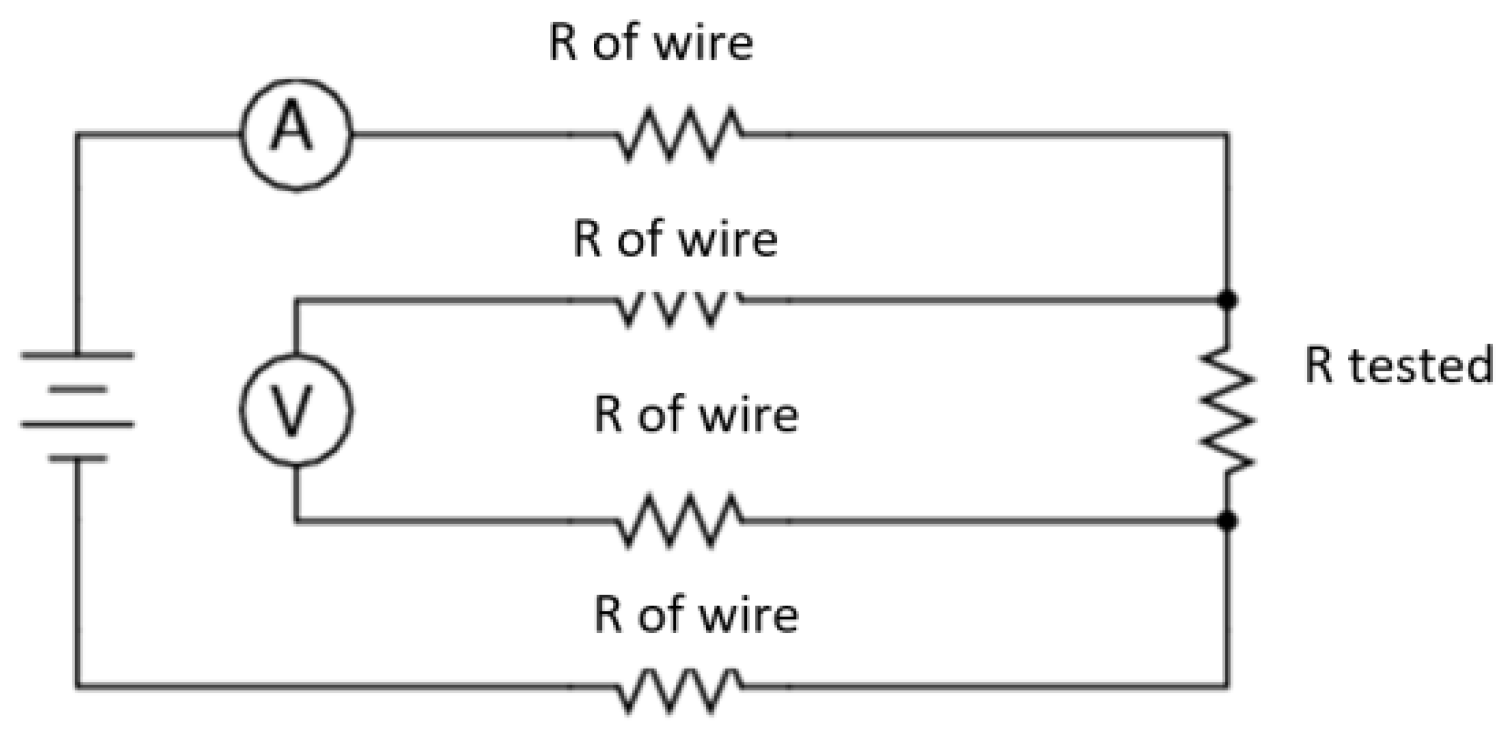

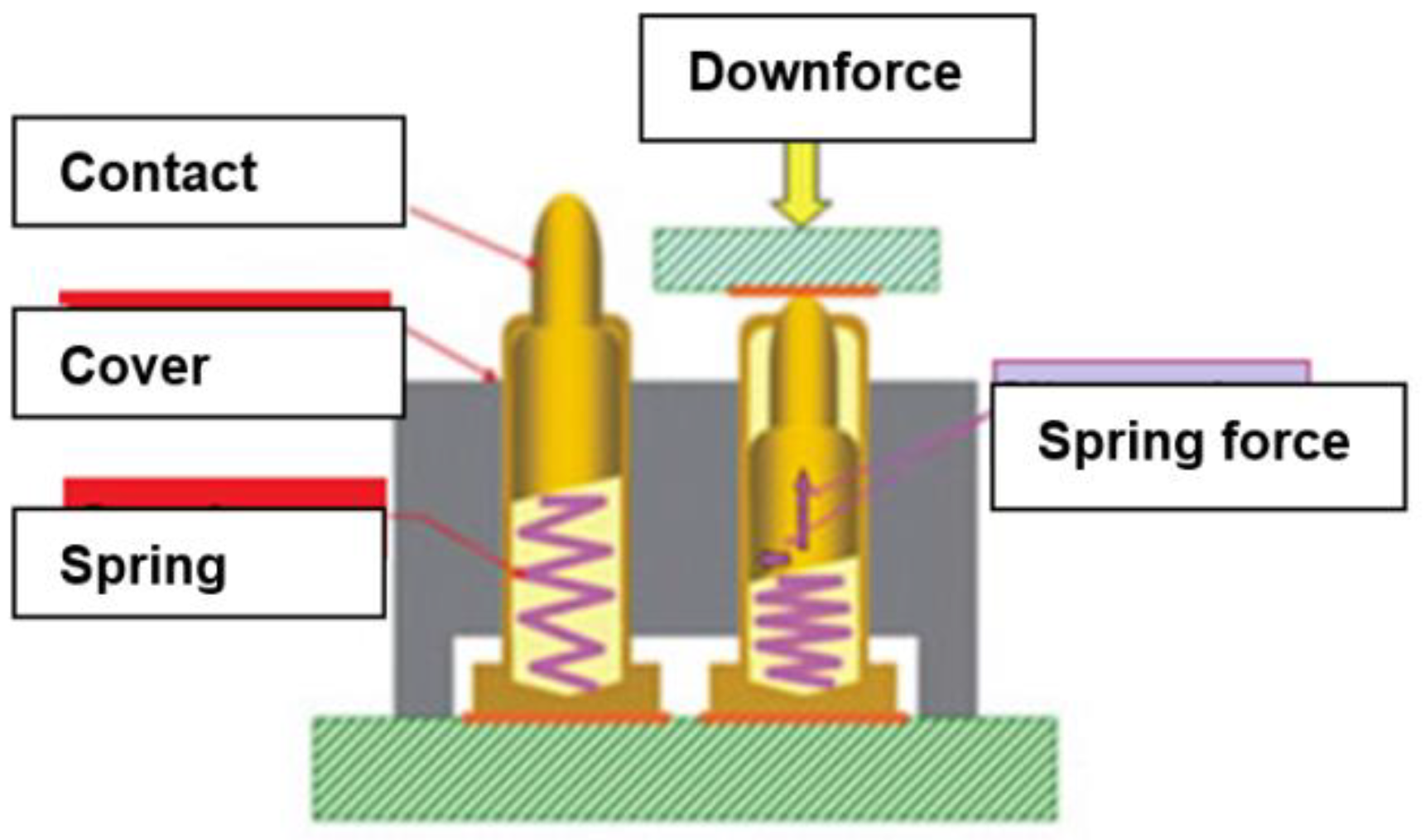

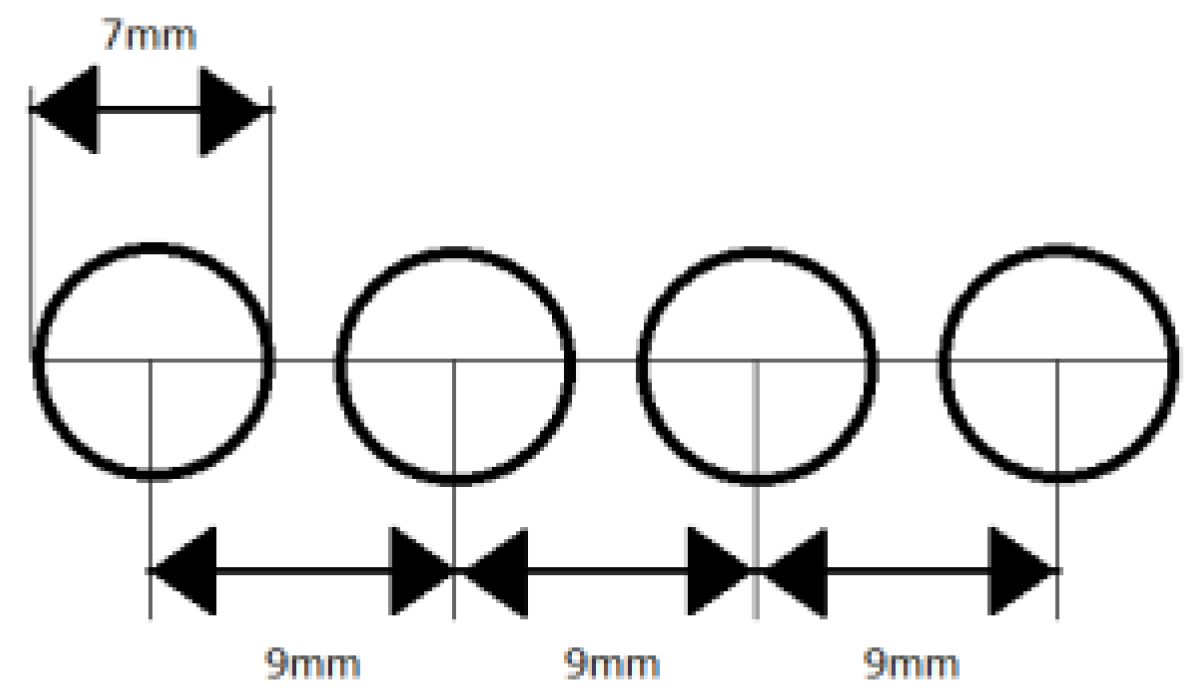

2.2.1. Surface Resistance Tests

2.2.2. Tensile Resistance of Polymer Film (Vulcanizates)

- tensile strength TS,

- elongation measurement section at break Eb.

2.2.3. Determination of Tear Strength of Composites

3. Results

3.1. Surface Resistance

3.2. Tensile Resistance

3.3. Tear Strength

4. Discussion

- Vulcanizates containing carbon black and additives,

- Vulcanizates containing silver and additives.

- with improved high tear strength composites with carbon black and the ionic liquid

- high tear strength composites with silver and ionic liquids.

5. Conclusions

- The inversely proportional effect of the filler content on the resistance surface was observed. The resistance values in GigaOhms (for 25 phr of silver) have decreased to kiloOhms (for 50 phr of silver).

- For polymer films with 50 phr of silver, there was observed a positive effect of the extrusion process and the addition of ionic liquids on the resistance values of the vulcanizates. In the case of using ionic liquid [bmim][PF6], the resistance value even showed 50 kΩ.

- Performed simulated aging cycles did not affect the electrical properties of the polymer films.

- Based on the results of tensile strength tests, it can be concluded that as a result of adding ionic liquids to the polymer as dispersants, the goal of improving the degree of dispersion of fillers in the polymer films was achieved.

- All composites polymer film made of ethylene-octene copolymer fabric showed good mechanical properties in terms of resistance to tearing.

- Further research works are required in order to ensure a higher level of homogeneity of the filler in polymer, as well as to verify the electrical properties under predicted ambient conditions (air humidity in particular).

6. Patents

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kazani, I.; Hertleer, C.; De Mey, G.; Schwarz, A.; Guxho, G.; Van Langenhove, L. Electrical conductive textiles obtained by screen printing, fibres and textiles in eastern europe. Fibres Text. East. Eur. 2012, 20, 57–63. [Google Scholar]

- Leśnikowski, J. Modelowanie Tekstylnych Linii Sygnałowych do Zastosowań w Tekstronice. Available online: http://repozytorium.p.lodz.pl/handle/11652/1277 (accessed on 18 March 2021).

- Mattila, H.R. Intelligent Textiles and Clothing; Woodhead Publishing Limited: Cambridge, UK, 2010. [Google Scholar]

- Tęsiorowski, Ł.; Gniotek, K. Radiowa transmisja sygnałów w systemie tekstronicznym. Przegląd Telekomunikacyjny+ Wiadomości Telekomunikacyjne 2008, 81, 1048–1051. [Google Scholar]

- Skrzetuska, E. Trendy rozwojowe w tekstronice–Rozwiązania tekstroniczne dla ochrony zdrowia. Przegląd Elektrotechniczny 2014, 90, 34–40. [Google Scholar]

- Bendkowska, W. Tekstylia inteligentne-przegląd zastosowań. Część II: Tekstylia elektroprzewodzące i tekstylia zintegrowane z mikrosystemami elektronicznymi. Przegląd Włókienniczy Technik Włókienniczy 2002, 9, 16–19. [Google Scholar]

- Walter, M.; Eilebrecht, B.; Wartzek, T.; Leonhardt, S. The smart car seat: Personalized monitoring of vital signs in automotive applications. Pers. Ubiquitous Comput. 2011, 15, 707–715. [Google Scholar] [CrossRef]

- Coyle, S.; Morris, D.; Lau, K.T.; Diamond, D.; Moyna, N. Textile-based wearable sensors for assisting sports performance. In 2009 Sixth International Workshop on Wearable and Implantable Body Sensor Networks; IEEE: New York, NY, USA, 2009; pp. 307–311. [Google Scholar]

- Scilingo, E.P.; Gemignani, A.; Paradiso, R.; Taccini, N.; Ghelarducci, B.; De Rossi, D. Performance evaluation of sensing fabrics for monitoring physiological and biomechanical variables. IEEE Trans. Inf. Technol. Biomed. 2005, 9, 345–352. [Google Scholar] [CrossRef] [PubMed]

- Krucińska, I.; Skrzetuska, E.; Urbaniak-Domagała, W. Prototypes of carbon nanotube-based textile sensors manufactured by the screen printing method. Fibres Text. East. Eur. 2012, 2, 79–83. [Google Scholar]

- Słoma, M.; Jakubowska, M. Thick Films: Properties, Technology and Applications; Panzini, M.I., Ed.; Nova Science Publishers: New York, NY, USA, 2012; Chapter 4; pp. 237–260. [Google Scholar]

- Tokarska, M. Characterization of electro-conductive textile materials by its biaxial anisotropy coefficient and resistivity. J. Mater. Sci. Mater. Electron. 2019, 30, 4093–4103. [Google Scholar] [CrossRef]

- Global Market Insights, 2017, Smart Clothing Market Size By Product (T-shirts, Pants, Shoes, Undergarments, Jackets, Socks), by Application (Sports & Fitness, Healthcare, Military & Defense, Industrial, Entertainment), Industry Analysis Report, Regional Outlook, Growth Potential, Price Trends, Competitive Market Share & Forecast, 2017–2024. Available online: https://www.gminsights.com/industry-analysis/smart-clothing-market (accessed on 14 April 2021).

- Tseghai, G.B.; Malengier, B.; Fante, K.A.; Nigusse, A.B.; Van Langenhove, L. Integration of conductive materials with textile structures, an overview. Sensors 2020, 20, 6910. [Google Scholar] [CrossRef] [PubMed]

- Angelucci, A.; Cavicchioli, M.; Cintorrino, I.A.; Lauricella, G.; Rossi, C.; Strati, S.; Aliverti, A. Smart textiles and sensorized garments for physiological monitoring: A review of available solutions and techniques. Sensors 2021, 21, 814. [Google Scholar] [CrossRef] [PubMed]

- Nowak, I.; Krucińska, I.; Januszkiewicz, Ł. Metallic electroconductive transmission lines obtained on textile substrates by magnetron sputtering. Fibres Text. East. Eur 2019, 23, 51–57. [Google Scholar] [CrossRef]

- Leśnikowski, J. Research into the textile-based signal lines made using ultrasonic welding technology. AUTEX Res. J. 2020. [Google Scholar] [CrossRef]

- Stempień, Z.; Rybicki, E.; Patykowska, A.; Rybicki, T.; Szynkowska, M.I. Shape-programmed inkjet-printed silver electro-conductive layers on textile Surface. J. Ind. Text. 2018, 47, 1321–1341. [Google Scholar] [CrossRef]

- Afroj, S.; Tan, S.; Abdelkader, A.M.; Novoselov, K.S.; Karim, N. Highly conductive, scalable, and machine washable graphene-based e-textiles for multifunctional wearable electronic applications. Adv. Funct. Mater. 2020, 30, 2000293. [Google Scholar] [CrossRef]

- Shahariar, H.; Kim, I.; Soewardiman, H.; Jur, J.S. Inkjet printing of reactive silver ink on textiles. ACS Appl. Mater. Interfaces 2019, 11, 6208–6216. [Google Scholar] [CrossRef] [PubMed]

- Kurczewska, A.; Masłowski, M.; Strąkowska, A.; Strzelec, K. Sposób Otrzymywania Materiałów Tekstylnych Elektroprzewodzących, Zwłaszcza do Zastosowania w Wyrobach Odzieżowych. Patent Office of the Republic of Poland Patent No. 232097, 27 December 2016. [Google Scholar]

- ASTM D2233-86(1997). Standard Specification for Chlorinated Aromatic Hydrocarbons (Askarels) for Capacitors (Withdrawn 2003); ASTM International: West Conshohocken, PA, USA, 1997. [Google Scholar]

- ISO 6330:2012 Textiles—Domestic Washing and Drying Procedures for Textile Testing. Available online: https://www.iso.org/obp/ui/#iso:std:iso:6330:ed-3:v1:en (accessed on 18 March 2021).

- ISO 7854:1995 Rubber- or Plastics-Coated Fabrics—Determination of Resistance to Damage by Flexing. Available online: https://www.iso.org/obp/ui/#iso:std:iso:7854:ed-2:v1:en (accessed on 18 March 2021).

- ISO 12947-2:2016 Textiles—Determination of the Abrasion Resistance of fabRics by the Martindale Method—Part 2: Determination of Specimen Breakdown. Available online: https://www.iso.org/obp/ui/#iso:std:iso:12947:-2:ed-2:v1:en (accessed on 18 March 2021).

- ISO 37:2005 Rubber, Vulcanized or Thermoplastic—Determination of Tensile Stress-Strain Properties. Available online: https://www.iso.org/standard/40200.html (accessed on 18 March 2021).

- ISO 34-1:2015 Rubber, Vulcanized or Thermoplastic—Determination of Tear Strength—Part 1: Trouser, Angle and Crescent Test Pieces. Available online: https://www.iso.org/obp/ui/#iso:std:iso:34:-1:ed-4:v1:en (accessed on 18 March 2021).

| Symbol | Samples Characteristics | Thickness and Surface Mass |

|---|---|---|

| A | Aramid fabric laminated with PES membrane–from the woven fabric side, threads in weft: 224, threads in warp: 324, twill weave | (0.38 ± 0.01) mm (220 ± 22) g/m2 |

| B | Aramid fabric laminated with PES membrane–from the membrane side, threads in weft: 224, threads in warp: 324, twill weave | (0.38 ± 0.01) mm (220 ± 22) g/m2 |

| C | Cotton fabric coated with polyurethane–film, threads in weft: 460, threads in warp: 670 | (0.27 ± 0.01) mm (148 ± 10) g/m2 |

| No. | EOR | Electroconductive Filler [phr] | Ionic Liquid/Extrusiom | |

|---|---|---|---|---|

| PRINTEX | Ag | |||

| P1 | 100 | 15 | - | -/- |

| P2 | 100 | 15 | - | [hmim][PF6]/- |

| P3 | 100 | 15 | - | [bmim][PF6]/- |

| P4 | 100 | 15 | - | [bmim][Cl]/- |

| P5 | 100 | 15 | - | -/extrusion |

| P6 | 100 | 20 | - | -/- |

| P7 | 100 | 20 | - | [hmim][PF6]/- |

| P8 | 100 | 20 | - | [bmim][PF6]/- |

| P9 | 100 | 20 | - | [bmim][Cl]/- |

| P10 | 100 | 20 | - | -/extrusion |

| P11 | 100 | 25 | - | -/- |

| P12 | 100 | 25 | - | [hmim][PF6]/- |

| P13 | 100 | 25 | - | [bmim][PF6]/- |

| P14 | 100 | 25 | - | [bmim][Cl]/- |

| P15 | 100 | 25 | - | -/extrusion |

| P16 | 100 | 30 | - | -/- |

| P17 | 100 | 30 | - | [hmim][PF6]/- |

| P18 | 100 | 30 | - | [bmim][PF6]/- |

| P19 | 100 | 30 | - | [bmim][Cl]/- |

| P20 | 100 | 30 | - | -/extrusion |

| A1 | 100 | - | 25 | [hmim][PF6]/- |

| A2 | 100 | - | 25 | [bmim][PF6]/- |

| A3 | 100 | - | 25 | [bmim][Cl]/- |

| A4 | 100 | - | 50 | -/- |

| A5 | 100 | - | 50 | [hmim][PF6]/- |

| A6 | 100 | - | 50 | [bmim][PF6]/- |

| A7 | 100 | - | 50 | [bmim][Cl]/- |

| A8 | 100 | - | 50 | -/extrusion |

| No | Composition of EOR Mixture | Surface Resistance |

|---|---|---|

| PRINTEX/Ilq | ||

| P1 | 15 | 4.5 ± 0.1 kΩ |

| P2 | 15/[hmim][PF6] | 2.5 ± 0.1 kΩ |

| P3 | 15/[bmim][PF6] | 6.4 ± 0.1 kΩ |

| P4 | 15/[bmim][Cl] | 3.4 ± 0.1 kΩ |

| P5 | 15/-(extruded) | 6.1 ± 0.1 kΩ |

| P6 | 20/- | 2.3 ± 0.1 kΩ |

| P7 | 20/[hmim][PF6] | 1.5 ± 0.1 kΩ |

| P8 | 20/[bmim][PF6] | 2.0 ± 0.1 kΩ |

| P9 | 20/[bmim][Cl] | 1.2 ± 0.1 kΩ |

| P10 | 20/-(extruded) | 3.1 ± 0.1 kΩ |

| P11 | 25/- | 1.7 ± 0.1 kΩ |

| P12 | 25/[hmim][PF6] | 1.2 ± 0.1 kΩ |

| P13 | 25/[bmim][PF6] | 1.3 ± 0.1 kΩ |

| P14 | 25/[bmim][Cl] | 1.0 ± 0.1 kΩ |

| P15 | 25/-(extruded) | 2.8 ± 0.1 kΩ |

| P16 | 30/- | 1.5 ± 0.1 kΩ |

| P17 | 30/[hmim][PF6] | 692 ± 20 Ω |

| P18 | 30/[bmim][PF6] | 1.2 ± 0.1 kΩ |

| P19 | 30/[bmim][Cl] | 962 ± 25 Ω |

| P20 | 30/-(extruded) | 1.7 ± 0.1 kΩ |

| Ag/Ilq | ||

| A1 | 25/[hmim][PF6] | 23 ± 1 GΩ |

| A2 | 25/[bmim][PF6] | 26 ± 1 GΩ |

| A3 | 25/[bmim][Cl] | 24 ± 1 GΩ |

| A4 | 50/- | 1.2 ± 0.1 MΩ |

| A5 | 50/[hmim][PF6] | 1.4 ± 0.1 kΩ |

| A6 | 50/[bmim][PF6] | 50 ± 2 kΩ |

| A7 | 50/[bmim][Cl] | 19 ± 1 GΩ |

| A8 | 50/-(extruded) | 110 ± 3 kΩ |

| No | Composite | Tensile Strength [MPa] | Elongation at Break [%] |

|---|---|---|---|

| EOR | EOR ref-pure polymer | 10.30 ± 1.21 | 608 ± 57 |

| EOR/Ag/Ilq | |||

| A4 | 50 | 9.97 ± 2.21 | 606 ± 32 |

| A5 | 50/[hmim][PF6] | 13.60 ± 0.99 | 610 ± 40 |

| A6 | 50/[bmim][PF6] | 13.20 ± 0.25 | 584 ± 36 |

| A7 | 50/[bmim][Cl] | 5.70 ± 0.97 | 355 ± 44 |

| A8 | 50 extrusion | 12.20 ± 0.71 | 535 ± 14 |

| EOR/PRINTEX/Ilq | |||

| P16 | 30 | 14.00 ± 1.06 | 304 ± 42 |

| P17 | 30/[hmim][PF6] | 14.80 ± 0.43 | 331 ± 18 |

| P18 | 30/[bmim][PF6] | 14.00 ± 0.81 | 330 ± 28 |

| P19 | 30/[bmim][Cl] | 14.60 ± 0.38 | 325 ± 18 |

| P20 | 30 extrusion | 18.70 ± 0.84 | 461 ± 20 |

| No | Composite | Tear Strength [N/mm] | ||

|---|---|---|---|---|

| A | B | C | ||

| Only textile material | 34.8 ± 0.3 | 34.8 ± 0.2 | 27.1 ± 2.5 | |

| EOR ref-pure polymer | 22.9 ± 1.0 | 28.7 ± 4.3 | 44.6 ± 3.3 | |

| EOR/Ag/Ilq | ||||

| A4 | 50 | 33.3 ± 0.13 | 32.2 ± 0.1 | 20.4 ± 1.4 |

| A5 | 50/[hmim][PF6] | 24.4 ± 1.5 | 30.6 ± 0.9 | 34.6 ± 1.0 |

| A6 | 50/[bmim][PF6] | 19.5 ± 0.8 | 29.9 ± 0.7 | 32.2 ± 2.3 |

| A7 | 50/[bmim][Cl] | 22.7 ± 3.5 | 26.7 ± 3.6 | 36.4 ± 1.2 |

| A8 | EOR extrusion | 21.4 ± 0.5 | 33.2 ± 4.8 | 31.0 ± 2.4 |

| EOR/PRINTEX/Ilq | ||||

| P16 | 30 | 70.6 ± 6.5 | 64.5 ± 10.1 | 45.3 ± 5.0 |

| P17 | 30/[hmim][PF6] | 53.7 ± 7.5 | 62.0 ± 9.9 | 44.6 ± 4.7 |

| P18 | 30/[bmim][PF6] | 63.8 ± 1.5 | 54.3 ± 2.0 | 42.6 ± 10.6 |

| P19 | 30/[bmim][Cl] | 65.7 ± 11.8 | 61.0 ± 7.3 | 51.1 ± 3.3 |

| P20 | 30 extrusion | 66.0 ± 9.3 | 57.3 ± 4.8 | 40.0 ± 3.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tabaczyńska, A.; Dąbrowska, A.; Masłowski, M.; Strąkowska, A. Mechanical and Electrical Performance of Flexible Polymer Film Designed for a Textile Electrically-Conductive Path. Materials 2021, 14, 2169. https://doi.org/10.3390/ma14092169

Tabaczyńska A, Dąbrowska A, Masłowski M, Strąkowska A. Mechanical and Electrical Performance of Flexible Polymer Film Designed for a Textile Electrically-Conductive Path. Materials. 2021; 14(9):2169. https://doi.org/10.3390/ma14092169

Chicago/Turabian StyleTabaczyńska, Agnieszka, Anna Dąbrowska, Marcin Masłowski, and Anna Strąkowska. 2021. "Mechanical and Electrical Performance of Flexible Polymer Film Designed for a Textile Electrically-Conductive Path" Materials 14, no. 9: 2169. https://doi.org/10.3390/ma14092169

APA StyleTabaczyńska, A., Dąbrowska, A., Masłowski, M., & Strąkowska, A. (2021). Mechanical and Electrical Performance of Flexible Polymer Film Designed for a Textile Electrically-Conductive Path. Materials, 14(9), 2169. https://doi.org/10.3390/ma14092169