Innovative Materials in Italy for Eco-Friendly and Sustainable Buildings

Abstract

1. Introduction

2. Literature Review for Sustainable, Safe, and Resilient Buildings

3. Materials and Methods

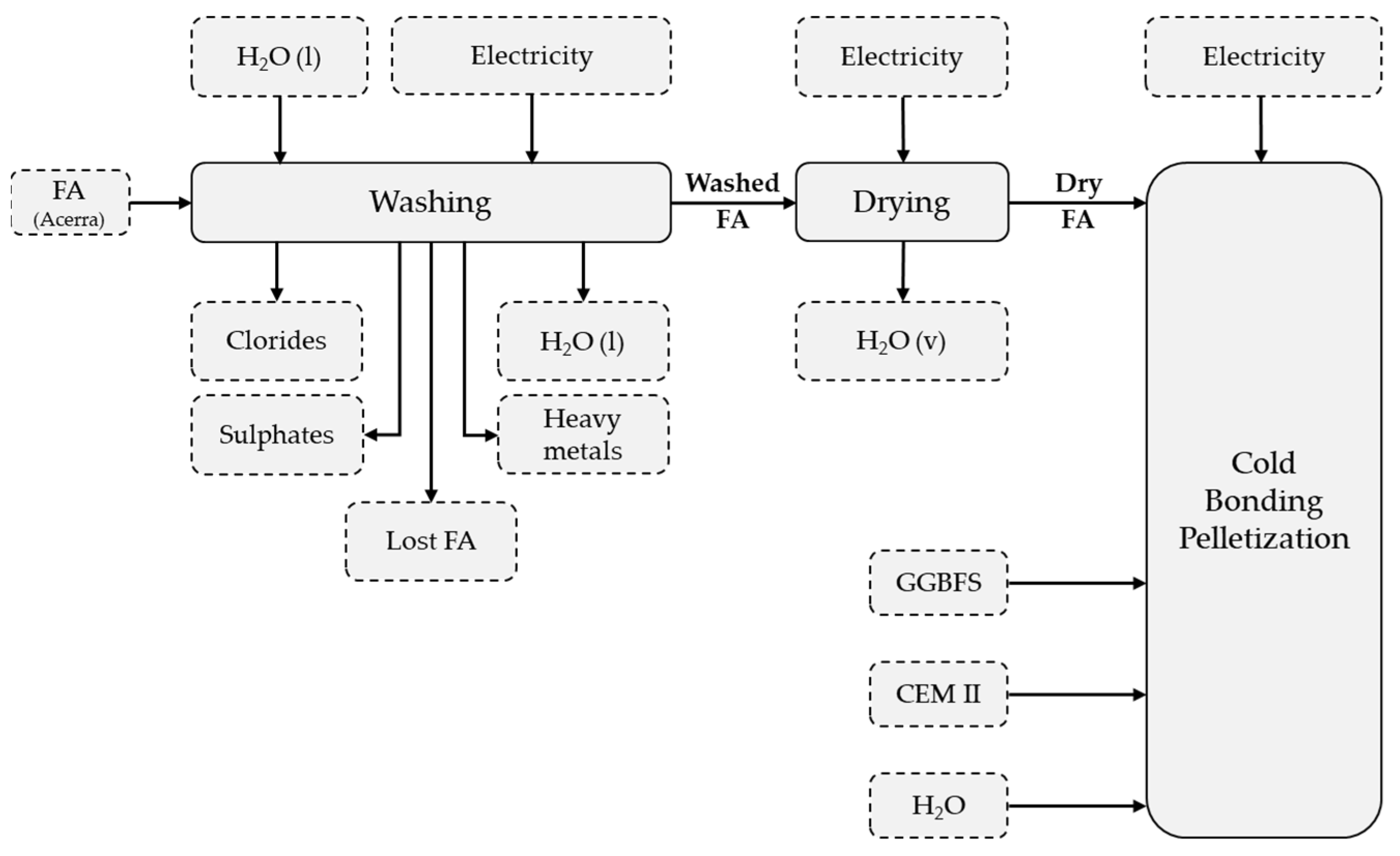

3.1. Artificial Lightweight Aggregates

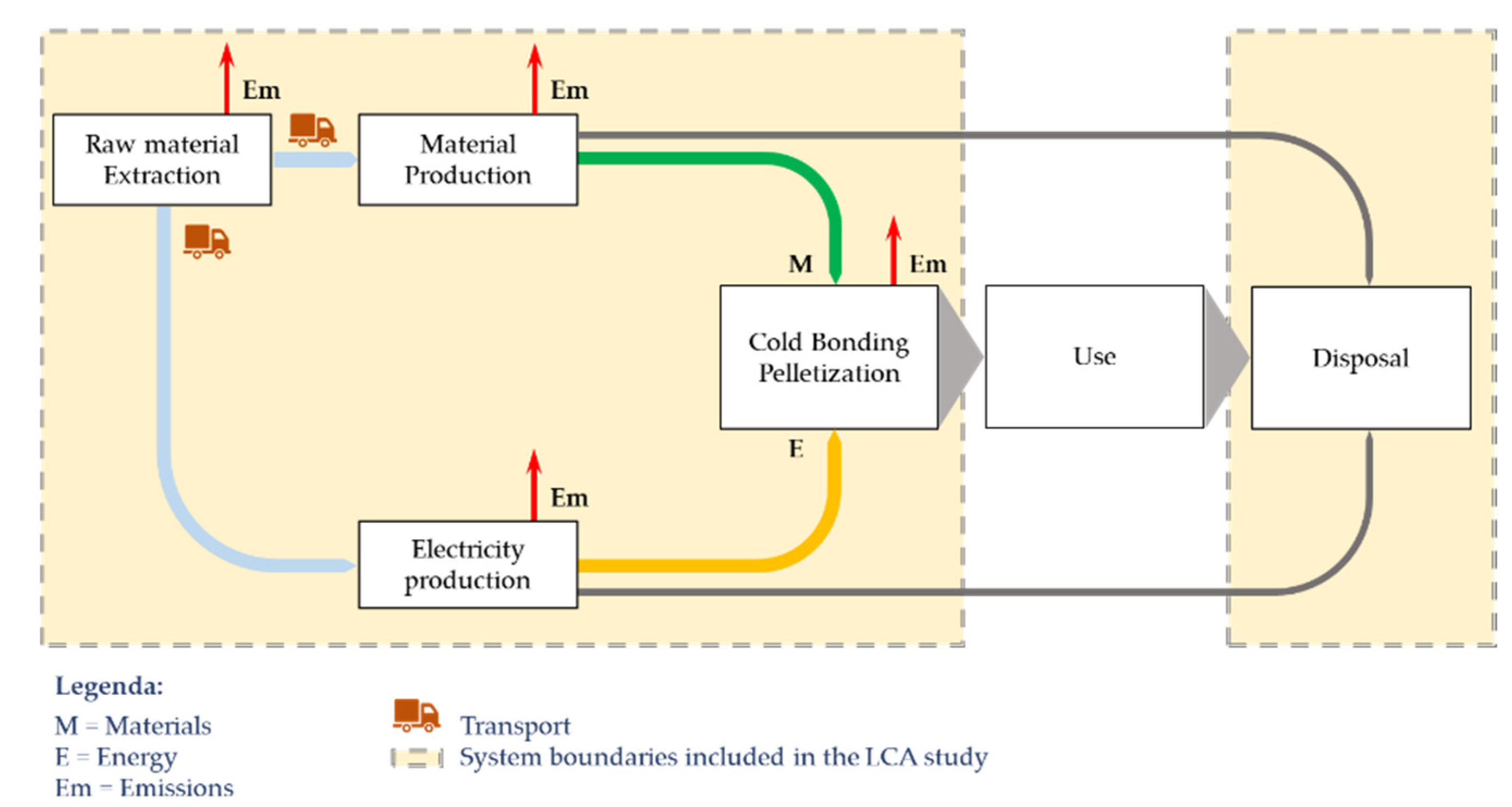

3.2. Life Cycle Assessment

4. Analysis for Optimizing Sustainability of LWA

4.1. Goal and Scope Definition

4.2. Life Cycle Inventory (LCI)

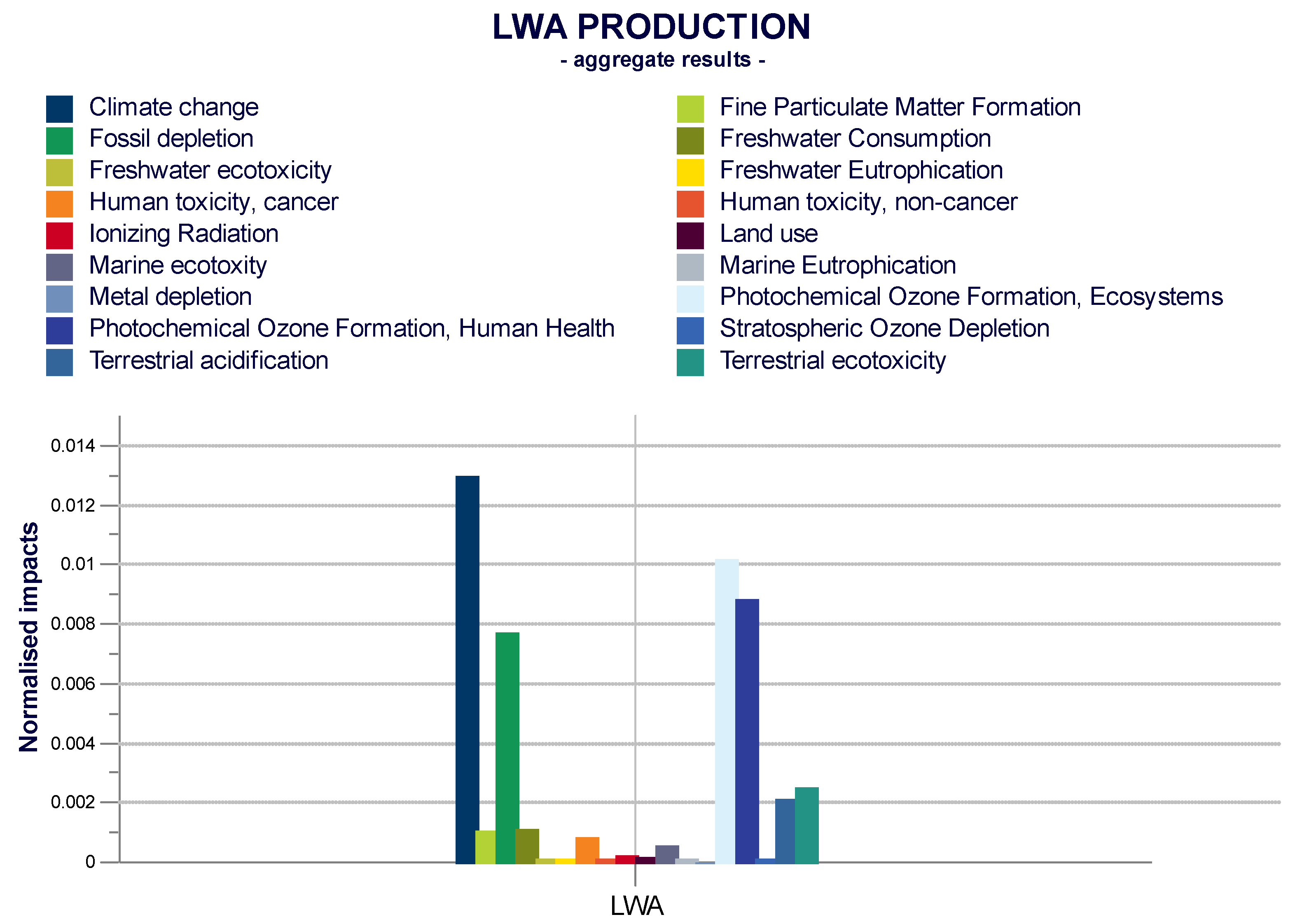

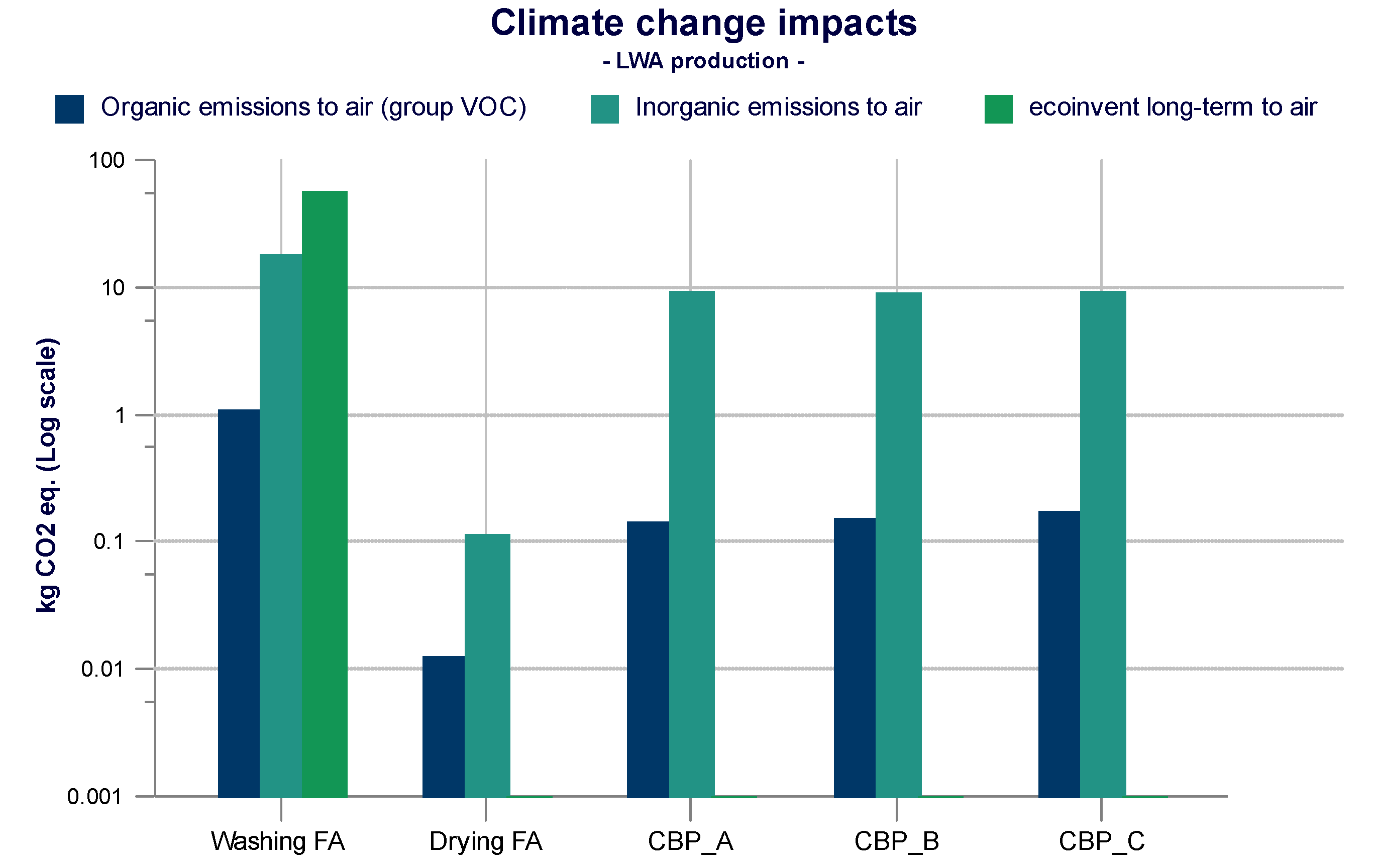

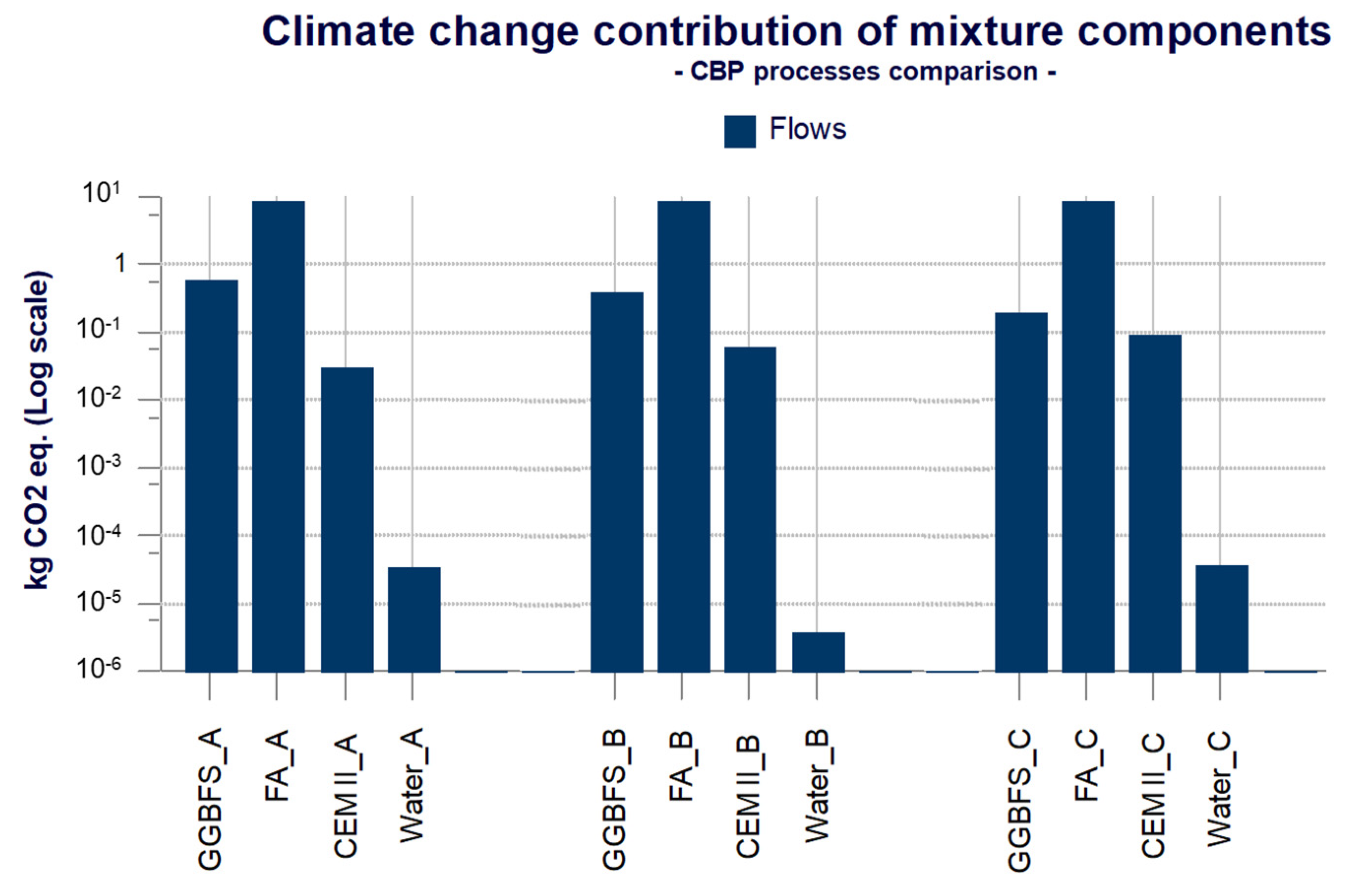

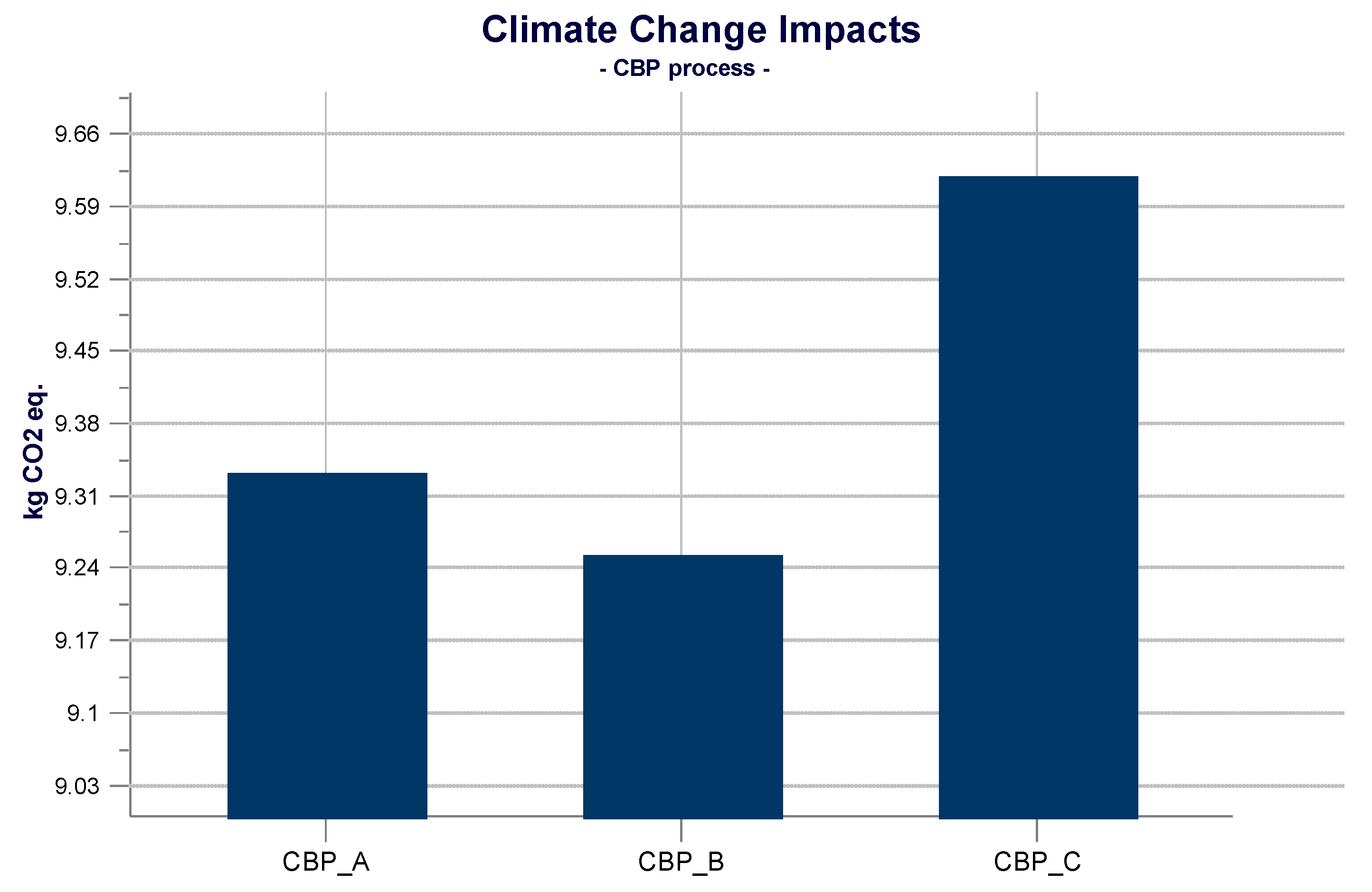

4.3. Results of Life Cycle Impact Assessment (LCIA)

4.4. Discussion of Interpretation of LCIA

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| CBP | Cold Bonding Pelletization |

| CEM II | Cement (CEM II 42.5) (EN15804 A1-A3) |

| FA | Fly Ash |

| FRP | Fiber-reinforced polymer matrix |

| GGBFS | Ground Granulated Blast Furnace Slag |

| LCA | Life Cycle Assessment |

| LCI | Life Cycle Inventory |

| LCIA | Life Cycle Impact Assessment |

| LWA | Lightweight Aggregate |

| LWAC | Lightweight Aggregate Concrete |

| MSWI | Municipal Solid Waste Incineration |

References

- Brunelli, A.; de Silva, F.; Piro, A.; Parisi, F.; Sica, S.; Silvestri, F.; Cattari, S. Numerical simulation of the seismic response and soil–structure interaction for a monitored masonry school building damaged by the 2016 Central Italy earthquake. Bull. Earthq. Eng. 2021, 19, 1181–1211. [Google Scholar] [CrossRef]

- Fabozzi, S.; Catalano, S.; Falcone, G.; Naso, G.; Pagliaroli, A.; Peronace, E.; Porchia, A.; Romagnoli, G.; Moscatelli, M. Stochastic approach to study the site response in presence of shear wave velocity inversion: Application to seismic microzonation studies in Italy. Eng. Geol. 2021, 280, 105914. [Google Scholar] [CrossRef]

- Felicetta, C.; Mascandola, C.; Spallarossa, D.; Pacor, F.; Hailemikael, S.; Di Giulio, G. Quantification of site effects in the Amatrice area (Central Italy): Insights from ground-motion recordings of the 2016–2017 seismic sequence. Soil Dyn. Earthq. Eng. 2021, 142, 106565. [Google Scholar] [CrossRef]

- Pischiutta, M.; Akinci, A.; Tinti, E.; Herrero, A. Broad-band ground-motion simulation of 2016 Amatrice earthquake, Central Italy. Geophys. J. Int. 2021, 224, 1753–1779. [Google Scholar] [CrossRef]

- Pagliacci, F.; Luciani, C.; Russo, M.; Esposito, F.; Habluetzel, A. The socioeconomic impact of seismic events on animal breeding A questionnaire-based survey from Central Italy. Int. J. Disaster Risk Reduct. 2021, 56, 102124. [Google Scholar] [CrossRef]

- Pecchioli, L.; Panzera, F.; Poggi, V. Cultural heritage and earthquakes: Bridging the gap between geophysics, archaeoseismology and engineering. Int. J. Seismol. 2020, 24, 725–728. [Google Scholar] [CrossRef]

- Colombi, M.; Borzi, B.; Crowley, H.; Onida, M.; Meroni, F.; Pinho, R. Deriving vulnerability curves using Italian earthquake damage data. Bull. Earthq. Eng. 2008, 6, 485–504. [Google Scholar] [CrossRef]

- Amato, A.; Azzara, R.; Chiarabba, C.; Cimini, G.B.; Cocco, M.; Di Bona, M.; Margheriti, L.; Mazza, S.; Mele, F.; Selvaggi, G.; et al. The 1997 Umbria-Marche, Italy, earthquake sequence: A first look at the main shocks and aftershocks. Geophys. Res. Lett. 1998, 25, 2861–2864. [Google Scholar] [CrossRef]

- Del Gaudio, C.; Di Ludovico, M.; Polese, M.; Manfredi, G.; Prota, A.; Ricci, P.; Verderame, G.M. Seismic fragility for Italian RC buildings based on damage data of the last 50 years. Bull. Earthq. Eng. 2020, 18, 2023–2059. [Google Scholar] [CrossRef]

- Tanda, K.; Spandana, N.; Kumar, D.V. Case Study on Earthquake Resistant Structures. Solid State Technol. 2021, 64, 10471–10480. [Google Scholar]

- Ornelas, C.; Guedes, J.M.; Sousa, F.; Breda-Vázquez, I. Supporting residential built heritage rehabilitation through an integrated assessment. Int. J. Archit. Herit. 2020, 1–14. [Google Scholar] [CrossRef]

- Mollo, L.; Agliata, R.; Iglesias, L.P.; Vigliotti, M. Typological GIS for knowledge and conservation of built heritage: A case study in Southern Italy. Inf. Construcción 2020, 72, e357. [Google Scholar] [CrossRef]

- Zan, L.; Baraldi, S.B.; Gordon, C. Cultural heritage between centralisation and decentralisation: Insights from the Italian context. Int. J. Cult. Policy 2007, 13, 49–70. [Google Scholar] [CrossRef]

- Mualam, N. Tracing the Effectiveness of Land Use Regulation: The Case of Heritage Protection Measures, Flexibility, and Adaptations. In Measuring the Effectiveness of Real Estate Regulation; Levine-Schnur, R., Ed.; Springer: Cham, Switzerland, 2020; pp. 61–84. [Google Scholar] [CrossRef]

- Stepinac, M.; Kisicek, T.; Renić, T.; Hafner, I.; Bedon, C. Methods for the Assessment of Critical Properties in Existing Masonry Structures under Seismic Loads—The ARES Project. Appl. Sci. 2020, 10, 1576. [Google Scholar] [CrossRef]

- Ashby, M.F. Materials and the Environment. Eco-informed Material Choice, 1st ed.; Elsevier: Amsterdam, The Netherlands, 2019; ISBN 9780080884486. [Google Scholar]

- Durakovic, B.; Yildiz, G.; Yahia, M.E. Comparative performance evaluation of conventional and renewable thermal insulation materials used in building envelops. Tehnički Vjesnik 2020, 27, 283–289. [Google Scholar] [CrossRef]

- Casprini, E.; Passoni, C.; Belleri, A.; Marini, A.; Bartoli, G.; Riva, P. Demolition-and-reconstruction or renovation? Towards a protocol for the assessment of the residual life of existing RC buildings. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Proceedings of the Central Europe towards Sustainable Building (CESB19), Prague, Czech Republic, 2–4 July 2019; IOP Publishing: Bristol, UK; Volume 290. [Google Scholar] [CrossRef]

- Rumyantseva, V.; Konovalova, V. Composite Reinforcement as a Way to Increase the Durability of Building Structures. Key Eng. Mater. 2020, 869, 336–341. [Google Scholar] [CrossRef]

- Gasch, T. Multiphysical Analysis Methods to Predict the Ageing and Durability of Concrete. Ph.D. Thesis, KTH Royal Institute of Technology, Department of Civil and Architectural Engineering, Division of Concrete Structures, Stockholm, Sweden, 2019. [Google Scholar]

- Shannag, M.J.; Higazey, M. Strengthening and Repair of a Precast Reinforced Concrete Residential Building. Civ. Eng. J. 2020, 6, 2457–2473. [Google Scholar] [CrossRef]

- Mak, K.; Fam, A. Fatigue Performance of Furfuryl Alcohol Resin Fiber-Reinforced Polymer for Structural Rehabilitation. J. Compos. Constr. 2020, 24, 04020012. [Google Scholar] [CrossRef]

- Hu, W.; Li, Y.; Yuan, H. Review of Experimental Studies on Application of FRP for Strengthening of Bridge Structures. Adv. Mater. Sci. Eng. 2020. [Google Scholar] [CrossRef]

- May, M.; Mohrmann, H.; Nahme, H. Visualization and Quantification of Stresses at the Ends of Short Fibers Embedded in Epoxy Resin. Key Eng. Mater. 2020, 858, 66–71. [Google Scholar] [CrossRef]

- Kuzina, E.; Cherkas, A.; Rimshin, V. Technical aspects of using composite materials for strengthening constructions. Iop Conf. Ser. Mater. Sci. Eng. 2018, 365, 032053. [Google Scholar] [CrossRef]

- Naser, M.Z.; Hawileh, R.A.; Abdalla, J.A. Fiber-reinforced polymer composites in strengthening reinforced concrete structures: A critical review. Eng. Struct. 2019, 198, 109542. [Google Scholar] [CrossRef]

- Malviya, R.K.; Singh, R.K.; Purohit, R.; Sinha, R. Natural fibre reinforced composite materials: Environmentally better life cycle assessment–A case study. Mater. Today Proc. 2020, 26, 3157–3160. [Google Scholar] [CrossRef]

- Wu, T.; Liu, G.; Fu, S.; Xing, F. Recent Progress of Fiber-Optic Sensors for the Structural Health Monitoring of Civil Infrastructure. Sensors 2020, 20, 4517. [Google Scholar] [CrossRef] [PubMed]

- Khandel, O.; Soliman, M.; Floyd, R.W.; Murray, C.D. Performance assessment of prestressed concrete bridge girders using fiber optic sensors and artificial neural networks. Struct. Infrastruct. Eng. 2020, 1–15. [Google Scholar] [CrossRef]

- Massoudinejad, M.; Amanidaz, N.; Santos, R.M.; Bakhshoodeh, R. Use of municipal, agricultural, industrial, construction and demolition waste in thermal and sound building insulation materials: A review article. J. Environ. Health Sci. Eng. 2019, 17, 1227–1242. [Google Scholar] [CrossRef] [PubMed]

- Raut, A.N.; Gomez, C.P. Development of thermally efficient fibre-based eco-friendly brick reusing locally available waste materials. Constr. Build. Mater. 2017, 133, 275–284. [Google Scholar] [CrossRef]

- Chippagiri, R.; Gavali, H.R.; Ralegaonkar, R.V.; Riley, M.; Shaw, A.; Bras, A. Application of sustainable prefabricated wall technology for energy efficient social housing. Sustainability 2021, 13, 1195. [Google Scholar] [CrossRef]

- Colangelo, F.; Cioffi, R. Mechanical properties and durability of mortar containing fine fraction of demolition wastes produced by selective demolition in South Italy. Compos. Part B Eng. 2017, 115, 43–50. [Google Scholar] [CrossRef]

- Xiao, J.; Sun, Y.; Falkner, H. Seismic performance of frame structures with recycled aggregate concrete. Eng. Struct. 2006, 28, 1–8. [Google Scholar] [CrossRef]

- Liu, C.; Fan, J.; Bai, G.; Quan, Z.; Fu, G.; Zhu, C.; Fan, Z. Cyclic load tests and seismic performance of recycled aggregate concrete (RAC) columns. Constr. Build. Mater. 2019, 195, 682–694. [Google Scholar] [CrossRef]

- Saribas, I.; Goksu, C.; Binbir, E.; Ilki, A. Seismic performance of full-scale RC columns containing high proportion recycled aggregate. Bull. Earthq. Eng. 2019, 17, 6009–6037. [Google Scholar] [CrossRef]

- Meng, E.; Yu, Y.; Zhang, X.; Su, Y. Seismic experiment and performance index studies on recycled aggregate concrete filled steel tube frames infilled with recycled hollow block filler walls. Struct. Concr. 2020. [Google Scholar] [CrossRef]

- Akan, A.E.; Ünal, F.; Koçyiğit, F. Investigation of Energy Saving Potential in Buildings Using Novel Developed Lightweight Concrete. Int. J. Thermophys. 2021, 42, 4. [Google Scholar] [CrossRef]

- Carrajola, R.; Hawreen, A.; Flores-Colen, I.; de Brito, J. Fresh properties of cement-based thermal renders with fly ash, air lime and lightweight aggregates. J. Build. Eng. 2021, 34, 101868. [Google Scholar] [CrossRef]

- Ibrahim, M.; Ahmad, A.; Barry, M.S.; Alhems, L.M.; Mohamed Suhoothi, A.C. Durability of Structural Lightweight Concrete Containing Expanded Perlite Aggregate. Int. J. Concr. Struct. Mater. 2020, 14, 50. [Google Scholar] [CrossRef]

- Ren, M.; Liu, Y.; Gao, X. Incorporation of phase change material and carbon nanofibers into lightweight aggregate concrete for thermal energy regulation in buildings. Energy 2020, 197, 117262. [Google Scholar] [CrossRef]

- Li, S.; Liu, K.; Sun, L. Effect of different kinds of lightweight aggregates on performance of composite insulation materials. J. Build. Mater. 2017, 20, 245–250. [Google Scholar] [CrossRef]

- Ferraro, A.; Colangelo, F.; Farina, I.; Race, M.; Cioffi, R.; Cheeseman, C.; Fabbricino, M. Cold-bonding process for treatment and reuse of waste materials: Technical designs and applications of pelletized products. Crit. Rev. Environ. Sci. Technol. 2020, 1–35. [Google Scholar] [CrossRef]

- Sakai, K.; Noguchi, T. The Sustainable Use of Concrete, 1st ed.; CRC Press/Taylor & Francis Group: Boca Raton, FL, USA, 2013; p. 176. ISBN 978-0-415-66720-3. [Google Scholar]

- Vandanapu, S.N.; Krishnamurthy, M. Seismic performance of lightweight concrete structures. Adv. Civil. Eng. 2018. [Google Scholar] [CrossRef]

- Rosado, L.P.; Vitale Penteado, C.S.G.; Arena, U. Life cycle assessment of natural and mixed recycled aggregate production in Brazil. J. Clean. Prod. 2017, 151, 634–642. [Google Scholar] [CrossRef]

- Tam, V.W.Y.; Soomro, M.; Evangelista, A.C.J. A review of recycled aggregate in concrete applications (2000–2017). Constr. Build. Mater. 2018, 172, 272–292. [Google Scholar] [CrossRef]

- Hossain, M.U.; Poon, C.S.; Lo, I.M.C.; Cheng, J.C.P. Comparative environmental evaluation of aggregate production from recycled waste materials and virgin sources by LCA. Resour. Conserv. Recycl. 2016, 109, 67–77. [Google Scholar] [CrossRef]

- Kurda, R.; Silvestre, J.D.; de Brito, J. Life cycle assessment of concrete made with high volume of recycled concrete aggregates and fly ash. Resour. Conserv. Recycl. 2018, 139, 407–417. [Google Scholar] [CrossRef]

- Kurda, R.; de Brito, J.; Silvestre, J.D. Carbonation of concrete made with high amount of fly ash and recycled concrete aggregates for utilization of CO2. J. CO2 Util. 2019, 29, 12–19. [Google Scholar] [CrossRef]

- Rodríguez-Robles, D.; Van Den Heede, P.; De Belie, N. Life Cycle Assessment Applied to Recycled Aggregate Concrete. In New Trends in Eco-Efficient and Recycled Concrete; Woodhead Publishing Series in Civil and Structural Engineering; Woodhead Publishing: Cambridge, UK, 2019; pp. 207–256. [Google Scholar] [CrossRef]

- Serres, N.; Braymand, S.; Feugeas, F. Environmental evaluation of concrete made from recycled concrete aggregate implementing life cycle assessment. J. Build. Eng. 2016, 5, 24–33. [Google Scholar] [CrossRef]

- EUR-lex. European Waste Catalog. Available online: https://eur-lex.europa.eu/legal-content/IT/TXT/?uri=celex%3A32000D0532 (accessed on 13 December 2020).

- Dichiarazione Ambientale by RINA S.p.A. for A2A. Ambiente Termovalorizzatore di Acerra. 2020. Available online: https://a2a-be.s3.eu-west-1.amazonaws.com/a2a/2020-06/DA%202020_TMV%20Acerra.pdf?null= (accessed on 9 November 2020).

- Colangelo, F.; Petrillo, A.; Cioffi, R.; Borrelli, C.; Forcina, A. Life cycle assessment of recycled concretes: A case study in southern Italy. Sci. Tot. Environ. 2018, 615, 1506–1517. [Google Scholar] [CrossRef] [PubMed]

- Archive of European Integration (AEI). Green Paper on Integrated Product Policy. Available online: http://aei.pitt.edu/42997/1/com2001_0068.pdf (accessed on 13 December 2020).

- EUR-lex. Comunicazione Della Commissione al Consiglio e al Parlamento Europeo: Politica Integrata dei Prodotti. Available online: https://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=COM:2003:0302:FIN:IT:PDF (accessed on 13 December 2020).

- Charter, M. Integrated Product Policy (IPP) and Eco-Product Development (EPD). In Proceedings of the Second International Symposium on Environmentally Conscious Design and Inverse Manufacturing, Tokyo, Japan, 11–15 December 2001; pp. 672–677. [Google Scholar] [CrossRef]

- EUR-lex. Comunicazione Della Commissione al Consiglio e al Parlamento Europeo. Available online: https://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=OJ:L:2009:342:0001:0045:IT:PDF (accessed on 13 December 2020).

- EUR-lex. Relazione Della Commissione al Parlamento Europeo e al Consiglio. Available online: https://eur-lex.europa.eu/legal-content/IT/ALL/?uri=CELEX:52017DC0355 (accessed on 13 December 2020).

- International Organization for Standardization (ISO). Environmental Management—Life Cycle Assessment—Principles and Framework; ISO 14040:2006; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- International Organization for Standardization (ISO). Environmental Management—Life Cycle Assessment—Requirements and Guidelines; ISO 14044:2006; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- Park, W.-J.; Kim, T.; Roh, S.; Kim, R. Analysis of Life Cycle Environmental Impact of Recycled Aggregate. Appl. Sci. 2019, 9, 1021. [Google Scholar] [CrossRef]

- Van den Heede, P.; De Belie, N. Environmental impact and life cycle assessment (LCA) of traditional and “green” concretes: Literature review and theoretical calculations. Cem. Concr. Compos. 2012, 34, 431–442. [Google Scholar] [CrossRef]

- Huijbregts, M.A.J.; Steinmann, Z.J.N.; Elshout, P.M.F.; Stam, G.; Verones, F.; Vieira, M.D.M.; Hollander, A.; Van Zelm, R. ReCiPe2016: A Harmonized Life Cycle Impact Assessment Method at Midpoint and Endpoint Level; Report I: Characterization, RIVM Report 2016-0104; National Institute for Human Health and the Environment: Bilthoven, The Netherlands, 2016. [Google Scholar]

| Compounds (wt%) | FA | GGBFS | CEM II |

|---|---|---|---|

| Fe2O3 | 0.86 | 25.53 | 3.41 |

| CaO | 24.31 | 17.48 | 67.16 |

| CO | 16.35 | 11.29 | - |

| SiO2 | 2.62 | - | 16.65 |

| Al2O3 | 1.53 | 8.93 | 4.21 |

| SO3 | 8.57 | - | 5.34 |

| ClO | 21.20 | - | - |

| MgO | 1.09 | 7.94 | 1.71 |

| ZnO | 2.85 | - | - |

| TiO2 | 0.36 | - | - |

| Na2O | 13.87 | - | - |

| K2O | 6.41 | - | 1.54 |

| Mn2O3 | - | 3.44 | - |

| Cr2O3 | - | 1.84 | - |

| NOx | - | 10.07 | - |

| Mixture (wt%) | FA | GGBFS | CEM II |

|---|---|---|---|

| LWA A | 80 | 15 | 5 |

| LWA B | 80 | 10 | 10 |

| LWA C | 80 | 5 | 15 |

| Mixture | FA | GGBFS | CEM II |

|---|---|---|---|

| LWA A | 92.73% | 6.13% | 0.32% |

| LWA B | 94.36% | 4.16% | 0.66% |

| LWA C | 96.03% | 2.12% | 1.00% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Colangelo, F.; Farina, I.; Travaglioni, M.; Salzano, C.; Cioffi, R.; Petrillo, A. Innovative Materials in Italy for Eco-Friendly and Sustainable Buildings. Materials 2021, 14, 2048. https://doi.org/10.3390/ma14082048

Colangelo F, Farina I, Travaglioni M, Salzano C, Cioffi R, Petrillo A. Innovative Materials in Italy for Eco-Friendly and Sustainable Buildings. Materials. 2021; 14(8):2048. https://doi.org/10.3390/ma14082048

Chicago/Turabian StyleColangelo, Francesco, Ilenia Farina, Marta Travaglioni, Cinzia Salzano, Raffaele Cioffi, and Antonella Petrillo. 2021. "Innovative Materials in Italy for Eco-Friendly and Sustainable Buildings" Materials 14, no. 8: 2048. https://doi.org/10.3390/ma14082048

APA StyleColangelo, F., Farina, I., Travaglioni, M., Salzano, C., Cioffi, R., & Petrillo, A. (2021). Innovative Materials in Italy for Eco-Friendly and Sustainable Buildings. Materials, 14(8), 2048. https://doi.org/10.3390/ma14082048