Silica and Silica–Titania Xerogels Doped with Iron(III) for Total Antioxidant Capacity Determination

Abstract

1. Introduction

2. Results and Discussion

2.1. Silica and Silica–Titania Xerogels Doped with Iron(III) Synthesis

| Material | SiFe | SiTi5Fe | SiTi12.5Fe | SiTi12.5Fe100 |

| Amount of iron(III), % wt | 0.022 | 0.032 | 0.047 | 2.80 |

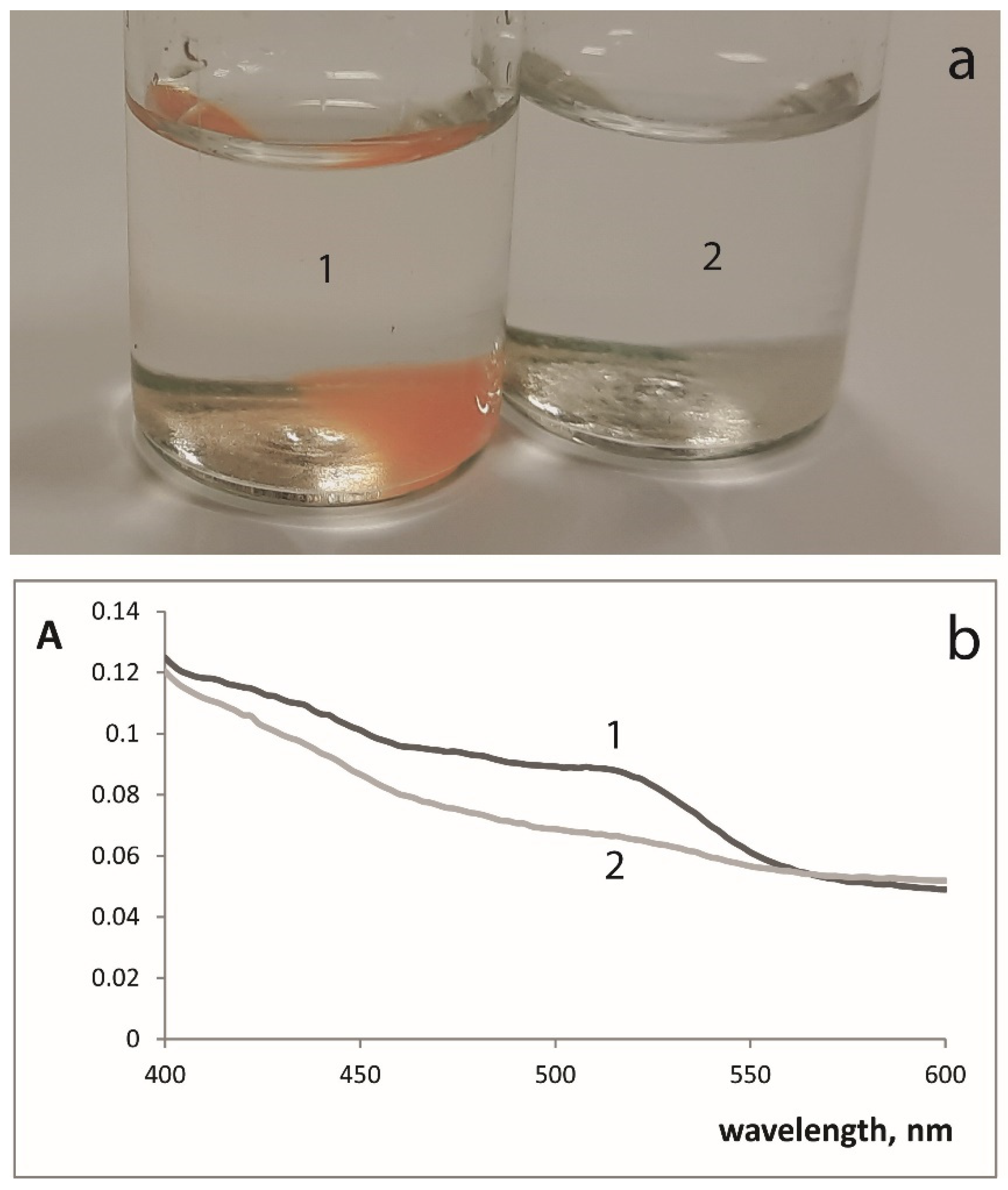

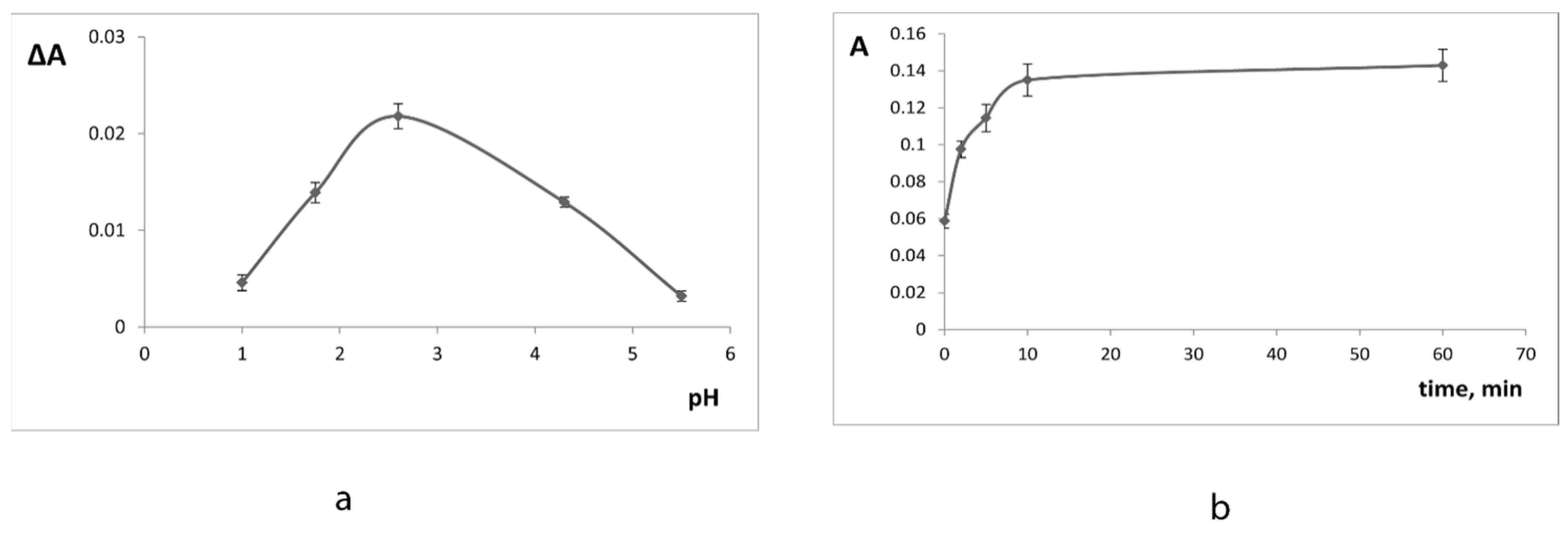

2.2. Immobilized Iron(III) Interaction with 1,10-Phenanthroline

2.3. The Analytical Application of the Modified Xerogels

3. Experimental

3.1. Reagents

3.2. Instrumentations

3.3. Synthesis of Silica and Silica–Titania Xerogels Doped with Iron(III)

3.4. General Procedure to Study the Interaction of Xerogels Doped with Iron(III) Interactions with Antioxidants in Presence of 1,10-Phenanthroline

3.5. Preparation of the Sensor Materials—Xerogels Doped with Iron(III) and Modified with 1,10-Phenanthroline

3.6. General Procedure to Study Interaction of Sensor Material with Antioxidants

3.7. Sample Preparation and Solid Phase Spectrophotometric Determination Procedure

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Csepregi, K.; Neugart, S.; Schreiner, M.; Hideg, E. Comparative Evaluation of Total Antioxidant Capacities of Plant Polyphenols. Molecules 2016, 21, 208. [Google Scholar] [CrossRef]

- Mukdasai, S.; Uppachai, P.; Srijaranai, S. A novel colorimetric paper sensor based on the layer-by-layer assembled multilayers of surfactants for the sensitive and selective determination of total antioxidant capacity. RSC Adv. 2019, 9, 28598. [Google Scholar] [CrossRef]

- Hoyos-Arbelaez, J.; Vazquez, M.; Contreras-Calderon, J. Electrochemical methods as a tool for determining the antioxidant capacity of food and beverages: A review. Food Chem. 2017, 221, 1371–1381. [Google Scholar] [CrossRef] [PubMed]

- Barroso, M.F.; Ramalhosa, M.J.; Alves, R.C.; Dias, A.; Soares, C.M.; Oliva-Teles, M.T.; Delerue-Matos, C. Total antioxidant capacity of plant infusions: Assessment using electrochemical DNA-based biosensor and spectrophotometric methods. Food Control. 2016, 68, 153–161. [Google Scholar] [CrossRef]

- Berker, K.I.; Guclu, K.; Tor, I.; Demirata, B.; Apak, R. Total Antioxidant Capacity Assay Using Optimized Ferricyanide/Prussian Blue Method. Food Anal. Methods 2010, 3, 154–168. [Google Scholar] [CrossRef]

- Berker, K.I.; Guclu, K.; Tor, I.; Demirata, B.; Apak, R. Comparative evaluation of Fe(III) reducing power-based antioxidant capacity assays in the presence of phenanthroline, batho-phenanthroline, tripyridyltriazine (FRAP), and ferricyanide reagents. Talanta 2007, 72, 1157–1165. [Google Scholar] [CrossRef] [PubMed]

- Bener, M.; Sen, F.B.; Kasgoz, A.; Apak, R. Carrageenan-based colorimetric sensor for total antioxidant capacity measurement. Sens. Actuat. B Chem. 2018, 273, 439–447. [Google Scholar] [CrossRef]

- Bener, M.; Sen, F.B.; Apak, R. Heparin-stabilized gold nanoparticles-based CUPRAC colorimetric sensor for antioxidant capacity measurement. Talanta 2018, 187, 148–155. [Google Scholar] [CrossRef]

- Bener, M.; Ozyurek, M.; Guclu, K.; Apak, R. Development of a Low-Cost Optical Sensor for Cupric Reducing Antioxidant Capacity Measurement of Food Extracts. Anal. Chem. 2010, 82, 4252–4258. [Google Scholar] [CrossRef]

- Bener, M.; Ozyurek, M.; Guclu, K.; Apak, R. Novel Optical Fiber Reflectometric CUPRAC Sensor for Total Antioxidant Capacity Measurement of Food Extracts and Biological Samples. J. Agric. Food Chem. 2013, 61, 8381–8388. [Google Scholar] [CrossRef]

- Isik, E.; Sahin, S.; Demir, C. Development of a new chromium reducing antioxidant capacity (CHROMAC) assay for plants and fruits. Talanta 2013, 111, 119–124. [Google Scholar] [CrossRef] [PubMed]

- Shahvar, A.; Saraji, M.; Gordan, H.; Shamsaei, D. Combination of paper-based thin film microextraction with smartphone-based sensing for sulfite assay in food samples. Talanta 2019, 197, 578–583. [Google Scholar] [CrossRef]

- Gavrilenko, N.A.; Saranchina, N.V.; Gavrilenko, M.A. Polymethacrylate Colorimetric Sensor for Evaluation of Total Antioxidant Capacity. Procedia Chem. 2014, 10, 97–102. [Google Scholar] [CrossRef]

- Bener, M.; Apak, R. Ferric-o-phenanthroline adsorbed on a Nafion membrane: A novel optical sensor for antioxidant capacity measurement of food extracts. Sens. Actuat. B 2017, 247, 155–162. [Google Scholar] [CrossRef]

- Ozyurt, D.; Demirata, B.; Apak, R. Determination of Total Antioxidant Capacity by a New Spectrofluorometric Method Based on Ce(IV) Reduction: Ce(III) Fluorescence Probe for CERAC Assay. J. Fluoresc. 2011, 21, 2069–2076. [Google Scholar] [CrossRef]

- Piyanan, T.; Athipornchai, A.; Henry, C.S.; Sameenoi, Y. An Instrument-free Detection of Antioxidant Activity Using Paper-based Analytical Devices Coated with Nanoceria. Anal. Sci. 2018, 34, 97–102. [Google Scholar] [CrossRef]

- Della Pelle, F.; Scroccarello, A.; Sergi, M.; Mascini, M.; Del Carlo, M.; Compagnone, D. Simple and rapid silver nanoparticles based antioxidant capacity assays: Reactivity study for phenolic compounds. Food Chem. 2018, 256, 342–349. [Google Scholar] [CrossRef]

- Jaberie, H.; Momeni, S.; Iraj Nabipour, I. Total antioxidant capacity assessment by a development of an antioxidant assay based on green synthesized MnO2 nanosheets. Microchem. J. 2020, 157, 104908. [Google Scholar] [CrossRef]

- Pedone, D.; Moglianetti, M.; Lettieri, M.; Marrazza, G.; Pompa, P.P. Platinum Nanozyme Enabled Colorimetric Determination of Total Antioxidant Level in Saliva. Anal. Chem. 2020, 92, 8660–8664. [Google Scholar] [CrossRef] [PubMed]

- Morosanova, E.I. Silica–Titania Sol–Gel Materials: Synthesis and Analytical Applications. J. Anal. Chem. 2018, 73, 1043–1052. [Google Scholar] [CrossRef]

- Morosanova, E.I.; Belyakov, M.V.; Zolotov, Y.A. Silicon–titanium xerogels: Synthesis and application to the determination of ascorbic acid and polyphenols. J. Anal. Chem. 2012, 67, 14–20. [Google Scholar] [CrossRef]

- Lopez, T.; Mendez, J.; Zamudio, T.; Villa, M. Spectroscopic study of sol-gel silica doped with iron ions. Mater. Chem. Phys. 1992, 30, 161–167. [Google Scholar] [CrossRef]

- Popovici, M.; Savii, C.; Enache, C.; Niziiansky, D.; Subrt, I.; Vecemikova, E. Sol-gel derived iron oxide-silica nanocomposites, starting from iron chloride and iron nitrate. J. Optoelectron. Adv. Mater. 2005, 5, 2753–2762. [Google Scholar] [CrossRef]

- Hung, W.C.; Fu, S.H.; Tseng, J.J.; Chu, H.; Ko, T.H. Study on photocatalytic degradation of gaseous dichloromethane using pure and iron ion-doped TiO2 prepared by the sol–gel method. Chemosphere 2007, 66, 2142–2151. [Google Scholar] [CrossRef]

- Velazquez-Martınez, S.; Silva-Martınez, S.; Pineda-Arellano, C.A.; Jimenez-Gonzalez, A.; Salgado-Transito, I.; Morales-Perez, A.A.; Pena-Cruz, M.I. Modified sol-gel/hydrothermal method for the synthesis of microsized TiO2 and iron-doped TiO2, its characterization and solar photocatalytic activity for an azo dye degradation. J. Photochem. Photobiol. A 2018, 359, 93–101. [Google Scholar] [CrossRef]

- Lopez, T.; Moreno, J.A.; Gomez, R.; Bokhimi, X.; Wang, J.A.; Yee-Madeira, H.; Pecchi, G.; Reyes, P. Characterization of iron-doped titania sol–gel materials. J. Mater. Chem. 2002, 12, 714–718. [Google Scholar] [CrossRef]

- Wang, M.C.; Lin, H.J.; Yang, T.S. Characteristics and optical properties of iron ion (Fe3+)-doped titanium oxide thin films prepared by a sol–gel spin coating. J. Alloys Compd. 2009, 473, 394–400. [Google Scholar] [CrossRef]

- Crisan, M.; Mardare, D.; Ianculescu, A.; Dragan, N.; Nitoi, I.; Crisan, D.; Voicescu, M.; Todan, L.; Oancea, P.; Adomnitei, C.; et al. Iron doped TiO2 films and their photoactivity in nitrobenzene removal from water. Appl. Surf. Sci. 2018, 455, 201–215. [Google Scholar] [CrossRef]

- Morosanova, M.A.; Morosanova, E.I. Silica-titania xerogel doped with Mo,P-heteropoly compounds for solid phase spectrophotometric determination of ascorbic acid in fruit juices, pharmaceuticals, and synthetic urine. Chem. Cent. J. 2017, 11, 3. [Google Scholar] [CrossRef] [PubMed]

- Morosanova, M.A.; Morosanova, E.I.; Anisimov, D.I.; Zolotov, Y.A. Using Silica–titania Xerogels for Solid Phase Spectrophotometric Determination of Fluoride in Oral Hygiene Products. Curr. Anal. Chem. 2014, 11, 291–299. [Google Scholar] [CrossRef]

- Morosanova, M.A.; Samodelov, Z.V.; Morosanova, E.I. Determination of Food Oxalates Using Silica–Titania Xerogel Modified with Eriochrome Cyanine R. Sensors 2018, 18, 864. [Google Scholar] [CrossRef] [PubMed]

- Nelson, J.W.; Batra, K.K. Simplified automated method for determination of urinary or serum uric acid, based on reduction of ferric-phenanthroline complex. Clin. Chem. 1975, 21, 125–129. [Google Scholar] [CrossRef] [PubMed]

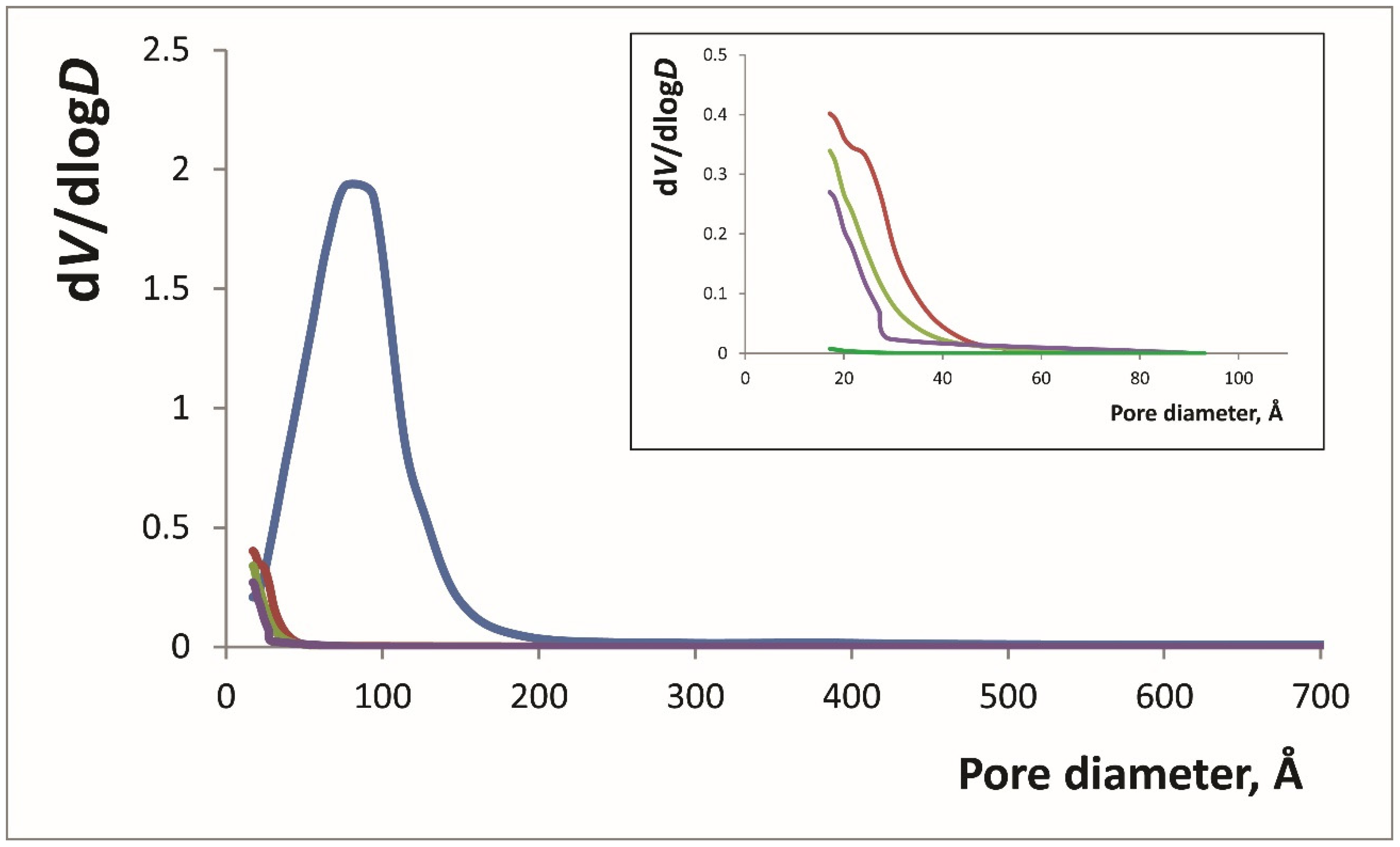

| Material | Composition | Textural Characteristics | |||||

|---|---|---|---|---|---|---|---|

| Titanium(IV) Tetraethoxyde Content, % Vol. | Iron(III) Concentration in Sol, M | BET Surface Area, m2/g | Micropore Area, m2/g | Total Pore Volume, cm3/g | Micropore Volume, cm3/g | Average Pore Diameter, Å | |

| SiFe | 0 | 0.001 | 696 | 50 | 0.92 | 0.01 | 53.0 |

| SiTi5Fe | 5 | 0.001 | 567 | 286 | 0.27 | 0.13 | 19.3 |

| SiTi12.5Fe | 12.5 | 0.001 | 520 | 316 | 0.24 | 0.14 | 18.6 |

| SiTi12.5Fe100 | 12.5 | 0.1 | 463 | 302 | 0.23 | 0.15 | 19.8 |

| SiTi12.5Fe/Phen | 12.5 | 0.001 | 348 | 195 | 0.16 | 0.09 | 18.3 |

| Material | Time Required for Interaction with 5.0 × 10−4 M Catechol, Min | Slopes, M−1 | ||

|---|---|---|---|---|

| Catechol | Gallic Acid | Sodium Sulfite | ||

| SiFe/Phen | 5 | 55 | 193 | 8 |

| SiTi5Fe/Phen | 1 | 229 | 855 | 22 |

| SiTi12.5Fe/Phen | <1 | 940 | 1435 | 24 |

| Analyte | Analytical Range, M | LOD, M (n = 3) |

|---|---|---|

| Catechol | 2.3 × 10−5–1.0 × 10−3 | 7.8 × 10−6 |

| Gallic acid | 1.6 × 10−5–5.0 × 10−4 | 5.4 × 10−6 |

| Ascorbic acid | 3.5 × 10−5–1.0 × 10−3 | 1.2 × 10−5 |

| Sodium sulfite | 9.4 × 10−4–5.0 × 10−3 | 3.1 × 10−4 |

| Analyte | SiTi12.5Fe/Phen | Iron(III)–Phen in Solution | p-Value (n = 3) |

|---|---|---|---|

| Catechol | 0.65 | 0.61 | 0.59 |

| Ascorbic acid | 0.43 | 0.49 | 0.13 |

| Sodium sulfite | 0.02 | 0.07 | 0.006 |

| Sample | TAC, M (GA Equivalents) | ||

|---|---|---|---|

| SiTi12.5Fe/Phen | Iron(III)–Phen in Solution | p-Value | |

| Black tea | (1.59 ± 0.17) × 10−4 | (1.50 ± 0.10) × 10−4 | 0.36 |

| Juice containing soft drink | (1.16 ± 0.08) × 10−4 | (1.19 ± 0.02) × 10−4 | 0.38 |

| Sensor Material | Analytical Signal | LOD, M | Time of Analysis, Min | Storage Time | Reference | |

|---|---|---|---|---|---|---|

| Gallic Acid | Ascorbic Acid | |||||

| Iron(III) and 1,10-phenanthroline immobilized in polymethacrylate matrix | Sensor material absorbance | 5.8 × 10−6 | 2.8 × 10−5 | 45 | Not studied | [13] |

| Iron(III) and 1,10-phenanthroline immobilized on Nafion membrane | Sensor material absorbance | 4.6 × 10−7 | 4.4 × 10−6 | 30 | 30 days | [14] |

| Copper(II)–neocuproine immobilized on carrageenan film | Sensor material absorbance | 2.3 × 10−6 | 3.6 × 10−6 | 90 | 14 days | [7] |

| Copper(II)–neocuproine immobilized on Nafion membrane | Sensor material absorbance | 3.1 × 10−7 | 2.1 × 10−6 | 30 | 15 days | [8] |

| Sensor material reflectance | 3.0 × 10−7 | 1.2 × 10−6 | 30 | 15 days | [9] | |

| Iron(III) immobilized on paper with multilayers of surfactants | Sensor material color | 3.5 × 10−7 | - | Immediate | Not studied | [2] |

| Cerium(IV) nanoparticles immobilized on paper | Length of the colored zone of the sensor material | 5.0 × 10−6 | 8.0 × 10−6 | Time required for paper drying | 50 days | [16] |

| Silica–titania xerogel | Sensor material absorbance | 5.9 × 10−6 | 1.1 × 10−5 | 7–10 | 12 months | [21] |

| Silica–titania xerogel doped with Mo,P-heteropoly compounds | Sensor material absorbance | - | 4.0 × 10−6 | 20 | 6 months | [29] |

| Silica–titania xerogel doped with iron(III) and modified with 1,10-phenanthroline | Sensor material absorbance | 5.4 × 10−6 | 1.2 × 10−5 | 5 | 6 months | Present work |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Morosanova, M.A.; Chaikun, K.V.; Morosanova, E.I. Silica and Silica–Titania Xerogels Doped with Iron(III) for Total Antioxidant Capacity Determination. Materials 2021, 14, 2019. https://doi.org/10.3390/ma14082019

Morosanova MA, Chaikun KV, Morosanova EI. Silica and Silica–Titania Xerogels Doped with Iron(III) for Total Antioxidant Capacity Determination. Materials. 2021; 14(8):2019. https://doi.org/10.3390/ma14082019

Chicago/Turabian StyleMorosanova, Maria A., Ksenia V. Chaikun, and Elena I. Morosanova. 2021. "Silica and Silica–Titania Xerogels Doped with Iron(III) for Total Antioxidant Capacity Determination" Materials 14, no. 8: 2019. https://doi.org/10.3390/ma14082019

APA StyleMorosanova, M. A., Chaikun, K. V., & Morosanova, E. I. (2021). Silica and Silica–Titania Xerogels Doped with Iron(III) for Total Antioxidant Capacity Determination. Materials, 14(8), 2019. https://doi.org/10.3390/ma14082019