Uniaxial Tensile Behavior, Flexural Properties, Empirical Calculation and Microstructure of Multi-Scale Fiber Reinforced Cement-Based Material at Elevated Temperature

Abstract

1. Introduction

2. Materials and Mix Proportion

2.1. Properties of Raw Materials

- (1)

- (2)

- Quartz sand: three kinds of Dalian local quartz sand were selected and obtained by gradation adjustment. The performance indexes and origin are shown in Table 1.

- (3)

- Polycarboxylic acid superplasticizer: ASTM C494F type, with a water reduction efficiency of 24.1%, Sika (China) Co., Ltd., Suzhou, China.

- (4)

- CW and Fiber: The basic properties and origin of CW, PVA fiber, and steel fiber are shown in Table 1.

2.2. Mix Proportion

3. Experimental Procedure

3.1. High Temperature Treatment Procedure

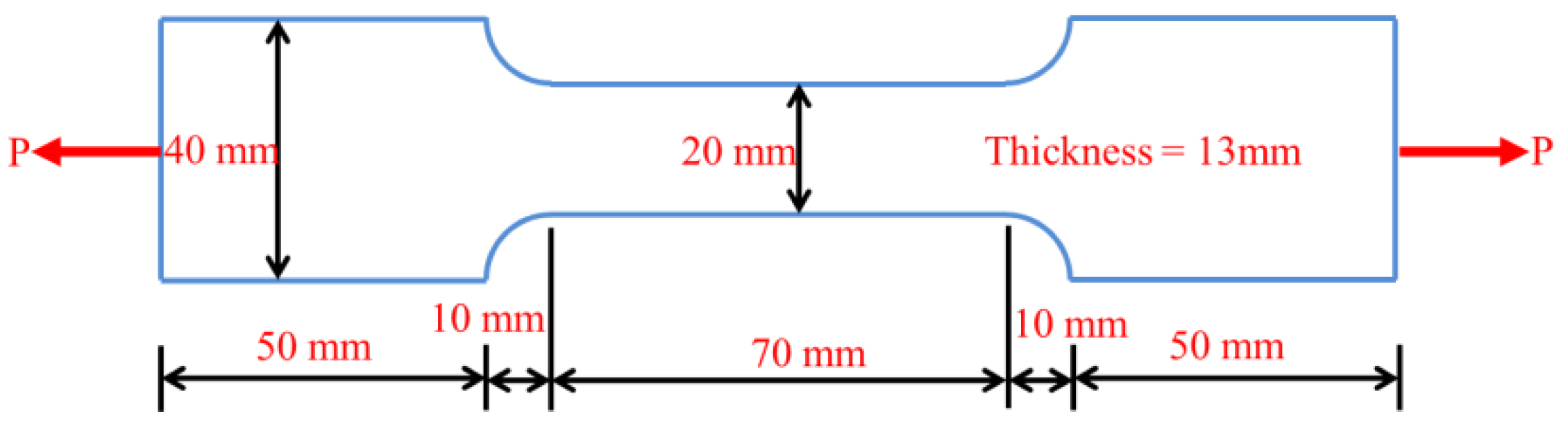

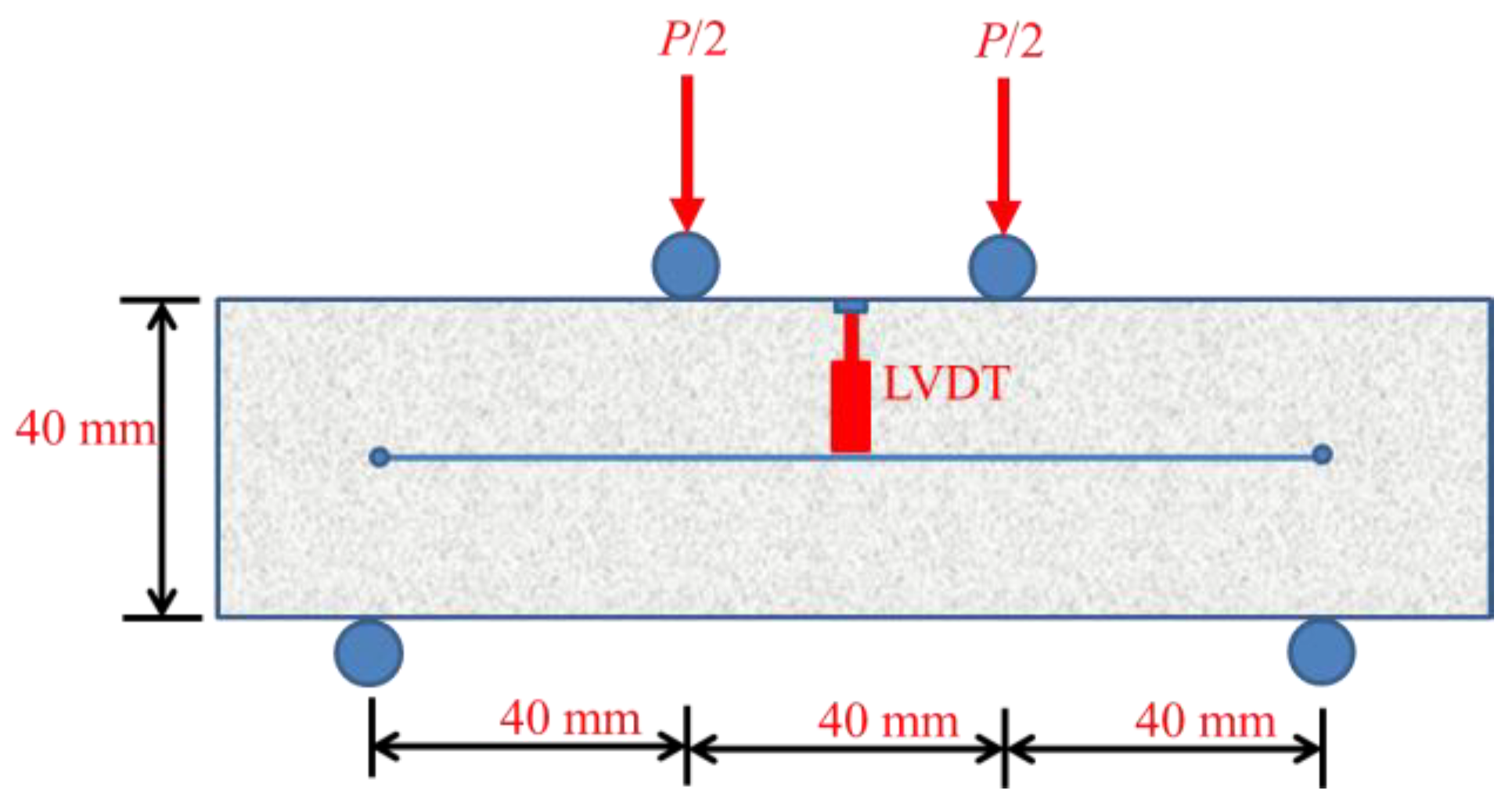

3.2. Uniaxial Tensile and Four Point Bending Test Methods

3.3. Multi-Scale Morphological Observation

4. Results and Discussion

4.1. Bending Performance

- (1)

- Flexural strength

- (2)

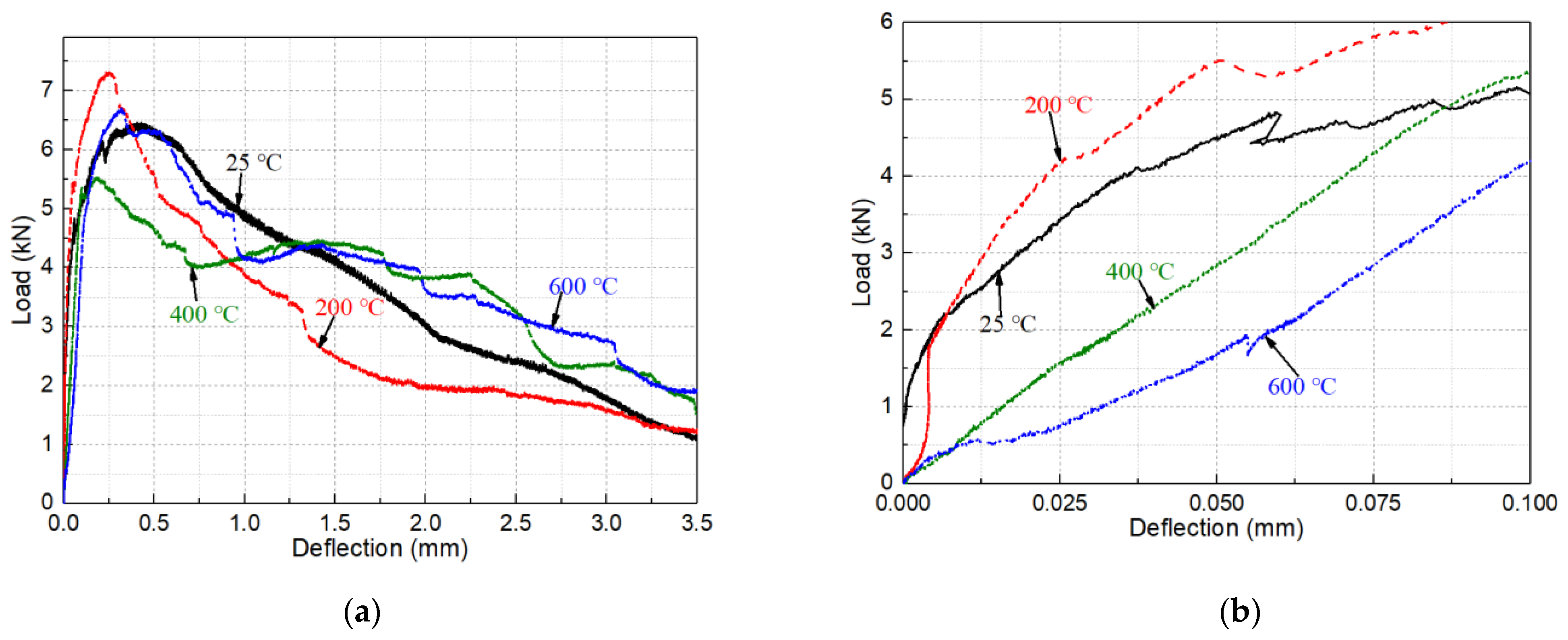

- Flexural load-deflection curves

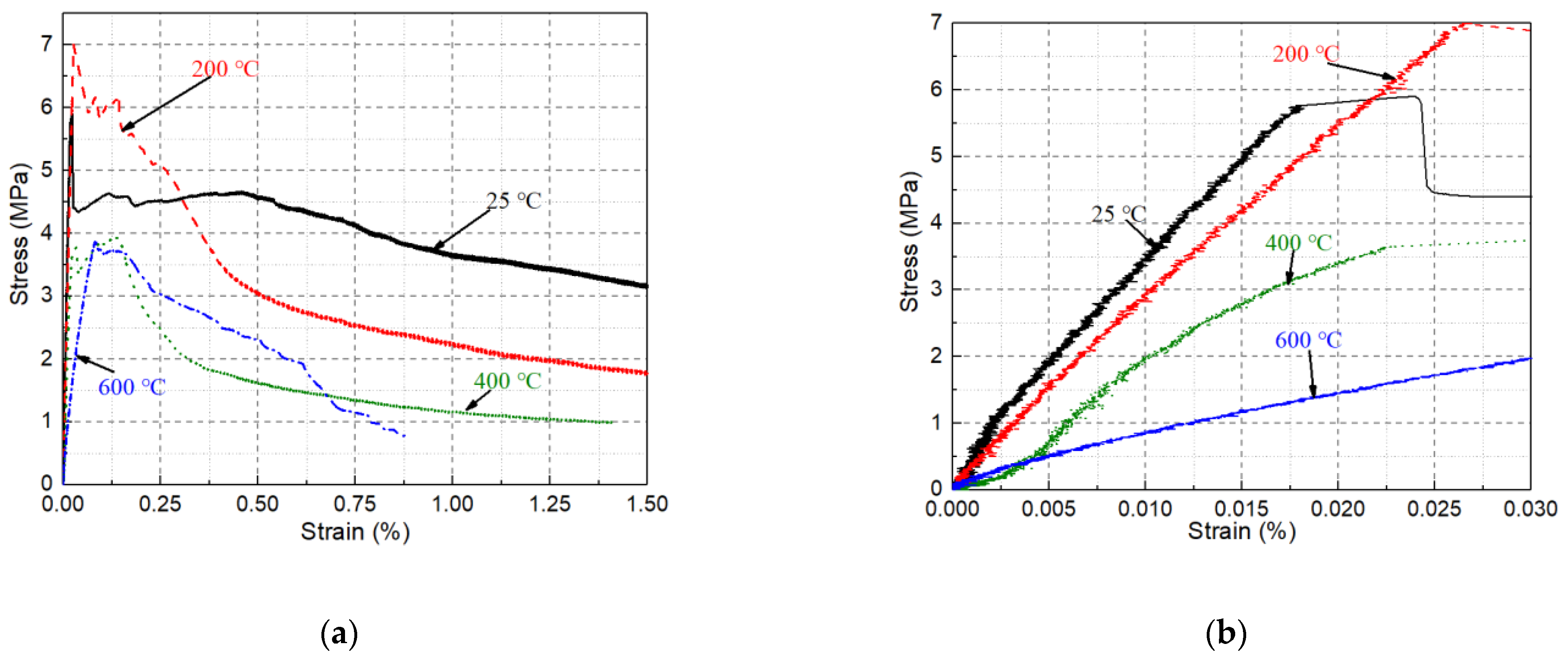

4.2. Uniaxial Tensile Properties

- (1)

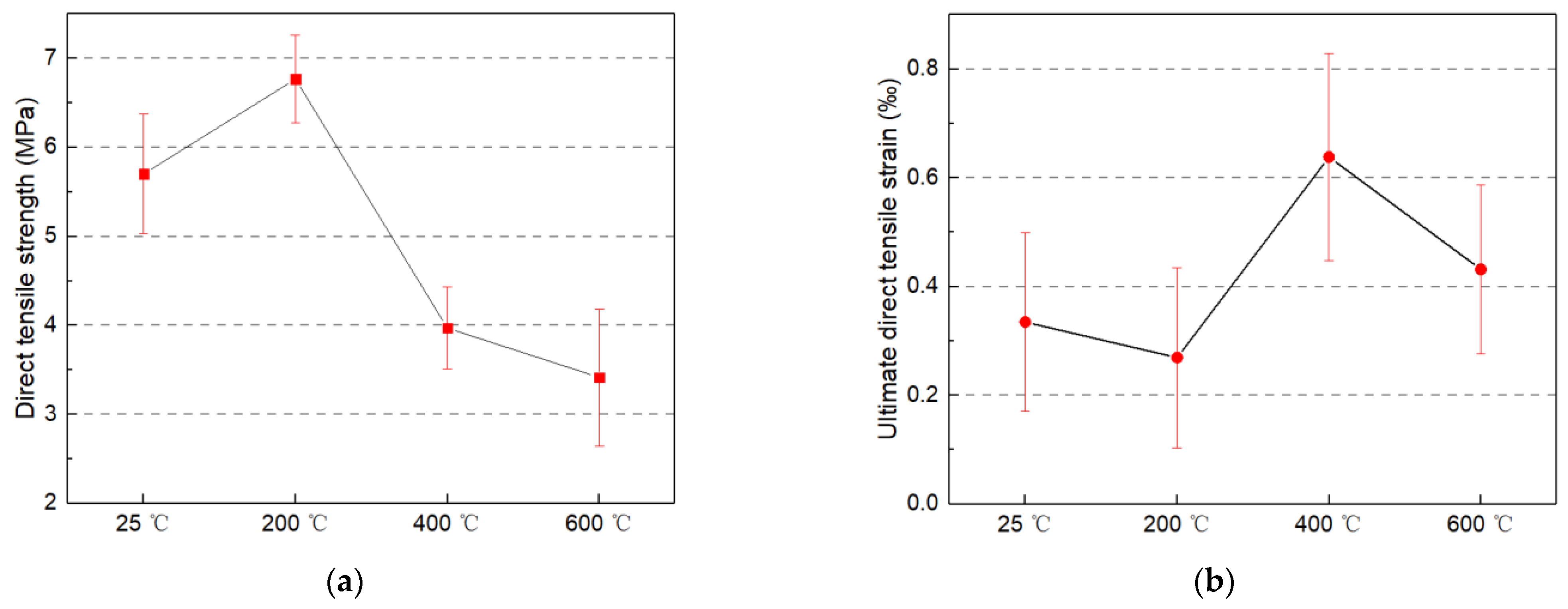

- Uniaxial tensile strength

- (2)

- Uniaxial tensile stress-strain curve

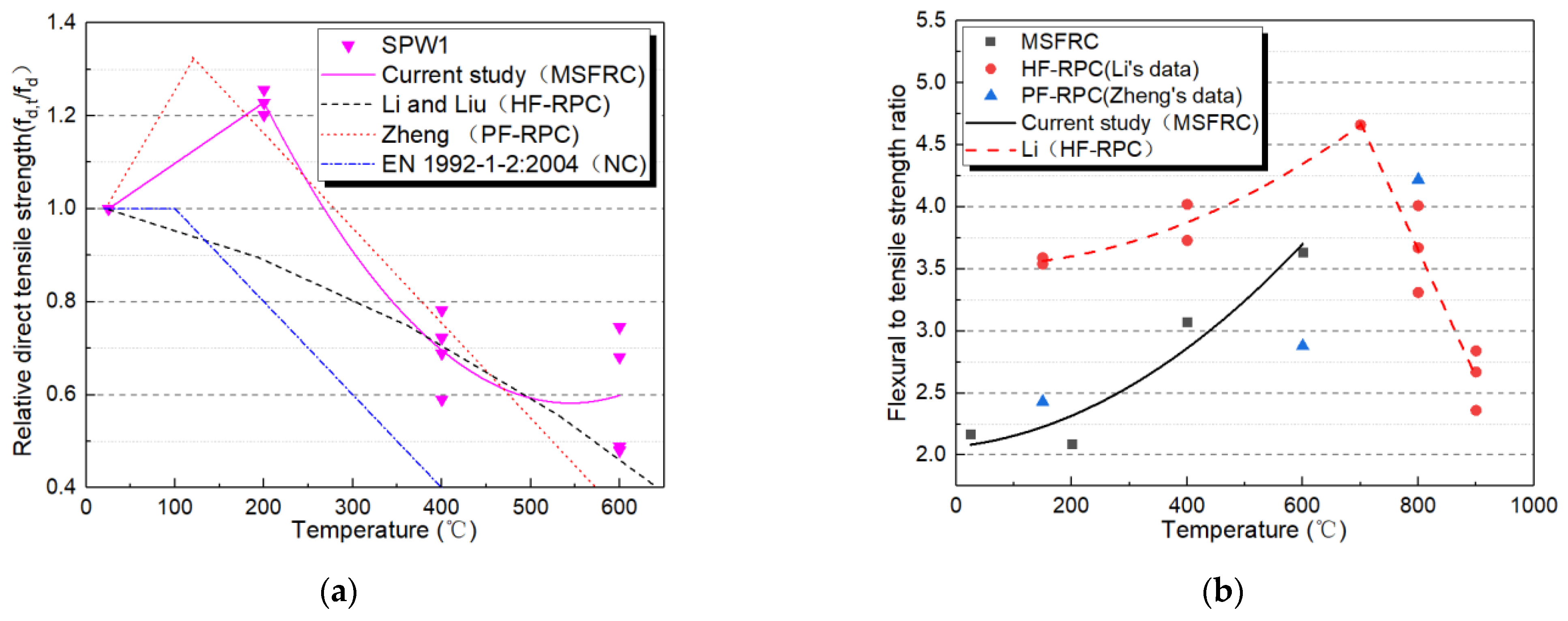

4.3. Calculation of Uniaxial Tensile and Flexural Strength

- (1)

- Empirical calculation of flexural strength

- (2)

- Empirical calculation of uniaxial tensile strength

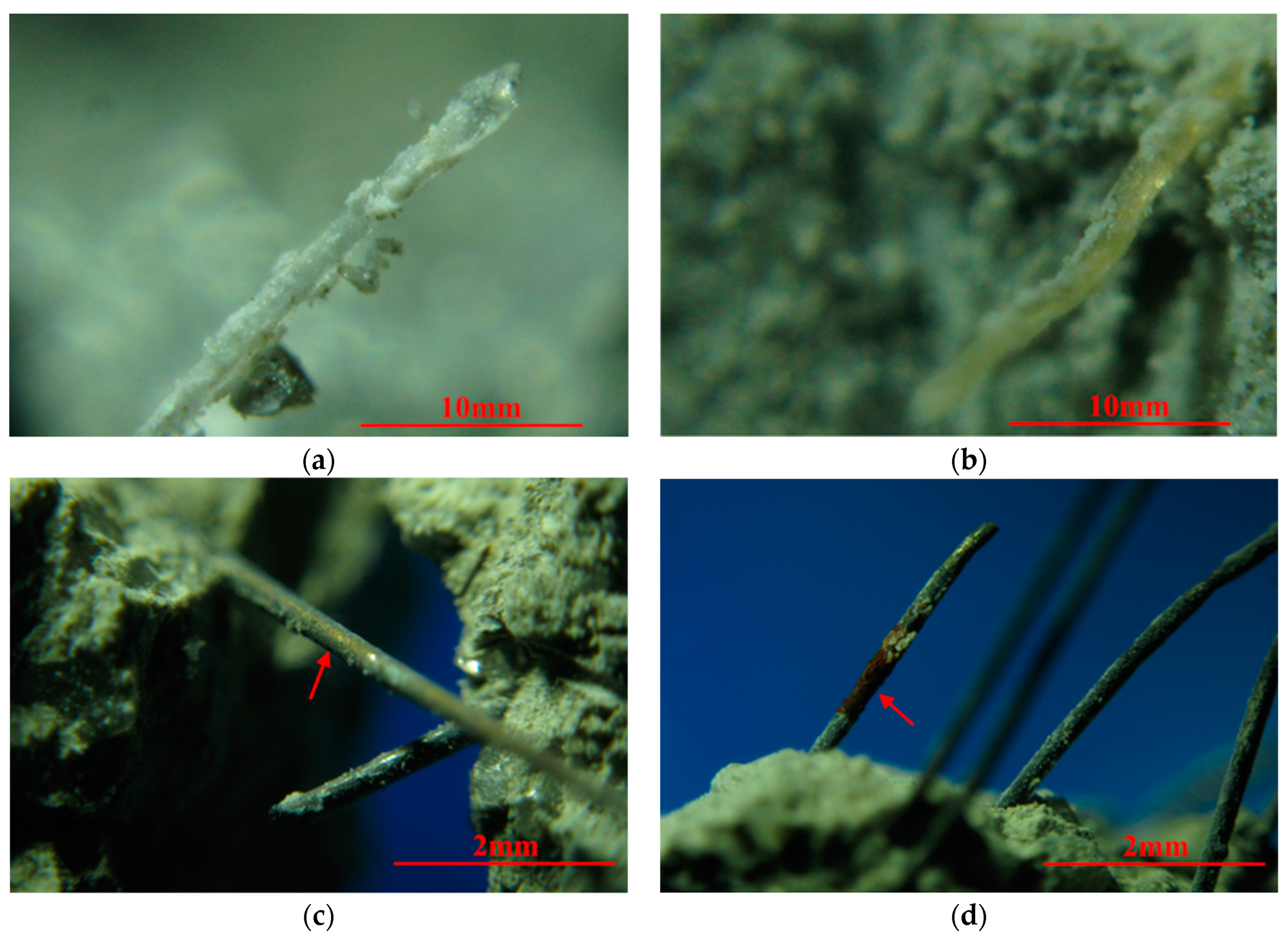

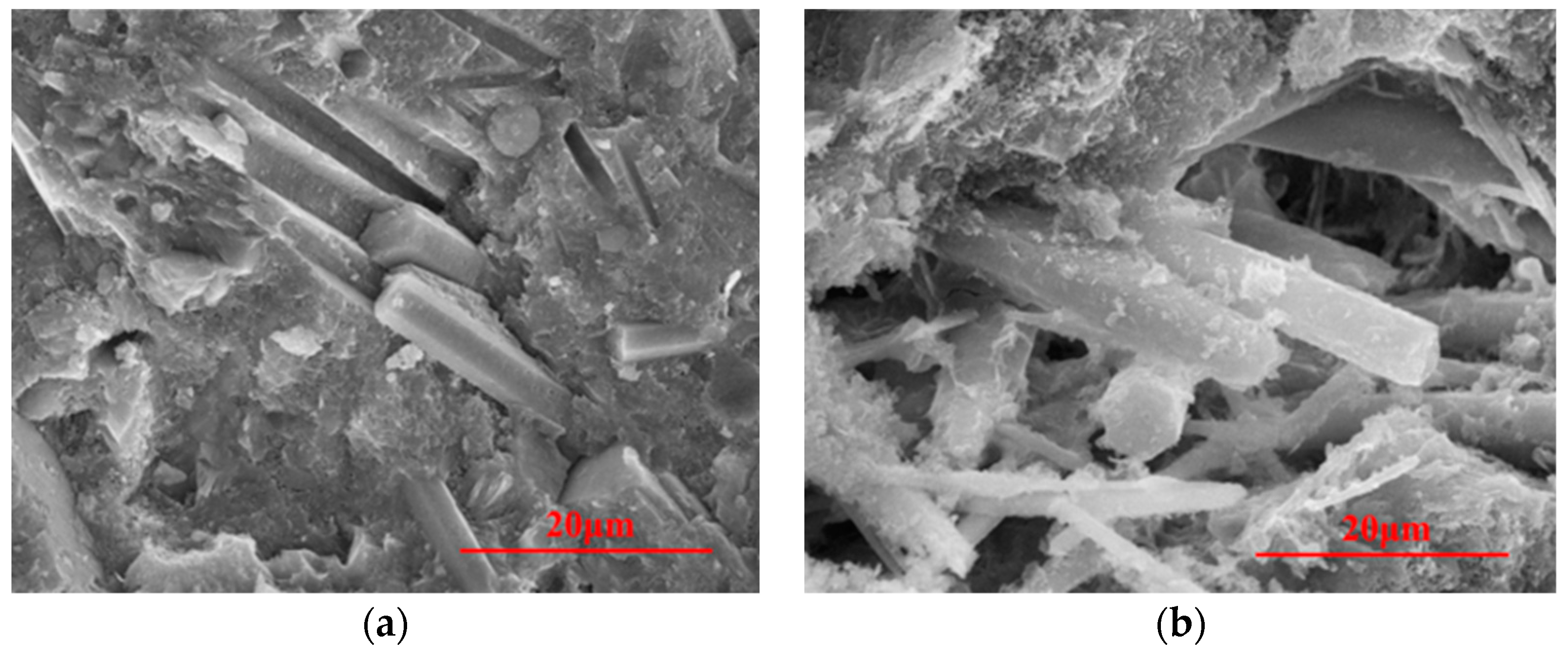

5. Microscopic Morphology Observation

6. Conclusions

- (1)

- The residual flexural and uniaxial tensile strength and toughness of MSFRC decreased with increased temperatures but decreased slowly at 600 °C and increased slightly at 200 °C. The deformation capacity of MSFRC (peak flexural deflection and peak tensile strain) decreased first and then improved with the temperature increase.

- (2)

- The nominal stiffness of MSFRC under flexural and uniaxial tensile loads decreased gradually with the increased temperature. The decrease rate of stiffness was more rapid than that of the strength, and the curve became flat gradually. However, the flexural properties are different from the uniaxial tensile properties. The flexural deflection curve deteriorates slowly or even improves slightly at 500 °C. The tensile properties of MSFRC are more sensitive to temperature changes. The load bearing capacity of MSFRC decreased by more than 30% at 200 °C, dropping sharply by about 70% at 400 °C.

- (3)

- Based on the above experimental results, the prediction models for the quantitative relationship between residual flexural (uniaxial tensile) strength and temperature of MSFRC was established. The calculation results of the models were close to the experimental results. Compared with the existing research results and prediction models in the literature, the new MSFRC has achieved an excellent high temperature resistance. The CW-PVA-steel multi-scale hybrid fiber system significantly alleviates the deterioration of mechanical properties of cement-based materials after high temperature, and improves the mechanical properties of cement-based composites at high temperatures.

- (4)

- The multi-scale morphology observation of OM and SEM shows that the flexural and uniaxial tensile properties of MSFRC at high temperatures result from the physical and chemical changes of steel fiber, PVA fiber, and calcium carbonate whisker at different temperatures.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| CW | CaCO3 whisker |

| PVA | polyvinyl alcohol |

| MSFRC | multi-scale fiber reinforced cement matrix composites |

| ECC | engineered cement-based composites |

| OM | optical microscope |

| SEM | scanning electron microscope |

| NC | normal concrete |

| PF-NC | polypropylene fiber reinforced normal concrete |

| HF-HSC | hybrid fiber reinforced high strength concrete |

| PF-RPC | polypropylene fiber reinforced reactive powder concrete |

| HF-ECC | hybrid fiber reinforced cement-based composites |

References

- Lee, J.-H.; Yoo, D.-Y.; Yoon, Y.-S. Mechanical behaviour of concrete with amorphous metallic and steel fibres. Mag. Concr. Res. 2016, 68, 1253–1264. [Google Scholar] [CrossRef]

- Song, W.; Yin, J. Hybrid Effect Evaluation of Steel Fiber and Carbon Fiber on the Performance of the Fiber Reinforced Concrete. Materials 2016, 9, 704. [Google Scholar] [CrossRef]

- Li, Y.; Yang, E.-H.; Tan, K.H. Flexural behavior of ultra-high performance hybrid fiber reinforced concrete at the ambient and elevated temperature. Constr. Build. Mater. 2020, 250, 118487. [Google Scholar] [CrossRef]

- Tjiptobroto, P.; Hansen, W. Mechanism for tensile strain hardening in high performance cement-based fiber reinforced composites. Cem. Concr. Compos. 1991, 13, 265–273. [Google Scholar] [CrossRef]

- Azmee, N.; Shafiq, N. Ultra-high performance concrete: From fundamental to applications. Case Stud. Constr. Mater. 2018, 9. [Google Scholar] [CrossRef]

- Tran, N.T.; Kim, D.J. Synergistic response of blending fibers in ultra-high-performance concrete under high rate tensile loads. Cem. Concr. Compos. 2017, 78, 132–145. [Google Scholar] [CrossRef]

- Li, L.; Cao, M.; Yin, H. Comparative roles between aragonite and calcite calcium carbonate whiskers in the hydration and strength of cement paste. Cem. Concr. Compos. 2019, 104, 103350. [Google Scholar] [CrossRef]

- Si, W.; Cao, M.; Li, L. Establishment of fiber factor for rheological and mechanical performance of polyvinyl alcohol (PVA) fiber reinforced mortar. Constr. Build. Mater. 2020, 265, 120347. [Google Scholar] [CrossRef]

- Li, L.; Gao, D.; Li, Z.; Cao, M.; Gao, J.; Zhang, Z. Effect of high temperature on morphologies of fibers and mechanical properties of multi-scale fiber reinforced cement-based composites. Constr. Build. Mater. 2020, 261, 120487. [Google Scholar] [CrossRef]

- Li, L.; Cao, M.; Xie, C.; Yin, H. Effects of CaCO3 whisker, hybrid fiber content and size on uniaxial compressive behavior of cementitious composites. Struct. Concr. 2019, 20, 506–518. [Google Scholar] [CrossRef]

- Cao, M.; Li, L.; Shen, S. Influence of Reinforcing Index on Rheology of Fiber-Reinforced Mortar. ACI Mater. J. 2019, 116, 95–105. [Google Scholar] [CrossRef]

- Cao, M.; Xie, C.; Li, L.; Khan, M. Effect of different PVA and steel fiber length and content on mechanical properties of CaCO3 whisker reinforced cementitious composites. Mater. Construcción 2019, 69, 200. [Google Scholar] [CrossRef]

- Cao, M.; Li, L.; Zhang, C.; Feng, J. Behaviour and damage assessment of a new hybrid-fibre-reinforced mortar under impact load. Mag. Concr. Res. 2018, 70, 905–918. [Google Scholar] [CrossRef]

- Cao, M.; Li, L.; Khan, M. Effect of hybrid fibers, calcium carbonate whisker and coarse sand on mechanical properties of cement-based composites. Mater. Construcción 2018, 68, 156. [Google Scholar] [CrossRef]

- Cao, M.; Li, L. New models for predicting workability and toughness of hybrid fiber reinforced cement-based composites. Constr. Build. Mater. 2018, 176, 618–628. [Google Scholar] [CrossRef]

- Li, M.; Yang, Y.; Liu, M.; Guo, X.; Zhou, S. Hybrid effect of calcium carbonate whisker and carbon fiber on the mechanical properties and microstructure of oil well cement. Constr. Build. Mater. 2015, 93, 995–1002. [Google Scholar] [CrossRef]

- Pan, J.; Cai, J.; Ma, H.; Leung, C.K.Y. Development of Multiscale Fiber-Reinforced Engineered Cementitious Composites with PVA Fiber and CaCO3 Whisker. J. Mater. Civ. Eng. 2018, 30, 04018106. [Google Scholar] [CrossRef]

- Yang, Y.; Zhou, Q.; Deng, Y.; Lin, J. Reinforcement effects of multi-scale hybrid fiber on flexural and fracture behaviors of ultra-low-weight foamed cement-based composites. Cem. Concr. Compos. 2020, 108. [Google Scholar] [CrossRef]

- Khan, M.; Cao, M.; Ali, M. Effect of basalt fibers on mechanical properties of calcium carbonate whisker-steel fiber reinforced concrete. Constr. Build. Mater. 2018, 192, 742–753. [Google Scholar] [CrossRef]

- Khan, M.; Cao, M. Effect of hybrid basalt fibre length and content on properties of cementitious composites. Mag. Concr. Res. 2021, 2021, 1–12. [Google Scholar] [CrossRef]

- Cao, M.; Khan, M.; Ahmed, S. Effectiveness of Calcium Carbonate Whisker in Cementitious Composites. Period. Polytech. Civ. Eng. 2020, 64, 265–275. [Google Scholar] [CrossRef]

- Khan, M.; Ali, M. Effectiveness of hair and wave polypropylene fibers for concrete roads. Constr. Build. Mater. 2018, 166, 581–591. [Google Scholar] [CrossRef]

- Xie, C.; Cao, M.; Si, W.; Khan, M. Experimental evaluation on fiber distribution characteristics and mechanical properties of calcium carbonate whisker modified hybrid fibers reinforced cementitious composites. Constr. Build. Mater. 2020, 265, 120292. [Google Scholar] [CrossRef]

- Cao, M.; Khan, M. Effectiveness of multiscale hybrid fiber reinforced cementitious composites under single degree of freedom hydraulic shaking table. Struct. Concr. 2021, 22, 535–549. [Google Scholar] [CrossRef]

- Khan, M.; Cao, M.; Ali, M. Cracking behaviour and constitutive modelling of hybrid fibre reinforced concrete. J. Build. Eng. 2020, 30, 101272. [Google Scholar] [CrossRef]

- Saulat, H.; Cao, M.; Khan, M.M.; Khan, M.; Khan, M.M.; Rehman, A. Preparation and applications of calcium carbonate whisker with a special focus on construction materials. Constr. Build. Mater. 2020, 236, 117613. [Google Scholar] [CrossRef]

- Xie, C.; Cao, M.; Khan, M.; Yin, H.; Guan, J. Review on different testing methods and factors affecting fracture properties of fiber reinforced cementitious composites. Constr. Build. Mater. 2021, 273, 121766. [Google Scholar] [CrossRef]

- Khan, M.; Cao, M.; Chaopeng, X.; Ali, M. Experimental and analytical study of hybrid fiber reinforced concrete prepared with basalt fiber under high temperature. Fire Mater. 2021. [Google Scholar] [CrossRef]

- Li, Y.; Pimienta, P.; Pinoteau, N.; Tan, K.H. Effect of aggregate size and inclusion of polypropylene and steel fibers on explosive spalling and pore pressure in ultra-high-performance concrete (UHPC) at elevated temperature. Cem. Concr. Compos. 2019, 99, 62–71. [Google Scholar] [CrossRef]

- Deshpande, A.A.; Kumar, D.; Ranade, R. Influence of high temperatures on the residual mechanical properties of a hybrid fiber-reinforced strain-hardening cementitious composite. Constr. Build. Mater. 2019, 208, 283–295. [Google Scholar] [CrossRef]

- Li, L.; Li, Z.; Cao, M.; Tang, Y.; Zhang, Z. Nanoindentation and Porosity Fractal Dimension of Calcium Carbonate Whisker Reinforced Cement Paste after Elevated Temperatures (up To 900 °C). Fractals 2021, 29. [Google Scholar] [CrossRef]

- Ming, X.; Cao, M.; Li, L.; Yin, H. Self-Healing Properties of Thermally Damaged Cement Blends. ACI Mater. J. 2021. [Google Scholar] [CrossRef]

- Cao, M.; Ming, X.; Yin, H.; Li, L. Influence of high temperature on strength, ultrasonic velocity and mass loss of calcium carbonate whisker reinforced cement paste. Compos. Part B Eng. 2019, 163, 438–446. [Google Scholar] [CrossRef]

- Cao, M.; Li, L.; Yin, H.; Ming, X. Microstructure and Strength of Calcium Carbonate (CaCO3) Whisker Reinforced Cement Paste after Exposed to High Temperatures. Fire Technol. 2019, 55, 1983–2003. [Google Scholar] [CrossRef]

- Li, L.; Cao, M.; Ming, X.; Yin, H.; Sun, Y.-N. Microstructure of calcium carbonate whisker reinforced cement paste after elevated temperature exposure. Constr. Build. Mater. 2019, 227, 116609. [Google Scholar] [CrossRef]

- Ming, X.; Cao, M.; Lv, X.; Yin, H.; Li, L.; Liu, Z. Effects of high temperature and post-fire-curing on compressive strength and microstructure of calcium carbonate whisker-fly ash-cement system. Constr. Build. Mater. 2020, 244, 118333. [Google Scholar] [CrossRef]

- Xu, L.; Huang, L.; Chi, Y.; Mei, G. Tensile Behavior of Steel-Polypropylene Hybrid Fiber-Reinforced Concrete. ACI Struct. J. 2016, 113, 219–229. [Google Scholar] [CrossRef]

- Piasta, J.; Sawicz, Z.; Rudzinski, L. Changes in the structure of hardened cement paste due to high temperature. Mater. Struct. 1984, 17, 291–296. [Google Scholar] [CrossRef]

- Li, Q.; Gao, X.; Xu, S.; Peng, Y.; Fu, Y. Microstructure and Mechanical Properties of High-Toughness Fiber-Reinforced Cementitious Composites after Exposure to Elevated Temperatures. J. Mater. Civ. Eng. 2016, 28, 04016132. [Google Scholar] [CrossRef]

- Banthia, N.; Majdzadeh, F.; Wu, J.; Bindiganavile, V. Fiber synergy in Hybrid Fiber Reinforced Concrete (HyFRC) in flexure and direct shear. Cem. Concr. Compos. 2014, 48, 91–97. [Google Scholar] [CrossRef]

- Yu, J.; Yu, K.; Lu, Z. Residual fracture properties of concrete subjected to elevated temperatures. Mater. Struct. 2012, 45, 1155–1165. [Google Scholar] [CrossRef]

- Bentz, D.P.; Ardani, A.; Barrett, T.; Jones, S.Z.; Lootens, D.; Peltz, M.A.; Sato, T.; Stutzman, P.E.; Tanesi, J.; Weiss, W.J. Multi-scale investigation of the performance of limestone in concrete. Constr. Build. Mater. 2015, 75, 1–10. [Google Scholar] [CrossRef]

- Li, H.; Liu, G. Tensile Properties of Hybrid Fiber-Reinforced Reactive Powder Concrete after Exposure to Elevated Temperatures. Int. J. Concr. Struct. Mater. 2016, 10, 29–37. [Google Scholar] [CrossRef]

- Xiao, J.; Ren, H.; Wang, P. Study on Residual Flexural Strength of High-Performance Concrete at Elevated Temperature. J. Tongji Univ. (Nat. Sci.) 2006, 34, 580–585. [Google Scholar]

- Gao, D.; Li, H.; Yang, F. High temperature performance of polypropylene—Steel fiber reinforced high strength concrete. Acta Mater. Compos. Sin. 2013, 30, 187–193. [Google Scholar]

- Zheng, W.; Li, H.; Wang, Y. Mechanical properties of reactive powder concrete with different dosage of polypropylene fiber after high temperature. J. Build. Struct. 2012, 33, 119–126. [Google Scholar]

- EN 1992-1-2: 2004. Eurocode 2: Design of Concrete Structures—Part 1–2: General Rules-Structural Fire Design; European Committee for Standardization: Brussels, Belgium, 2004. [Google Scholar]

| Raw Materials | Density (g/cm3) | Size | Mechanical Property | Origin |

|---|---|---|---|---|

| Cement | 3.20 | Specific surface area 356 m2/kg | - | Dalian Onoda Cement Co. Ltd. |

| Silica sand | 2.65 | Fineness modulus 1.9 Media sand | Moh’s hardness 7 | Dalian |

| Steel fiber | 7.8 | Length 13 mm Diameter 200 μm | Tensile strength ≥ 2 GPa Elastic modulus 200–210 GPa | Bekaert |

| PVA fiber | 1.29 | Length 6 mm Diameter 31 μm | Tensile strength 1.1 GPa Elastic modulus 41 GPa | Wanwei High-tech Material Co. Ltd., Hefei, China |

| CaCO3 whisker | 2.86 | Length 20–30 μm Diameter 0.5–2 μm | Tensile strength 3–6 GPa Elastic modulus 410–710 GPa | Shanghai Fengzhu Co. Ltd. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, L.; Khan, M.; Bai, C.; Shi, K. Uniaxial Tensile Behavior, Flexural Properties, Empirical Calculation and Microstructure of Multi-Scale Fiber Reinforced Cement-Based Material at Elevated Temperature. Materials 2021, 14, 1827. https://doi.org/10.3390/ma14081827

Li L, Khan M, Bai C, Shi K. Uniaxial Tensile Behavior, Flexural Properties, Empirical Calculation and Microstructure of Multi-Scale Fiber Reinforced Cement-Based Material at Elevated Temperature. Materials. 2021; 14(8):1827. https://doi.org/10.3390/ma14081827

Chicago/Turabian StyleLi, Li, Mehran Khan, Chengying Bai, and Ke Shi. 2021. "Uniaxial Tensile Behavior, Flexural Properties, Empirical Calculation and Microstructure of Multi-Scale Fiber Reinforced Cement-Based Material at Elevated Temperature" Materials 14, no. 8: 1827. https://doi.org/10.3390/ma14081827

APA StyleLi, L., Khan, M., Bai, C., & Shi, K. (2021). Uniaxial Tensile Behavior, Flexural Properties, Empirical Calculation and Microstructure of Multi-Scale Fiber Reinforced Cement-Based Material at Elevated Temperature. Materials, 14(8), 1827. https://doi.org/10.3390/ma14081827