The Critical Raw Materials Issue between Scarcity, Supply Risk, and Unique Properties

Abstract

1. Introduction

- EURARE (Development of a sustainable exploitation scheme for Europe’s Rare Earth ore deposits), 1 January 2013–31 December 2017, aiming to set the basis for the development of a European rare earth elements REE industry that will safeguard the uninterrupted supply of REE raw materials and products crucial for the EU economy industrial sectors. Grant agreement ID: 309,373 co-funded by the European Commission (EC) under the 2012 Cooperation Work Programme for Nanotechnologies, Materials, and new Production Technologies and specifically the raw materials topic NMP.2012.4.1-1 “New environmentally friendly approaches in minerals processing” [12].

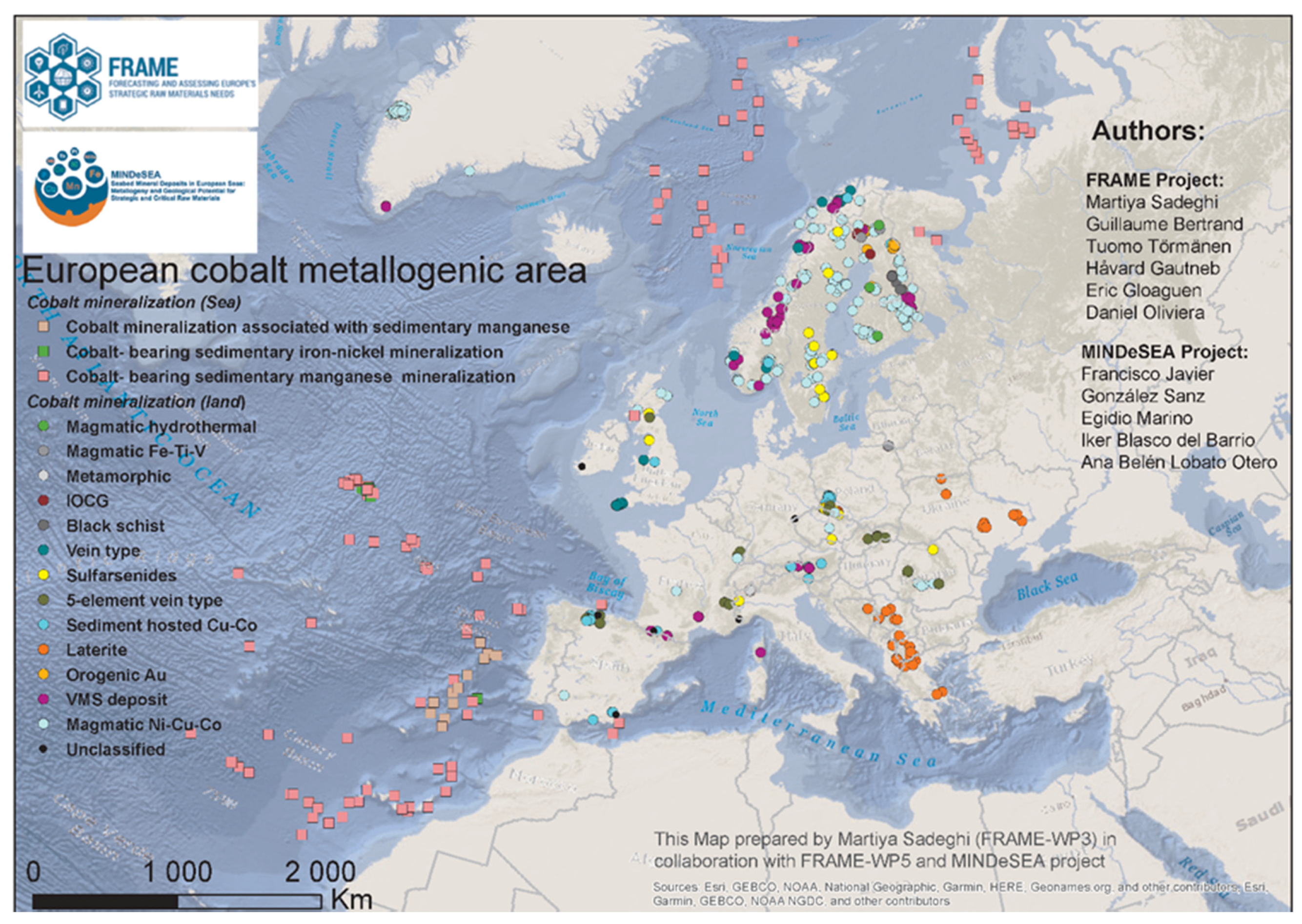

- FRAME (Forecasting And Assessing Europe’s Strategic Raw Materials Needs) and MINDeSEA (Seabed Mineral Deposits in European Seas: Metallogeny and Geological Potential for Strategic and Critical Raw Materials) these two scientific projects of GeoERA (Establishing the European Geological Surveys Research Area to deliver a Geological Service for Europe), 1 July 2018–31 December 2021, aiming to expand the strategic and CRM knowledge through a compilation of mineral potential and metallogenic areas of critical raw materials resources in Europe, which is focused on related metal associations on land and the marine environment. The GeoERA project has received funding from the European Union’s Horizon 2020 research and innovation program under grant agreement No. 731,166 [13].

- SUBST-EXTREME (Sustainable substitution in extreme conditions) is an EIP Commitment, 1 January 2014–30 December 2019, which develops substitutes for CRMs in energy, aerospace, and mining industries. Materials used in these industries at this moment are heat-resistant alloys, stainless steels, and hard materials. The whole value chain is present in this Raw Material Commitment, RMC, covering research/development, manufacturing, and end-users [14,15].

- ProSUM (Prospecting Secondary raw materials in the Urban mine and Mining wastes), 1 January 20153–1 December 2017, provides a factual basis for policy makers to design appropriate legislation, academia to define research priorities and to identify innovation opportunities in recovering CRMs for the recycling industry. The ProSUM project has received funding from the European Union’s Horizon 2020 research and innovation program under grant agreement N° 641,999 [16].

- SMART GROUND (Smart Ground–SMART data collection and inteGRation platform to enhance availability and accessibility of data and infOrmation in the EU territory on SecoNDary Raw Materials) project, 1 October 2015–31 March 2018, intended to address the issue of waste management and resource recovery from industrial, mining, and municipal landfills, improving the availability and accessibility of data and information on Secondary Raw Materials (SRM) in the EU, while creating synergies among the different stakeholders involved in the SRM value chain. The SMART GROUND project has received funding from the European Union’s Horizon 2020 research and innovation program under Grant Agreement No. 641,988 [17,18].

- MSP-REFRAM (Multi-Stakeholder Platform for a Secure Supply of Refractory Metals in Europe), 1 December 2015–31 August 2017, the project goal is to create a platform composed of multiple stakeholders to a secure supply of refractory metals in Europe, program H2020 Enabling the transition towards a green economy and society through eco-innovation. Grant agreement ID: 688,993 [19].

- VERAM (Vision and Roadmap for European Raw Materials), 1 December 2015–31 May 2018, aimed to produce a common medium-term (2030) and long-term 2050 vision and roadmap for relevant raw materials including metals, industrial minerals, and aggregates and wood that will enhance international cooperation on raw material policies and investments. The VERAM project has received funding from the European Union’s Horizon 2020 research and innovation program under grant agreement No 690,388 [20,21].

- SUPERMAT (The VIRTUAL Centre for Integration of INNOVATIVE synthesis and Processing methods for SUSTAINABLE advanced Materials operating under Extreme Conditions), 1 January 2016–31 December 2018, its expected results include elaboration of innovative technologies based on thermodynamic prediction methods enabling sustainable synthesis of novel systems and validation in pilot scale conditions, reducing or even fully replacing CRMs in extreme environments applications. Grant agreement ID: 692,216 [22].

- MIN-GUIDE (Minerals Policy Guidance for Europe), 1 February 2016–31 January 2019, is a project addressing the need for a secure and sustainable supply of minerals in Europe by developing a ‘Minerals Policy Guide’. Grant agreement ID: 689,527 [23].

- Flintstone2020 “Next generation of superhard non-CRM materials and solutions in tooling”, 1 February 2016–31 January 2020, aims to provide a perspective for the replacement of two important CRMs—tungsten (W) and cobalt (Co)—which are the main constituents for two important classes of hard materials (cemented carbides/WC-Co, and PCD/diamond-Co), by developing innovative alternative solutions for tooling operating under extreme conditions. The Flintstone2020 project has received funding from the European Union’s Horizon 2020 research and innovation program under grant agreement No. 689,279 [24].

- EQUINOX (A novel process for manufacturing complex shaped Fe-Al intermetallic parts resistant to extreme environments), 1 February 2016–31 July 2019, has as its main objective developing a novel near net shape production technology that allows substituting stainless steel parts in high volume end consumer markets by a new class of CRM-free, ductile Fe-Al based intermetallics. Grant agreement ID: 689,510 [25].

- CRM-EXTREME (Solutions for Critical Raw Materials Under Extreme Conditions), May 2016 to April 2020, is a COST action-focused project on the possibility of the substitution of CRMs (such as Cr, Co, Nb, W, Y, and other rare earth elements) in high value alloys and metal–matrix composites used under extreme conditions of temperature, loading, friction, wear, and corrosion, in Energy, Transportation, and Machinery manufacturing industries. This action originated another project: ITHACA (Innovative and sustainable TecHnologies for reducing critical raw mAterials dependence for Cleaner transportation Applications), a COST INNOVATORS’ GRANT (CIG), which is one of the four CIGs funded for the first time by the COST Association in 2019 [26,27].

- MINEA (Mining the European Anthroposphere), May 2016–April 2020, a COST Action that aims to actuate the reporting of material resources/reserves in the anthroposphere. The focus is on (1) construction and demolition waste, (2) waste regained from landfills, and (3) solid residues from waste incineration [28].

- FORAM (Towards a World Forum on Raw Materials), 1st November 2016–31st October 2018, funded by the European Union’s Horizon 2020 research and innovation programme, helps developing a platform of international experts and stakeholders. FORAM aims to share experiences and increase understanding of all aspects of trade in raw materials [29].

- SCALE (Production of Scandium compounds and Scandium Aluminum alloys from European metallurgical by-products), 1 December 2016–31 May 2021, aims toward the efficient exploitation of EU high concentration scandium containing resources to develop a stable and secure EU scandium supply chain to serve the needs of EU aerospace and high tech industry. Grant agreement ID: 730,127 [30].

- SCRREEN (Solutions for CRitical Raw materials-a European Expert Network), 1 November 2016–31 December 2019, established six Expert Groups within an EU Expert Network that provided expertise on market, governments and policies, resources, circular economy, production, substitution, CSA coordination, and support action. Grant agreement ID: 730227. There is also the ongoing project SCRREEN 2 (Solutions for CRitical Raw materials-a European Expert Network 2), 1 November 2020–31 October 2023, aiming to continue to provide expertise [31].

- Minerals4EU (EU Minerals Intelligence Network for Europe), 1 September 2013–31 August 2015, developed a structure that delivered a web portal, a European Minerals Yearbook, and foresight studies followed by the project MICA (The Mineral Intelligence Capacity Analysis), 1 December 2015–31 January 2018, which contributed to raw materials knowledge infrastructure at the EU level and was followed by EUMINET (European Mineral Information Network), 1 May 2014–01 January 2020. With EGDI, the European Geological Survey Organizations provide a data infrastructure that hosts that information and its updates by GeoERA scientific projects. FP7-NMP-2013-CSA-7. Grant agreement ID: 608,921 [32].

- BlueMining (Sustainable extraction of raw materials from oceanic depths), 1 February 2014–31 January 2018, addressed challenges associated with the extraction of deep sea minerals, ranging from their discovery and assessment to exploitation technologies and the necessary legal and regulatory framework. Grant agreement ID: 604,500 [33].

- MinFuture (Global material flows and demand-supply forecasting for mineral strategies), 1 December 2016–30 November 2018, aims to identify, integrate, and develop expertise for global material flow analysis and scenario modeling. MinFuture is funded by the Horizon 2020 Framework Programme of the European Union under Grant Agreement no. 730,330 [34].

- EXTREME (Substitution of CRMs in components and coatings used under extreme conditions), a project founded by the KIC EIT Raw Materials, is a network of European infrastructures owned by partners with skills and expertise on the substitution/reduction of CRMs used under challenging conditions of temperature, wear, friction, loading, corrosion, etc., that are easily reached in several technological and industrial fields, such as manufacturing, machining, transport, and construction sectors [35].

- MONAMIX (New concepts for efficient extraction of mixed rare earths oxides from monazite concentrates and their potential use as dopant in high-temperature coatings and sintered materials) project addresses the topic 2 of ERAMIN II call: Design: 2.1: Product design for increased raw material efficiency and 2.4: Product design for critical materials substitution. This project deals with a hydro-chemical method for monazite concentrates purification by selective leaching and their use for hydrothermal synthesis of mixed nanostructured zirconia doped with different REOs/ZrO2 [36].

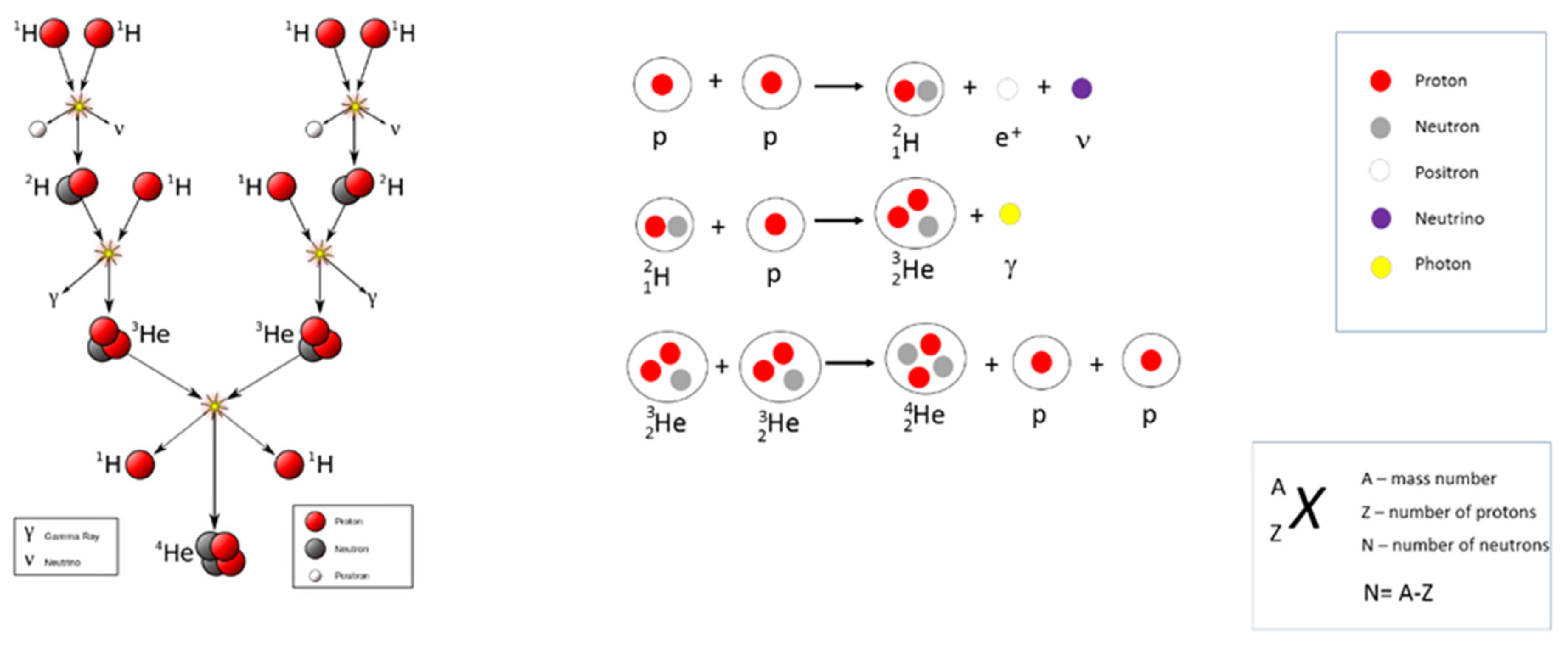

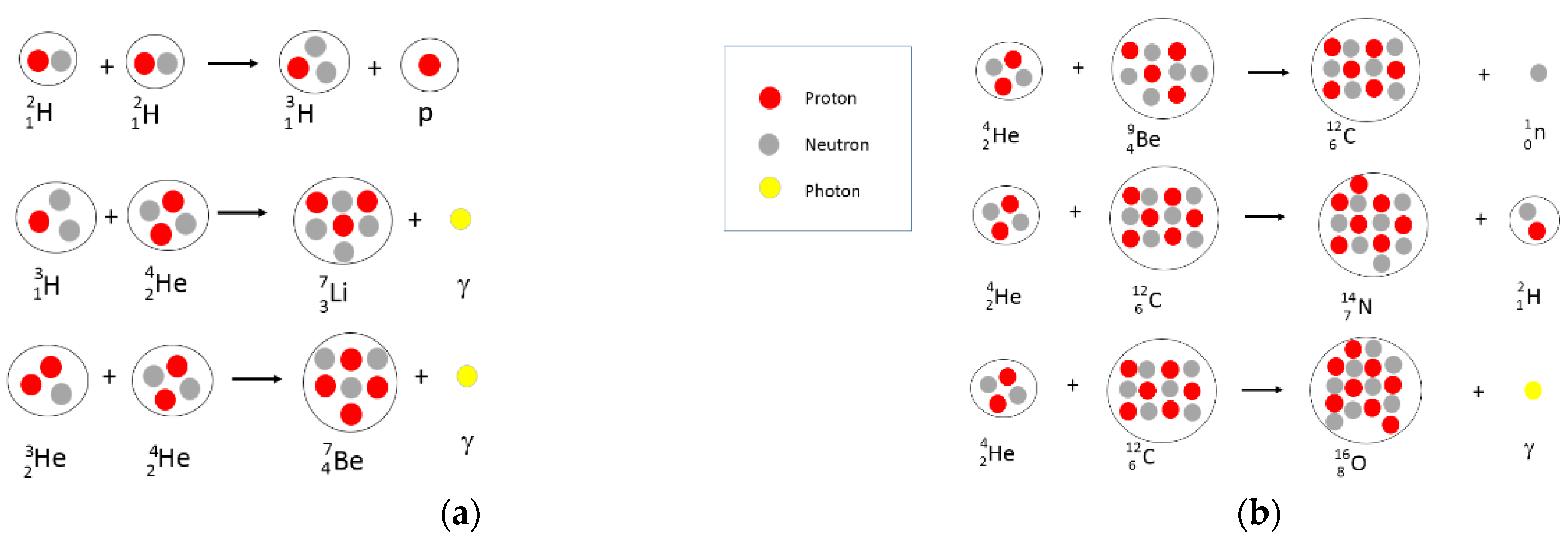

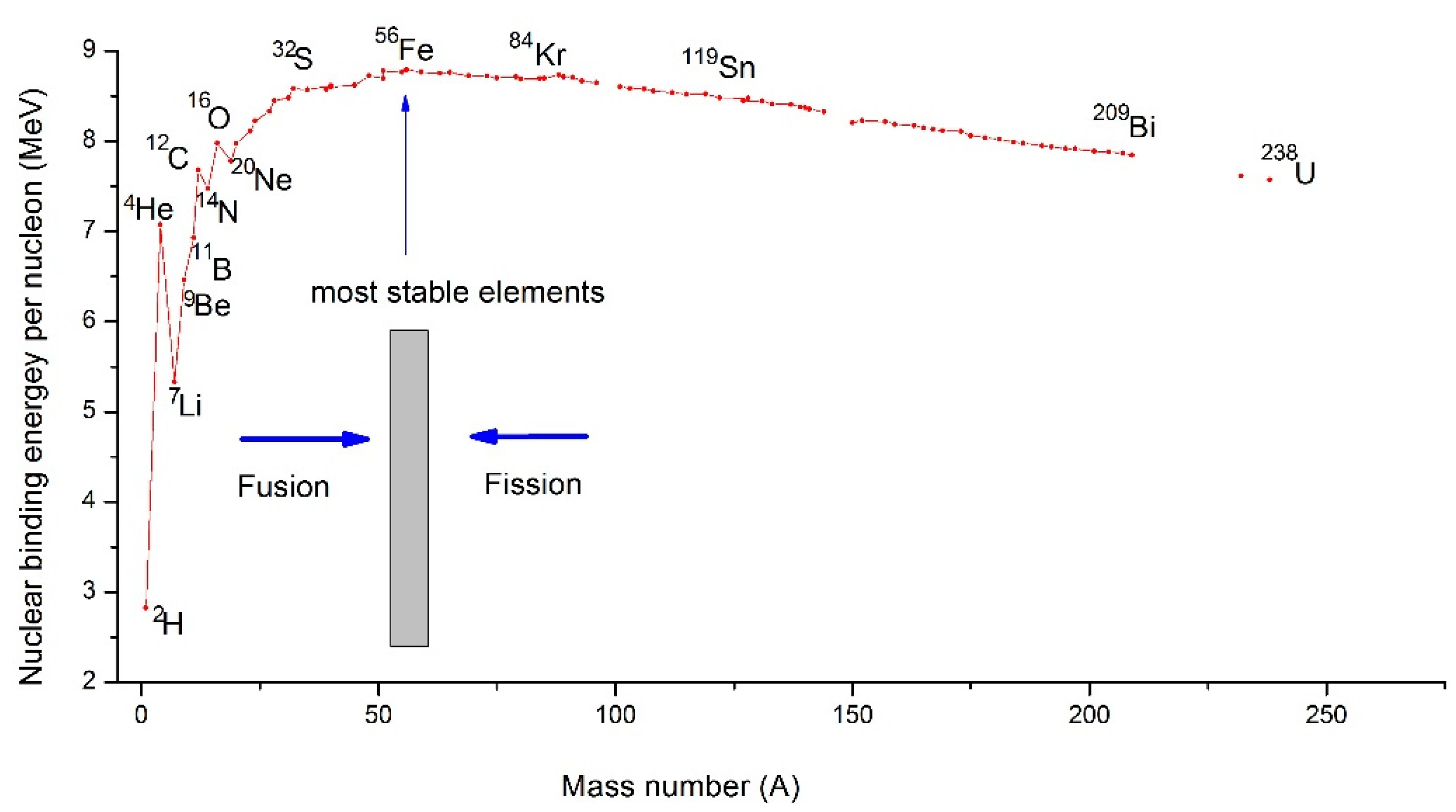

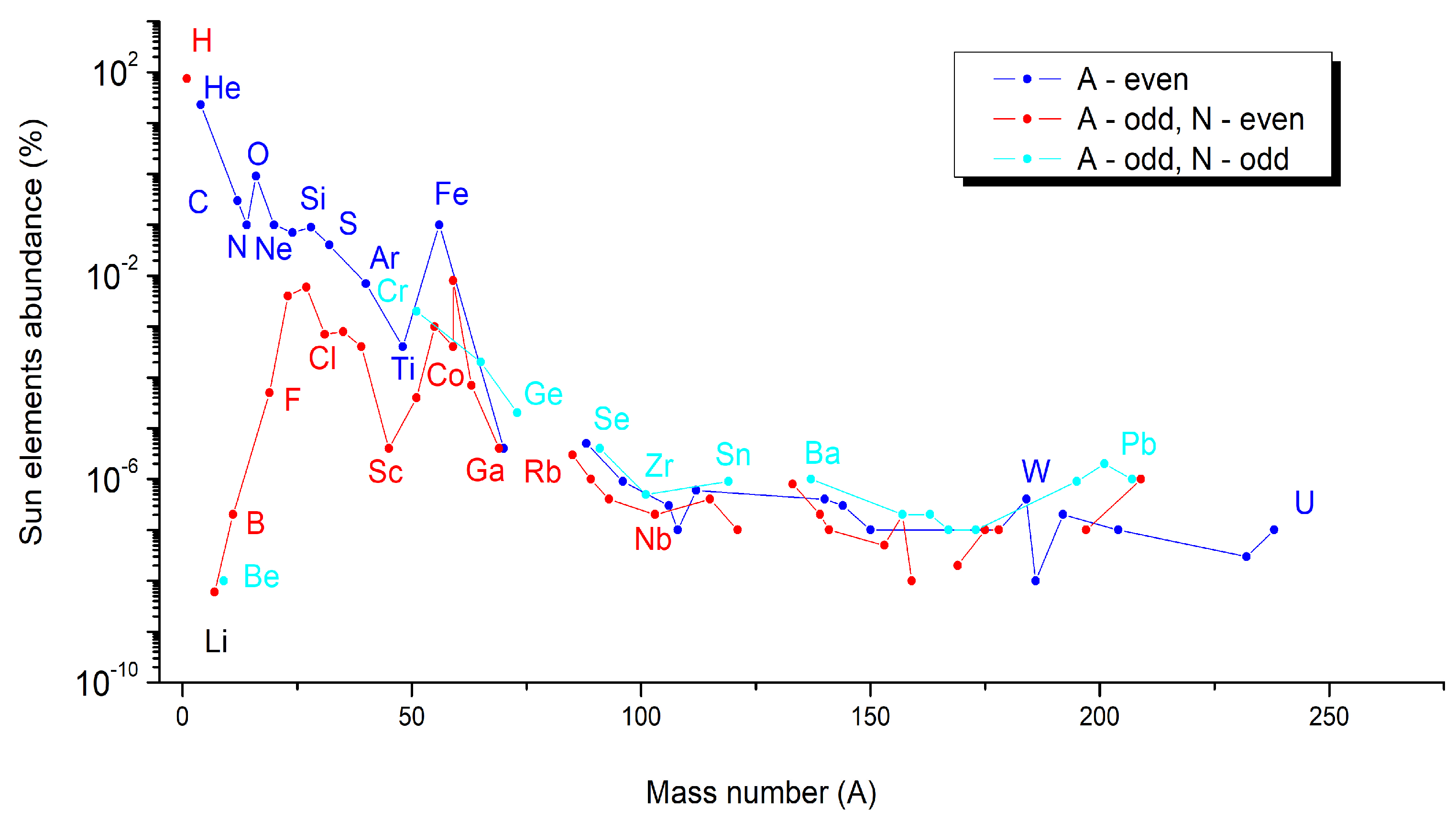

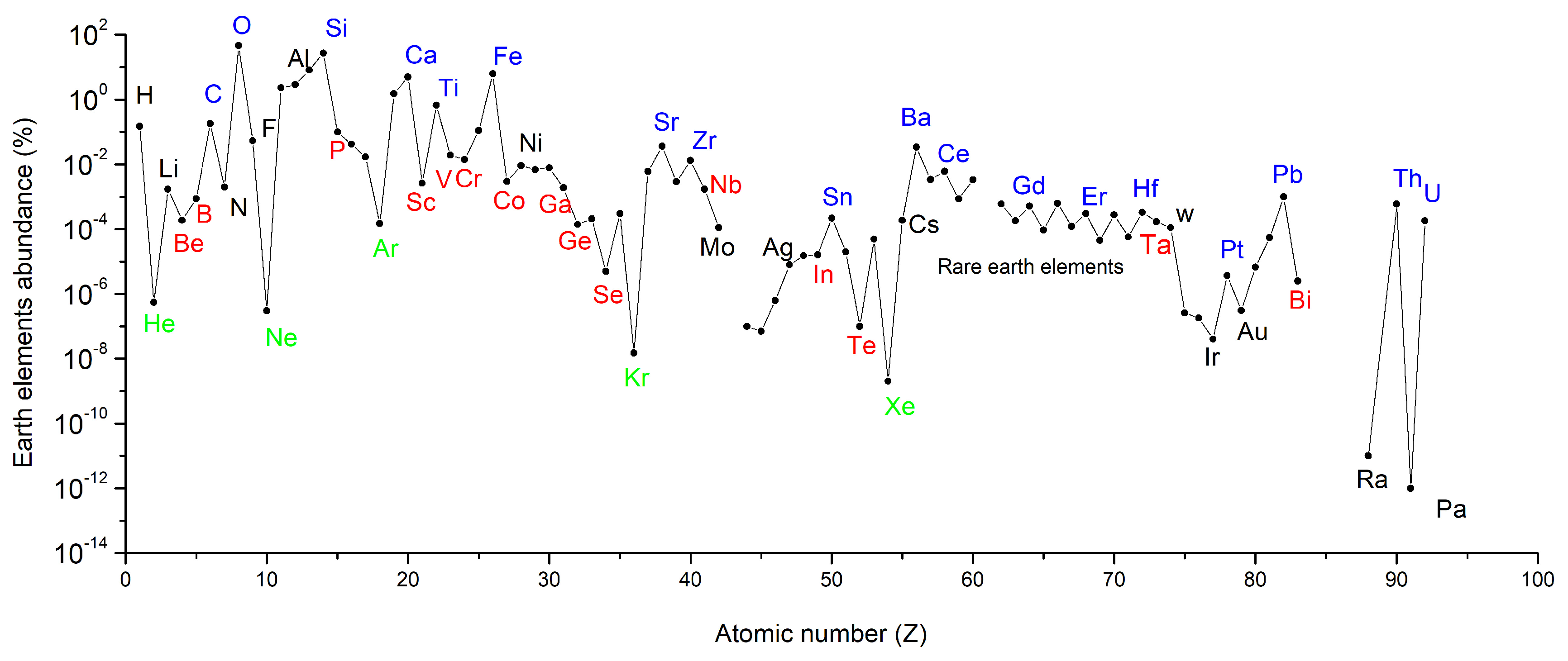

2. Abundance and Scarcity of Elements on Earth and Universe

3. From Solar Nebula to Planet Earth

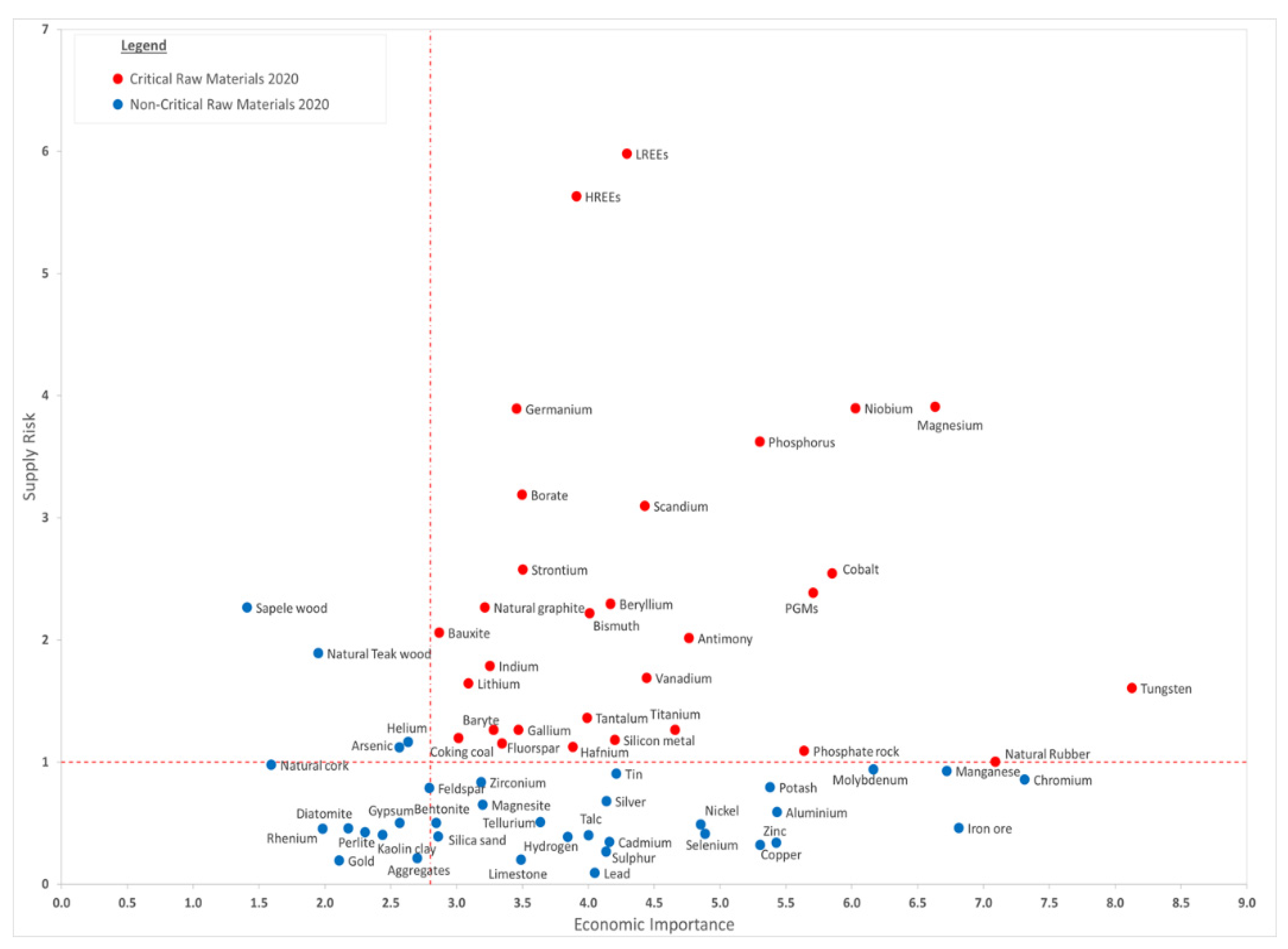

4. Principles on the Availability from EU Sources

5. Conclusions: Which Solutions for Critical Raw Materials under Extreme Conditions?

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- European Commission. The Raw Materials Initiative—Meeting Our Critical Needs for Growth and Jobs in Europe 6; European Comission: Brussels, Belgium, 2008. [Google Scholar]

- European Commission. Tackling the Challenges in Commodity Markets and on the Raw Materials 2011; European Comission: Brussels, Belgium, 2011. [Google Scholar]

- European Commission. Study on the EU’s List of Critical Raw Materials Final Report 2020; European Comission: Brussels, Belgium, 2020. [Google Scholar]

- European Commission. Critical Raw Materials Resilience: Charting a Path Towards Greater Security and Sustainability 2020; European Comission: Brussels, Belgium, 2020. [Google Scholar]

- European Commission. On the Review of the List of Critical Raw Materials for the EU 2014; European Comission: Brussels, Belgium, 2014. [Google Scholar]

- European Commission. On the 2017 List of Critical Raw Materials for the EU EN; European Comission: Brussels, Belgium, 2017. [Google Scholar]

- Grilli, M.L.; Bellezze, T.; Gamsjäger, E.; Rinaldi, A.; Novak, P.; Balos, S.; Piticescu, R.R.; Ruello, M.L. Solutions for Critical Raw Materials under Extreme Conditions: A Review. Materials 2017, 10, 285. [Google Scholar] [CrossRef]

- The European Innovation Partnership (EIP) on Raw Materials. Available online: https://ec.europa.eu/growth/sectors/raw-materials/eip_en/ (accessed on 19 March 2021).

- EIT Raw Material. Available online: https://eitrawmaterials.eu/ (accessed on 19 March 2021).

- EBA European Battery Alliance. Available online: https://www.eba250.com/ (accessed on 19 March 2021).

- ERMA European Raw Materials Alliance. Available online: https://erma.eu/ (accessed on 19 March 2021).

- EURARE Sustainable Exploitation. Available online: http://eurare.org/ (accessed on 19 March 2021).

- GeoERA. Establishing the European Geological Surveys Research Area to Deliver a Geological Service for Europe. Available online: https://geoera.eu/ (accessed on 19 March 2021).

- SUBST-EXTREME. Available online: http://ec.europa.eu/health/eu_world/docs (accessed on 19 March 2021).

- Recognised Raw Material Commitments. Available online: https://ec.europa.eu/growth/sectors/raw-materials/eip/commitments_en (accessed on 19 March 2021).

- ProSUM. Prospecting Secondary Raw Materials in the Urban Mine and Mining Wastes. Available online: http://www.prosumproject.eu/ (accessed on 19 March 2021).

- SMART GROUND. SMART Data Collection and Integration Platform to Enhance Availability and Accessibility of Data and Information in the EU Territory on Secondary Raw Materials. Available online: https://cordis.europa.eu/project/id/641988 (accessed on 19 March 2021).

- Dino, G.A.; Rossetti, P.; Biglia, G.; Coulon, F.; Gomes, D.; Wagland, S.; Luste, S.; Särkkä, H.; Ver, C.; Delafeld, M.; et al. SMART GROUND Project: SMART Data Collection and Integration Platform to Enhance Availability and Accessibility of Data and Information in the EU Territory on Secondary Raw Materials. Energy Procedia 2016, 97, 15–22. [Google Scholar] [CrossRef]

- MSP-REFRAM. Multi-Stakeholder Platform for a Secure Supply of Refractory Metals in Europe. Available online: https://prometia.eu/resources/ (accessed on 19 March 2021).

- VERAM. Vision and Roadmap for European Raw Materials. Available online: http://veram2050.eu/veram-the-project/ (accessed on 19 March 2021).

- Mobili, A.; Tittarelli, F.; Revel, G.M.; Wall, P. VERAM, for a sustainable and competitive future for EU Raw Materials. IOP Conf. Ser. Mater. Sci. Eng. 2018, 329, 12001. [Google Scholar] [CrossRef]

- SUPERMAT. The VIRTUAL Centre for Integration of INNOVATIVE Synthesis and Processing Methods for Sustainable Advanced Materials Operating Under Extreme Conditions. Available online: https://imnr.ro/supermat/ (accessed on 19 March 2021).

- MIN-GUIDE. Minerals Policy Guidance for Europe Innovative Processing. Available online: https://cordis.europa.eu/project/id/689527 (accessed on 19 March 2021).

- Flintstone2020 Next Generation of Superhard Non-CRM Materials and Solutions in Tooling. Available online: https://flintstone2020.eu/ (accessed on 19 March 2021).

- EQUINOX. A Novel Process for Manufacturing Complex Shaped Fe-Al Inter-Metallic Parts Resistant to Extreme Environments. Available online: http://www.equinox-project.eu/index.html (accessed on 19 March 2021).

- CA15102—Solutions for Critical Raw Materials Under Extreme Conditions (CRM-EXTREME). Available online: https://www.cost.eu/actions/CA15102/#tabs%7CName:overview (accessed on 19 March 2021).

- Let ’s Sail from ITHACA. Available online: https://www.crm-extreme.eu/WP/ (accessed on 19 March 2021).

- CA15115—Mining the European Anthroposphere (MINEA). Available online: https://www.cost.eu/actions/CA15115/#tabs%7CName:overview (accessed on 19 March 2021).

- FORAM. Towards a World Forum on Raw Materials. Available online: http://www.foramproject.net/ (accessed on 19 March 2021).

- Rtd, A.N.; Dedicateddevel, P. SCALE: Production of Scandium Compounds and Scandium Aluminum Alloys from European Metallurgical By-Products. Available online: http://scale-project.eu/ (accessed on 19 March 2021).

- SCRREEN. Solutions for CRitical Raw Materials—A European Expert Network. Available online: http://scrreen.eu/ (accessed on 19 March 2021).

- Minerals4EU. EU Minerals Intelligence Network for Europe. Available online: http://www.minerals4eu.eu/ (accessed on 19 March 2021).

- Blue Mining. Available online: https://bluemining.eu/project/ (accessed on 19 March 2021).

- MinFuture. Global Material Flows and Demand-Supply Forecasting for Mineral Strategies. Available online: https://minfuture.eu/ (accessed on 19 March 2021).

- EXTREME Network. Available online: http://www.network-extreme.eu/ (accessed on 19 March 2021).

- MONAMIX. Available online: https://imnr.ro/monamix/ (accessed on 19 March 2021).

- Carrara, S.; Alves Dias, P.; Plazzotta, B.; Pavel, C. Raw Materials Demand for Wind and Solar PV Technologies in the Transition Towards a Decarbonised Energy System, EUR 30095 EN; Publication Office of the European Union: Luxembourg, 2020; ISBN 978-92-76-16225-4. [Google Scholar]

- Bethe, H.A. Energy production in stars. Phys. Rev. 1939, 55, 434–456. [Google Scholar] [CrossRef]

- Bethe, H.A. Energy production in stars [2]. Phys. Rev. 1939, 55, 103. [Google Scholar] [CrossRef]

- Arnett, D.; Bazan, G. Nucleosynthesis in stars: Recent developments. Science 1997, 276, 1359–1362. [Google Scholar] [CrossRef] [PubMed]

- Arnould, M.; Goriely, S.; Takahashi, K. The r-process of stellar nucleosynthesis: Astrophysics and nuclear physics achievements and mysteries. Phys. Rep. 2007, 450, 97–213. [Google Scholar] [CrossRef]

- Marigo, P.; Chiosi, C.; Kudritzki, R.-P. Zero-metallicity stars II. Evolution of very massive objects with mass loss. Astron. Astrophys. 2003, 399, 617–630. [Google Scholar] [CrossRef]

- Marigo, P.; Girardi, L.; Chiosi, C.; Wood, P.R. Zero-metallicity stars. Evolution at constant mass. Astron. Astrophys. 2001, 371, 152–173. [Google Scholar] [CrossRef]

- Nomoto, K.; Kobayashi, C.; Tominaga, N. Nucleosynthesis in stars and the chemical enrichment of galaxies. Annu. Rev. Astron. Astrophys. 2013, 51, 457–509. [Google Scholar] [CrossRef]

- Signore, M.; Puy, D. Primordial nucleosynthesis. New Astron. Rev. 1999, 43, 185–200. [Google Scholar] [CrossRef]

- Truran, J.W. Theories of nucleosynthesis. Space Sci. Rev. 1973, 15, 23–49. [Google Scholar] [CrossRef]

- Bernas, R.; Gradsztajn, E.; Reeves, H.; Schatzman, E. On the nucleosynthesis of lithium, beryllium, and boron. Ann. Phys. 1967, 44, 426–478. [Google Scholar] [CrossRef]

- Anders, E.; Grevesse, N. Abundances of the elements: Meteoritic and solar. Geochim. Cosmochim. Acta 1989, 53, 197–214. [Google Scholar] [CrossRef]

- Gray, T.; Whitby, M.; Mann, N. Periodic Table of Elements. Available online: https://periodictable.com/index.html; https://periodictable.com/Properties/A/UniverseAbundance.html; https://periodictable.com/Properties/A/SolarAbundance.sp.log.html; https://periodictable.com/Properties/A/CrustAbundance.html (accessed on 19 March 2021).

- Yaroshevsky, A.A. Abundances of chemical elements in the Earth’s crust. Geochem. Int. 2006, 44, 48–55. [Google Scholar] [CrossRef]

- Lodders, K. Solar System Abundances and Condensation Temperatures of the Elements. Astrophys. J. Lett. 2003, 591, 1220. [Google Scholar] [CrossRef]

- Schmitt, R.A.; Smith, R.H.; Lasch, J.E.; Mosen, A.W.; Olehy, D.A.; Vasilevskis, J. Abundances of the fourteen rare-earth elements, scandium, and yttrium in meteoritic and terrestrial matter. Geochim. Cosmochim. Acta 1963, 27, 577–622. [Google Scholar] [CrossRef]

- Sneden, C.; Lawler, J.E.; Cowan, J.J.; Ivans, I.I.; Den Hartog, E.A. New rare earth element abundance distributions for the sun and five r-process-rich very metal-poor stars. Astrophys. J. Suppl. Ser. 2009, 182, 80–96. [Google Scholar] [CrossRef]

- Cameron, A.G.W. From interstellar gas to the Earth-Moon system. Meteorit. Planet. Sci. 2001, 36, 9–22. [Google Scholar] [CrossRef]

- Rubie, D.C.; Nimmo, F.; Melosh, H.J. Formation of Earth’s Core. In Treatise on Geophysics, 2nd ed.; Elsevier: Oxford, UK, 2015; pp. 43–79. [Google Scholar]

- Carlson, R.W.; Garçon, M.; O’Neil, J.; Reimink, J.; Rizo, H. The nature of Earth’s first crust. Chem. Geol. 2019, 530, 119321. [Google Scholar] [CrossRef]

- Lehmann, B. Formation of tin ore deposits: A reassessment. Lithos 2020, 105756. [Google Scholar] [CrossRef]

- Hartmann, W.K.; Davis, D.R. Satellite-sized planetesimals and lunar origin. Icarus 1975, 25, 504–515. [Google Scholar] [CrossRef]

- Wada, K.; Kokubo, E.; Makino, J. High-Resolution Simulations of a Moon-forming Impact and Postimpact Evolution. Astrophys. J. 2006, 638, 1180–1186. [Google Scholar] [CrossRef][Green Version]

- Wade, J.; Wood, B.J. The oxidation state and mass of the Moon-forming impactor. Earth Planet. Sci. Lett. 2016, 442, 186–193. [Google Scholar] [CrossRef]

- Dhuime, B.; Hawkesworth, C.J.; Cawood, P.A.; Storey, C.D. A Change in the Geodynamics of Continental Growth 3 Billion Years Ago. Science 2012, 355, 1334–1337. [Google Scholar] [CrossRef] [PubMed]

- Tang, M.; Chen, K.; Rudnick, R.L. Archean upper crust transition from mafic to felsic marks the onset of plate tectonics. Science 2016, 351, 372–375. [Google Scholar] [CrossRef] [PubMed]

- Rudnick, R.L.; Gao, S. Composition of the Continental Crust. In Treatise on Geochemistry; Holland, H.D., Turekian, K.K., Eds.; Elsevier: Oxford, UK, 2003; pp. 1–64. [Google Scholar]

- Plant, J.A.; Whittaker, A.; Demetriades, A.; de Vivo, B.; Lexa, J. The Geological and Tectonic Framework of Europe. In Geochemical Atlas of Europe; Salminen, R., Ed.; The Association of the Geological Surveys of The European Union (EuroGeoSurveys)/The Geological Survey of Finland: Espoo, Finland, 2005; Volume 2, p. 20. [Google Scholar]

- Vos, W.D.; Batista, M.J.; Demetriades, A.; Duris, M.; Lexa, J.; Lis, J.; Marsina, K.; O’Connor, P.J. Metallogenic Mineral Provinces and World Class Ore Deposits in Europe. In Geochemical Atlas of Europe; Salminen, R., Ed.; The Association of the Geological Surveys of The European Union (EuroGeoSurveys)/The Geological Survey of Finland: Espoo, Finland, 2005; Volume 1, pp. 43–49. ISBN 951-690-913-2. [Google Scholar]

- Neubauer, F. Geology of Europe. In Geology; De Vivo, B., Grasemann, B., Stüwe, K., Eds.; EOLSS Publications: Oxford, UK, 2009; ISBN 978-1-84826-457-1. [Google Scholar]

- Dewey, J.F.; Windley, B.F. Growth and differentiation of the continental crust. Philos. Trans. R. Soc. Lond. Math. Phys. Sci. 1981, 301, 189–206. [Google Scholar] [CrossRef]

- Nutman, A.P.; Bennett, V.C.; Friend, C.R.L.; Hidaka, H.; Yi, K.; Lee, S.R.; Kamiichi, T. The itsaq gneiss complex of greenland: Episodic 3900 to 3660 Ma juvenile crust formation and recycling in the 3660 to 3600 Ma Isukasian orogeny. Am. J. Sci. 2013, 313, 877–911. [Google Scholar] [CrossRef]

- Baadsgaard, H. U-Th-Pb dates on zircons from the early precambrian Amîtsoq Gneisses, Godthaab District, West Greenland. Earth Planet. Sci. Lett. 1973, 19, 22–28. [Google Scholar] [CrossRef]

- Wittig, N.; Webb, M.; Pearson, D.G.; Dale, C.W.; Ottley, C.J.; Hutchison, M.; Jensen, S.M.; Luguet, A. Formation of the North Atlantic Craton: Timing and mechanisms constrained from Re-Os isotope and PGE data of peridotite xenoliths from S.W. Greenland. Chem. Geol. 2010, 276, 166–187. [Google Scholar] [CrossRef]

- Bridgwater, D.; McGregor, V.R.; Myers, J.S. A horizontal tectonic regime in the Archaean of Greenland and its implications for early crustal thickening. Precambrian Res. 1975, 1, 179–197. [Google Scholar] [CrossRef]

- Anhaeusser, C.R. Archaean greenstone belts and associated granitic rocks—A review. J. Afr. Earth Sci. 2014, 100, 684–732. [Google Scholar] [CrossRef]

- Galley, A.; Hannington, M.D.; Jonasson, I. Volcanogenic Massive Sulphide Deposits. In Mineral Deposits of Canada: A Synthesis of Major Deposit-Types, District Metallogeny, the Evolution of Geological Provinces, and Exploration Methods; Special Publication No. 5; Goodfellow, W.D., Ed.; Geological Association of Canada, Mineral Deposits Division: St. John’s, NL, Canada, 2007; pp. 141–161. ISBN 978-1-897095-24-9. [Google Scholar]

- Osipowicz, G.; Kerneder-Gubała, K.; Bosiak, M.; Makowiecki, D.; Orłowska, J. The oldest osseous mining tools in Europe? New discoveries from the chocolate flint mine in Orońsko, site 2 (Southern Poland). Quat. Int. 2019, 512, 82–98. [Google Scholar] [CrossRef]

- Steblez, W.G. The chromium resources of Albania. Int. Geol. Rev. 1994, 36, 785–795. [Google Scholar] [CrossRef]

- Williams-Jones, A.E.; Vasyukova, O.V. The economic geology of scandium, the runt of the rare earth element litter. Econ. Geol. 2018, 113, 973–988. [Google Scholar] [CrossRef]

- Sarapää, O.; Al Ani, T.; Lahti, S.I.; Lauri, L.S.; Sarala, P.; Torppa, A.; Kontinen, A. Rare earth exploration potential in Finland. J. Geochem. Expl. 2013, 133, 25–41. [Google Scholar] [CrossRef]

- Melfos, V.; Voudouris, P.C. Geological, mineralogical and geochemical aspects for critical and rare metals in Greece. Minerals 2012, 2, 300–317. [Google Scholar] [CrossRef]

- Fitros, M.; Tombros, S.F.; Kokkalas, S.; Kilias, S.P.; Perraki, M.; Skliros, V.; Simos, X.C.; Papaspyropoulos, K.; Avgouropoulos, G.; Williams-Jones, A.E.; et al. REE-enriched skarns in collisional settings: The example of Xanthi’s Fe-skarn, Rhodope Metallogenetic Massif, Northern Greece. Lithos 2020, 370–371, 105638. [Google Scholar] [CrossRef]

- Járóka, T.; Seifert, T.; Pfänder, J.A.; Staude, S.; Seibel, H.V.L.; Krause, J.; Bauer, M.E. Geology, sulfide mineralogy and petrogenesis of the Angstberg Ni-Cu-(PGE)sulfide mineralization (Lausitz Block, Bohemian Massif, Germany): A potential Ni-Cu exploration target in Central Europe? Ore Geol. Rev. 2019, 110, 102924. [Google Scholar] [CrossRef]

- Melcher, F.; Onuk, P. Potential of Critical High-technology Metals in Eastern Alpine Base Metal Sulfide OresPotenzial für kritische Hochtechnologie-Metalle in ostalpinen Buntmetallsulfidvorkommen. BHM Berg Hüttenmännische Mon. 2019, 164, 71–76. [Google Scholar] [CrossRef]

- Adamczyk, Z.; Komorek, J.; Białecka, B.; Nowak, J.; Klupa, A. Assessment of the potential of polish fly ashes as a source of rare earth elements. Ore Geol. Rev. 2020, 124, 103638. [Google Scholar] [CrossRef]

- Jesus, A.P.; Mateus, A.; Benoit, M.; Tassinari, C.C.G.; Bento dos Santos, T. The timing of sulfide segregation in a Variscan synorogenic gabbroic layered intrusion (Beja, Portugal): Implications for Ni-Cu-PGE exploration in orogenic settings. Ore Geol. Rev. 2020, 126, 103767. [Google Scholar] [CrossRef]

- De Oliveira, D.P.S.; Filipe, A.; Santos, S.; Albardeiro, L. Critical Raw Materials Deposits Map in Mainland Portugal; Laboratorio Nacional de Energia e Geologia (LNEG): Amadora, Portugal, 2021; ISBN 978-989-675-101-2. [Google Scholar]

- Sterba, J.; Krzemień, A.; Fidalgo Valverde, G.; Diego Álvarez, I.; Castañón Fernández, C. Energy-sustainable industrialized growth in the Czech Republic: The Cínovec lithium mining project. Resour. Policy 2020, 68, 101707. [Google Scholar] [CrossRef]

- Bertrand, G.; Cassard, D.; Arvanitidis, N.; Stanley, G. Map of Critical Raw Material Deposits in Europe. Energy Procedia 2016, 97, 44–50. [Google Scholar] [CrossRef]

- Horn, S.; Gunn, A.G.; Petavratzi, E.; Shaw, R.; Eilu, P.; Törmänen, T.; Bjerkgård, T.; Sandstad, J.S.; Jonsson, E.; Kountourelis, S.; et al. Cobalt resources in Europe and the potential for new discoveries. Ore Geol. Rev. 2021, 130, 103915. [Google Scholar] [CrossRef]

- González, J.; Ferreira, P.; Magalhaes, V. Pan-European Map of Submarine “Energy-Critical Elements.” MINDeSEA_D1-1 Annex. Map Submar. “Energy-Critical Elem. v1, GeoERA (Grant Agreem. No 731166, Proj. GeoE.171.001). 2008. Available online: https://geoera.eu/wp-content/uploads/2019/10/MINDeSEA_WP1_MINDeSEA_-D1-1-Annex_Pan-European-Map-of-Submarine-%E2%80%9CEnergy-Critical-Elements%E2%80%9D-v1.pdf (accessed on 5 March 2021).

- González, J.; Medialdea, T.; Schiellerup, H.; Zananiri, I.; Ferreira, P.; Somoza, L.; Monteys, X.; MINDeSEA Team. Are the pan-European seas a promising source for critical metals supply ? The project GeoERA-MINDeSEA. Eur. Geol. J. 2020, 49, 38–41. [Google Scholar]

- Terrinha, P.; Medialdea, T.; Batista, L.; Somoza, L.; Magalhães, V.; González, F.J.; Noiva, J.; Lobato, A.; Rosa, M.; Marino, E.; et al. Integrated thematic geological mapping of the Atlantic Margin of Iberia. Geol. Soc. Lond. Spec. Publ. 2020, 505, SP505. [Google Scholar] [CrossRef]

- European Commission. A New Industrial Strategy for Europe; European Comission: Brussels, Belgium, 2020; pp. 1–16. [Google Scholar]

| Atomic Number | Element | Main Production Country | Applications |

|---|---|---|---|

| Z = 3 | Li | Chile, Australia, China, Argentina | Batteries |

| Z = 4 | Be | United States, China, Kazakhstan | Foils used as radiation windows for X-ray detectors due to the low absorption of X-ray radiation High-speed aircrafts, satellites, and telescopes due to its stiffness and light weight Alloys with high electrical conductivity, high strength and hardness, corrosion, and fatigue resistant Mirrors Radio communications, nuclear applications, acoustic, electronics |

| Z = 5 | B | Turkey, United States | Glass fibers, borosilicate glass with good resistance to thermal shocks Ceramics High-hardness and abrasive compounds Steels for nuclear industry Semiconductors Magnets Pharmaceutical applications |

| Z = 15 | P | China, Morocco, US, Russia | Metallurgy, electronics (light-emitting diodes) |

| Z = 21 | Sc | Ukraine, China, Russia | Aluminum alloys Mirrors for aerospace applications, lamps |

| Z = 22 | Ti | China, Japan, Russia | Engines, alloys, paints, medical applications, aerospace industry, etc. |

| Z = 23 | V | China, South Africa, Russia | Electrically conductive and thermal insulating metal, harder than most metals, with good resistance to corrosion, stable against strong acids; hence, it has a lot of application in industry Alloys as steel additive Catalysts |

| Z = 24 | Cr 1 | South Africa, Kazakhstan, India, Russia, Turkey | Metallurgy, steel alloys due to excellent high temperature properties, high hardness and corrosion resistance Pigments |

| Z = 27 | Co | Congo, Russia, Australia, Canada, Rwanda | Alloys corrosion resistant for gas turbines and aircraft jet engines Magnets Batteries (LiCoO2) Catalysts Pigments and coloring (blue) |

| Z = 31 | Ga | China, Japan, South Korea, Russia, Ukraine | Semiconductors Alloys |

| Z = 32 | Ge | China, Russia, United States | Optical applications Electronics |

| Z = 34 | Se 1 | Germany, Japan, Belgium, Russia | Glass production Alloys Batteries, solar cells |

| Z = 38 | Sr | China, Spain, Mexico | Radiopharmaceutical, cathode ray tubes |

| Z = 41 | Nb | Brazil, Canada | Steel production Alloys and superalloys Superconducting magnets Electroceramics |

| Z = 49 | In | China, South Korea, Japan, Canada | Semiconductors |

| Z = 51 | Sb | China, Russia, Tajikistan, Bolivia | Flame retardants Alloys Semiconductors Catalyst |

| Z = 52 | Te 1 | Z = 52 | Metallurgy Semiconductors, solar cells |

| Z = 73 | Ta | Rwanda, Congo, Brazil | Electronics Alloys |

| Z = 74 | W | China, Vietnam, Russia | Electrodes, heating elements, super-alloys, wear-resistant coatings, chemical applications, electronics etc. |

| Z = 83 | Bi | China, Vietnam, Mexico | Pigments Alloys |

| Z = 57 to Z = 71 | Rare Earth Elements | China | Catalyst Metallurgy Glass Ceramics |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Girtan, M.; Wittenberg, A.; Grilli, M.L.; de Oliveira, D.P.S.; Giosuè, C.; Ruello, M.L. The Critical Raw Materials Issue between Scarcity, Supply Risk, and Unique Properties. Materials 2021, 14, 1826. https://doi.org/10.3390/ma14081826

Girtan M, Wittenberg A, Grilli ML, de Oliveira DPS, Giosuè C, Ruello ML. The Critical Raw Materials Issue between Scarcity, Supply Risk, and Unique Properties. Materials. 2021; 14(8):1826. https://doi.org/10.3390/ma14081826

Chicago/Turabian StyleGirtan, Mihaela, Antje Wittenberg, Maria Luisa Grilli, Daniel P. S. de Oliveira, Chiara Giosuè, and Maria Letizia Ruello. 2021. "The Critical Raw Materials Issue between Scarcity, Supply Risk, and Unique Properties" Materials 14, no. 8: 1826. https://doi.org/10.3390/ma14081826

APA StyleGirtan, M., Wittenberg, A., Grilli, M. L., de Oliveira, D. P. S., Giosuè, C., & Ruello, M. L. (2021). The Critical Raw Materials Issue between Scarcity, Supply Risk, and Unique Properties. Materials, 14(8), 1826. https://doi.org/10.3390/ma14081826