Geometric Specification of Non-Circular Pulleys Made with Various Additive Manufacturing Techniques

Abstract

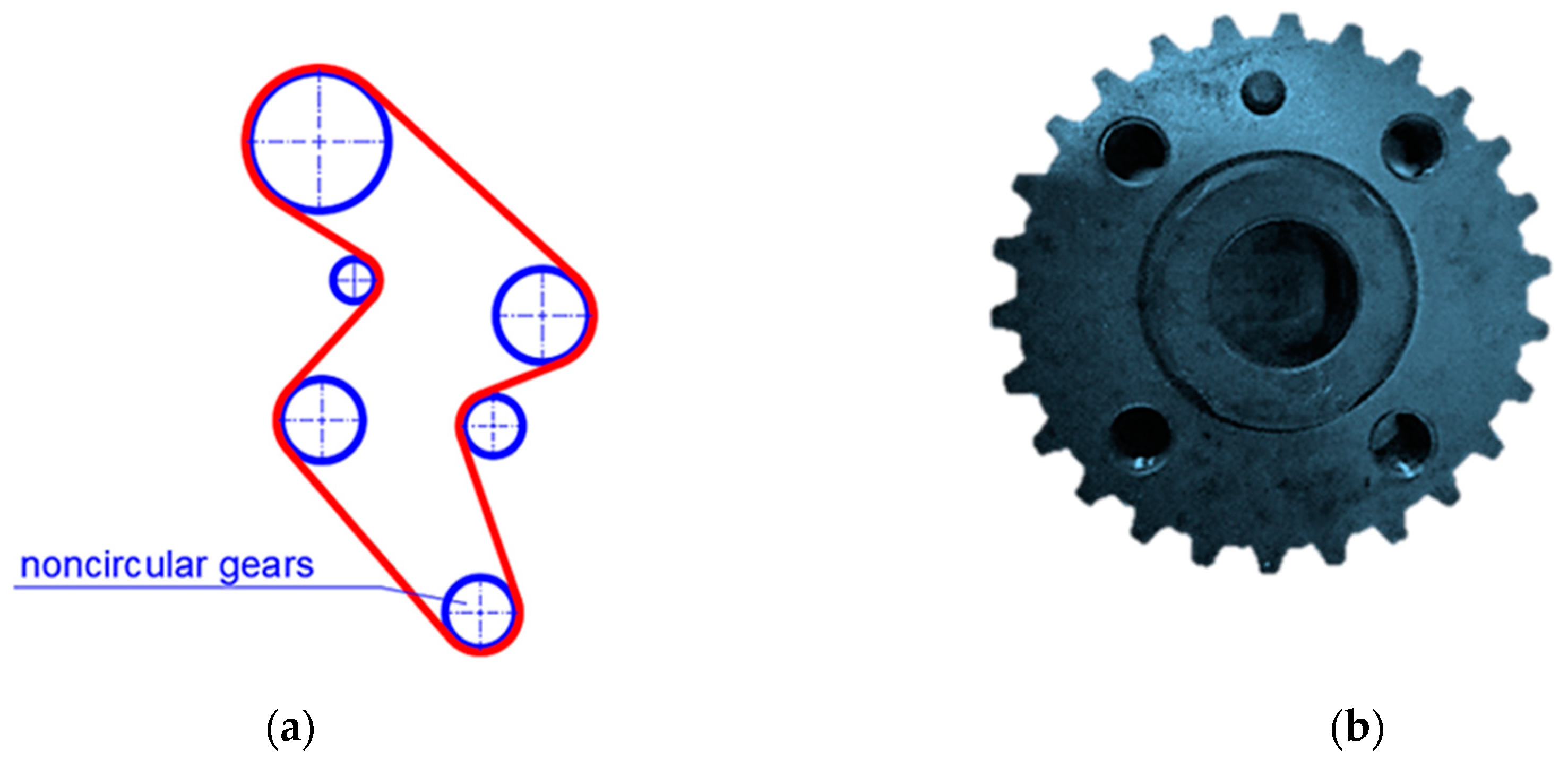

:1. Introduction

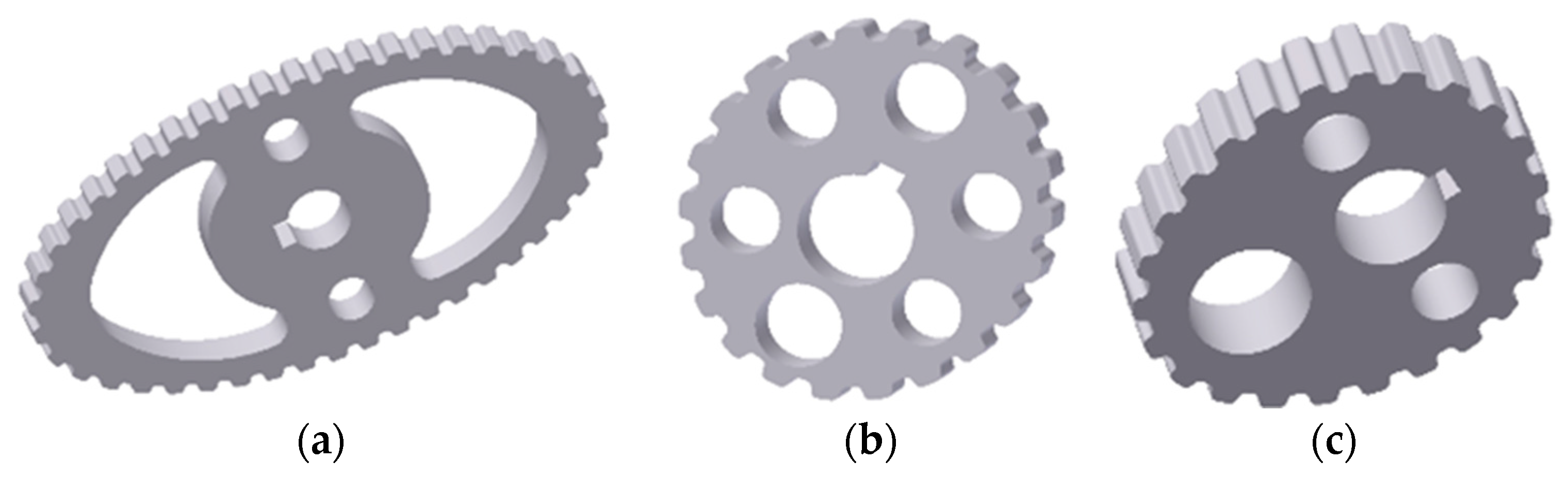

2. Materials and Methods

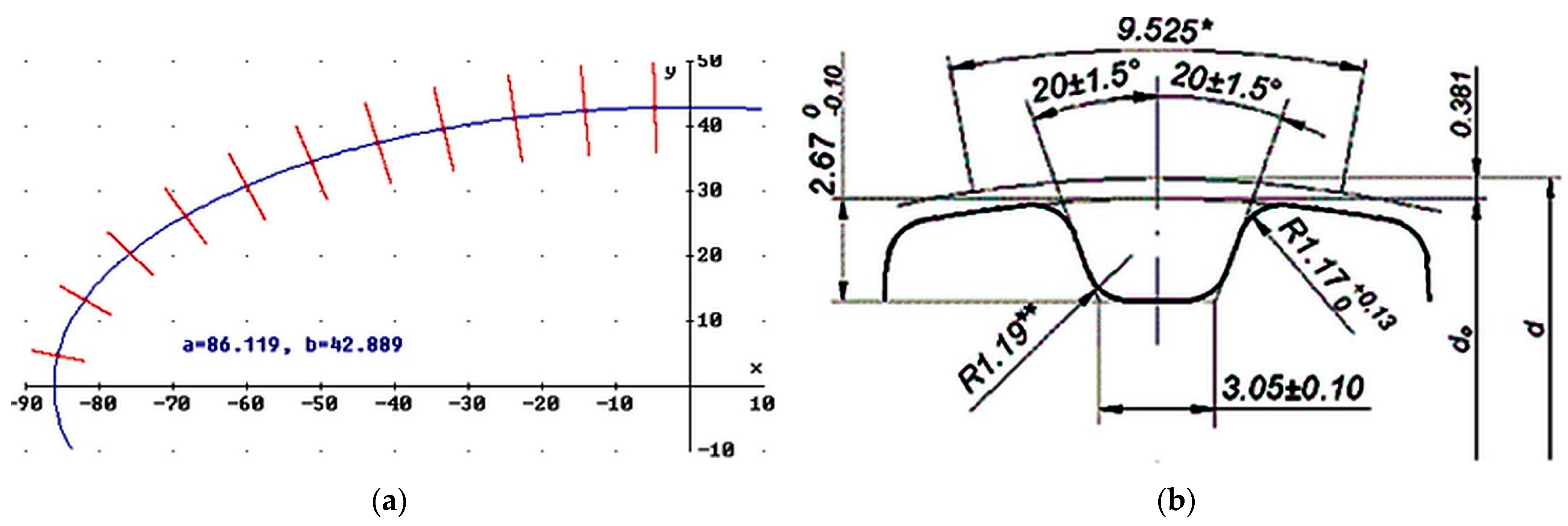

2.1. Design Methods

2.2. Workpiece Materials

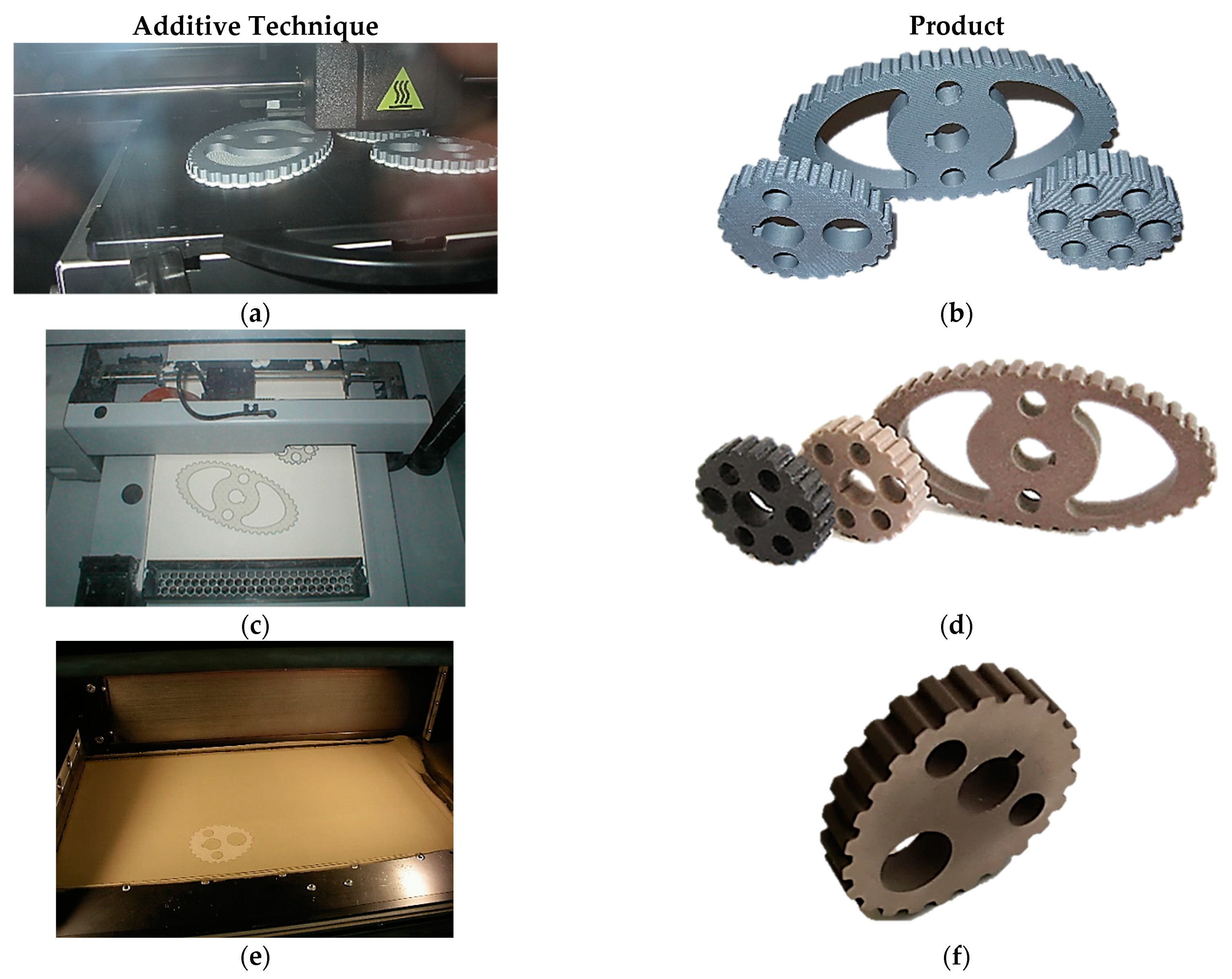

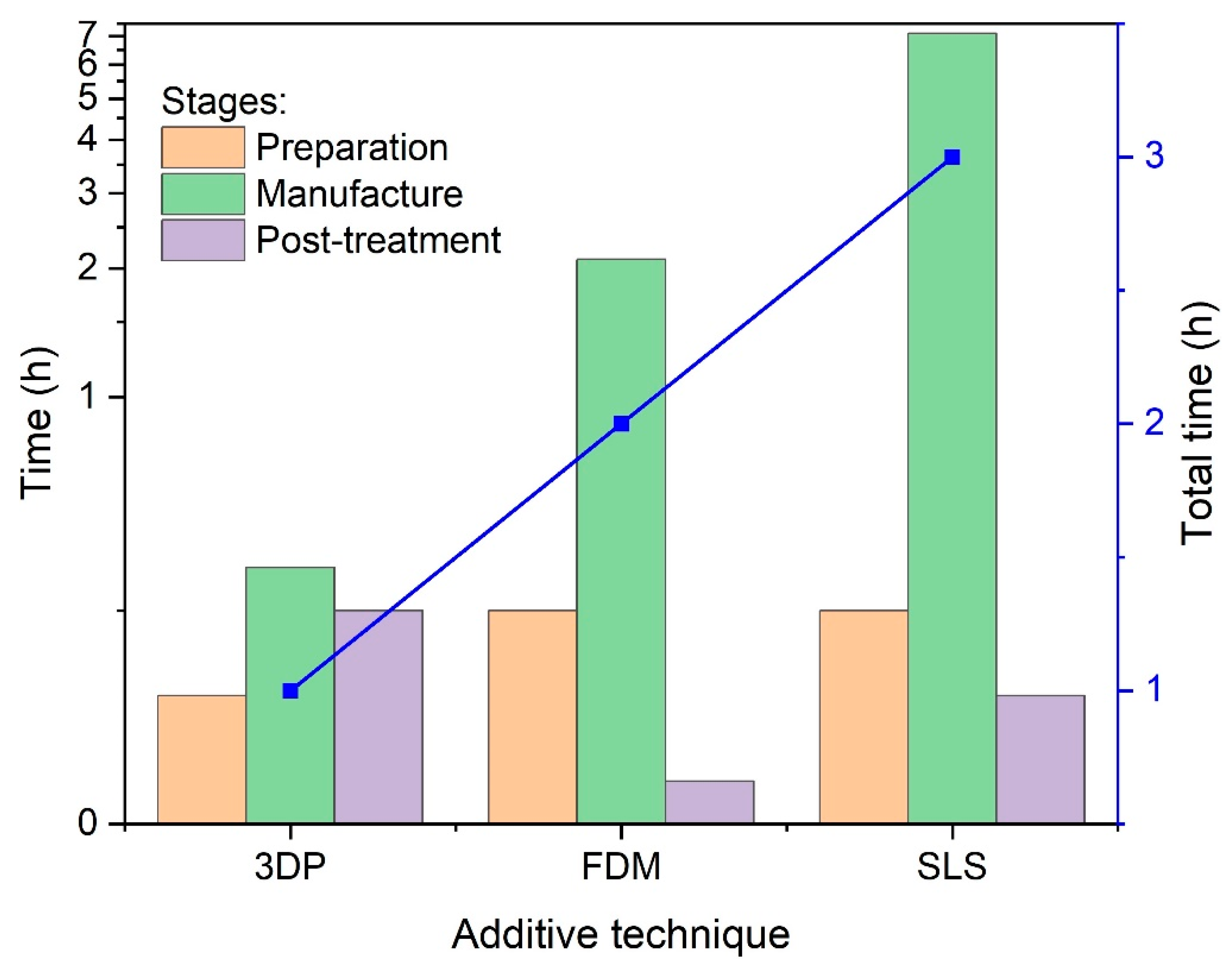

2.3. Characterization of Manufacturing Methods

2.4. Measurements of Mechanical Properties and Geometric Features of Manufactured Wheels

3. Results and Discussions

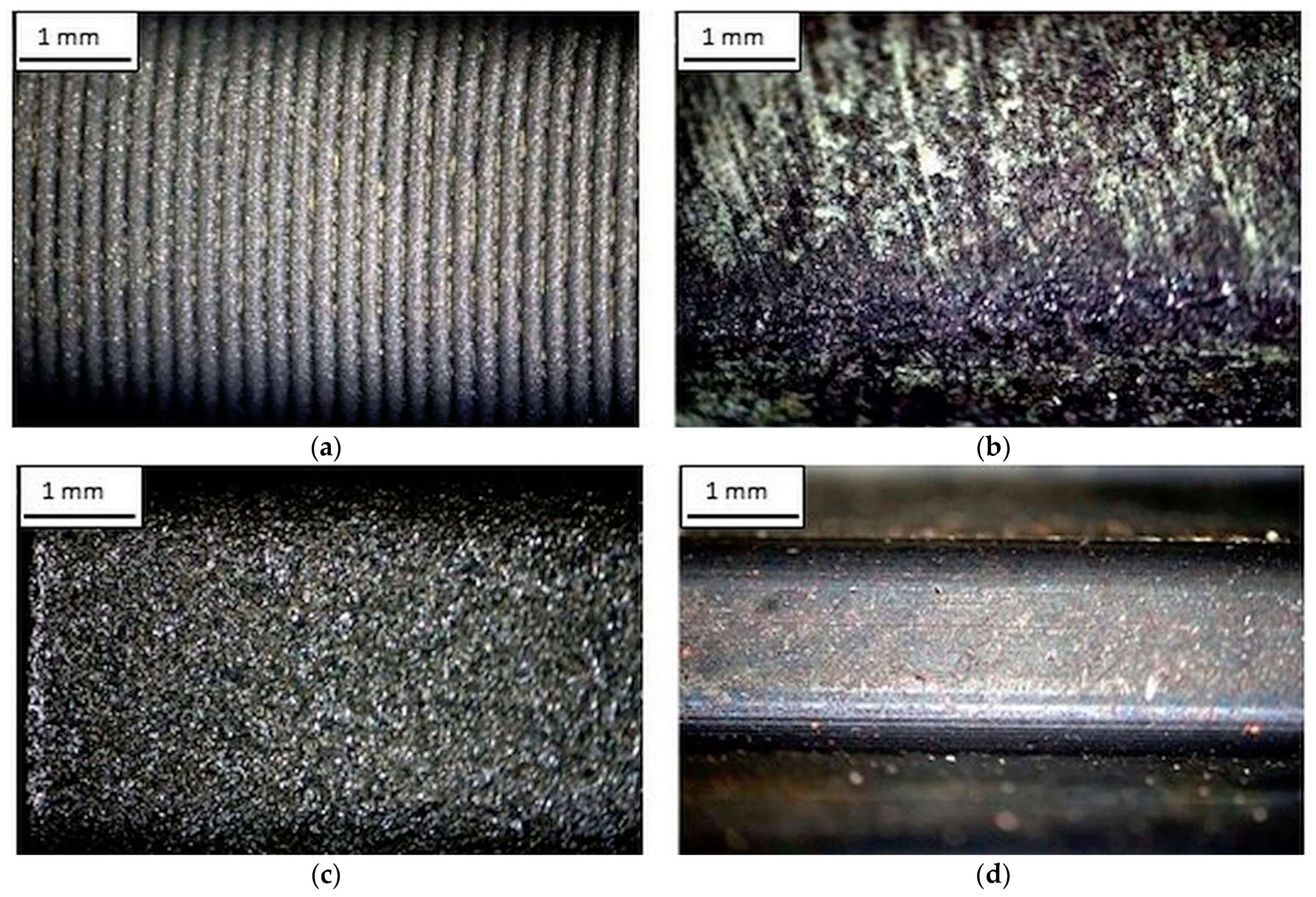

3.1. The Surface Morphology of the Manufactured Parts

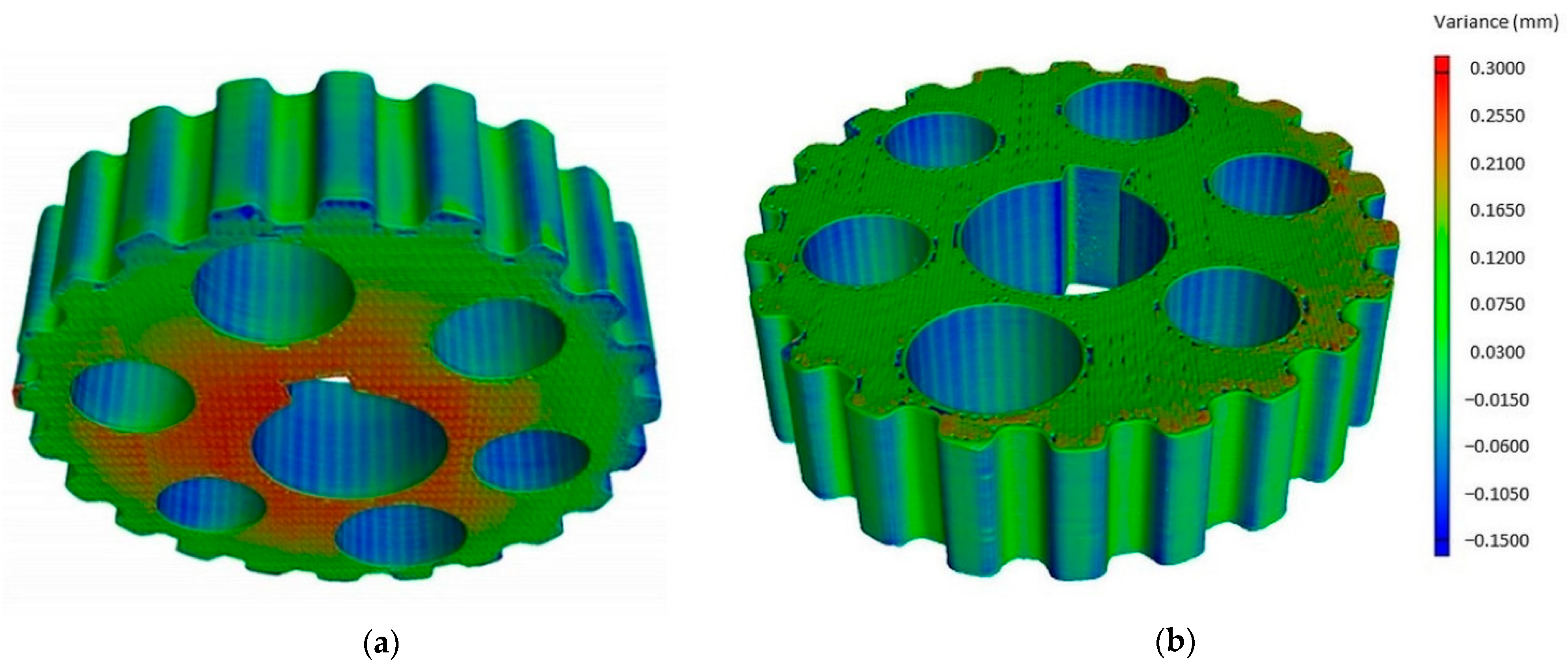

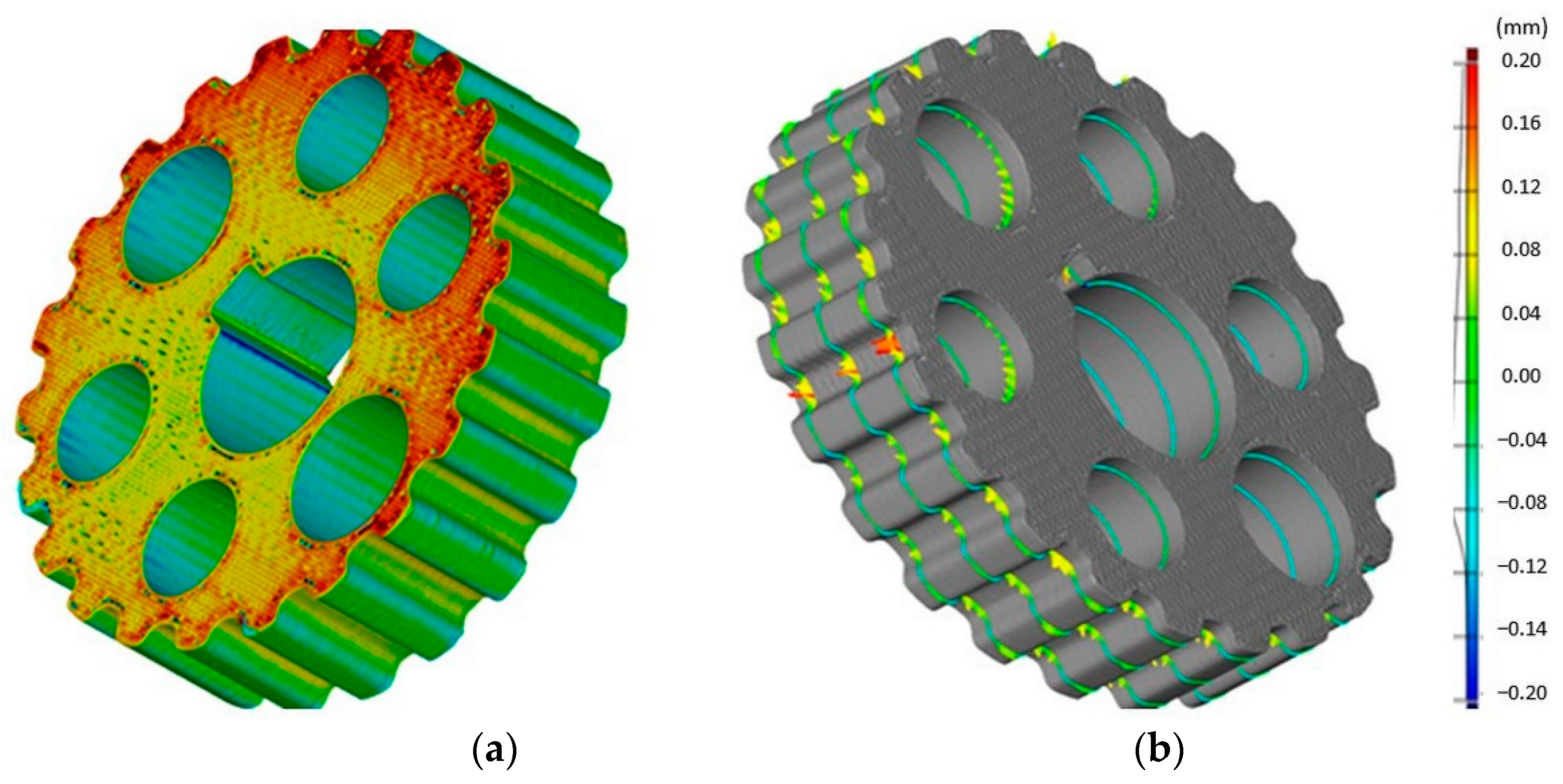

3.2. Evaluation of Geometric Specification of Non-Circular Pulleys with the Use of Contact and Non-Contact Methods

4. Conclusions

- It is not recommended to make prototype non-circular pulleys using the 3D printing method because the accuracy of the tooth profile at the level of ±0.1 mm prevents the correct installation of the toothed belt. This is due to the technology of layering the composite material of the sintered powder.

- The FDM method guarantees a much greater accuracy of the tooth representation (± 0.06 mm), which makes it suitable for the initial assessment of the correctness of geometric features. This is due to the fact that FDM specimens show anisotropic mechanical properties since they vary with filament extrusion direction.

- In the case of the selective laser sintering (SLS) technique, the tooth reproduction accuracy was 0.01 mm of geometric and stereometric surface features, which means the highest surface quality. This result is confirmed by the assessment of the morphology of the surface of the teeth of gears made with this technique, characterized by a uniform structure of the working surface of the wheel, while maintaining a high tolerance of outer profile of gear for SLS at the level of ±0.03 mm.

- The conducted geometric part specification tests revealed that the prototype non-circular pulleys made with the FDM and SLS methods are characterized by the relatively highest geometric quality. As a consequence, they can be employed in a non-parallel belt transmission without the torque load (only frictional resistance) and thus, used in a belt transmission operating under working conditions.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tymrak, B.M.; Kreiger, M.; Pearce, J.M. Mechanical properties of components fabricated with open-source 3-D printers under realistic environmental conditions. Mater. Des. 2014, 58, 242–246. [Google Scholar] [CrossRef] [Green Version]

- Czarnecka-Komorowska, D.; Mencel, K. Modification of polyamide 6 and polyoxymethylene with [3-(2-aminoethyl) amino] propyl-heptaisobutyl-polysilsesquioxane nanoparticles. Przem. Chem. 2014, 93, 392–396. [Google Scholar] [CrossRef]

- Gawdzinska, K.; Paszkiewicz, S.; Piesowicz, E.; Bryll, K.; Irska, I.; Lapis, A.; Sobolewska, E.; Kochmanska, A.; Slaczka, W. Preparation and Characterization of Hybrid Nanocomposites for Dental Applications. Appl. Sci. 2019, 9, 1381. [Google Scholar] [CrossRef] [Green Version]

- Krawiec, P.; Warguła, Ł.; Małozięć, D.; Kaczmarzyk, P.; Dziechciarz, A.; Czarnecka-Komorowska, D. The Toxicological Testing and Thermal Decomposition of Drive and Transport Belts Made of Thermoplastic Multilayer Polymer Materials. Polymers 2020, 12, 2232. [Google Scholar] [CrossRef]

- Krawiec, P.; Warguła, Ł.; Waluś, K.; Adamiec, J. Wear evaluation study of the multiple grooved pulleys with optical method. MATEC Web Conf. 2019, 254. [Google Scholar] [CrossRef]

- Krawiec, P.; Różański, L.; Czarnecka-Komorowska, D.; Warguła, Ł. Evaluation of the Thermal Stability and Surface Characteristics of Thermoplastic Polyurethane V-Belt. Materials 2020, 3, 1502. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- The 2.0l FSI Engine with Turbocharge. Available online: www.volkspage.net/technik/ssp/ssp/SSP_337.pdf (accessed on 20 February 2021).

- Audi/VW 2.0TFSI Engine Design & Function. Available online: www.vaglinks.com/vaglinks_com/Docs/SSP/VWUSA.COM_SSP_821503_FSI_Turbo_Motor.pdf (accessed on 20 February 2021).

- Branowski, B.; Fedorczuk, J. Przekładnia rowerowa. Poland Patent 211,706, 2012. [Google Scholar]

- Wieczorek, B.; Warguła, Ł.; Rybarczyk, D. Impact of a hybrid assisted wheelchair propulsion system on motion kinematics during climbing up a slope. Appl. Sci. 2020, 10, 1025. [Google Scholar] [CrossRef] [Green Version]

- Wieczorek, B.; Kukla, M. Biomechanical Relationships Between Manual Wheelchair Steering and the Position of the Human Body’s Center of Gravity. J. Biomech. Eng. 2020, 142. [Google Scholar] [CrossRef]

- Sága, M.; Blatnický, M.; Vaško, M.; Dižo, J.; Kopas, P.; Gerlici, J. Experimental Determination of the Manson-Coffin Curves for an Original Unconventional Vehicle Frame. Materials 2020, 13, 4675. [Google Scholar] [CrossRef]

- Saga, M.; Blatnicka, M.; Blatnicky, M.; Dižo, J.; Gerlici, J. Research of the Fatigue Life of Welded Joints of High Strength Steel S960 QL Created Using Laser and Electron Beams. Materials 2020, 13, 2539. [Google Scholar] [CrossRef] [PubMed]

- Przestacki, D.; Szymanski, P.; Wojciechowski, S. Formation of surface layer in metal matrix composite A359/20SiCP during laser assisted turning. Compos. Part A Appl. Sci. Manuf. 2016, 91, 370–379. [Google Scholar] [CrossRef]

- Przestacki, D.; Chwalczuk, T.; Wojciechowski, S. The study on minimum uncut chip thickness and cutting forces during laserassisted turning of WC/NiCr clad layers. Int. J. Adv. Manuf. Technol. 2017, 91. [Google Scholar] [CrossRef]

- Galeta, T.; Raos, P.; Stojšić, J.; Pakši, I. Influence of structure on mechanical properties of 3D printed objects. Procedia Eng. 2016, 149, 100–104. [Google Scholar] [CrossRef] [Green Version]

- Vaško, M.; Sága, M.; Majko, J.; Vaško, A.; Handrik, M. Impact Toughness of FRTP Composites Produced by 3D Printing. Materials 2020, 13, 5654. [Google Scholar] [CrossRef]

- Blatnicky, M.; Saga, M.; Dizo, J.; Bruna, M. Application of Light Metal Alloy EN AW 6063 to Vehicle Frame Construction with an Innovated Steering Mechanism. Materials 2020, 13, 817. [Google Scholar] [CrossRef] [Green Version]

- Blatnicky, M.; Dizo, J.; Saga, M.; Gerlici, J.; Kuba, E. Design of a Mechanical Part of an Automated Platform for Oblique Manipulation. Appl. Sci. 2020, 10, 8467. [Google Scholar] [CrossRef]

- Krawiec, P.; Domek, G.; Warguła, Ł.; Waluś, K.; Adamiec, J. The application of the optical system ATOS II for rapid prototyping methods of non-classical models of cogbelt pulleys. MATEC Web Conf. 2018, 157. [Google Scholar] [CrossRef] [Green Version]

- Krawiec, P.; Marlewski, A. Spline description of non-typical gears for belt transmissions. J. Theor. Appl. Mech. 2011, 49, 355–367. [Google Scholar]

- Krawiec, P.; Marlewski, A. Profile design of noncircular belt pulleys. J. Theor. Appl. Mech. 2016, 54, 561–570. [Google Scholar] [CrossRef] [Green Version]

- Przemysłowy Instytut Motoryzacji. Przekładnie Pasowe Zębate. Koła Pasowe. Wymiary; Przemysłowy Instytut Motoryzacji: Warsaw, Poland, 1984. [Google Scholar]

- International Organization for Standardization. Synchronous Belt Drives—Pulleys; International Organization for Standardization: Geneve, Switzerland, 1989. [Google Scholar]

- Leturia, M.; Benali, M.; Lagarde, S.; Ronga, I.; Saleh, K. Characterization of flow properties of cohesive powders: A comparative study of traditional and new testing methods. Powder Technol. 2014, 253, 406–423. [Google Scholar] [CrossRef]

- Rojek, I.; Mikołajewski, D.; Dostatni, E.; Macko, M. AI-Optimized Technological Aspects of the Material Used in 3D Printing Processes for Selected Medical Applications. Materials 2020, 13, 5437. [Google Scholar] [CrossRef] [PubMed]

- Karta Materiału. Ekonomiczny i wszechstronn. Available online: https://cf.zortrax.com/wp-content/uploads/2019/01/Z-ABS_Technical_Data_Sheet_pl.pdf (accessed on 20 December 2020).

- 3DP Consumables Catalog. Available online: https://sldtech.com/wp-content/uploads/2008/10/consumables_catalog_.pdf (accessed on 20 December 2020).

- DirectMetal 20 material for EOSINT M 250 Xtended. Available online: www.3d-prototip.si/files/directmetal-20.pdf (accessed on 20 December 2020).

- Ruszaj, A.; Chuchro, M.; Wyszynski, D. Zastosowanie technologii selektywnego spiekania laserowego (SLS) w inżynierii maszyn (Selective laser sintering (SLS) technology application in mechanical Engineering). Inżynieria Maszyn 2006, 11, 38–47. [Google Scholar]

- Alaimo, G.; Marconi, S.; Costato, L.; Auricchio, F. Influence of meso-structure and chemical composition on FDM 3D-printed parts. Compos. Part B Eng. 2017, 113, 371–380. [Google Scholar] [CrossRef]

- Z Corporation zprinter 450 Quick Start Manual. Available online: www.manualslib.com/manual/1193373/Z-Corporation-Zprinter-450.html (accessed on 20 December 2020).

- The Standard in Metal 3D Printing. Available online: www.eos.info/en/additive-manufacturing/3d-printing-metal/eos-metal-systems (accessed on 20 December 2020).

- International Organization for Standardization. Plastics—Methods for Determining the Density of Non-Cellular Plastics—Part 1: Immersion Method, Liquid Pycnometer Method and Titration Method; Polish Committee for Standardization: Warsaw, Poland, 2013. [Google Scholar]

- International Organization for Standardization. Plastics—Determination of hardness—Part 1: Ball Indentation Method; Polish Committee for Standardization: Warsaw, Poland, 2004. [Google Scholar]

- Industrial microCT and nanoCT Scanner Featuring Unparalleled Flexibility and Efficiency. Available online: www.bakerhughesds.com/industrial-x-ray-ct-scanners/phoenix-vtomex-s-micro-ct (accessed on 20 December 2020).

- Technologia przemysłowego skanowania 3D. Available online: www.gom.com/pl/systemy-pomiarowe/atos.html (accessed on 20 December 2020).

- ZEISS CONTURA—Spolehlivé Zajištění Kvality. Available online: www.zeiss.pl/metrologia/produkty/systemy/portalowe-maszyny-pomiarowe/contura-2019.html (accessed on 20 December 2020).

- Form Talysurf® i-Series. Available online: www.atecorp.com/atecorp/media/pdfs/data-sheets/taylor-hobson-fts-i-series-surface-roughness-tester-data-sheet.pdf?ext=.pdf (accessed on 20 December 2020).

- Vega, V.; Clements, J.; Lam, T.; Abad, A.; Fritz, B.; Ula, N.; Es-Said, O.S. The Effect of Layer Orientation on the Mechanical Properties and Microstructure of a Polymer. J. Mater. Eng. Perform. 2010, 20, 978–988. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, D.; Huang, T.; Hu, Q.; Lammer, H. Three-Dimensional Printing of Continuous Flax Fiber-Reinforced Thermoplastic Composites by Five-Axis Machine. Materials 2020, 13, 1678. [Google Scholar] [CrossRef] [Green Version]

- Gan, X.; Wang, J.; Wang, Z.; Zheng, Z.; Lavorgna, M.; Ronca, A.; Fei, G.; Xia, H. Simultaneous realization of conductive segregation network microstructure and minimal surface porous macrostructure by SLS 3D printing. Mater. Des. 2019, 178, 107874. [Google Scholar] [CrossRef]

| xj (mm) | yj (mm) | αj (°) |

|---|---|---|

| −4.752 | 42.823 | 6.3293 |

| −14.235 | 42.298 | 18.600 |

| −23.670 | 41.236 | 29.862 |

| −33.330 | 39.540 | 40.127 |

| −42.261 | 37.369 | 48.514 |

| −51.291 | 34.452 | 56.110 |

| −60.025 | 30.754 | 62.871 |

| −68.292 | 26.128 | 69.062 |

| −75.791 | 20.364 | 74.960 |

| −81.921 | 13.226 | 80.828 |

| −85.610 | 4.6520 | 86.889 |

| Symbol | Material | Thickness (mm) | Ball Hardness (N/mm2) | Density (g/cm3) |

|---|---|---|---|---|

| FDM | ABS | 15 ± 0.1 | 56.0 ± 4.2 | 1.040 ± 0.011 |

| 3DP | Zp130 | 15 ± 0.1 | 114 ± 7.5 | 1.517 ± 0.014 |

| SLS | DirectMetal20 | 15 ± 0.1 | 374 ± 25.0 | 6.962 ± 0.020 |

| Machining | C45E steel | 25 ± 0.1 | 390 ± 25.1 | 7.850 ± 0.018 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Krawiec, P.; Czarnecka-Komorowska, D.; Warguła, Ł.; Wojciechowski, S. Geometric Specification of Non-Circular Pulleys Made with Various Additive Manufacturing Techniques. Materials 2021, 14, 1682. https://doi.org/10.3390/ma14071682

Krawiec P, Czarnecka-Komorowska D, Warguła Ł, Wojciechowski S. Geometric Specification of Non-Circular Pulleys Made with Various Additive Manufacturing Techniques. Materials. 2021; 14(7):1682. https://doi.org/10.3390/ma14071682

Chicago/Turabian StyleKrawiec, Piotr, Dorota Czarnecka-Komorowska, Łukasz Warguła, and Szymon Wojciechowski. 2021. "Geometric Specification of Non-Circular Pulleys Made with Various Additive Manufacturing Techniques" Materials 14, no. 7: 1682. https://doi.org/10.3390/ma14071682

APA StyleKrawiec, P., Czarnecka-Komorowska, D., Warguła, Ł., & Wojciechowski, S. (2021). Geometric Specification of Non-Circular Pulleys Made with Various Additive Manufacturing Techniques. Materials, 14(7), 1682. https://doi.org/10.3390/ma14071682