Model-Based Adaptive Machine Learning Approach in Concrete Mix Design

Abstract

1. Introduction

2. Concrete Mix Design and Machine Learning

2.1. Contemporary Engineering Practice in Concrete Mix Design

2.2. Machine Learning in Prediction of Concrete Features

3. Materials and Methods

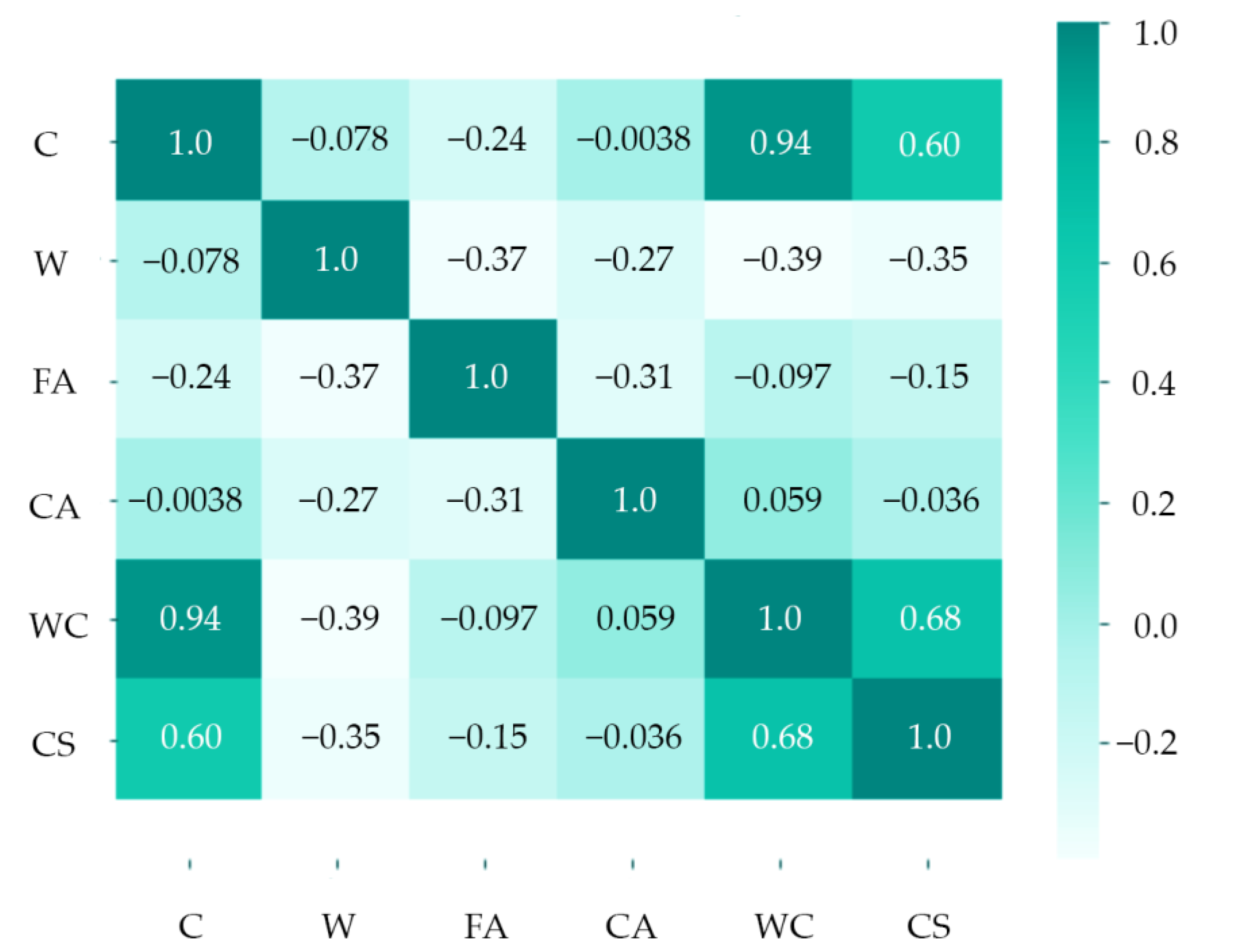

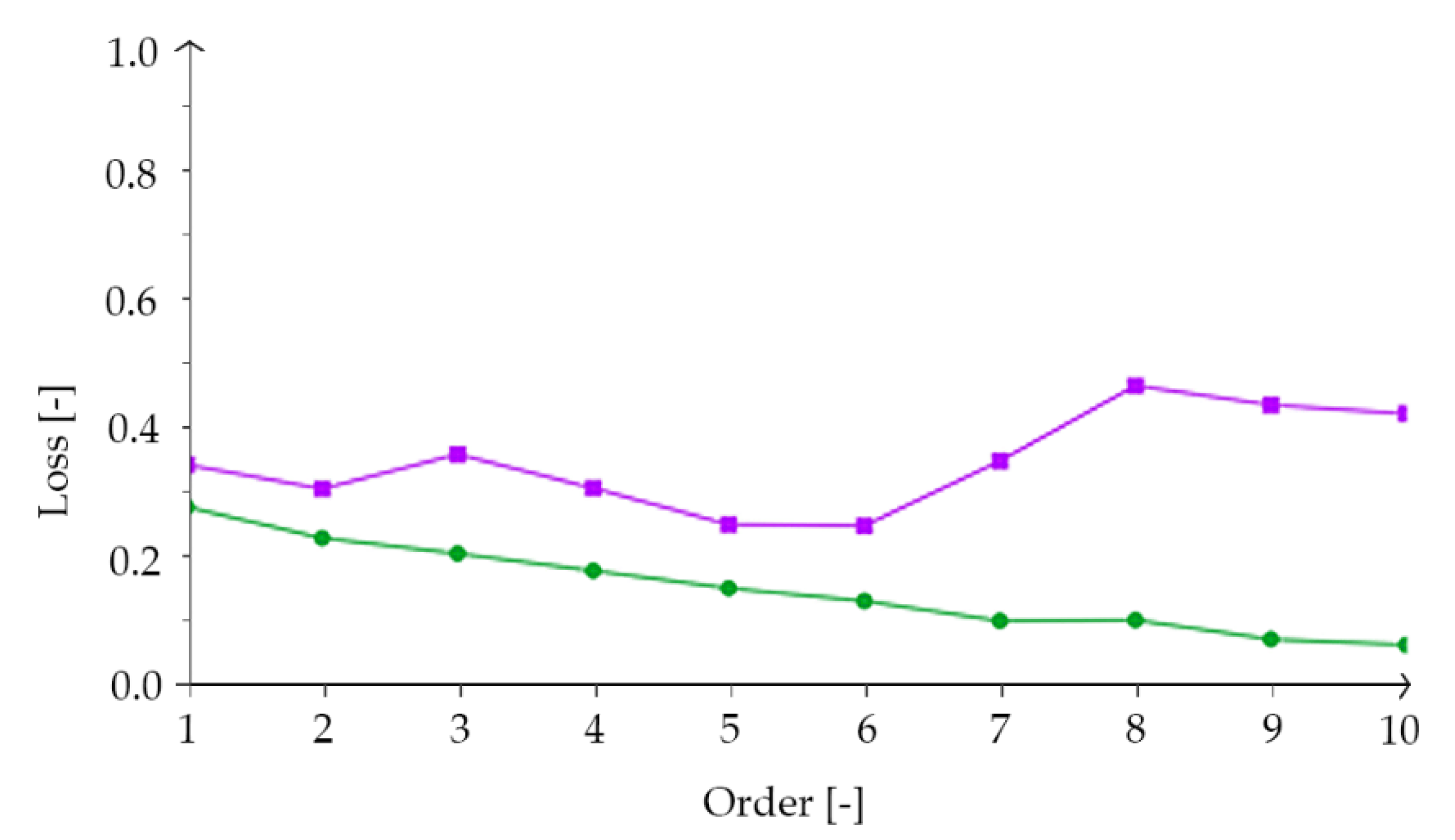

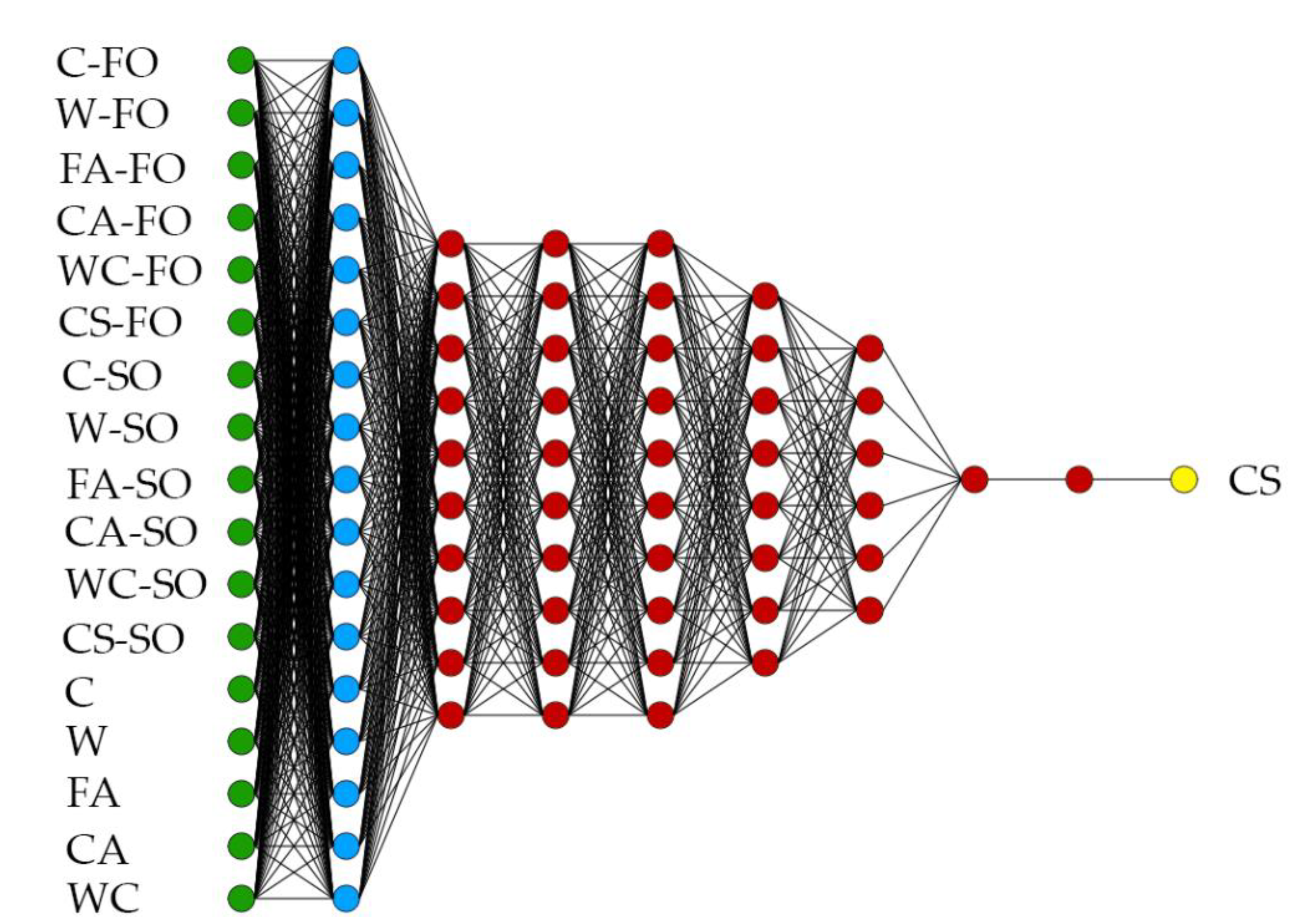

3.1. Essentials

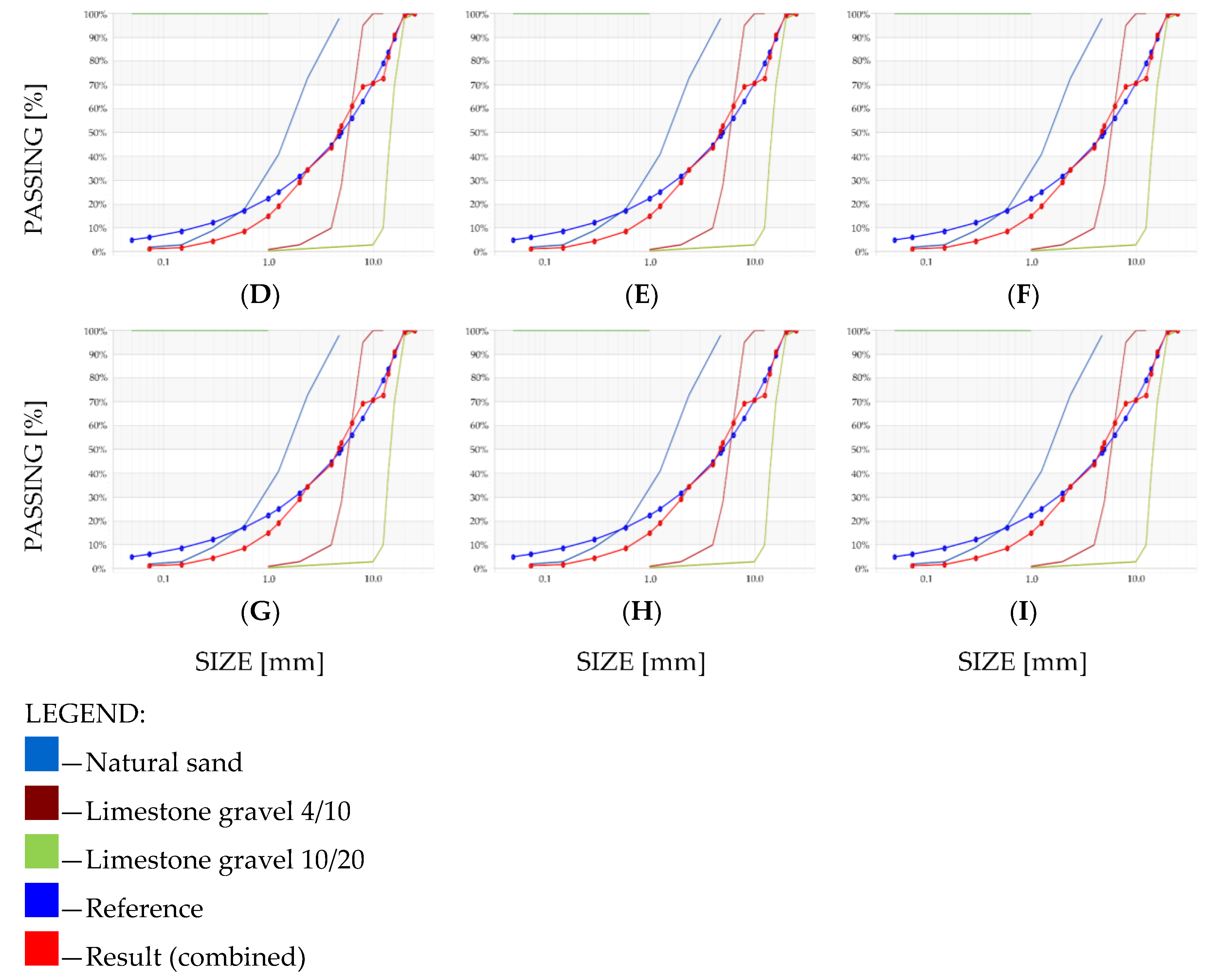

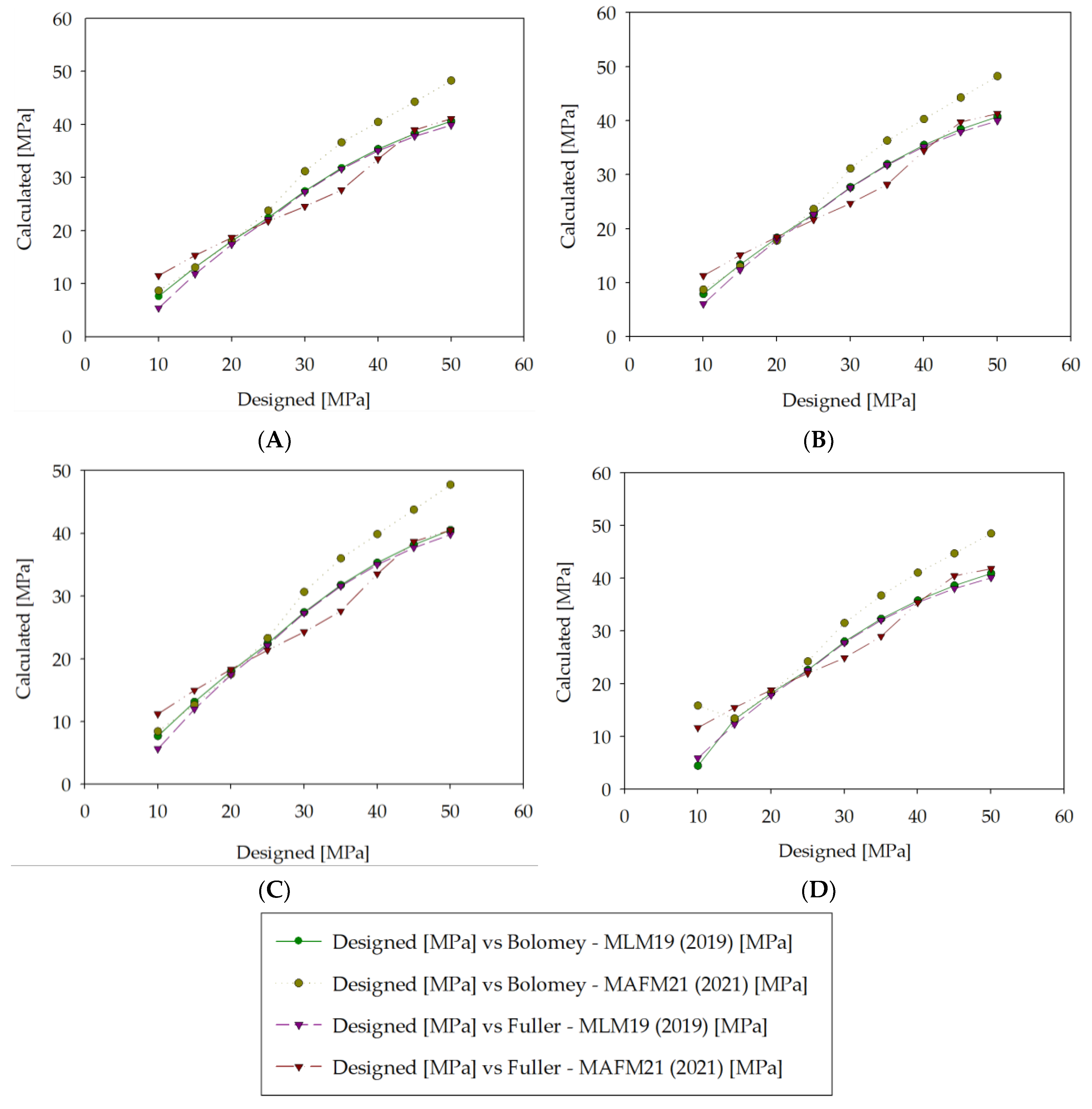

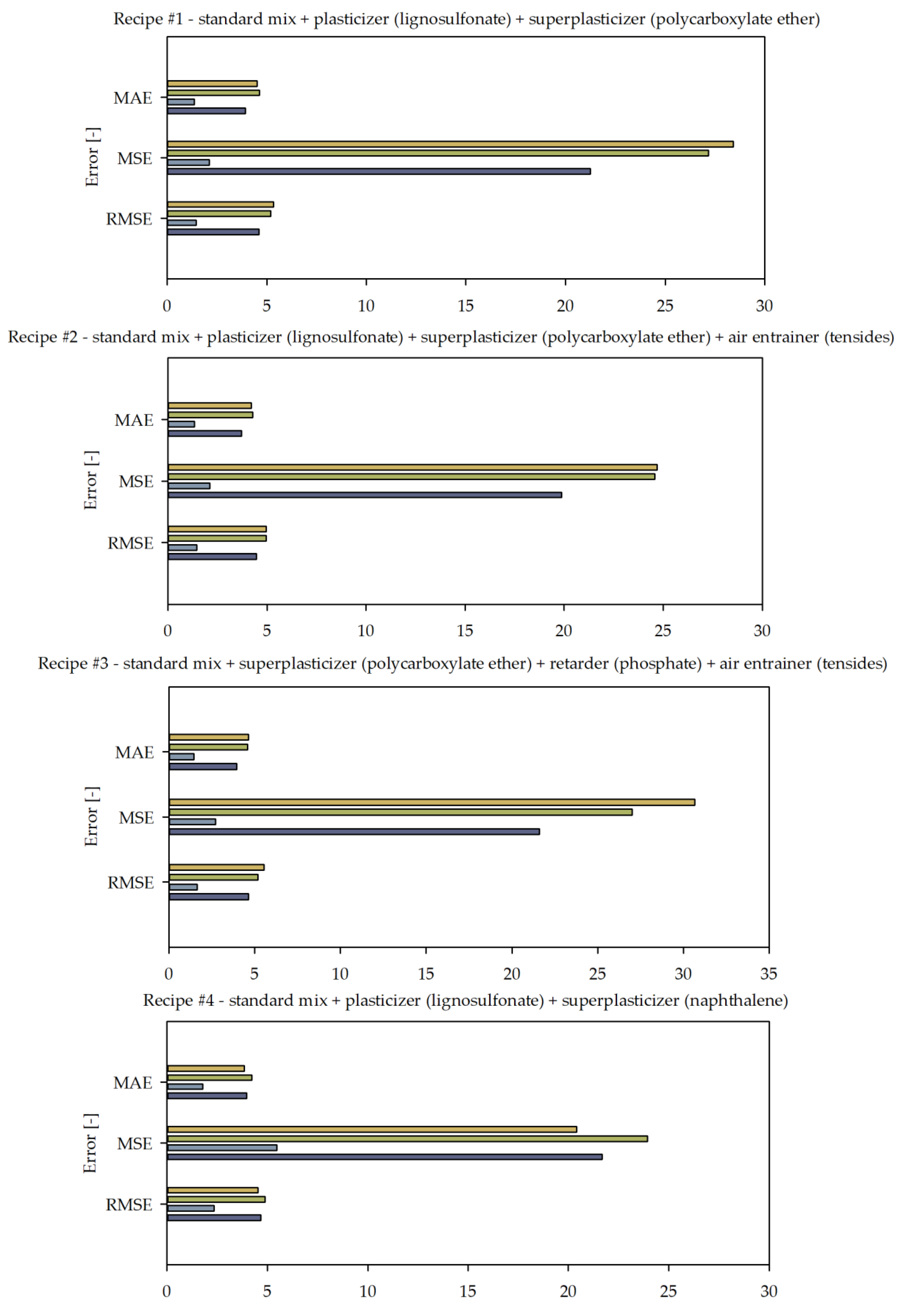

3.2. Results and Discussion

4. Summary and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

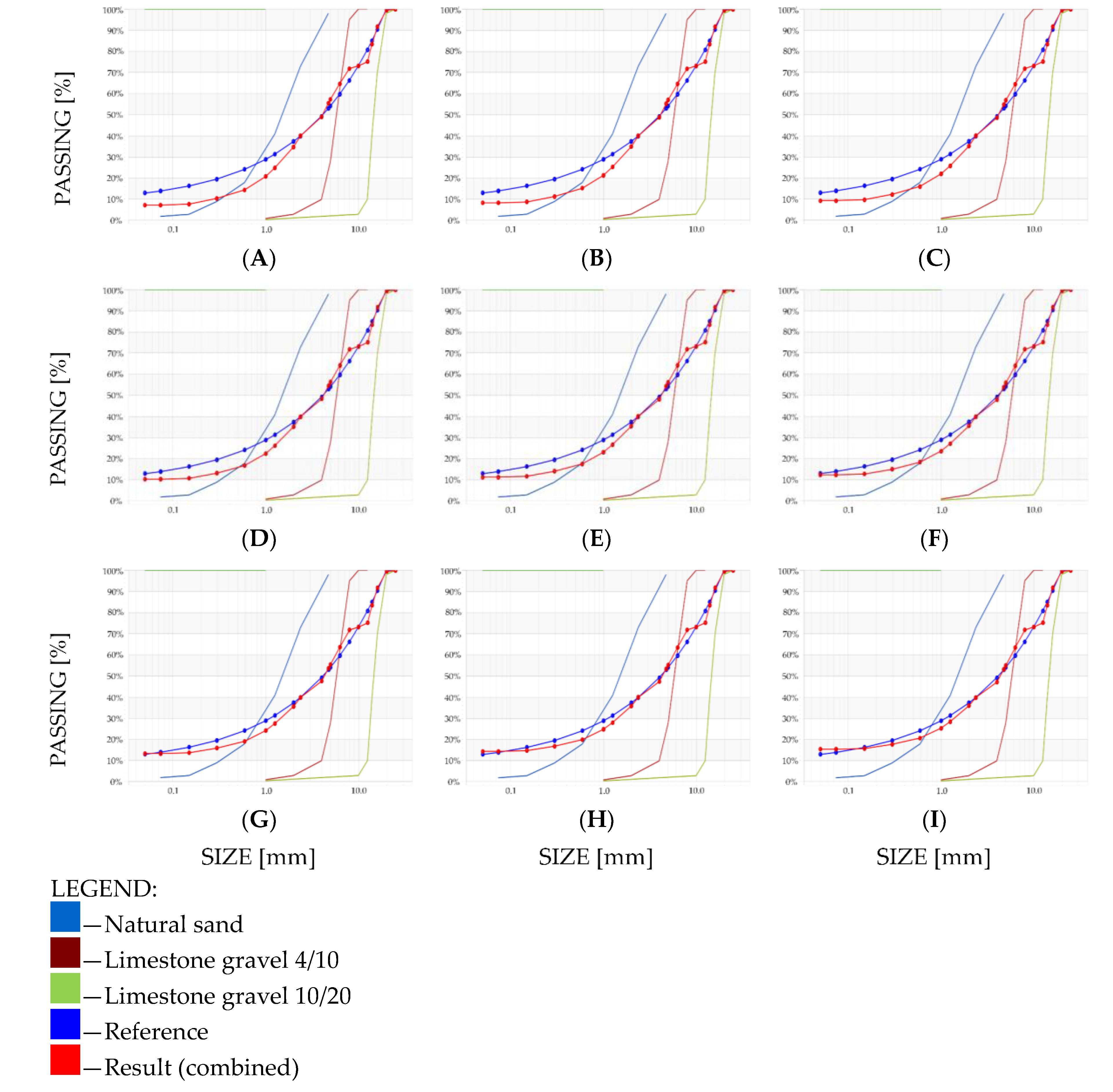

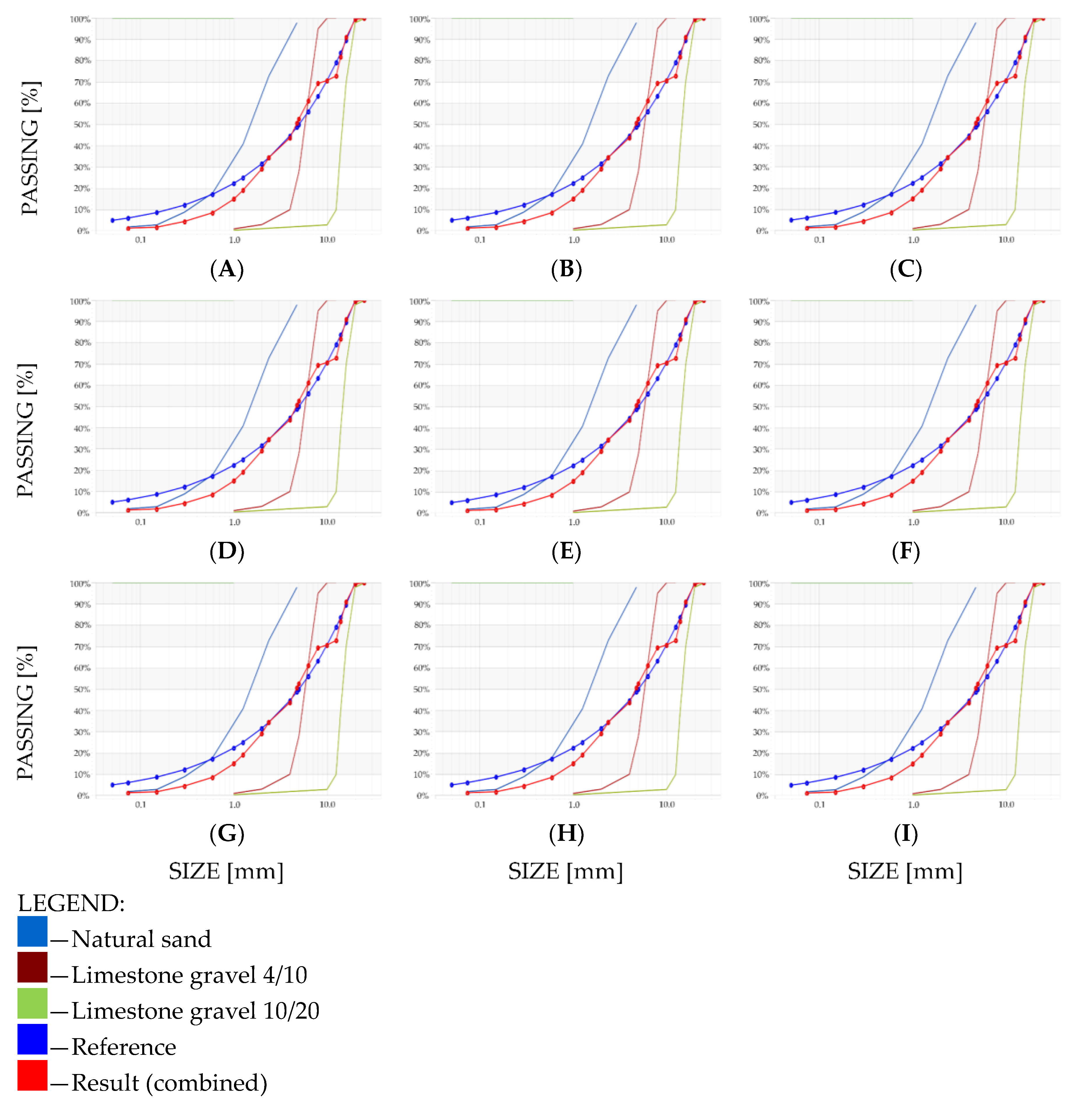

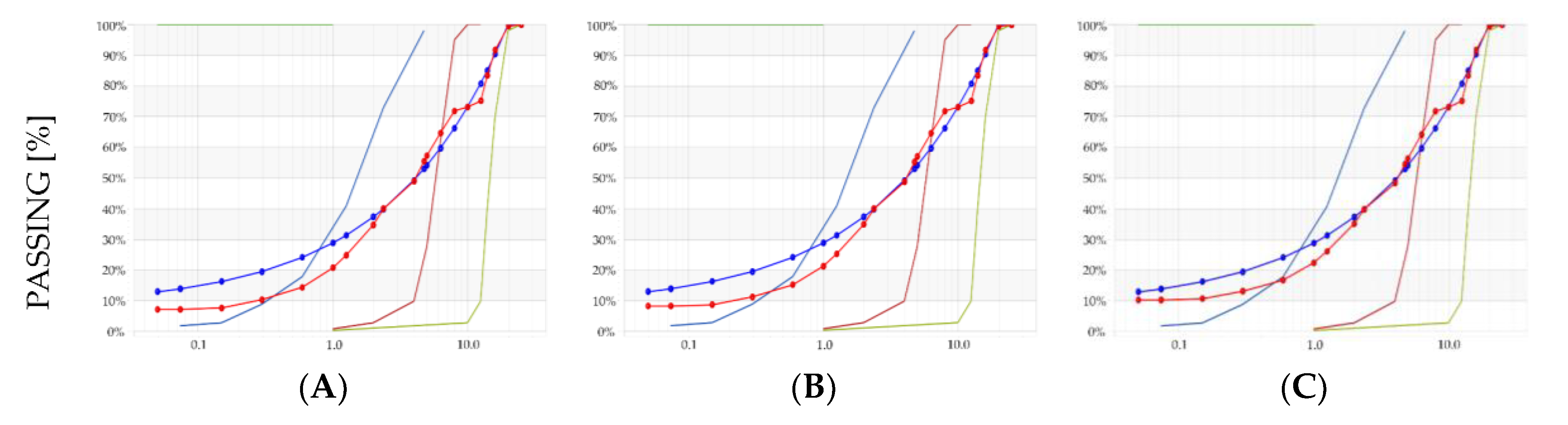

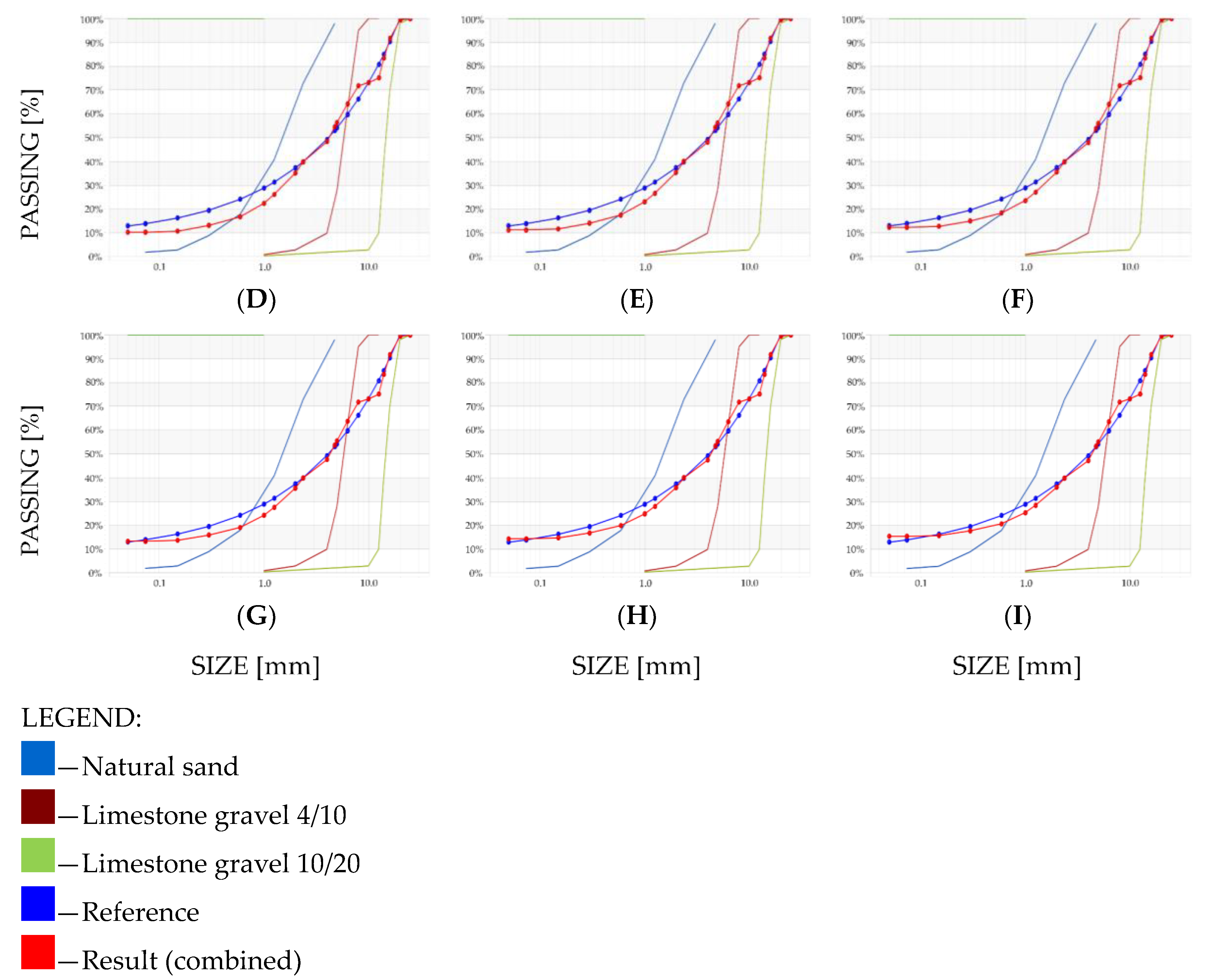

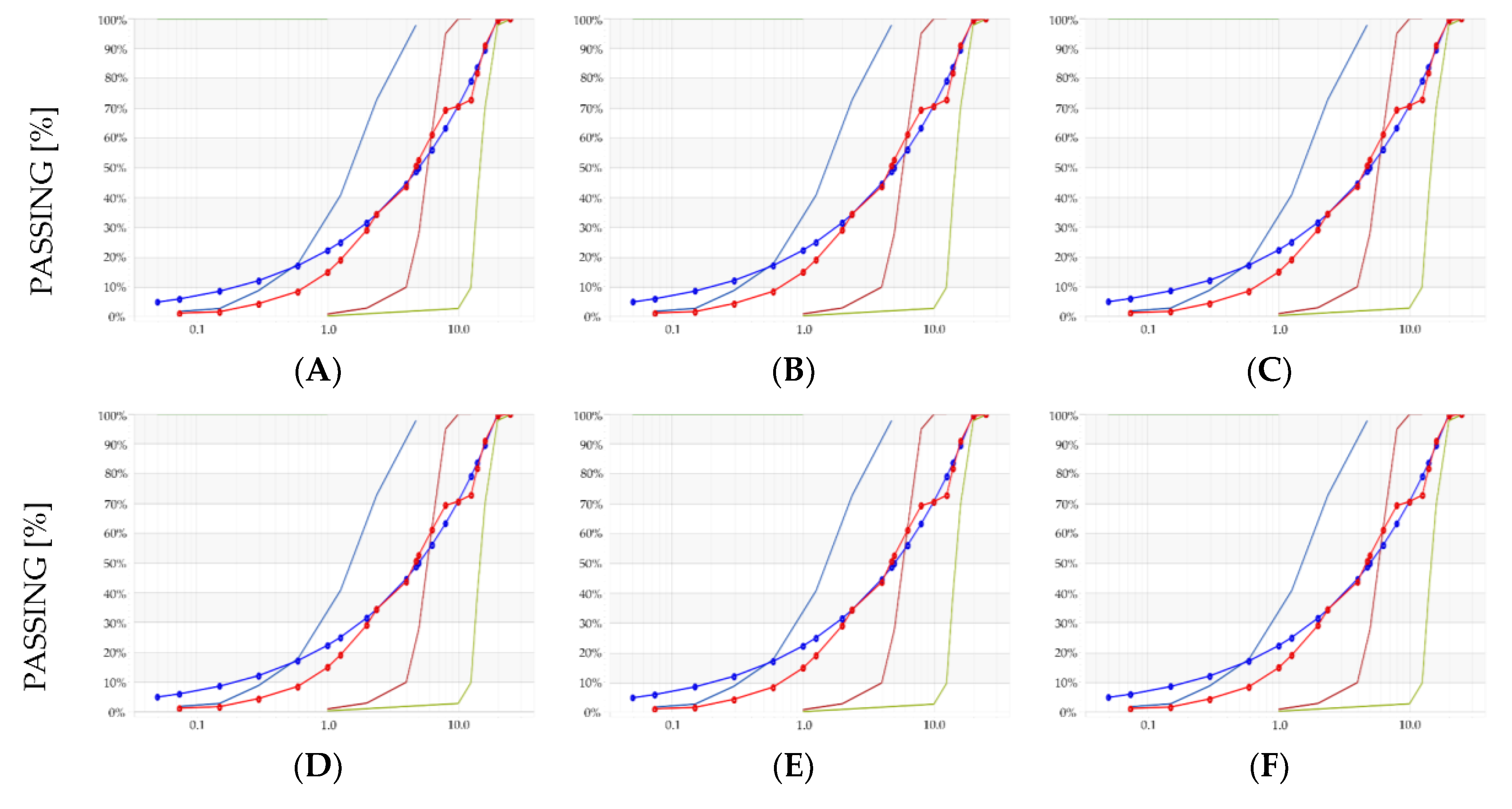

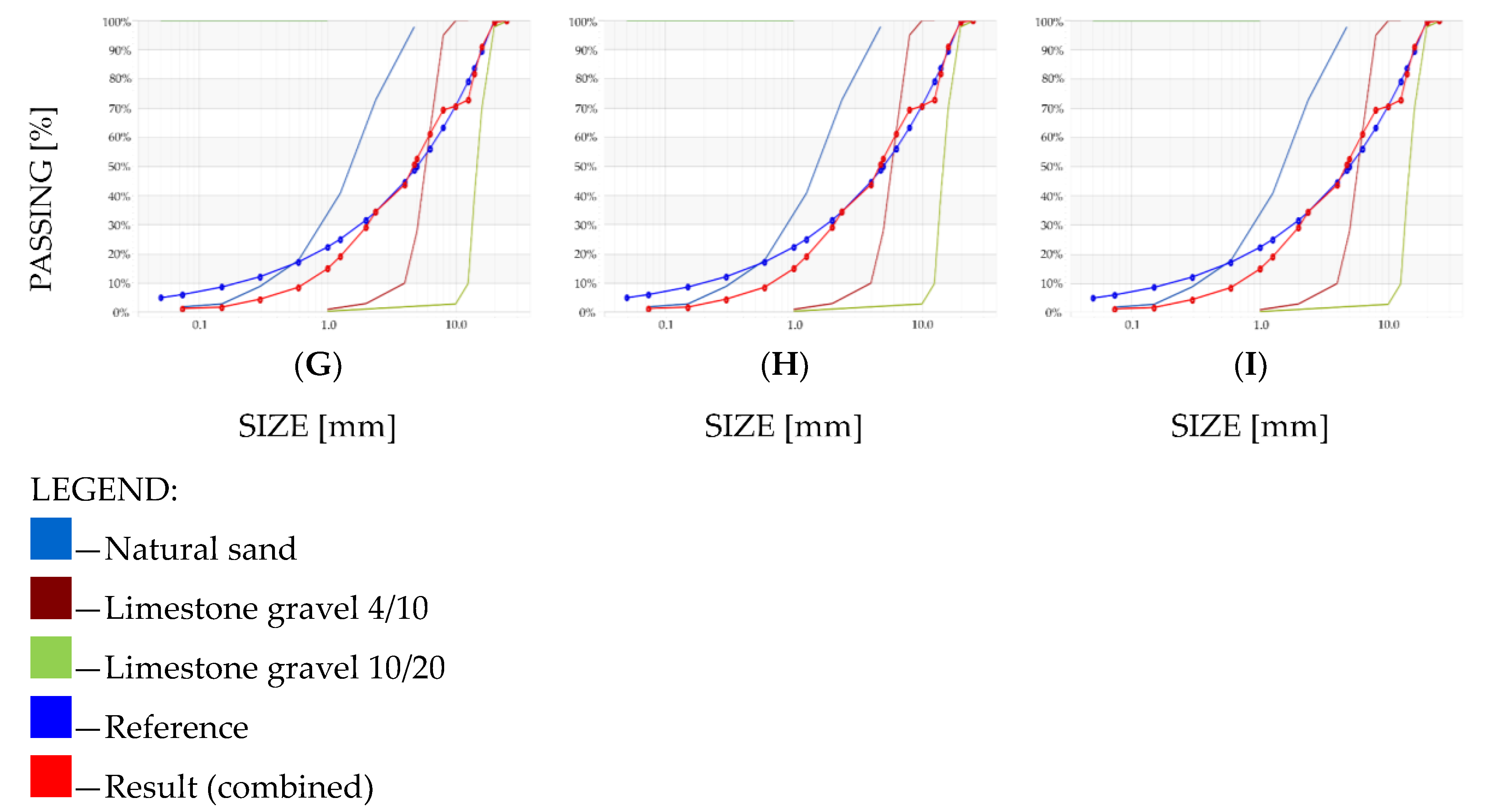

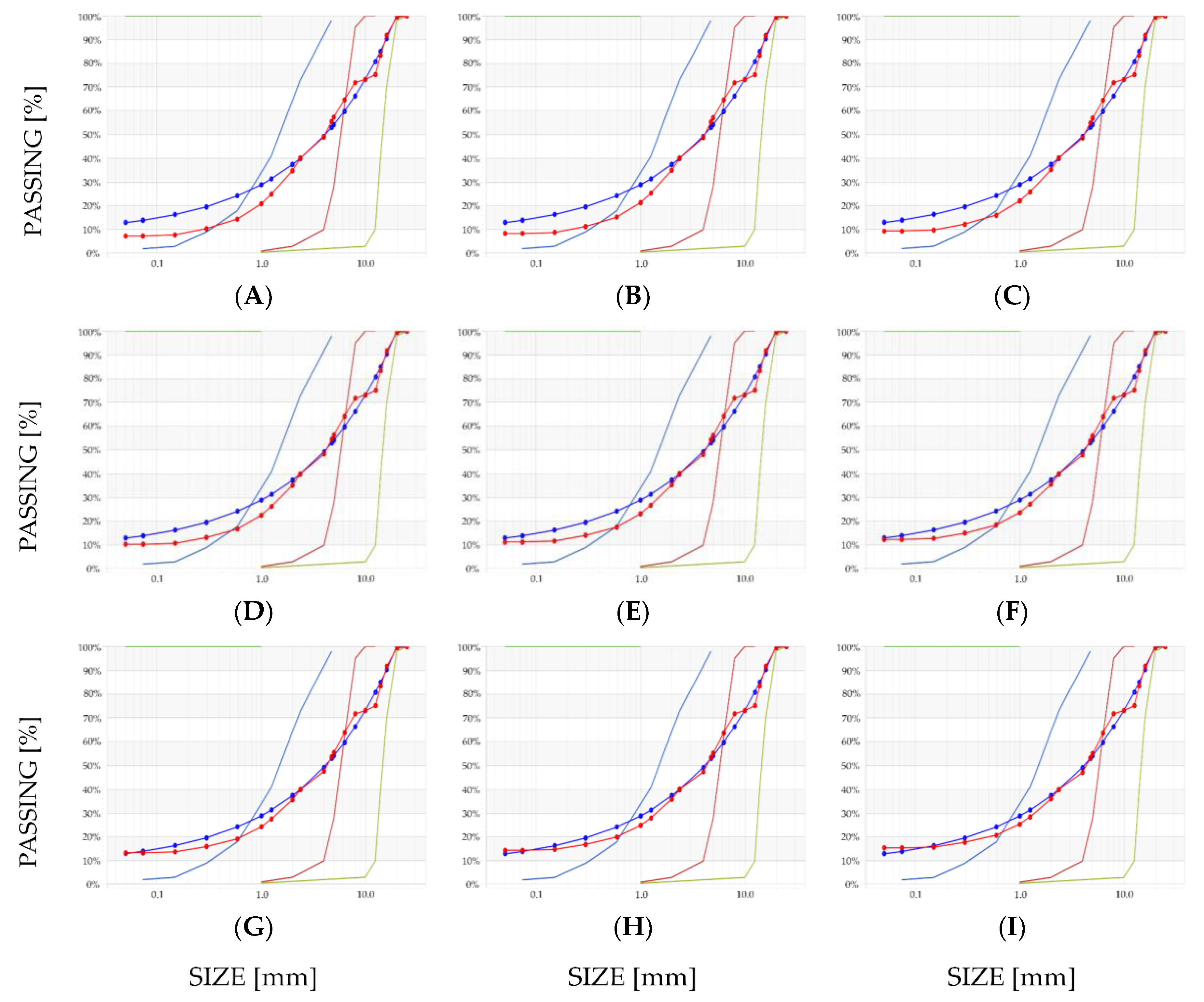

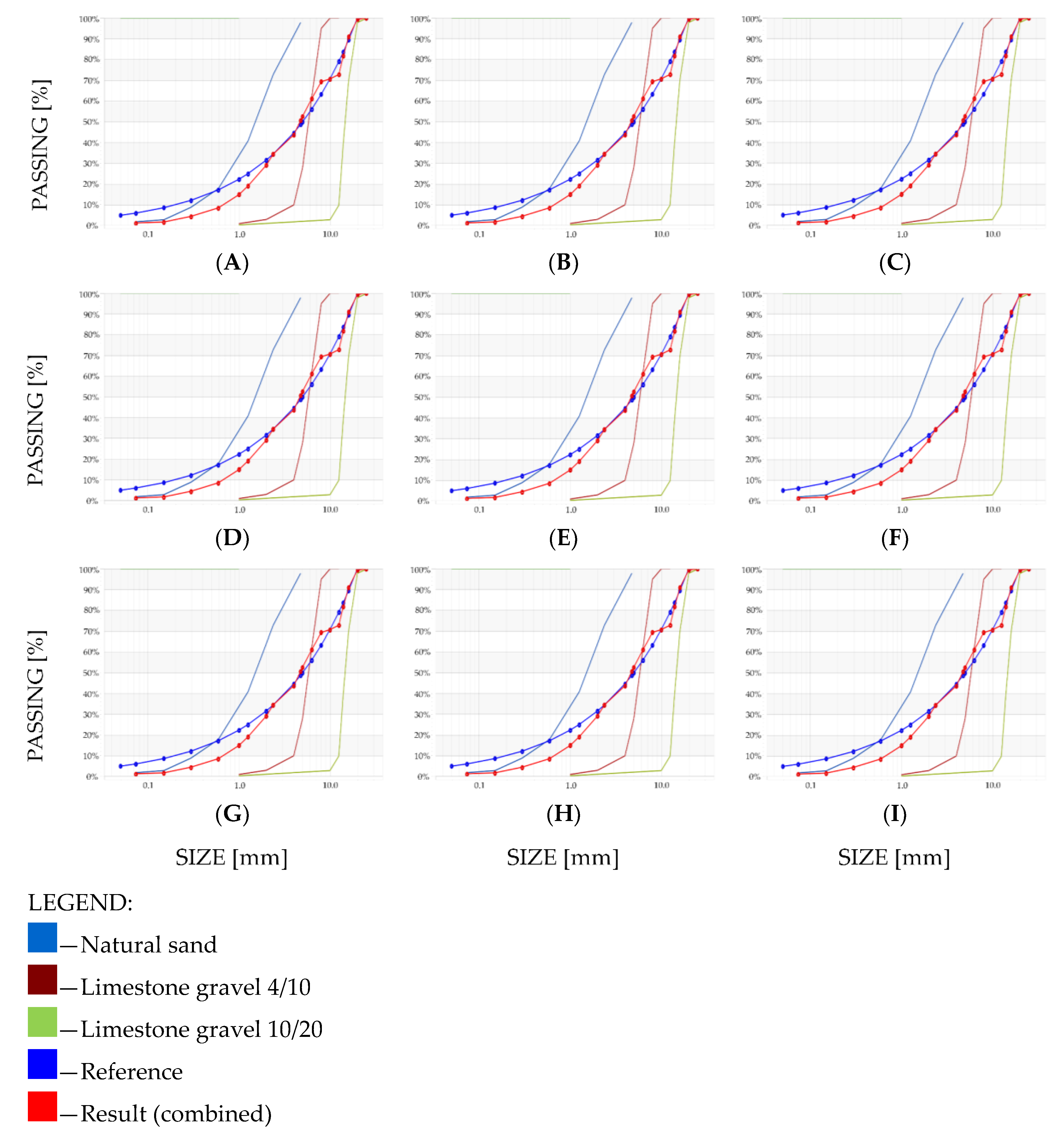

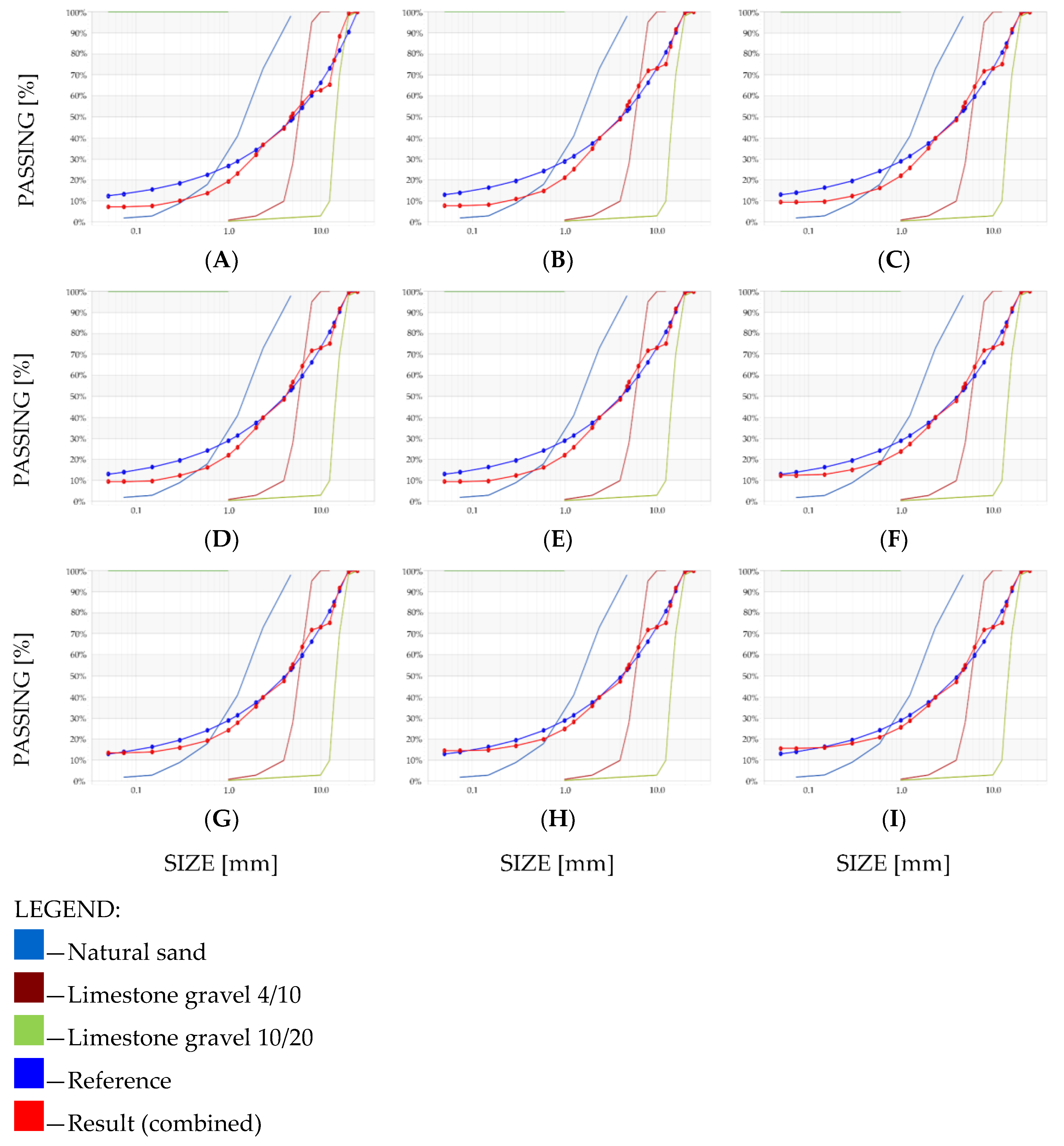

Appendix A

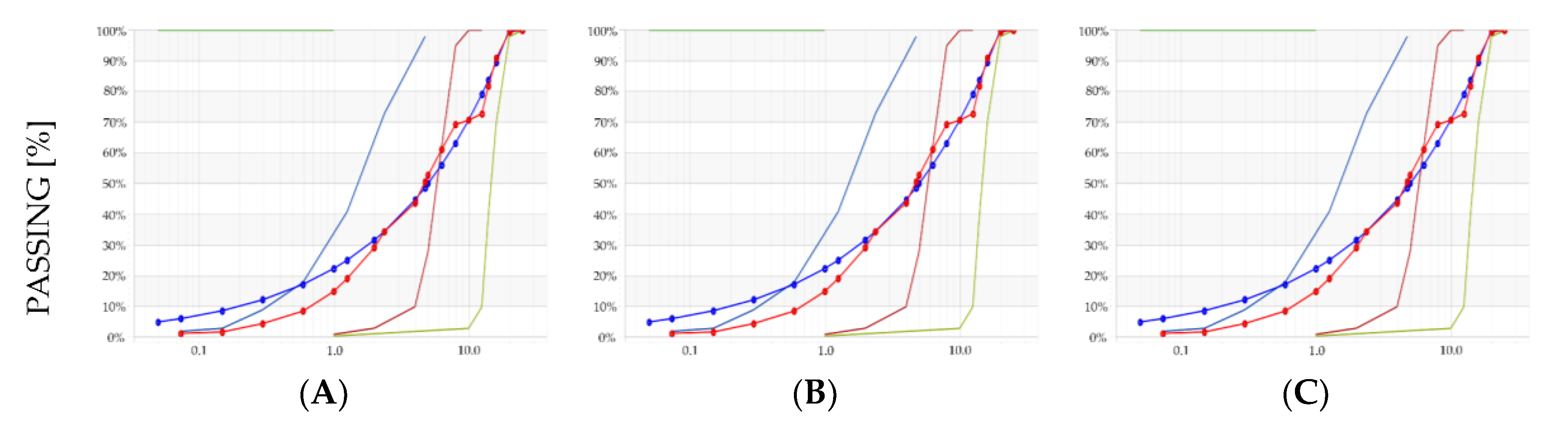

Appendix B

References

- Dimov, D.; Amit, I.; Gorrie, O.; Barnes, M.D.; Townsend, N.J.; Neves, A.I.S.; Withers, F.; Russo, S.; Craciun, M.F. Ultrahigh Performance Nanoengineered Graphene-Concrete Composites for Multifunctional Applications. Adv. Funct. Mater. 2018, 28, 28. [Google Scholar] [CrossRef]

- Marchon, D.; Cement and Concrete Research. Mechanisms of Cement Hydration; Elsevier: Amsterdam, The Netherlands, 2016. [Google Scholar]

- Scrivener, K.; Snellings, R.; Lothenbach, B. A Practical Guide to Microstructural Analysis of Cementitious Materials; CRC Press: Boca Raton, FL, USA, 2018. [Google Scholar]

- Kurdowski, W. Cement and Concrete Chemistry; Springer: Heidelberg, Germany, 2014. [Google Scholar]

- Young, J.F.; Mindess, S.; Darwin, D. Concrete; Prentice Hall: Upper Saddle River, NJ, USA, 2002; ISBN 0130646326. [Google Scholar]

- Hover, K.C. The influence of water on the performance of concrete. Constr. Build. Mater. 2011, 25, 3003–3013. [Google Scholar] [CrossRef]

- Jensen, O.; Cement and Concrete Research. Water-Entrained Cement-Based Materials: I. Principles and Theoretical Background; Elsevier: Amsterdam, The Netherlands, 2001. [Google Scholar]

- Jensen, O.; Cement and Concrete Research. Water-Entrained Cement-Based Materials: II. Experimental Observations; Elsevier: Amsterdam, The Netherlands, 2002. [Google Scholar]

- Jiménez, C.; Barra, M.; Valls, S.; Aponte, D.; Vázquez, E. Durabilidad de Hormigones Con Áridos Reciclados Diseñados Con El Método de Volumen de Mortero Equivalente (EMV): Validación Bajo El Contexto Español y Adaptación a La Metodología de Bolomey; Durability of Recycled Aggregate Concrete Designed with the Equivalent Mortar Volume (EMV) Method: Validation under the Spanish Context and Its Adaptation to Bolomey Methodology. Mater. Constr. 2014, 64, 6. [Google Scholar] [CrossRef]

- Abdelgader, H.S. How to design concrete produced by a two-stage concreting method. Cem. Concr. Res. 1999, 29, 331–337. [Google Scholar] [CrossRef]

- Abdelgader, H.S.; Suleiman, R.E.; El-Baden, A.S.; Fahema, A.H.; Angelescu, N. Concrete mix proportioning using three equations method (Laboratory Study). In Proceedings of the UKIERI Concrete Congress Innovations in Concrete Construction, Jalandhar, Punjab, India, 5–8 March 2013. [Google Scholar]

- Iqbal, M.F.; Liu, Q.-F.; Azim, I.; Zhu, X.; Yang, J.; Javed, M.F.; Rauf, M. Prediction of mechanical properties of green concrete incorporating waste foundry sand based on gene expression programming. J. Hazard. Mater. 2020, 384, 121322. [Google Scholar] [CrossRef] [PubMed]

- Iqbal, M.F.; Javed, M.F.; Rauf, M.; Azim, I.; Ashraf, M.; Yang, J.; Liu, Q.-F. Sustainable utilization of foundry waste: Forecasting mechanical properties of foundry sand based concrete using multi-expression programming. Sci. Total. Environ. 2021, 146524, 146524. [Google Scholar] [CrossRef]

- Renigier-Biłozor, M.; Chmielewska, A.; Walacik, M.; Janowski, A.; Lepkova, N. Genetic algorithm application for real estate market analysis in the uncertainty conditions. Neth. J. Hous. Environ. Res. 2021, 1–42. [Google Scholar] [CrossRef]

- Liu, Q.-F.; Iqbal, M.F.; Yang, J.; Lu, X.-Y.; Zhang, P.; Rauf, M. Prediction of chloride diffusivity in concrete using artificial neural network: Modelling and performance evaluation. Constr. Build. Mater. 2021, 268, 121082. [Google Scholar] [CrossRef]

- Ziolkowski, P.; Niedostatkiewicz, M. Machine Learning Techniques in Concrete Mix Design. Materials 2019, 12, 1256. [Google Scholar] [CrossRef]

- Kurpinska, M.; Kułak, L. Predicting Performance of Lightweight Concrete with Granulated Expanded Glass and Ash Aggregate by Means of Using Artificial Neural Networks. Materials 2019, 12, 2002. [Google Scholar] [CrossRef]

- Czarnecki, S.; Sadowski, Ł.; Hoła, J. Artificial neural networks for non-destructive identification of the interlayer bonding between repair overlay and concrete substrate. Adv. Eng. Softw. 2020, 141, 102769. [Google Scholar] [CrossRef]

- Aitcin, P. The durability characteristics of high performance concrete: A review. Cem. Concr. Compos. 2003, 25, 409–420. [Google Scholar] [CrossRef]

- Al-Obaidi, S.; Bamonte, P.; Luchini, M.; Mazzantini, I.; Ferrara, L. Durability-Based Design of Structures Made with Ultra-High-Performance/Ultra-High-Durability Concrete in Extremely Aggressive Scenarios: Application to a Geothermal Water Basin Case Study. Infrastructures 2020, 5, 102. [Google Scholar] [CrossRef]

- Cheng, Y.; Zhang, Y.; Tan, G.; Jiao, Y. Effect of Crack on Durability of RC Material under the Chloride Aggressive Environment. Sustainability 2018, 10, 430. [Google Scholar] [CrossRef]

- Kępniak, M.; Woyciechowski, P.; Łukowski, P.; Kuziak, J.; Kobyłka, R. The Durability of Concrete Modified by Waste Limestone Powder in the Chemically Aggressive Environment. Materials 2019, 12, 1693. [Google Scholar] [CrossRef] [PubMed]

- Ambroziak, A.; Ziolkowski, P. Concrete Compressive Strength Under Changing Environmental Conditions During Placement Processes. Materials 2020, 13, 4577. [Google Scholar] [CrossRef]

- Abdelgader, H.S.; Saud, A.F.; Othman, A.M.; Fahema, A.H.; El-Baden, A.S. Concrete Mix Design Using the Double-Coating Method. Plant Precast. Technol. 2014, 80, 66–74. [Google Scholar]

- Rajamane, N.P.; Ambily, P.S.; Nataraja, M.C.; Das, L. Discussion: Modified Bolomey equation for strength of lightweight concretes containing fly ash aggregates. Mag. Concr. Res. 2014, 66, 1286–1288. [Google Scholar] [CrossRef]

- Zhang, X.-B.; Deng, S.-C.; Deng, X.-H.; Qin, Y.-H. Experimental research on regression coefficients in recycled concrete Bolomey formula. J. Central South Univ. Technol. 2007, 14, 314–317. [Google Scholar] [CrossRef]

- Gołaszewski, J.; Kostrzanowska-Siedlarz, A.; Cygan, G.; Drewniok, M. Mortar as a model to predict self-compacting concrete rheological properties as a function of time and temperature. Constr. Build. Mater. 2016, 124, 1100–1108. [Google Scholar] [CrossRef]

- Abdelgader, H.S.; El-Baden, A.S.; Shilstone, J.M. Bolomeya model for normal concrete mix design. J. Concr. Plant Int. 2012, 2, 68–74. [Google Scholar]

- Kaplan, G.; Yaprak, H.; Memiş, S.; Alnkaa, A. Artificial Neural Network Estimation of the Effect of Varying Curing Conditions and Cement Type on Hardened Concrete Properties. Buildings 2019, 9, 10. [Google Scholar] [CrossRef]

- Tang, C.-W.; Cheng, C.-K.; Tsai, C.-Y. Mix Design and Mechanical Properties of High-Performance Pervious Concrete. Materials 2019, 12, 2577. [Google Scholar] [CrossRef] [PubMed]

- Yeh, I.-C. Modeling of strength of high-performance concrete using artificial neural networks. Cem. Concr. Res. 1998, 28, 1797–1808. [Google Scholar] [CrossRef]

- Lee, S.-C. Prediction of concrete strength using artificial neural networks. Eng. Struct. 2003, 25, 849–857. [Google Scholar] [CrossRef]

- Hoła, J.; Schabowicz, K. New technique of nondestructive assessment of concrete strength using artificial intelligence. NDT E Int. 2005, 38, 251–259. [Google Scholar] [CrossRef]

- Hoła, J.; Schabowicz, K.; Hoùa, J. Application of Artificial Neural Networks to Determine Concrete Compressive Strength Based on Non-Destructive Tests. J. Civ. Eng. Manag. 2005, 6, 23–32. [Google Scholar] [CrossRef]

- Gupta, R.; Kewalramani, M.A.; Goel, A. Prediction of Concrete Strength Using Neural-Expert System. J. Mater. Civ. Eng. 2006, 18, 462–466. [Google Scholar] [CrossRef]

- Bui, D.-K.; Nguyen, T.; Chou, J.-S.; Nguyen-Xuan, H.; Ngo, T.D. A modified firefly algorithm-artificial neural network expert system for predicting compressive and tensile strength of high-performance concrete. Constr. Build. Mater. 2018, 180, 320–333. [Google Scholar] [CrossRef]

- Deng, F.; He, Y.; Zhou, S.; Yu, Y.; Cheng, H.; Wu, X. Compressive strength prediction of recycled concrete based on deep learning. Constr. Build. Mater. 2018, 175, 562–569. [Google Scholar] [CrossRef]

- Naderpour, H.; Rafiean, A.H.; Fakharian, P. Compressive strength prediction of environmentally friendly concrete using artificial neural networks. J. Build. Eng. 2018, 16, 213–219. [Google Scholar] [CrossRef]

- McCormac, J.; Brown, R. Design of Reinforced Concrete; John Wiley & Sons Inc.: Hoboken, NJ, USA, 2015. [Google Scholar]

- Adil, M.; Ullah, R.; Noor, S.; Gohar, N. Effect of number of neurons and layers in an artificial neural network for generalized concrete mix design. Neural Comput. Appl. 2020, 1–9. [Google Scholar] [CrossRef]

- Nunez, I.; Marani, A.; Nehdi, M.L. Mixture Optimization of Recycled Aggregate Concrete Using Hybrid Machine Learning Model. Materials 2020, 13, 4331. [Google Scholar] [CrossRef] [PubMed]

- Marani, A.; Jamali, A.; Nehdi, M.L. Predicting Ultra-High-Performance Concrete Compressive Strength Using Tabular Generative Adversarial Networks. Materials 2020, 13, 4757. [Google Scholar] [CrossRef]

- Toniolo, G.; Prisco, M. Reinforced Concrete Design to Eurocode 2; Springer: Heidelberg, Germany, 2017. [Google Scholar]

- Andrei, N. An adaptive scaled BFGS method for unconstrained optimization. Numer. Algorithms 2018, 77, 413–432. [Google Scholar] [CrossRef]

- Battiti, R.; Masulli, F. BFGS Optimisation for Faster and Automated Supervised Learning. In International Neural Network Conference; Springer: Dordrecht, The Netherlands, 1990; pp. 757–760. [Google Scholar]

- Berahas, A.S.; Takáč, M. A robust multi-batch L-BFGS method for machine learning. Optim. Methods Softw. 2019, 35, 191–219. [Google Scholar] [CrossRef]

- Hagan, M.; Menhaj, M. Training feedforward networks with the Marquardt algorithm. IEEE Trans. Neural Netw. 1994, 5, 989–993. [Google Scholar] [CrossRef] [PubMed]

- Li, D.-H.; Fukushima, M. A modified BFGS method and its global convergence in nonconvex minimization. J. Comput. Appl. Math. 2001, 129, 15–35. [Google Scholar] [CrossRef]

- Abdi, F.; Shakeri, F. A globally convergent BFGS method for pseudo-monotone variational inequality problems. Optim. Methods Softw. 2017, 34, 25–36. [Google Scholar] [CrossRef]

- Grabowska, K.; Szczuko, P. Ship Resistance Prediction with Artificial Neural Networks. In Proceedings of the IEEE 2015 Signal Processing: Algorithms, Architectures, Arrangements, and Applications (SPA), Poznan, Poland, 23–25 September 2015. [Google Scholar]

- Le, D.; Huang, W.; Johnson, E. Neural network modeling of monthly salinity variations in oyster reef in Apalachicola Bay in response to freshwater inflow and winds. Neural Comput. Appl. 2019, 31, 6249–6259. [Google Scholar] [CrossRef]

- Luenberger, D.G.; Ye, Y. Linear and Nonlinear Programming; Springer: New York, NY, USA, 2008. [Google Scholar]

- Yildizel, S.A.; Arslan, Y. Flexural Strength Estimation of Basalt Fiber Reinforced Fly-Ash Added Gypsum Based Composites. J. Eng. Res. Appl. Sci. 2018, 7, 829–834. [Google Scholar]

- Sanjuán, M.A.; Argiz, C.; Menéndez, E. Efecto de la adición de mezclas de ceniza volante y ceniza de fondo procedentes del carbón en la resistencia mecánica y porosidad de cementos Portland. Mater. Construcción 2013, 63, 49–64. [Google Scholar] [CrossRef]

- Sanjuán, M.Á.; Estévez, E.; Argiz, C.; del Barrio, D. Effect of curing time on granulated blast-furnace slag cement mortars carbonation. Cem. Concr. Compos. 2018, 90, 257–265. [Google Scholar] [CrossRef]

- Poloju, K.K.; Anil, V.; Manchiryal, R.K. Properties of Concrete as Influenced by Shape and Texture of Fine Aggregate. Am. J. Appl. Sci. Res. 2017, 3, 28. [Google Scholar] [CrossRef]

- Chinchillas-Chinchillas, M.J.; Corral-Higuera, R.; Gómez-Soberón, J.M.; Arredondo-Rea, S.P.; Alamaral-Sánchez, J.L.; Acuña-Aguero, O.H.; Rosas-Casarez, C.A. Influence of the Shape of the Natural Aggregates, Recycled and Silica Fume on the Mechanical Properties of Pervious Concrete. Int. J. Adv. Comput. Sci. Appl. 2014, 4, 216–220. [Google Scholar]

- Jo, H.-S.; Park, C.; Lee, E.; Choi, H.K.; Park, J. Path Loss Prediction Based on Machine Learning Techniques: Principal Component Analysis, Artificial Neural Network, and Gaussian Process. Sensors 2020, 20, 1927. [Google Scholar] [CrossRef]

- Choi, Y.-Y.; Shon, H.; Byon, Y.-J.; Kim, D.-K.; Kang, S. Enhanced Application of Principal Component Analysis in Machine Learning for Imputation of Missing Traffic Data. Appl. Sci. 2019, 9, 2149. [Google Scholar] [CrossRef]

- Gadekallu, T.R.; Khare, N.; Bhattacharya, S.; Singh, S.; Maddikunta, P.K.R.; Ra, I.-H.; Alazab, M. Early Detection of Diabetic Retinopathy Using PCA-Firefly Based Deep Learning Model. Electronics 2020, 9, 274. [Google Scholar] [CrossRef]

- Abdi, H.; Williams, L.J. Principal Component Analysis. Wiley Interdiscip. Rev. Comput. Stat. 2010, 2, 433–459. [Google Scholar] [CrossRef]

- Song, F.; Guo, Z.; Mei, D. Feature Selection Using Principal Component Analysis. In 2010 International Conference on System Science, Engineering Design and Manufacturing Informatization, Proceedings of the 2010 International Conference on System Science, Engineering Design and Manufacturing, Yichang, China, 18 November 2010; Institute of Electrical and Electronics Engineers (IEEE): New York, NY, USA, 2010; Volume 1, pp. 27–30. [Google Scholar]

- Tabakhi, S.; Moradi, P.; Akhlaghian, F. An unsupervised feature selection algorithm based on ant colony optimization. Eng. Appl. Artif. Intell. 2014, 32, 112–123. [Google Scholar] [CrossRef]

- Song, Y.; Liang, J.; Lu, J.; Zhao, X. An efficient instance selection algorithm for k nearest neighbor regression. Neurocomputing 2017, 251, 26–34. [Google Scholar] [CrossRef]

- Yu, H.; Reiner, P.D.; Xie, T.; Bartczak, T.; Wilamowski, B.M. An Incremental Design of Radial Basis Function Networks. IEEE Trans. Neural Netw. Learn. Syst. 2014, 25, 1793–1803. [Google Scholar] [CrossRef] [PubMed]

- Iqbal, S.Z.; Gull, H.; Ahmed, J. Incremental Sorting Algorithm. In 2009 Second International Conference on Computer and Electrical Engineering, Proceedings of the 2009 Second International Conference on Computer and Electrical Engineering, Dubai, United Arab Emirates, 15 January 2010; Institute of Electrical and Electronics Engineers (IEEE): New York, NY, USA, 2009; Volume 2, pp. 378–381. [Google Scholar]

- Gürbüzbalaban, M.; Ozdaglar, A.; Parrilo, P.A. On the Convergence Rate of Incremental Aggregated Gradient Algorithms. SIAM J. Optim. 2017, 27, 1035–1048. [Google Scholar] [CrossRef]

- Shobha, G.; Rangaswamy, S. Machine Learning. In Handbook of Statistics; Elsevier B.V.: Amsterdam, The Netherlands, 2018; Volume 38, pp. 197–228. ISBN 9780444640420. [Google Scholar]

| Parameter | Compressive Strength after 28 days | Cement | Water | Sand 0–2 mm | Aggregate above 2 mm | Water–Cement Ratio |

|---|---|---|---|---|---|---|

| Codename | cs_28 | cement | water | fine_grained_aggregate | coarse_aggregate | water_cement_ratio |

| Type | Target | Input | Input | Input | Input | Input |

| Description | The 28 day compressive strength of concrete that is considered to have most of its strength. | Content of cement added to the mixture, expressed in kg. | Content of water added to the mixture, expressed in L. | Content of fine-grained aggregate added to the mixture, expressed in kg. | Content of coarse-grained aggregate with a size more than 2 mm, added to the mixture, expressed in kg. | Water-to-cement ratio. |

| Input Variable | Minimum | Maximum | Mean | Median | Dominant |

|---|---|---|---|---|---|

| Cement | 86.00 kg/m3 | 540.00 kg/m3 | 278.00 kg/m3 | 275.00 kg/m3 | 425.00 kg/m3 |

| Water | 121.80 kg/m3 | 247.00 kg/m3 | 182.42 kg/m3 | 185.00 kg/m3 | 192.00 kg/m3 |

| Fine-grained aggregate (sand 0–2 mm) | 372.00 kg/m3 | 1329.00 kg/m3 | 768.55 kg/m3 | 777.80 kg/m3 | 594.00 kg/m3 |

| Coarse aggregate (aggregate above 2 mm) | 597.00 kg/m3 | 1490.00 kg/m3 | 969.08 kg/m3 | 967.00 kg/m3 | 932.00 kg/m3 |

| Water–cement ratio | 0.27 | 1.88 | 0.76 | 0.69 | 0.45 |

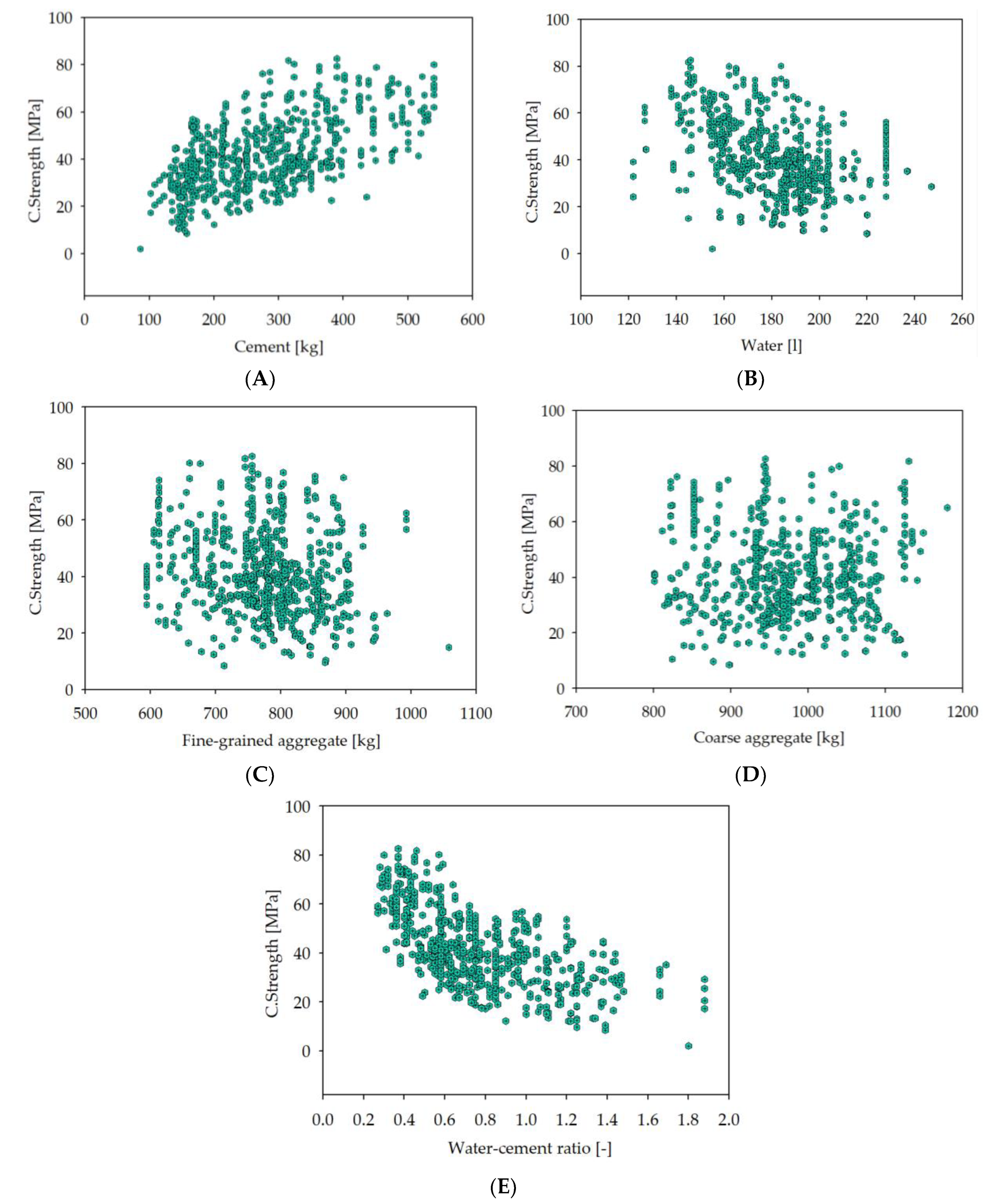

| Designed Concrete Compressive Strength | Cement (kg/m3) | Water (L/m3) | Natural Sand (kg/m3) | Limestone Gravel 4/10 (kg/m3) | Limestone Gravel 10/20 (kg/m3) | Water–Cement Ratio (-) |

|---|---|---|---|---|---|---|

| Recipe #1—standard mix + plasticizer (lignosulfonate) + superplasticizer (polycarboxylate ether) | ||||||

| 10 | 177.09 | 57.56 | 1106.54 | 525.32 | 681.00 | 0.325 |

| 15 | 204.57 | 66.49 | 1059.83 | 531.08 | 674.29 | 0.325 |

| 20 | 232.05 | 75.42 | 1014.45 | 535.33 | 667.74 | 0.325 |

| 25 | 259.53 | 84.35 | 968.28 | 540.54 | 661.04 | 0.325 |

| 30 | 287.01 | 88.17 | 930.22 | 547.64 | 658.12 | 0.307 |

| 35 | 314.49 | 91.12 | 892.82 | 555.61 | 656.02 | 0.290 |

| 40 | 341.97 | 94.16 | 855.60 | 563.45 | 653.64 | 0.275 |

| 45 | 369.45 | 97.26 | 818.51 | 570.86 | 651.40 | 0.263 |

| 50 | 396.93 | 100.41 | 781.08 | 578.63 | 649.00 | 0.253 |

| Recipe #2—standard mix + plasticizer (lignosulfonate) + superplasticizer (polycarboxylate ether) + air entrainer (tensides) | ||||||

| 10 | 178.26 | 57.93 | 1105.90 | 527.60 | 677.03 | 0.325 |

| 15 | 205.58 | 66.81 | 1060.69 | 532.11 | 670.39 | 0.325 |

| 20 | 233.33 | 75.83 | 1015.00 | 536.35 | 663.75 | 0.325 |

| 25 | 261.47 | 84.98 | 968.79 | 540.62 | 656.93 | 0.325 |

| 30 | 288.63 | 88.67 | 929.92 | 549.20 | 654.18 | 0.307 |

| 35 | 315.36 | 91.38 | 894.37 | 556.25 | 652.29 | 0.290 |

| 40 | 343.21 | 94.50 | 856.65 | 564.08 | 649.89 | 0.275 |

| 45 | 371.42 | 97.78 | 817.79 | 572.16 | 647.64 | 0.263 |

| 50 | 399.12 | 100.97 | 780.12 | 580.04 | 645.11 | 0.253 |

| Recipe #3—standard mix + superplasticizer (polycarboxylate ether) + retarder (phosphate) + air entrainer (tensides) | ||||||

| 10 | 176.46 | 57.35 | 1107.69 | 526.38 | 677.27 | 0.325 |

| 15 | 203.84 | 66.25 | 1062.94 | 530.80 | 670.17 | 0.325 |

| 20 | 231.22 | 75.15 | 1016.61 | 536.10 | 663.75 | 0.325 |

| 25 | 258.60 | 84.05 | 971.48 | 540.13 | 657.40 | 0.325 |

| 30 | 285.99 | 87.86 | 932.98 | 548.07 | 654.22 | 0.307 |

| 35 | 313.37 | 90.80 | 896.19 | 555.60 | 652.09 | 0.290 |

| 40 | 340.75 | 93.82 | 859.54 | 562.61 | 650.09 | 0.275 |

| 45 | 368.13 | 96.92 | 821.81 | 571.15 | 647.48 | 0.263 |

| 50 | 395.51 | 100.05 | 784.51 | 578.91 | 645.11 | 0.253 |

| Recipe #4—standard mix + plasticizer (lignosulfonate) + superplasticizer (naphthalene) | ||||||

| 10 | 179.00 | 58.17 | 998.39 | 369.05 | 947.31 | 0.325 |

| 15 | 206.77 | 67.20 | 1058.77 | 532.40 | 675.41 | 0.325 |

| 20 | 234.55 | 76.23 | 1012.64 | 537.16 | 668.59 | 0.325 |

| 25 | 262.32 | 85.26 | 966.36 | 542.02 | 661.83 | 0.325 |

| 30 | 290.10 | 89.12 | 925.90 | 547.94 | 652.76 | 0.307 |

| 35 | 317.88 | 92.10 | 890.13 | 553.89 | 650.72 | 0.290 |

| 40 | 345.65 | 95.17 | 850.22 | 564.03 | 648.42 | 0.275 |

| 45 | 373.43 | 98.31 | 812.49 | 571.92 | 646.00 | 0.263 |

| 50 | 401.20 | 101.49 | 774.79 | 579.60 | 643.63 | 0.253 |

| Designed CC of Concrete Mix | Cement (kg/m3) | Water (L/m3) | Natural Sand (kg/m3) | Limestone Gravel 4/10 (kg/m3) | Limestone Gravel 10/20 (kg/m3) | Water–Cement Ratio (-) |

|---|---|---|---|---|---|---|

| Recipe #1—standard mix + plasticizer (lignosulfonate) + superplasticizer (polycarboxylate ether) | ||||||

| 10 | 177.09 | 57.56 | 1056.81 | 566.37 | 702.13 | 0.325 |

| 15 | 204.57 | 66.49 | 1035.14 | 554.76 | 687.74 | 0.325 |

| 20 | 232.05 | 75.42 | 1013.48 | 543.14 | 673.34 | 0.325 |

| 25 | 259.53 | 84.35 | 991.81 | 531.54 | 658.95 | 0.325 |

| 30 | 287.01 | 88.17 | 976.42 | 523.29 | 648.72 | 0.307 |

| 35 | 314.49 | 91.12 | 962.09 | 515.61 | 639.20 | 0.290 |

| 40 | 341.97 | 94.16 | 947.66 | 507.87 | 629.61 | 0.275 |

| 45 | 369.45 | 97.26 | 933.15 | 500.10 | 619.97 | 0.263 |

| 50 | 396.93 | 100.41 | 918.57 | 492.29 | 610.29 | 0.253 |

| Recipe #2—standard mix + plasticizer (lignosulfonate) + superplasticizer (polycarboxylate ether) + air entrainer (tensides) | ||||||

| 10 | 178.26 | 57.93 | 1055.89 | 565.88 | 696.32 | 0.325 |

| 15 | 205.58 | 66.81 | 1034.35 | 554.33 | 682.12 | 0.325 |

| 20 | 233.33 | 75.83 | 1012.47 | 542.61 | 667.69 | 0.325 |

| 25 | 261.47 | 84.98 | 990.29 | 530.72 | 653.06 | 0.325 |

| 30 | 288.63 | 88.67 | 975.18 | 522.62 | 643.10 | 0.307 |

| 35 | 315.36 | 91.38 | 961.44 | 515.26 | 634.04 | 0.290 |

| 40 | 343.21 | 94.50 | 946.76 | 507.39 | 624.36 | 0.275 |

| 45 | 371.42 | 97.78 | 931.75 | 499.34 | 614.45 | 0.263 |

| 50 | 399.12 | 100.97 | 917.04 | 491.47 | 604.76 | 0.253 |

| Recipe #3—standard mix + superplasticizer (polycarboxylate ether) + retarder (phosphate) + air entrainer (tensides) | ||||||

| 10 | 176.46 | 57.35 | 1057.31 | 566.64 | 697.26 | 0.325 |

| 15 | 203.84 | 66.25 | 1035.72 | 555.07 | 683.02 | 0.325 |

| 20 | 231.22 | 75.15 | 1014.13 | 543.50 | 668.79 | 0.325 |

| 25 | 258.60 | 84.05 | 992.55 | 531.93 | 654.55 | 0.325 |

| 30 | 285.99 | 87.86 | 977.20 | 523.71 | 644.44 | 0.307 |

| 35 | 313.37 | 90.80 | 962.93 | 516.06 | 635.02 | 0.290 |

| 40 | 340.75 | 93.82 | 948.55 | 508.35 | 625.54 | 0.275 |

| 45 | 368.13 | 96.92 | 934.09 | 500.60 | 616.00 | 0.263 |

| 50 | 395.51 | 100.05 | 919.57 | 492.82 | 606.43 | 0.253 |

| Recipe #4—standard mix + plasticizer (lignosulfonate) + superplasticizer (naphthalene) | ||||||

| 10 | 179.00 | 58.17 | 1055.30 | 565.56 | 701.13 | 0.325 |

| 15 | 206.77 | 67.20 | 1033.41 | 553.83 | 686.59 | 0.325 |

| 20 | 234.55 | 76.23 | 1011.51 | 542.09 | 672.04 | 0.325 |

| 25 | 262.32 | 85.26 | 989.61 | 530.36 | 657.49 | 0.325 |

| 30 | 290.10 | 89.12 | 974.05 | 522.20 | 642.36 | 0.307 |

| 35 | 317.88 | 92.10 | 959.57 | 514.25 | 632.80 | 0.290 |

| 40 | 345.65 | 95.17 | 944.98 | 506.44 | 623.18 | 0.275 |

| 45 | 373.43 | 98.31 | 930.32 | 498.58 | 613.51 | 0.263 |

| 50 | 401.20 | 101.49 | 915.59 | 490.68 | 603.80 | 0.253 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ziolkowski, P.; Niedostatkiewicz, M.; Kang, S.-B. Model-Based Adaptive Machine Learning Approach in Concrete Mix Design. Materials 2021, 14, 1661. https://doi.org/10.3390/ma14071661

Ziolkowski P, Niedostatkiewicz M, Kang S-B. Model-Based Adaptive Machine Learning Approach in Concrete Mix Design. Materials. 2021; 14(7):1661. https://doi.org/10.3390/ma14071661

Chicago/Turabian StyleZiolkowski, Patryk, Maciej Niedostatkiewicz, and Shao-Bo Kang. 2021. "Model-Based Adaptive Machine Learning Approach in Concrete Mix Design" Materials 14, no. 7: 1661. https://doi.org/10.3390/ma14071661

APA StyleZiolkowski, P., Niedostatkiewicz, M., & Kang, S.-B. (2021). Model-Based Adaptive Machine Learning Approach in Concrete Mix Design. Materials, 14(7), 1661. https://doi.org/10.3390/ma14071661