Straining Behavior of Mortar Reinforced by Cold Drawn Crimped and Dog-Bone-Shaped Fibers under Monotonic and Cyclic Compressions

Abstract

:1. Introduction

2. Experimental Program

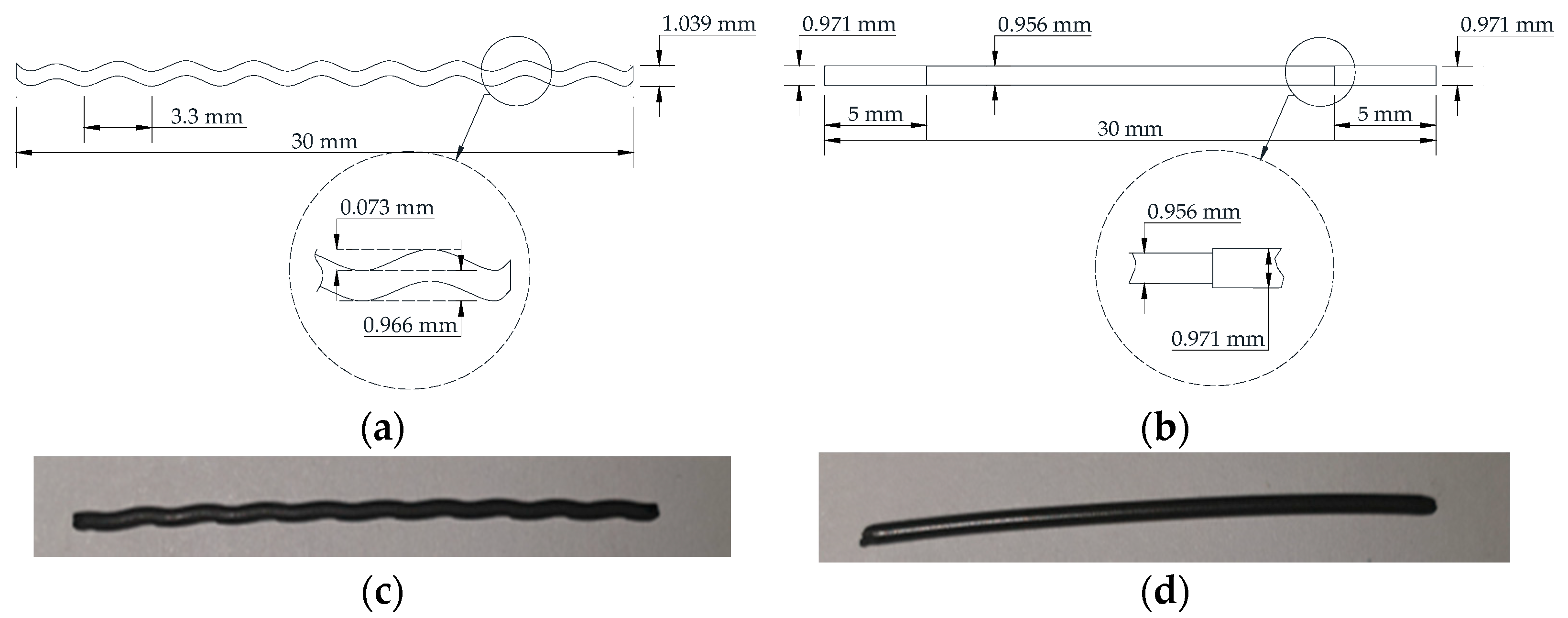

2.1. Material

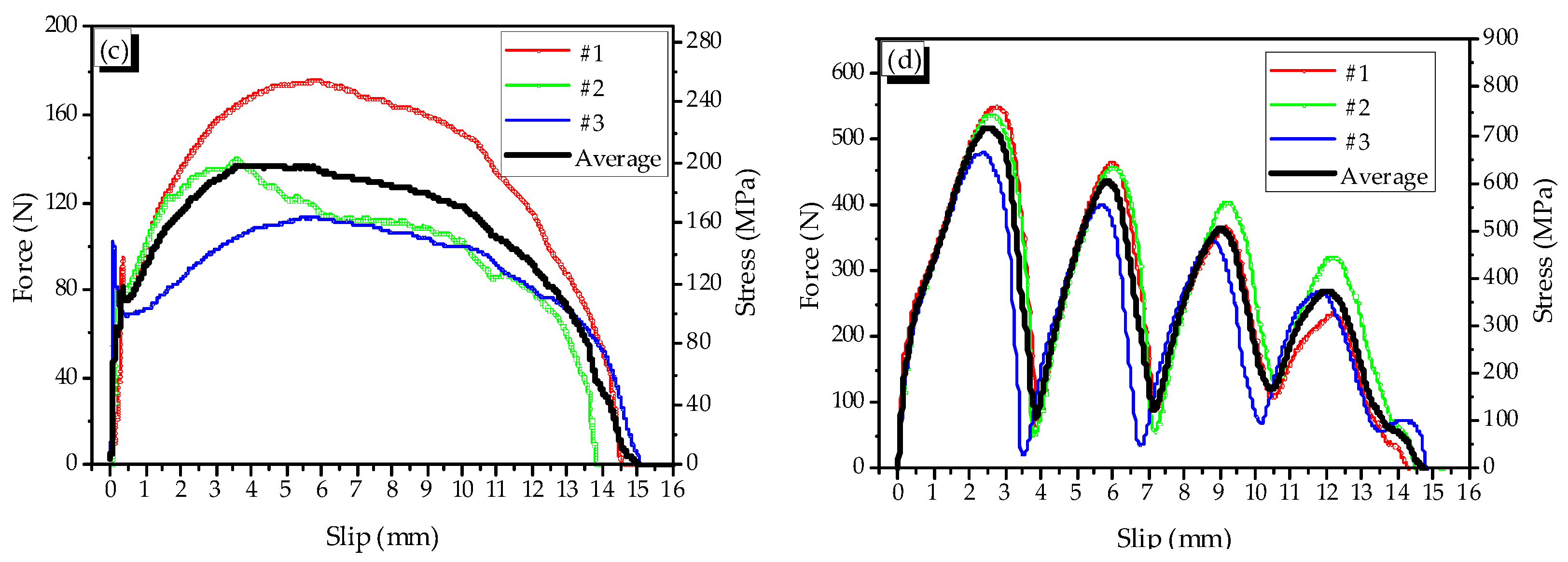

2.2. Instruments and Test Set-Up

3. Strain Behavior under Monotonic Compression

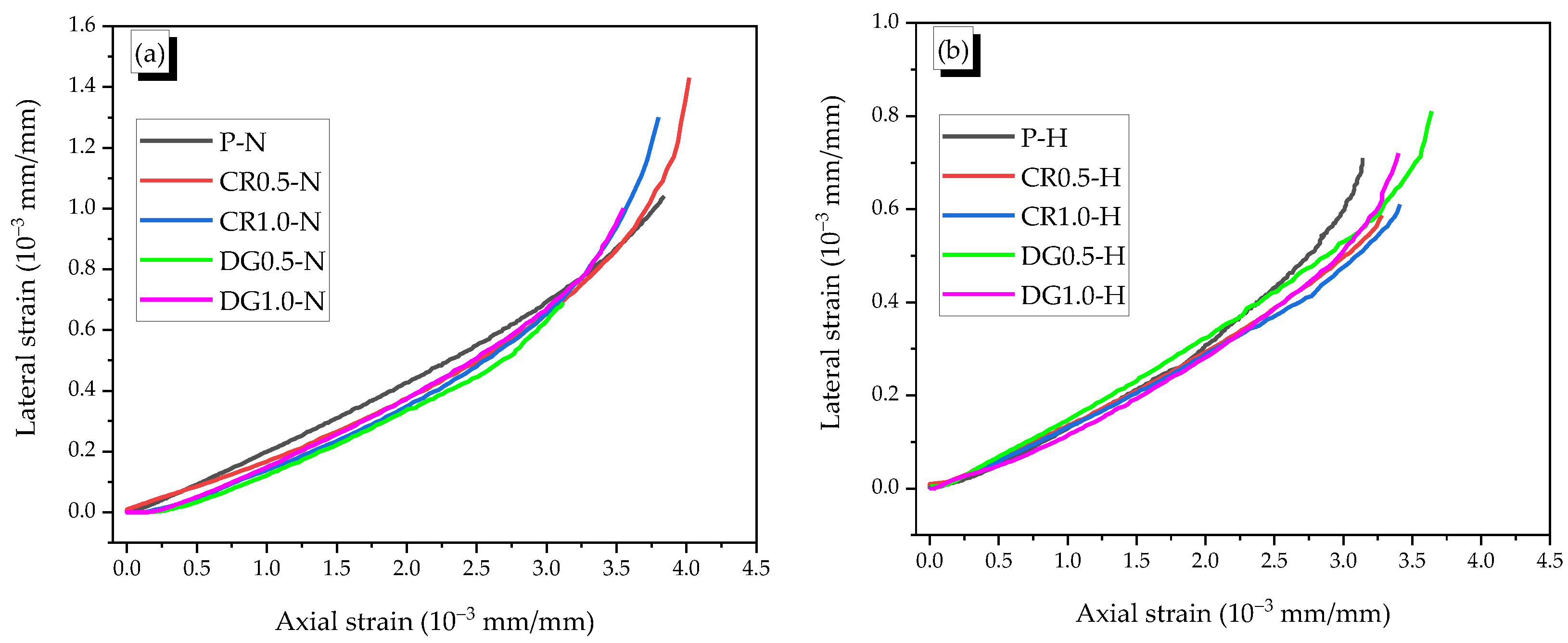

3.1. Axial–Lateral Strain Behavior

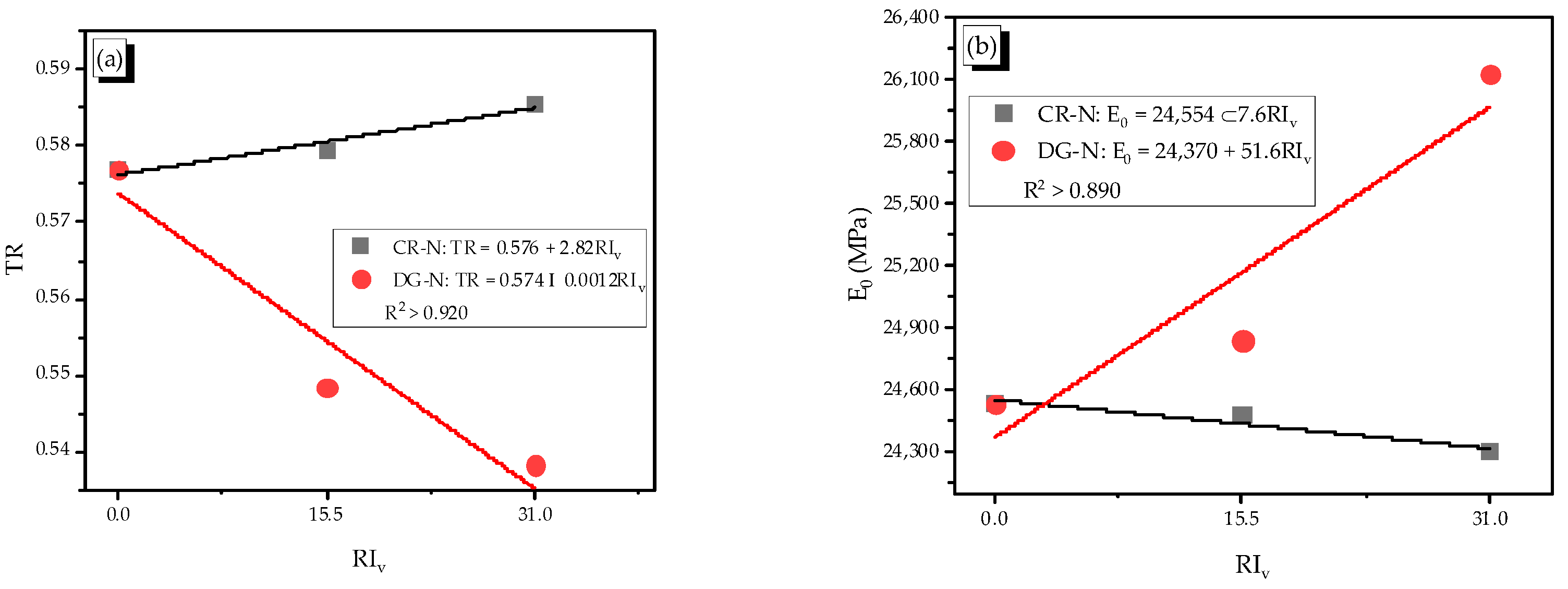

3.2. Axial Stress–Strain Behavior

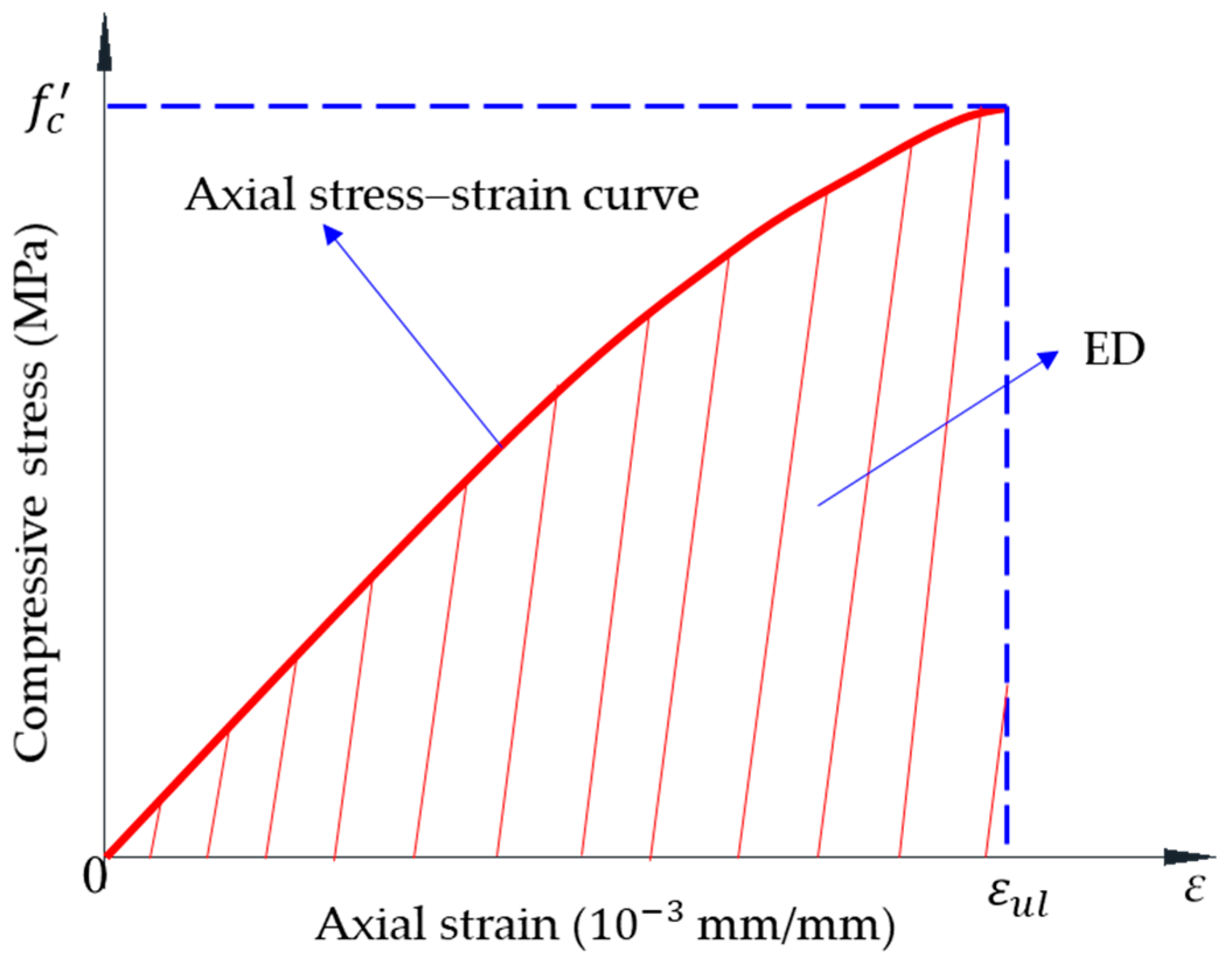

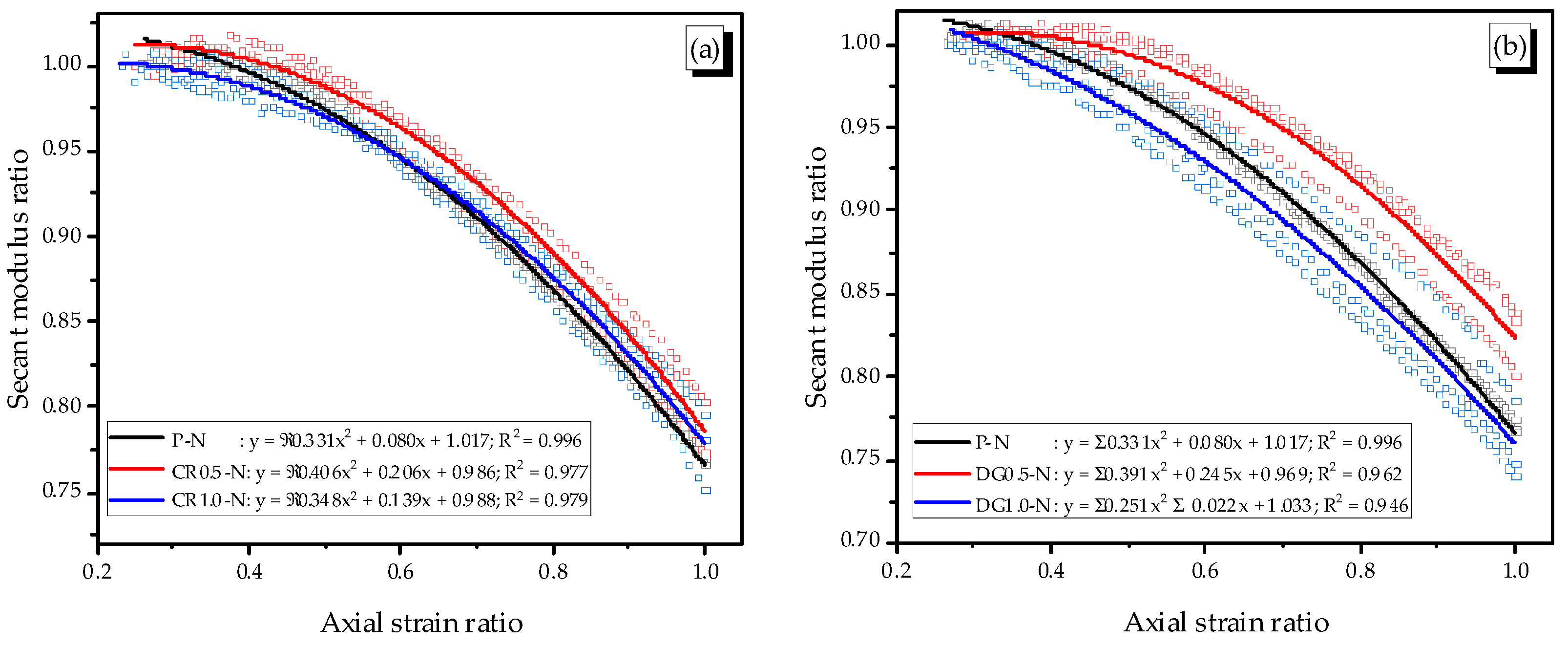

3.3. Damage Evolution

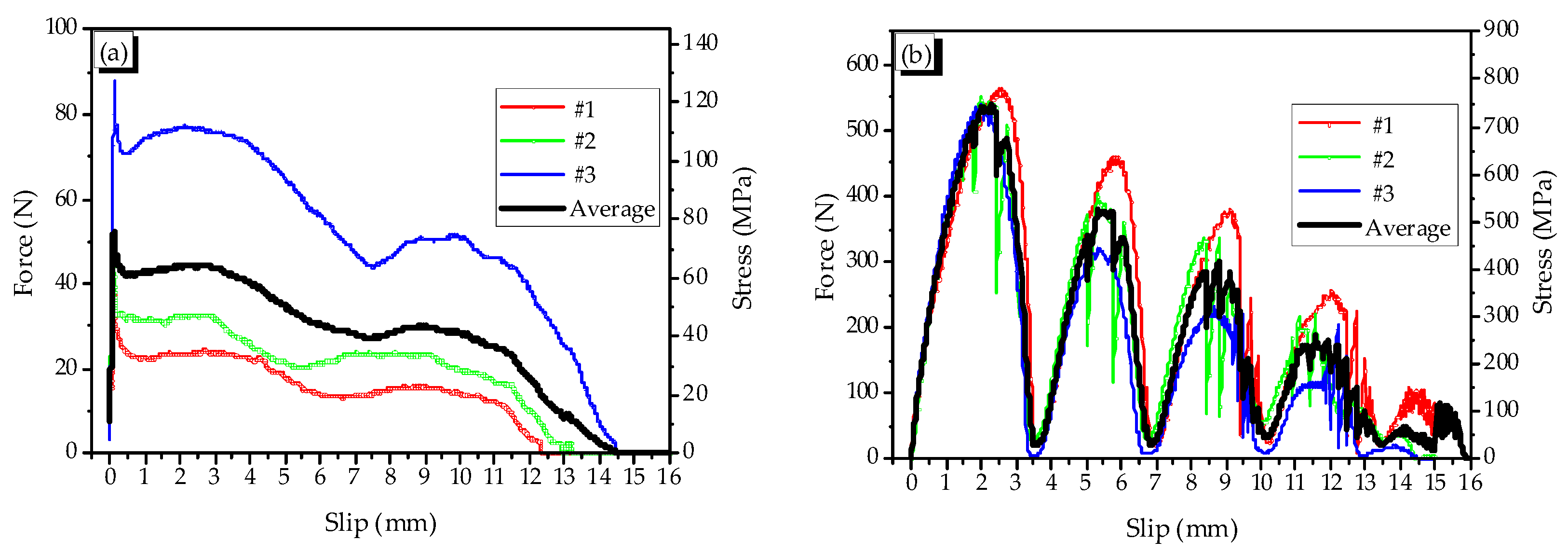

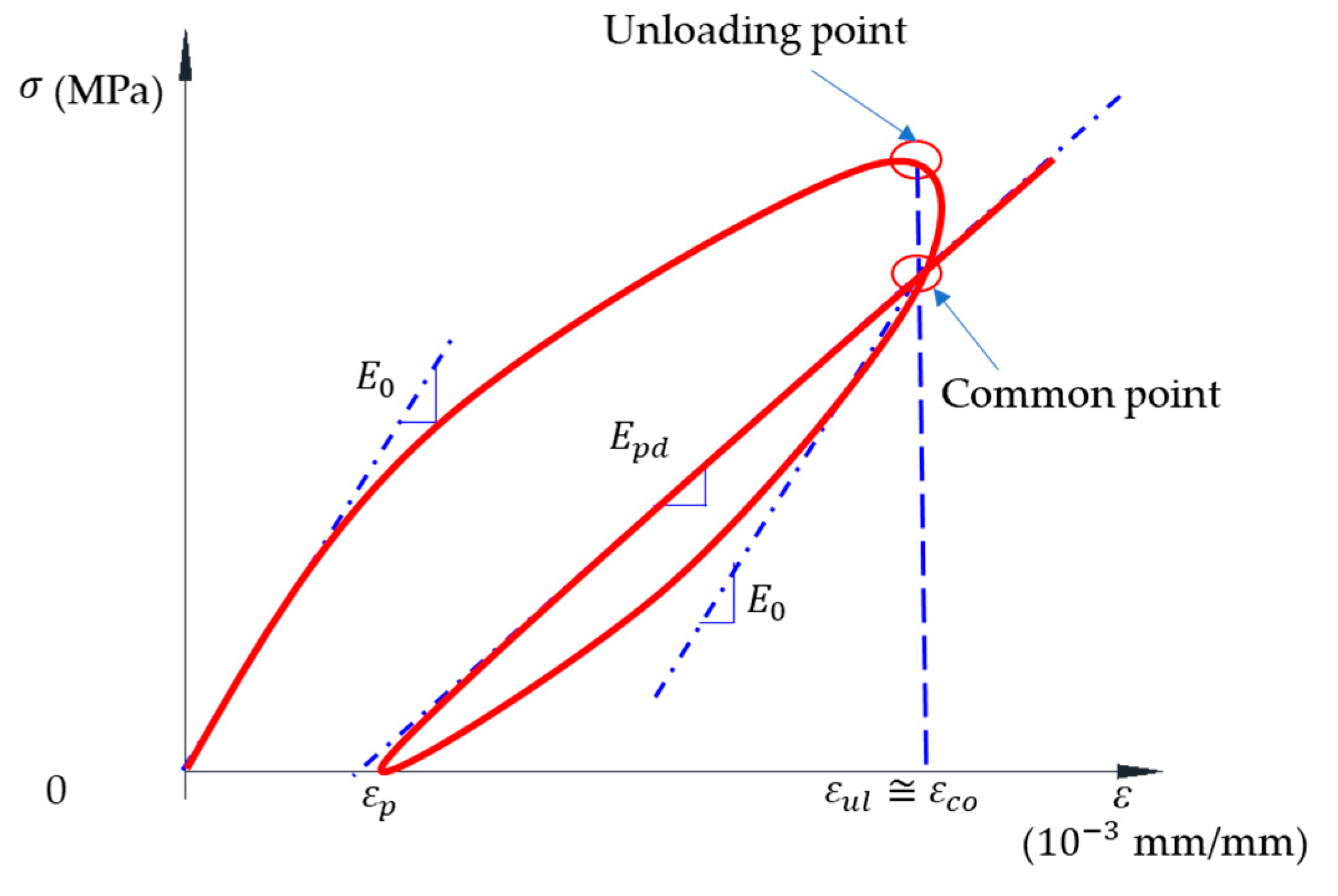

4. Strain Behavior under Cyclic Compression

4.1. Axial–Lateral Strain Behavior

4.2. Axial Stress–Strain Behavior

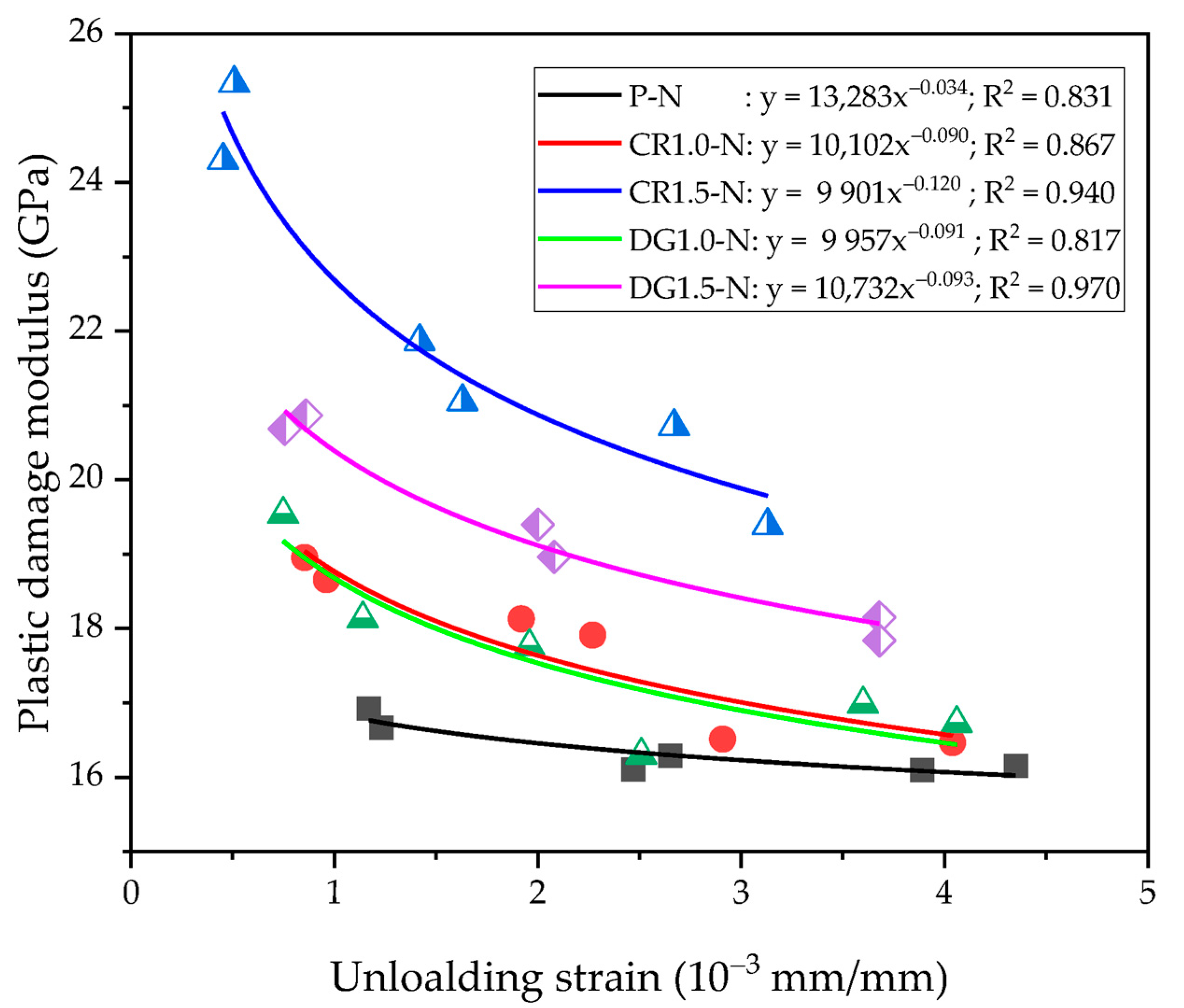

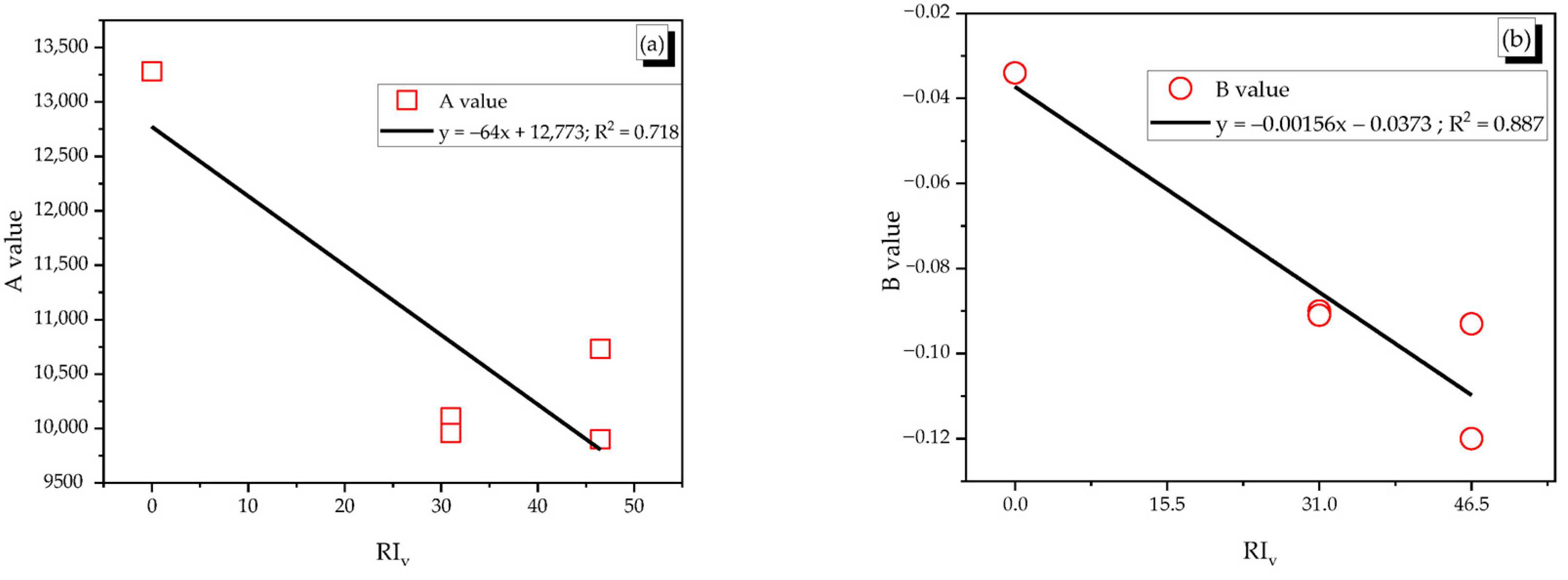

4.3. Damage Law

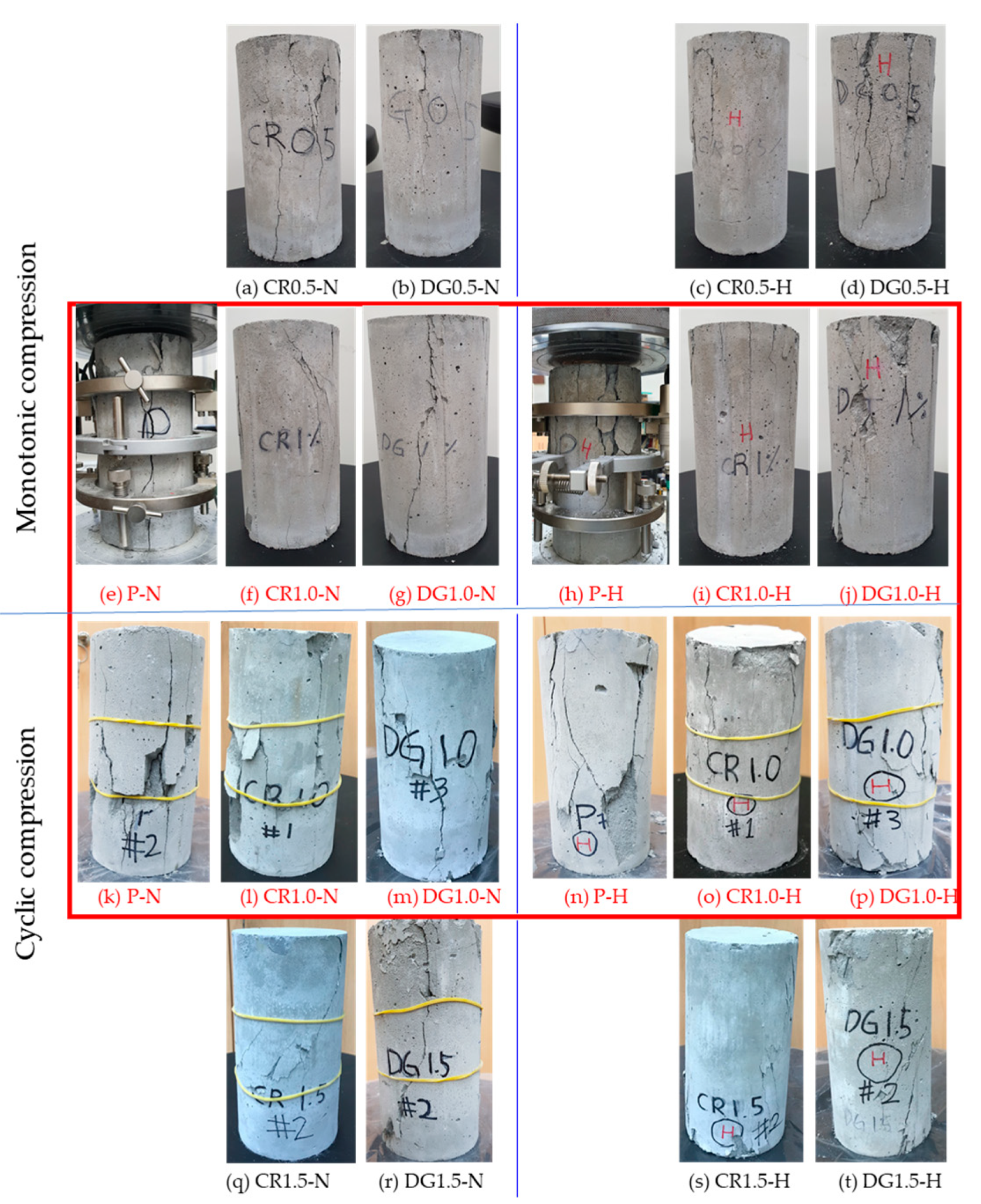

5. Comparison Failure Mode of Specimens under Monotonic and Cyclic Compressions

6. Conclusions

- The SMA fibers with a high tensile strength and anchoring bond helped to reduce the Poisson’s ratio of specimen. The crimped fiber was more effective than the dog-bone-shaped fiber due to the higher composite capacity. However, after cracking, the dog-bone-shaped fiber had a higher controlling strain due to the high anchoring bond while crimped fiber was uninfluenced due to the stretching effect.

- For heating, the fibers did not influence much on straining behavior in the elastic phase. In the plastic phase, the dog-bone-shaped fiber slips larger than the crimped fiber; thus, crimped fiber had a higher effect on reducing strain in post-cracking.

- The straining behavior was different with different load types. For the cyclic test, the non-heated SMA fibers reduced the axial recovery deformation significantly in the unloading process; thus, the axial strain of reinforced specimens was less than that of the plain specimen.

- The SMA fibers were effective increasing the elastic modulus of the composite mortar when adding into the lower elastic modulus matrix; however, they did not influence much in the higher elastic modulus matrix or even had a negative effect due to the porosity.

- The speed of damage in the monotonic test was slow when adding a 0.5% volume fraction of SMA fibers; however, the higher fiber content did not have any effect. For the cyclic test, the damage law was presented by an equation, which depended on the fiber content, length, and thickness of SMA fibers.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Singh, H. Steel Fiber Reinforced Concrete: Behavior, Modelling and Design; Springer: Berlin/Heidelberg, Germany, 2016. [Google Scholar]

- Zheng, Z.; Feldman, D. Synthetic fibre-reinforced concrete. Prog. Polym. Sci. 1995, 20, 185–210. [Google Scholar] [CrossRef]

- Poon, C.-K.; Zhou, L.-M.; Jin, W.; Shi, S.-Q. Interfacial debond of shape memory alloy composites. Smart Mater. Struct. 2005, 14, N29–N37. [Google Scholar] [CrossRef]

- Kim, D.J.; Kim, H.A.; Chung, Y.-S.; Choi, E. Pullout resistance of deformed shape memory alloy fibers embedded in cement mortar. J. Intell. Mater. Syst. Struct. 2014, 27, 249–260. [Google Scholar] [CrossRef]

- Choi, E.; Kim, D.; Chung, Y.-S.; Nam, T.-H. Bond–slip characteristics of SMA reinforcing fibers obtained by pull-out tests. Mater. Res. Bull. 2014, 58, 28–31. [Google Scholar] [CrossRef]

- Kim, M.K.; Kim, D.J.; Chung, Y.-S.; Choi, E. Direct tensile behavior of shape-memory-alloy fiber-reinforced cement composites. Constr. Build. Mater. 2016, 102, 462–470. [Google Scholar] [CrossRef]

- Farmani, M.A.; Ghassemieh, M. Shape memory alloy-based moment connections with superior self-centering properties. Smart Mater. Struct. 2016, 25, 075028. [Google Scholar] [CrossRef]

- Kim, M.K.; Kim, D.J.; Chung, Y.-S.; Choi, E. Effects of a Short Heat Treatment Period on the Pullout Resistance of Shape Memory Alloy Fibers in Mortar. Materials 2019, 12, 2278. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Choi, E.; Mohammadzadeh, B.; Hwang, J.-H.; Kim, W.J. Pullout behavior of superelastic SMA fibers with various end-shapes embedded in cement mortar. Constr. Build. Mater. 2018, 167, 605–616. [Google Scholar] [CrossRef]

- Choi, E.; Kim, H.S.; Nam, T.-H. Effect of crimped SMA fiber geometry on recovery stress and pullout resistance. Compos. Struct. 2020, 247, 112466. [Google Scholar] [CrossRef]

- Choi, E.; Ho, H.V.; Jeon, J.-S. Active Reinforcing Fiber of Cementitious Materials Using Crimped NiTi SMA Fiber for Crack-Bridging and Pullout Resistance. Materials 2020, 13, 3845. [Google Scholar] [CrossRef]

- Choi, E.; Ostadrahimi, A.; Park, J. On mechanical properties of NiTi SMA wires prestrained by cold rolling. Smart Mater. Struct. 2020, 29, 065009. [Google Scholar] [CrossRef]

- Choi, E.; Kim, D.J.; Chung, Y.-S.; Kim, H.S.; Jung, C. Crack-closing of cement mortar beams using NiTi cold-drawn SMA short fibers. Smart Mater. Struct. 2014, 24, 015018. [Google Scholar] [CrossRef]

- Lee, K.-J.; Lee, J.-H.; Jung, C.-Y.; Choi, E. Crack-closing performance of NiTi and NiTiNb fibers in cement mortar beams using shape memory effects. Compos. Struct. 2018, 202, 710–718. [Google Scholar] [CrossRef]

- Lee, J.-H.; Lee, K.-J.; Choi, E. Flexural capacity and crack-closing performance of NiTi and NiTiNb shape-memory alloy fibers randomly distributed in mortar beams. Compos. Part B Eng. 2018, 153, 264–276. [Google Scholar] [CrossRef]

- Choi, E.; Nam, T.-H.; Cho, S.-C.; Chung, Y.-S.; Park, T. The behavior of concrete cylinders confined by shape memory alloy wires. Smart Mater. Struct. 2008, 17, 065032. [Google Scholar] [CrossRef]

- Choi, E.; Hong, H.-K.; Kim, H.S.; Chung, Y.-S. Hysteretic behavior of NiTi and NiTiNb SMA wires under recovery or pre-stressing stress. J. Alloy. Compd. 2013, 577, S444–S447. [Google Scholar] [CrossRef]

- Choi, E.; Kim, D.J.; Youn, H.; Nam, T.-H. Repairing cracks developed in mortar beams reinforced by cold-drawn NiTi or NiTiNb SMA fibers. Smart Mater. Struct. 2015, 24, 125010. [Google Scholar] [CrossRef]

- Choi, E.; Mohammadzadeh, B.; Kim, D.; Jeon, J.-S. A new experimental investigation into the effects of reinforcing mortar beams with superelastic SMA fibers on controlling and closing cracks. Compos. Part B Eng. 2018, 137, 140–152. [Google Scholar] [CrossRef]

- Sherif, M.M.; Khakimova, E.M.; Tanks, J.; Ozbulut, O.E. Cyclic flexural behavior of hybrid SMA/steel fiber reinforced concrete analyzed by optical and acoustic techniques. Compos. Struct. 2018, 201, 248–260. [Google Scholar] [CrossRef]

- Choi, E.; Mohammadzadeh, B.; Hwang, J.H.; Lee, J.H. Displacement-recovery-capacity of superelastic SMA fibers reinforced cementitious materials. Smart Struct. Syst. 2019, 24, 157–171. [Google Scholar]

- Kytinou, V.K.; Chalioris, C.E.; Karayannis, C.G.; Elenas, A. Effect of steel fibers on the hysteretic performance of concrete beams with steel reinforcement—Tests and analysis. Materials 2020, 13, 2923. [Google Scholar] [CrossRef]

- ASTM. ASTM C469/C469M-14: Standard Test Method for Static Modulus of Elasticity and Poisson’s Ratio of Concrete in Compression; Annual Book of ASTM Standards; ASTM International: West Conshohocken, PA, USA, 2014; Volume 49. [Google Scholar]

- Mangat, P.; Azari, M.M. Influence of steel fibre and stirrup reinforcement on the properties of concrete in compression members. Int. J. Cem. Compos. Light. Concr. 1985, 7, 183–192. [Google Scholar] [CrossRef]

- Dehghani, A.; Aslani, F. The synergistic effects of shape memory alloy, steel, and carbon fibres with polyvinyl alcohol fibres in hybrid strain-hardening cementitious composites. Constr. Build. Mater. 2020, 252, 119061. [Google Scholar] [CrossRef]

- Saad, M.; Abo-El-Enein, S.; Hanna, G.; Kotkata, M. Effect of temperature on physical and mechanical properties of concrete containing silica fume. Cem. Concr. Res. 1996, 26, 669–675. [Google Scholar] [CrossRef]

- Ma, Q.; Guo, R.; Zhao, Z.; Lin, Z.; He, K. Mechanical properties of concrete at high temperature—A review. Constr. Build. Mater. 2015, 93, 371–383. [Google Scholar] [CrossRef]

- Ezeldin, A.S.; Balaguru, P.N. Normal-and high-strength fiber-reinforced concrete under compression. J. Mater. Civ. Eng. 1992, 4, 415–429. [Google Scholar] [CrossRef]

- Nataraja, M.; Dhang, N.; Gupta, A. Stress–strain curves for steel-fiber reinforced concrete under compression. Cem. Concr. Compos. 1999, 21, 383–390. [Google Scholar] [CrossRef]

- Bhargava, P.; Sharma, U.K.; Kaushik, S.K. Compressive Stress-Strain Behavior of Small Scale Steel Fibre Reinforced High Strength Concrete Cylinders. J. Adv. Concr. Technol. 2006, 4, 109–121. [Google Scholar] [CrossRef] [Green Version]

- Krahl, P.A.; Gidrão, G.D.M.S.; Carrazedo, R. Cyclic behavior of UHPFRC under compression. Cem. Concr. Compos. 2019, 104, 103363. [Google Scholar] [CrossRef]

- Li, B.; Xu, L.; Chi, Y.; Huang, B.; Li, C. Experimental investigation on the stress-strain behavior of steel fiber reinforced concrete subjected to uniaxial cyclic compression. Constr. Build. Mater. 2017, 140, 109–118. [Google Scholar] [CrossRef]

- Dehghani, A.; Aslani, F. The effect of shape memory alloy, steel, and carbon fibres on fresh, mechanical, and electrical properties of self-compacting cementitious composites. Cem. Concr. Compos. 2020, 112, 103659. [Google Scholar] [CrossRef]

| Type of Test | Portland Cement Type I | Silica Sand | Fly Ash | Water | Water Reducing Admixture |

|---|---|---|---|---|---|

| Monotonic compression | 1.0 | 1.0 | 0.15 | 0.35 | 0.009 |

| Cyclic compression | 1.0 | 1.0 | 1.0 | 0.698 | 0.0 |

| Type of Test | Specimen | Crimped Fiber | Dog-Bone-Shaped Fiber | Heating | Sample | ||||

|---|---|---|---|---|---|---|---|---|---|

| 0.5% | 1.0% | 1.5% | 0.5% | 1.0% | 1.5% | ||||

| Monotonic compression | P-N | 3 | |||||||

| CR0.5-N | √ | 3 | |||||||

| CR1.0-N | √ | 3 | |||||||

| DG0.5-N | √ | 3 | |||||||

| DG1.0-N | √ | 3 | |||||||

| P-H | √ | 3 | |||||||

| CR0.5-H | √ | √ | 3 | ||||||

| CR1.0-H | √ | √ | 3 | ||||||

| DG0.5-H | √ | √ | 3 | ||||||

| DG1.0-H | √ | √ | 3 | ||||||

| Cyclic compression | P-N | 3 | |||||||

| CR1.0-N | √ | 3 | |||||||

| CR1.5-N | √ | 3 | |||||||

| DG1.0-N | √ | 3 | |||||||

| DG1.5-N | √ | 3 | |||||||

| P-H | √ | 3 | |||||||

| CR1.0-H | √ | √ | 3 | ||||||

| CR1.5-H | √ | √ | 3 | ||||||

| DG1.0-H | √ | √ | 3 | ||||||

| DG1.5-H | √ | √ | 3 | ||||||

| Type | Poisson’s Ratio | Poisson’s Ratio | Secant Dilation Ratio |

|---|---|---|---|

| P-N | 0.21 | 0.22 | 0.33 |

| CR0.5-N | 0.15 | 0.20 | 0.51 |

| CR1.0-N | 0.17 | 0.21 | 0.51 |

| DG0.5-N | 0.19 | 0.20 | 0.32 |

| DG1.0-N | 0.19 | 0.22 | 0.40 |

| P-H | 0.13 | 0.16 | 0.34 |

| CR0.5-H | 0.13 | 0.16 | 0.22 |

| CR1.0-H | 0.13 | 0.16 | 0.22 |

| DG0.5-H | 0.16 | 0.18 | 0.29 |

| DG1.0-H | 0.11 | 0.16 | 0.31 |

| Sample | Compressive Strength (MPa) | Axial Peak Strain (10−3 mm/mm) | Energy Absorption | Average Strength (MPa) | Average Axial Peak Strain (10−3 mm/mm) | Average TR | Elastic Modulus (GPa) | Average Elastic Modulus (GPa) |

|---|---|---|---|---|---|---|---|---|

| P-N#1 | 63.0 | 3.6 | 0.141 | 68.0 | 3.7 | 0.58 | 23.04 | 24.50 |

| P-N#2 | 74.1 | 3.8 | 0.164 | 24.52 | ||||

| P-N#3 | 66.9 | 3.5 | 0.126 | 26.04 | ||||

| CR0.5-N#1 | 76.4 | 3.9 | 0.165 | 75.5 | 3.8 | 0.58 | 25.50 | 24.48 |

| CR0.5-N#2 | 75.7 | 4.0 | 0.174 | 23.45 | ||||

| CR0.5-N#3 | 74.5 | 3.5 | 0.157 | 24.48 | ||||

| CR1.0-N#1 | 73.4 | 3.7 | 0.163 | 75.0 | 3.9 | 0.59 | 24.92 | 24.30 |

| CR1.0-N#2 | 75.0 | 3.7 | 0.163 | 26.14 | ||||

| CR1.0-N#3 | 76.6 | 4.4 | 0.192 | 21.83 | ||||

| DG0.5-N#1 | 74.7 | 3.2 | 0.126 | 72.5 | 3.4 | 0.55 | 27.65 | 24.84 |

| DG0.5-N#2 | 71.9 | 3.5 | 0.152 | 23.44 | ||||

| DG0.5-N#3 | 70.8 | 3.4 | 0.124 | 23.44 | ||||

| DG1.0-N#1 | 78.1 | 3.8 | 0.173 | 75.7 | 3.7 | 0.54 | 26.44 | 26.13 |

| DG1.0-N#2 | 73.2 | 3.7 | 0.151 | 25.91 | ||||

| DG1.0-N#3 | 75.9 | 3.6 | 0.125 | 26.05 | ||||

| P-H#1 | 77.0 | 3.2 | 0.126 | 76.1 | 2.9 | 0.50 | 24.41 | 25.01 |

| P-H#2 | 71.2 | 2.6 | 0.090 | 25.32 | ||||

| P-H#3 | 80.2 | 2.8 | 0.111 | 25.29 | ||||

| CR0.5-H#1 | 77.9 | 2.9 | 0.108 | 76.9 | 3.0 | 0.50 | 24.89 | 25.18 |

| CR0.5-H#2 | 77.9 | 2.9 | 0.117 | 25.08 | ||||

| CR0.5-H#3 | 75.1 | 3.3 | 0.124 | 25.56 | ||||

| CR1.0-H#1 | 91.9 | 3.3 | 0.174 | 84.7 | 3.2 | 0.54 | 27.57 | 25.43 |

| CR1.0-H#2 | 80.4 | 3.2 | 0.132 | 25.19 | ||||

| CR1.0-H#3 | 82.0 | 3.2 | 0.138 | 23.54 | ||||

| DG0.5-H#1 | 77.6 | 3.5 | 0.137 | 80.9 | 3.4 | 0.51 | 24.05 | 26.27 |

| DG0.5-H#2 | 83.3 | 3.2 | 0.138 | 28.48 | ||||

| DG0.5-H#3 | 81.6 | 3.3 | 0.139 | 26.27 | ||||

| DG1.0-H#1 | 88.4 | 3.4 | 0.149 | 86.4 | 3.2 | 0.49 | 26.97 | 26.97 |

| DG1.0-H#2 | 84.4 | 3.0 | 0.123 | 26.97 |

| Type | Average Secant Dilation Ratio | Average Secant Dilation Ratio | Average Secant Dilation Ratio |

|---|---|---|---|

| P-N | 0.04 | 0.08 | 0.27 |

| CR1.0-N | 0.09 | 0.22 | 0.40 |

| CR1.5-N | 0.13 | 0.16 | 0.34 |

| DG1.0-N | 0.17 | 0.20 | 0.37 |

| DG1.5-N | 0.13 | 0.22 | 0.57 |

| P-H | 0.08 | 0.10 | 0.14 |

| CR1.0-H | 0.07 | 0.09 | 0.20 |

| CR1.5-H | 0.06 | 0.09 | 0.17 |

| DG1.0-H | 0.09 | 0.15 | 0.30 |

| DG1.5-H | 0.07 | 0.15 | 0.26 |

| Cycle | P-N | CR1.0-N | CR1.5-N | DG1.0-N | DG1.5-N | |||||

| The first | 1.25 | 17.11 | 0.95 | 19.02 | 1.64 | 21.67 | 0.76 | 20.89 | 0.64 | 22.76 |

| The second | 2.67 | 16.95 | 2.29 | 18.38 | 3.19 | 19.64 | 1.96 | 17.83 | 1.77 | 21.72 |

| The third | 4.38 | 16.34 | 4.09 | 16.75 | 4.99 | 17.67 | 3.66 | 17.34 | 3.10 | 20.41 |

| Cycle | P-H | CR1.0-H | CR1.5-H | DG1.0-H | DG1.5-H | |||||

| The first | 1.63 | 12.55 | 0.74 | 18.93 | 0.69 | 19.49 | 0.91 | 21.35 | 0.62 | 20.71 |

| The second | 3.45 | 12.43 | 1.84 | 17.63 | 1.86 | 19.44 | 2.00 | 21.33 | 1.72 | 19.21 |

| The third | - | - | 3.10 | 17.61 | 3.40 | 18.25 | 3.38 | 20.50 | 3.11 | 18.16 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ho, H.V.; Choi, E.; Kim, D.; Kang, J. Straining Behavior of Mortar Reinforced by Cold Drawn Crimped and Dog-Bone-Shaped Fibers under Monotonic and Cyclic Compressions. Materials 2021, 14, 1522. https://doi.org/10.3390/ma14061522

Ho HV, Choi E, Kim D, Kang J. Straining Behavior of Mortar Reinforced by Cold Drawn Crimped and Dog-Bone-Shaped Fibers under Monotonic and Cyclic Compressions. Materials. 2021; 14(6):1522. https://doi.org/10.3390/ma14061522

Chicago/Turabian StyleHo, Ha Vinh, Eunsoo Choi, Duhyeon Kim, and Joowon Kang. 2021. "Straining Behavior of Mortar Reinforced by Cold Drawn Crimped and Dog-Bone-Shaped Fibers under Monotonic and Cyclic Compressions" Materials 14, no. 6: 1522. https://doi.org/10.3390/ma14061522

APA StyleHo, H. V., Choi, E., Kim, D., & Kang, J. (2021). Straining Behavior of Mortar Reinforced by Cold Drawn Crimped and Dog-Bone-Shaped Fibers under Monotonic and Cyclic Compressions. Materials, 14(6), 1522. https://doi.org/10.3390/ma14061522