Development of Toughened Flax Fiber Reinforced Composites. Modification of Poly(lactic acid)/Poly(butylene adipate-co-terephthalate) Blends by Reactive Extrusion Process

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sample Preparation

2.3. Material Characterization

3. Results and Discussion

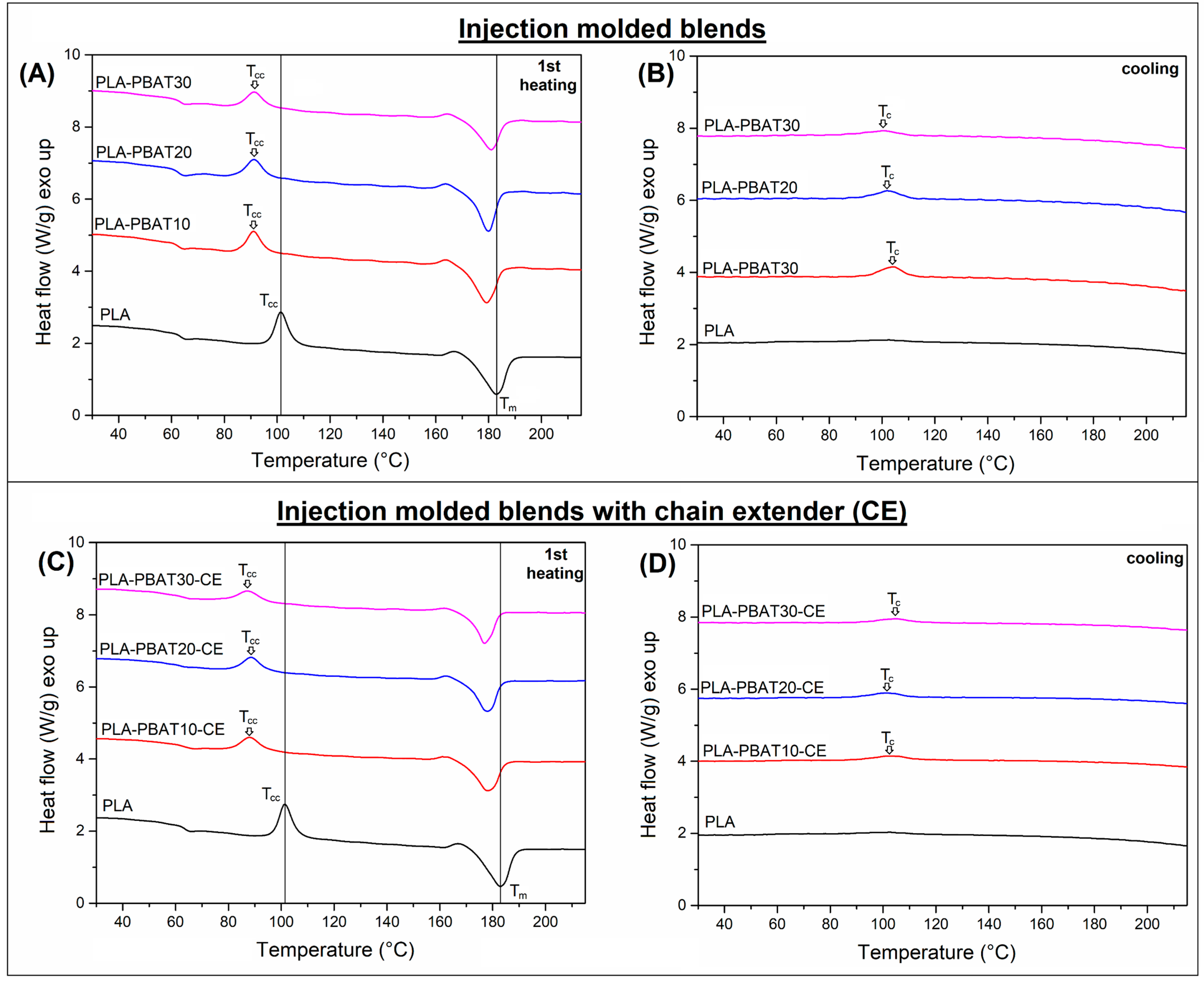

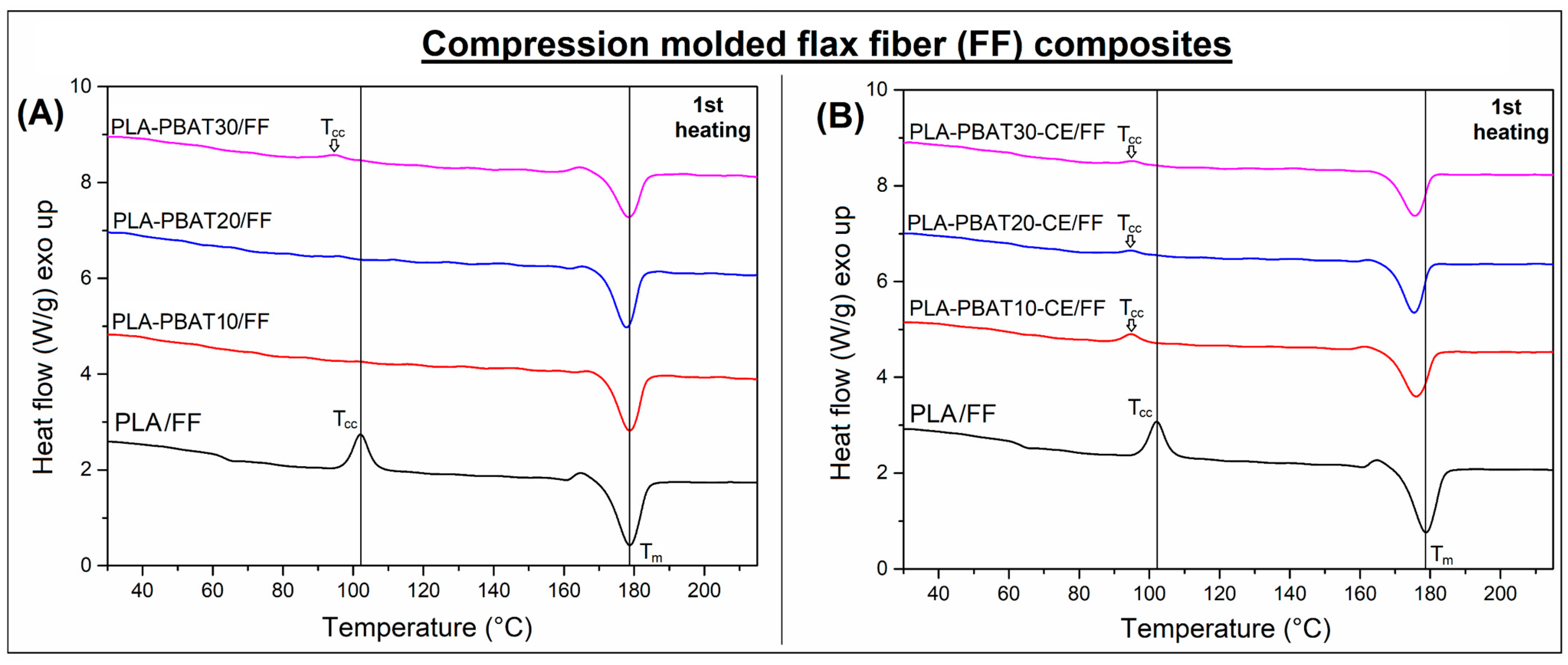

3.1. Differential Scanning Calorimetry—Phase Transition and Crystallinity

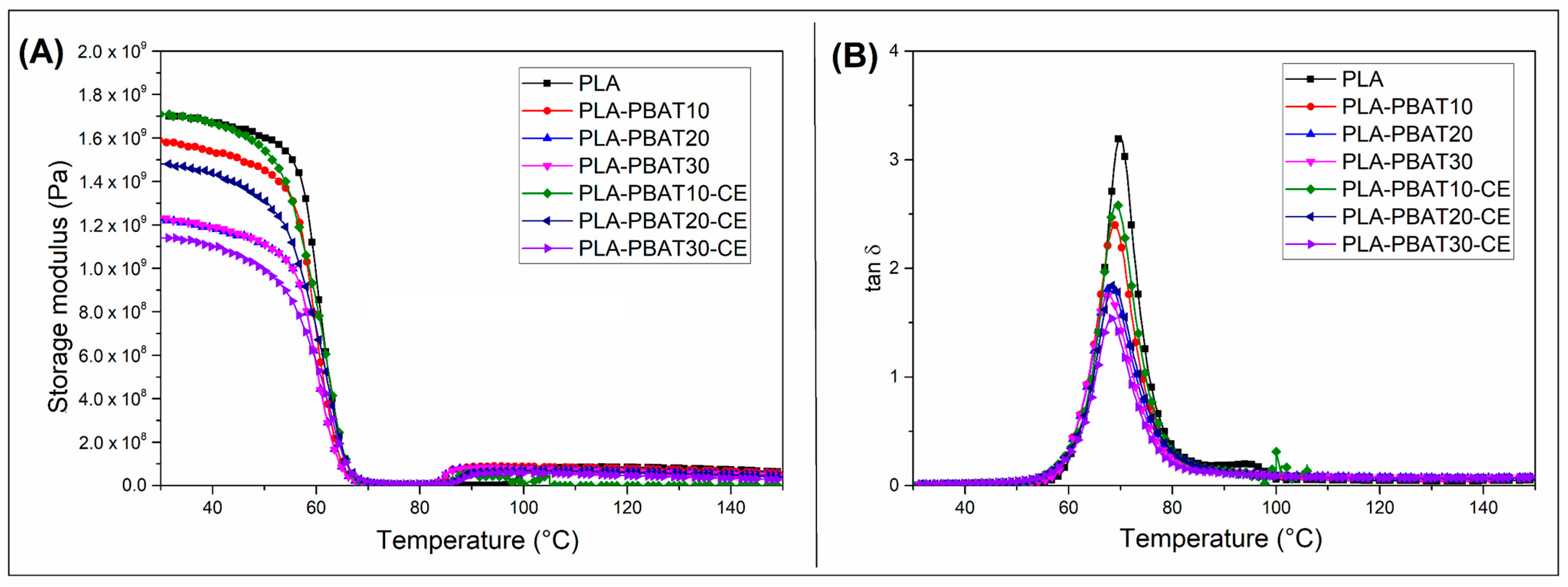

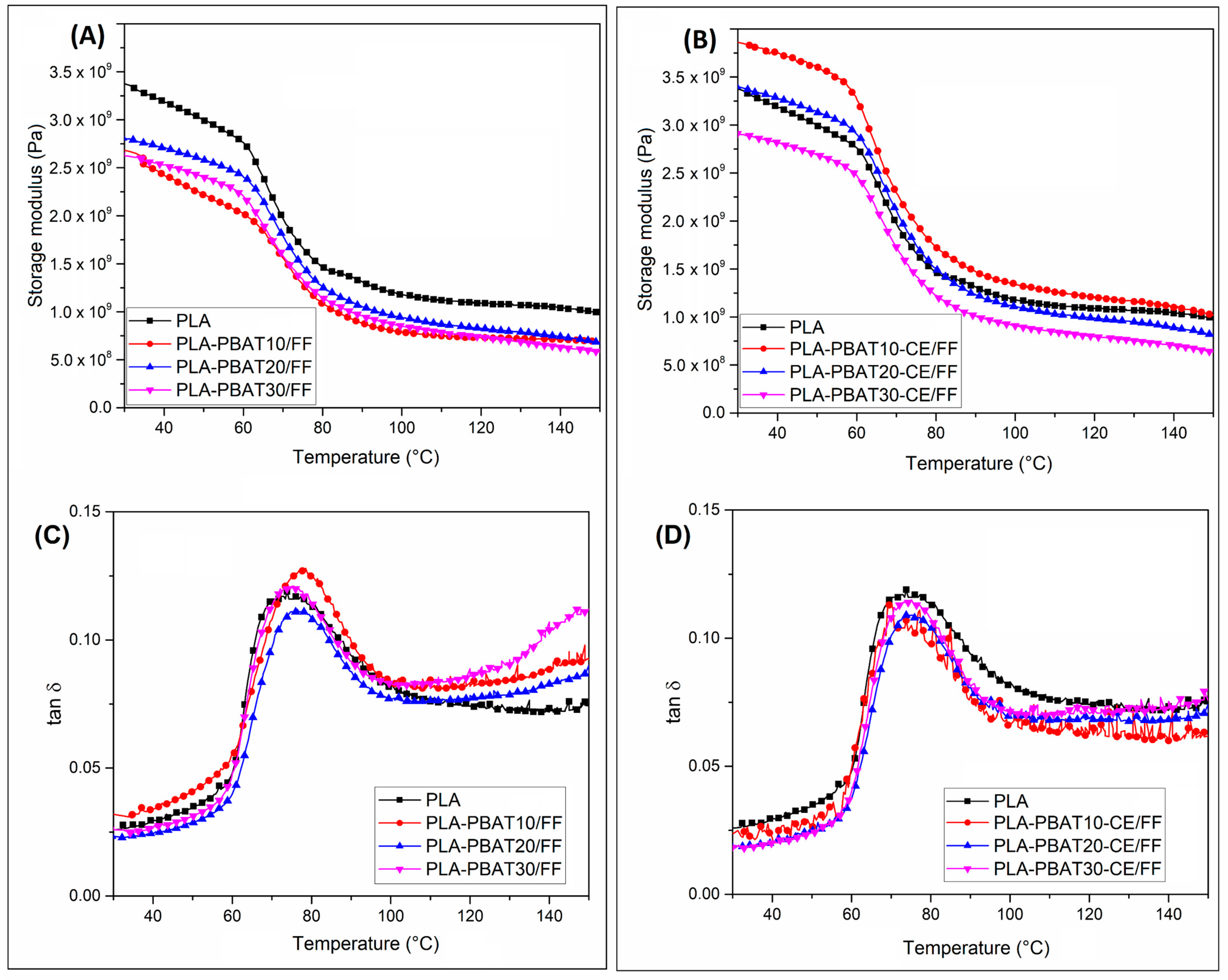

3.2. Thermo—Mechanical Analysis—Heat Resistance

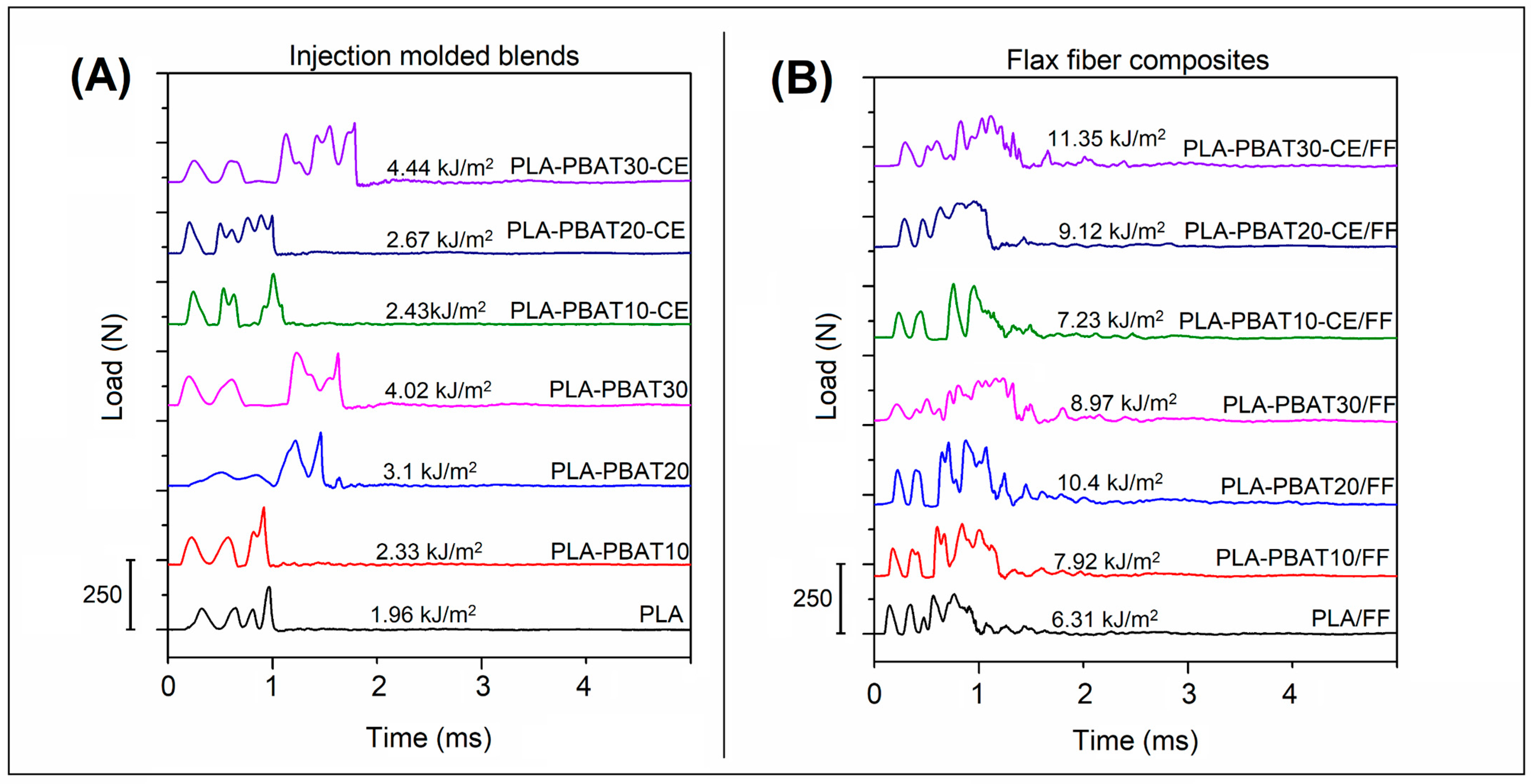

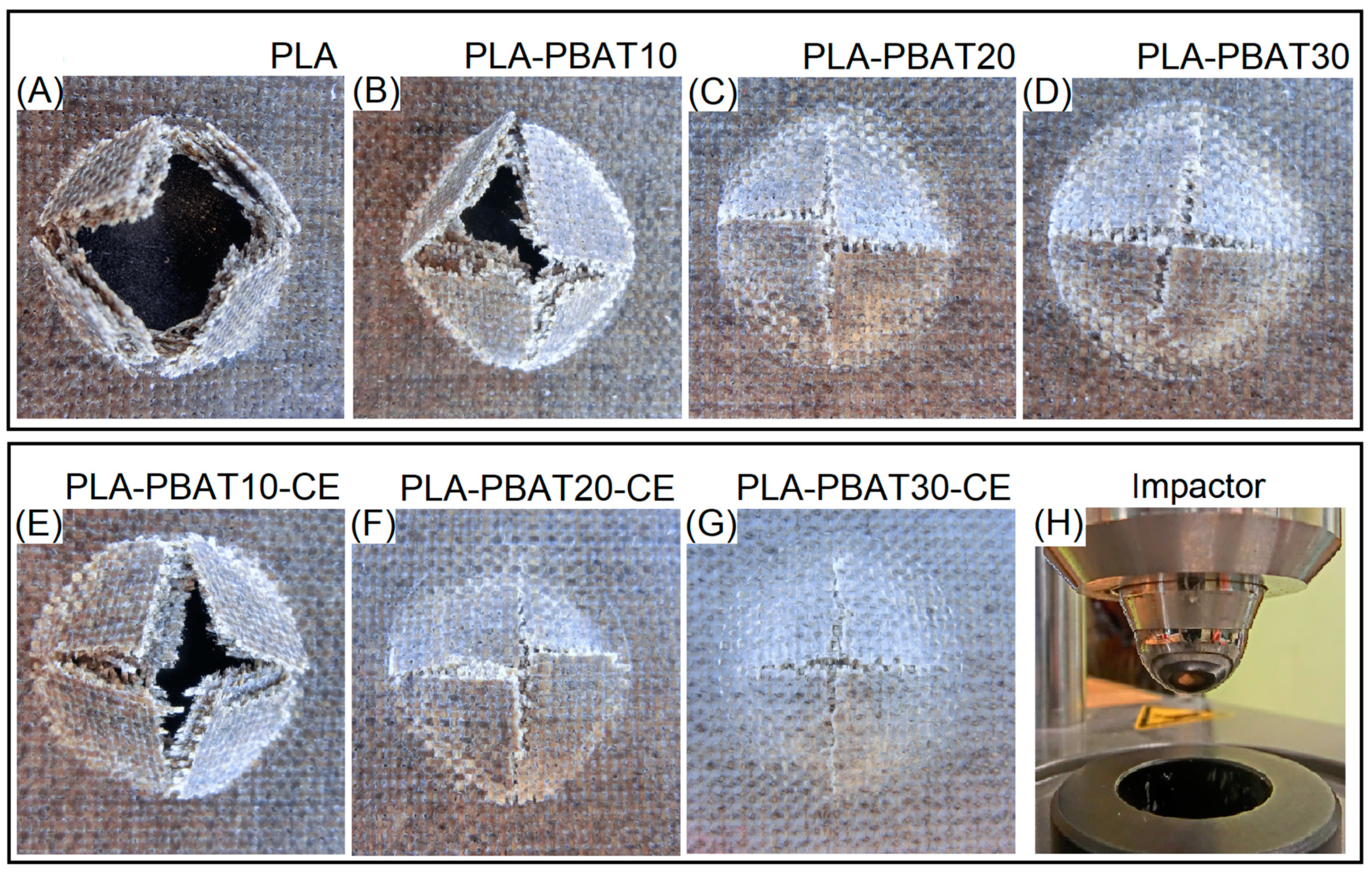

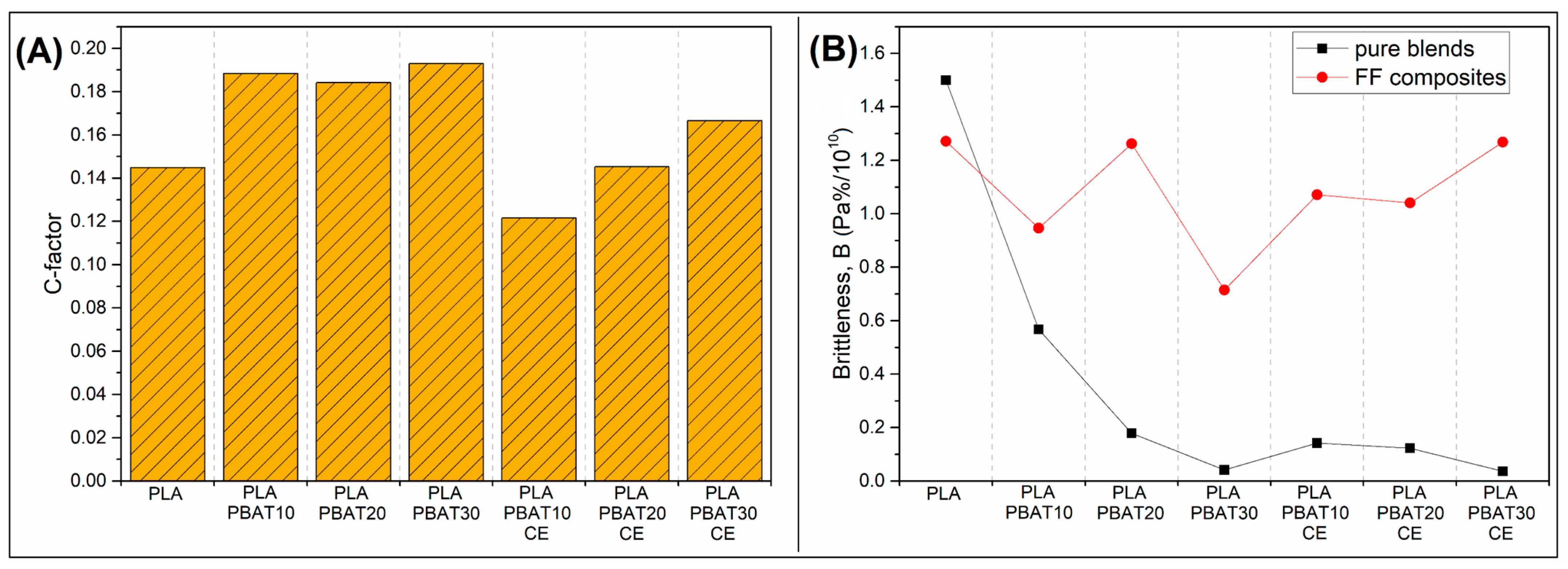

3.3. Mechanical Properties Characterization

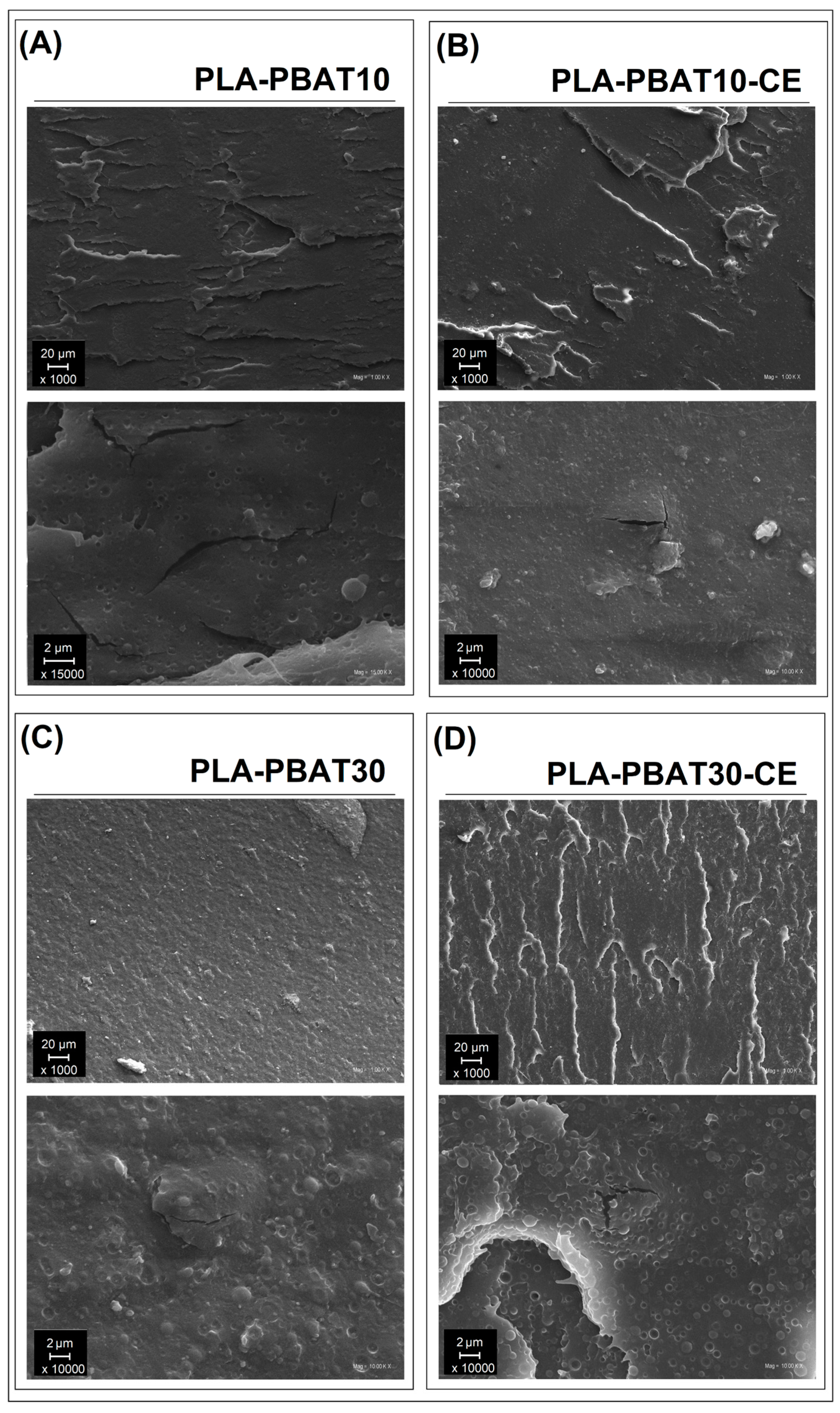

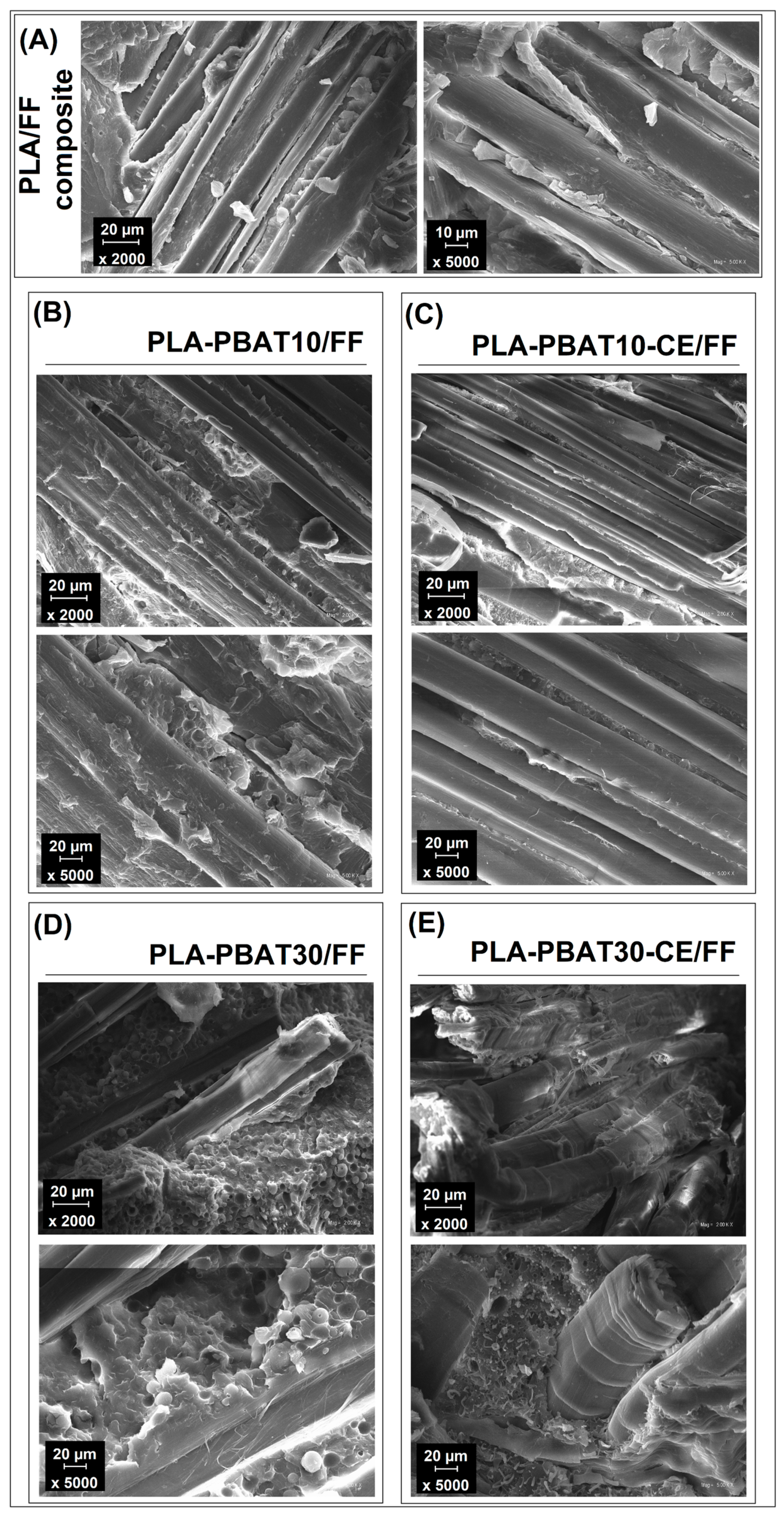

3.4. Composite Structure—Scanning Electron Microscopy Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Markarian, J. Biopolymers present new market opportunities for additives in packaging. Plast. Addit. Compd. 2008, 10, 22–25. [Google Scholar] [CrossRef]

- Rocha, D.B.; Souza de Carvalho, J.; de Oliveira, S.A.; dos Santos Rosa, D. A new approach for flexible PBAT/PLA/CaCO3 films into agriculture. J. Appl. Polym. Sci. 2018, 135, 46660. [Google Scholar] [CrossRef]

- Li, X.; Ai, X.; Pan, H.; Yang, J.; Gao, G.; Zhang, H.; Yang, H.; Dong, L. The morphological, mechanical, rheological, and thermal properties of PLA/PBAT blown films with chain extender. Polym. Adv. Technol. 2018, 29, 1706–1717. [Google Scholar] [CrossRef]

- Al-Itry, R.; Lamnawar, K.; Maazouz, A.; Billon, N.; Combeaud, C. Effect of the simultaneous biaxial stretching on the structural and mechanical properties of PLA, PBAT and their blends at rubbery state. Eur. Polym. J. 2015, 68, 288–301. [Google Scholar] [CrossRef]

- Zhou, S.-Y.; Huang, H.-D.; Ji, X.; Yan, D.-X.; Zhong, G.-J.; Hsiao, B.S.; Li, Z.-M. Super-Robust Polylactide Barrier Films by Building Densely Oriented Lamellae Incorporated with Ductile in Situ Nanofibrils of Poly(butylene adipate- co -terephthalate). ACS Appl. Mater. Interfaces 2016, 8, 8096–8109. [Google Scholar] [CrossRef] [PubMed]

- Jian, J.; Xiangbin, Z.; Xianbo, H. An overview on synthesis, properties and applications of poly(butylene-adipate-co-terephthalate)–PBAT. Adv. Ind. Eng. Polym. Res. 2020, 3, 19–26. [Google Scholar] [CrossRef]

- Ogunsona, E.O.; Misra, M.; Mohanty, A.K. Sustainable biocomposites from biobased polyamide 6,10 and biocarbon from pyrolyzed miscanthus fibers. J. Appl. Polym. Sci. 2017, 134, 44221. [Google Scholar] [CrossRef]

- Oliver-Ortega, H.; Méndez, J.A.; Espinach, F.X.; Tarrés, Q.; Ardanuy, M.; Mutjé, P. Impact strength and water uptake behaviors of fully bio-based PA11-SGW composites. Polymers 2018, 10, 717. [Google Scholar] [CrossRef] [PubMed]

- Matykiewicz, D. Biochar as an Effective Filler of Carbon Fiber Reinforced Bio-Epoxy Composites. Processes 2020, 8, 724. [Google Scholar] [CrossRef]

- Ferdosian, F.; Zhang, Y.; Yuan, Z.; Anderson, M.; Xu, C.C. Curing kinetics and mechanical properties of bio-based epoxy composites comprising lignin-based epoxy resins. Eur. Polym. J. 2016, 82, 153–165. [Google Scholar] [CrossRef]

- François, C.; Pourchet, S.; Boni, G.; Rautiainen, S.; Samec, J.; Fournier, L.; Robert, C.; Thomas, C.M.; Fontaine, S.; Gaillard, Y.; et al. Design and synthesis of biobased epoxy thermosets from biorenewable resources. Comptes Rendus Chim. 2017, 20, 1006–1016. [Google Scholar] [CrossRef]

- Czarnecka-Komorowska, D.; Wiszumirska, K. Sustainability design of plastic packaging for the Circular Economy. Polimery 2020, 65, 8–17. [Google Scholar] [CrossRef]

- Gere, D.; Czigany, T. Future trends of plastic bottle recycling: Compatibilization of PET and PLA. Polym. Test. 2020, 81, 106160. [Google Scholar] [CrossRef]

- Srebrenkoska, V.; Bogoeva Gaceva, G.; Dimeski, D. Biocomposites based on polylactic acid and their thermal behavior after recycing. Maced. J. Chem. Chem. Eng. 2014, 33, 277. [Google Scholar] [CrossRef][Green Version]

- SaŁasinska, K.; Ryszkowska, J. Composites of polylactic acid reinforced with plant fillers obtained from farm and food industry. Przem. Chem. 2013, 92, 2027–2031. [Google Scholar]

- Mysiukiewicz, O.; Barczewski, M. Crystallization of polylactide-based green composites filled with oil-rich waste fillers. J. Polym. Res. 2020, 27, 374. [Google Scholar] [CrossRef]

- Yu, W.; Wang, X.; Ferraris, E.; Zhang, J. Melt crystallization of PLA/Talc in fused filament fabrication. Mater. Des. 2019, 182, 108013. [Google Scholar] [CrossRef]

- Nagarajan, V.; Mohanty, A.K.; Misra, M. Crystallization behavior and morphology of polylactic acid (PLA) with aromatic sulfonate derivative. J. Appl. Polym. Sci. 2016, 133, 1–11. [Google Scholar] [CrossRef]

- Nofar, M. Rheological, Thermal, and Foaming Behaviors of Different Polylactide Grades. Int. J. Mater. Sci. Res. 2018, 1, 16–22. [Google Scholar] [CrossRef]

- Suksut, B.; Deeprasertkul, C. Effect of Nucleating Agents on Physical Properties of Poly(lactic acid) and Its Blend with Natural Rubber. J. Polym. Environ. 2011, 19, 288–296. [Google Scholar] [CrossRef]

- Barczewski, M.; Mysiukiewicz, O.; Matykiewicz, D.; Skórczewska, K.; Lewandowski, K.; Andrzejewski, J.; Piasecki, A. Development of polylactide composites with improved thermomechanical properties by simultaneous use of basalt powder and a nucleating agent. Polym. Compos. 2020, 41, 2947–2957. [Google Scholar] [CrossRef]

- Nagarajan, V.; Zhang, K.; Misra, M.; Mohanty, A.K. Overcoming the Fundamental Challenges in Improving the Impact Strength and Crystallinity of PLA Biocomposites: Influence of Nucleating Agent and Mold Temperature. ACS Appl. Mater. Interfaces 2015, 7, 11203–11214. [Google Scholar] [CrossRef]

- Fan, Y.; Zhu, J.; Yan, S.; Chen, X.; Yin, J. Nucleating effect and crystal morphology controlling based on binary phase behavior between organic nucleating agent and poly(l-lactic acid). Polymer 2015, 67, 63–71. [Google Scholar] [CrossRef]

- Barczewski, M.; Mysiukiewicz, O.; Matykiewicz, D.; Kloziński, A.; Andrzejewski, J.; Piasecki, A. Synergistic effect of different basalt fillers and annealing on the structure and properties of polylactide composites. Polym. Test. 2020, 89, 106628. [Google Scholar] [CrossRef]

- Huda, M.S.; Drzal, L.T.; Mohanty, A.K.; Misra, M. Effect of fiber surface-treatments on the properties of laminated biocomposites from poly(lactic acid) (PLA) and kenaf fibers. Compos. Sci. Technol. 2008, 68, 424–432. [Google Scholar] [CrossRef]

- Matykiewicz, D.; Barczewski, M.; Pucała, H. Influence of the compression molding temperature on thermomechanical properties of the basalt-reinforced poly(Lactic acid) (PLA) composites. Rev. Rom. Mater. Rom. J. Mater. 2018, 48, 108–114. [Google Scholar]

- Liu, H.; Zhang, J. Research progress in toughening modification of poly(lactic acid). J. Polym. Sci. Part B Polym. Phys. 2011, 49, 1051–1083. [Google Scholar] [CrossRef]

- Yuryev, Y.; Mohanty, A.K.; Misra, M. A New Approach to Supertough Poly(lactic acid): A High Temperature Reactive Blending. Macromol. Mater. Eng. 2016, 301, 1443–1453. [Google Scholar] [CrossRef]

- Chen, Q.; Shan, P.; Tong, C.; Yan, D.; Zhang, Y.; Liu, H.; Hao, C. Influence of reactive blending temperature on impact toughness and phase morphologies of PLA ternary blend system containing magnesium ionomer. J. Appl. Polym. Sci. 2019, 136, 47682. [Google Scholar] [CrossRef]

- Andrzejewski, J.; Skórczewska, K.; Klozinski, A. Improving the toughness and thermal resistance of polyoxymethylene/poly(lactic acid) blends: Evaluation of structure-properties correlation for reactive processing. Polymers 2020, 12, 307. [Google Scholar] [CrossRef]

- Yuryev, Y.; Mohanty, A.K.; Misra, M. Novel super-toughened bio-based blend from polycarbonate and poly(lactic acid) for durable applications. RSC Adv. 2016, 6, 105094–105104. [Google Scholar] [CrossRef]

- Hou, A.L.; Qu, J.P. Super-toughened poly(lactic Acid) with poly(“-caprolactone) and ethylene-methyl acrylate-glycidyl methacrylate by reactive melt blending. Polymers 2019, 11, 771. [Google Scholar] [CrossRef] [PubMed]

- Wu, H.; Hou, A.; Qu, J.P. Phase Morphology and Performance of Supertough PLA/EMA-GMA/ZrP Nanocomposites Prepared through Reactive Melt-Blending. ACS Omega 2019, 4, 19046–19053. [Google Scholar] [CrossRef] [PubMed]

- Zolali, A.M.; Favis, B.D. Toughening of Cocontinuous Polylactide/Polyethylene Blends via an Interfacially Percolated Intermediate Phase. Macromolecules 2018, 51, 3572–3581. [Google Scholar] [CrossRef]

- Wahit, M.U.; Hassan, A.; Ibrahim, A.N.; Zawawi, N.A.; Kunasegeran, K. Mechanical, Thermal and Chemical Resistance of Epoxidized Natural Rubber Toughened Polylactic Acid Blends. Sains Malays. 2015, 44, 1615–1623. [Google Scholar]

- Wang, Y.; Chen, K.; Xu, C.; Chen, Y. Supertoughened Biobased Poly(lactic acid)-Epoxidized Natural Rubber Thermoplastic Vulcanizates: Fabrication, Co-continuous Phase Structure, Interfacial in Situ Compatibilization, and Toughening Mechanism. J. Phys. Chem. B 2015, 119, 12138–12146. [Google Scholar] [CrossRef]

- Huang, J.; Fan, J.; Yuan, D.; Zhang, S.; Chen, Y. Facile Preparation of Supertoughened Polylactide-Based Thermoplastic Vulcanizates without Sacrificing the Stiffness Based on the Selective Distribution of Silica. Ind. Eng. Chem. Res. 2020, 59, 9950–9958. [Google Scholar] [CrossRef]

- Sathornluck, S.; Choochottiros, C. Modification of epoxidized natural rubber as a PLA toughening agent. J. Appl. Polym. Sci. 2019, 136, 48267. [Google Scholar] [CrossRef]

- Jain, S.; Reddy, M.M.; Mohanty, A.K.; Misra, M.; Ghosh, A.K. A new biodegradable flexible composite sheet from poly(lactic acid)/poly(e-caprolactone) blends and micro-talc. Macromol. Mater. Eng. 2010, 295, 750–762. [Google Scholar] [CrossRef]

- Ostafinska, A.; Fortelný, I.; Hodan, J.; Krejčíková, S.; Nevoralová, M.; Kredatusová, J.; Kruliš, Z.; Kotek, J.; Šlouf, M. Strong synergistic effects in PLA/PCL blends: Impact of PLA matrix viscosity. J. Mech. Behav. Biomed. Mater. 2017, 69, 229–241. [Google Scholar] [CrossRef]

- Bouakaz, B.S.; Habi, A.; Grohens, Y.; Pillin, I. Organomontmorillonite/graphene-PLA/PCL nanofilled blends: New strategy to enhance the functional properties of PLA/PCL blend. Appl. Clay Sci. 2017, 139, 81–91. [Google Scholar] [CrossRef]

- Przybysz-Romatowska, M.; Haponiuk, J.; Formela, K. Poly(ε-caprolactone)/poly(lactic acid) blends compatibilized by peroxide initiators: Comparison of two strategies. Polymers 2020, 12, 228. [Google Scholar] [CrossRef] [PubMed]

- Semba, T.; Kitagawa, K.; Ishiaku, U.S.; Hamada, H. The effect of crosslinking on the mechanical properties of polylactic acid/polycaprolactone blends. J. Appl. Polym. Sci. 2006, 101, 1816–1825. [Google Scholar] [CrossRef]

- Olejnik, O.; Masek, A. Effect of silymarin on thermooxidative degradation of PLA/PHB blends. Inżynieria Mater. 2020, 1, 9–13. [Google Scholar] [CrossRef]

- Abdelwahab, M.A.; Flynn, A.; Chiou, B.-S.; Imam, S.; Orts, W.; Chiellini, E. Thermal, mechanical and morphological characterization of plasticized PLA–PHB blends. Polym. Degrad. Stab. 2012, 97, 1822–1828. [Google Scholar] [CrossRef]

- D’Anna, A.; Arrigo, R.; Frache, A. PLA/PHB Blends: Biocompatibilizer Effects. Polymers 2019, 11, 1416. [Google Scholar] [CrossRef]

- Frone, A.N.; Batalu, D.; Chiulan, I.; Oprea, M.; Gabor, A.R.; Nicolae, C.A.; Raditoiu, V.; Trusca, R.; Panaitescu, D.M. Morpho-structural, thermal and mechanical properties of PLA/PHB/Cellulose biodegradable nanocomposites obtained by compression molding, extrusion, and 3d printing. Nanomaterials 2020, 10, 51. [Google Scholar] [CrossRef]

- Mosnáčková, K.; Danko, M.; Šišková, A.; Falco, L.M.; Janigová, I.; Chmela, Š.; Vanovčanová, Z.; Omaníková, L.; Chodák, I.; Mosnáček, J. Complex study of the physical properties of a poly(lactic acid)/poly(3-hydroxybutyrate) blend and its carbon black composite during various outdoor and laboratory ageing conditions. RSC Adv. 2017, 7, 47132–47142. [Google Scholar] [CrossRef]

- Shirai, M.A.; Zanela, J.; Kunita, M.H.; Pereira, G.M.; Rubira, A.F.; Müller, C.M.O.; Grossmann, M.V.E.; Yamashita, F. Influence of Carboxylic Acids on Poly(lactic acid)/Thermoplastic Starch Biodegradable Sheets Produced by Calendering–Extrusion. Adv. Polym. Technol. 2018, 37, 332–338. [Google Scholar] [CrossRef]

- Imre, B.; García, L.; Puglia, D.; Vilaplana, F. Reactive compatibilization of plant polysaccharides and biobased polymers: Review on current strategies, expectations and reality. Carbohydr. Polym. 2019, 209, 20–37. [Google Scholar] [CrossRef]

- Mittal, V.; Akhtar, T.; Luckachan, G.; Matsko, N. PLA, TPS and PCL binary and ternary blends: Structural characterization and time-dependent morphological changes. Colloid Polym. Sci. 2015, 293, 573–585. [Google Scholar] [CrossRef]

- Vigil Fuentes, M.A.; Thakur, S.; Wu, F.; Misra, M.; Gregori, S.; Mohanty, A.K. Study on the 3D printability of poly(3-hydroxybutyrate-co-3-hydroxyvalerate)/poly(lactic acid) blends with chain extender using fused filament fabrication. Sci. Rep. 2020, 10, 1–12. [Google Scholar] [CrossRef]

- Hedrick, M.M.; Wu, F.; Mohanty, A.K.; Misra, M. Morphology and performance relationship studies on biodegradable ternary blends of poly(3-hydroxybutyrate-: Co -3-hydroxyvalerate), polylactic acid, and polypropylene carbonate. RSC Adv. 2020, 10, 44624–44632. [Google Scholar] [CrossRef]

- Kanda, G.S.; Al-Qaradawi, I.; Luyt, A.S. Morphology and property changes in PLA/PHBV blends as function of blend composition. J. Polym. Res. 2018, 25, 196. [Google Scholar] [CrossRef]

- Muniyasamy, S.; Ofosu, O.; John, M.J.; Anandjiwala, R.D. Mineralization of poly(lactic acid) (PLA), Poly(3-hydroxybutyrate-co-valerate) (PHBV) and PLA/PHBV blend in compost and soil environments. J. Renew. Mater. 2016, 4, 133–145. [Google Scholar] [CrossRef]

- Meereboer, K.W.; Pal, A.K.; Cisneros-López, E.O.; Misra, M.; Mohanty, A.K. The effect of natural fillers on the marine biodegradation behaviour of poly(3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBV). Sci. Rep. 2021, 11, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Muthuraj, R.; Misra, M.; Mohanty, A.K. Biodegradable compatibilized polymer blends for packaging applications: A literature review. J. Appl. Polym. Sci. 2018, 135, 45726. [Google Scholar] [CrossRef]

- Adrar, S.; Habi, A.; Ajji, A.; Grohens, Y. Synergistic effects in epoxy functionalized graphene and modified organo-montmorillonite PLA/PBAT blends. Appl. Clay Sci. 2018, 157, 65–75. [Google Scholar] [CrossRef]

- Wu, F.; Misra, M.; Mohanty, A.K. Super Toughened Poly(lactic acid)-Based Ternary Blends via Enhancing Interfacial Compatibility. ACS Omega 2019, 4, 1955–1968. [Google Scholar] [CrossRef]

- Jin, X.; Chen, X.; Cheng, Q.; Zhang, N.; Cai, S.; Ren, J. Non-isothermal crystallization kinetics of ramie fiber-reinforced polylactic acid biocomposite. RSC Adv. 2017, 7, 46014–46021. [Google Scholar] [CrossRef]

- Yu, T.; Jiang, N.; Li, Y. Study on short ramie fiber/poly(lactic acid) composites compatibilized by maleic anhydride. Compos. Part A Appl. Sci. Manuf. 2014, 64, 139–146. [Google Scholar] [CrossRef]

- Morales, A.P.; Güemes, A.; Fernandez-Lopez, A.; Valero, V.C.; de La Rosa Llano, S. Bamboo-polylactic acid (PLA) composite material for structural applications. Materials 2017, 10, 1286. [Google Scholar] [CrossRef] [PubMed]

- Chen, T.; Wu, Y.; Qiu, J.; Fei, M.; Qiu, R.; Liu, W. Interfacial compatibilization via in-situ polymerization of epoxidized soybean oil for bamboo fibers reinforced poly(lactic acid) biocomposites. Compos. Part A Appl. Sci. Manuf. 2020, 138, 106066. [Google Scholar] [CrossRef]

- Korol, J.; Hejna, A.; Burchart-Korol, D.; Chmielnicki, B.; Wypiór, K. Water Footprint Assessment of Selected Polymers, Polymer Blends, Composites, and Biocomposites for Industrial Application. Polymers 2019, 11, 1791. [Google Scholar] [CrossRef]

- de Macedo, J.R.N.; dos Santos, D.J.; dos Santos Rosa, D. Poly(lactic acid)–thermoplastic starch–cotton composites: Starch-compatibilizing effects and composite biodegradability. J. Appl. Polym. Sci. 2019, 136, 47490. [Google Scholar] [CrossRef]

- de Oliveira, S.A.; Nunes de Macedo, J.R.; dos Santos Rosa, D. Eco-efficiency of poly (lactic acid)-Starch-Cotton composite with high natural cotton fiber content: Environmental and functional value. J. Clean. Prod. 2019, 217, 32–41. [Google Scholar] [CrossRef]

- Bogoeva-Gaceva, G.; Dimeski, D.; Srebrenkoska, V. Biocomposites based on poly(lactic acid) and kenaf fibers: Effect of micro-fibrillated cellulose. Maced. J. Chem. Chem. Eng. 2013, 32, 331. [Google Scholar] [CrossRef]

- Georgiopoulos, P.; Kontou, E.; Georgousis, G. Effect of silane treatment loading on the flexural properties of PLA/flax unidirectional composites. Compos. Commun. 2018, 10, 6–10. [Google Scholar] [CrossRef]

- Morreale, M.; Mistretta, M.C.; Fiore, V. Creep behavior of poly(lactic acid) based biocomposites. Materials 2017, 10, 395. [Google Scholar] [CrossRef]

- Alimuzzaman, S.; Gong, R.H.; Akonda, M. Impact Property of PLA/Flax Nonwoven Biocomposite. Conf. Pap. Mater. Sci. 2013, 2013, 1–6. [Google Scholar] [CrossRef]

- Andrzejewski, J.; Szostak, M. Preparation of hybrid poly(lactic acid)/flax composites by the insert overmolding process: Evaluation of mechanical performance and thermomechanical properties. J. Appl. Polym. Sci. 2020, 138, 49646. [Google Scholar] [CrossRef]

- Couture, A.; Lebrun, G.; Laperrière, L. Mechanical properties of polylactic acid (PLA) composites reinforced with unidirectional flax and flax-paper layers. Compos. Struct. 2016, 154, 286–295. [Google Scholar] [CrossRef]

- Rytlewski, P.; Moraczewski, K.; Malinowski, R.; Żenkiewicz, M. Assessment of dicumyl peroxide ability to improve adhesion between polylactide and flax or hemp fibres. Compos. Interfaces 2014, 21, 671–683. [Google Scholar] [CrossRef]

- Rytlewski, P.; Stepczynska, M.; Moraczewski, K.; Malinowski, R.; Jagodzinski, B.; Zenkiewicz, M. Mechanical properties and biodegradability of flax fiber-reinforced composite of polylactide and polycaprolactone. Polimery 2018, 63, 603–610. [Google Scholar] [CrossRef]

- Garlotta, D. A Literature Review of Poly(Lactic Acid). J. Polym. Environ. 2001, 9, 63–84. [Google Scholar] [CrossRef]

- Fischer, E.W.; Sterzel, H.J.; Wegner, G. Investigation of the structure of solution grown crystals of lactide copolymers by means of chemical reactions. Kolloid Z. Z. Polym. 1973, 251, 980–990. [Google Scholar] [CrossRef]

- ISO-Committee. Plastics—Determination of Temperature of Deflection under Load (ISO 75); ISO-Committee: Geneva, Switzerland, 2013; pp. 1–8. [Google Scholar]

- ISO-Committee. Plastics—Determination of Tensile Properties (ISO 527-1); ISO-Committee: Geneva, Switzerland, 2012. [Google Scholar]

- ISO-Committee. Plastics—Determination of Flexural Properties (ISO 178:2001); ISO-Committee: Geneva, Switzerland, 2001. [Google Scholar]

- ISO-Committee. Plastics—Determination of Charpy Impact Properties (ISO 179-1); ISO-Committee: Geneva, Switzerland, 2010. [Google Scholar]

- Hao, M.; Wu, H.; Qiu, F.; Wang, X. Interface bond improvement of sisal fibre reinforced polylactide composites with added epoxy oligomer. Materials 2018, 11, 398. [Google Scholar] [CrossRef]

- Wu, H.; Hao, M. Strengthening and toughening of polylactide/sisal fiber biocomposites via in-situ reaction with epoxy-functionalized oligomer and poly (butylene-adipate-terephthalate). Polymers 2019, 11, 1747. [Google Scholar] [CrossRef]

- Hao, M.; Wu, H.; Zhu, Z. In situ reactive interfacial compatibilization of polylactide/sisal fiber biocomposites via melt-blending with an epoxy-functionalized terpolymer elastomer. RSC Adv. 2017, 7, 32399–32412. [Google Scholar] [CrossRef]

- Nakayama, D.; Wu, F.; Mohanty, A.K.; Hirai, S.; Misra, M. Biodegradable Composites Developed from PBAT/PLA Binary Blends and Silk Powder: Compatibilization and Performance Evaluation. ACS Omega 2018, 3, 12412–12421. [Google Scholar] [CrossRef] [PubMed]

- Battegazzore, D.; Abt, T.; Maspoch, M.L.; Frache, A. Multilayer cotton fabric bio-composites based on PLA and PHB copolymer for industrial load carrying applications. Compos. Part B Eng. 2019, 163, 761–768. [Google Scholar] [CrossRef]

- Wis, A.A.; Kodal, M.; Ozturk, S.; Ozkoc, G. Overmolded polylactide/jute-mat eco-composites: A new method to enhance the properties of natural fiber biodegradable composites. J. Appl. Polym. Sci. 2019, 137, 48692. [Google Scholar] [CrossRef]

- Akonda, M.; Alimuzzaman, S.; Shah, D.U.; Rahman, A.N.M.M. Physico-mechanical, thermal and biodegradation performance of random flax/polylactic acid and unidirectional flax/polylactic acid biocomposites. Fibers 2018, 6, 98. [Google Scholar] [CrossRef]

- Zhu, J.; Zhu, H.; Njuguna, J.; Abhyankar, H. Recent development of flax fibres and their reinforced composites based on different polymeric matrices. Materials 2013, 6, 5171–5198. [Google Scholar] [CrossRef] [PubMed]

- Osman, M.J.; Ibrahim, N.A.; Md Zin Wanyunus, W. Effect of modified clay on the morphological and thermal properties of poly lactic acid, poly butylene adipate-co-terephthalate nanocomposites. Orient. J. Chem. 2017, 33, 3015–3023. [Google Scholar] [CrossRef]

- Wang, B.; Jin, Y.; Kang, K.; Yang, N.; Weng, Y.; Huang, Z.; Men, S. Investigation on compatibility of PLA/PBAT blends modified by epoxy-terminated branched polymers through chemical micro-crosslinking. e-Polymers 2020, 20, 39–54. [Google Scholar] [CrossRef]

| Sample | PLA | PBAT | CE |

|---|---|---|---|

| (%) | (%) | (phr) | |

| PLA | 100 | - | - |

| PLA-PBAT10 | 90 | 10 | - |

| PLA-PBAT20 | 80 | 20 | - |

| PLA-PBAT30 | 70 | 30 | - |

| PLA-PBAT10-CE | 90 | 10 | 0.5 |

| PLA-PBAT20-CE | 80 | 20 | 0.5 |

| PLA-PBAT30-CE | 70 | 30 | 0.5 |

| Matrix Type | Injection Molding | Compression Molding | ||||

|---|---|---|---|---|---|---|

| ΔHcc (J/g) | ΔHm (J/g) | χc (%) | ΔHcc (J/g) | ΔHm (J/g) | χc (%) | |

| PLA | 36.9 | 58.5 | 23.0 | 22.8 | 61.6 | 41.4 |

| PLA-PBAT10 | 23.9 | 50.6 | 31.6 | - | 51.3 | 60.8 |

| PLA-PBAT20 | 25.3 | 50.4 | 33.5 | - | 50.7 | 67.6 |

| PLA-PBAT30 | 21.6 | 40.9 | 29.4 | 5.5 | 41.0 | 54.1 |

| PLA-PBAT10-CE | 22.1 | 47.0 | 29.5 | 5.8 | 45.9 | 47.5 |

| PLA-PBAT20-CE | 20.3 | 42.0 | 28.9 | 4.6 | 42.4 | 50.4 |

| PLA-PBAT30-CE | 18.2 | 39.4 | 32.3 | 3.8 | 40.5 | 55.9 |

| Matrix Polymer | HDT (0.45 MPa) (°C) | |

|---|---|---|

| Injection Molded Blends | Flax Fiber Composites | |

| PLA | 60.5 (±0.4) | 145.4 (±4.8) |

| PLA-PBAT10 | 61.9 (±1.2) | 131.0 (±5.5) |

| PLA-PBAT20 | 62.2 (±0.5) | 112.4 (±0.4) |

| PLA-PBAT30 | 59.1 (±0.3) | 98.4 (±8.3) |

| PLA-PBAT10-CE | 58.1 (±0.8) | 126.6 (±1.6) |

| PLA-PBAT20-CE | 59.8 (±0.7) | 110.1 (±4.7) |

| PLA-PBAT30-CE | 61.3 (±0.8) | 109.0 (±0.2) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Andrzejewski, J.; Nowakowski, M. Development of Toughened Flax Fiber Reinforced Composites. Modification of Poly(lactic acid)/Poly(butylene adipate-co-terephthalate) Blends by Reactive Extrusion Process. Materials 2021, 14, 1523. https://doi.org/10.3390/ma14061523

Andrzejewski J, Nowakowski M. Development of Toughened Flax Fiber Reinforced Composites. Modification of Poly(lactic acid)/Poly(butylene adipate-co-terephthalate) Blends by Reactive Extrusion Process. Materials. 2021; 14(6):1523. https://doi.org/10.3390/ma14061523

Chicago/Turabian StyleAndrzejewski, Jacek, and Michał Nowakowski. 2021. "Development of Toughened Flax Fiber Reinforced Composites. Modification of Poly(lactic acid)/Poly(butylene adipate-co-terephthalate) Blends by Reactive Extrusion Process" Materials 14, no. 6: 1523. https://doi.org/10.3390/ma14061523

APA StyleAndrzejewski, J., & Nowakowski, M. (2021). Development of Toughened Flax Fiber Reinforced Composites. Modification of Poly(lactic acid)/Poly(butylene adipate-co-terephthalate) Blends by Reactive Extrusion Process. Materials, 14(6), 1523. https://doi.org/10.3390/ma14061523