Formation, Structure and Magnetic Properties of MFe2O4@SiO2 (M = Co, Mn, Zn, Ni, Cu) Nanocomposites

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

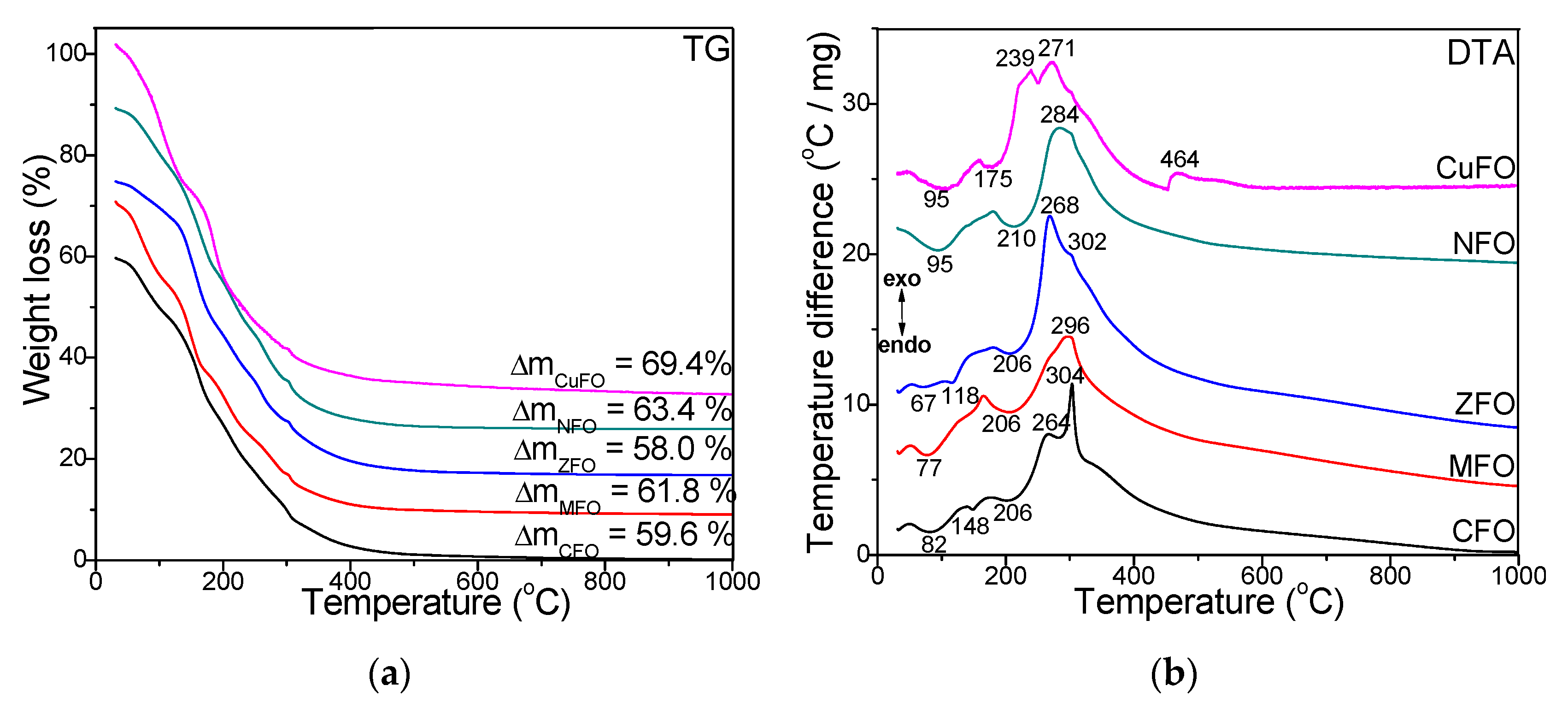

3.1. Thermal Analysis

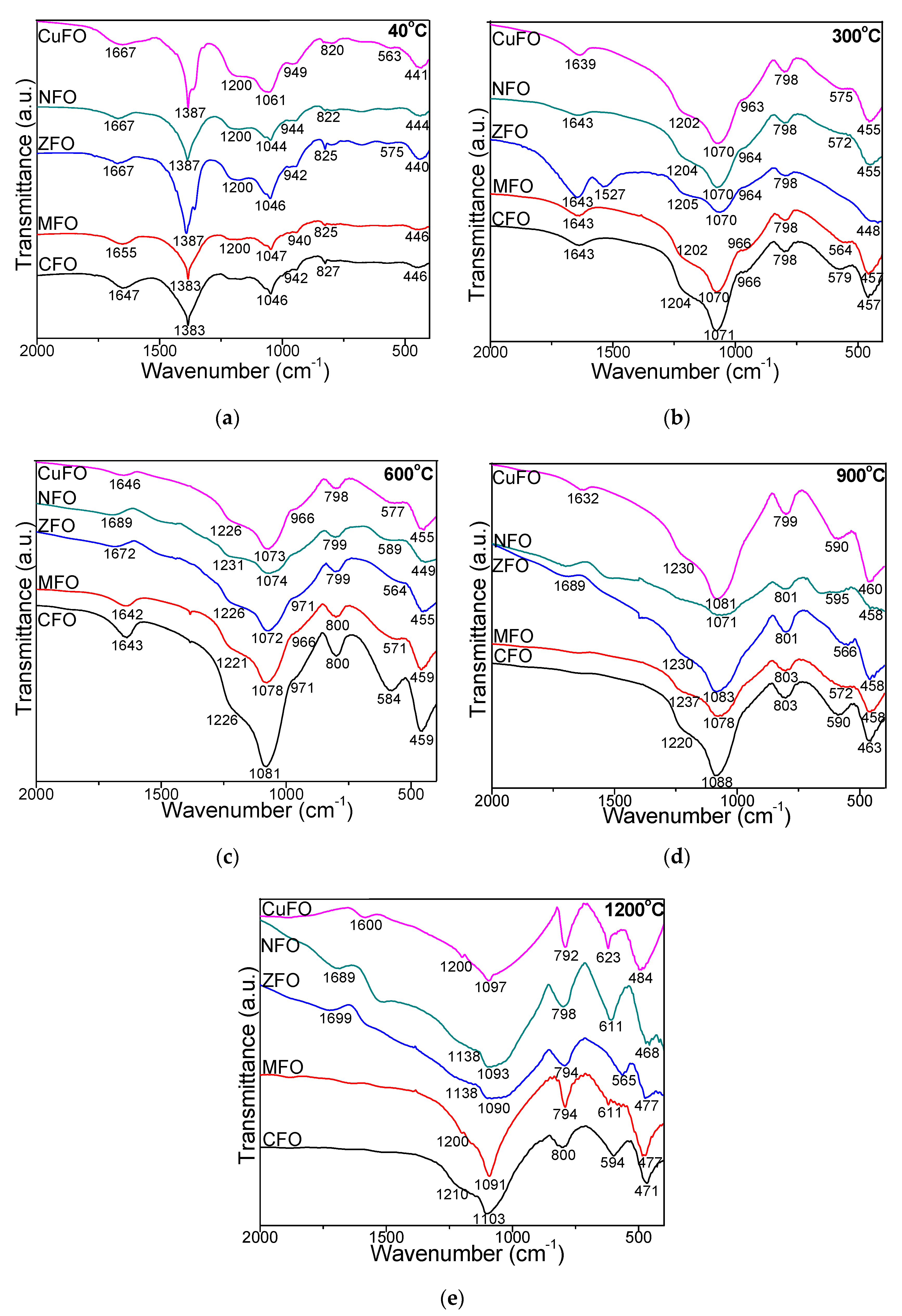

3.2. FT-IR Analysis

3.3. Chemical Analysis

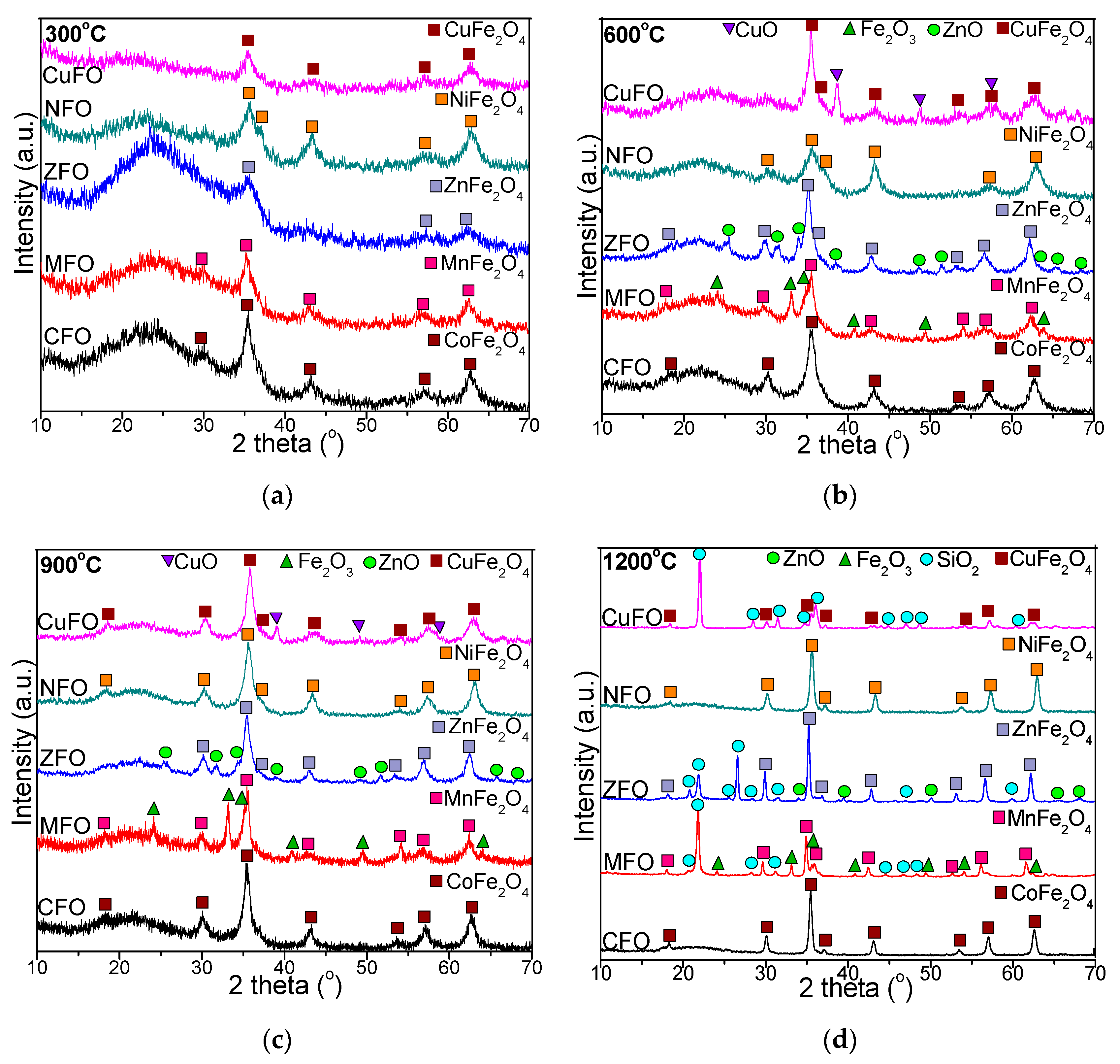

3.4. XRD Analysis

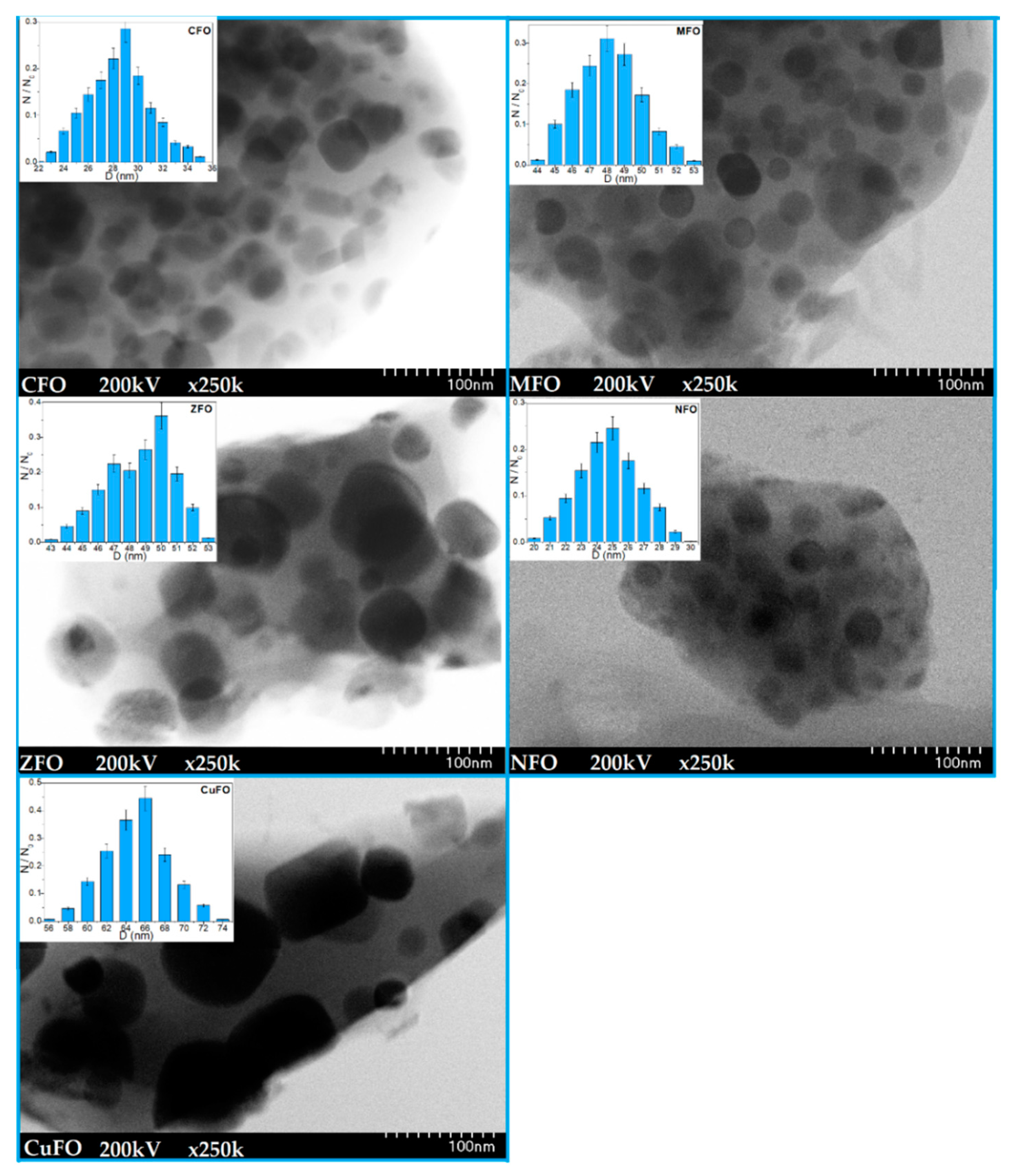

3.5. Transmission Electron Microscopy

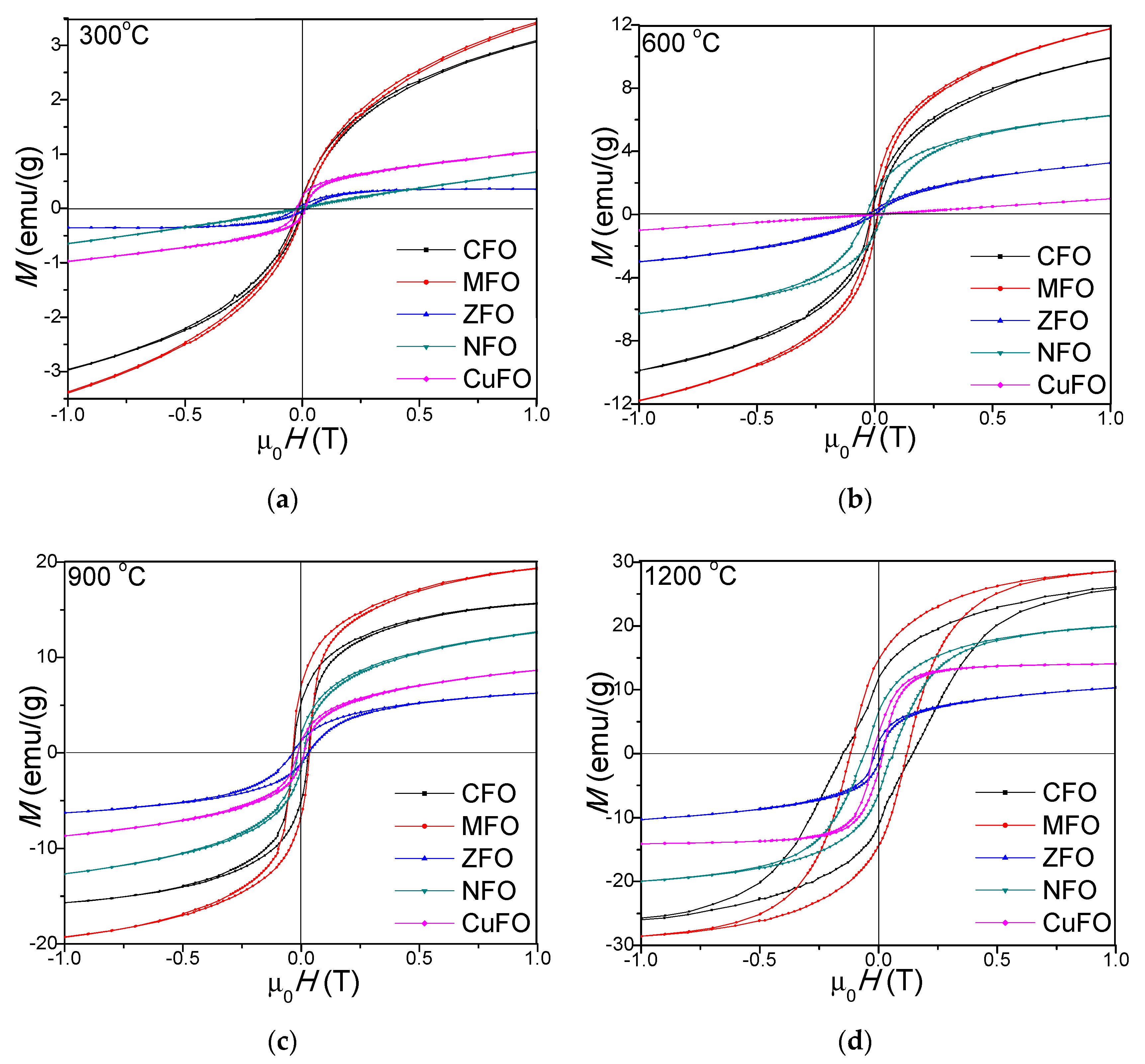

3.6. Magnetic Behavior

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Mylarappa, M.; Venkata, L.V.; Vishnu, M.K.R.; Raghavendra, N.; Nagaswarupa, H.P. Cyclic voltammetry, im-pedance and thermal properties of CoFe2O4 obtained from waste Li-Ion batteries. Mater. Today Proc. 2018, 5, 22425–22432. [Google Scholar] [CrossRef]

- Dippong, T.; Levei, E.A.; Lengauer, C.L.; Daniel, A.; Toloman, D.; Cadar, O. Investigation of thermal, structural, morphological and photocatalytic properties of CuxCo1−xFe2O4 nanoparticles embedded in SiO2 matrix. Mater. Charact. 2020, 163. [Google Scholar] [CrossRef]

- Xiong, Q.Q.; Tu, J.P.; Shi, S.J.; Liu, X.J.; Wang, X.L.; Gu, C.D. Ascorbic acid-assisted synthesis of cobalt ferrite (CoFe2O4) hier-archical flower-like microspheres with enhanced lithium storage properties. J. Power Sources 2014, 256, 153–159. [Google Scholar] [CrossRef]

- Shetty, K.; Renuka, L.; Nagaswarupa, H.; Nagabhushana, H.; Anantharaju, K.; Rangappa, D.; Prashantha, S.; Ashwini, K. A comparative study on CuFe2O4, ZnFe2O4 and NiFe2O4: Morphology, Impedance and Photocatalytic studies. Mater. Today Proc. 2017, 4, 11806–11815. [Google Scholar] [CrossRef]

- Asghar, K.; Qasim, M.; Das, D. Preparation and characterization of mesoporous magnetic MnFe2O4@mSiO2 nanocomposite for drug delivery application. Mater. Today Proc. 2020, 26, 87–93. [Google Scholar] [CrossRef]

- Chand, P.; Vaish, S.; Kumar, P. Structural, optical and dielectric properties of transition metal (MFe2O4; M = Co, Ni and Zn) nanoferrites. Phys. B Condens. Matter 2017, 524, 53–63. [Google Scholar] [CrossRef]

- Revathi, J.; Abel, M.J.; Archana, V.; Sumithra, T.; Thiruneelakandan, R.; Prince, J.J. Synthesis and characterization of CoFe2O4 and Ni-doped CoFe2O4 nanoparticles by chemical Co-precipitation technique for photo-degradation of organic dyestuffs under direct sunlight. Phys. B Condens. Matter 2020, 587. [Google Scholar] [CrossRef]

- Amulya, M.S.; Nagaswarupa, H.; Kumar, M.A.; Ravikumar, C.; Kusuma, K.; Prashantha, S. Evaluation of bifunctional applications of CuFe2O4 nanoparticles synthesized by a sonochemical method. J. Phys. Chem. Solids 2021, 148. [Google Scholar] [CrossRef]

- Wang, L.; Lu, M.; Liu, Y.; Li, J.; Liu, M.; Li, H. The structure, magnetic properties and cation distribution of Co1−xMgxFe2O4/SiO2 nanocomposites synthesized by sol–gel method. Ceram. Int. 2015, 41, 4176–4181. [Google Scholar] [CrossRef]

- Sarkar, K.; Mondal, R.; Dey, S.; Kumar, S. Cation vacancy and magnetic properties of ZnFe2O4 microspheres. Phys. B Condens. Matter 2020, 583. [Google Scholar] [CrossRef]

- Philipse, A.P.; van Bruggen, M.P.B.; Pathmamanoharan, C. Magnetic silica dispersions: Preparation and stability of sur-face-modified silica particles with a magnetic core. Lengmuir 1994, 10, 92–99. [Google Scholar] [CrossRef]

- Vestal, C.R.; Zhang, Z.J. Synthesis and Magnetic Characterization of Mn and Co Spinel Ferrite-Silica Nanoparticles with Tunable Magnetic Core. Nano Lett. 2003, 3, 1739–1743. [Google Scholar] [CrossRef]

- El Mendili, Y.; Bardeau, J.F.; Grasset, F.; Greneche, J.M.; Cador, O.; Guizouarn, T.; Randrianantoandro, N. Magnetic interac-tions in γ-Fe2O3@SiO2 nanocomposites. J. Appl. Phys. 2014, 116. [Google Scholar] [CrossRef]

- Tago, T.; Hatsuta, T.; Miyajima, K.; Kishida, M.; Tashiro, S.; Wakabayashi, K. Novel synthesis of silica-coated ferrite nano-particles prepared using water-in-oil microemulsion. J. Am. Ceram. Soc. 2002, 85, 2188–2194. [Google Scholar] [CrossRef]

- Iqbal, M.J.; Yaqub, N.; Sepiol, B.; Ismail, B. A study of the influence of crystallite size on the electrical and magnetic properties of CuFe2O4. Mater. Res. Bull. 2011, 46, 1837–1842. [Google Scholar] [CrossRef]

- Li, X.; Sun, Y.; Zong, Y.; Wei, Y.; Liu, X.; Li, X.; Peng, Y.; Zheng, X. Size-effect induced cation redistribution on the magnetic properties of well-dispersed CoFe2O4 nanocrystals. J. Alloys Compd. 2020, 841. [Google Scholar] [CrossRef]

- Mohanty, D.; Satpathy, S.K.; Behera, B.; Mohapatra, R.K. Dielectric and frequency dependent transport properties in mag-nesium doped CuFe2O4 composite. Mater. Today Proc. 2020, 33, 5226–5231. [Google Scholar] [CrossRef]

- Sivakumar, P.; Ramesh, R.; Ramanand, A.; Ponnusamy, S.; Muthamizhchelvan, C. Synthesis and characterization of NiFe2O4 nanoparticles and nanorods. J. Alloys Compd. 2013, 563, 6–11. [Google Scholar] [CrossRef]

- Ozçelik, B.; Ozçelik, S.; Amaveda, H.; Santos, H.; Borrell, C.J.; Puche, S.R.; de la Fuente, G.F.; Angurel, L.A. High speed processing of NiFe2O4 spinel using laser furnance. J. Mater. 2020, 6, 661–670. [Google Scholar]

- Majid, F.; Rauf, J.; Ata, S.; Bibi, I.; Malik, A.; Ibrahim, S.M.; Ali, A.; Iqbal, M. Synthesis and characterization of NiFe2O4 ferrite: Sol–gel and hydrothermal synthesis routes effect on magnetic, structural and dielectric characteristics. Mater. Chem. Phys. 2021, 258. [Google Scholar] [CrossRef]

- Junlabhut, P.; Nuthongkum, P.; Pechrapa, W. Influences of calcination temperature on structural properties of MnFe2O4 nanopowders synthesized by co-precipitation method for reusable absorbent materials. Mater. Today Proc. 2018, 5, 13857–13864. [Google Scholar] [CrossRef]

- Sivakumar, A.; Dhas, S.S.J. Assessment of crystallographic and magnetic phase stabilities on MnFe2O4 nano crystalline materials at shocked conditions. Solid State Sci. 2020, 107. [Google Scholar] [CrossRef]

- Ge, Y.C.; Wang, Z.L.; Yi, M.Z.; Ran, L.P. Fabrication and magnetic transformation from paramagnetic to ferrimagnetic of ZnFe2O4 hollow spheres. Trans. Nonferrous Met. Soc. China 2019, 29, 1503–1509. [Google Scholar] [CrossRef]

- Kremenović, A.; Antić, B.; Vulić, P.; Blanuša, J.; Tomic, A. ZnFe2O4 antiferromagnetic structure redetermination. J. Magn. Magn. Mater. 2017, 426, 264–266. [Google Scholar] [CrossRef]

- Boucher, B.; Buhl, R.; Perrin, P. Structure magnetique du spinelle antiferromagnetique ZnFe2O4. Phys. State Sol. 1970, 40, 171–182. [Google Scholar] [CrossRef]

- Gharibshahian, M.; Mirzae, O.; Nourbakhsh, M.S. Evaluation of superparamagnetic and biocompatible properties of meso-porous silica coated cobalt ferrite nanoparticles synthesized via microwave modified Pechini method. J. Magn. Magn. Mater. 2017, 425, 48–56. [Google Scholar] [CrossRef]

- El Mendili, Y.; Bardeau, J.F.; Randrianantoandro, N.; Greneche, J.M.; Grasset, F. Structural behavior of laser-irradiated γ-Fe2O3 nanocrystals dispersed in porous silica matrix: γ-Fe2O3 to α-Fe2O3 phase transition and formation of ε-Fe2O3. Sci. Technol. Adv. Mater. 2016, 17, 597–609. [Google Scholar] [CrossRef]

- Dippong, T.; Cadar, O.; Levei, E.A.; Deac, I.G.; Borodi, G. Formation of CoFe2O4/PVA-SiO2 nanocomposites: Effect of diol chain length on the structure and magnetic properties. Ceram. Int. 2018, 44, 10478–10485. [Google Scholar] [CrossRef]

- Dippong, T.; Levei, E.A.; Deac, I.G.; Neag, E.; Cadar, O. Influence of Cu2+, Ni2+ and Zn2+ ions doping on the structure, mor-phology and magnetic properties of Co-ferrite embedded in SiO2 matrix obtained by an innovative sol-gel route. Nanomaterials 2020, 10, 580. [Google Scholar] [CrossRef]

- Dippong, T.; Levei, E.A.; Cadar, O. Preparation of CoFe2O4/SiO2 Nanocomposites at Low Temperatures Using Short Chain Diols. J. Chem. 2017, 2017, 1–11. [Google Scholar] [CrossRef]

- Aparna, M.L.; Grace, A.N.; Sathyanarayanan, P.; Sahu, N.K. A comparative study on supercapacitive behavior of sol-votermally prepared metal ferrite (MFe2O4, M=Fe, Co, Ni, Mn, Cu, Zn) nanoassemblies. J. Alloy Comp. 2018, 745, 385–395. [Google Scholar] [CrossRef]

- Joint Committee on Powder Diffraction Standards. International Center for Diffraction Data; ASTM: Philadelphia, PA, USA, 1999. [Google Scholar]

- Routray, K.L.; Saha, S.; Behera, D. Nanosized CoFe2O4-graphene nanoplatelets with massive dielectric enhancement for high frequency device application. Mater. Sci. Eng. B 2020, 257, 4548. [Google Scholar] [CrossRef]

- Yadav, S.P.; Shinde, S.S.; Bhatt, P.; Meena, S.S.; Rajpure, K.Y. Distribution of cations in Co1−xMnxFe2O4 using XRD, magneti-zation and Mossbauer spectroscopy. J. Alloys Comp. 2015, 646, 550–556. [Google Scholar] [CrossRef]

- Stefanescu, M.; Stoia, M.; Dippong, T.; Stefanescu, O.; Barvinschi, P. Preparation of CoXFe3−XO4 Oxydic System Starting from Metal Nitrates and Propanediol. Acta Chim. Slov. 2009, 56, 379–385. [Google Scholar]

- Dippong, T.; Cadar, O.; Levei, E.A.; Deac, I.G. Microstructure, porosity and magnetic properties of Zn0.5Co0.5Fe2O4/SiO2 nanocomposites prepared by sol-gel method using different polyols. J. Magn. Magn. Mater. 2020, 498, 166168. [Google Scholar] [CrossRef]

- Barvinschi, P.; Stefanescu, O.; Dippong, T.; Sorescu, S.; Stefanescu, M. CoFe2O4/SiO2 nanocomposites by thermal decomposi-tion of some complex combinations embedded in hybrid silica gels. J. Therm. Anal. Calorim. 2013, 112, 447–453. [Google Scholar] [CrossRef]

- Lemine, O.; Bououdina, M.; Sajieddine, M.; Saie, A.A.; Shafi, M.; Khatab, A.; Hilali, A.M.; Henini, M. Synthesis, structural, magnetic and optical properties of nanocrystalline ZnFe2O4. Phys. B Condens. Matter 2011, 406, 1989–1994. [Google Scholar] [CrossRef]

- Sontu, U.B.; Rao, N.G.; Chou, F.C.; Reddy, V.R.M. Temperature dependent and applied field strength dependent magnetic study of cobalt nickel ferrite nano particles: Synthesized by an environmentally benign method. J. Magn. Magn. Mater. 2018, 452, 398–406. [Google Scholar] [CrossRef]

- Ashour, A.; Batal, E.A.I.; Maksoud, M.A.; Sayyad, E.G.S.; Labib, S.; Abdeltwab, E.; Okr, E.M. Antimicrobial activity of metal-substituted cobalt ferrite nanoparticles synthesized by sol-gel technique. Particuology 2018, 40, 141–151. [Google Scholar] [CrossRef]

- Atif, M.; Turtelli, R.S.; Grössinger, R.; Siddique, M.; Nadeem, M. Effect of Mn substitution on the cation distribution and tem-perature dependence of magnetic anisotropy constant in Co1−xMnxFe2O4 (0.0f ct of of Okr). Ceram. Int. 2014, 40, 471–748. [Google Scholar] [CrossRef]

- Ati, A.A.; Othaman, Z.; Samavati, A. Influence of cobalt on structural and magnetic properties of nickel ferrite nanoparticles. J. Mol. Struct. 2013, 1052, 177–182. [Google Scholar] [CrossRef]

- Grasset, F.; Labhsetwar, N.; Li, D.; Park, D.C.; Saito, N.; Haneda, H.; Cador, O.; Roisnel, T.; Mornet, S.; Duguet, E.; et al. Synthesis and Magnetic Characterization of Zinc Ferrite Nanoparticles with Different Environments: Powder, Colloidal Solution, and Zinc Ferrite−Silica Core−Shell Nanoparticles. Langmuir 2002, 18, 8209–8216. [Google Scholar] [CrossRef]

- Salunkhe, A.B.; Khot, V.M.; Phadatare, M.R.; Thorat, N.D.; Joshi, R.S.; Yadav, H.M.; Pawar, S.H. Low temperature combus-tion synthesis and magnetostructural properties of Co-Mn nanoferrites. J. Magn. Magn. Mater. 2014, 352, 91–98. [Google Scholar] [CrossRef]

- Jia, Z.; Ren, D.; Zhi, R. Synthesis, characterization and magnetic properties of CoFe2O4 nanorods. Mater. Lett. 2012, 66, 128–131. [Google Scholar] [CrossRef]

- Sontu, U.B.; Yelasani, V.; Musugu, V.R.R. Structural, electrical and magnetic characteristics of nickel substituted cobalt ferrite nanoparticles, synthesized by self-combustion method. J. Magn. Magn. Mater. 2015, 374, 376–380. [Google Scholar] [CrossRef]

- Shakil, M.; Inayat, U.; Arshad, M.; Nabi, G.; Khalid, N.; Tariq, N.; Shah, A.; Iqbal, M. Influence of zinc and cadmium co-doping on optical and magnetic properties of cobalt ferrites. Ceram. Int. 2020, 46, 7767–7773. [Google Scholar] [CrossRef]

- Dar, M.; Varshney, D. Effect of d-block element Co2+ substitution on structural, Mössbauer and dielectric properties of spinel copper ferrites. J. Magn. Magn. Mater. 2017, 436, 101–112. [Google Scholar] [CrossRef]

- Kombaiah, K.; Vijaya, J.J.; Kennedy, L.J.; Bououdina, M.; Al-Najar, B. Conventional and microwave combustion synthesis of optomagnetic CuFe2O4 nanoparticles for hyperthermia studies. J. Phys. Chem. Solids 2018, 115, 162–171. [Google Scholar] [CrossRef]

- Varma, P.R.; Manna, R.S.; Banerjee, D.; Varma, M.R.; Suresh, K.; Nigam, A. Magnetic properties of CoFe2O4 synthesized by solid state, citrate precursor and polymerized complex methods: A comparative study. J. Alloys Compd. 2008, 453, 298–303. [Google Scholar] [CrossRef]

- Alarifi, A.; Deraz, N.; Shaban, S. Structural, morphological and magnetic properties of NiFe2O4 nano-particles. J. Alloys Compd. 2009, 486, 501–506. [Google Scholar] [CrossRef]

- Shanmugavel, T.; Raj, S.G.; Rajarajan, G.; Kumar, G.R. Tailoring the Structural and Magnetic Properties and of Nickel Ferrite by Auto Combustion Method. Procedia Mater. Sci. 2014, 6, 1725–1730. [Google Scholar] [CrossRef]

- Singh, A.; Pathak, S.; Kumar, P.; Sharma, P.; Rathi, A.; Basheed, G.; Maurya, K.; Pant, R. Tuning the magnetocrystalline anisotropy and spin dynamics in CoxZn1-xFe2O4 (0 ≤ x ≤ 1) nanoferrites. J. Magn. Magn. Mater. 2020, 493. [Google Scholar] [CrossRef]

- Chen, Z.H.; Sun, Y.P.; Kang, Z.T.; Chen, D. Preparation of ZnxCo1−xFe2O4 nanoparticles by microwave-assisted ball milling. Ceram. Int. 2014, 40, 14687–14692. [Google Scholar] [CrossRef]

| Temperature (°C) | Co/Fe | Mn/Fe | Zn/Fe | Ni/Fe | Cu/Fe |

|---|---|---|---|---|---|

| 300 | 0.99/2.01 | 0.97/2.03 | 0.99/2.01 | 0.97/2.03 | 0.96/2.04 |

| 600 | 0.98/2.02 | 0.97/2.03 | 0.99/2.01 | 0.98/2.03 | 0.97/2.03 |

| 900 | 0.99/2.01 | 0.98/2.02 | 1.00/2.00 | 0.99/2.01 | 0.98/2.02 |

| 1200 | 1.00/2.00 | 0.99/2.01 | 1.00/2.00 | 0.99/2.01 | 1.00/2.00 |

| NC | Temperature (°C) | CFO | MFO | ZFO | NFO | CuFO |

|---|---|---|---|---|---|---|

| DPS (nm) | 1200 | 29 | 48 | 50 | 25 | 65 |

| DCS (nm) | 300 600 900 1200 | 7 11 18 28 | 6 15 33 45 | 4 11 21 49 | 3 8 10 23 | 9 20 38 60 |

| a (Å) | 300 600 900 1200 | 8.223 8.271 8.367 8.438 | 8.331 8.391 8.434 8.484 | 8.324 8.365 8.380 8.427 | 8.319 8.356 8.363 8.382 | 8.123 8.174 8.214 8.246 |

| Ms (emu/g) | 300 600 900 1200 | 3.5 9.8 15.6 26.3 | 3.6 11.7 19.4 28.5 | 0.7 3.3 6.1 10.8 | 0.7 6.3 12.7 20.1 | 1.1 1.3 8.6 14.5 |

| MR (emu/g) | 300 600 900 1200 | 0.25 0.97 5.10 11.96 | 0.26 1.39 6.66 14.83 | 0.07 0.31 1.23 1.67 | 0.03 1.19 1.36 6.82 | 0.23 0.03 0.92 3.03 |

| Hc (T) | 300 600 900 1200 | 0.015 0.016 0.031 0.144 | 0.017 0.018 0.035 0.119 | 0.013 0.003 0.025 0.015 | 0.016 0.024 0.026 0.061 | 0.009 0.032 0.019 0.018 |

| K·103 (erg/cm3) | 300 600 900 1200 | 0.033 0.098 0.304 2.378 | 0.038 0.132 0.426 3.392 | 0.005 0.006 0.096 0.102 | 0.007 0.094 0.207 0.770 | 0.006 0.028 0.103 0.163 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dippong, T.; Levei, E.A.; Cadar, O. Formation, Structure and Magnetic Properties of MFe2O4@SiO2 (M = Co, Mn, Zn, Ni, Cu) Nanocomposites. Materials 2021, 14, 1139. https://doi.org/10.3390/ma14051139

Dippong T, Levei EA, Cadar O. Formation, Structure and Magnetic Properties of MFe2O4@SiO2 (M = Co, Mn, Zn, Ni, Cu) Nanocomposites. Materials. 2021; 14(5):1139. https://doi.org/10.3390/ma14051139

Chicago/Turabian StyleDippong, Thomas, Erika Andrea Levei, and Oana Cadar. 2021. "Formation, Structure and Magnetic Properties of MFe2O4@SiO2 (M = Co, Mn, Zn, Ni, Cu) Nanocomposites" Materials 14, no. 5: 1139. https://doi.org/10.3390/ma14051139

APA StyleDippong, T., Levei, E. A., & Cadar, O. (2021). Formation, Structure and Magnetic Properties of MFe2O4@SiO2 (M = Co, Mn, Zn, Ni, Cu) Nanocomposites. Materials, 14(5), 1139. https://doi.org/10.3390/ma14051139