Eco-Friendly Fired Brick Produced from Industrial Ash and Natural Clay: A Study of Waste Reuse

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

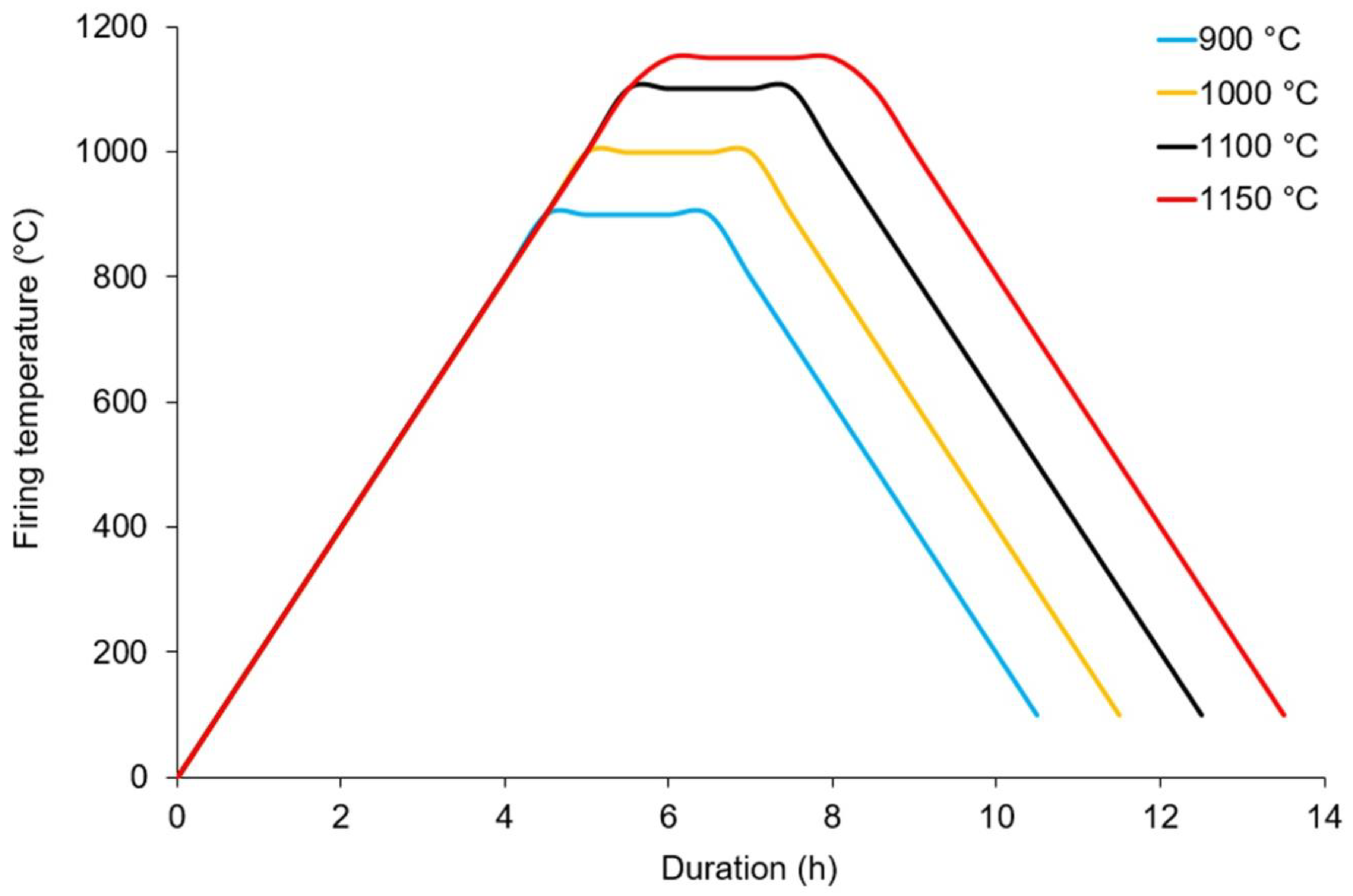

2.2. Methods

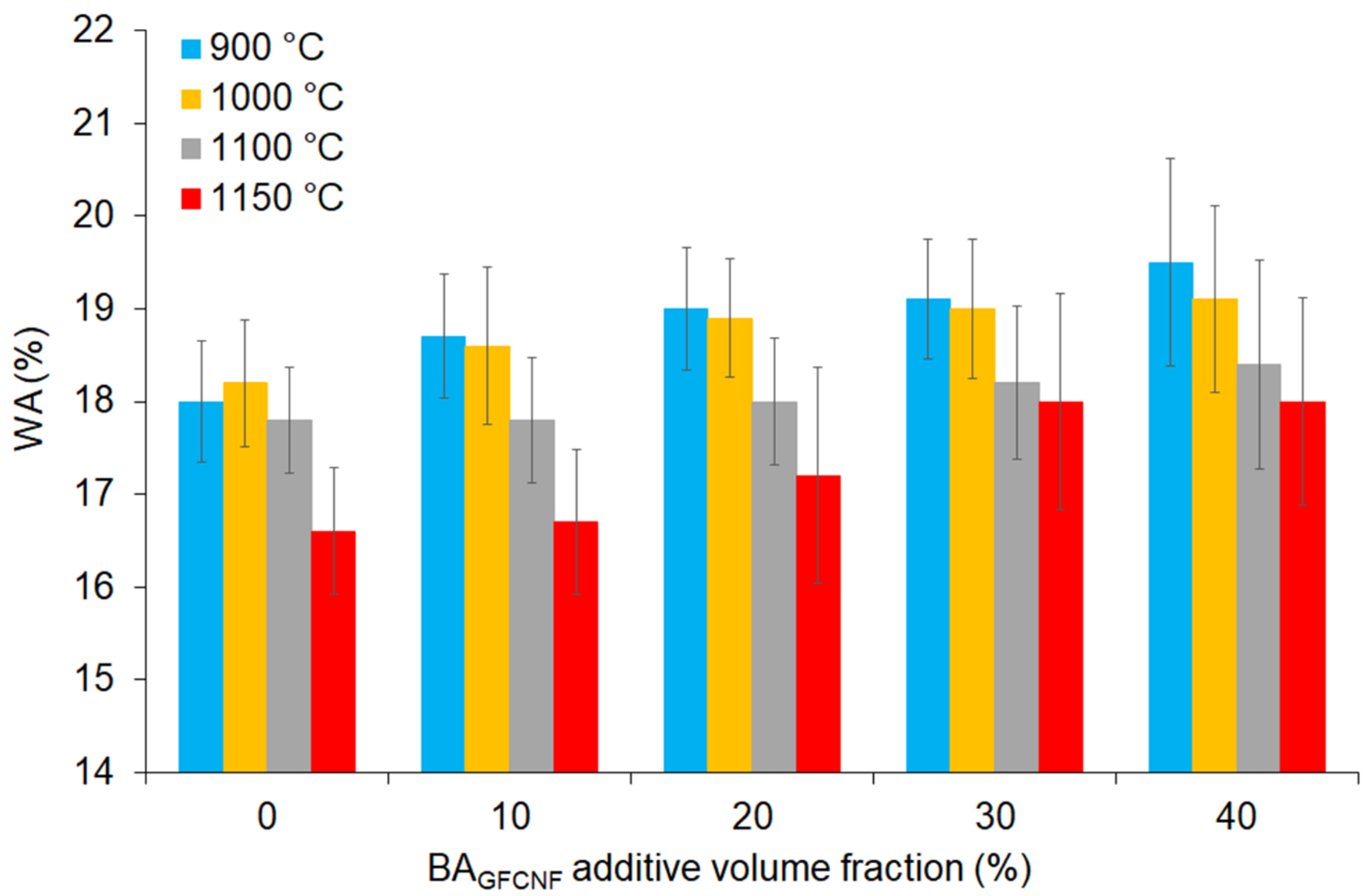

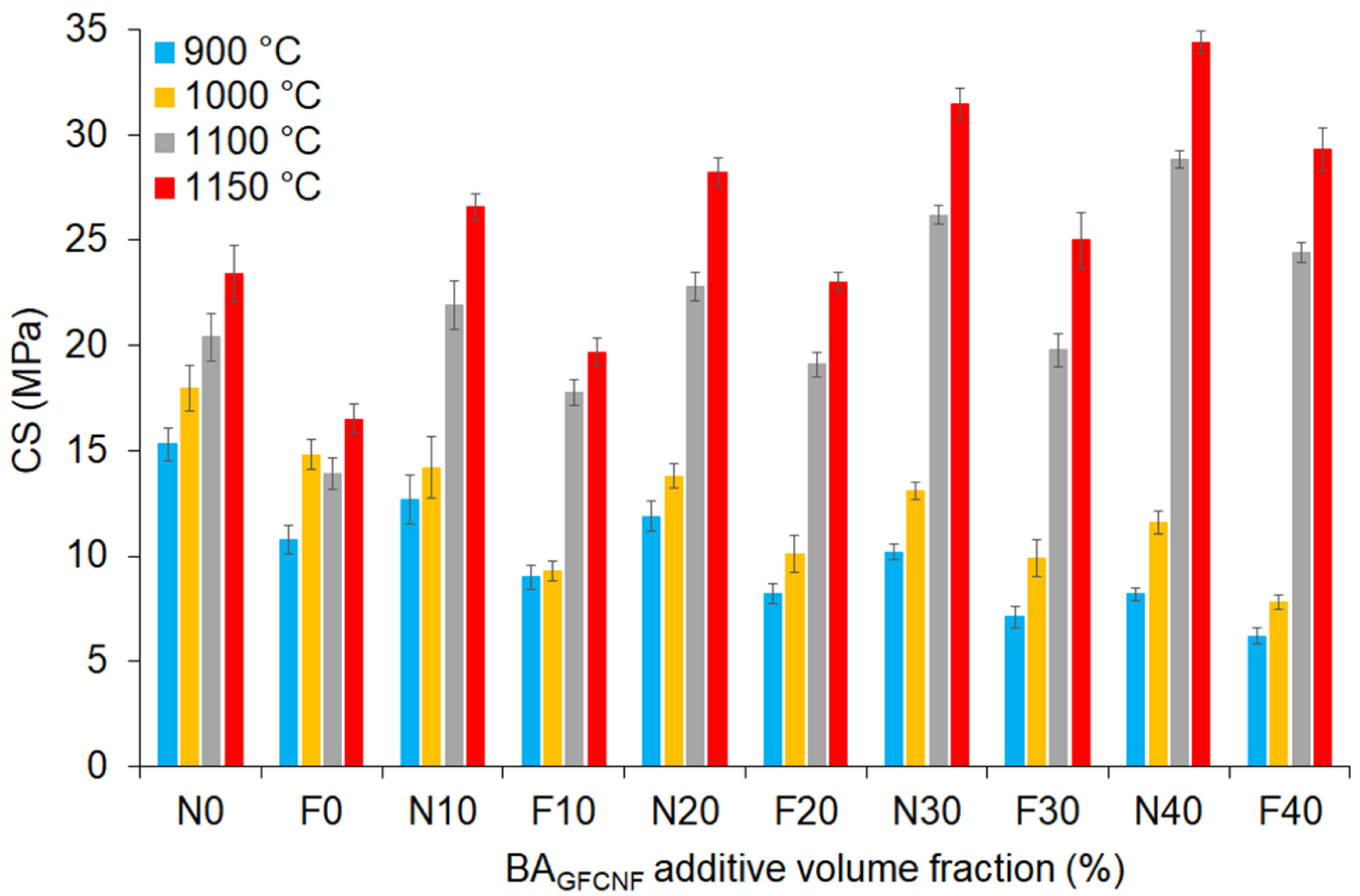

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yazıcı, H. Termik Santral Atığı Yapay Alçı-Uçucu Kül-Taban Külü Esaslı Yapı Malzemesi Geliştirilmesi. Ph.D. Thesis, Graduate School of Natural and Applied Sciences, Dokuz Eylül University, İzmir, Turkey, 2004. (in Turkish). [Google Scholar]

- Hamada, H.M.; Jokhio, G.A.; Al-Attar, A.A.; Yahaya, F.M.; Muthusamy, K.; Humada, A.M.; Gul, Y. The use of palm oil clinker as a sustainable construction material: A review. Cem. Concr. Compos. 2020, 106, 103447. [Google Scholar] [CrossRef]

- Chore, H.S.; Joshi, M.P. Strength characterization of concrete using industrial waste as cement replacing materials for rigid pavement. Innov. Infrastruct. Solut. 2020, 5, 78. [Google Scholar] [CrossRef]

- Palankar, N.; Shankar, A.U.R.; Mithun, B.M. Studies on eco-friendly concrete incorporating industrial waste as aggregates. Int. J. Sustain. Built Environ. 2015, 4, 378–390. [Google Scholar] [CrossRef]

- Raut, S.P.; Ralegaonkar, R.V.; Mandavgane, S.A. Development of sustainable construction material using industrial and agricultural solid waste: A review of waste-create bricks. Constr. Build. Mater. 2011, 25, 4037–4042. [Google Scholar] [CrossRef]

- Devlet Planlama Teşkilatı (DPT) Sekizinci Beş Yıllık Kalkınma Planı Madencilik Özel Ihtisas Komisyonu Raporu. In Endüstriyel Hammaddeler alt Komisyonu Toprak Sanayi Hammaddeleri (Çimento Hammaddeleri) Çalışma Grubu Raporu; State Planning Organisation (DPT): Ankara, Turkey, 2001. (in Turkish)

- Aouba, L.; Coutand, M.; Perrin, B. Predicting thermal performance of fired clay bricks lightened by adding organic matter: Improvement of brick geometry. J. Build. Phys. 2015, 38, 531–547. [Google Scholar] [CrossRef]

- Metz, B. Intergovernmental Panel on Climate Change. Climate Change 2001: Mitigation; Cambridge University Press: Cambridge, UK, 2001. [Google Scholar]

- Munoz, P.; Morales, M.P.; Mendivil, M.A.; Juarez, M.C.; Munoz, L. Using of waste pumice from winery industry to improve thermal insulation of fired clay bricks. Eco-friendly way of building construction. Constr. Build. Mater. 2014, 71, 181–187. [Google Scholar] [CrossRef]

- Wouter, P. Energy Performance of Building: Assessment of Innovative Technologies; Final Report; ENPER-TEBUC: Watford, UK, 2004. [Google Scholar]

- Çiçek, T.; Tanrıverdi, M. Kömüre Dayalı Termik Santral Uçucu Küllerinden Otoklav Yöntemi ile Hafif Tuğla Üretimi. In Proceedings of the 5th Industrial Raw Materials Symposium, İzmir, Turkey, 13–14 May 2004; pp. 76–82. (in Turkish). [Google Scholar]

- Kızgut, S.; Çuhadaroğlu, D.; Çolak, K. Çatalağzı Termik Santralı Uçucu Küllerinden Tuğla Üretim Olanaklarının Araştırılması. In Proceedings of the Türkiye 17th Mining Congress and Exhibition/TUMAKS, Ankara, Turkey, 19–22 June 2001; pp. 395–416. (in Turkish). [Google Scholar]

- Bai, Y.; Darcy, F.; Basheer, P.A.M. Strength and drying shrinkage properties of concrete containing furnace bottom ash as fine aggregate. Constr. Build. Mater. 2005, 19, 691–697. [Google Scholar] [CrossRef]

- Yüksel, İ.; Özkan, Ö.; Bilir, T. Kazan altı külü ile briket üretimi. Gazi Ünv. Müh. Mim. Fak. Dergisi 2006, 21, 527–532. (in Turkish). [Google Scholar]

- Bentli, İ.; Uyanık, A.O.; Demir, U.; Şahbaz, O. Seyitömer Termik Santrali Uçucu Küllerinin Tuğla Katkı Hammaddesi Olarak Kullanımı. In Proceedings of the Türkiye 19th Mining Congress and Exhibition/IMCET, İzmir, Turkey, 9–12 June 2005; pp. 385–389. (in Turkish). [Google Scholar]

- Lingling, X.; Wei, G.; Tao, W.; Nanru, Y. Study on firebricks with replacing clay by fly ash in high volume ratio. Constr. Build. Mater. 2005, 19, 243–247. [Google Scholar] [CrossRef]

- Topçu, İ.B.; Işıkdağ, B. Manufacture of high heat conductivity resistant clay bricks containing perlite. Build. Environ. 2007, 42, 3540–3546. [Google Scholar] [CrossRef]

- Demir, İ. Effect of organic residues addition on the technological properties of clay bricks. Waste Manag. 2008, 28, 622–627. [Google Scholar] [CrossRef]

- Zhang, L. Production of bricks from waste materials-A review. Constr. Build. Mater. 2013, 47, 643–655. [Google Scholar] [CrossRef]

- Sutcu, M.; Akkurt, S. The use of recycled paper processing residue in making porous brick with reduced thermal conductivity. Ceram. Int. 2009, 35, 2625–2631. [Google Scholar] [CrossRef]

- Kadir, A.A.; Mohajerani, A.; Roddick, F.; Buckeridge, J. Density, strength, thermal conductivity and leachate characteristics of light-weight fired clay bricks incorporating cigarette butts. World Acad. Sci. Eng. Technol. 2009, 53, 1035–1040. [Google Scholar]

- Rahman, M.A. Properties of clay-sand-rice husk ash mixed bricks. Int. J. Cem. Compos. Lightweight Concr. 1987, 9, 105–118. [Google Scholar] [CrossRef]

- Gürhan, G.; Simsek, O. Porous clay bricks manufactured with rice husks. Constr. Build. Mater. 2013, 40, 390–396. [Google Scholar] [CrossRef]

- Demir, İ.; Baspinar, M.S.; Orhan, M. Utilization of Kraft pulp production residues in clay brick production. Build. Environ. 2005, 40, 1533–1547. [Google Scholar] [CrossRef]

- Demir, İ. An investigation on the production of construction brick with processed waste tea. Build. Environ. 2006, 41, 1274–1288. [Google Scholar] [CrossRef]

- Bachir, C.; Halima, C. Effect of adding sawdust on mechanical-physical properties of ceramic bricks to obtain lightweight building material. World Acad. Sci. Eng. Technol. 2012, 71, 1608–1612. [Google Scholar]

- Velasco, P.M.; Ortiz, M.P.M.; Giró, M.A.M.; Melia, D.M.; Rehbein, J.H. Development of sustainable fired clay bricks by adding kindling from vine shoot: Study of thermal and mechanical properties. Appl. Clay Sci. 2015, 107, 156–164. [Google Scholar] [CrossRef]

- Saiah, R.; Perrin, B.; Rigal, L. Improvement of thermal properties of fired clays by introduction of vegetable matter. J. Build. Phys. 2010, 34, 124–142. [Google Scholar] [CrossRef]

- Chan, C.M. Effects of natural fibres inclusion in clay bricks: Physicomechanical properties. Int. J. Civ. Environ. Eng. 2011, 3, 51–57. [Google Scholar]

- Faria, K.C.P.; Gurgel, R.F.; Holanda, J.N.F. Recycling of sugarcane bagasse ash waste in the production of clay bricks. J. Environ. Manag. 2012, 101, 7–12. [Google Scholar] [CrossRef]

- Aouba, L.; Bories, C.; Coutand, M.; Perrin, B.; Lemercier, H. Properties of fired clay bricks with incorporated biomasses: Cases of olive stone flour and wheat straw residues. Constr. Build. Mater. 2016, 102, 7–13. [Google Scholar] [CrossRef]

- Nkayem, D.E.N.; Mbey, J.A.; Kenne Diffo, B.B.; Njopwouo, D. Preliminary study on the use of corn cob as pore forming agent in lightweight clay bricks: Physical and mechanical features. J. Build. Eng. 2016, 5, 254–259. [Google Scholar] [CrossRef]

- Mohammed, M.S.; Ahmed, S.I.; Osman, R.M.; Khattab, I. Combinations of organic and inorganic wastes for brick production. Polym. Compos. 2014, 35, 174–179. [Google Scholar] [CrossRef]

- Leiva, C.; Arenas, C.; Alonso-Fariñas, B.; Vilches, L.F.; Peceño, B.; Rodriguez-Galán, M.; Baena, F. Characteristics of fired bricks with co-combustion fly ashes. J. Build. Eng. 2016, 5, 114–118. [Google Scholar] [CrossRef]

- Basha, S.H.; Kaushik, H.B. Suitability of fly ash brick masonry as infill in reinforced concrete frames. Mater. Struct. 2016, 49, 3831–3845. [Google Scholar] [CrossRef]

- Arumugam, C.; Shaik, S. Transforming waste disposals into building materials to investigate energy savings and carbon emission mitigation potential. Environ. Sci. Pollut. Res. 2020. [Google Scholar] [CrossRef]

- Łach, M.; Mierzwiński, D.; Korniejenko, K.; Mikuła, J.; Hebda, M. Geopolymers as a material suitable for immobilization of fly ash from municipal waste incineration plants. J. Air. Waste Manag. Assoc. 2018, 68, 1190–1197. [Google Scholar] [CrossRef]

- Lin, W.-T.; Lin, K.-L.; Chen, K.; Korniejenko, K.; Hebda, M.; Lach, M. Circulation fluidized bed combustion fly ash as partial replacement of fine aggregates in roller compacted concrete. Materials 2019, 12, 4204. [Google Scholar] [CrossRef]

- Menezes, R.R.; Ferreira, H.S.; Neves, G.A.; Lira, H.L.; Ferreira, H.C. Use of granite sawing wastes in the production of ceramic bricks and tiles. J. Eur. Ceram. Soc. 2005, 27, 1149–1158. [Google Scholar] [CrossRef]

- Lin, K.L. Feasibility study of using brick made from municipal solid waste incinerator fly ash slag. J. Hazard. Mater. 2006, 137, 1810–1816. [Google Scholar] [CrossRef]

- El-Mahllawy, M.S. Characteristics of acid resisting bricks made from quarry residues and waste steel slag. Constr. Build. Mater. 2008, 22, 1887–1896. [Google Scholar] [CrossRef]

- Quijorna, N.; Coz, A.; Andres, A.; Cheeseman, C. Recycling of Waelz slag and waste foundry sand in red clay bricks. Resour. Conserv. Recycl. 2012, 65, 1–10. [Google Scholar] [CrossRef]

- Santos, P.; Martins, C.; Júlio, E. Enhancement of the thermal performance of perforated clay brick walls through the addition of industrial nano-crystalline aluminium sludge. Constr. Build. Mater. 2015, 101, 227–238. [Google Scholar] [CrossRef]

- Phonphuak, N.; Kanyakam, S.; Chindaprasirt, P. Utilization of waste glass to enhance physical and mechanical properties of fired clay brick. J. Clean. Product. 2016, 112, 3057–3062. [Google Scholar] [CrossRef]

- Gado, R.A.; Hebda, M.; Lach, M.; Mikula, J. Alkali activation of waste clay bricks: Influence of the silica modulus, SiO2/Na2O, H2O/Na2O molar ratio, and liquid/solid ratio. Materials 2020, 13, 383. [Google Scholar] [CrossRef] [PubMed]

- Łach, M.; Hebdowska-Krupa, M.; Stefańska, A.; Stefanek, J.; Stanek, A.; Mikuła, J.; Hebda, M. Characterisation of post-production raw material from the Raciszyn II deposit as a material suitable for the production of alkaline-activated materials. J. Therm. Anal. Calorim. 2019, 138, 4551–4559. [Google Scholar] [CrossRef]

- Szechyńska-Hebda, M.; Marczyk, J.; Ziejewska, C.; Hordyńska, N.; Mikuła, J.; Hebda, M. Neutral geopolymer foams reinforced with cellulose studied with the FT-Raman spectroscopy. IOP Conf. Series Mater. Sci. Eng. 2019, 706, 012017. [Google Scholar] [CrossRef]

- Szechyńska-Hebda, M.; Marczyk, J.; Ziejewska, C.; Hordyńska, N.; Mikuła, J.; Hebda, M. Optimal design of pH-neutral geopolymer foams for their use in ecological plant cultivation systems. Materials 2019, 12, 2999. [Google Scholar] [CrossRef] [PubMed]

- Beal, B.; Selby, A.; Atwater, C.; James, C.; Viens, C.; Almquist, C. A Comparison of thermal and mechanical properties of clay bricks prepared with three different pore-forming additives: Vermiculite, wood ash and sawdust. Environ. Prog. Sustain. Energy 2019, 38, 1–10. [Google Scholar] [CrossRef]

- Cobirzan, N.; Thalmaier, G.; Balog, A.A.; Constantinescu, H.; Timiş, I.; Streza, M. Thermophysical properties of fired clay bricks with waste ceramics and paper pulp as pore-forming agent. J. Therm. Anal. Calorim. 2018, 134, 843–851. [Google Scholar] [CrossRef]

- TS EN 771-1+A1 Specification for Masonry Units-Part 1: Clay Masonry Units; Türk Standardları Enstitüsü (Turkish Standards Institution): Ankara, Turkey, 2020.

- TS EN 772-13 Methods of Test for Masonry Units-Part 13: Determination of Net and Gross Dry Density of Masonry Units (Except for Natural Stone); Türk Standardları Enstitüsü (Turkish Standards Institution): Ankara, Turkey, 2020.

- TS EN 772-11 Methods of Test for Masonry Units-Part 11: Determination of Water Absorption of Aggregate Concrete, Autoclaved Aerated Concrete, Manufactured Stone and Natural Stone Masonry Units Due to Capillary Action and the Initial Rate of Water Absorption of Clay Masonry Units; Türk Standardları Enstitüsü (Turkish Standards Institution): Ankara, Turkey, 2020.

- TS EN 772-1+A1 Methods of Test for Masonry Units-Part 1: Determination of Compressive Strength; Türk Standardları Enstitüsü (Turkish Standards Institution): Ankara, Turkey, 2020.

- TS EN 772-18 Methods of Test for Masonry Units-Part 18: Determination of Freeze-Thaw Resistance of Calcium Silicate Masonry Units; Türk Standardları Enstitüsü (Turkish Standards Institution): Ankara, Turkey, 2020.

- TS EN 772-3 Methods of Test for Masonry Units-Part 3: Determination of Net Volume and Percentage of Voids of Clay Masonry Units by Hydrostatic Weighing; Türk Standardları Enstitüsü (Turkish Standards Institution): Ankara, Turkey, 2020.

- Rawlings, R.D.; Wu, J.P.; Boccaccini, A.R. Glass-ceramics: Their production from wastes—A Review. J. Mater. Sci. 2006, 41, 733–761. [Google Scholar] [CrossRef]

- Hossain, S.S.; Roy, P.K. Sustainable ceramics derived from solid wastes: A review. J. Asian Ceram. Soc. 2020, 8, 984–1009. [Google Scholar] [CrossRef]

- Taurino, R.; Karamanova, E.; Barbieri, L.; Atanasova-Vladimirova, S.; Andreola, F.; Karamanov, A. New fired bricks based on municipal solid waste incinerator bottom ash. Waste Manag. Res. 2017, 35, 1055–1063. [Google Scholar] [CrossRef]

- Johari, I.; Said, S.; Hisham, B.; Bakar, A.; Ahmad, Z.A. Effect of the Change of Firing Temperature on Microstruture and Physical Properties of Clay Bricks from Beruas (Malaysia). Sci. Sinter. 2010, 42, 245–254. [Google Scholar] [CrossRef]

- Şimşek, O. Yapı malzemesi-II (Building material-II); Seçkin Yayıncılık: Ankara, Turkey, 2013; 269p. (in Turkish) [Google Scholar]

- Stryszewska, T.; Kanka, S. Forms of Damage of Bricks Subjected to Cyclic Freezing and Thawing in Actual Condtions. Materials 2019, 12, 1165. [Google Scholar] [CrossRef]

- ASTM C67. Standard Test Methods for Sampling and Testing Brick and Structural Clay Tile; ASTM International: West Conshohocken, PA, USA, 2007. [Google Scholar]

- ASTM C62. Standard Specification for Building Brick (Solid Masonry Units Made from Clay or Shale); ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- Belmonte, L.J.; Ottosen, L.M.; Kirkelund, G.M.; Jensen, P.E.; Vestbø, A.P. Screening of heavy metal containing waste types for use as raw material in Arctic clay-based bricks. Environ. Sci. Pollut. Res. 2018, 25, 32831–32843. [Google Scholar] [CrossRef]

- Łach, M.; Gado, R.; Marczyk, J.; Ziejewska, C.; Doğan-Sağlamtimur, N.; Szechyńska-Hebda, M.; Hebda, M. Process design for a production of sustainable materials from post-production clay. Materials 2021, 14, 953. [Google Scholar]

| Compounds | Amount (%) | |

|---|---|---|

| BAGFCNF | CNKR | |

| SiO2 | 27.36 | 50.97 |

| Al2O3 | 12.68 | 11.58 |

| Fe2O3 | 8.23 | 7.77 |

| CaO | 39.31 | 9.40 |

| MgO | 0.74 | 3.90 |

| Na2O | 1.88 | 1.83 |

| K2O | 0.43 | 2.31 |

| SO3 | 5.94 | 3.13 |

| Others | 3.43 | 9.11 |

| Samples | FS (%) | UUW (γ, g/cm3) | WWA/p (%) | CS (σ, MPa) | CS-AF (σF, MPa) |

|---|---|---|---|---|---|

| FB0–900 | 1.07 ± 0.04 | 1.89 ± 0.02 | 18.00 ± 0.65 | 15.30 ± 0.78 | 10.80 ± 0.70 |

| FB10–900 | 1.43 ± 0.05 *** | 1.77 ± 0.01 *** | 18.70 ± 0.67 ns | 12.70 ± 1.17 *** | 9.00 ± 0.56 ns |

| FB20–900 | 1.53 ± 0.03 *** | 1.70 ± 0.01 *** | 19.00 ± 0.66 * | 11.90 ± 0.72 *** | 8.20 ± 0.46 ** |

| FB30–900 | 1.66 ± 0.06 *** | 1.68 ± 0.02 *** | 19.10 ± 0.65 * | 10.20 ± 0.39 *** | 7.10 ± 0.53 * |

| FB40–900 | 1.65 ± 0.05 *** | 1.63 ± 0.02 *** | 19.50 ± 1.12 ns | 8.20 ± 0.32 *** | 6.20 ± 0.36 *** |

| FB0–1000 | 1.52 ± 0.04 *** | 1.87 ± 0.02 ns | 18.20 ± 0.68 ns | 18.00 ± 1.08 * | 14.83 ± 0.70 * |

| FB10–1000 | 1.53 ± 0.06 ns/ns | 1.76 ± 0.01 ***/ns | 18.60 ± 0.85 ns/ns | 14.20 ± 1.47 */*** | 9.30 ± 0.46 **/ns |

| FB20–1000 | 1.59 ± 0.06 ns/ns | 1.72 ± 0.02 ***/*** | 18.90 ± 0.64 */ns | 13.80 ± 0.57 ***/* | 10.10 ± 0.90 **/ns |

| FB30–1000 | 1.62 ± 0.07 */ns | 1.64 ± 0.03 ***/ns | 19.00 ± 0.75 ns/ns | 13.10 ± 0.41 ***/ns | 9.90 ± 0.87 */* |

| FB40–1000 | 1.65 ± 0.05 */ns | 1.62 ± 0.02 ***/ns | 19.10 ± 1.00 ns/ns | 11.63 ± 0.51 ***/*** | 7.80 ± 0.36 ***/* |

| FB0–1100 | 1.53 ± 0.05 *** | 1.85 ± 0.02 ns | 17.83 ± 0.57 ns | 20.40 ± 1.12 *** | 13.90 ± 0.72 *** |

| FB10–1100 | 1.58 ± 0.04 ns/* | 1.75 ± 0.04 ***/ns | 17.83 ± 0.67 ns/ns | 21.90 ± 1.15 ns/*** | 17.80 ± 0.61 */*** |

| FB20–1100 | 1.62 ± 0.06 ns/* | 1.68 ± 0.03 ***/ns | 18.00 ± 0.68 ns/ns | 22.80 ± 0.68 */*** | 19.13 ± 0.60 ***/*** |

| FB30–1100 | 1.64 ± 0.05 */ns | 1.62 ± 0.02 ***/* | 18.20 ± 0.83 ns/ns | 26.20 ± 0.43 ***/*** | 19.80 ± 0.78 ***/*** |

| FB40–1100 | 1.68 ± 0.07 */ns | 1.60 ± 0.02 ***/ns | 18.40 ± 1.13 ns/ns | 28.80 ± 0.41 ***/*** | 24.43 ± 0.47 **/*** |

| FB0–1150 | 1.52 ± 0.07 *** | 1.82 ± 0.02 ** | 16.60 ± 0.68 ns | 23.40 ± 1.33 *** | 16.50 ± 0.70 ** |

| FB10–1150 | 1.56 ± 0.05 ns/* | 1.66 ± 0.01 ***/*** | 16.70 ± 0.78 ns/* | 26.60 ± 0.59 **/*** | 19.70 ± 0.62 ***/*** |

| FB20–1150 | 1.70 ± 0.07 **/*** | 1.62 ± 0.02 ***/*** | 17.20 ± 1.16 ns/ns | 28.20 ± 0.68 ***/*** | 23.00 ± 0.44 ***/*** |

| FB30–1150 | 1.76 ± 0.06 **/* | 1.54 ± 0.02 ***/*** | 18.00 ± 1.16 ns/* | 31.50 ± 0.74 ***/*** | 25.03 ± 1.30 ***/*** |

| FB40–1150 | 1.80 ± 0.07 ***/* | 1.51 ± 0.01 ***/*** | 117.98 ± 1.12 */* | 34.40 ± 0.50 ***/*** | 29.30 ± 0.98 **/*** |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Doğan-Sağlamtimur, N.; Bilgil, A.; Szechyńska-Hebda, M.; Parzych, S.; Hebda, M. Eco-Friendly Fired Brick Produced from Industrial Ash and Natural Clay: A Study of Waste Reuse. Materials 2021, 14, 877. https://doi.org/10.3390/ma14040877

Doğan-Sağlamtimur N, Bilgil A, Szechyńska-Hebda M, Parzych S, Hebda M. Eco-Friendly Fired Brick Produced from Industrial Ash and Natural Clay: A Study of Waste Reuse. Materials. 2021; 14(4):877. https://doi.org/10.3390/ma14040877

Chicago/Turabian StyleDoğan-Sağlamtimur, Neslihan, Ahmet Bilgil, Magdalena Szechyńska-Hebda, Sławomir Parzych, and Marek Hebda. 2021. "Eco-Friendly Fired Brick Produced from Industrial Ash and Natural Clay: A Study of Waste Reuse" Materials 14, no. 4: 877. https://doi.org/10.3390/ma14040877

APA StyleDoğan-Sağlamtimur, N., Bilgil, A., Szechyńska-Hebda, M., Parzych, S., & Hebda, M. (2021). Eco-Friendly Fired Brick Produced from Industrial Ash and Natural Clay: A Study of Waste Reuse. Materials, 14(4), 877. https://doi.org/10.3390/ma14040877