Regulating Effect of Cement Accelerator on High Content Solid-Wastes Autoclaved Aerated Concrete (HCS-AAC) Slurry Performance and Subsequent Influence

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Mixture Design and Preparation Procedure

2.2.1. Mixture Design

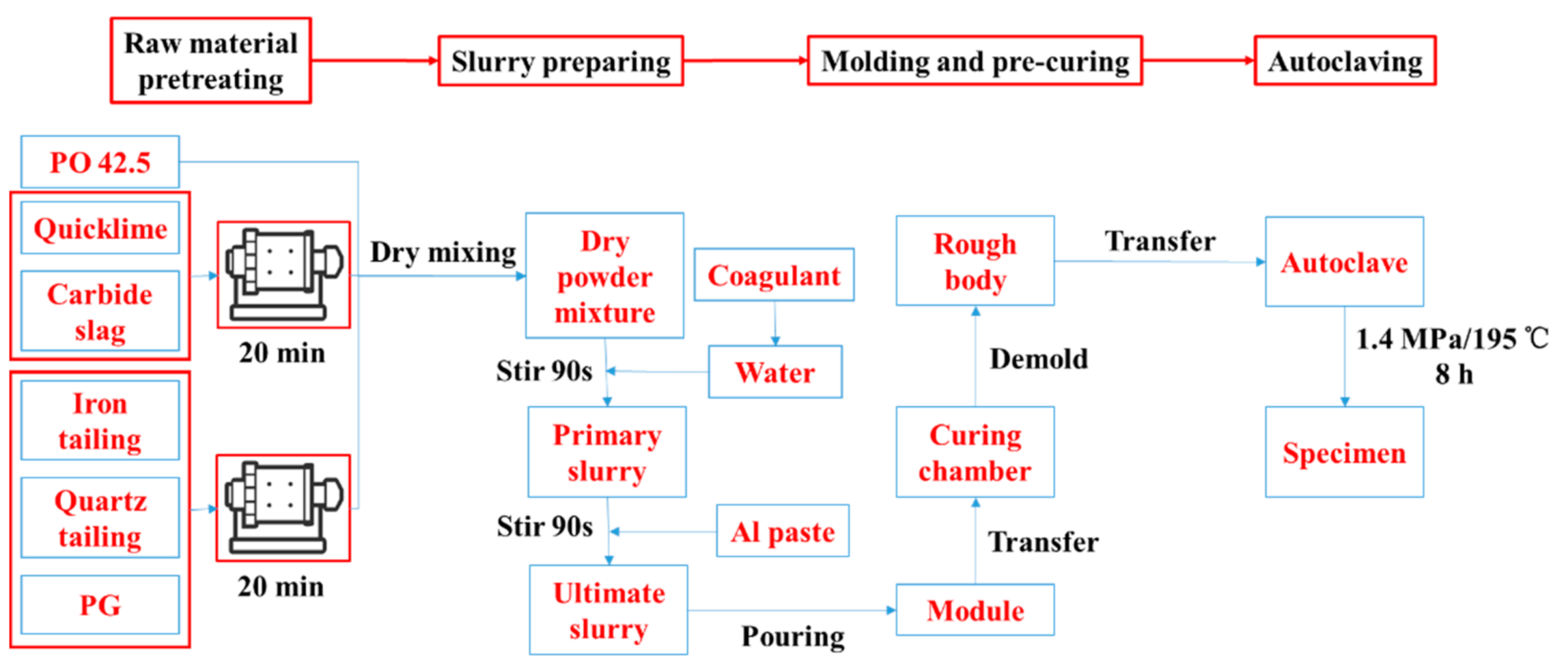

2.2.2. Preparation Procedure

2.3. Characterization Methods

2.3.1. Raw Material Characteristics

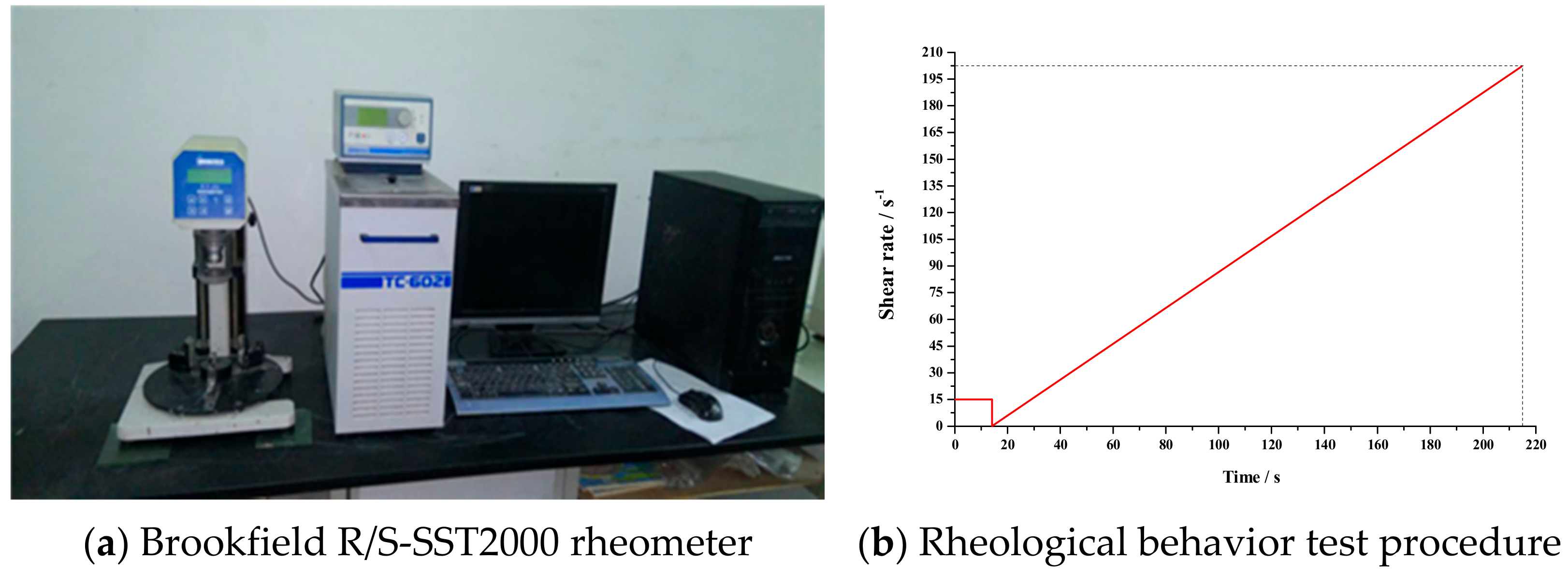

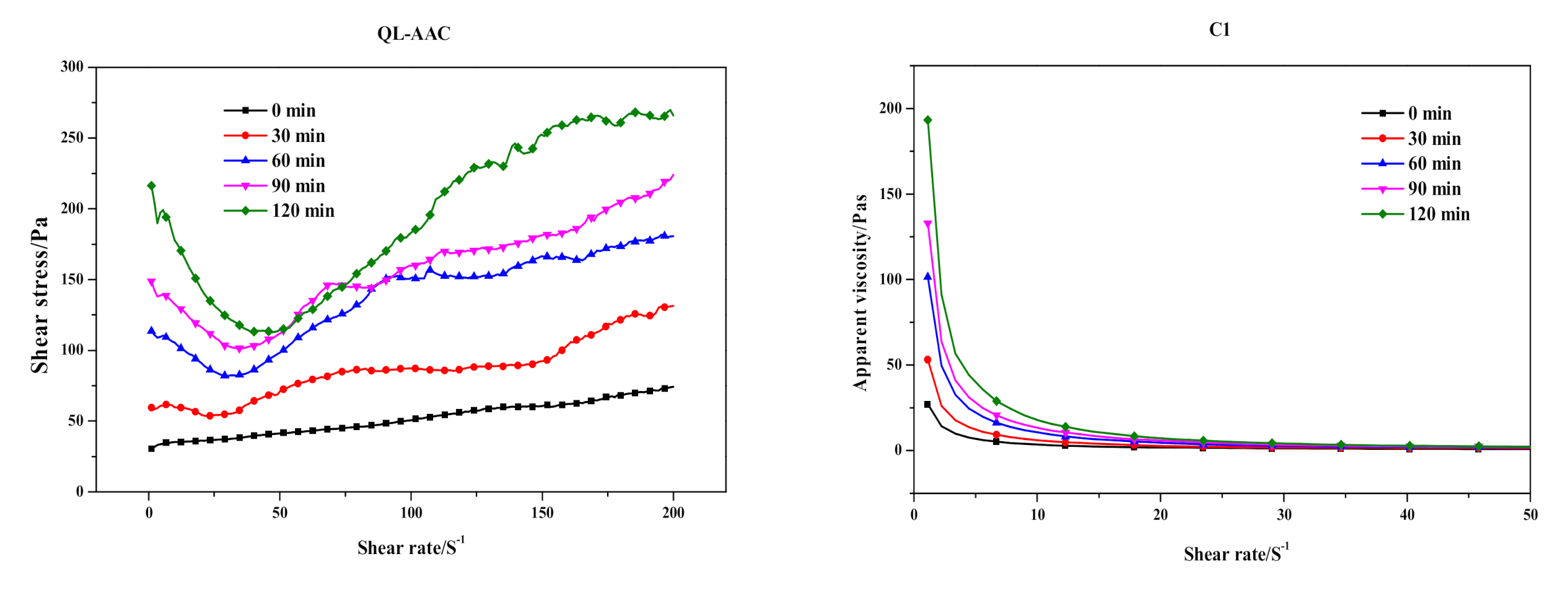

2.3.2. Slurry Performance

2.3.3. Physical-Mechanical Property

2.3.4. Hydration Products

3. Results and Discussion

3.1. Performance and Characteristics of Quicklime and Carbide Slag AAC

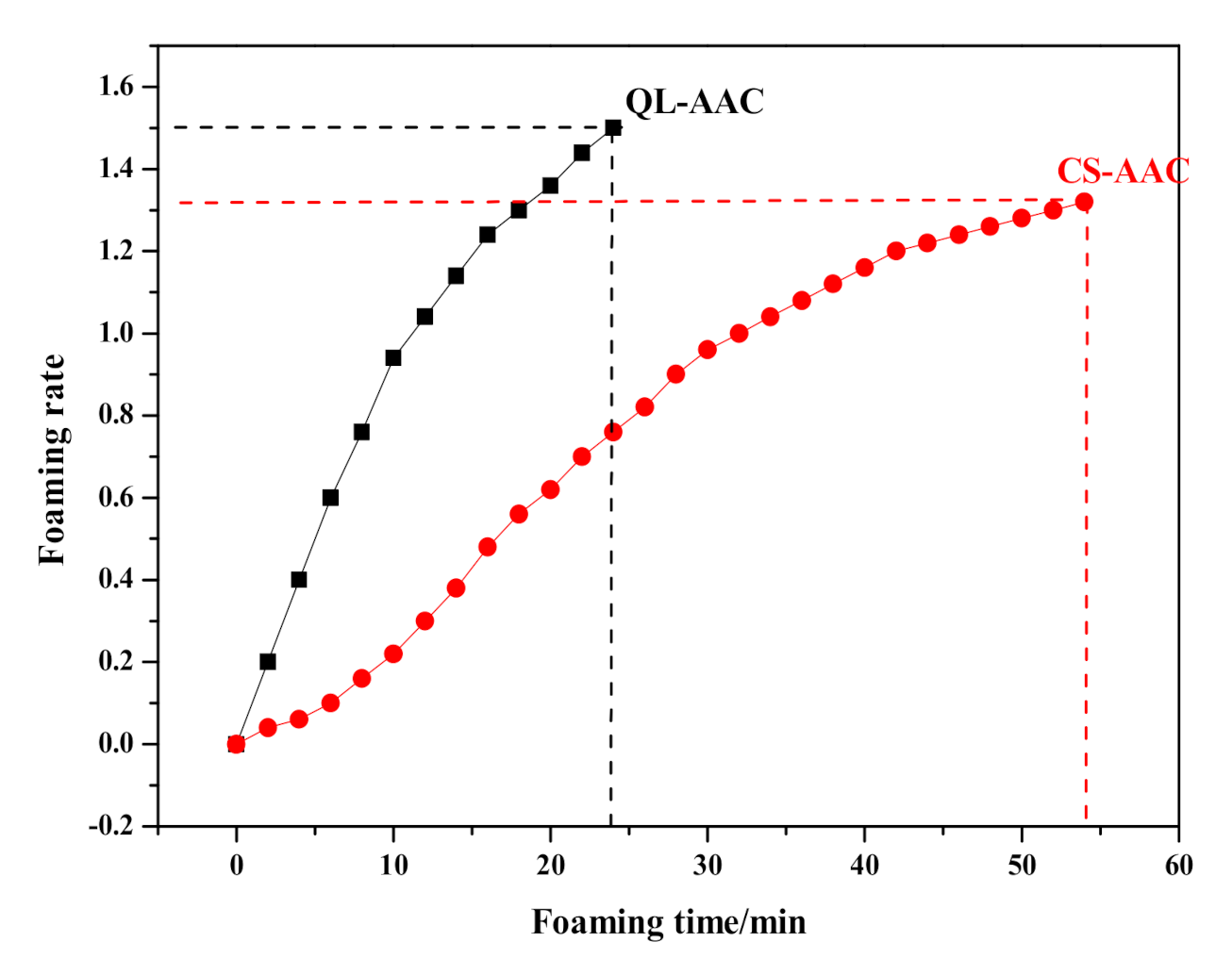

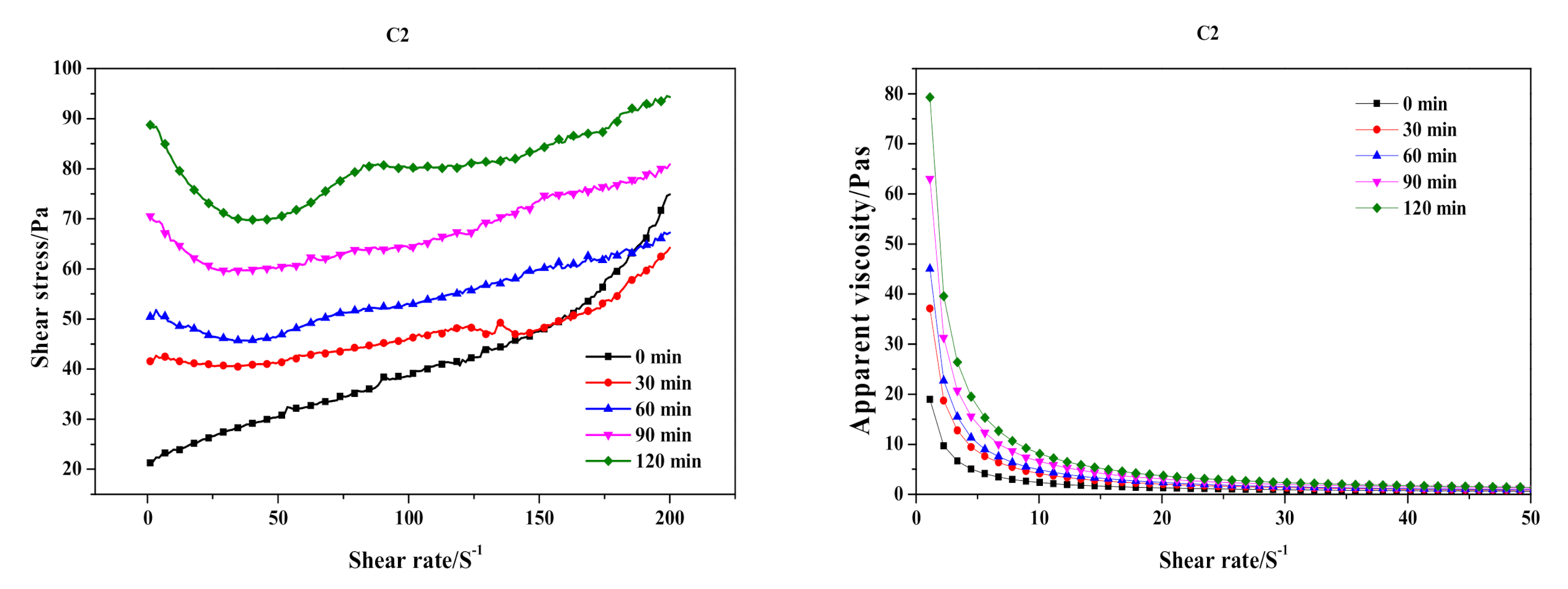

3.1.1. Slurry and Physical-Mechanical Performance

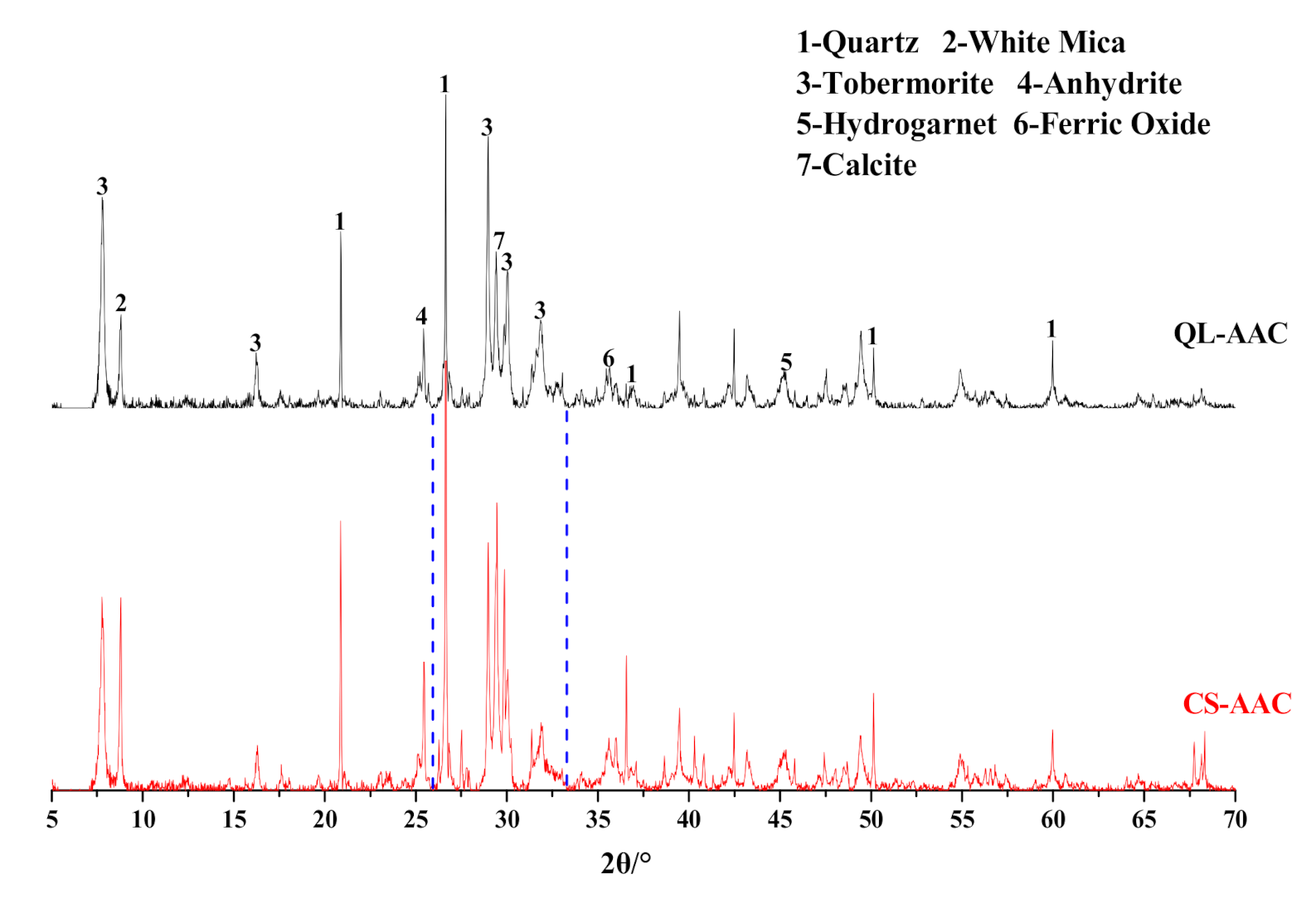

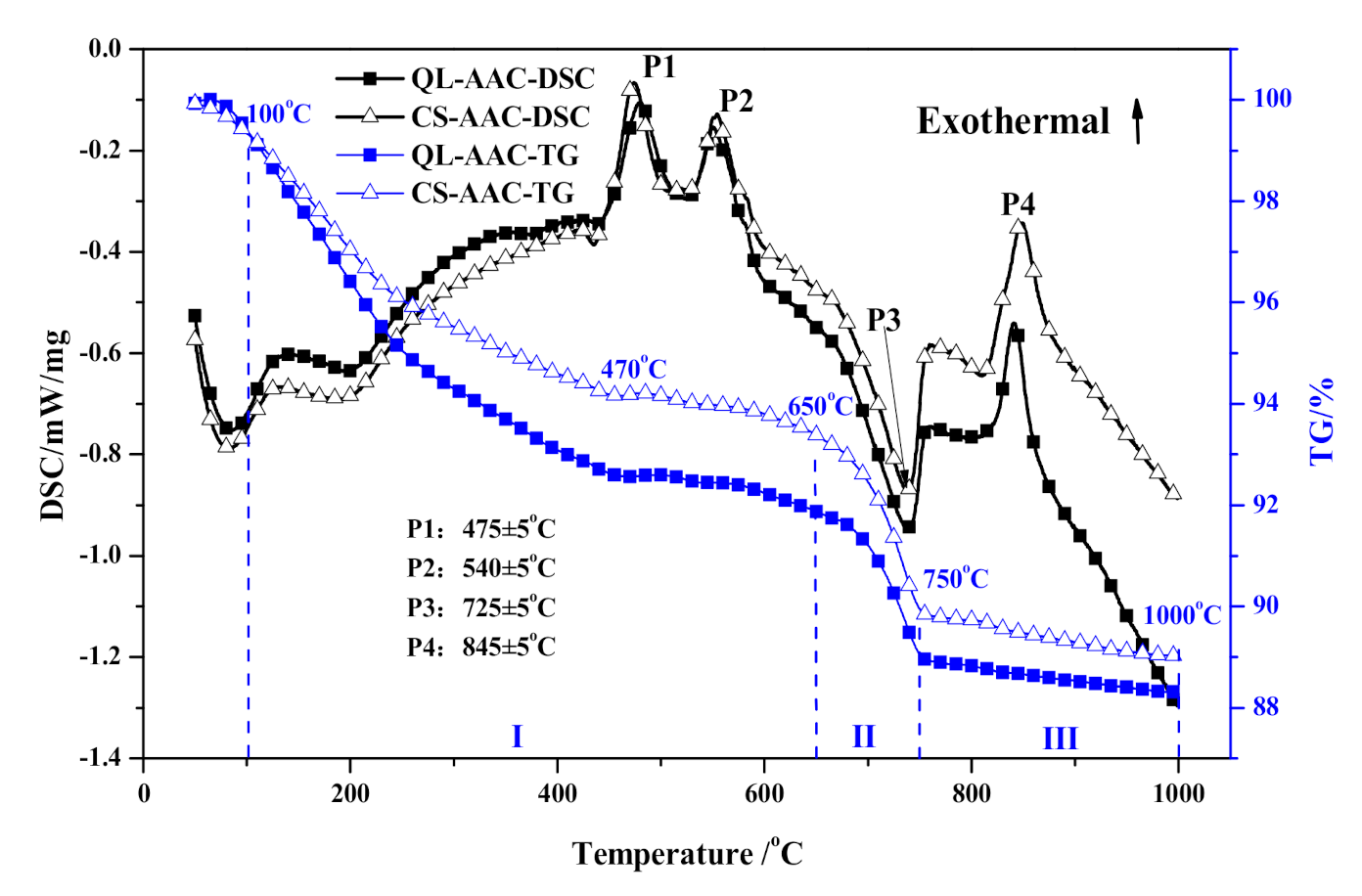

3.1.2. Hydration Products

3.2. Coagulating Mechanism of Na2SO4 and Na2O·2.0SiO2 in Cement Paste

3.3. Slurry Performance Regulating Effect of Cement Accelerator on HCS-AAC

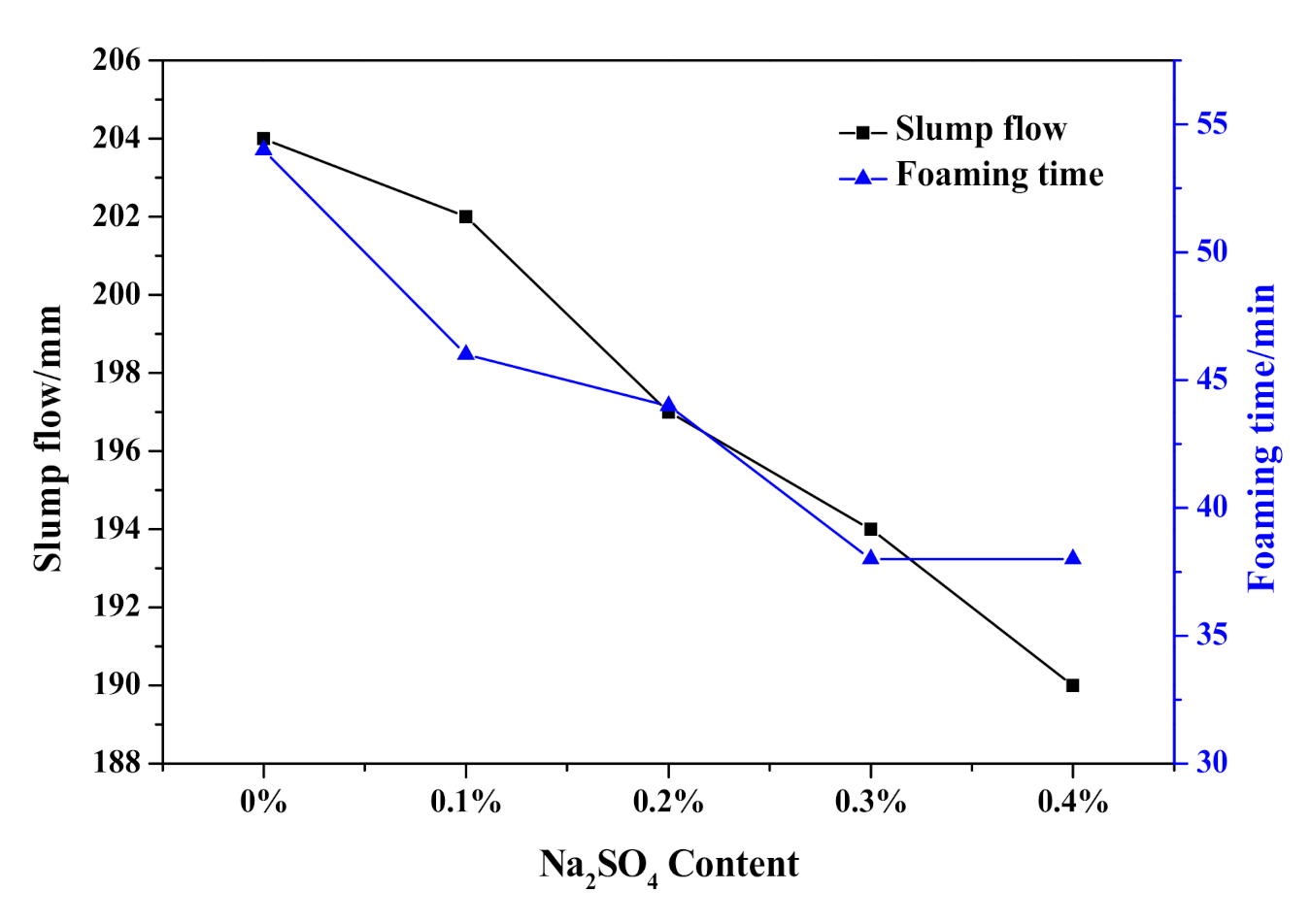

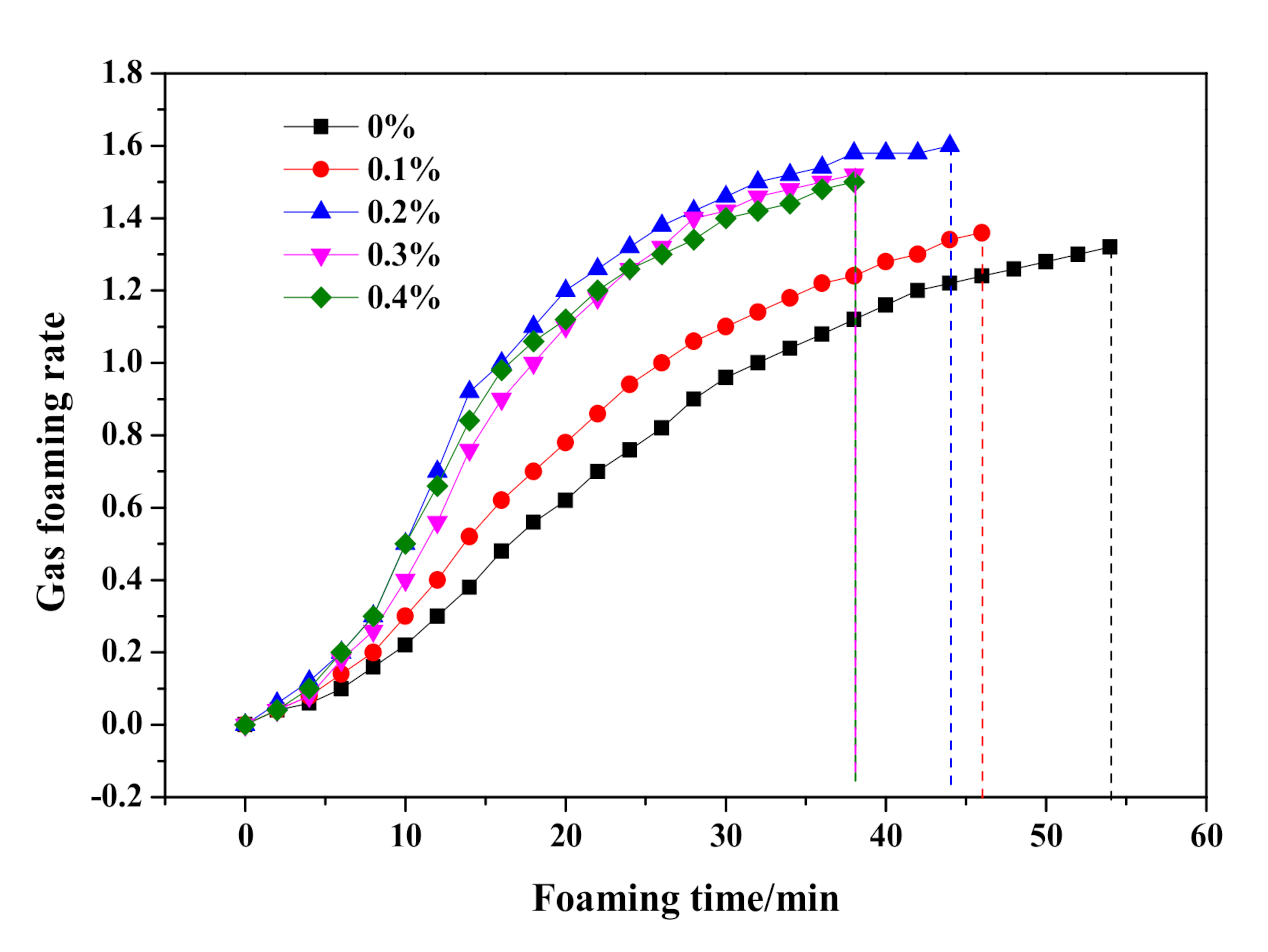

3.3.1. Regulating Effect of Na2SO4

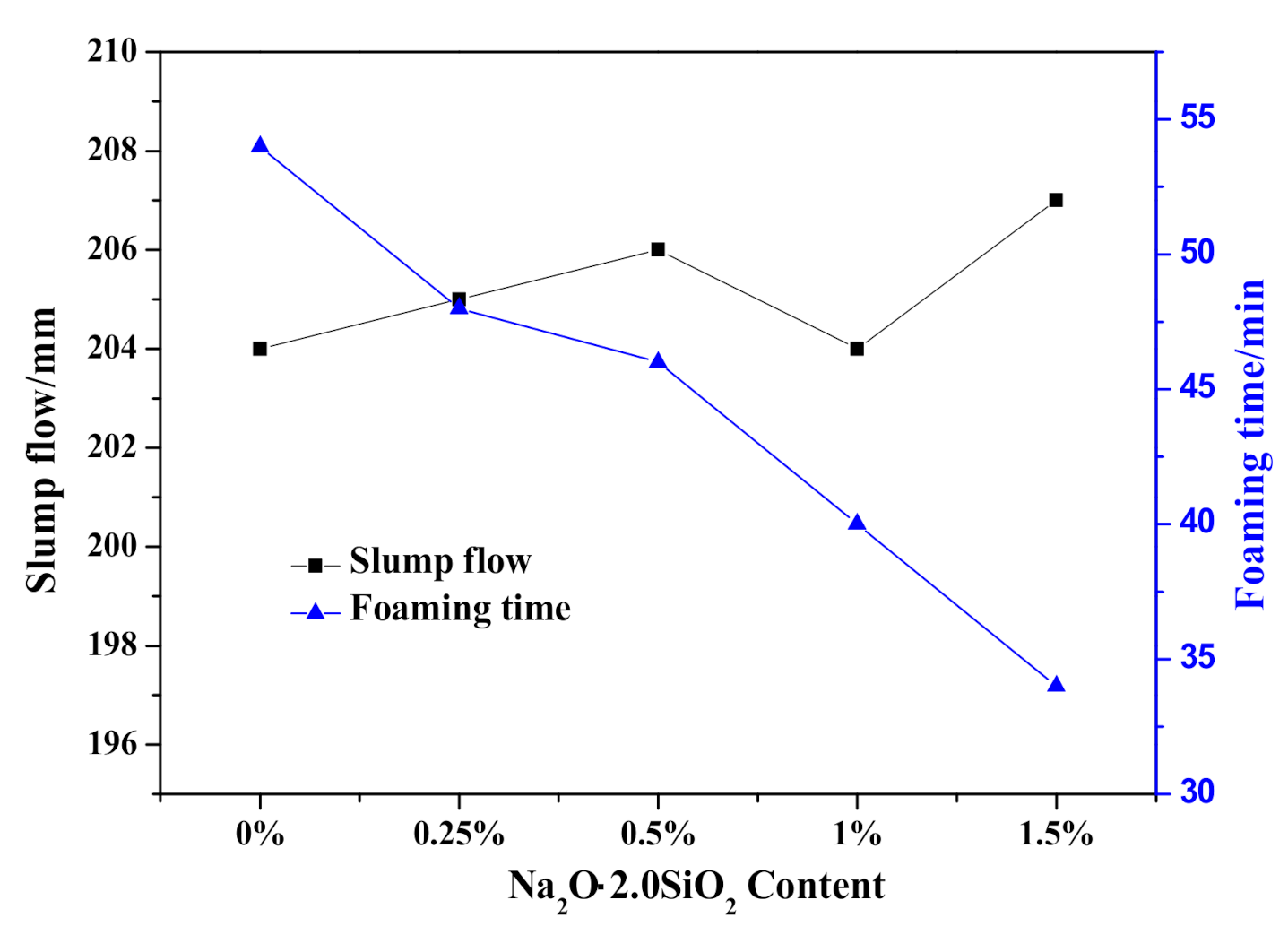

3.3.2. Regulating Effect of Na2O·2.0SiO2

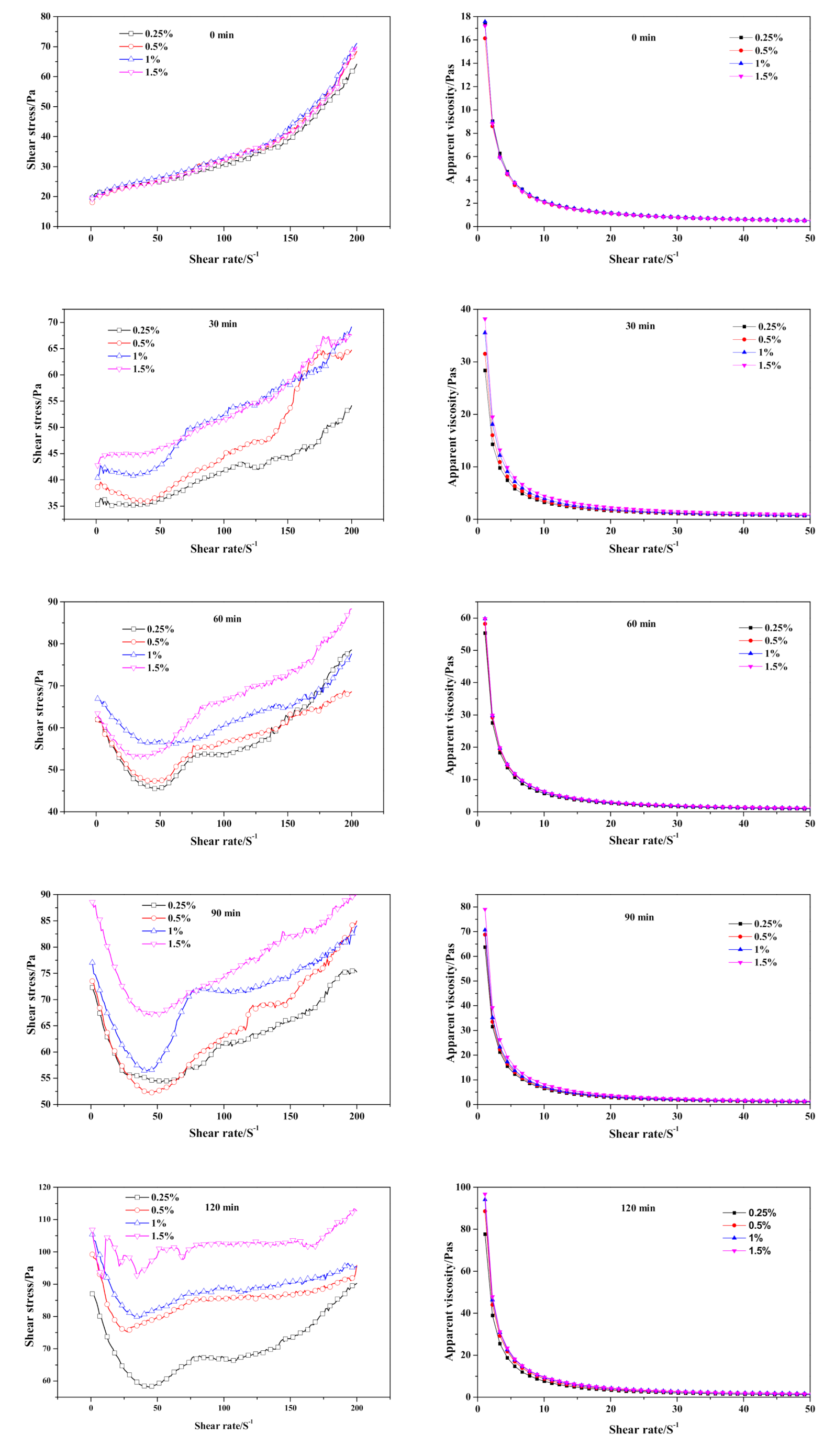

3.3.3. Effect Mechanism Analysis

3.4. Effect of Cement Accelerator on HCS-AAC Physical-Mechanical Properties

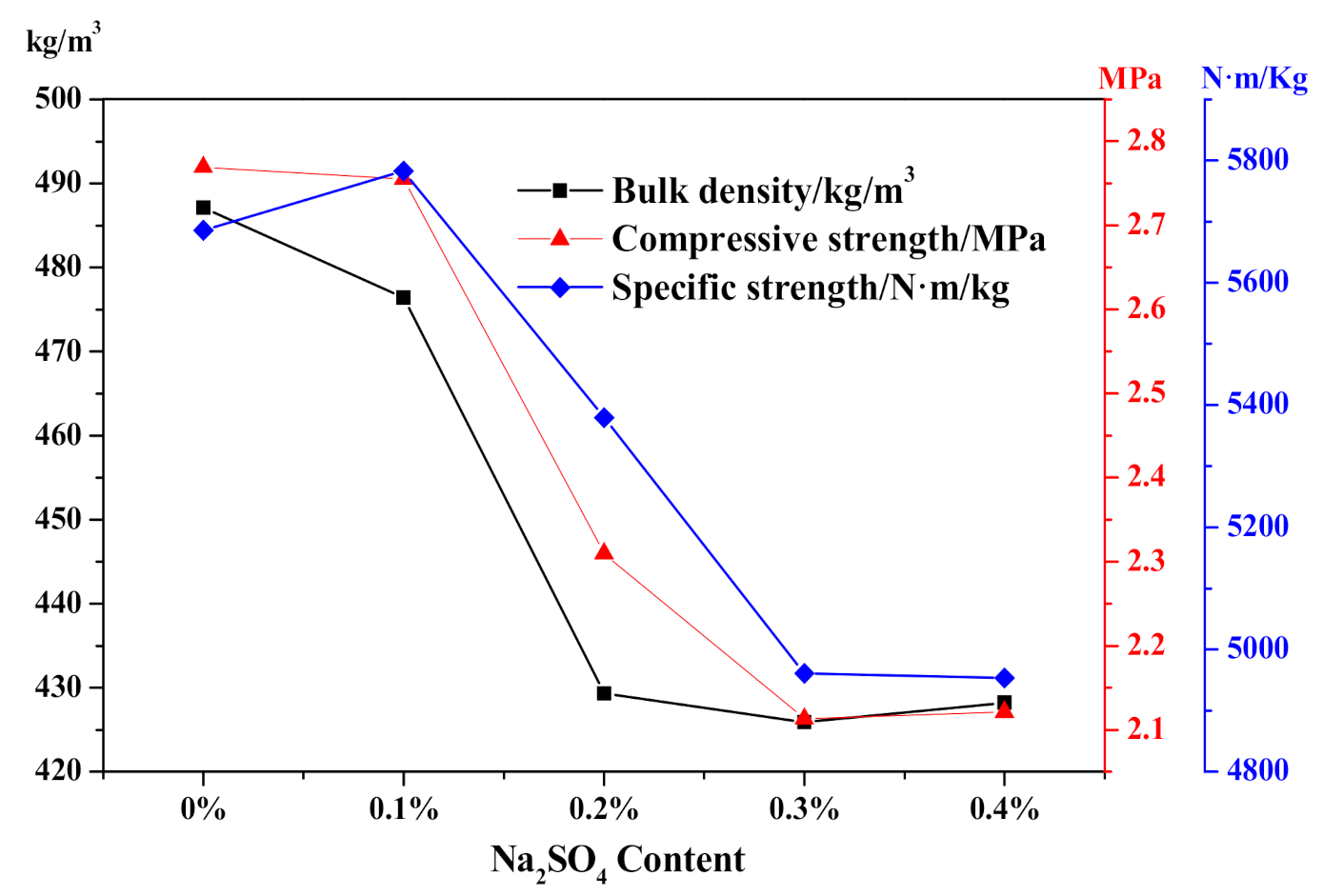

3.4.1. Effect of Na2SO4

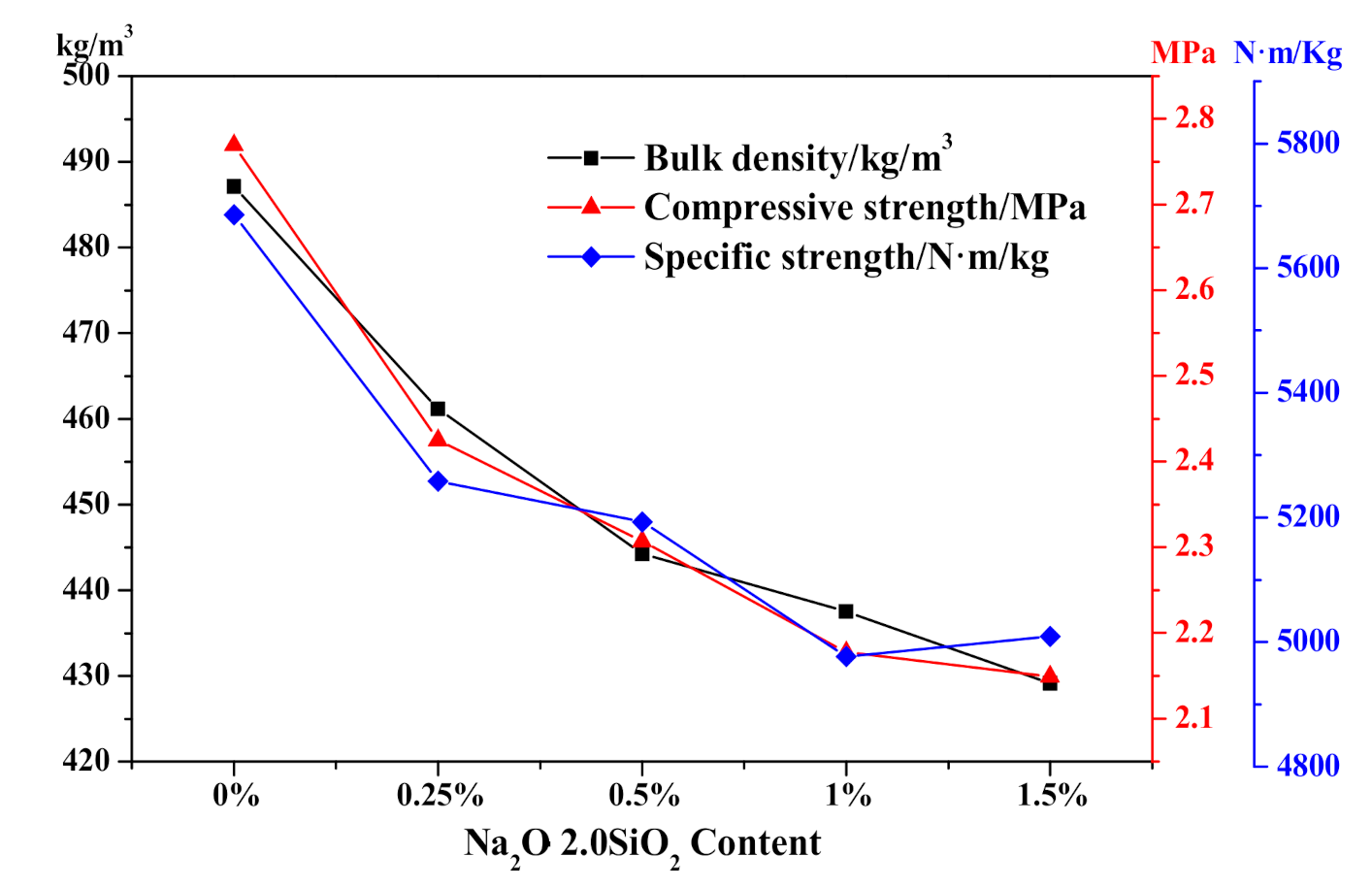

3.4.2. Effect of Na2O·2.0SiO2

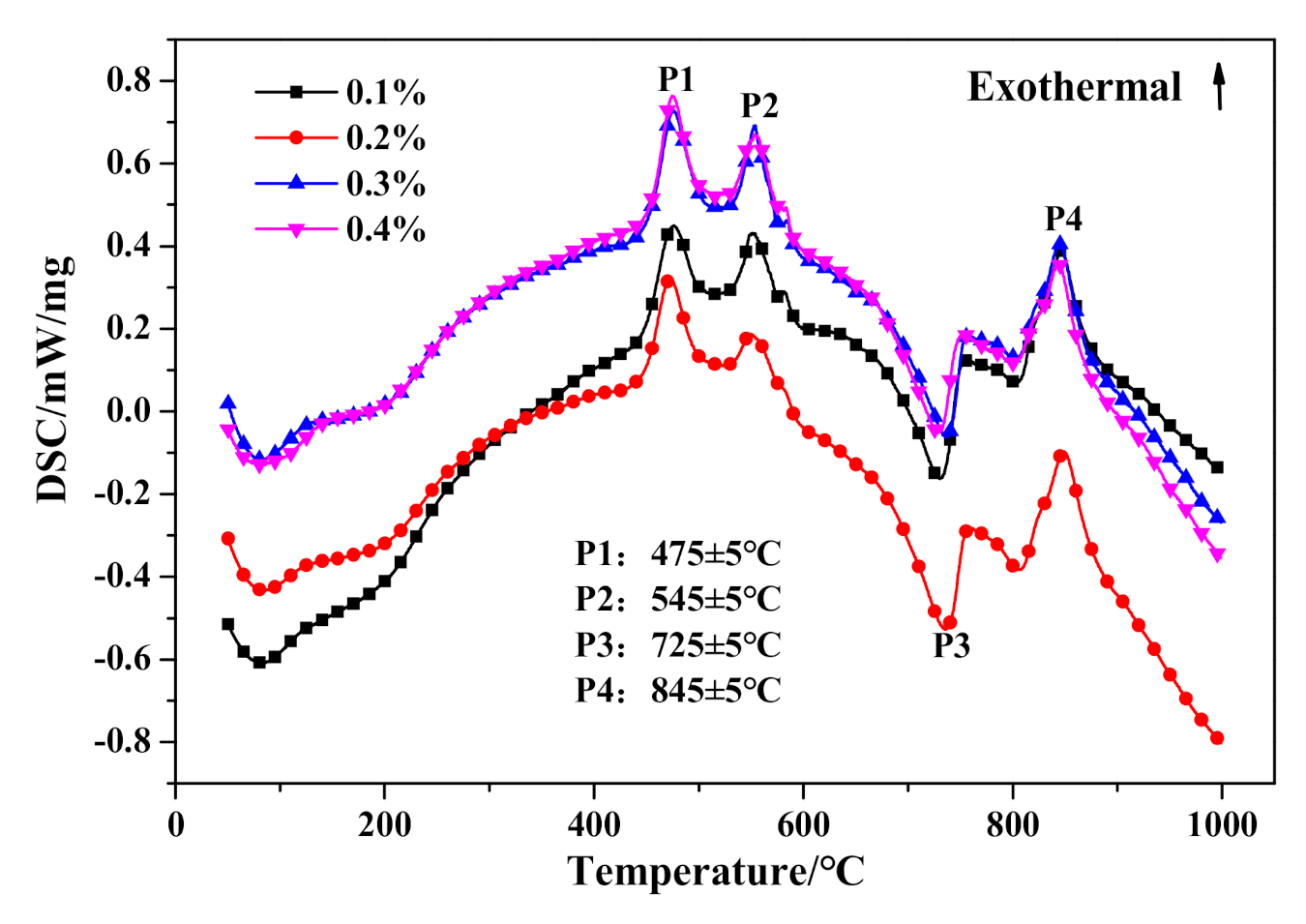

3.5. Effect of Cement Accelerator on HCS-AAC Hydration Products

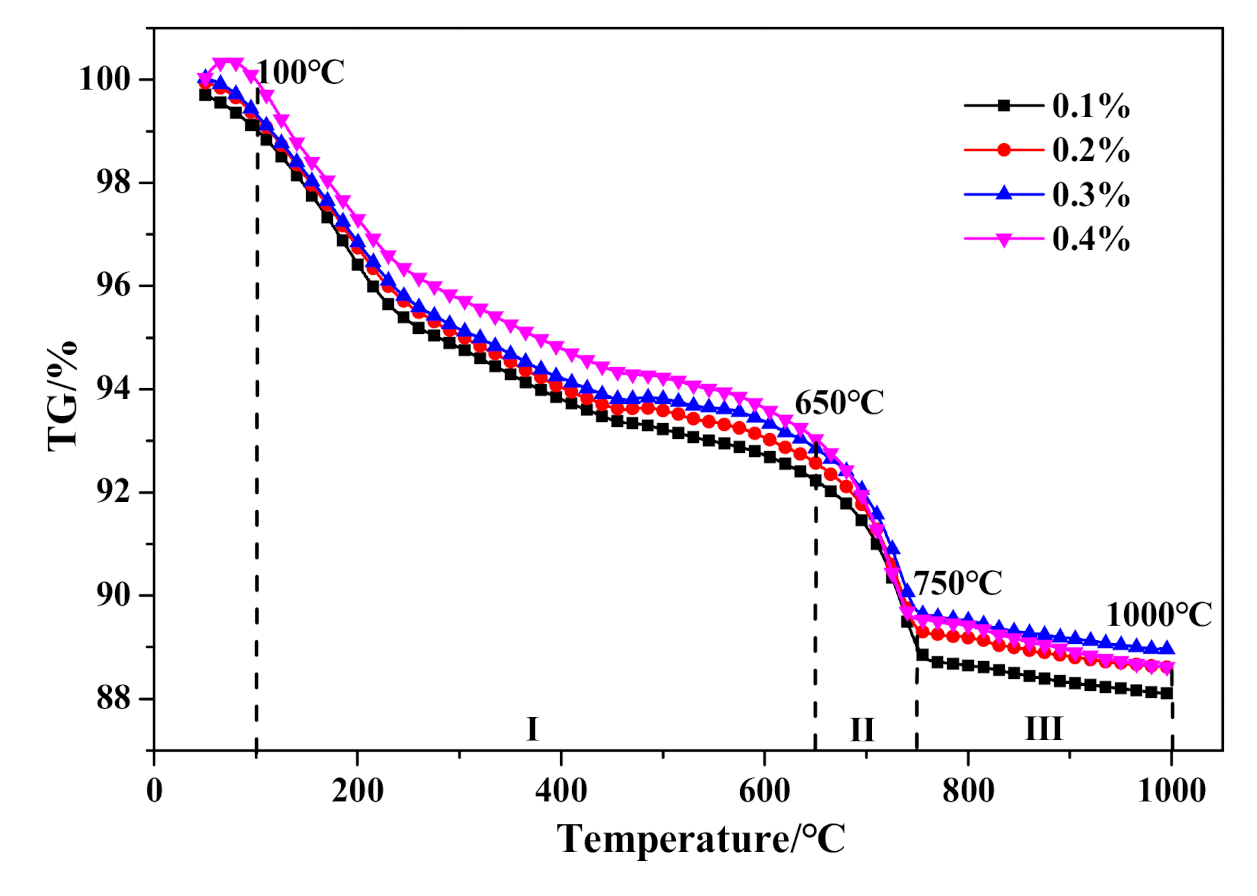

3.5.1. Effect of Na2SO4

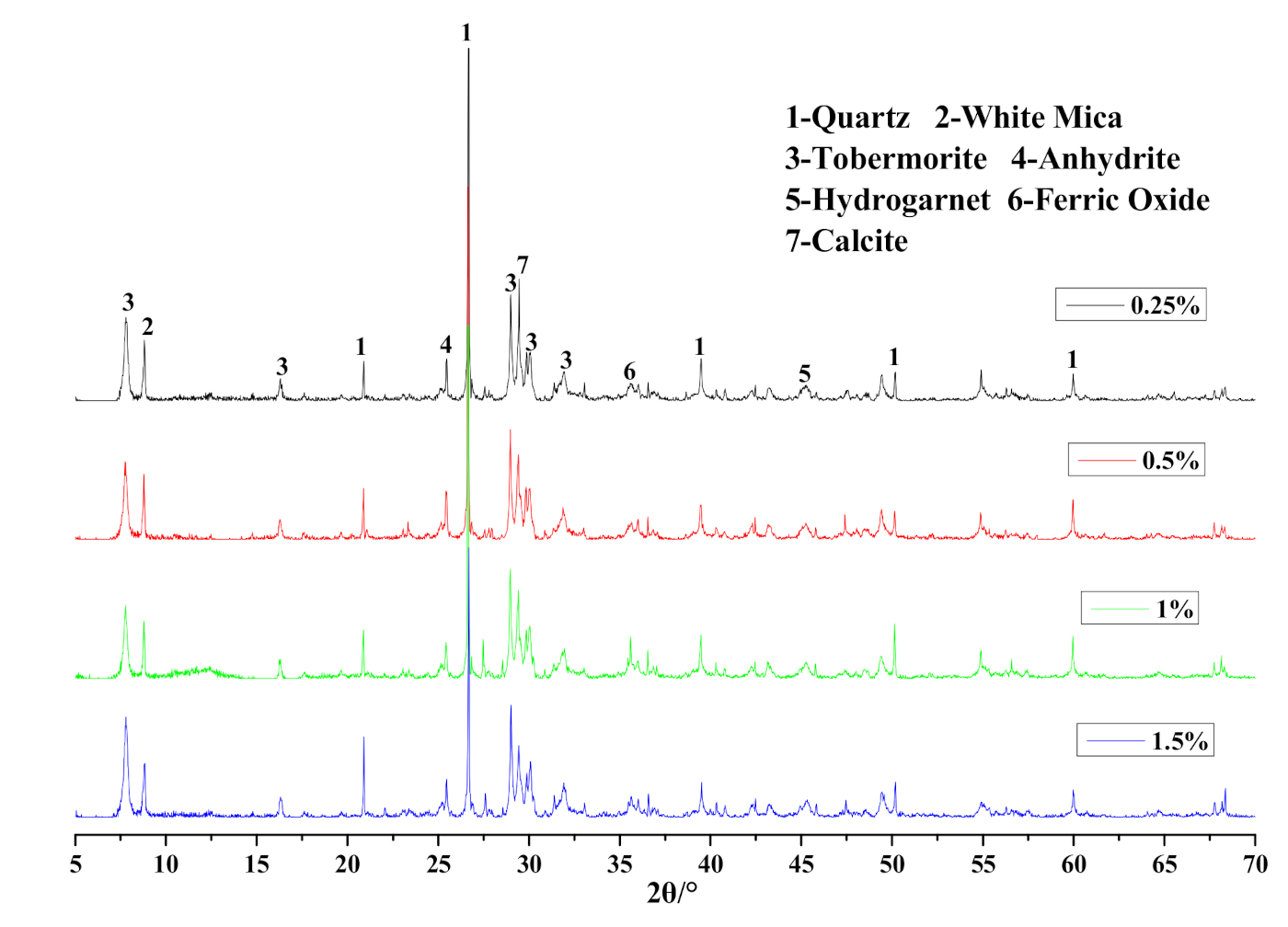

3.5.2. Effect of Na2O·2.0SiO2

3.5.3. Effect Mechanism Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Narayanan, N.; Ramamurthy, K. Structure and properties of aerated concrete: A review. Cem. Concr. Compos. 2000, 22, 321–329. [Google Scholar] [CrossRef]

- Karakurt, C.; Kurama, H.; Topçu, I.B. Utilization of natural zeolite in aerated concrete production. Cem. Concr. Compos. 2010, 32, 1–8. [Google Scholar] [CrossRef]

- Jerman, M.; Keppert, M.; Výborný, J.; Černý, R. Hygric, thermal and durability properties of autoclaved aerated concrete. Constr. Build. Mater. 2013, 41, 352–359. [Google Scholar] [CrossRef]

- Jatymowicz, H.; Siejko, J.; Zapotoczna-Sytek, G. Technologia Autoklawizowanego Betonu Komòrkowego; Arkady War-Szawa: Warsaw, Poland, 1975; pp. 13–24. (In Polish) [Google Scholar]

- Zhang, J.; Gu, T. Aerated Concrete Production Process; Wuhan University of Technology Press: Wuhan, China, 1992; pp. 10–23. (In Chinese) [Google Scholar]

- Cai, L.; Li, X.; Liu, W.; Ma, B.; Lv, Y. The slurry and physical-mechanical performance of autoclaved aerated concrete with high content solid wastes: Effect of grinding process. Constr. Build. Mater. 2019, 218, 28–39. [Google Scholar] [CrossRef]

- Yuan, B.B.; Straub, C.C.; Segers, S.S.; Yu, Q.Q.; Brouwers, H.J. Sodium carbonate activated slag as cement replacement in autoclaved aerated concrete. Ceram. Int. 2017, 43, 6039–6047. [Google Scholar] [CrossRef]

- Mostafa, N. Influence of air-cooled slag on physicochemical properties of autoclaved aerated concrete. Cem. Concr. Res. 2005, 35, 1349–1357. [Google Scholar] [CrossRef]

- Kurama, H.; Topçu, I.; Karakurt, C. Properties of the autoclaved aerated concrete produced from coal bottom ash. J. Mater. Process. Technol. 2009, 209, 767–773. [Google Scholar] [CrossRef]

- Huang, X.-Y.; Ni, W.; Cui, W.-H.; Wang, Z.-J.; Zhu, L.-P. Preparation of autoclaved aerated concrete using copper tailings and blast furnace slag. Constr. Build. Mater. 2012, 27, 1–5. [Google Scholar] [CrossRef]

- Wang, C.-L.; Ni, W.; Zhang, S.-Q.; Wang, S.; Gai, G.-S.; Wang, W.-K. Preparation and properties of autoclaved aerated concrete using coal gangue and iron ore tailings. Constr. Build. Mater. 2016, 104, 109–115. [Google Scholar] [CrossRef]

- Wang, C.L.; Liu, S.C.; Zheng, Y.C. Autoclaved aerated concrete prepared with calcium carbide residue and iron ore tailings as raw materials. Acta Mineral. Sin. 2015, 35, 373–378. (In Chinese) [Google Scholar]

- Kumar, G.S.; Ramakrishnan, A.; Hung, Y.T. Lime Calcination. Advanced Physicochemical Treatment Technologies; Humana Press: New York, NY, USA, 2007; pp. 611–633. [Google Scholar]

- Ramasamy, P.; Periathamby, A.; Ibrahim, S. Carbide sludge management in acetylene producing plants by using vacuum filtration. Waste Manag. Res. 2002, 20, 536–540. [Google Scholar] [CrossRef]

- Cai, L.; Li, X.; Ma, B.; Lv, Y. Effect of binding materials on carbide slag based high utilization solid-wastes autoclaved aerated concrete (HUS-AAC): Slurry, physic-mechanical property and hydration products. Constr. Build. Mater. 2018, 188, 221–236. [Google Scholar] [CrossRef]

- Wang, Y.L.; Liu, S.X.; Luo, S.Q.; Guan, X.M. Research on preparation of autoclaved aerated concrete block with solid waste. J. Henan Polytech. Univ. (Nat. Sci.) 2012, 31, 613–616. (In Chinese) [Google Scholar]

- Fan, J.; Cao, D.; Jing, Z.-Z.; Zhang, Y.; Pu, L.; Jing, Y. Synthesis and microstructure analysis of autoclaved aerated concrete with carbide slag addition. J. Wuhan Univ. Technol. Sci. Ed. 2014, 29, 1005–1010. [Google Scholar] [CrossRef]

- Cai, L.X.; Tang, T.; Liu, M.; Xie, D. Comparative study of carbide slag autoclaved aerated concrete (AAC) manu-factured under thermal oven and microwave pre-curing process: Foaming course, rough body strength and phys-ic-mechanical properties. Constr. Build. Mater. 2020, 236, 117550. [Google Scholar] [CrossRef]

- Taylor, F.W.H. Cement Chemistry, 2nd ed.; Thomas Telford: London, UK, 1997; pp. 227–230. [Google Scholar]

- Salvador, R.P.; Cavalaro, S.H.P.; Segura, I.; De Figueiredo, A.D.; Pérez, I.S. Early age hydration of cement pastes with alkaline and alkali-free accelerators for sprayed concrete. Constr. Build. Mater. 2016, 111, 386–398. [Google Scholar] [CrossRef]

- Salvador, R.P.; Cavalaro, S.H.; Cincotto, M.A.; De Figueiredo, A.D. Parameters controlling early age hydration of cement pastes containing accelerators for sprayed concrete. Cem. Concr. Res. 2016, 89, 230–248. [Google Scholar] [CrossRef]

- Won, J.-P.; Hwang, U.-J.; Kim, C.-K.; Lee, S.-J. Mechanical performance of shotcrete made with a high-strength cement-based mineral accelerator. Constr. Build. Mater. 2013, 49, 175–183. [Google Scholar] [CrossRef]

- Feneuil, B.; Roussel, N.; Pitois, O. Optimal cement paste yield stress for the production of stable cement foams. Cem. Concr. Res. 2019, 120, 142–151. [Google Scholar] [CrossRef]

- Wang, Y.; Shao, Y.; Matovic, M.D.; Whalen, J.K. Recycling of switchgrass combustion ash in cement: Characteristics and pozzolanic activity with chemical accelerators. Constr. Build. Mater. 2014, 73, 472–478. [Google Scholar] [CrossRef]

- Straub, C.; Quercia, G.; Florea, M.V.A.; Brouwers, H.J.H. Slump flow of autoclaved aeratedconcrete slurries. In Proceedings of the 5th International Conference Non-Traditional Cement and Concrete, Brno, Czech Republic, 6–19 June 2014; pp. 237–240. [Google Scholar]

- Zhang, Y.; Luo, X.; Kong, X.; Wang, F.; Gao, L. Rheological properties and microstructure of fresh cement pastes with varied dispersion media and superplasticizers. Powder Technol. 2018, 330, 219–227. [Google Scholar] [CrossRef]

- Oh, J.E.; Clark, S.M.; Wenk, H.-R.; Monteiro, P.J.M. Experimental determination of bulk modulus of 14Å tobermorite using high pressure synchrotron X-ray diffraction. Cem. Concr. Res. 2012, 42, 397–403. [Google Scholar] [CrossRef]

- Zhou, J.-C.; Zhao, H.-C.; Pan, K.-H.; Xu, Q.-P. Current recognition and management of intra-abdominal hypertension and abdominal compartment syndrome among tertiary Chinese intensive care physicians. J. Zhejiang Univ. Sci. B 2011, 12, 156–162. [Google Scholar] [CrossRef] [PubMed]

- Bensted, J.; Barnes, P. Structure and Performance of Cements, 2nd ed.; Spon Press: New York, NY, USA, 2002. [Google Scholar]

- Cai, L.; Ma, B.; Li, X.; Lv, Y.; Liu, Z.; Jian, S. Mechanical and hydration characteristics of autoclaved aerated concrete (AAC) containing iron-tailings: Effect of content and fineness. Constr. Build. Mater. 2016, 128, 361–372. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhang, Y.; Chen, T.; Chen, Y.; Bao, S. Preparation of high strength autoclaved bricks from hematite tailings. Constr. Build. Mater. 2012, 28, 450–455. [Google Scholar] [CrossRef]

- Klimesch, D.S.; Ray, A. DTA-TGA evaluations of the CaO -Al2O3 -SiO2 -H2O system treated hydrothermally. Thermochim. Acta 1999, 334, 115–122. [Google Scholar] [CrossRef]

- Scrivener, K.; Snellings, R.; Lothenbach, B. A Practical Guide to Microstructural Analysis of Cementitious Materials; CRC Press: Boca Raton, FL, USA, 2016; pp. 177–212. [Google Scholar]

- Yang, N.; Yue, W. The Handbook of Inorganic Metalloid Materials Atlas; Wuhan University of Technology Press: Wuhan, China, 2000; pp. 200–276. (In Chinese) [Google Scholar]

| Raw Materials | SiO2 | Al2O3 | CaO | Fe2O3 | MgO | Na2O | K2O | SO3 | CO2 | LOI |

|---|---|---|---|---|---|---|---|---|---|---|

| PO 42.5 | 17.76 | 3.94 | 61.11 | 4.04 | 1.78 | — | 0.29 | 3.52 | 6.32 | 0.73 |

| Carbide slag | 2.57 | 1.88 | 65.03 | 0.09 | 0.14 | 0.09 | — | 0.67 | — | 28.31 |

| Quicklime | 2.78 | 1.02 | 73.64 | 0.73 | 1.45 | — | 0.13 | 0.33 | 12.7 | 6.94 |

| Iron tailing | 42.90 | 10.75 | 12.97 | 7.51 | 7.10 | 2.06 | 1.96 | 9.04 | — | 4.48 |

| Quartz tailing | 93.23 | 1.68 | 0.33 | 0.56 | 0.14 | — | 0.64 | — | — | 0.78 |

| PG | 10.64 | 1.22 | 25.39 | 0.54 | 0.19 | 0.23 | 0.50 | 36.56 | — | 22.91 |

| Raw Materials | PO 42.5 | Quicklime | Carbide Slag a | Siliceous Mix Powder b |

|---|---|---|---|---|

| Specific surface area (m2/kg) | 336 | 328 | 284 | 306 |

| 80 μm screen residue weight (%) | 10.8 | 9.3 | 20.03 | 14.9 |

| NO | PO 42.5 | Calcareous Material | Siliceous Material | PG | Al Paste | W/P | ||

|---|---|---|---|---|---|---|---|---|

| Quicklime | Carbide Slag | Iron Tailing | Quartz Tailing | |||||

| a QL-AAC | 10% | 31% | — | 28% | 28% | 3% | 0.14% | 0.54 |

| b CS-AAC | 10% | — | 31% | 28% | 28% | 3% | 0.14% | 0.54 |

| Properties | Slump Flow/mm | Foaming Time/min | Bulk Density/kg/m3 | Compressive Strength/MPa | Specific Strength /N·m/kg |

|---|---|---|---|---|---|

| QL-AAC | 158 | 24 | 497.46 | 2.94 | 5910 |

| CS-AAC | 204 | 54 | 514.41 | 2.77 | 5385 |

| Mineral-d(A) | Tobermorite 11.3 Å | Tobermorite 3.08 Å | White Mica-9.93 Å | Quartz-3.34 Å | ||||

|---|---|---|---|---|---|---|---|---|

| Group | QL-AAC | CS-AAC | C1QL-AAC | CS-AAC | QL-AAC | CS-AAC | QL-AAC | CS-AAC |

| Intensity/cps | 2450 | 2115 | 3140 | 2618 | 1011 | 2198 | 3618 | 11,299 |

| Area | 37,935 | 31,301 | 34,622 | 28,139 | 10,427 | 14,292 | 20,304 | 45,458 |

| Temperature Range/°C | Weight Loss/% | |

|---|---|---|

| QL-AAC | CS-AAC | |

| I-(100–650) | −7.53103 | −5.95798 |

| II-(650–750) | −2.82582 | −3.43866 |

| III-(750–1000) | −0.73270 | −0.92116 |

| d(A) | 11.3 Å | 3.08 Å | ||||||

|---|---|---|---|---|---|---|---|---|

| Content/% | 0.1 | 0.2 | 0.3 | 0.4 | 0.1 | 0.2 | 0.3 | 0.4 |

| Intensity/cps | 2547 | 2708 | 2711 | 2566 | 2994 | 3275 | 3242 | 3098 |

| Area | 37,464 | 37,947 | 38,420 | 35,861 | 29,845 | 32,383 | 33,084 | 30,835 |

| Temperature Range/°C | Weight Loss/% | |||

|---|---|---|---|---|

| 0.1% | 0.2% | 0.3% | 0.4% | |

| I-(100–650) | −6.46143 | −6.47767 | −6.47988 | −6.48829 |

| II-(650–750) | −3.34939 | −3.20937 | −3.15367 | −3.05467 |

| III-(750–1000) | −0.7884 | −0.75968 | −0.74335 | −0.74236 |

| d(A) | 11.3 Å | 3.08 Å | ||||||

|---|---|---|---|---|---|---|---|---|

| Content/% | 0.25 | 0.5 | 1 | 1.5 | 0.25 | 0.5 | 1 | 1.5 |

| Intensity/cps | 2442 | 2598 | 2663 | 2830 | 2972 | 3027 | 3064 | 3165 |

| Area | 36,126 | 36,649 | 36,835 | 43,120 | 30,087 | 30,138 | 30,656 | 31,192 |

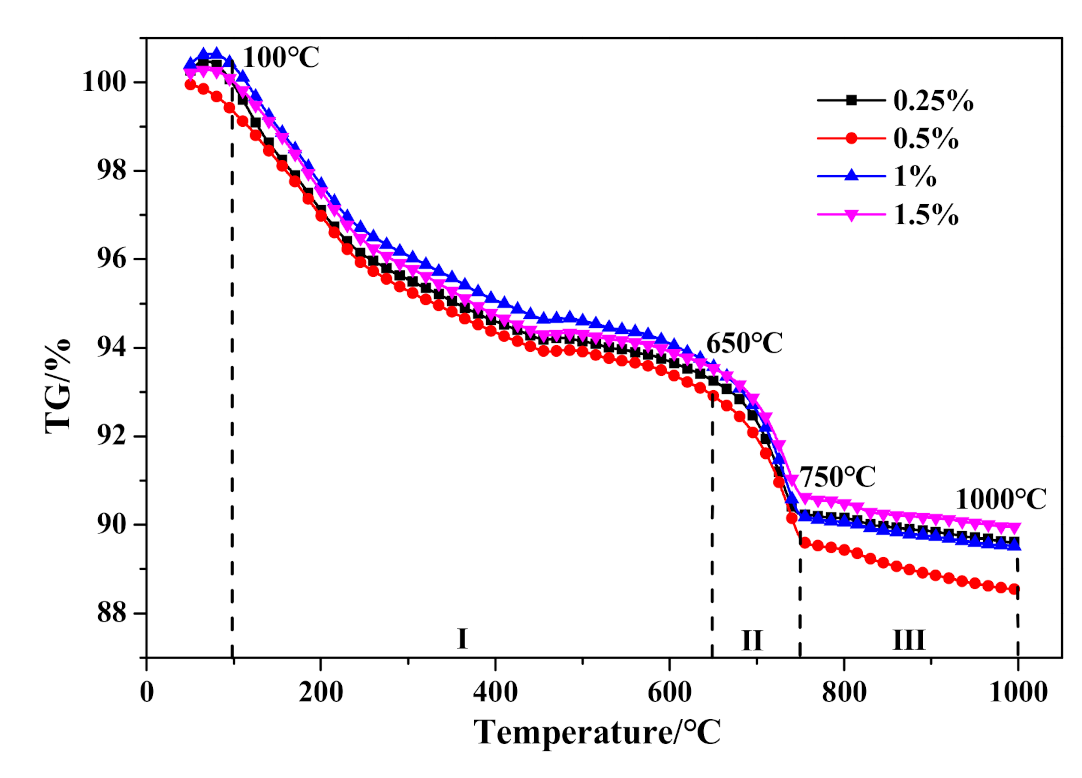

| Temperature Range/°C | Weight Loss/% | |||

|---|---|---|---|---|

| 0.25% | 0.5% | 1% | 1.5% | |

| I-(100–650) | −6.41159 | −6.47184 | −6.67727 | −6.84848 |

| II-(650–750) | −3.01298 | −3.21536 | −3.35119 | −2.84811 |

| III-(750–1000) | −0.63945 | −1.1606 | −0.70715 | −0.74665 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, D.; Cai, L.; Wang, J. Regulating Effect of Cement Accelerator on High Content Solid-Wastes Autoclaved Aerated Concrete (HCS-AAC) Slurry Performance and Subsequent Influence. Materials 2021, 14, 799. https://doi.org/10.3390/ma14040799

Xie D, Cai L, Wang J. Regulating Effect of Cement Accelerator on High Content Solid-Wastes Autoclaved Aerated Concrete (HCS-AAC) Slurry Performance and Subsequent Influence. Materials. 2021; 14(4):799. https://doi.org/10.3390/ma14040799

Chicago/Turabian StyleXie, Dingkun, Lixiong Cai, and Jie Wang. 2021. "Regulating Effect of Cement Accelerator on High Content Solid-Wastes Autoclaved Aerated Concrete (HCS-AAC) Slurry Performance and Subsequent Influence" Materials 14, no. 4: 799. https://doi.org/10.3390/ma14040799

APA StyleXie, D., Cai, L., & Wang, J. (2021). Regulating Effect of Cement Accelerator on High Content Solid-Wastes Autoclaved Aerated Concrete (HCS-AAC) Slurry Performance and Subsequent Influence. Materials, 14(4), 799. https://doi.org/10.3390/ma14040799