Influence of Cu Content on Structure, Thermal Stability and Magnetic Properties in Fe72−xNi8Nb4CuxSi2B14 Alloys

Abstract

1. Introduction

2. Materials and Methods

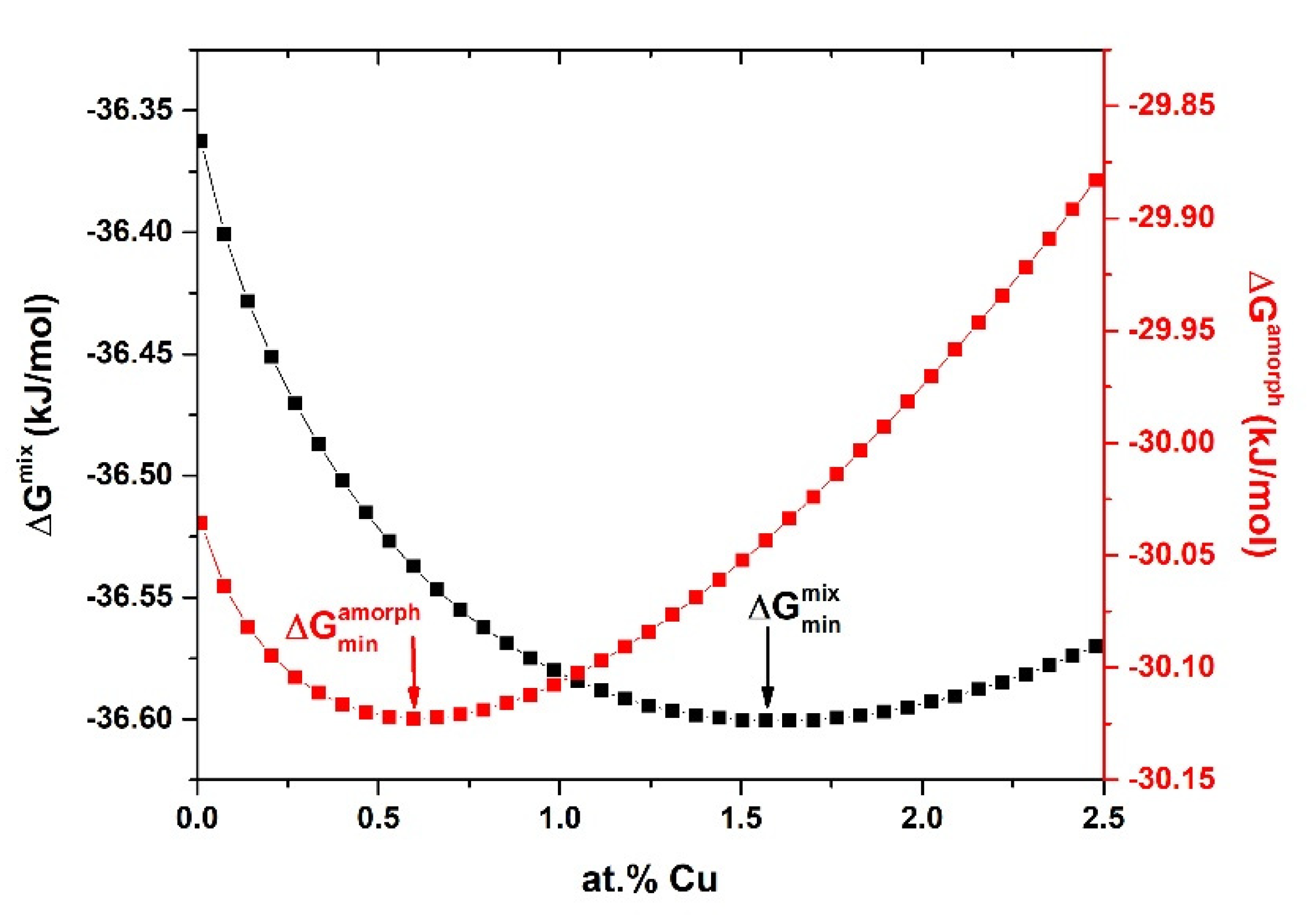

3. Thermodynamic Calculation

4. Results

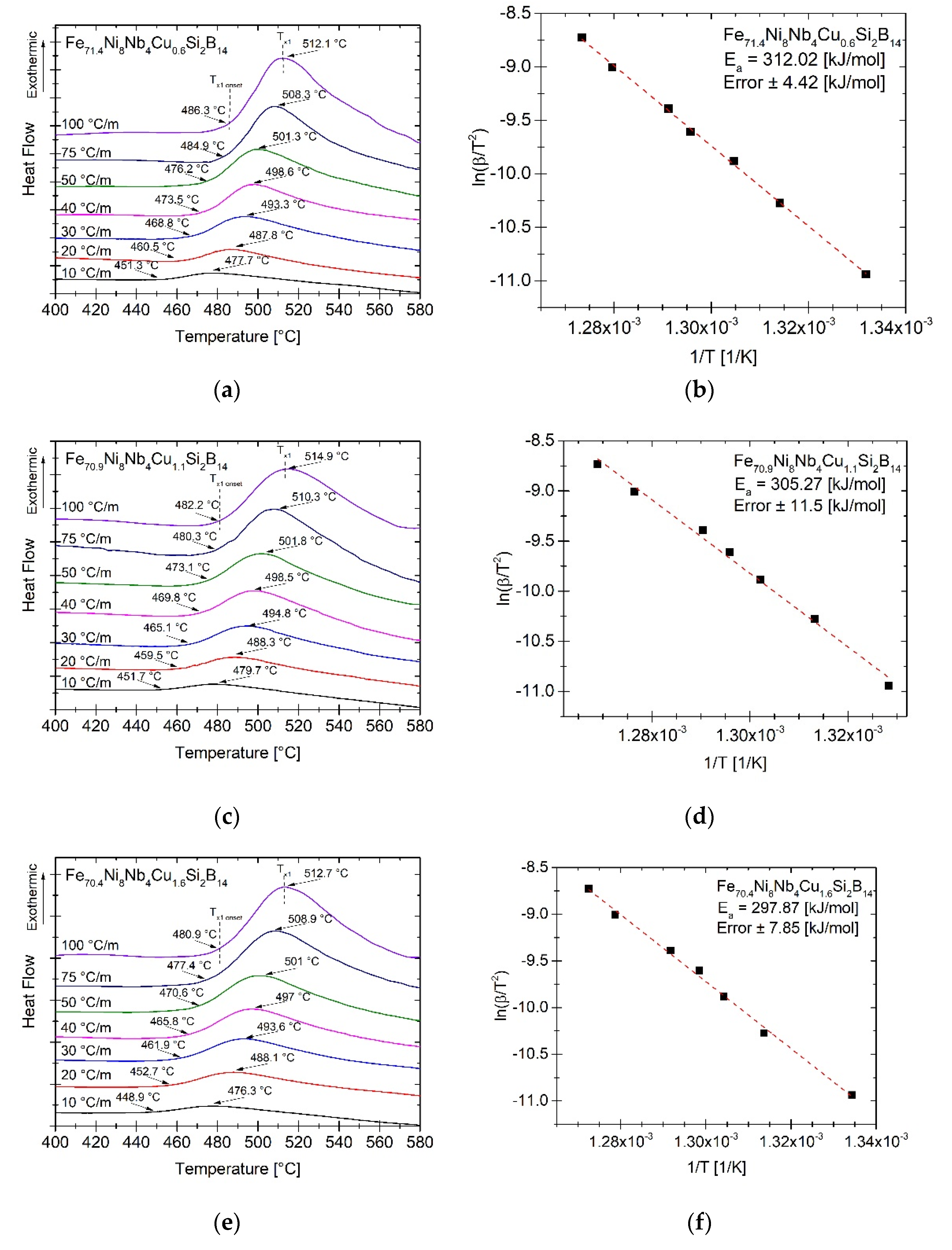

4.1. Kinetic and Structure Studies of As-Spun Alloys

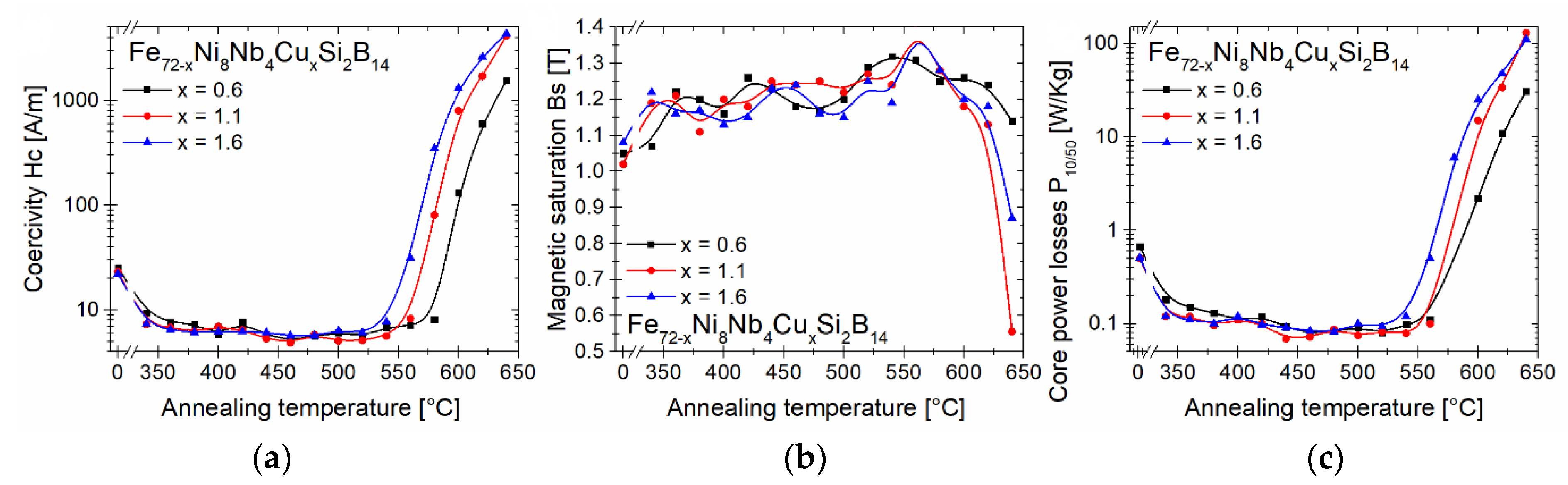

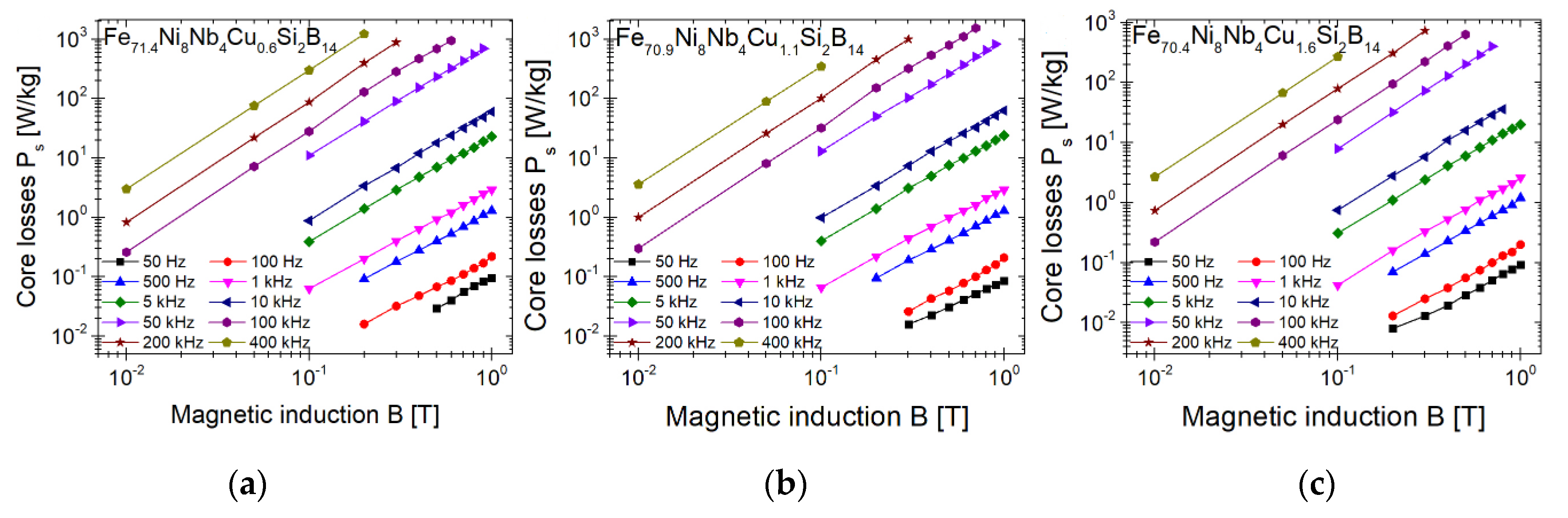

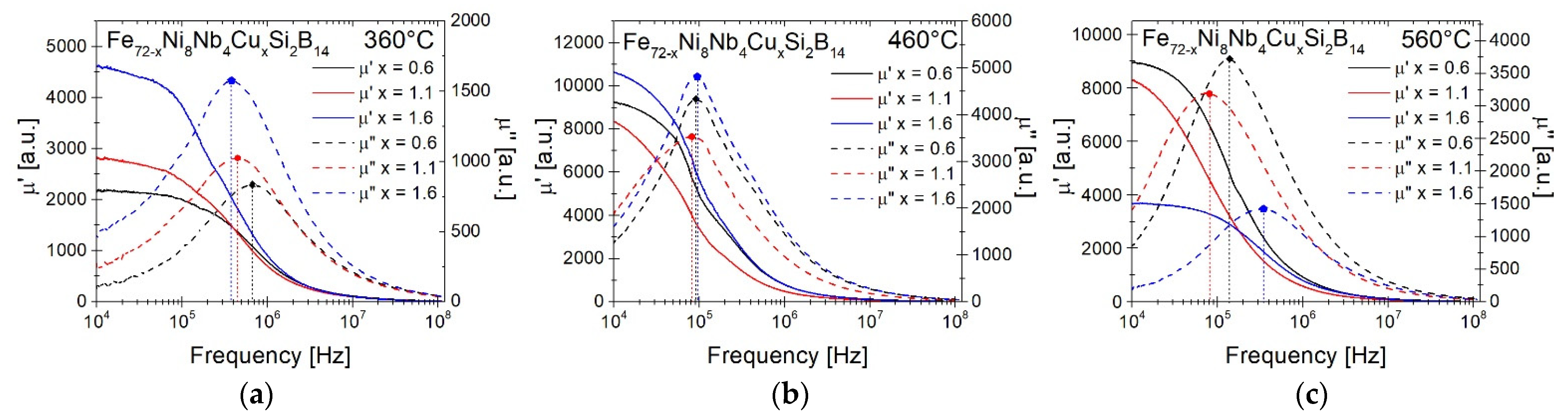

4.2. Magnetic Properties Studies

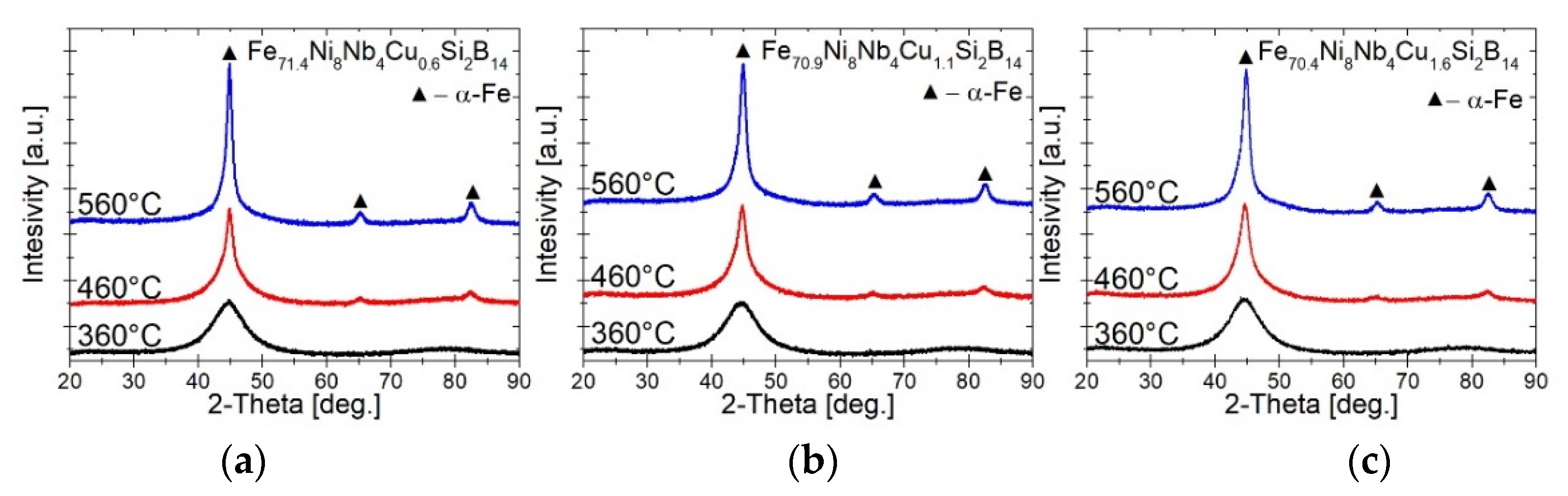

4.3. Crystal Structure of Annealed Alloys

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Eckard, R. Soft Magnetic Materials: Applications and Markets; BCC Publishing: Wellesley, MA, USA, 2020; MFG072A. [Google Scholar]

- Wang, J.; Sheng, W.; Wang, L.; Yang, H. Study on technical and economical efficiency of amorphous alloy transformer and on-load capacity regulating transformer in distribution network application. In Proceedings of the International Conference on Electricity Distribution (CICED), Shenzhen, China, 23–26 September 2014; pp. 30–34. [Google Scholar]

- Yurekten, S.; Kara, A.; Mardikyan, K. Energy efficient green transformer manufacturing with amorphous cores. In Proceedings of the 2013 International Conference on Renewable Energy Research and Applications (ICRERA), Madrid, Spain, 20–23 October 2013; pp. 534–536. [Google Scholar]

- Wang, L.J.; Pei, Y.; Wang, L.Y. Inverter cores using FeMoCuSib nanocrystalline soft magnetic alloys. Mater. Sci. Eng. A 2001, 304–306, 1075–1077. [Google Scholar] [CrossRef]

- Rabiul Islam, M.; Guo, Y.; Wei Lin, Z.; Zhu, J. An amorphous alloy core medium frequency magnetic-link for medium voltage photovoltaic inverters. J. Appl. Phys. 2014, 115, 17E710. [Google Scholar] [CrossRef]

- Okamoto, S.; Denis, N.; Kato, Y.; Ieki, M.; Fujisaki, K. Core Loss Reduction of an Interior Permanent-Magnet Synchronous Motor Using Amorphous Stator Core. IEEE Trans. Ind. Appl. 2016, 52, 2261–2268. [Google Scholar] [CrossRef]

- Matizamhuka, W. The impact of magnetic materials in renewable energy-related technologies in the 21st century industrial revolution: The case of South Africa. Adv. Mater. Sci. Eng. 2018, 2018, 3149412. [Google Scholar] [CrossRef]

- Islam, M.R.; Guo, Y.; Zhu, J. A medium frequency transformer with multiple secondary windings for medium voltage converter based wind turbine power generating systems. J. Appl. Phys. 2013, 113, 17A324. [Google Scholar] [CrossRef]

- Krings, A.; Boglietti, A.; Cavagnino, A.; Sprague, S. Soft Magnetic Material Status and Trends in Electric Machines. IEEE Trans. Ind. Electron. 2017, 64, 2405–2414. [Google Scholar] [CrossRef]

- Ferch, M. Application overview of nanocrystalline inductive components in today’s power electronic systems. Magn. GmbH 2013. Available online: https://www.semanticscholar.org/paper/Application-overview-of-nanocrystalline-inductive-%E2%80%99-Ferch/74ad44215c5bc16a68c8976f752caa5e7ce282f2 (accessed on 3 February 2021).

- Zhang, P.; Wei, H.; Wei, X.; Long, Z.; Su, X. Evaluation of glass-forming ability for bulk metallic glasses based on characteristic temperatures. J. Non-Cryst. Solids 2009, 355, 2183–2189. [Google Scholar] [CrossRef]

- Shi, L.; Yao, K. Composition design for Fe-based soft magnetic amorphous and nanocrystalline alloys with high Fe content. Mater. Des. 2020, 189, 108511. [Google Scholar] [CrossRef]

- Tang, C.; Zhou, H. Thermodynamics and the Glass Forming Ability of Alloys. In Thermodynamics: Physical Chemistry of Aqueous Systemsed; IntechOpen: London, UK, 2011. [Google Scholar]

- Lashgari, H.R.; Chu, D.; Xie, S.; Sun, H.; Ferry, M.; Li, S. Composition dependence of the microstructure and soft magnetic properties of Fe-based amorphous/nanocrystalline alloys: A review study. J. Non Cryst. Solids 2014, 391, 61–82. [Google Scholar] [CrossRef]

- Yao, B.; Si, L.; Tan, H.; Zhang, Y.; Li, Y. Effects of high boron content on crystallization, forming ability and magnetic properties of amorphous Fe91-xZr5B xNb4 alloy. J. Non Cryst. Solids 2003, 331, 43–52. [Google Scholar] [CrossRef]

- Jung, H.Y.; Yi, S. Enhanced glass forming ability and soft magnetic properties through an optimum Nb addition to a Fe-C-Si-B-P bulk metallic glass. Intermetallics 2010, 18, 1936–1940. [Google Scholar] [CrossRef]

- Zhu, M.; Chen, S.; Yao, L.; Li, Y.; Wang, Y.; Jian, Z.; Chang, F. The influence of Ni or Co substitution for Fe on glass forming ability and magnetic properties in the quaternary Fe-Nb-B-Ni and (Fe, Ni, Co)-Nb-B alloy systems. J. Mater. Res. 2015, 30, 811–817. [Google Scholar] [CrossRef]

- Efthimiadis, K.G.; Chrissafis, K.; Polychroniadis, E.K. Combined study of crystallization of amorphous Fe75-xNixSi9B16 alloy. Mater. Sci. Eng. A 2004, 366, 211–220. [Google Scholar] [CrossRef]

- Rahman, A.; Luo, Q.; Lu, Y.; Shen, J. Recurring effects of Cu addition on magnetic properties in Fe-based bulk metallic glasses. J. Non-Cryst. Solids 2015, 442, 1–5. [Google Scholar] [CrossRef]

- Fan, X.; Ma, A.; Men, H.; Xie, G.; Shen, B.; Makino, A.; Inoue, A. Fe-based nanocrystalline FeBCCu soft magnetic alloys with high magnetic flux density. J. Appl. Phys. 2011, 109, 07A314. [Google Scholar] [CrossRef]

- Jiao, Z.B.; Li, H.X.; Gao, J.E.; Wu, Y.; Lu, Z.P. Effects of alloying elements on glass formation, mechanical and soft-magnetic properties of Fe-based metallic glasses. Intermetallics 2011, 19, 1502–1508. [Google Scholar] [CrossRef]

- Jia, Y.; Zeng, S.; Shan, S.; Zhang, L.; Fan, C.; Zhang, B.; Zhan, Z.; Liu, R.; Wang, W. Effect of copper addition on the glass forming ability of a Fe-Co based alloy. J. Alloys Compd. 2007, 440, 113–116. [Google Scholar] [CrossRef]

- Dou, L.; Liu, H.; Hou, L.; Xue, L.; Yang, W.; Zhao, Y.; Chang, C.; Shen, B. Effects of Cu substitution for Fe on the glass-forming ability and soft magnetic properties for Fe-based bulk metallic glasses. J. Magn. Magn. Mater. 2014, 358–359, 23–26. [Google Scholar] [CrossRef]

- Takeuchi, A.; Inoue, A. Classification of bulk metallic glasses by atomic size difference, heat of mixing and period of constituent elements and its application to characterization of the main alloying element. Mater. Trans. 2005, 46, 2817–2829. [Google Scholar] [CrossRef]

- Li, H.X.; Gao, J.E.; Wu, Y.; Jiao, Z.B.; Ma, D.; Stoica, A.D.; Wang, X.L.; Ren, Y.; Miller, M.K.; Lu, Z.P. Enhancing glass-forming ability via frustration of nano-clustering in alloys with a high solvent content. Sci. Rep. 2013, 3, 1983. [Google Scholar] [CrossRef]

- Lesz, S.; Babilas, R.; Dośpial, M.; Nowosielski, R. Effect of Cu addition on the GFA, structure and properties of Fe-Co-based alloy. Arch. Mater. Sci. Eng. 2012, 55, 70–77. [Google Scholar]

- Radoń, A.; Babilas, R.; Włodarczyk, P.; Zackiewicz, P.; Łukowiec, D.; Polak, M.; Kądziołka-Gaweł, M.; Kolano-Burian, A.; Hawełek, Ł. Influence of copper addition and heat treatment parameters on nanocrystallization process of Fe-Co-Mo-B-Si amorphous ribbons with high saturation magnetization about 1.6 T. J. Magn. Magn. Mater. 2020, 496, 165951. [Google Scholar] [CrossRef]

- Warski, T.; Wlodarczyk, P.; Polak, M.; Zackiewicz, P.; Radon, A.; Wojcik, A.; Szlezynger, M.; Kolano-Burian, A.; Hawelek, L. Influence of Cu content on structure and magnetic properties in Fe86-xCuxB14 alloys. Materials 2020, 13, 1451. [Google Scholar] [CrossRef] [PubMed]

- Aronhime, N.; Zoghlin, E.; Keylin, V.; Jin, X.; Ohodnicki, P.; McHenry, M.E. Magnetic properties and crystallization kinetics of (Fe100−xNix)80Nb4Si2B14 metal amorphous nanocomposites. Scr. Mater. 2018, 142, 133–137. [Google Scholar] [CrossRef]

- Aronhime, N.; DeGeorge, V.; Keylin, V.; Ohodnicki, P.; McHenry, M.E. The Effects of Strain-Annealing on Tuning Permeability and Lowering Losses in Fe-Ni-Based Metal Amorphous Nanocomposites. JOM 2017, 69, 2164–2170. [Google Scholar] [CrossRef]

- Gutiérrez, J.; Barandiarán, J.M.; Mínguez, P.; Kaczkowski, Z.; Ruuskanen, P.; Vlasák, G.; Svec, P.; Duhaj, P. Influence of heat treatment on the magnetic and piezomagnetic properties of amorphous and nanocrystalline Fe64Ni10Nb 3Cu1Si13B9 alloy strips. Sens. Actuators A Phys. 2003, 106, 69–72. [Google Scholar] [CrossRef]

- Vacuumschmelze. VITROPERM 250 Product Information. 2010. Available online: https://www.vacuumschmelze.com/Nanocrystalline-Material (accessed on 3 February 2021).

- Hawelek, L.; Warski, T.; Wlodarczyk, P.; Polak, M.; Zackiewicz, P.; Maziarz, W.; Wojcik, A.; Steczkowska-Kempka, M.; Kolano-Burian, A. The Structure and Magnetic Properties of Rapidly Quenched Fe72Ni8Nb4Si2B14 Alloy. Materials 2021, 14, 5. [Google Scholar] [CrossRef] [PubMed]

- De Boer, F.R.; Boom, R.; Mattens, W.C.M.; Miedema, A.R.; Niessen, A.K. Cohesion in Metals: Transition Metal Alloys; Cohesion and Structure vol.1; North Holland: Amsterdam, The Netherlands, 1989; ISBN 0444870989. [Google Scholar]

- Zhang, R.F.; Sheng, S.H.; Liu, B.X. Predicting the formation enthalpies of binary intermetallic compounds. Chem. Phys. Lett. 2007, 442, 511–514. [Google Scholar] [CrossRef]

- Bakker, H. Material Science Foundations: Enthalpies in Alloys—Miedema’s Semi-Empirical Model; Enfield Publishing & Distribution Company: Zurich, Switzerland, 1998; ISBN 0878497838. [Google Scholar]

- Zhang, R.F.; Rajan, K. Statistically based assessment of formation enthalpy for intermetallic compounds. Chem. Phys. Lett. 2014, 612, 177–181. [Google Scholar] [CrossRef]

- Kong, L.H.; Gao, Y.L.; Song, T.T.; Wang, G.; Zhai, Q.J. Non-isothermal crystallization kinetics of FeZrB amorphous alloy. Thermochim. Acta 2011, 552, 166–172. [Google Scholar] [CrossRef]

| Alloy | Annealing Temperatures [°C] | Hc [A/m] | Bs [T] | P10/50 [W/kg] |

|---|---|---|---|---|

| Fe71.4Ni8Nb4Cu0.6Si2B14 | As-spun | 25.7 | 1.05 | 0.67 |

| 360 | 7.64 | 1.22 | 0.15 | |

| 460 | 5.17 | 1.18 | 0.079 | |

| 560 | 7.19 | 1.31 | 0.11 | |

| Fe70.9Ni8Nb4Cu1.1Si2B14 | As-spun | 23.3 | 1.02 | 0.5 |

| 360 | 6.8 | 1.21 | 0.12 | |

| 460 | 4.88 | 1.24 | 0.072 | |

| 560 | 8.28 | 1.41 | 0.1 | |

| Fe70.4Ni8Nb4Cu1.6Si2B14 | As-spun | 22.2 | 1.08 | 0.51 |

| 360 | 6.48 | 1.16 | 0.11 | |

| 460 | 5.69 | 1.24 | 0.084 | |

| 560 | 31.4 | 1.41 | 0.5 | |

| Fe72Ni8Nb4Si2B14 [33] | 370 | 3.95 | 1.09 | 0.092 |

| Ps [W/kg] | x = 0.6 | x = 1.1 | x = 1.6 | x = 0 [33] |

|---|---|---|---|---|

| P10/100 | 0.22 | 0.21 | 0.2 | 0.28 |

| P10/500 | 1.3 | 1.3 | 1.2 | 1.8 |

| P10/1000 | 2.9 | 2.9 | 2.6 | 4.2 |

| P10/5000 | 23 | 24 | 20 | 35 |

| P5/10,000 | 18 | 19 | 16 | 29 |

| P5/50,000 | 232 | 261 | 202 | 321 |

| P1/100,000 | 28 | 32 | 24 | 39 |

| P1/200,000 | 87 | 102 | 79 | 110 |

| P0.5/400,000 | 76 | 89 | 67 | 88 |

| Alloy | Annealing Temperature [°C] | Magnetic Permeability µ′ at 104 Hz | Cut-Off Frequency [Hz] |

|---|---|---|---|

| Fe71.4Ni8Nb4Cu0.6Si2B14 | 360 | 2152 | 6.7 × 105 |

| 460 | 9252 | 8.9 × 104 | |

| 560 | 8946 | 1.39 × 105 | |

| Fe70.9Ni8Nb4Cu1.1Si2B14 | 360 | 2825 | 4.17 × 105 |

| 460 | 8350 | 8 × 104 | |

| 560 | 8309 | 6.8 × 104 | |

| Fe70.4Ni8Nb4Cu1.6Si2B14 | 360 | 4623 | 3.8 × 105 |

| 460 | 10,630 | 9.3 × 104 | |

| 560 | 3679 | 3.35 × 105 | |

| Fe72Ni8Nb4Si2B14 [33] | 370 | 3100 | 5.07 × 105 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Warski, T.; Radon, A.; Zackiewicz, P.; Wlodarczyk, P.; Polak, M.; Wojcik, A.; Maziarz, W.; Kolano-Burian, A.; Hawelek, L. Influence of Cu Content on Structure, Thermal Stability and Magnetic Properties in Fe72−xNi8Nb4CuxSi2B14 Alloys. Materials 2021, 14, 726. https://doi.org/10.3390/ma14040726

Warski T, Radon A, Zackiewicz P, Wlodarczyk P, Polak M, Wojcik A, Maziarz W, Kolano-Burian A, Hawelek L. Influence of Cu Content on Structure, Thermal Stability and Magnetic Properties in Fe72−xNi8Nb4CuxSi2B14 Alloys. Materials. 2021; 14(4):726. https://doi.org/10.3390/ma14040726

Chicago/Turabian StyleWarski, Tymon, Adrian Radon, Przemyslaw Zackiewicz, Patryk Wlodarczyk, Marcin Polak, Anna Wojcik, Wojciech Maziarz, Aleksandra Kolano-Burian, and Lukasz Hawelek. 2021. "Influence of Cu Content on Structure, Thermal Stability and Magnetic Properties in Fe72−xNi8Nb4CuxSi2B14 Alloys" Materials 14, no. 4: 726. https://doi.org/10.3390/ma14040726

APA StyleWarski, T., Radon, A., Zackiewicz, P., Wlodarczyk, P., Polak, M., Wojcik, A., Maziarz, W., Kolano-Burian, A., & Hawelek, L. (2021). Influence of Cu Content on Structure, Thermal Stability and Magnetic Properties in Fe72−xNi8Nb4CuxSi2B14 Alloys. Materials, 14(4), 726. https://doi.org/10.3390/ma14040726