The Effect of Stretching on the Crystal Structure and Crystal Orientation of PA510/SiO2 Films

Abstract

:1. Introduction

2. Experiment

2.1. Materials

2.2. The Preparation of PA510/SiO2 Cast Films

2.3. The Preparation of PA510/SiO2 Biaxially Stretched Films

2.4. Characterization of PA510/SiO2 Films

3. Results and Discussion

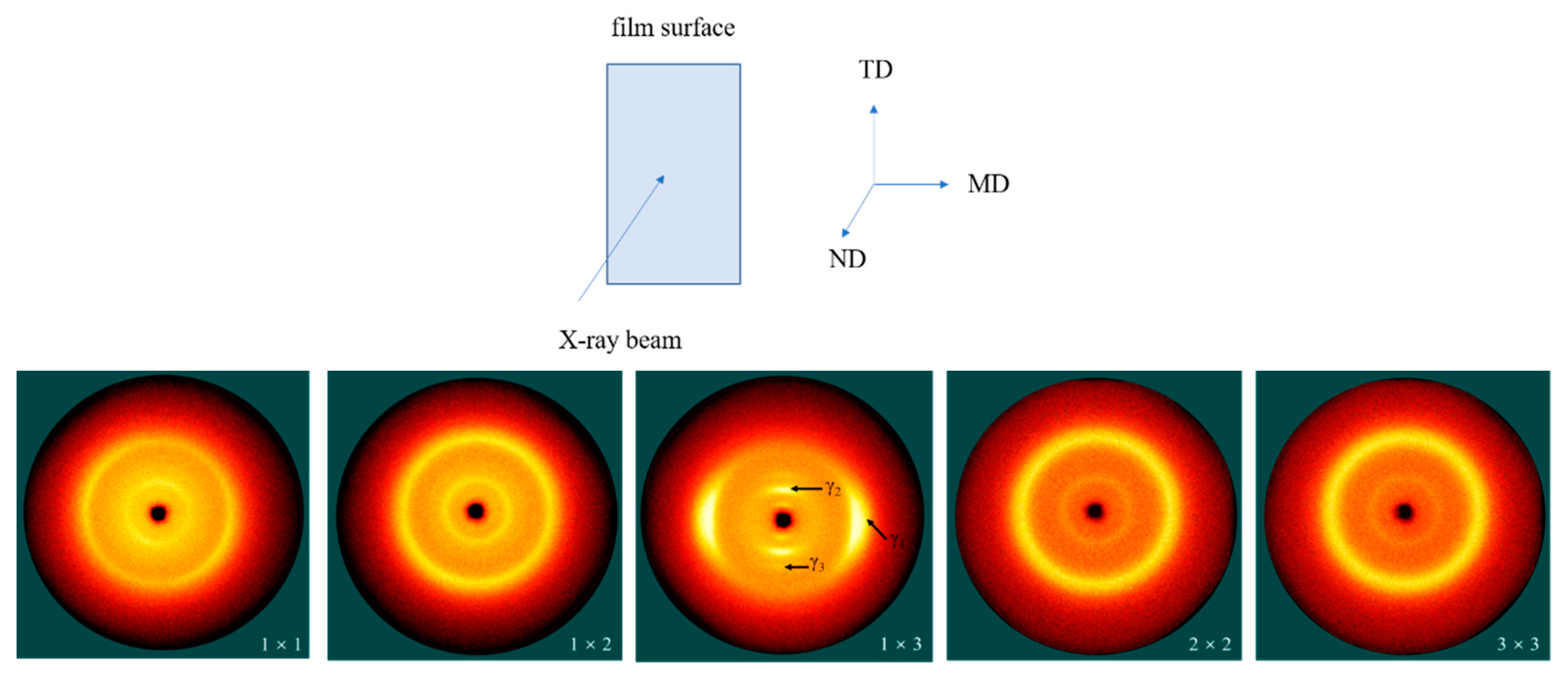

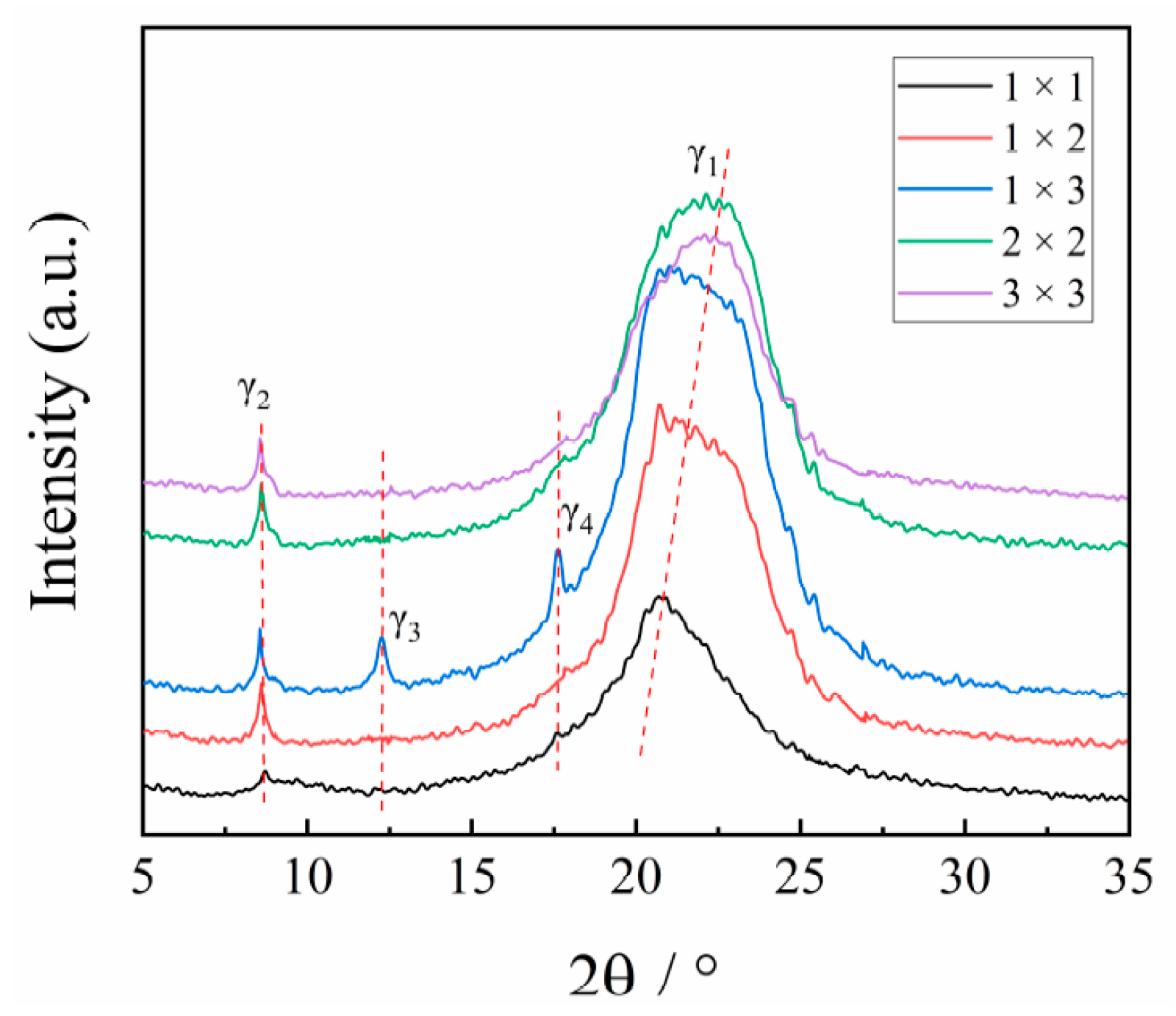

3.1. The Effect of Stretching on Crystal Structure of PA510/SiO2 Films

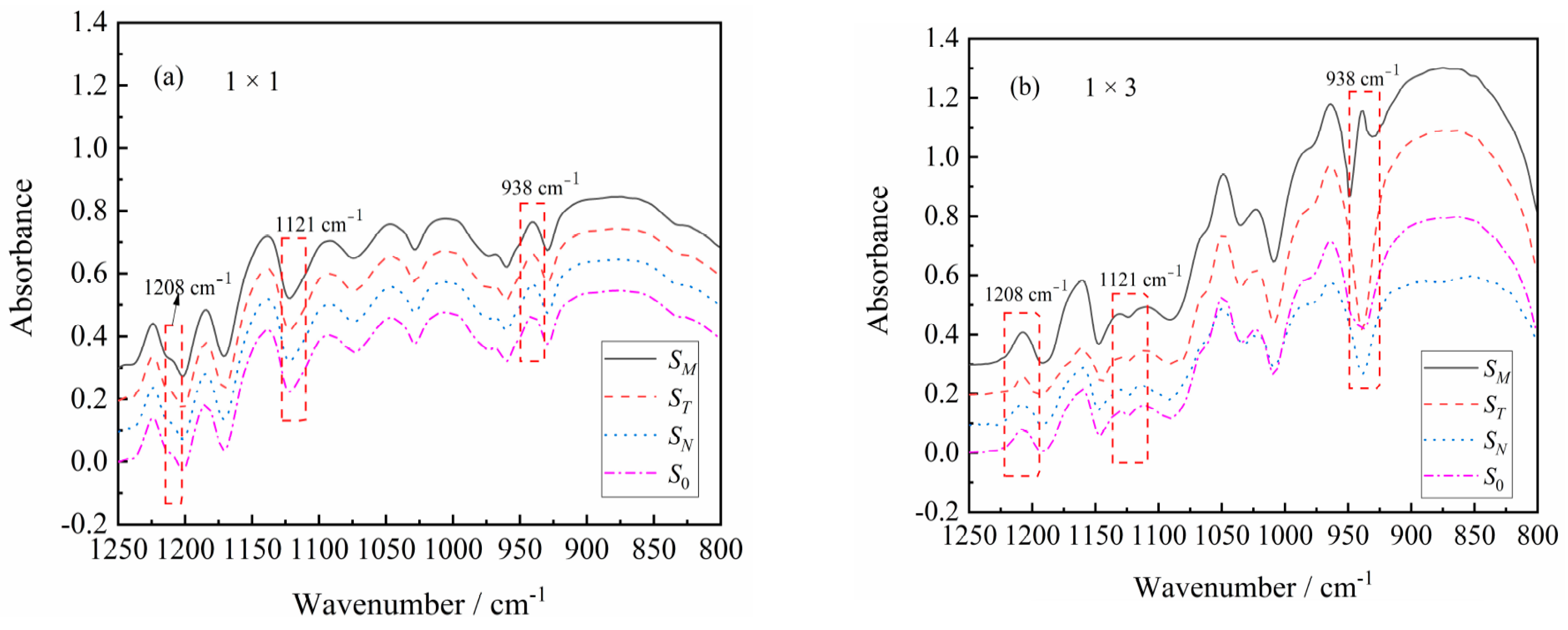

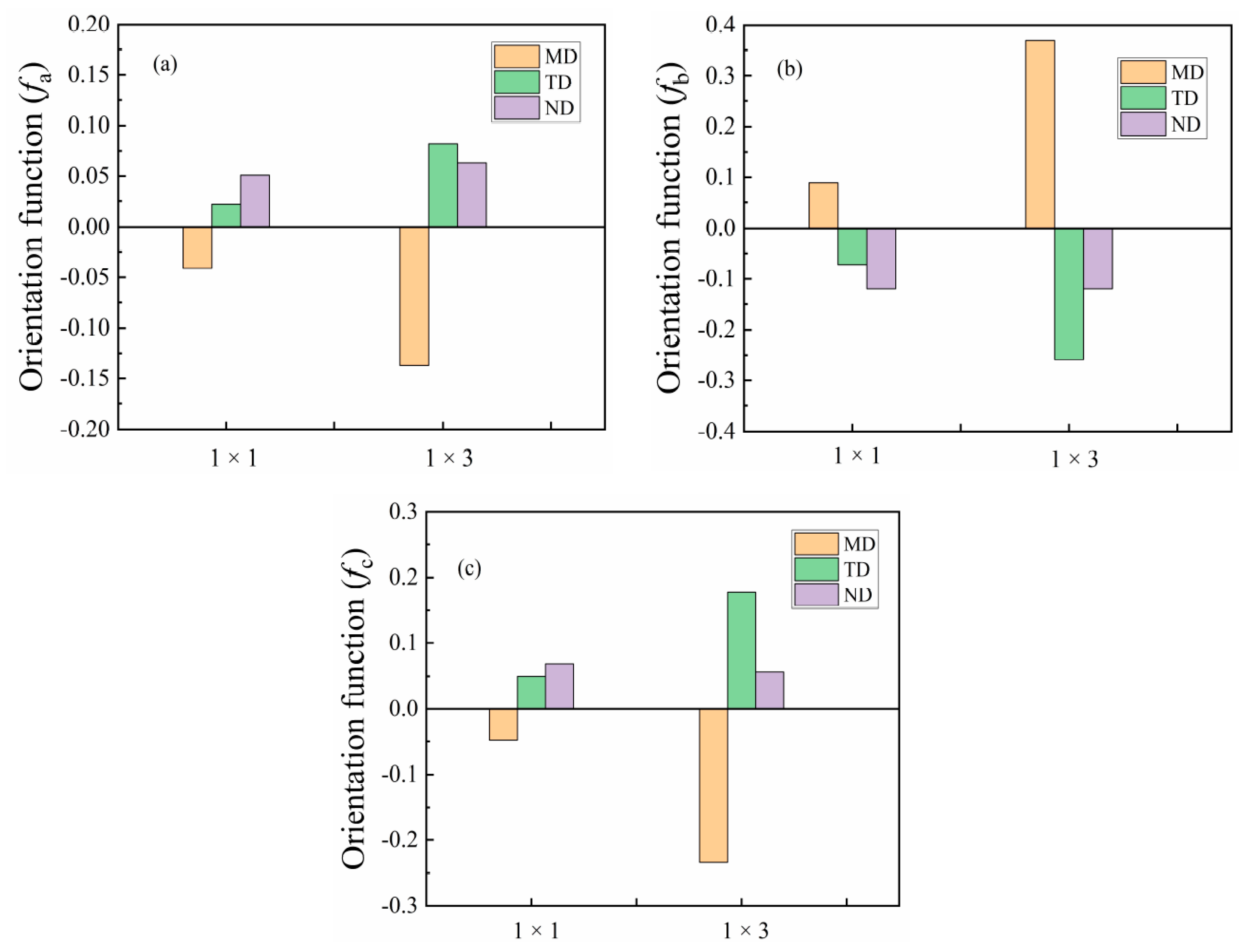

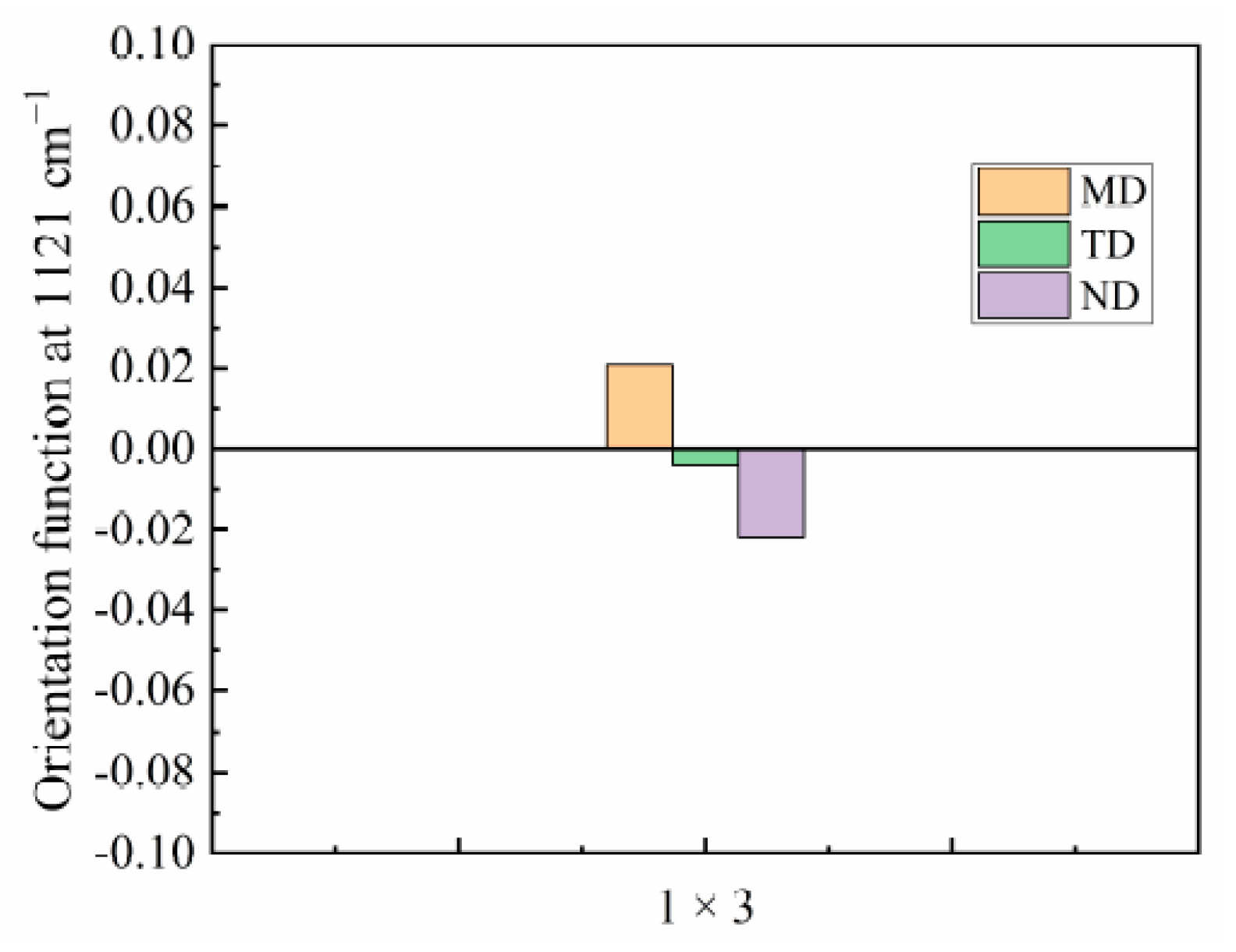

3.2. The Effect of Stretching on Orientation of PA510/SiO2 Films Crystalline Phase

3.3. The Effect of Stretching on the Thermal Properties of PA510/SiO2 Films

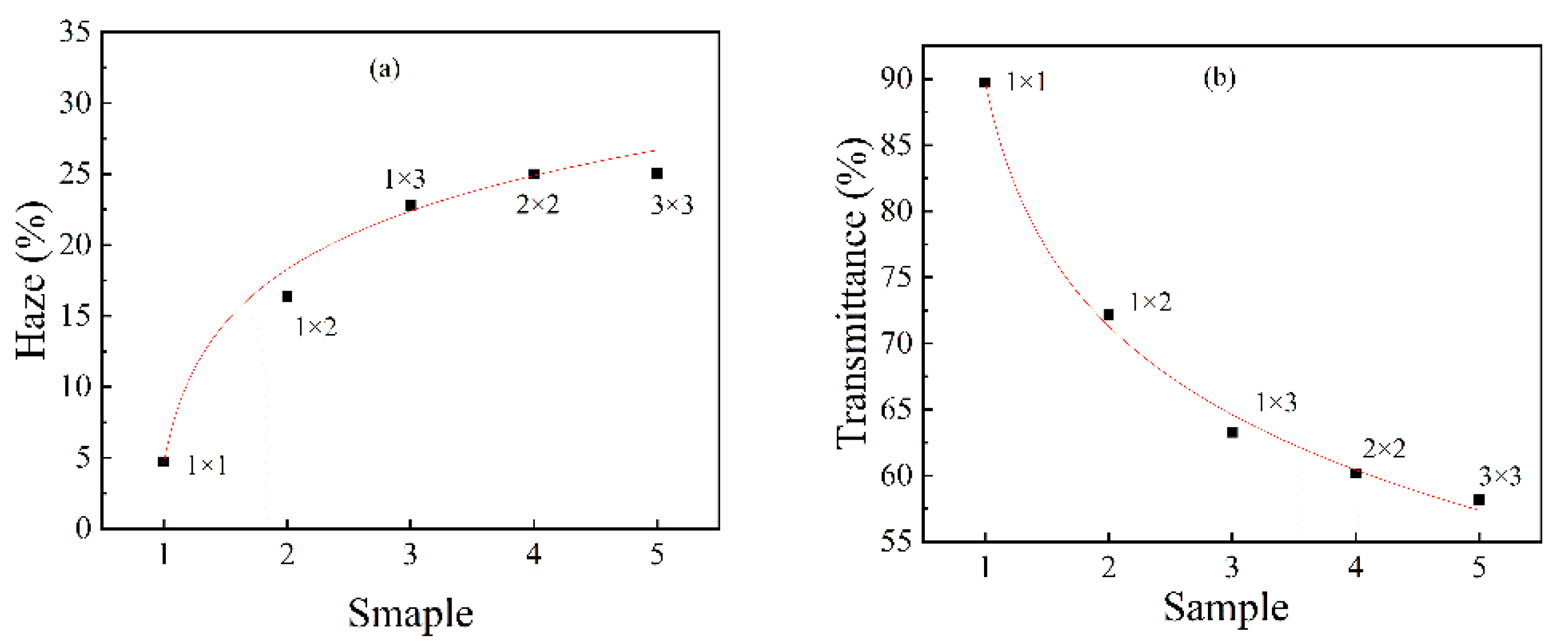

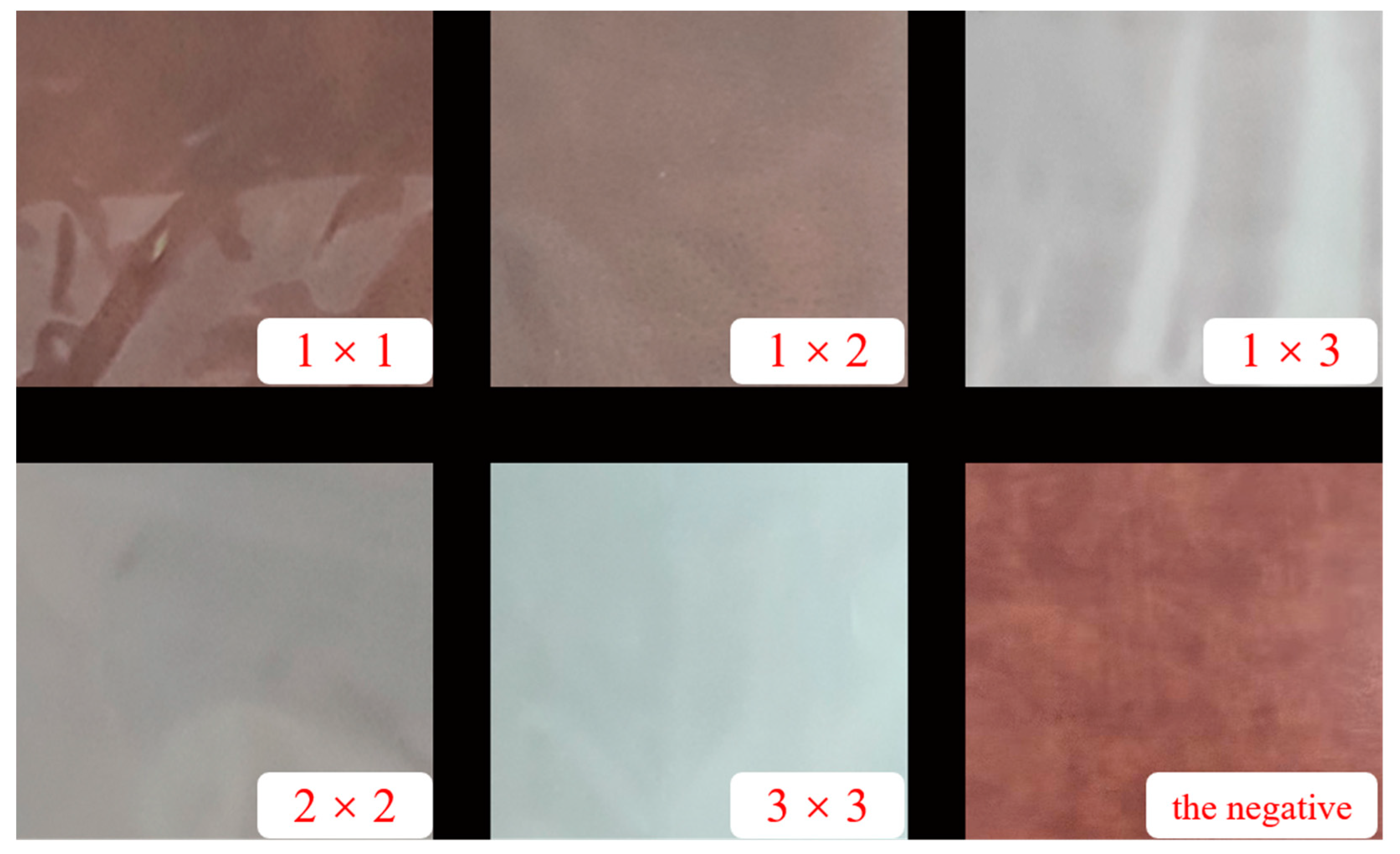

3.4. The Effect of Stretching on the Optical Properties of PA510/SiO2 Films

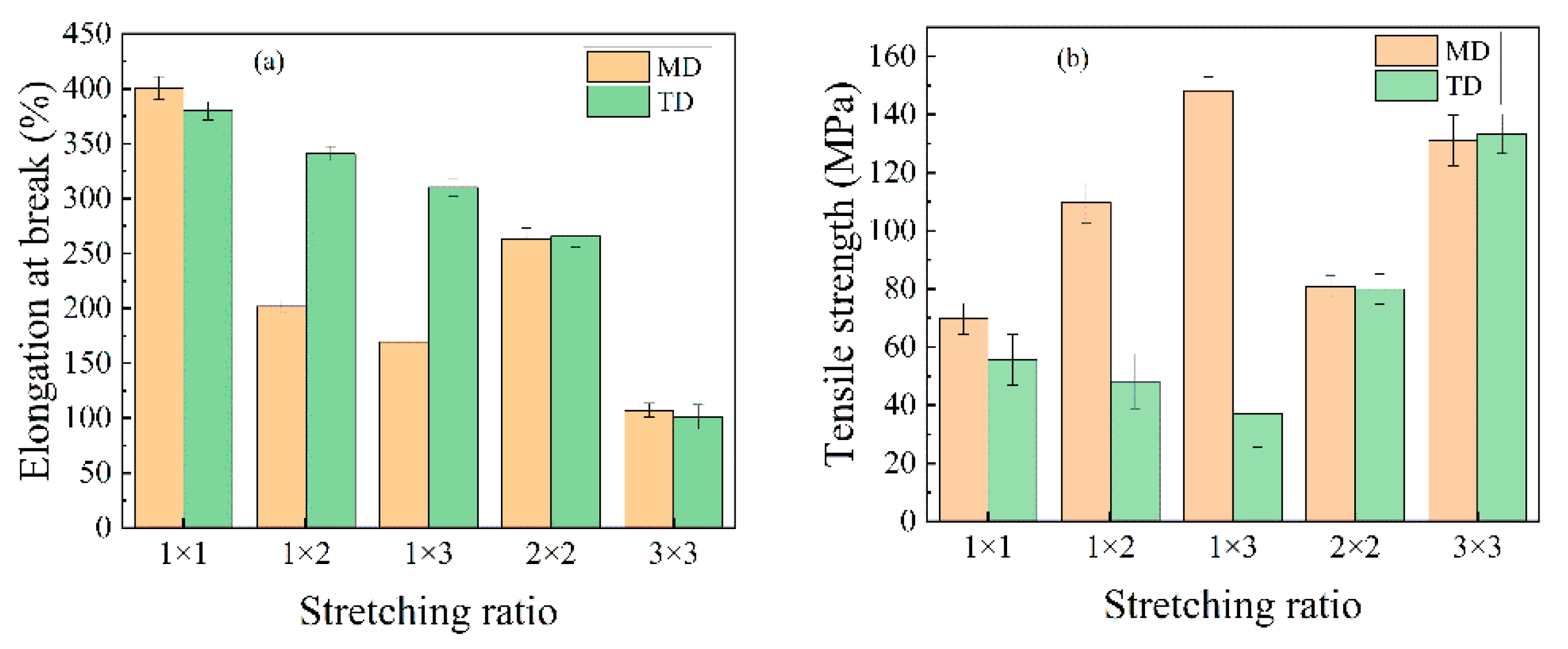

3.5. The Effect of Stretching on the Mechanical Properties of PA510/SiO2 Films

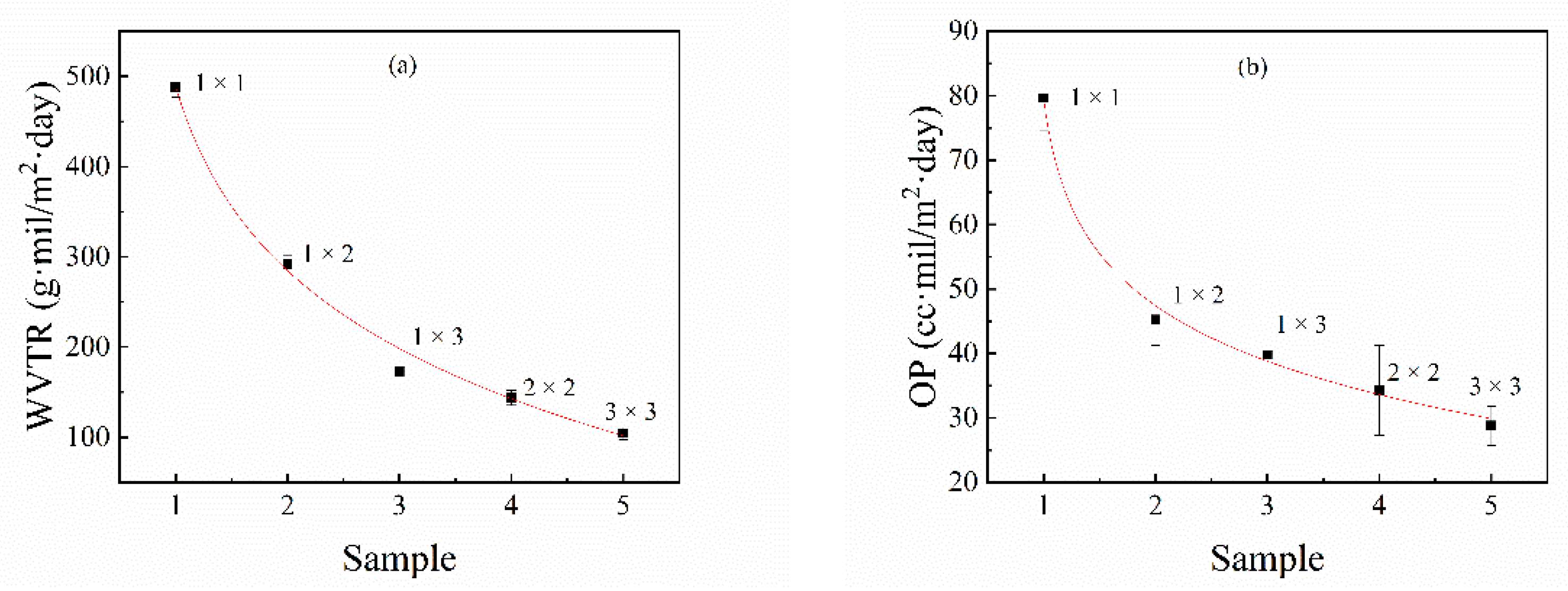

3.6. The Effect of Stretching on the Barrier Properties of PA510/SiO2 Films

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tabatabaei, S.H.; Carreau, P.J.; Ajji, A. Structure and properties of MDO stretched polypropylene. Polymer 2009, 50, 3981–3989. [Google Scholar] [CrossRef]

- Lin, Y.J.; Dias, P.; Chen, H.Y. Oxygen permeability of biaxially oriented polypropylene films. Polym. Eng. Sci. 2008, 48, 642–648. [Google Scholar] [CrossRef]

- Chu, F.; Kimura, Y. Structure and gas permeability of microporous films prepared by biaxial drawing of β-form polypropylene. Polymer 1996, 37, 573–579. [Google Scholar] [CrossRef]

- Tabatabaei, S.H.; Carreau, P.J.; Ajji, A. Microporous membranes obtained from polypropylene blend films by stretching. J. Membrane. Sci. 2008, 325, 772–782. [Google Scholar] [CrossRef]

- Soon, K.; Harkin-Jones, E.; Rajeev, R.S. Morphology, barrier, and mechanical properties of biaxially deformed poly (ethylene terephthalate)-mica nanocomposites. Polym. Eng. Sci. 2012, 52, 532–548. [Google Scholar] [CrossRef]

- Abu-Zurayk, R.; Harkin-Jones, E. The influence of processing route on the structuring and properties of high-density polyethylene (HDPE)/clay nanocomposites. Polym. Eng. Sci. 2012, 52, 2360–2368. [Google Scholar] [CrossRef]

- Tabatabaei, S.H.; Carreau, P.J.; Ajji, A. Microporous membranes obtained from PP/HDPE multilayer films by stretching. J. Membrane. Sci. 2009, 345, 148–159. [Google Scholar] [CrossRef]

- Kaixi, T. Development and application of new polyamide engineering plastics with long carbon chain. Modern. Plast. Process. Appl. 2001, 5, 7–10. [Google Scholar]

- Jia, H. The present situation and prospect for the development of the engineering plastics industry in China. Eng. Plast. Appl. 2006, 34, 66–67. [Google Scholar]

- China becomes largest importer of engineering plastics. Plast. Addit. Compound. 2005, 7, 10–11. [CrossRef]

- Huang, S.; Wang, M.; Liu, T. Morphology, thermal, and rheological behavior of nylon 11/multi-walled carbon nanotube nanocomposites prepared by melt compounding. Polym. Eng. Sci. 2010, 49, 1063–1068. [Google Scholar] [CrossRef]

- Hu, Y.; Shen, L.; Yang, H. Nanoindentation studies on Nylon 11/clay nanocomposites. Polym. Test. 2006, 25, 492–497. [Google Scholar] [CrossRef]

- O’Neill, A.; Bishop, D.; Dalton, B.; Archer, E.; McIlhagger, A.; Dixon, D. Preparation and properties of polyamide 6 nanocomposites covalently linked with amide functional graphene oxide. J. Thermoplast. Compos. 2018, 31, 162–180. [Google Scholar] [CrossRef]

- Penel-Pierron, L.; Depecker, C.R.; Séguéla, R. Structural and mechanical behavior of nylon 6 films part I. Identification and stability of the crystalline phases. J. Polym. Sci. Pol. Phys. 2015, 39, 484–495. [Google Scholar] [CrossRef]

- Penel-Pierron, L.; Seguela, R.; Lefebvre, J.M. Structural and mechanical behavior of nylon-6 films. II. Uniaxial and biaxial drawing. J. Polym. Sci. Pol. Phys. 2001, 39, 1224–1236. [Google Scholar] [CrossRef]

- Rhee, S.; White, J.L. Crystal structure, morphology, orientation, and mechanical properties of biaxially oriented polyamide 6 films. Polymer 2002, 43, 5903–5914. [Google Scholar] [CrossRef]

- Yoshida, T.; Asano, T.; Matsuura, M. Structure and mechanical properties of nylon 6.12 prepared by temperature slope crystallization. I. Crystallization of oriented spherulitic textures. J. Macromol. Sci. B 1997, 36, 789–798. [Google Scholar] [CrossRef]

- Fornes, T.D.; Paul, D.R. Structure and properties of nanocomposites based on Nylon11 and -12 compared with those based on nylon6. Macromolecules 2012, 37, 7698–7709. [Google Scholar] [CrossRef]

- Cole, K.C.; Denault, J.; Bureau, M.N. Infrared spectroscopy studies of structure and orientation in clay-reinforced polyamide-6 nanocomposites. Macromol. Symp. 2004, 205, 47–60. [Google Scholar] [CrossRef]

- Garton, A.; Carlsson, D.J.; Wiles, D.M. Molecular orientation measurements in polymers by infrared spectral subtraction. Appl. Spectrosc. 1981, 35, 432–435. [Google Scholar] [CrossRef]

- Cole, K.C.; Depecker, C.; Jutigny, M. Biaxial deformation of polyamide-6: Assessment of orientation by means of infrared trichroism. Polym. Eng. Sci. 2004, 44, 231–240. [Google Scholar] [CrossRef]

- Van Krevelen, D.W. Properties of polymers. Popular. Plast. Packaging. 2009, 54, 75. [Google Scholar]

- Samuels, J.E. High-barrier flexible polyvinylidene chloride composite applications. In Current Technologies in Flexible Packaging: A Symposium Sponsored by ASTM Committee F-2 on Flexible Barrier Materials and the Flexible Packaging Association, St. Charles, IL, 1 Nov. 1984; ASTM International: West Conshohocken, PA, USA, 1986; Volume 912, p. 6. [Google Scholar]

- Avena-Bustillos, R.J.; Krochta, J.M. Water vapor permeability of caseinate-based edible films as affected by pH, calcium crosslinking and lipid content. J. Food. Sci. 1993, 58, 904–907. [Google Scholar] [CrossRef]

- Wu, S.H.; Wang, F.Y.; Ma, C.C.M. Mechanical, thermal and morphological properties of glass fiber and carbon fiber reinforced polyamide-6 and polyamide-6/clay nanocomposites. Mater. Lett. 2001, 49, 327–333. [Google Scholar] [CrossRef]

- Wu, T.; Cai, B.; Wang, J. Tempo-oxidized cellulose nanofibril/layered double hydroxide nanocomposite films with improved hydrophobicity, flame retardancy and mechanical properties. Compos. Sci. Technol. 2019, 171, 111–117. [Google Scholar] [CrossRef]

- Fereydoon, M.; Tabatabaei, S.H.; Ajji, A. Effect of uniaxial stretching on thermal, oxygen barrier, and mechanical properties of polyamide 6 and poly (m-xylene adipamide) nanocomposite films. Polym. Eng. Sci. 2015, 55, 1113–1127. [Google Scholar] [CrossRef]

- Villaseñor, P.; Franco, L.; Subirana, J.A. On the crystal structure of odd–even nylons: Polymorphism of nylon 510. J. Polym. Sci. Pol. Phys. 1999, 37, 2383–2395. [Google Scholar] [CrossRef]

| Stretching Ratio (TD × MD) | Melting Temperature (°C) | Melting Enthalpy (J/g) | Crystallinity (%) |

|---|---|---|---|

| 1 × 1 | 216.61 | 59.88 | 31.50 |

| 1 × 2 | 215.67 | 61.31 | 32.30 |

| 1 × 3 | 215.18 | 74.76 | 39.30 |

| 2 × 2 | 216.21 | 64.56 | 34.00 |

| 3 × 3 | 215.76 | 62.27 | 32.80 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cui, L.; Dong, Y.; Liu, Y.; Fan, S. The Effect of Stretching on the Crystal Structure and Crystal Orientation of PA510/SiO2 Films. Materials 2021, 14, 705. https://doi.org/10.3390/ma14040705

Cui L, Dong Y, Liu Y, Fan S. The Effect of Stretching on the Crystal Structure and Crystal Orientation of PA510/SiO2 Films. Materials. 2021; 14(4):705. https://doi.org/10.3390/ma14040705

Chicago/Turabian StyleCui, Lingna, Yu Dong, Yuejun Liu, and Shuhong Fan. 2021. "The Effect of Stretching on the Crystal Structure and Crystal Orientation of PA510/SiO2 Films" Materials 14, no. 4: 705. https://doi.org/10.3390/ma14040705

APA StyleCui, L., Dong, Y., Liu, Y., & Fan, S. (2021). The Effect of Stretching on the Crystal Structure and Crystal Orientation of PA510/SiO2 Films. Materials, 14(4), 705. https://doi.org/10.3390/ma14040705