Thermal Cycling of (RE)BCO-Based Superconducting Tapes Joined by Lead-Free Solders

Abstract

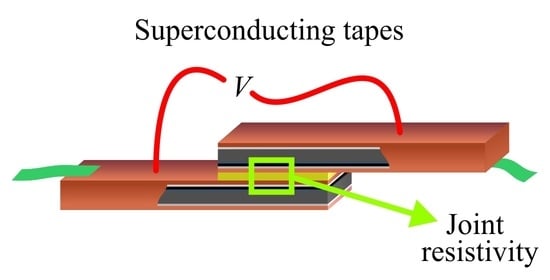

1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Superconducting Tapes

2.1.2. Solders

2.1.3. Fluxes and their Deposition

2.1.4. Cleaning Agents

2.2. Methods

2.2.1. Preparation of the Joints

2.2.2. Cross-Sections for SEM Analysis

2.2.3. Thermal Cycling

2.2.4. I–V Measurements

3. Results and Discussion

3.1. Group 1 Joints: Selection of Materials and Optimization of the Preparation Procedure

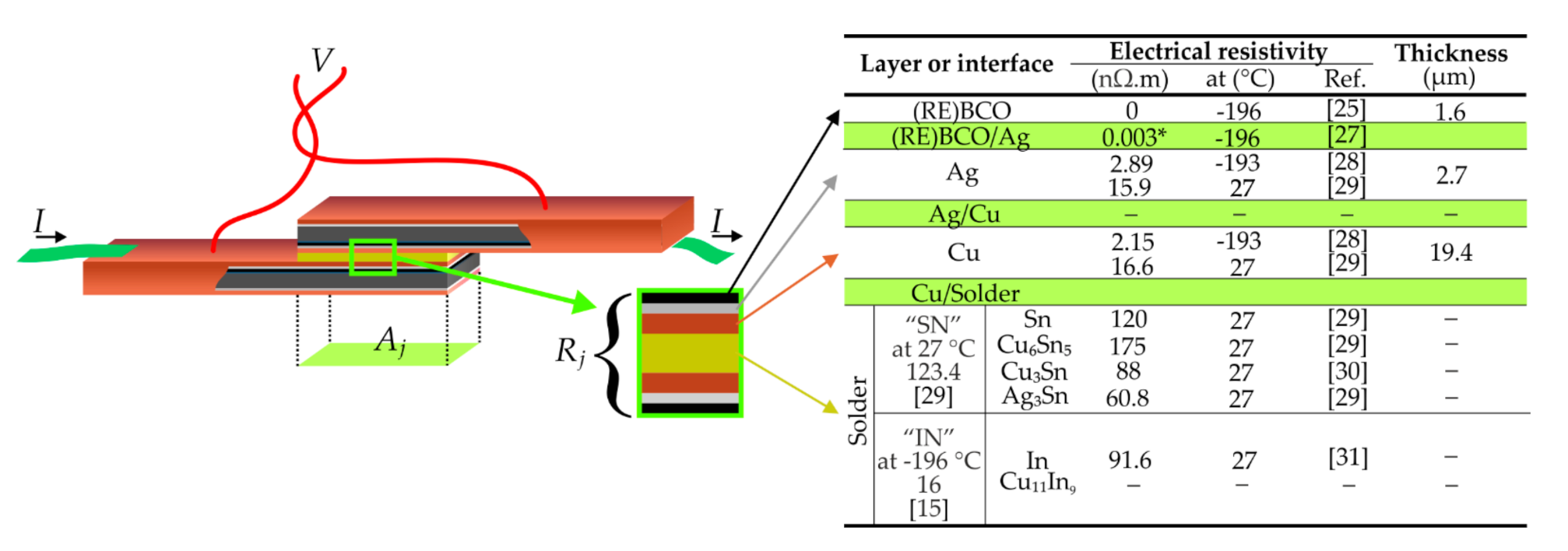

3.1.1. Initial State of the Joints

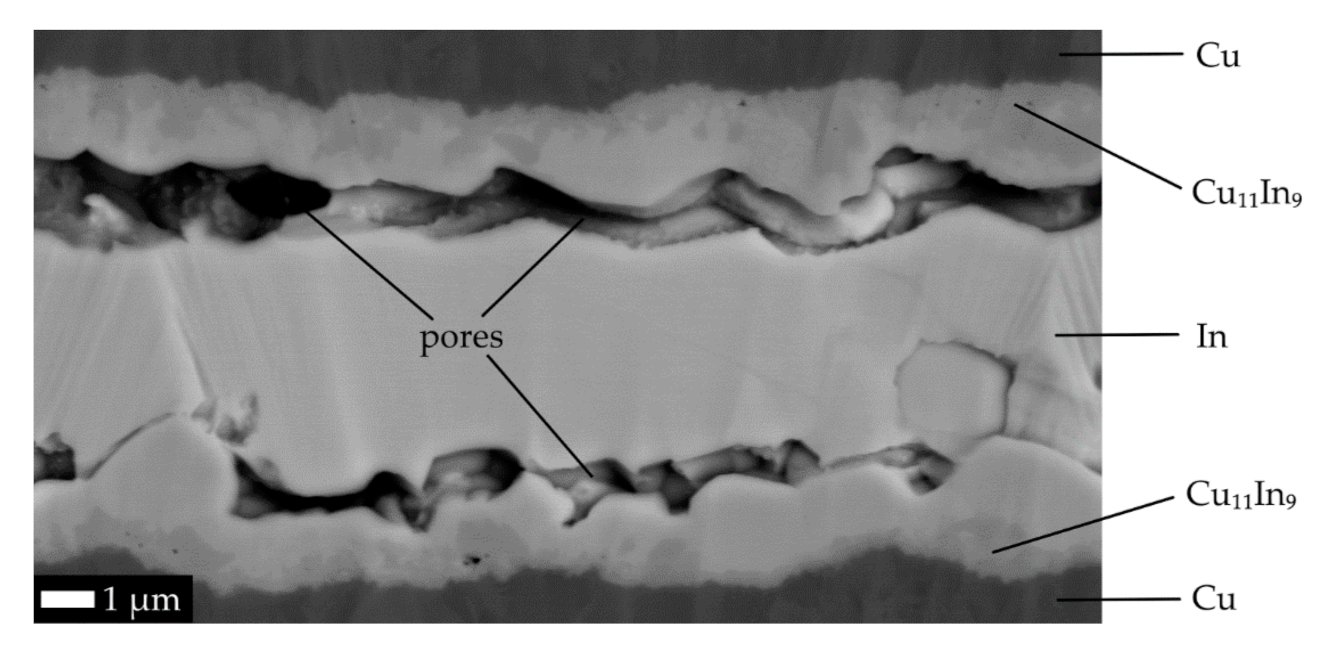

3.1.1.1. Joints with the “IN” Solder

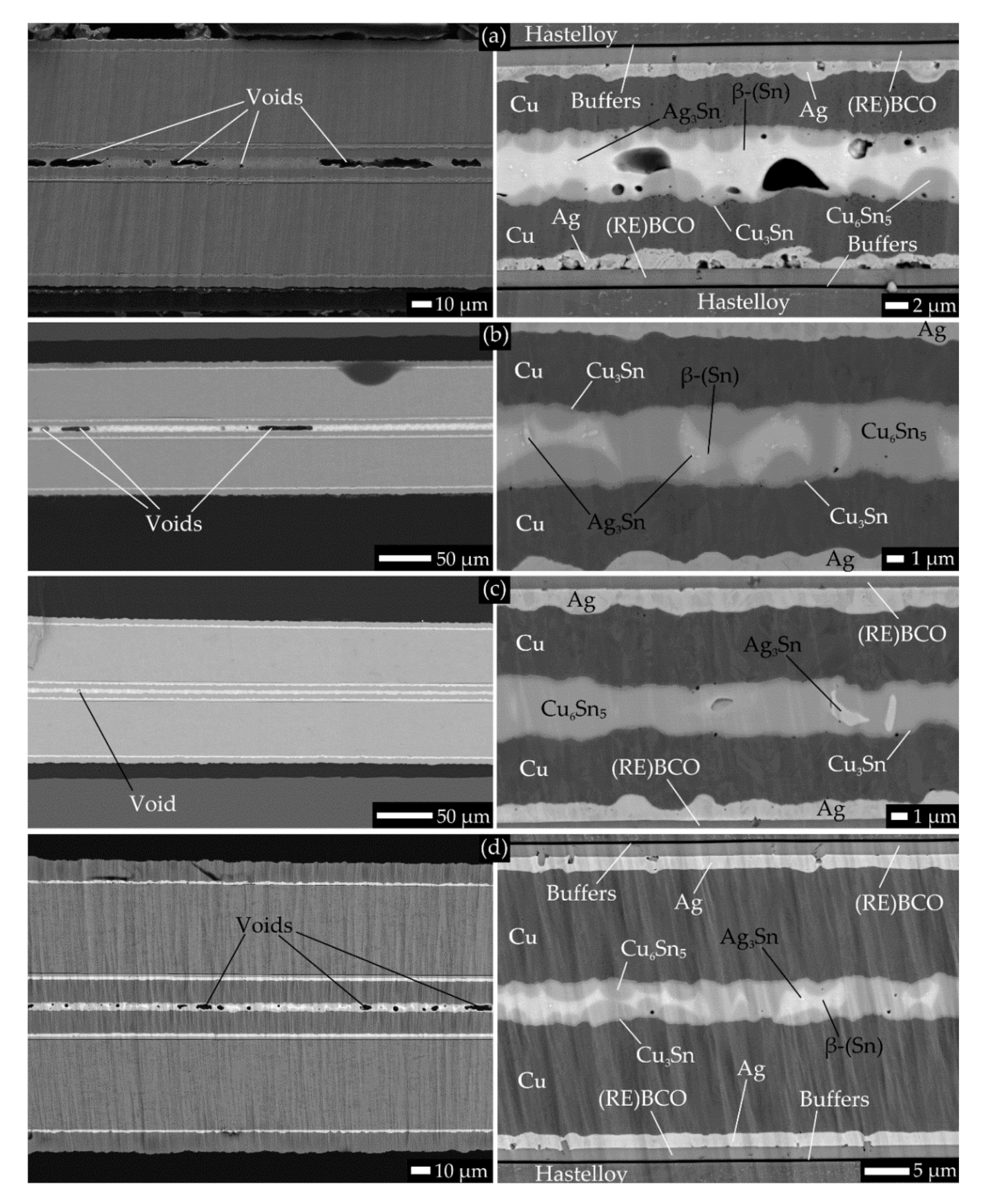

3.1.1.2. Joints with the “SN” Solder

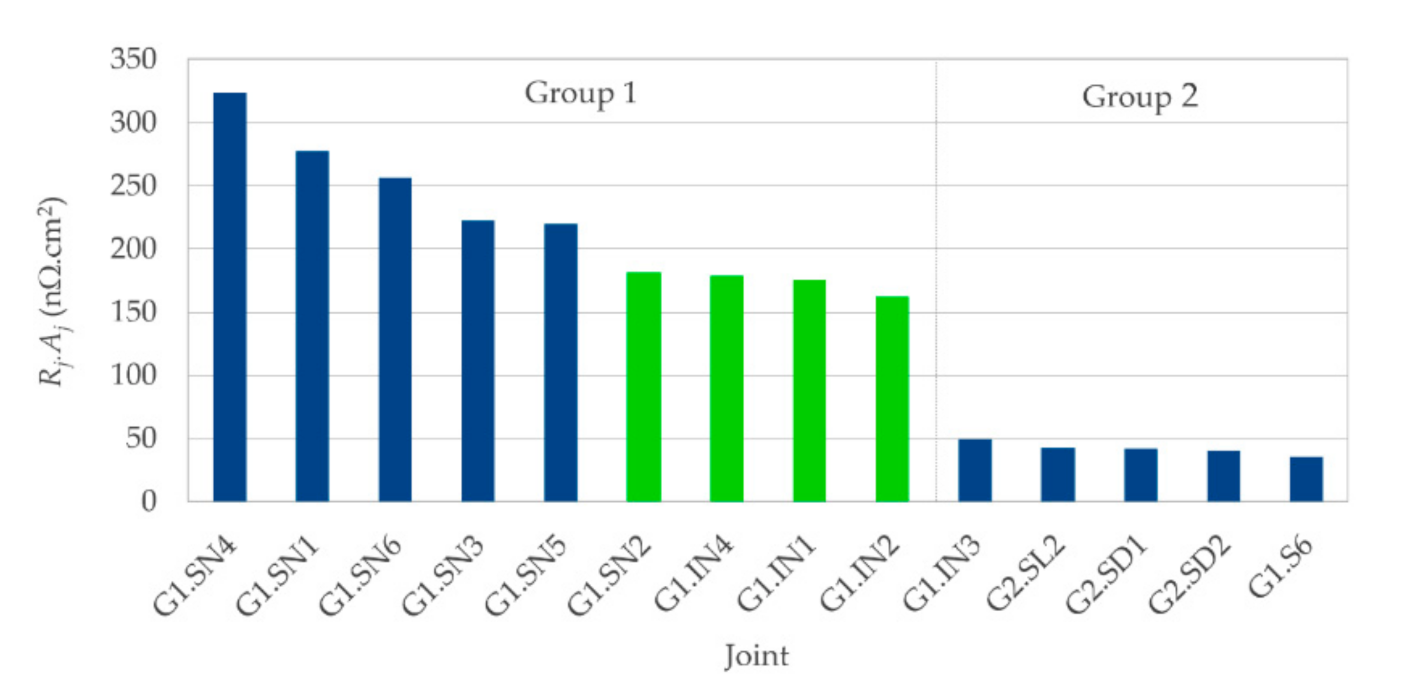

3.1.1.3. Group 1 Joints: Summary of the Initial State

3.1.2. Thermal Cycling of the Joints

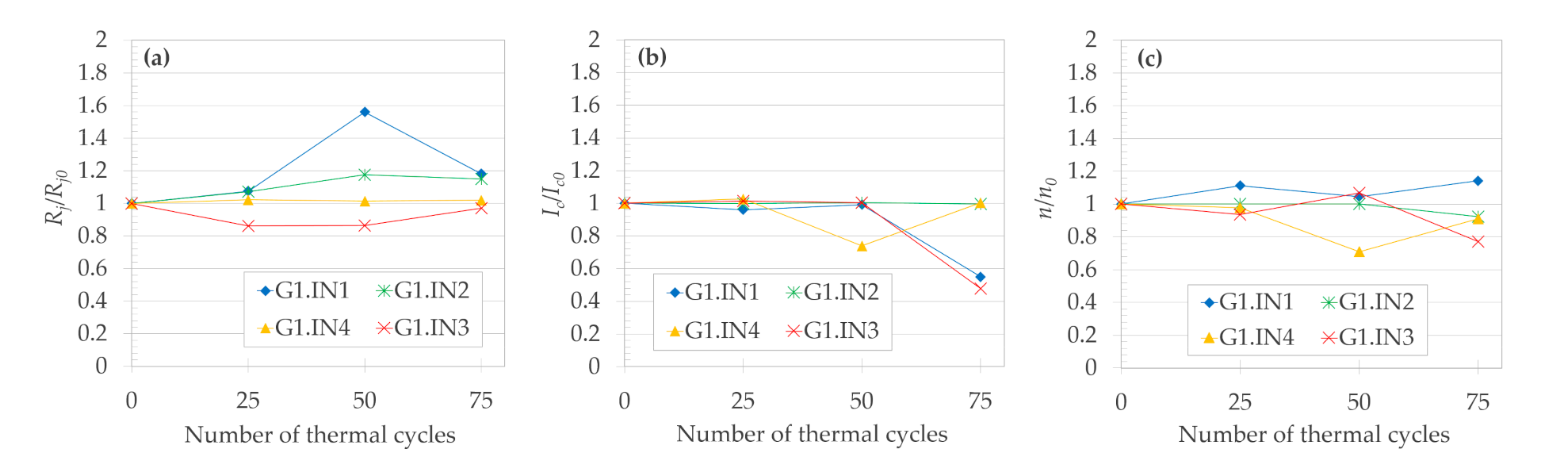

3.1.2.1. Joints with the “IN” Solder

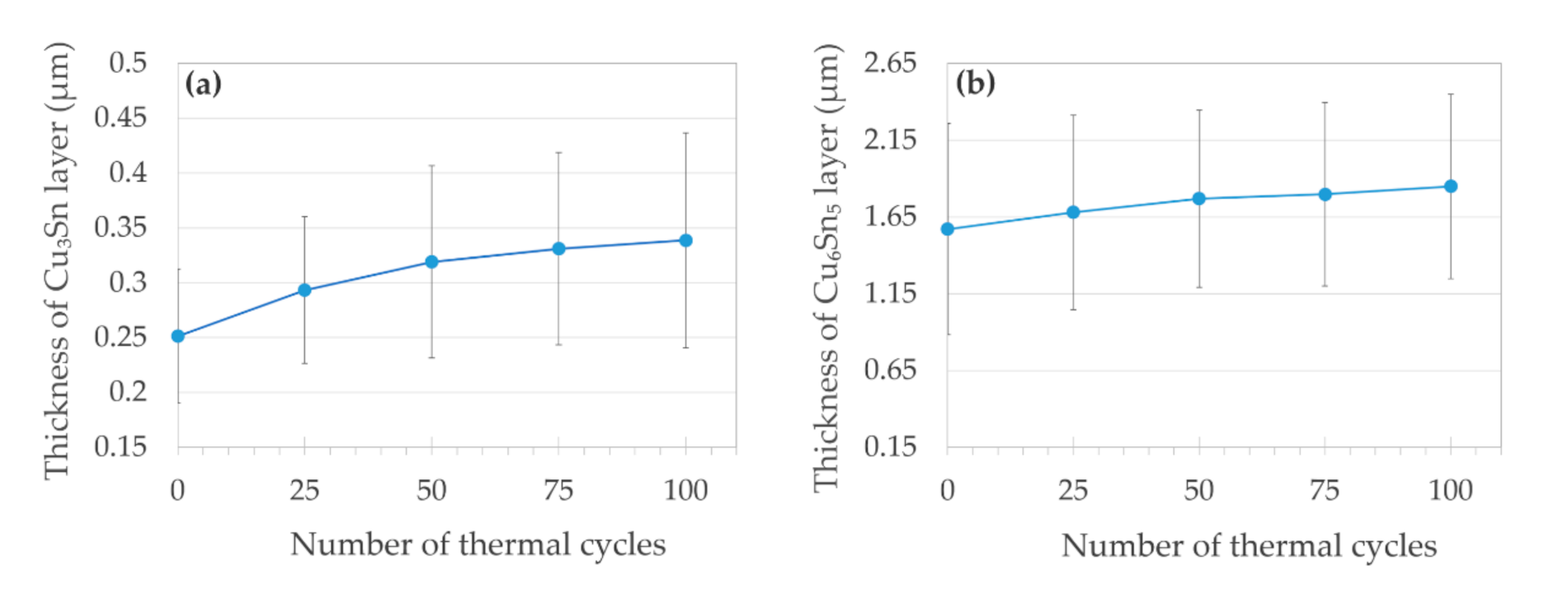

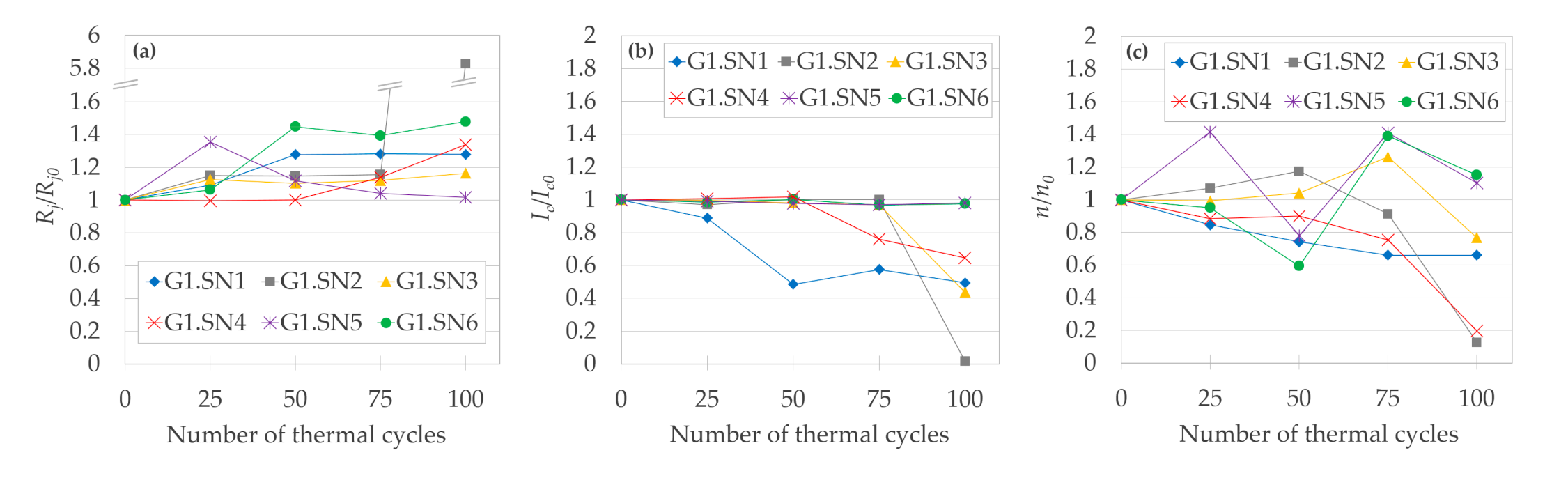

3.1.2.2. Joints with the “SN” Solder

3.1.2.3. Group 1 Joints: Summary of Thermal Cyclings

3.2. Group 2 joints: Performance of Good Quality Joints during Thermal Cycling

3.2.1. Initial State of the Joints

3.2.2. Thermal Cycling of the Joints

3.2.2.1. Evolution of Rj/Rj0

3.2.2.2. Evolution of Ic/Ic0 and n/n0

3.2.2.3. Minimum of Rj.Aj at 30 TC in the Joint G2.SL2

3.3. Summary of AllJoints

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Baldan, C.A.; Oliveira, U.R.; Shigue, C.Y.; Filho, E.R. Evaluation of Electrical Properties of Lap Joints for BSCCO and YBCO Tapes. IEEE Trans. Appl. Supercond. 2009, 19, 2831–2834. [Google Scholar] [CrossRef]

- Shin, H.S.; Jung, C.H.; Nisay, A.R. Joint characteristics of ultrasonic welded CC bridge joints for HTS coil applications. Supercond. Sci. Technol. 2020, 33, 115007. [Google Scholar] [CrossRef]

- Ito, S.; Ohinata, T.; Bromberg, L.; Hashizume, H. Structure improvement and joint resistance estimation in demountable butt and edge joints of a stacked REBCO conductor within a metal jacket. IEEE Trans. Appl. Supercond. 2013, 23, 4802408. [Google Scholar] [CrossRef]

- Kirchner, A.; Nielsch, K.; Hühne, R. Towards a reliable bridge joint between REBCO coated conductors. J. Phys. Conf. Ser. 2020, 1559, 012033. [Google Scholar] [CrossRef]

- Ito, S.; Fujii, H.T.; Hayasaka, R.; Sato, Y.S.; Hashizume, H. Induction Soldering of Coated Conductor High-Temperature Superconducting Tapes with Lead-Free Solder Alloys. IEEE Trans. Appl. Supercond. 2019, 29, 6600405. [Google Scholar] [CrossRef]

- Nishio, T.; Ito, S.; Hashizume, H. Heating and Loading Process Improvement for Indium Inserted Mechanical Lap Joint of REBCO Tapes. IEEE Trans. Appl. Supercond. 2017, 27, 4603305. [Google Scholar] [CrossRef]

- Celentano, G.; Augieri, A.; Mauretti, A.; Vannozzi, A.; Armenio, A.A.; Galluzzi, V.; Gaudio, S.; Mancini, A.; Rufoloni, A.; Davoli, I.; et al. Electrical and Mechanical Characterization of Coated Conductors Lap Joints. IEEE Trans. Appl. Supercond. 2010, 20, 1549–1552. [Google Scholar] [CrossRef]

- Park, Y.; Lee, M.; Ann, H.; Choi, Y.H.; Lee, H. A superconducting joint for GdBa2Cu3O7−δ -coated conductors. NPG Asia Mater. 2014, 6, 1–5. [Google Scholar] [CrossRef]

- Ohki, K.; Nagaishi, T.; Kato, T.; Yokoe, D.; Hirayama, T.; Ikuhara, Y.; Ueno, T.; Yamagishi, K.; Takao, T.; Piao, R. Fabrication, microstructure and persistent current measurement of an intermediate grown superconducting (iGS) joint between REBCO-coated conductors. Supercond. Sci. Technol. 2017, 30, 115017. [Google Scholar] [CrossRef]

- Shin, H.-S.; Dedicatoria, M.J.; Oh, S.-S. Critical Current Degradation Behavior in Lap-Jointed Coated Conductor Tapes With IBAD Substrate Under Uniaxial Tension. IEEE Trans. Appl. Supercond. 2010, 20, 1447–1450. [Google Scholar] [CrossRef]

- Huang, D.; Gu, H.; Dong, Z.; Shang, Z.; Xu, W.; Li, T.; Xie, B.; Zhang, H.; Ding, F. Study on Electromechanical Properties of Solder Jointed YBCO Coated Conductors With Etched Copper Stabilizer Under Axial Tension. IEEE Trans. Appl. Supercond. 2020, 30, 8400106. [Google Scholar] [CrossRef]

- Balashov, N.N.; Degtyarenko, P.N.; Ivanov, S.S.; Kopylov, S.I.; Gorbunova, D.A.; Molodyk, A.A.; Samoilenkov, S.V.; Sytnikov, V.E.; Zheltov, V.V. Low-Resistance Soldered Joints of Commercial 2G HTS Wire Prepared at Various Values of Applied Pressure. IEEE Trans. Appl. Supercond. 2018, 28, 6602604. [Google Scholar] [CrossRef]

- Lécrevisse, P.; Bascuñán, J.; Hahn, S.; Kim, Y.; Song, J.; Iwasa, Y. Tape-to-Tape Joint Resistances of a Magnet Assembled From (RE)BCO Double-Pancake Coils. IEEE Trans. Appl. Supercond. 2015, 25, 6602505. [Google Scholar] [CrossRef]

- Baldan, C.A.; Oliveira, U.R.; Bernardes, A.A.; Oliveira, V.P.; Shigue, C.Y.; Ruppert, E. Electrical and Superconducting Properties in Lap Joints for YBCO Tapes. J. Supercond. Nov. Magn. 2013, 26, 2089–2092. [Google Scholar] [CrossRef]

- Zhang, S.; Li, F.; Yang, G.; Xu, S.; Han, Z.; Fan, Z.; Jiang, P.; Chen, Y. Enhanced Electrical and Mechanical Performances of Soldered Joint Between Copper Stabilized REBCO Superconducting Tapes. IEEE Trans. Appl. Supercond. 2019, 29, 8800807. [Google Scholar] [CrossRef]

- Bagrets, N.; Weiss, K.-P.; Nast, R.; Heller, R. Correlation Between Resistances of Face-to-Face Soldered Joints and Interface Resistance Between Layers in Superconducting Tapes. IEEE Trans. Appl. Supercond. 2018, 28, 6600204. [Google Scholar] [CrossRef]

- Kim, Y.; Bascuñán, J.; Lecrevisse, T.; Hahn, S.; Voccio, J.; Park, D.K.; Iwasa, Y. YBCO and Bi2223 Coils for High Field LTS/HTS NMR Magnets: HTS-HTS Joint Resistivity. IEEE Trans. Appl. Supercond. 2013, 23, 6800704. [Google Scholar] [CrossRef] [PubMed]

- Han, Z.; Guangtong, M.; Xingtian, L.; Jinfang, P.; Zhibiao, X.; Tianyong, G.; Minhao, Z. A Simple and Effective Process to Join Coated Super- conductors at a Low Resistance. Rare Met. Mat. Eng. 2018, 47, 0748–0753. [Google Scholar] [CrossRef]

- Zhang, Y.; Duckworth, R.C.; Ha, T.T.; Gouge, M.J. Solderability study of RABiTS-based YBCO coated conductors. Physica C 2011, 437–443. [Google Scholar] [CrossRef]

- Tsui, Y.; Surrey, E.; Hampshire, D. Soldered joints—An essential component of demountable high temperature superconducting fusion magnets. Supercond. Sci. Technol. 2016, 29, 075005. [Google Scholar] [CrossRef]

- Lu, J.; Han, K.; Sheppard, W.R.; Viouchkov, Y.L.; Pickard, K.W.; Markiewicz, W.D. Lap Joint Resistance of YBCO Coated Conductors. IEEE Trans. Appl. Supercond. 2011, 21, 3009–3012. [Google Scholar] [CrossRef]

- Drienovsky, M.; Michalcová, E.; Pekarčíková, M.; Palcut, M.; Frolek, L.; Gogola, P.; Jančuška, I.; Mišík, J.; Gömöry, F. Induction Soldering of Coated Conductor High-Temperature Superconducting Tapes With Lead-Free Solder Alloys. IEEE Trans. Appl. Supercond. 2018, 28, 6601305. [Google Scholar] [CrossRef]

- Balashov, N.N.; Degtyarenko, P.N.; Ivanov, S.S. Investigation of soldered low-resistance joints for coated conductors. Prog. Supercon. Cryo. 2015, 17, 25–27. [Google Scholar] [CrossRef]

- Michalcová, E.; Gömöry, F.; Frolek, L.; Drienovský, M.; Pekarčíková, M.; Skarba, M.; Mišík, J.; Janovec, J. Joining of CC Tapes With Lead-Free Solders. IEEE Trans. Appl. Supercond. 2016, 26. [Google Scholar] [CrossRef]

- Park, D.K.; Ahn, M.C.; Kim, H.M.; Lee, H.G.; Chang, K.S.; Lee, S.J.; Yang, S.E.; Ko, T.K. Analysis of a Joint Method Between Superconducting YBCO Coated Conductors. IEEE Trans. Appl. Supercond. 2007, 17, 3266–3269. [Google Scholar] [CrossRef]

- Preuss, A.; Fietz, W.H.; Immel, F.; Kauffmann-Weiss, S.; Wolf, M.J. Critical Current Degradation of Coated Conductors under Soldering Conditions. IEEE Trans. Appl. Supercond. 2018, 28, 2804094. [Google Scholar] [CrossRef]

- Polak, M.; Barnes, P.N.; Levin, G.A. YBCO/Ag boundary resistivity in YBCO tapes with metallic substrates. Supercond. Sci. Technol. 2006, 19, 817–820. [Google Scholar] [CrossRef]

- Lide, D.R. CRC Handbook of Chemistry and Physics, 84th ed.; CRC Press: Cleveland, OH, USA, 2004; p. 2123. [Google Scholar] [CrossRef]

- Amin, N.A.A.M.; Shnawah, D.A.; Said, S.M.; Sabri, M.F.M.; Arof, H. Effect of Ag content and the minor alloying element Fe on the electrical resistivity of Sn–Ag–Cu solder alloy. J. Alloy Compd. 2014, 599, 114–120. [Google Scholar] [CrossRef]

- Frederikse, H.P.R.; Fields, R.J.; Feldman, A. Thermal and electrical properties of coppertin and nickeltin intermetallics. J. Appl. Phys. 1992, 72, 2879–2882. [Google Scholar] [CrossRef]

- Fogelholm, R.; Rapp, Ö.; Grimvall, G. Electrical resistivity of indium: Deviation from linearity at high temperatures. Phys. Rev. B 1981, 23, 3845. [Google Scholar] [CrossRef]

- Libot, J.B.; Alexis, J.; Dalverny, O.; Arnaud, L.; Milesi, P.; Dulondel, F. Microstructural evolutions of Sn-3.0Ag-0.5Cu solder joints during thermal cycling. Microelectron. Reliab. 2018, 64–76. [Google Scholar] [CrossRef]

- Zijie, C. Reduction of Lead Free Solder Aging Effects Using Doped SAC Alloys. Dissertation Thesis, Auburn University, Auburn, AL, USA. December 2012.

- Mueller, M.; Wiese, S.; Roellig, M.; Wolter, K.-J. Effect of Composition and Cooling Rate on the Microstructure of SnAgCu-Solder Joints. In Proceedings of the Electronic Components and Technology Conference, Sparks, NV, USA, 29 May–1 June 2007. [Google Scholar] [CrossRef]

- Mu, D.K.; McDonald, S.D.; Read, J.; Huang, H.; Nogita, K. Critical properties of Cu6Sn5 in electronic devices: Recent progress and a review Curr. Opt. Solid State Mater. Sci. 2016, 20, 55–76. [Google Scholar] [CrossRef]

- Rimikis, A.; Kimmich, R.; Schneider, T. Investigation of n-values of Composite Superconductors. IEEE Trans. Appl. Supercond. 2000, 10, 1239–1242. [Google Scholar] [CrossRef]

- Soldering Instructions. Available online: http://www.superpower-inc.com/system/files/SP_Soldering+Instructions_2014_v1.pdf (accessed on 22 January 2021).

- Mogro-Campero, A.; Paik, K.W.; Turner, L.G. Degradation of Thin Films of YBa2Cu3O7 by Annealing in Air and in Vacuum. J. Supercond. 1995, 8, 95–98. [Google Scholar] [CrossRef]

- Solder Alloys: Physical and Mechanical Properties. Available online: http://alasir.com/reference/solder_alloys/ (accessed on 28 January 2021).

- Hulačová, S. Lead-Free Soldering of Superconducting Tapes Using Different Fluxes. Bachelor Thesis, Slovak University of Technology in Bratislava, Trnava, Slovakia. 10 May 2020.

- SuperPower®2G HTS Wire Specifications. Available online: http://www.superpower-inc.com/system/files/SP_2G+Wire+Spec+Sheet_for+web_0509.pdf (accessed on 22 January 2021).

- Cuninková, E. Degradation of Superconducting Tapes by Mechanical Stress. Dissertation Thesis, Slovak University of Technology in Bratislava, Trnava, Slovakia, 2019. [Google Scholar]

- Humpston, G.; Jacobson, D.M. Principles of Soldering, 1st ed.; ASM International: Materials Park, OH, USA, 2004. [Google Scholar] [CrossRef]

- Li, T.; Ding, D.; Tao, Y.; Guo, J.; He, T.; Yu, Y. Effect of Ar Reflow Atmosphere on the SAC305 Solder Joint Reliability. In Proceedings of the 15th International Conference on Electronic Packaging Technology, Chengdu, China, 12–15 August 2014. [Google Scholar]

- Jeong, M.-H.; Lim, G.-T.; Kim, B.-J.; Lee, K.-W.; Kim, J.-D.; Joo, Y.C.; Park, Y.-B. Interfacial Reaction Effect on Electrical Reliability of Cu Pillar/Sn Bumps. J. Electron. Mater. 2010, 39, 2368–2374. [Google Scholar] [CrossRef]

- Yao, Y.; Keer, L.M.; Fine, M.E. Electromigration effect on pancake type void propagation near the interface of bulk solder and intermetallic compound. J. Appl. Phys. 2009, 105, 063710. [Google Scholar] [CrossRef]

- Di Maio, D.; Murdoch, C.; Thomas, O.; Hunt, C. The Degradation of Solder Joints under High Current Density and Low-Cycle Fatigue. In Proceedings of the 11th International Conference on Thermal, Mechanical and Multiphysics Simulation and Experiments in Micro-Electronics and Micro-Systems, EuroSimE, Bordeaux, France, 21–22 April 2010. [Google Scholar]

- Yunus, A.; Primavera, A.; Srihari, K.; Pitarresi, J.M. Effect of voids on the reliability of BGA/CSP solder joints. In Proceedings of the IEEE/CPMT Int’l Electronics Manufacturing Technology Symposium, Santa Clara, CA, USA, 2–3 October 2000; p. 207. [Google Scholar]

- Li, H.; An, R.; Wang, C.; Tian, Y.; Jiang, Z. Effect of Cu grain size on the voiding propensity at the interface of SnAgCu/Cu solder joints. Mater. Lett. 2015, 144, 97–99. [Google Scholar] [CrossRef]

- Skwarek, A.; Illés, B.; Hurtony, T.; Bušek, D.; Dušek, K. Effect of recrystallization on β to α-Sn allotropic transition in Sn99.3Cu0.7 solder alloy inoculated with InSb. Materials 2020, 13, 968. [Google Scholar] [CrossRef]

- Tin Pest: A Forgotten Issue in the Field of Applied Superconductivity? Available online: https://arxiv.org/ftp/arxiv/papers/1204/1204.1443.pdf (accessed on 31 January 2021).

| Composition of Used Solder | Joint Resistivity Rj.Aj (nΩ·cm2) | Ref. | |||||

|---|---|---|---|---|---|---|---|

| SuperPower | SuNAM | SuperOx | AMSC | SHSC | Self-Made | ||

| InBi | 4 | – | – | – | – | 8 | [10] |

| Sn63Pb37 | 5–36 | – | – | – | – | – | [11] |

| Sn61Pb39 | 12–33 | 45–88 | 8–13 | – | – | – | [12] |

| In80Pb15Ag5 | 9–648 | – | – | – | – | – | [13] |

| SnIn, SnPb | 17–671 | – | – | 73–880 | – | – | [14] |

| In66Bi34, In52Sn48,In97, Sn63Pb37 | – | – | – | – | – | 20–66 | [15] |

| In52Sn48, Pb63Sn37 | – | – | – | 21–880 | – | – | [1] |

| Sn60Pb40 | 60–77 | 124–137 | 27–49 | – | 26–41 | – | [16] |

| In alloy, Sn60Pb40In80Pb15Ag5 | 28–1093 | – | – | – | – | – | [17] |

| SnBi | 28–52 | – | – | – | – | – | [18] |

| In100, In52Sn48, Bi67In33 | – | – | – | 29–684 | – | – | [19] |

| Pb38Sn62, In52Sn48 | 30–50 | – | – | – | – | – | [20] |

| Sn63Pb37 | 37–1746 | – | – | – | – | – | [21] |

| Sn96.5Ag3Cu0.5, Sn99Ag0.3Cu0.7 | 41–81 | – | – | – | – | – | [22] |

| Sn52In48, Sn61Pb39 | 60–133 | – | 168–174 | – | – | – | [23] |

| Sn96.5Ag3Cu0.5 | 67–164 | – | – | – | – | – | [24] |

| InBi | – | – | – | 300–7047 | – | – | [25] |

| Abbrev. | Type | Icprod(A) | nprod | Width (mm) | Layer Thickness (µm) | ||||

|---|---|---|---|---|---|---|---|---|---|

| Cu (top) | Ag (top) | (RE)BCO | Buffer | Hastelloy | |||||

| S4 | SCS4050-AP | 117 | 30 | 4.01 | 9.67 ± 0.17 | 1.24 ± 0.07 | 1.43 ± 0.01 | 0.26 ± 0.01 | 46.38 ± 0.14 |

| S6 | SCS6050-AP | 215 | 29 | 6.05 | 12.43 ± 0.24 | 1.50 ± 0.16 | 1.40 ± 0.03 | 0.29 ± 0.01 | 45.45 ± 0.13 |

| Abbrev. | Commercial Name | Chem. Composition | Rs (nΩ.m) | Tliquidus (°C) | Supplier | Note |

|---|---|---|---|---|---|---|

| IN | – | In97Ag3 | 75 at 20 °C [39] | 143 | “Research Kit” by Indium Corp. | Low resistivity |

| SN | SAC305 | Sn96.5Ag3Cu0.5 | 123.4 at 27 °C [29] | 220 | Good solderability with Cu | |

| FL | Fluitin 1532 | Sn60Pb38Cu2 | – | 183 | Alpha Metals | Only for SCT to tape terminals joints |

| Abbrev. | Commercial Name | Type | Tactivation (°C) | Consistence | Supplier | Deposition |

|---|---|---|---|---|---|---|

| SD | SMD291 | Synthetic, no-clean | 140 | Thick paste | Chip Quik, NY, USA | Spread onto by plastic tip |

| SL | SMD291NL | Synthetic, no-clean | 140 | Thick paste | Chip Quik, NY, USA | Spread onto by plastic tip |

| F2 | FLUX-2 | – | 100–371 | Liquid | Indium Corp. | As a thin film by a brush |

| RN | – | High-purity rosin | – | Solid | AV-EL mak., Slovakia | As finely ground powder, sintered at 80 °C for 10 min |

| R5 | – | 50 wt% of “RN” dissolved in 99.8 vol% ethanol | – | Liquid | Self-made | By pipette, solvent evaporated at room temperature |

| Jointlabel | Joint Materials | Cleaning | Soldering Conditions | ||||

|---|---|---|---|---|---|---|---|

| SCT | Solder | Flux | Pressure (kPa) | Tq (°C) | tl→q (s) | ||

| G1.IN1 | S4 | IN | F2 | Nital | 309 | 160 | 45 |

| G1.IN2 | S4 | IN | F2 | Nital | 309 | 160 | 45 |

| G1.IN3 | S4 | IN | SD | Nital | 309 | 180 | 77 |

| G1.IN4 | S4 | IN | F2 | Acetone | 397 | 180 | 45 |

| G1.SN1 | S4 | SN | F2 | Nital | 397 | 240 | 38 |

| G1.SN2 | S4 | SN | R5 | Nital | 397 | 240 | 39 |

| G1.SN3 | S4 | SN | F2 | Acetone | 442 | 245 | 40 |

| G1.SN4 | S4 | SN | RN | Nital | 175 → 309 * | 219 → 240 * | 100 → 170 * |

| G1.SN5 | S4 | SN | RN | Nital | 175 → 309 * | 220 → 240 * | 50 → 60 * |

| G1.SN6 | S4 | SN | SL | Nital | 309 | 245 | 87 |

| G1.S6 | S6 | SN | SL | Nital | 292 | 245 | 70 |

| G2.SD1 | S6 | SN | SD | Nital | 292 | 245 | 80 |

| G2.SD2 | S6 | SN | SD | Nital | 292 | 245 | 65 |

| G2.SL1 | S6 | SN | SL | Nital | 292 | 245 | – |

| G2.SL2 | S6 | SN | SL | Nital | 292 | 245 | 66 |

| TC Stage | Heating in Oven | Immersion in LN2 | At room Temperature | |

|---|---|---|---|---|

| Temperature (°C) | ≤ 150 | 150 → −196 | ≥ −196 | |

| Dwell time (s) | Group 1 | 60 | 10 | 10 |

| Group 2 | 600 | 60 | 60 | |

| Joint Label | I–V Measurements | Soldered Layer | ||||

|---|---|---|---|---|---|---|

| Rj0.Aj (nΩ.cm2) | Ic0(A) | Ic0/Icprod (%) | n0 | Thickness (µm) | Porosity (vol%) | |

| G1.IN1 | 178.9 | 109.4 | 94 | 24 | 12.8 | 85 |

| G1.IN2 | 175.3 | 103.9 | 89 | 22 | 12.8 | 85 |

| G1.IN3 | 162.5 | 99.6 | 85 | 22 | 9.5 | 90 |

| G1.IN4 | 181.3 | 120.9 | 103 | 32 | 11.0 | 60 |

| G1.SN1 | 323.4 | 123.2 | 105 | 31 | 6.5 | 75 |

| G1.SN2 | 220.1 | 115.2 | 98 | 23 | 8.1 | 95 |

| G1.SN3 | 256.3 | 121.4 | 104 | 29 | 6.4 | 85 |

| G1.SN4 | 340.7 | 117.5 | 100 | 31 | 8.5 | 20 |

| G1.SN5 | 222.4 | 116.6 | 100 | 26 | 5.5 | 20 |

| G1.SN6 | 277.6 | 93.3 | 80 | 21 | 3.3 | 10 |

| G1.S6 | 40.6 | 221.3 | 103 | 31 | 3.0 | 25 |

| Joint Label | I–V Measurements | |||

|---|---|---|---|---|

| Rj0.Aj (nΩ.cm2) | Ic0 (A) | Ic0/Icprod (%) | n0 | |

| G2.SD1 | 42.9 | 224.0 | 104 | 25 |

| G2.SD2 | 42.2 | 216.5 | 104 | 25 |

| G2.SL1 | 35.3 | 217.5 | 101 | 20 |

| G2.SL2 | 49.4 | 179.7 | 84 | 18 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Skarba, M.; Pekarčíková, M.; Frolek, L.; Cuninková, E.; Necpal, M. Thermal Cycling of (RE)BCO-Based Superconducting Tapes Joined by Lead-Free Solders. Materials 2021, 14, 1052. https://doi.org/10.3390/ma14041052

Skarba M, Pekarčíková M, Frolek L, Cuninková E, Necpal M. Thermal Cycling of (RE)BCO-Based Superconducting Tapes Joined by Lead-Free Solders. Materials. 2021; 14(4):1052. https://doi.org/10.3390/ma14041052

Chicago/Turabian StyleSkarba, Michal, Marcela Pekarčíková, Lubomír Frolek, Eva Cuninková, and Martin Necpal. 2021. "Thermal Cycling of (RE)BCO-Based Superconducting Tapes Joined by Lead-Free Solders" Materials 14, no. 4: 1052. https://doi.org/10.3390/ma14041052

APA StyleSkarba, M., Pekarčíková, M., Frolek, L., Cuninková, E., & Necpal, M. (2021). Thermal Cycling of (RE)BCO-Based Superconducting Tapes Joined by Lead-Free Solders. Materials, 14(4), 1052. https://doi.org/10.3390/ma14041052