Author Contributions

Conceptualization, D.J.Y. and S.S.; methodology, D.J.Y., R.A. and S.S.; software, M.F.A.C.R.; validation, M.F.A.C.R.; formal analysis, M.F.A.C.R. and D.J.Y.; investigation, M.F.A.C.R., D.J.Y. and R.A.; resources, R.A. and Y.S.; data curation, M.F.A.C.R., D.J.Y., R.A. and Y.S.; writing—original draft preparation, M.F.A.C.R. and D.J.Y.; writing—review and editing, Y.S. and S.S.; visualization, M.F.A.C.R.; supervision, D.J.Y., Y.S. and S.S.; project administration, D.J.Y. and S.S.; funding acquisition, D.J.Y. and S.S. All authors read and agreed to the published version of the manuscript.

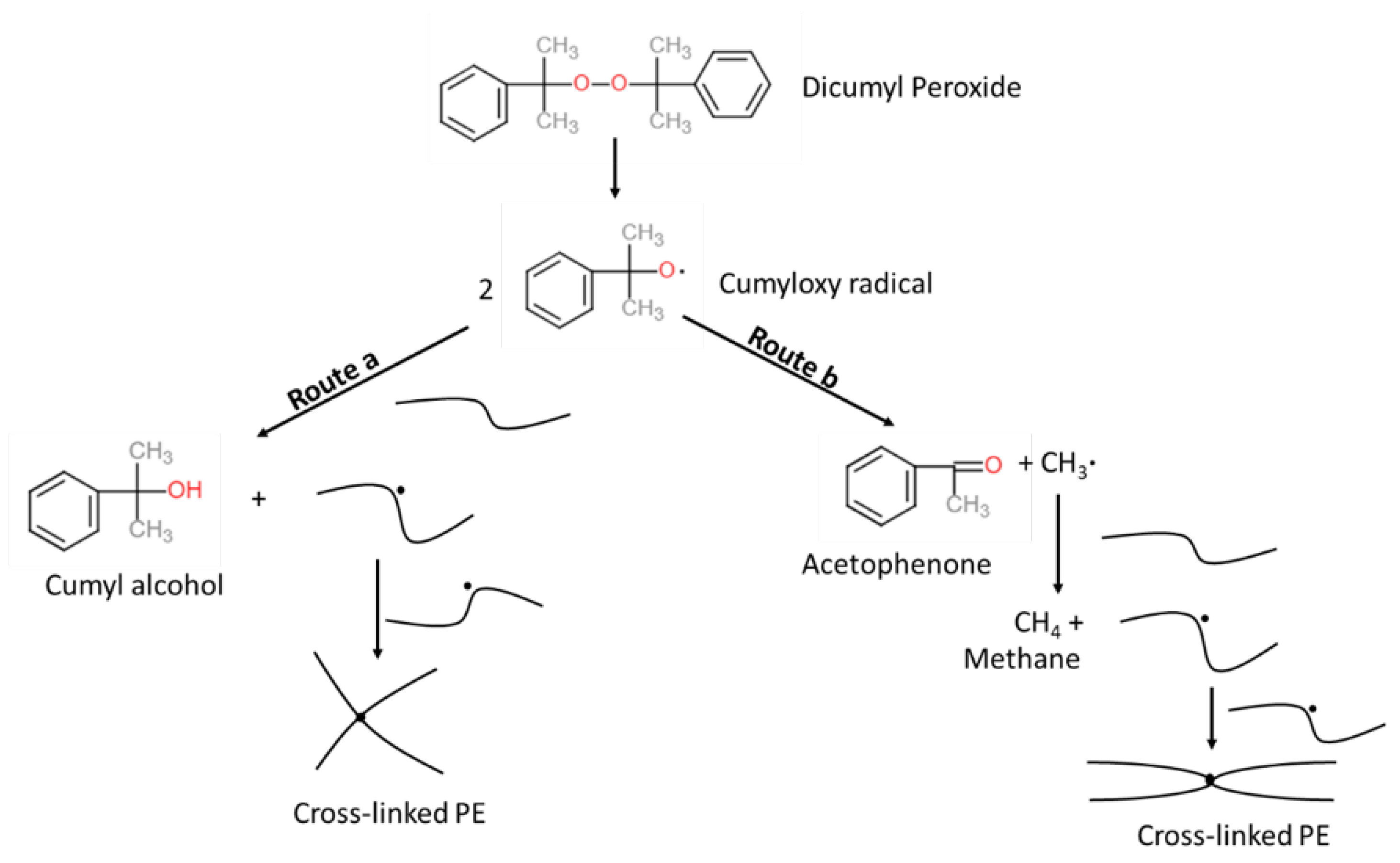

Figure 1.

DCP-initiated PE cross-linking reaction scheme [

5].

Figure 1.

DCP-initiated PE cross-linking reaction scheme [

5].

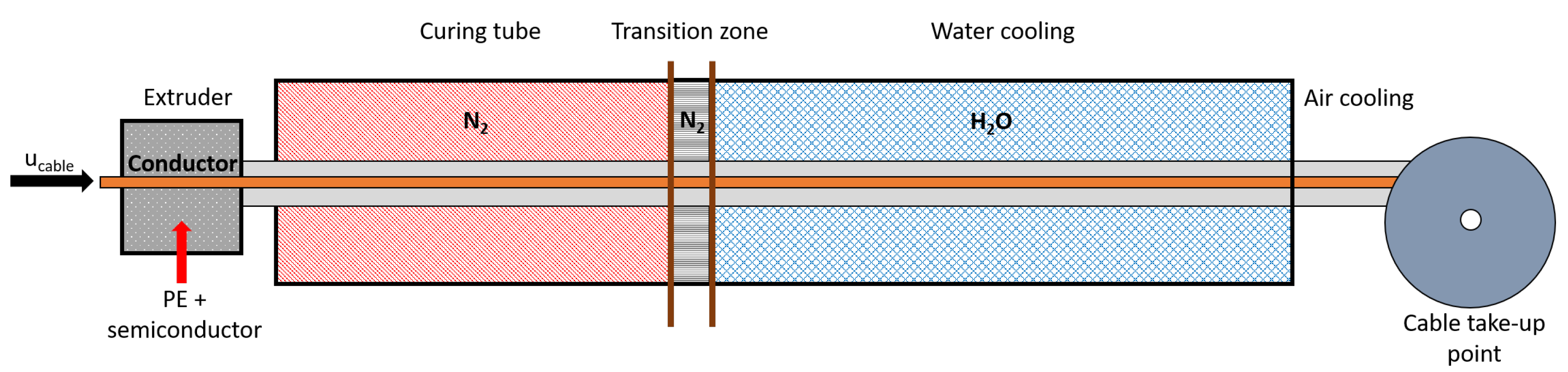

Figure 2.

Schematic of typical power cable production line.

Figure 2.

Schematic of typical power cable production line.

Figure 3.

Schematic of the cooling section for the power cable production line with online relaxation.

Figure 3.

Schematic of the cooling section for the power cable production line with online relaxation.

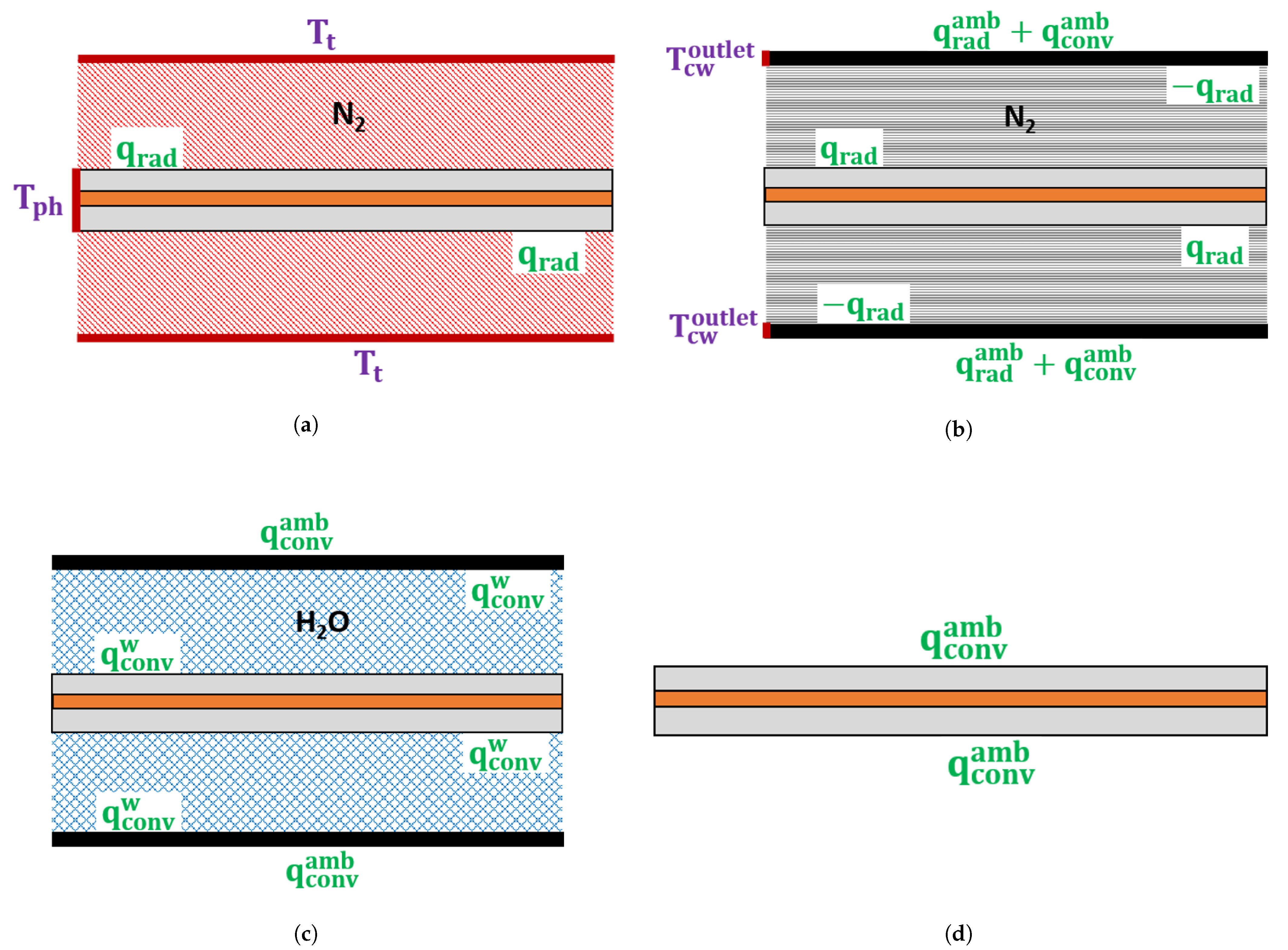

Figure 4.

Schematic of the heat transfer model in the (a) heating zone, (b) transition zone, (c) water-cooling section, and (d) air-cooling section.

Figure 4.

Schematic of the heat transfer model in the (a) heating zone, (b) transition zone, (c) water-cooling section, and (d) air-cooling section.

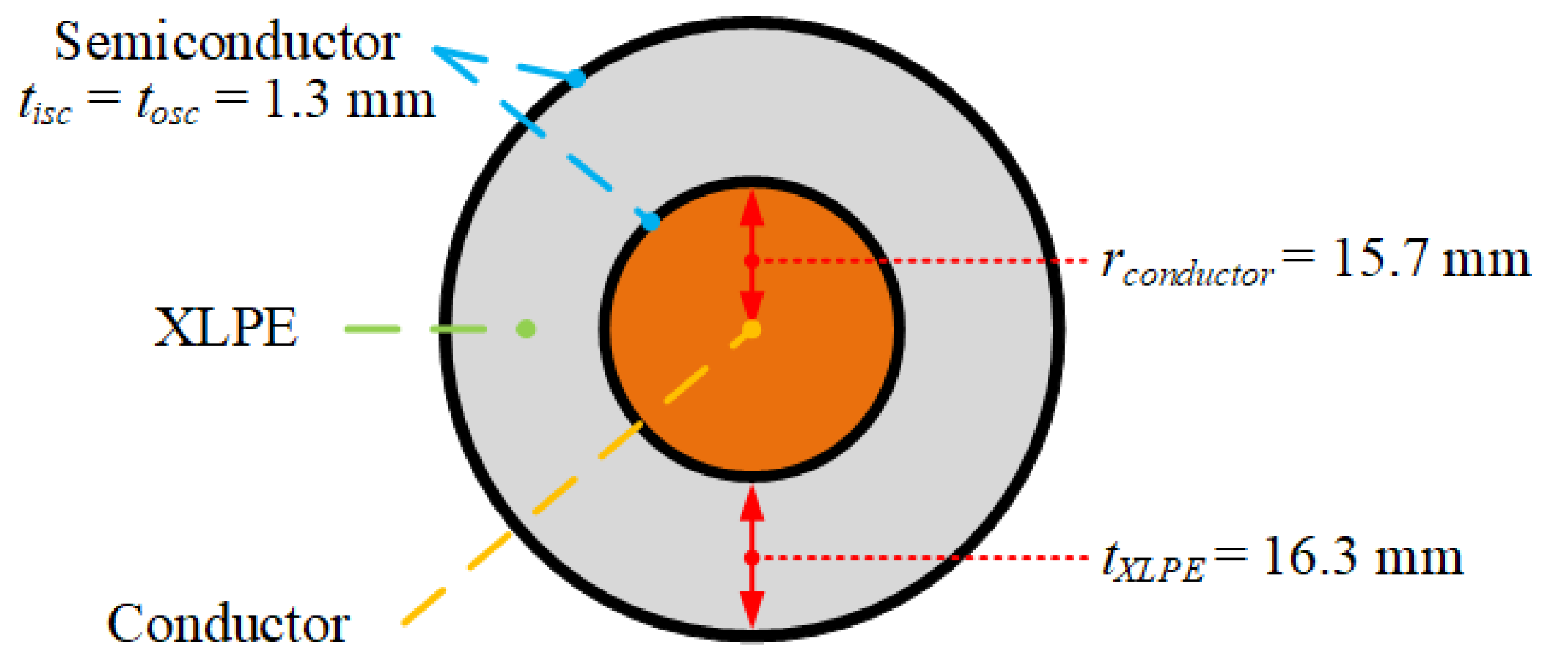

Figure 5.

132 kV cable specification [

5].

Figure 5.

132 kV cable specification [

5].

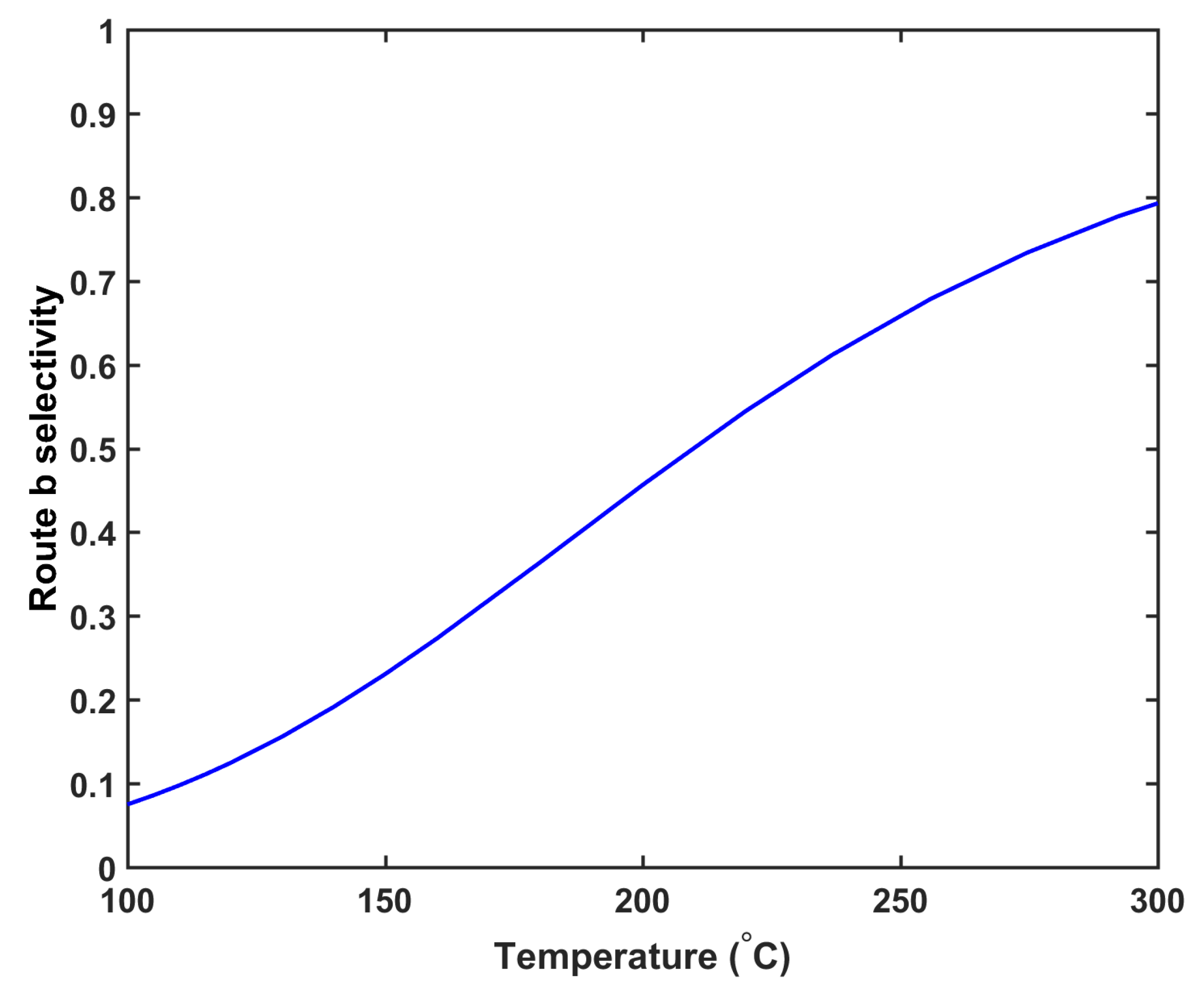

Figure 6.

Route

b reaction selectivity profile estimated by the kinetic parameters in Rado et al. [

33].

Figure 6.

Route

b reaction selectivity profile estimated by the kinetic parameters in Rado et al. [

33].

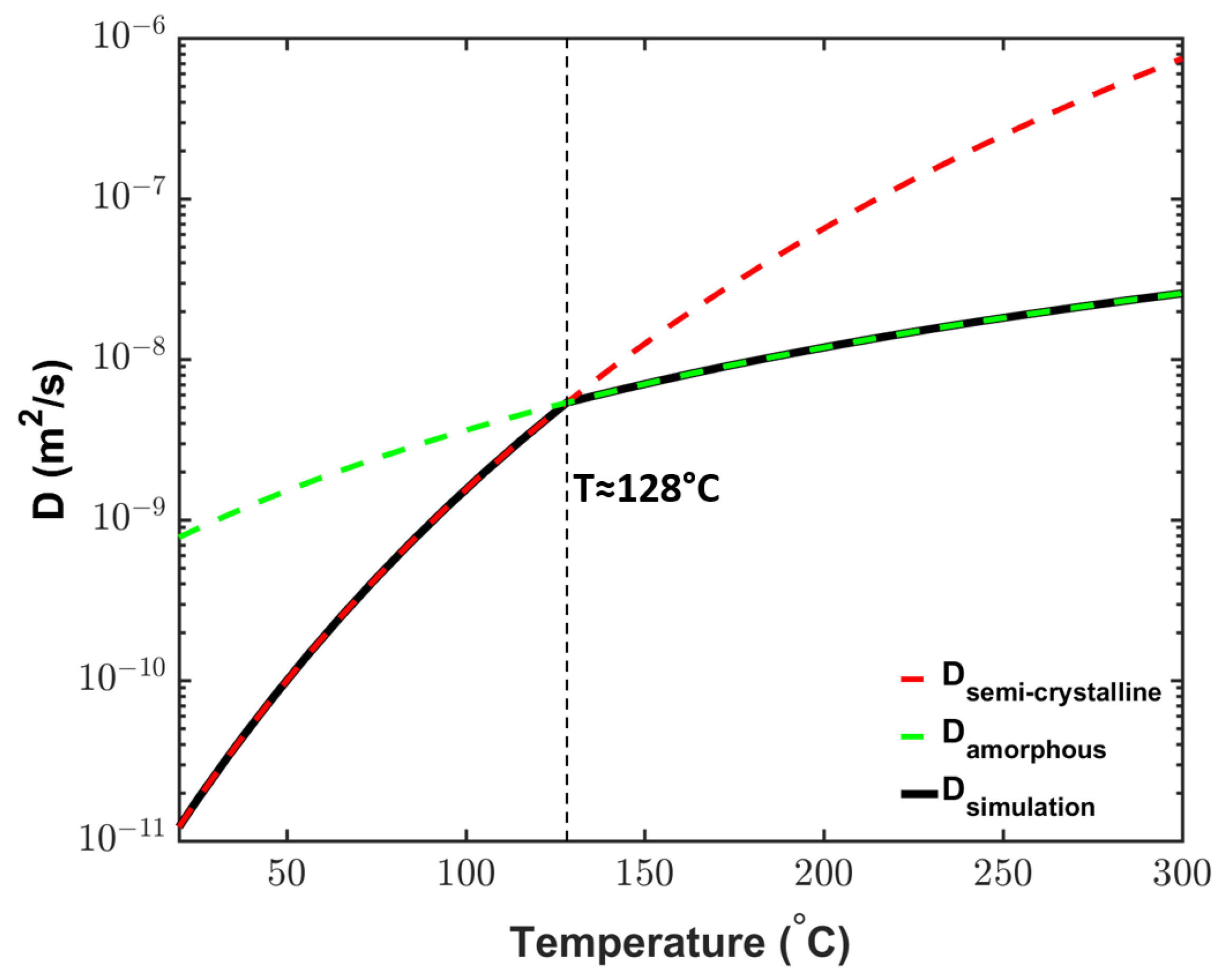

Figure 7.

CH

diffusion coefficient variations in XLPE as semi-crystalline (red line) and amorphous (green line) phases of the XLPE, which were then combined to represent the diffusion coefficient variation applied in the simulation (black line) [

5]. The kinetic parameters for the red and green lines are from Sun and Person [

22] and Yang et al. [

41], respectively.

Figure 7.

CH

diffusion coefficient variations in XLPE as semi-crystalline (red line) and amorphous (green line) phases of the XLPE, which were then combined to represent the diffusion coefficient variation applied in the simulation (black line) [

5]. The kinetic parameters for the red and green lines are from Sun and Person [

22] and Yang et al. [

41], respectively.

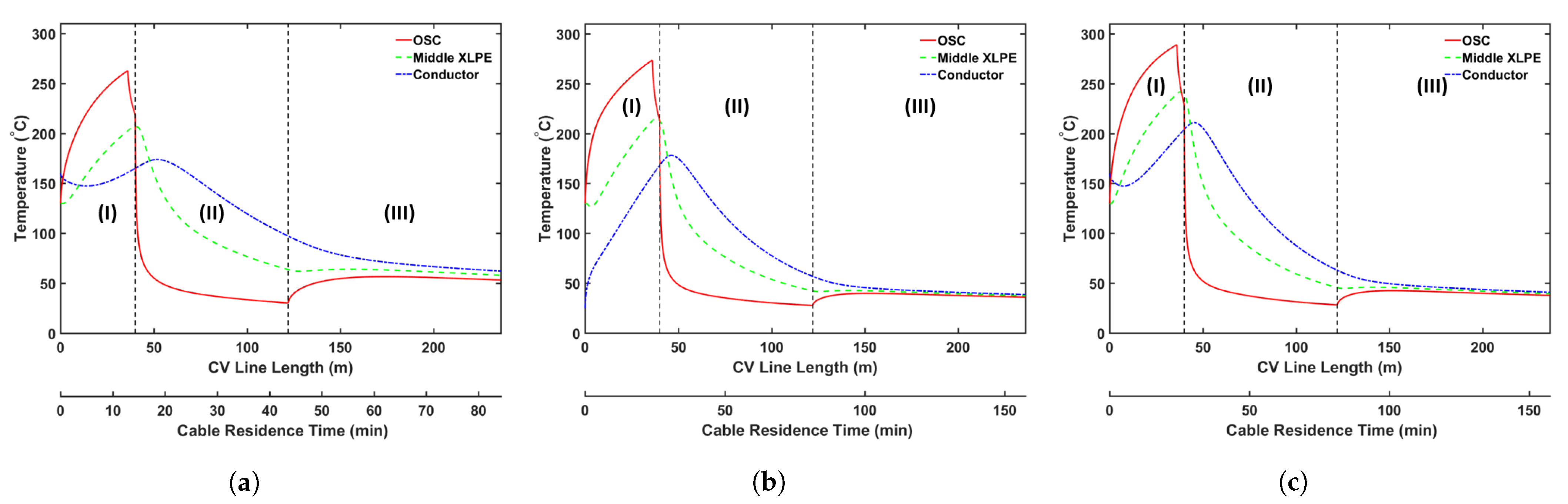

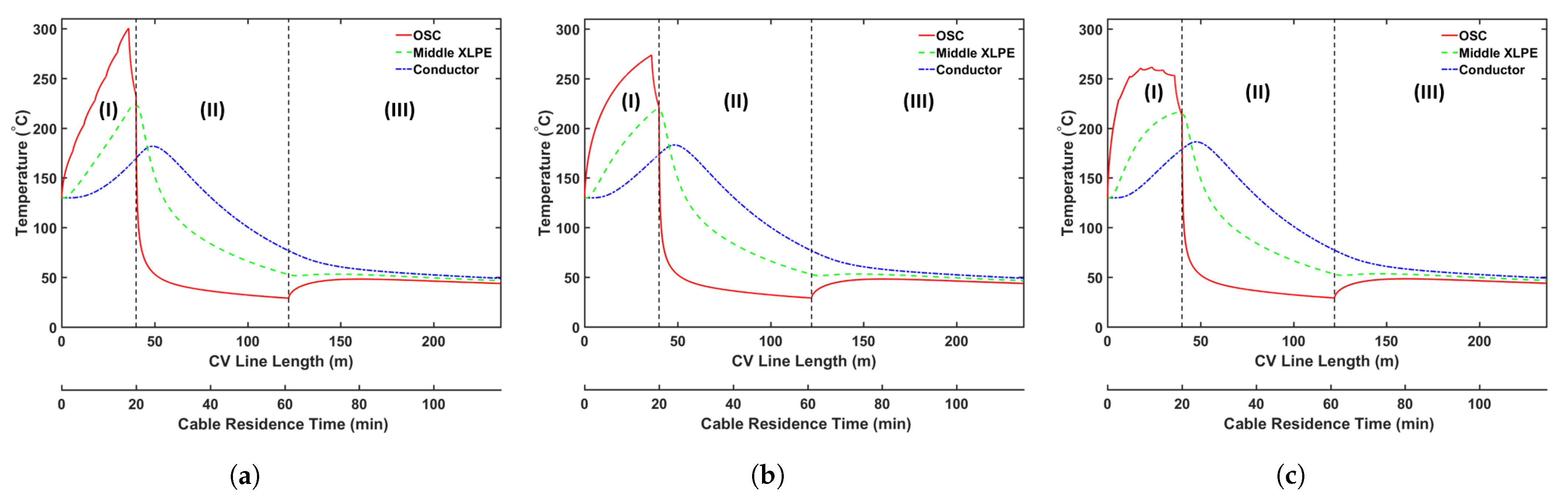

Figure 8.

Temperature profile across the CV line for the conductor temperature study: (a) Case 1a, (b) Case 1b, and (c) Case 1c. Segments (I)–(III) correspond to the curing tube and transition zone, the water-cooling segment, and the air-cooling segment, respectively.

Figure 8.

Temperature profile across the CV line for the conductor temperature study: (a) Case 1a, (b) Case 1b, and (c) Case 1c. Segments (I)–(III) correspond to the curing tube and transition zone, the water-cooling segment, and the air-cooling segment, respectively.

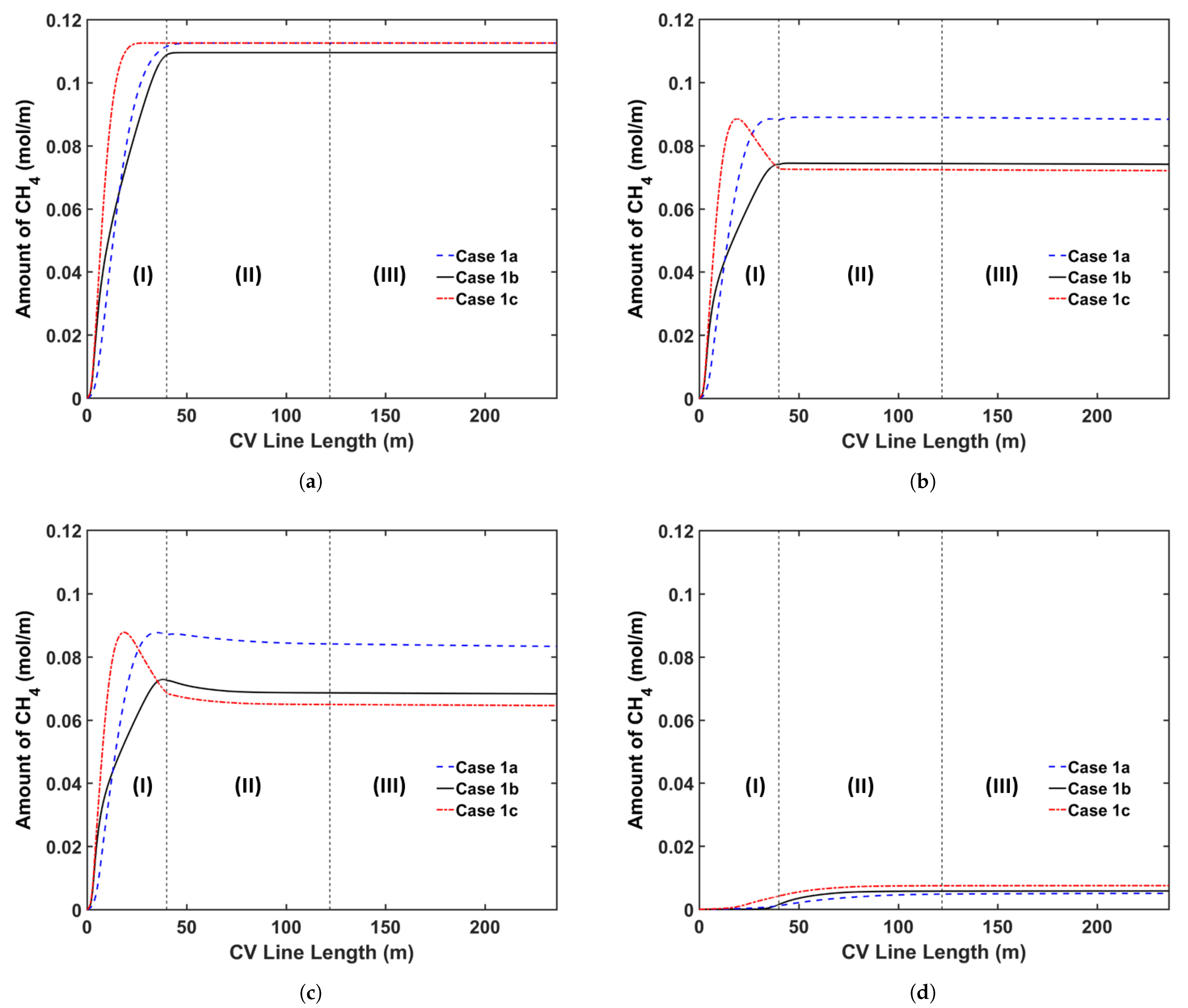

Figure 9.

Axial CH concentration profile across the CV line for the conductor temperature study: (a) total CH generated, (b) CH concentration in the entire cable, (c) CH concentration in XLPE+SC, and (d) CH concentration in the conductor. Segments (I)–(III) correspond to the curing tube and transition zone, the water-cooling segment, and the air-cooling segment, respectively.

Figure 9.

Axial CH concentration profile across the CV line for the conductor temperature study: (a) total CH generated, (b) CH concentration in the entire cable, (c) CH concentration in XLPE+SC, and (d) CH concentration in the conductor. Segments (I)–(III) correspond to the curing tube and transition zone, the water-cooling segment, and the air-cooling segment, respectively.

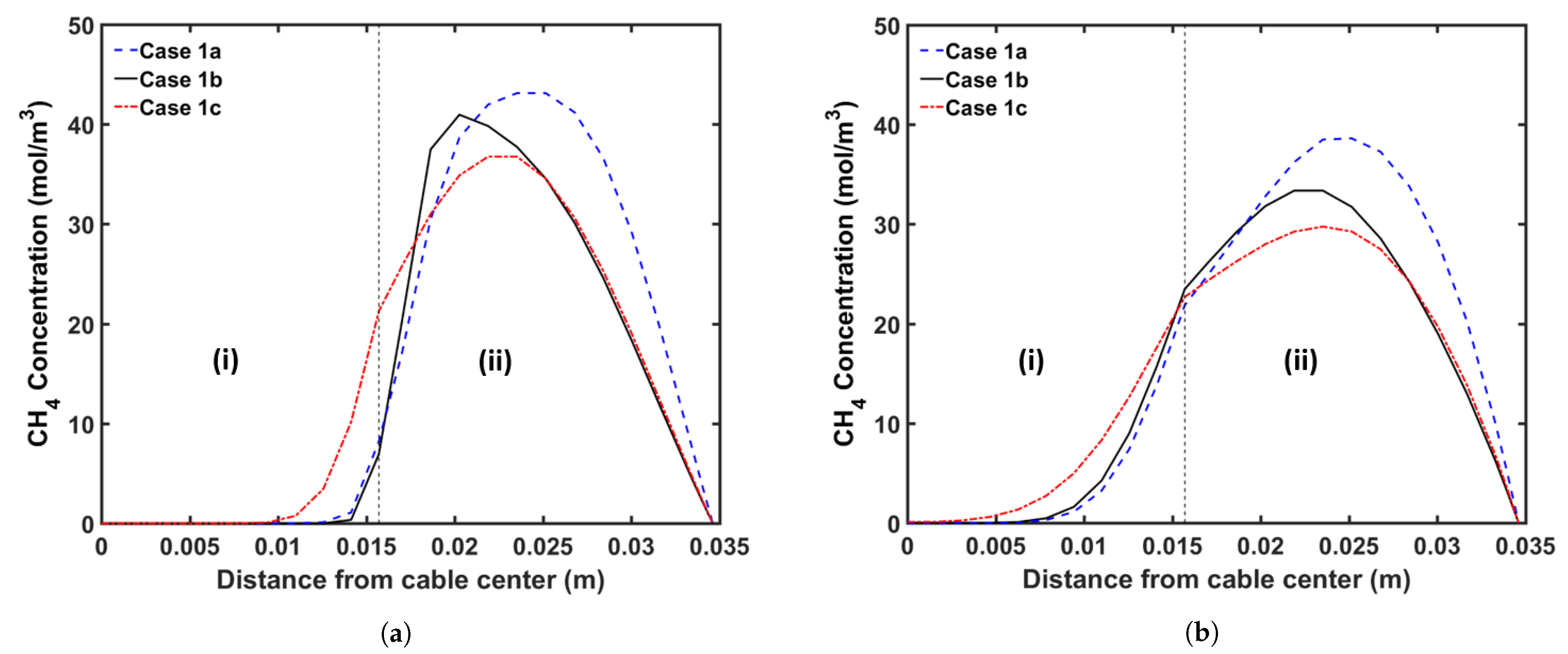

Figure 10.

Radial CH concentration profile for the conductor temperature study at (a) the curing tube exit and (b) the cable take-up point. Segment (i) corresponds to the conductor, and Segment (ii) corresponds to the XLPE and SC layers.

Figure 10.

Radial CH concentration profile for the conductor temperature study at (a) the curing tube exit and (b) the cable take-up point. Segment (i) corresponds to the conductor, and Segment (ii) corresponds to the XLPE and SC layers.

Figure 11.

Temperature profile across the CV line for the curing tube temperature distribution study: (a) Case 2a, (b) Case 2b, and (c) Case 2c. Segments (I)–(III) correspond to the curing tube and transition zone, the water-cooling segment, and the air-cooling segment, respectively.

Figure 11.

Temperature profile across the CV line for the curing tube temperature distribution study: (a) Case 2a, (b) Case 2b, and (c) Case 2c. Segments (I)–(III) correspond to the curing tube and transition zone, the water-cooling segment, and the air-cooling segment, respectively.

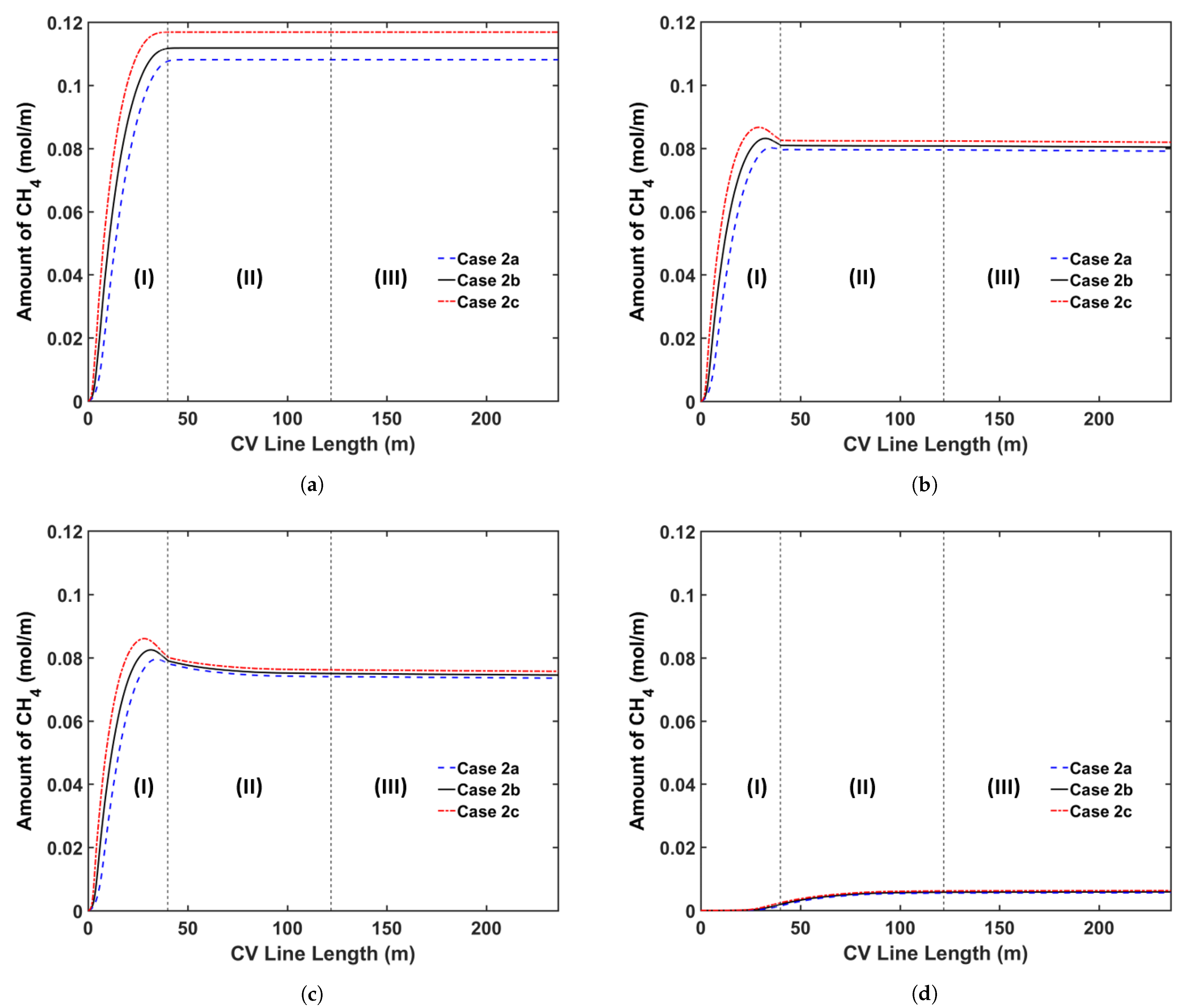

Figure 12.

Axial CH concentration profile across the CV line for the curing tube temperature distribution study: (a) total CH generated, (b) CH concentration in the entire cable, (c) CH concentration in XLPE+SC, and (d) CH concentration in the conductor. Segments (I)–(III) correspond to the curing tube and transition zone, the water-cooling segment, and the air-cooling segment, respectively.

Figure 12.

Axial CH concentration profile across the CV line for the curing tube temperature distribution study: (a) total CH generated, (b) CH concentration in the entire cable, (c) CH concentration in XLPE+SC, and (d) CH concentration in the conductor. Segments (I)–(III) correspond to the curing tube and transition zone, the water-cooling segment, and the air-cooling segment, respectively.

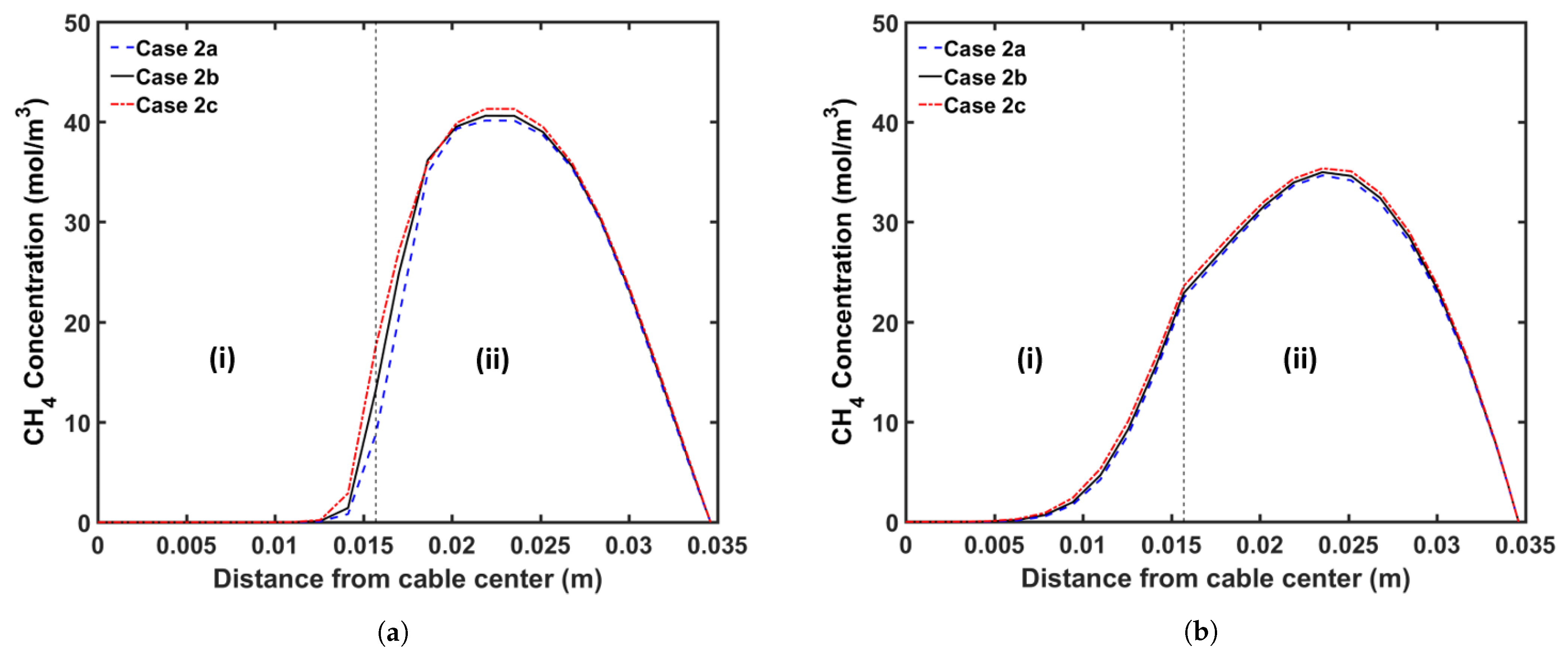

Figure 13.

Radial CH concentration profile for the curing tube temperature distribution study at (a) the curing tube exit and (b) the cable take-up point. Segment (i) corresponds to the conductor, and Segment (ii) corresponds to the XLPE and SC layers.

Figure 13.

Radial CH concentration profile for the curing tube temperature distribution study at (a) the curing tube exit and (b) the cable take-up point. Segment (i) corresponds to the conductor, and Segment (ii) corresponds to the XLPE and SC layers.

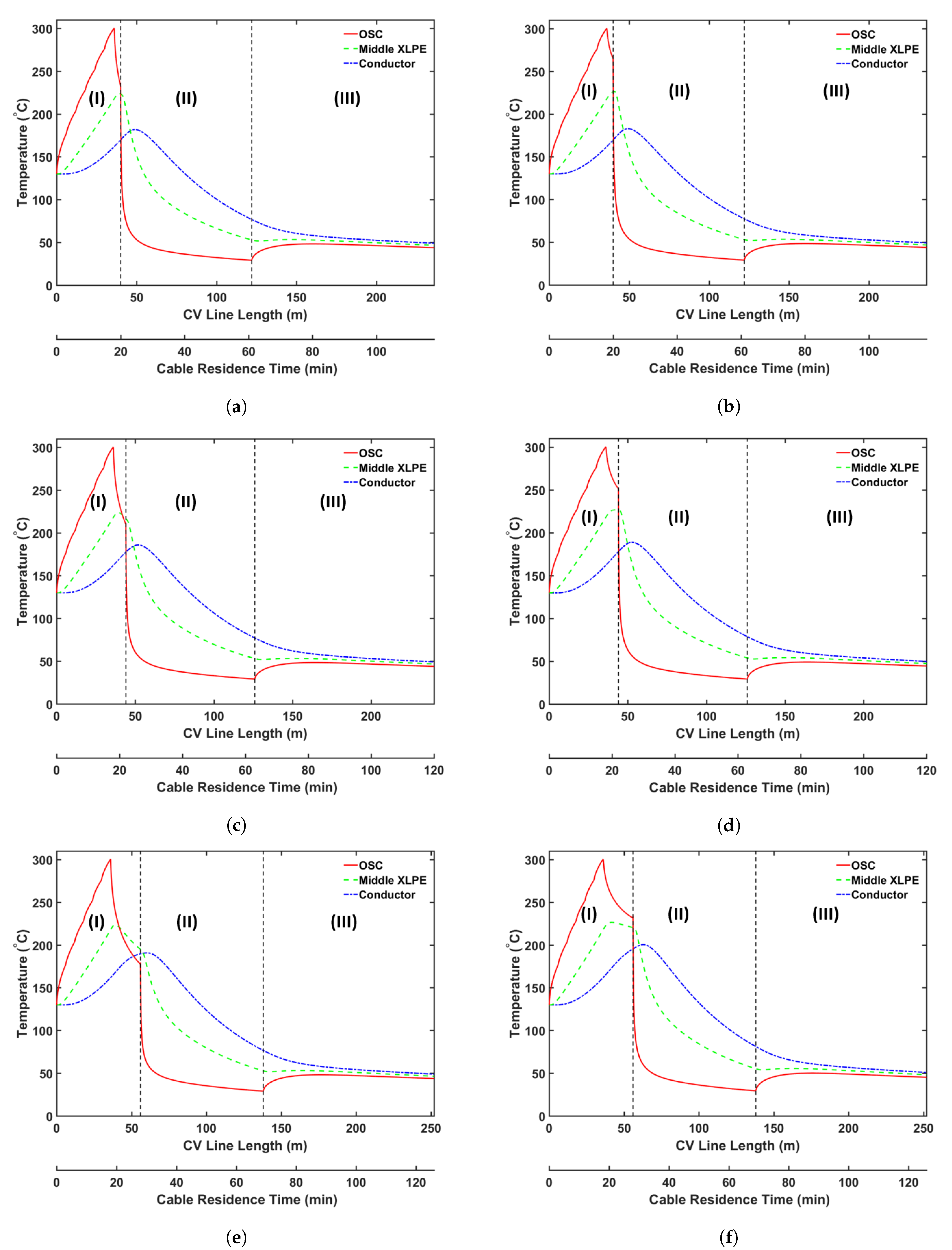

Figure 14.

Temperature profile across the CV line for the transition zone study: (a) Case 3a, (b) Case 3b, (c) Case 3c, (d) Case 3d, (e) Case 3e, and (f) Case 3f. Segments (I)–(III) correspond to the curing tube and transition zone, the water-cooling segment, and the air-cooling segment, respectively.

Figure 14.

Temperature profile across the CV line for the transition zone study: (a) Case 3a, (b) Case 3b, (c) Case 3c, (d) Case 3d, (e) Case 3e, and (f) Case 3f. Segments (I)–(III) correspond to the curing tube and transition zone, the water-cooling segment, and the air-cooling segment, respectively.

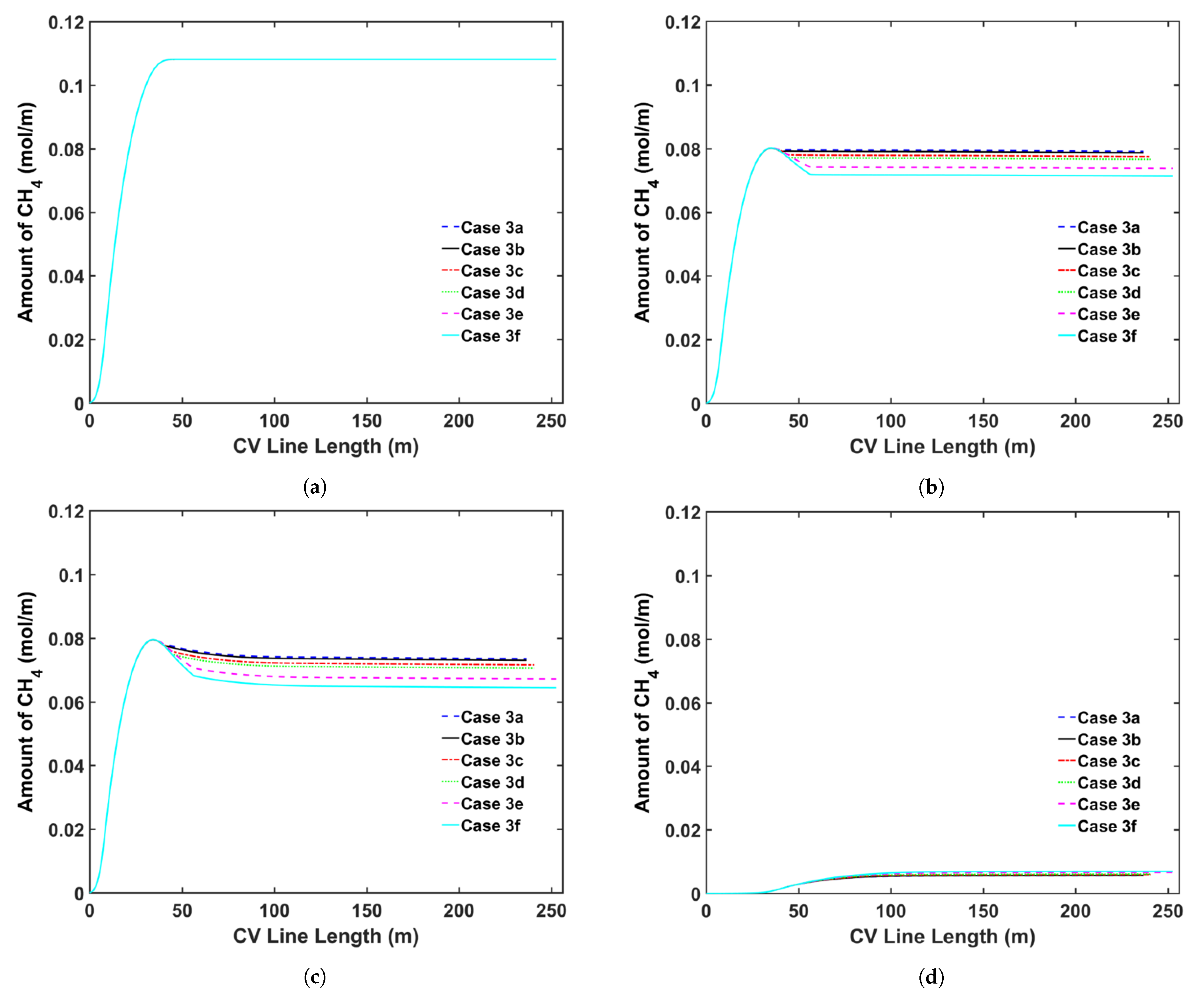

Figure 15.

Axial CH concentration profile across the CV line for the transition zone study: (a) total CH generated, (b) CH concentration in the entire cable, (c) CH concentration in XLPE + SC, and (d) CH concentration in the conductor.

Figure 15.

Axial CH concentration profile across the CV line for the transition zone study: (a) total CH generated, (b) CH concentration in the entire cable, (c) CH concentration in XLPE + SC, and (d) CH concentration in the conductor.

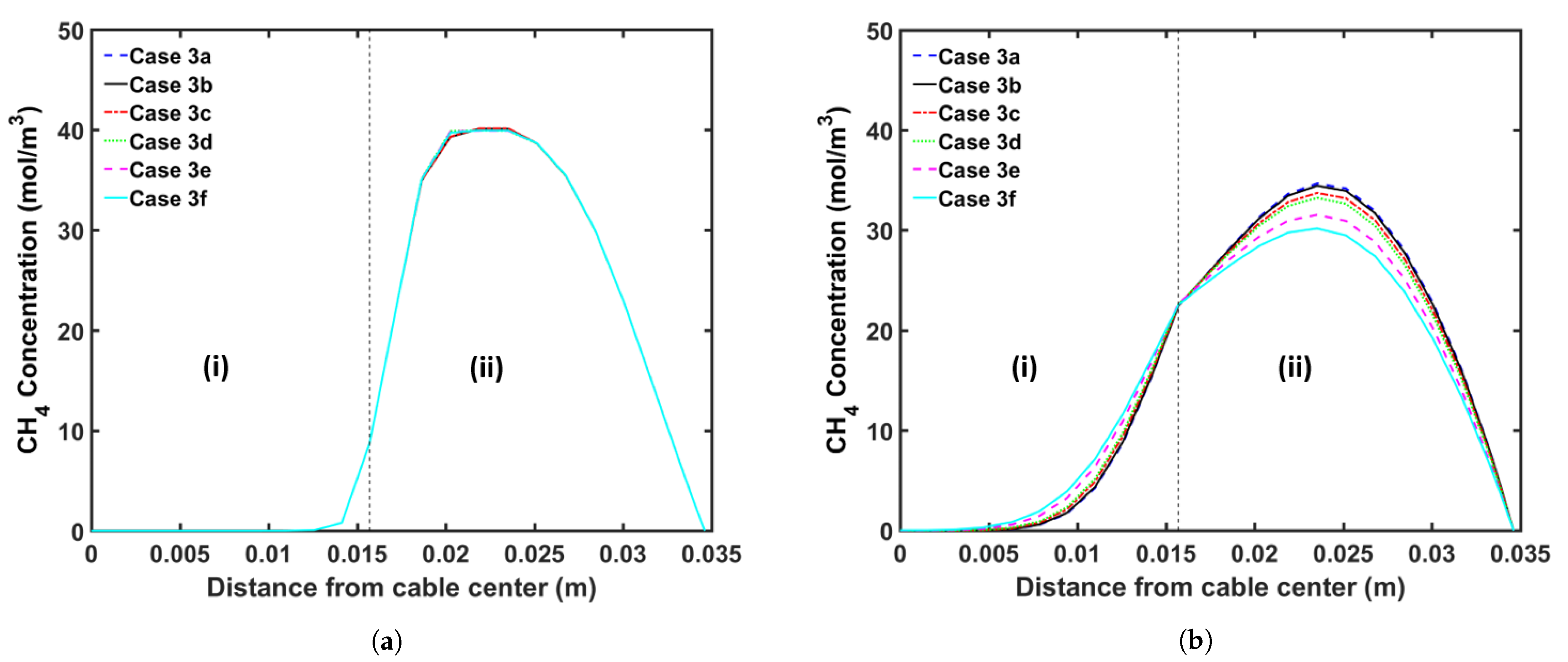

Figure 16.

Radial CH concentration profile for the transition zone study at (a) the curing tube exit and (b) the cable take-up point. Segment (i) corresponds to the conductor, and Segment (ii) corresponds to the XLPE and SC layers.

Figure 16.

Radial CH concentration profile for the transition zone study at (a) the curing tube exit and (b) the cable take-up point. Segment (i) corresponds to the conductor, and Segment (ii) corresponds to the XLPE and SC layers.

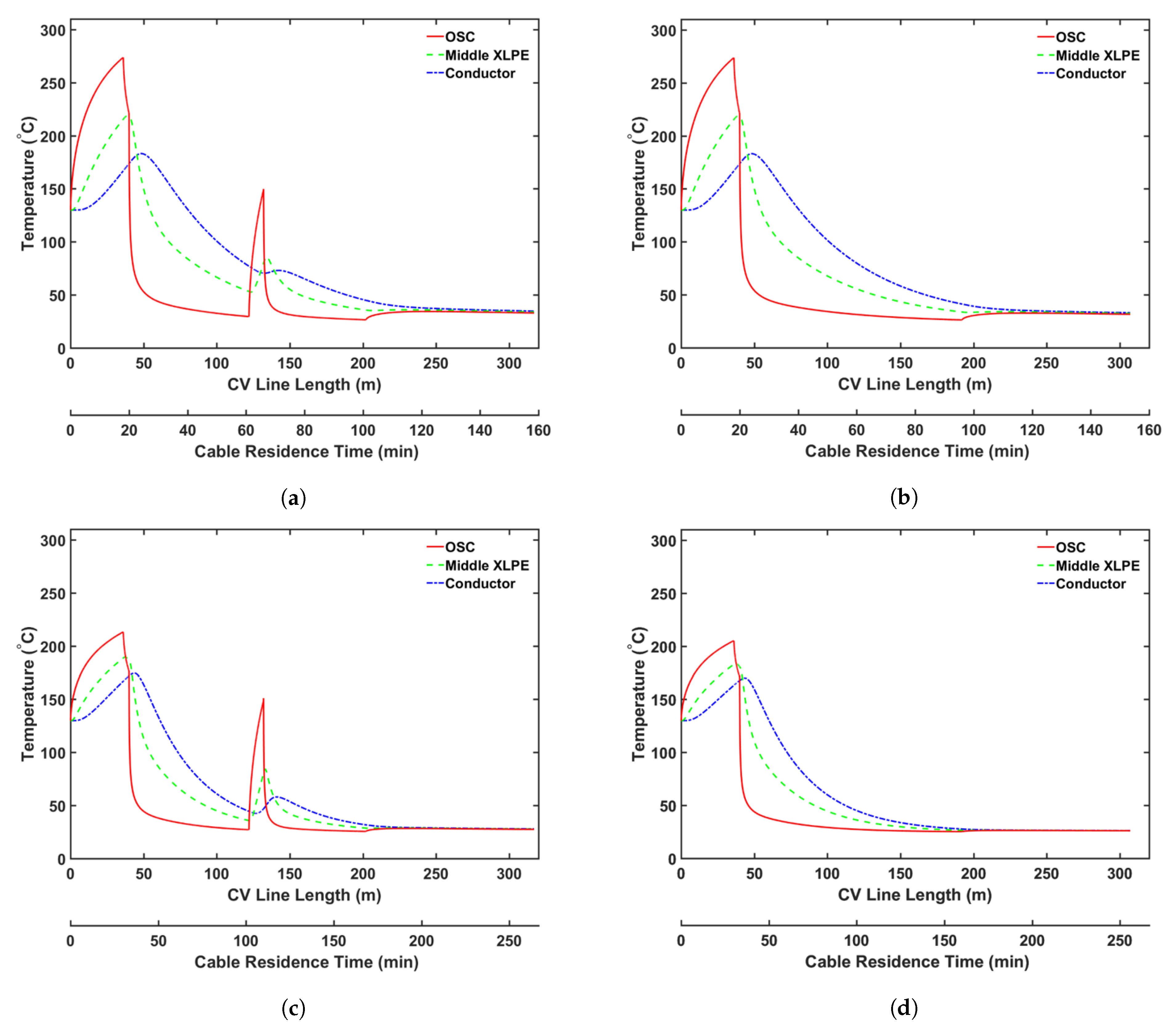

Figure 17.

Temperature profile across the CV line for the online relaxation study: (a) Case 4a, (b) Case 4b, (c) Case 4c, and (d) Case 4d.

Figure 17.

Temperature profile across the CV line for the online relaxation study: (a) Case 4a, (b) Case 4b, (c) Case 4c, and (d) Case 4d.

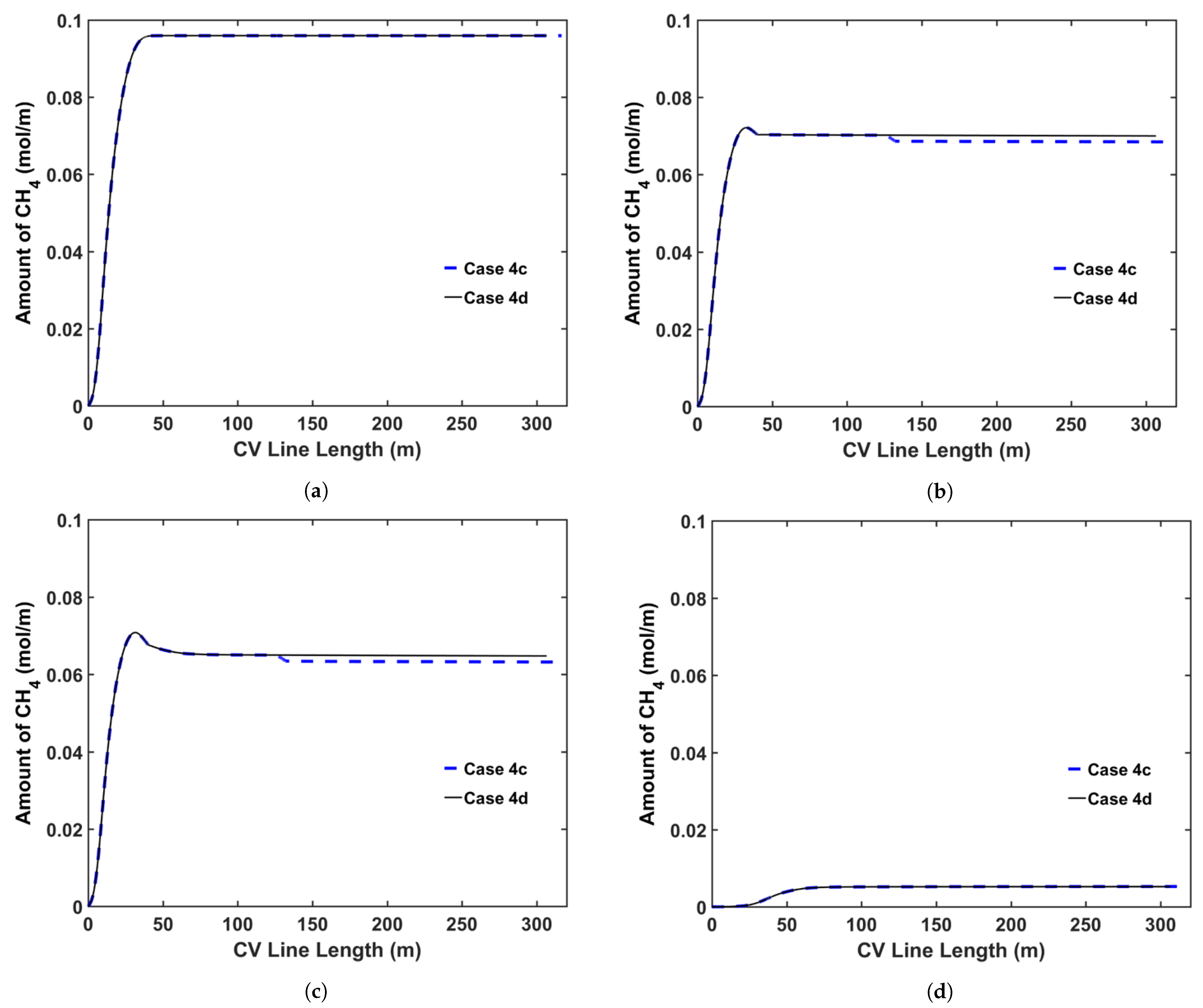

Figure 18.

Axial CH concentration profile across the CV line for the online relaxation study (Case 4c and Case 4d): (a) total CH generated, (b) CH concentration in the entire cable, (c) CH concentration in XLPE+SC, (d) CH concentration in the conductor.

Figure 18.

Axial CH concentration profile across the CV line for the online relaxation study (Case 4c and Case 4d): (a) total CH generated, (b) CH concentration in the entire cable, (c) CH concentration in XLPE+SC, (d) CH concentration in the conductor.

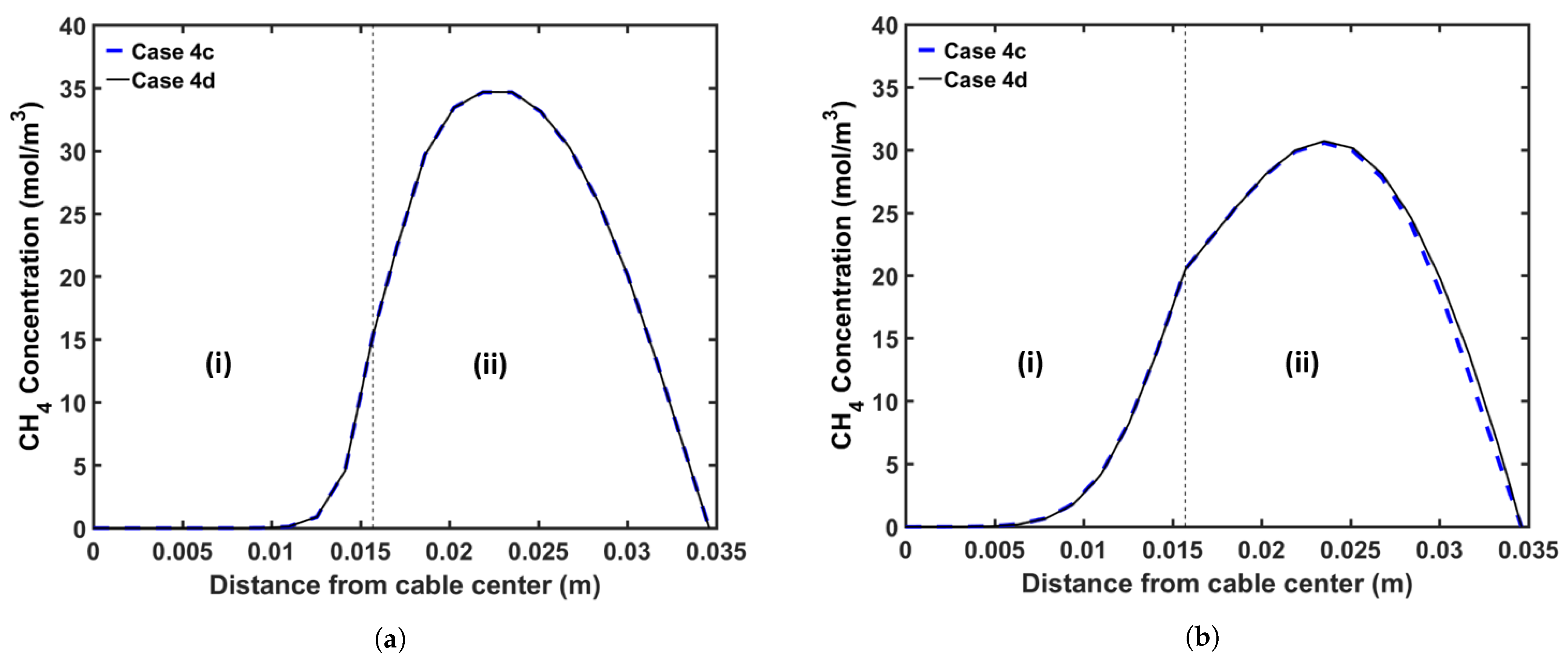

Figure 19.

Radial CH concentration profile for the online relaxation study (Case 4c and Case 4d) at (a) the curing tube exit and (b) the cable take-up point. Segment (i) corresponds to the conductor, and Segment (ii) corresponds to the XLPE and SC layers.

Figure 19.

Radial CH concentration profile for the online relaxation study (Case 4c and Case 4d) at (a) the curing tube exit and (b) the cable take-up point. Segment (i) corresponds to the conductor, and Segment (ii) corresponds to the XLPE and SC layers.

Table 1.

CV line dimensions [

5,

30].

Table 1.

CV line dimensions [

5,

30].

| Section | Curing Tube | Transition Zone | Water Cooling | Air Cooling |

|---|

| Length (m) | 36 | 4 | 82 | 115 |

Table 2.

CV line operating condition.

Table 2.

CV line operating condition.

| Parameter | Cable Inlet Temp. | Water Flow Rate | Water Inlet Temp. |

|---|

| Operating condition | 130 °C | 3 m/h | 25 °C |

Table 3.

Reaction kinetic parameters [

31,

33,

34].

Table 3.

Reaction kinetic parameters [

31,

33,

34].

| Parameter | Cross-Linking | Hydrogen Abstraction | -Scission |

|---|

| | | (Route a) | (Route b) |

|---|

| A | 9.24 × s | 1.35 × L·mols | 2.29 × s |

| 152.67 kJ·mol | 1.8 kJ·mol | 35.9 kJ·mol |

Table 4.

Thermal and mechanical properties of the cable [

4,

5,

28,

30].

Table 4.

Thermal and mechanical properties of the cable [

4,

5,

28,

30].

| Property | Copper | XLPE | Semiconductor (SC) |

|---|

| Density, (kg/m) | 8960 | 922 | 1050 |

| Specific heat capacity, (J·kgK) | 401 | 2700 | 1950 |

| Thermal conductivity, k (W·mK) | 385 | 0.335 | 0.53 |

Table 5.

Case codes and parameters of conductor temperature studies.

Table 5.

Case codes and parameters of conductor temperature studies.

| Case Code | Conductor Temperature (°C) | Production Speed (m/min) |

|---|

| 1a | 160 | 2.8 |

| 1b | 25 | 1.5 |

| 1c | 160 | 1.5 |

Table 6.

Remaining concentration of CH (mol/m) in each cable component at the cable take-up point for the study of the conductor temperature.

Table 6.

Remaining concentration of CH (mol/m) in each cable component at the cable take-up point for the study of the conductor temperature.

| Case Code | Conductor | XLPE + SC | Entire Cable | Total CH | %CH |

|---|

| 1a | 0.0050 | 0.0833 | 0.0883 | 0.1125 | 19.2 |

| 1b | 0.0058 | 0.0683 | 0.0741 | 0.1095 | 0.0 |

| 1c | 0.0075 | 0.0646 | 0.0721 | 0.1126 | −2.7 |

Table 7.

Case codes and parameters of curing tube temperature distribution studies.

Table 7.

Case codes and parameters of curing tube temperature distribution studies.

| Case Code | Curing-Tube Temperature Distribution |

|---|

| 2a | Linear increase from 300 °C to 400 °C |

| 2b | Constant temperature of 350 °C |

| 2c | Linear decrease from 400 °C to 300 °C |

Table 8.

Remaining concentration of CH (mol/m) in each cable component at the cable take-up point for the study of the curing tube temperature distribution.

Table 8.

Remaining concentration of CH (mol/m) in each cable component at the cable take-up point for the study of the curing tube temperature distribution.

| Case Code | Conductor | XLPE + SC | Entire Cable | Total CH | %CH |

|---|

| 2a | 0.0056 | 0.0735 | 0.0791 | 0.1081 | 0.0 |

| 2b | 0.0059 | 0.0745 | 0.0804 | 0.1118 | 1.6 |

| 2c | 0.0063 | 0.0757 | 0.0820 | 0.1169 | 3.7 |

Table 9.

Case codes and parameters of the transition zone study.

Table 9.

Case codes and parameters of the transition zone study.

| Case Code | Transition Zone Length (m) | Thermal Insulation at Transition Zone Wall |

|---|

| 3a | 4 | No |

| 3b | 4 | Yes |

| 3c | 8 | No |

| 3d | 8 | Yes |

| 3e | 20 | No |

| 3f | 20 | Yes |

Table 10.

Remaining concentration of CH (mol/m) in each cable component at the cable take-up point for the study of the transition zone.

Table 10.

Remaining concentration of CH (mol/m) in each cable component at the cable take-up point for the study of the transition zone.

| Case Code | Conductor | XLPE + SC | Entire Cable | Total CH | %CH |

|---|

| 3a | 0.0056 | 0.0735 | 0.0791 | 0.1081 | 0.0 |

| 3b | 0.0056 | 0.0731 | 0.0787 | −0.5 |

| 3c | 0.0059 | 0.0716 | 0.0775 | −2.0 |

| 3d | 0.0060 | 0.0706 | 0.0766 | −3.2 |

| 3e | 0.0066 | 0.0672 | 0.0738 | −6.7 |

| 3f | 0.0069 | 0.0645 | 0.0714 | −9.7 |

Table 11.

CV line parameters considered for the online relaxation study.

Table 11.

CV line parameters considered for the online relaxation study.

| CV Line Code | Curing Tube (m) | Transition Zone (m) | 1st Water -Cooling (m) | Online Relaxation (m) | 2nd Water -Cooling (m) | Air -Cooling (m) | Total (m) |

|---|

| CVa | 36 | 4 | 82 | 10 | 70 | 115 | 317 |

| CVb | 152 | NA | NA | 307 |

Table 12.

Case codes and parameters of the online relaxation study.

Table 12.

Case codes and parameters of the online relaxation study.

| Case Code | CV Line Code | Average Curing Tube Temperature (°C) | Production Speed (m/min) | Online Relaxation Temperature (°C) |

|---|

| 4a | CVa | 350 | 2.0 | 345 |

| 4b | CVb | NA |

| 4c | CVa | 250 | 1.1 | 320 |

| 4d | CVb | NA |

Table 13.

Remaining concentration of CH (mol/m) in each cable component at the cable take-up point for the study of online relaxation.

Table 13.

Remaining concentration of CH (mol/m) in each cable component at the cable take-up point for the study of online relaxation.

| Case Code | Conductor | XLPE+SC | Entire Cable | Total CH | %CH |

|---|

| 4a | 0.0059 | 0.0734 | 0.0793 | 0.1118 | −1.4 |

| 4b | 0.0059 | 0.0745 | 0.0804 | 0.0 |

| 4c | 0.0053 | 0.0632 | 0.0685 | 0.0960 | −2.2 |

| 4d | 0.0052 | 0.0648 | 0.0700 | 0.0 |