Reactivity and Pozzolanic Properties of Biomass Ashes Generated by Wheat and Soybean Straw Combustion

Abstract

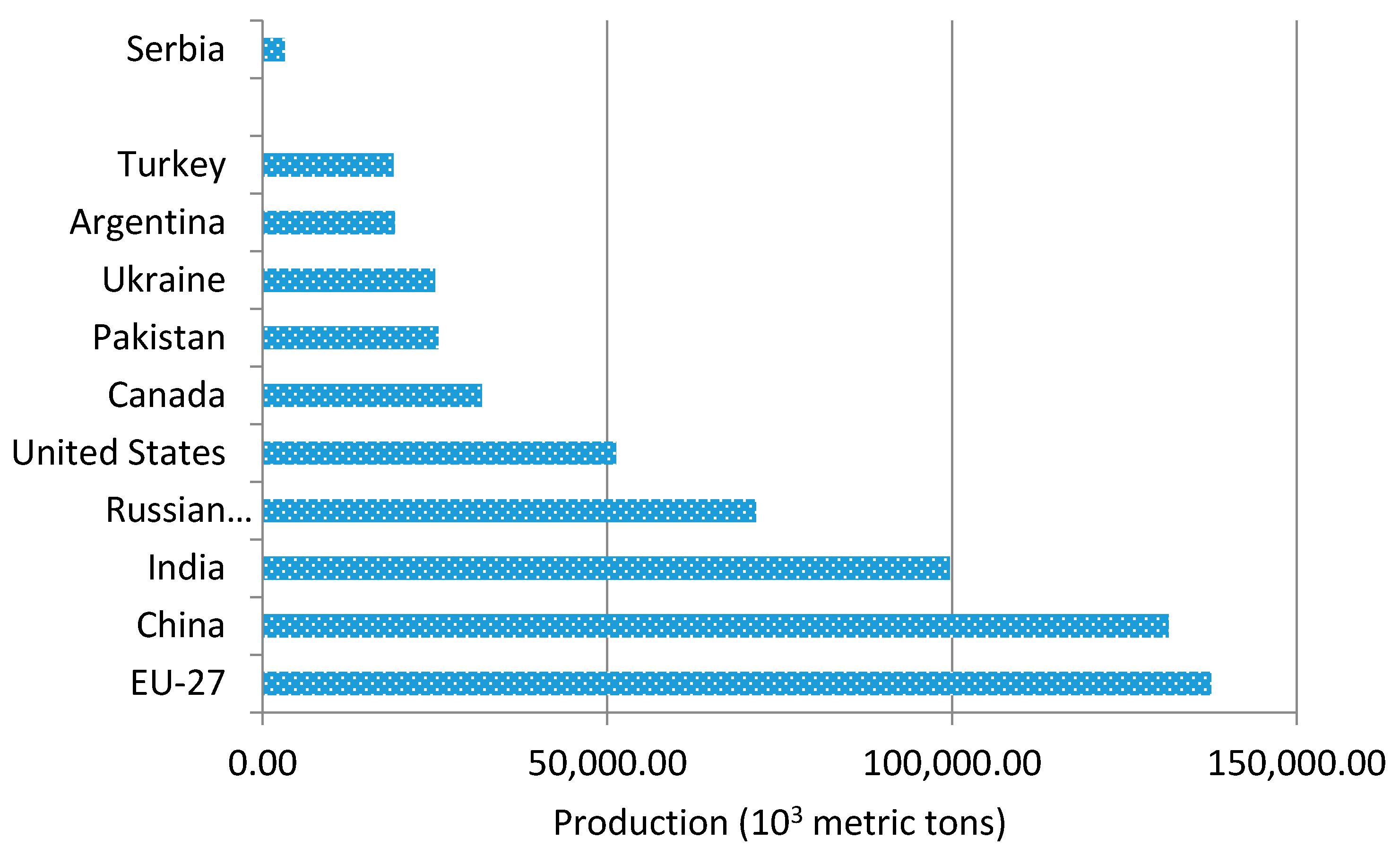

1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Cement

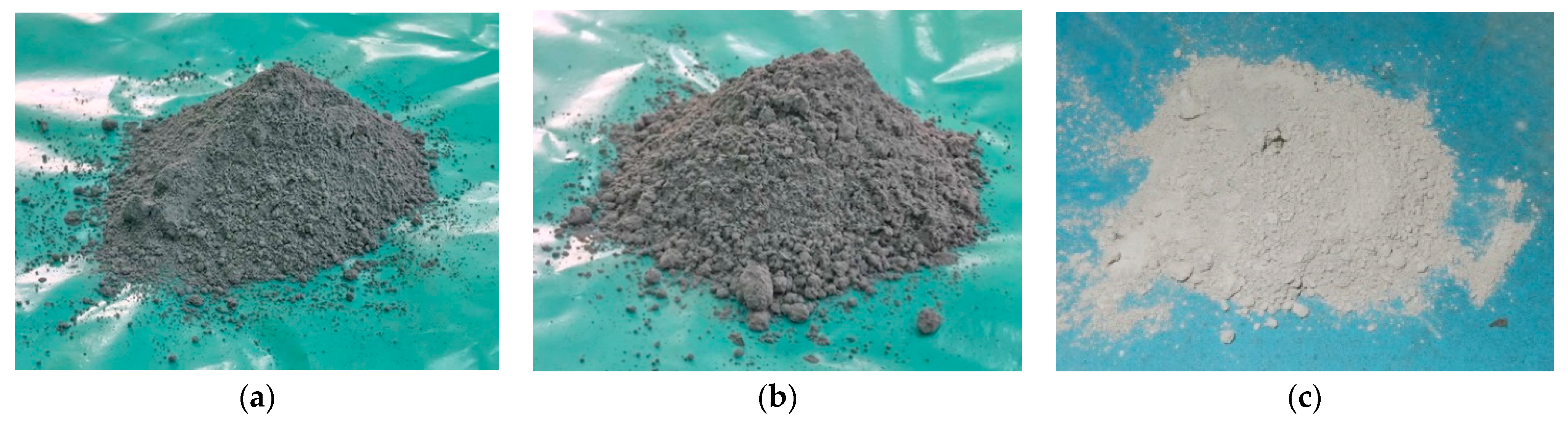

2.1.2. Biomass Ashes

2.1.3. Silica Fume

2.1.4. Fine Aggregate

2.2. Methods

3. Test Results and Discussion

3.1. Chemical Analyses

3.1.1. Chemical Composition

3.1.2. Heavy Metals

3.1.3. Leaching of Heavy Metals

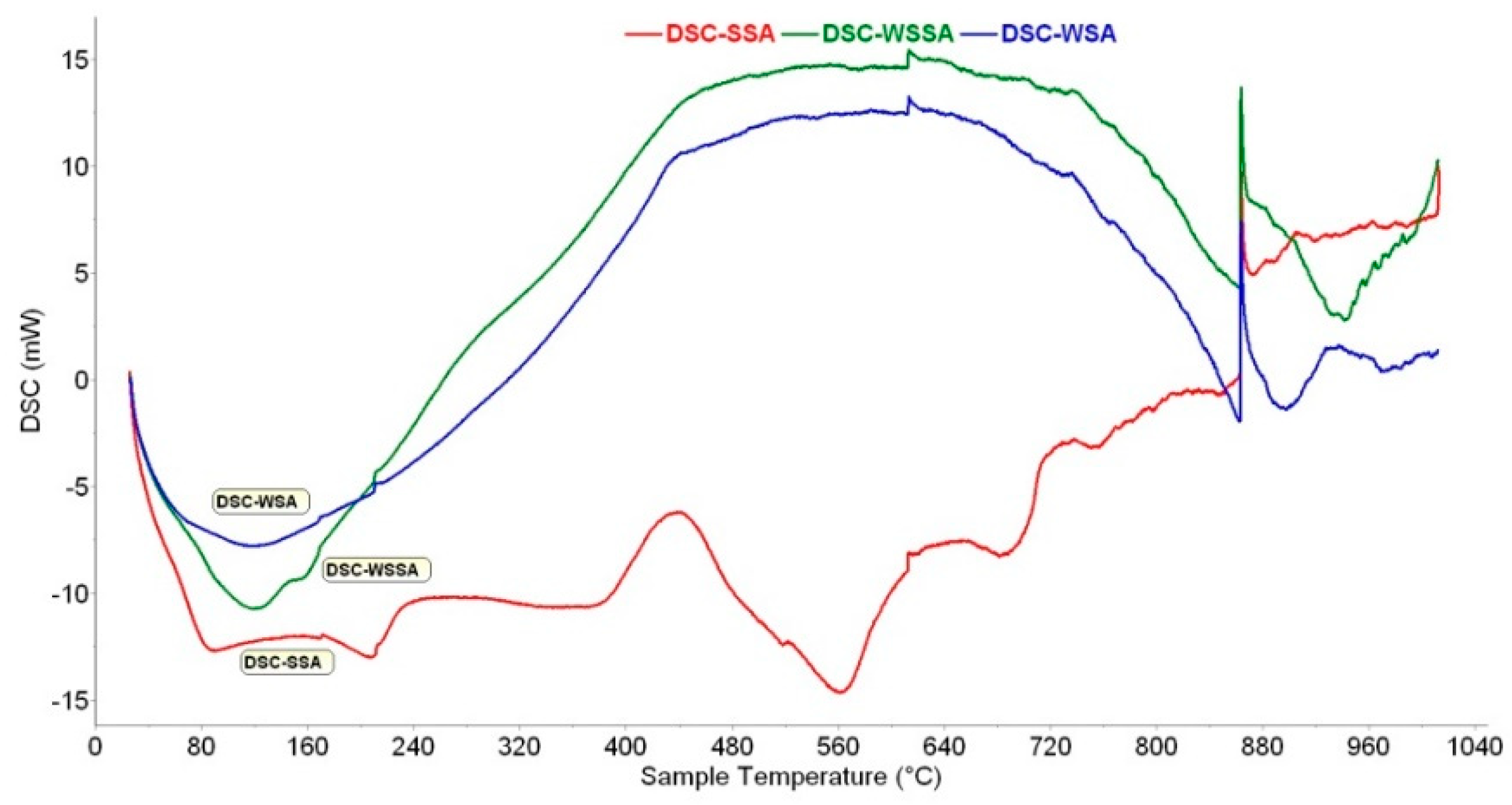

3.1.4. TGA/DSC

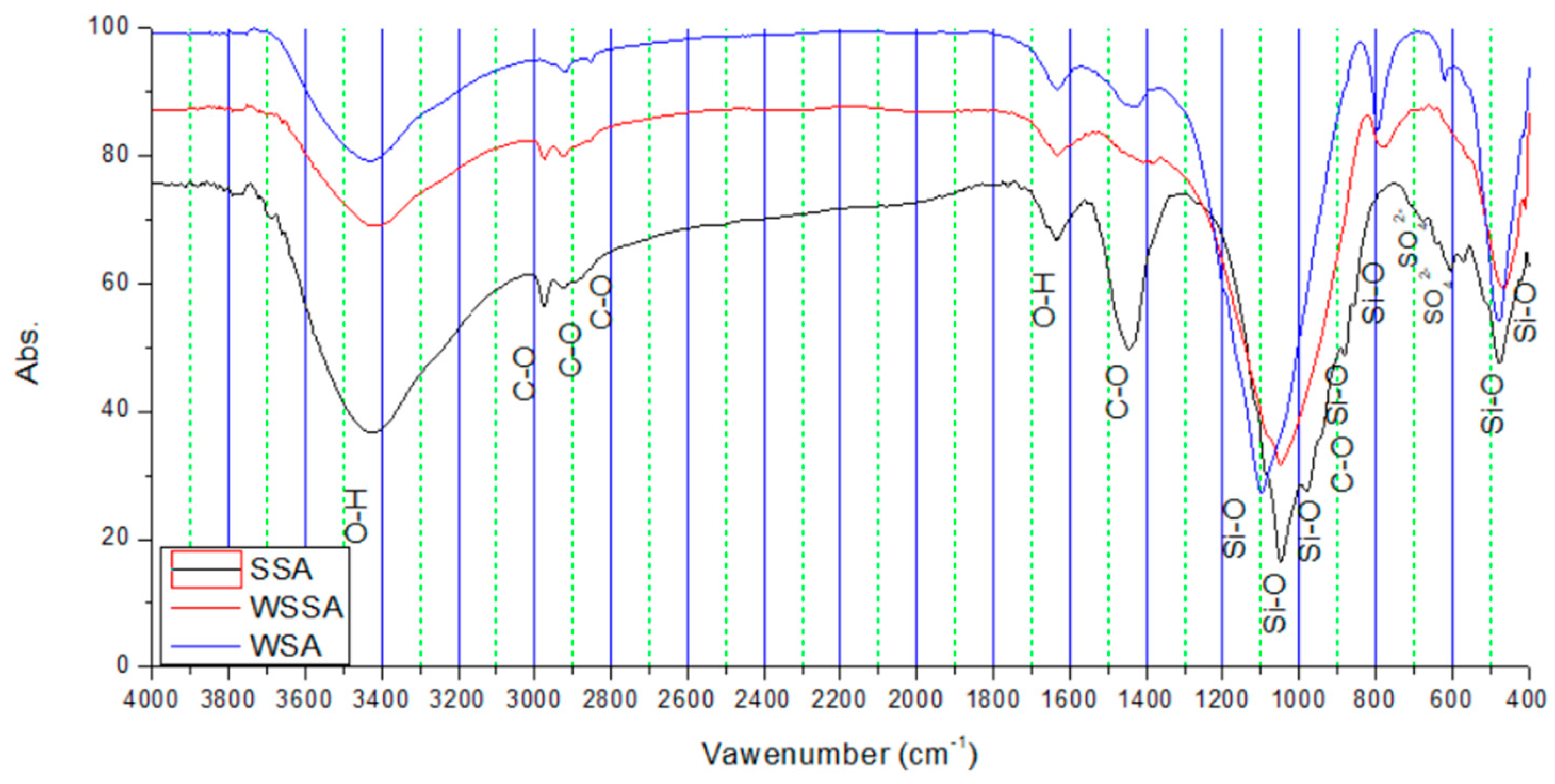

3.1.5. FTIR

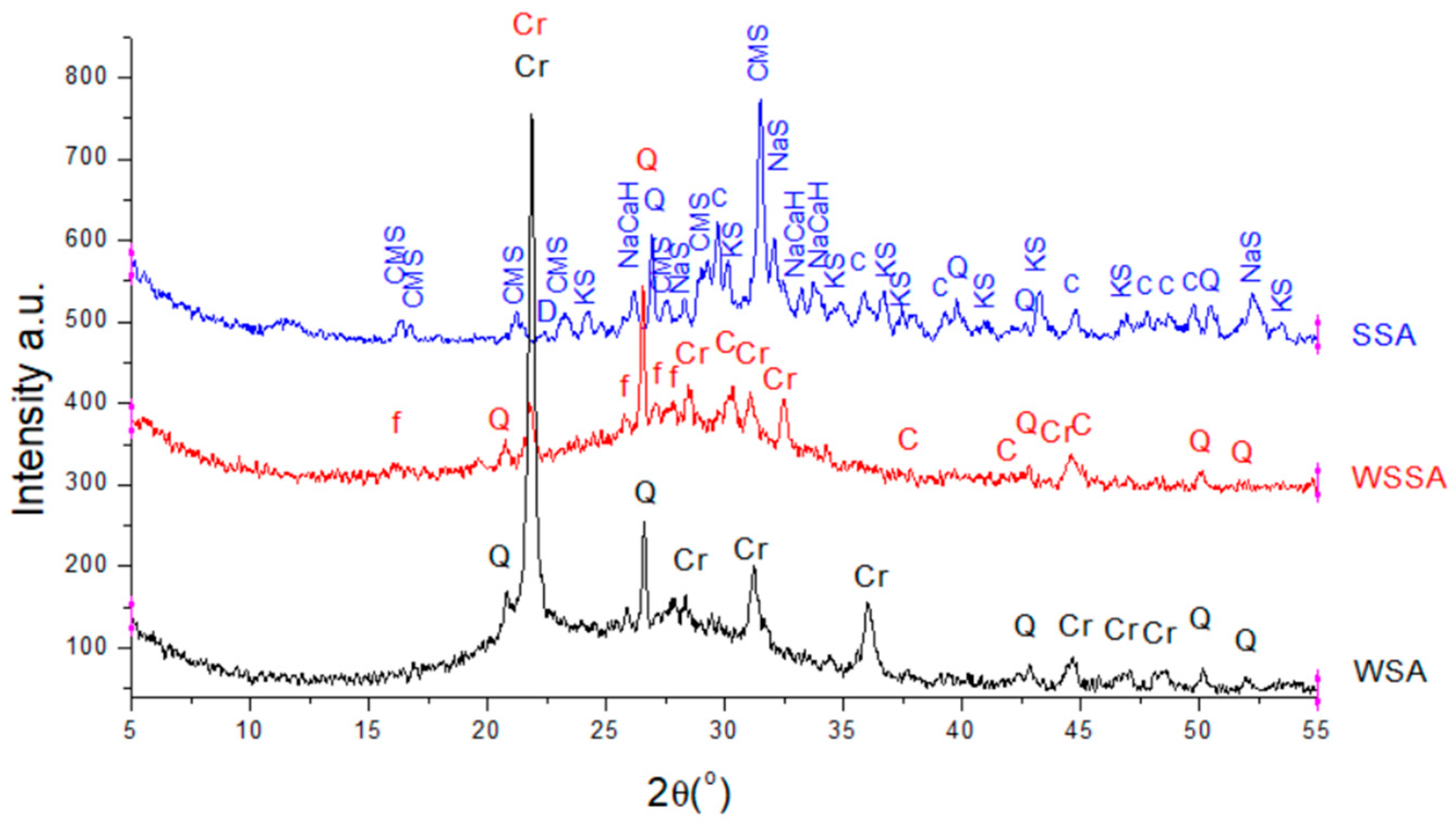

3.1.6. X-ray Diffraction

3.2. Physical Properties of Biomass Ashes

3.3. Pozzolanic Activity

3.4. Setting Time

3.5. Soundness

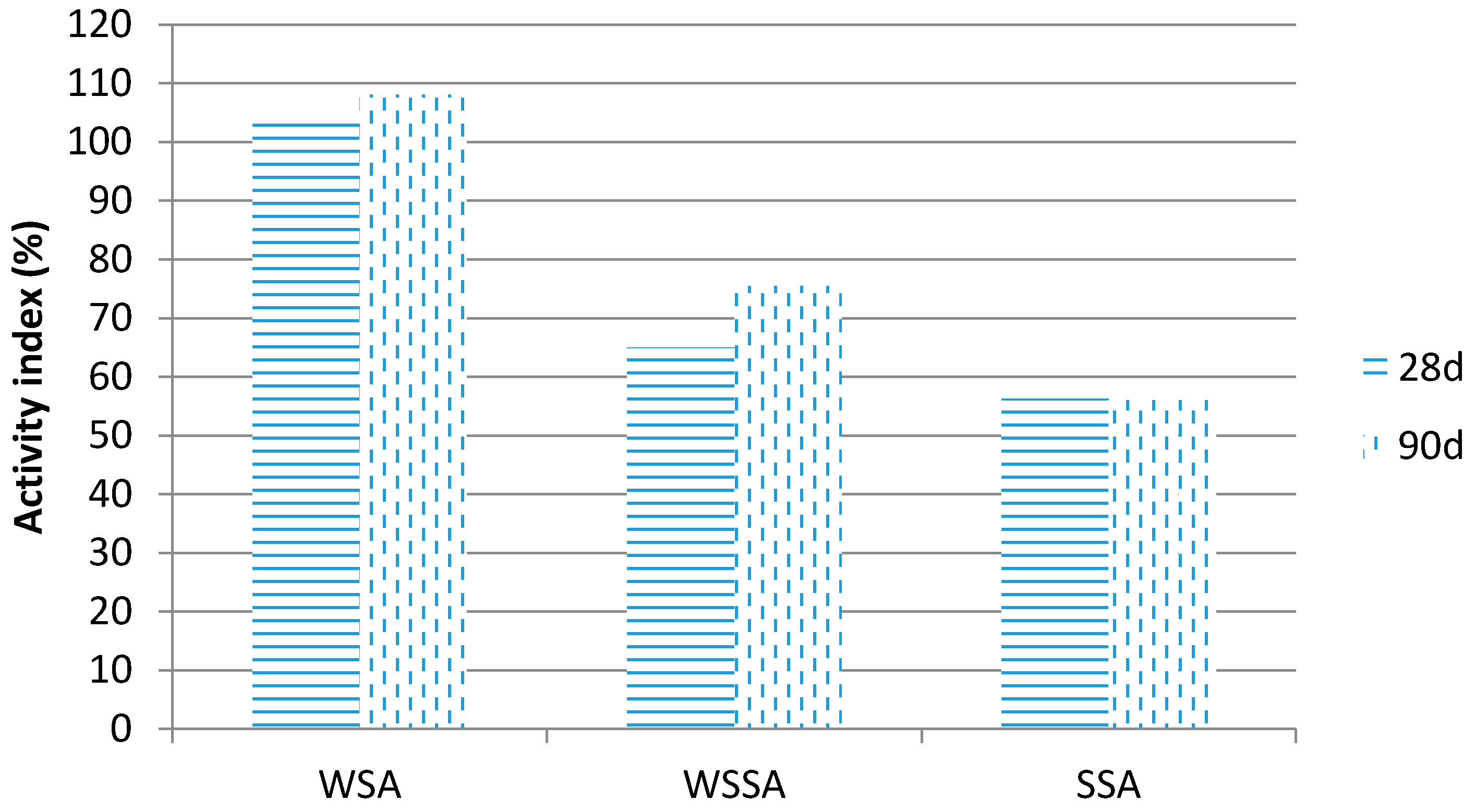

3.6. Activity Index

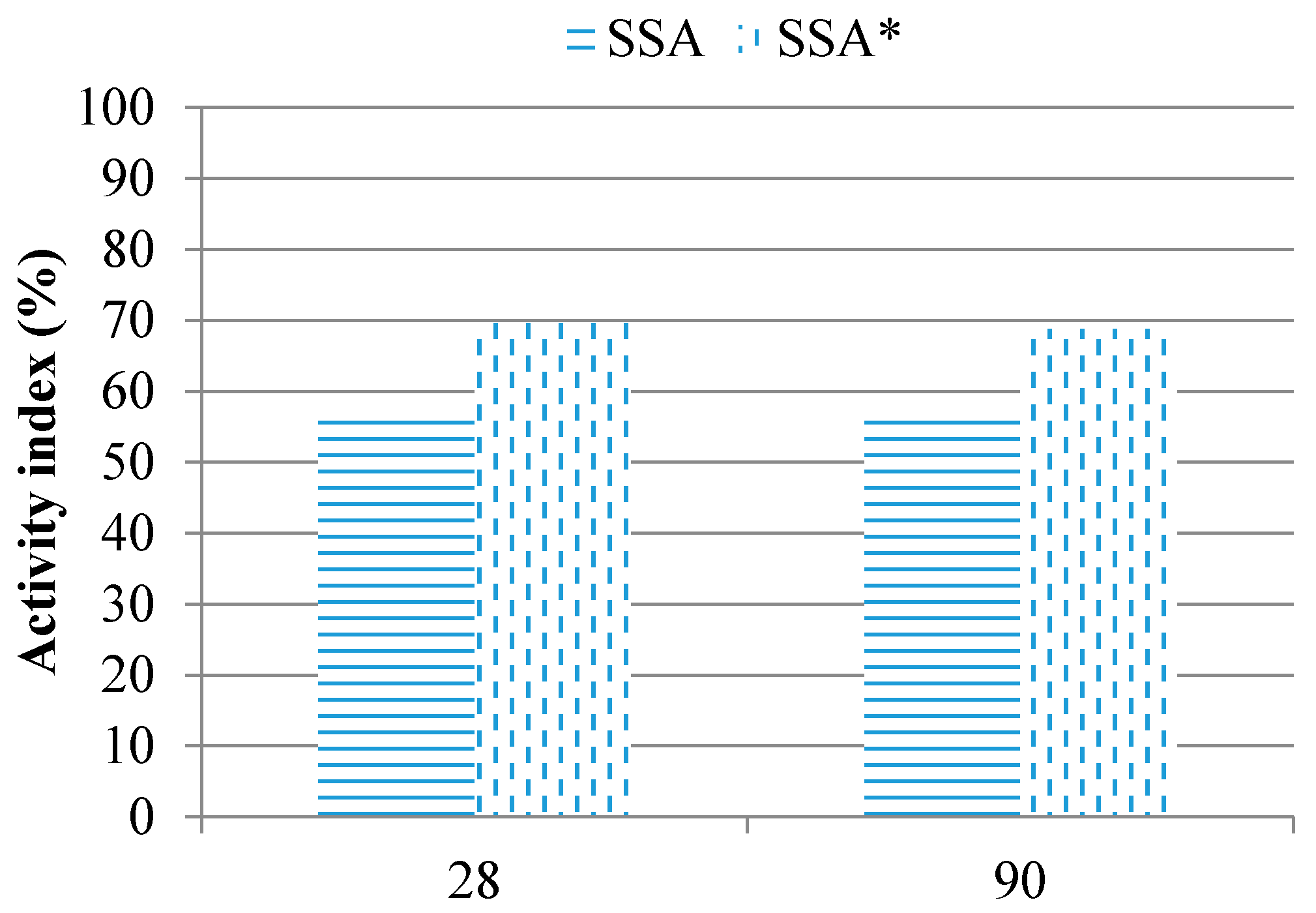

3.7. Improving Activity Index with Additional Grinding

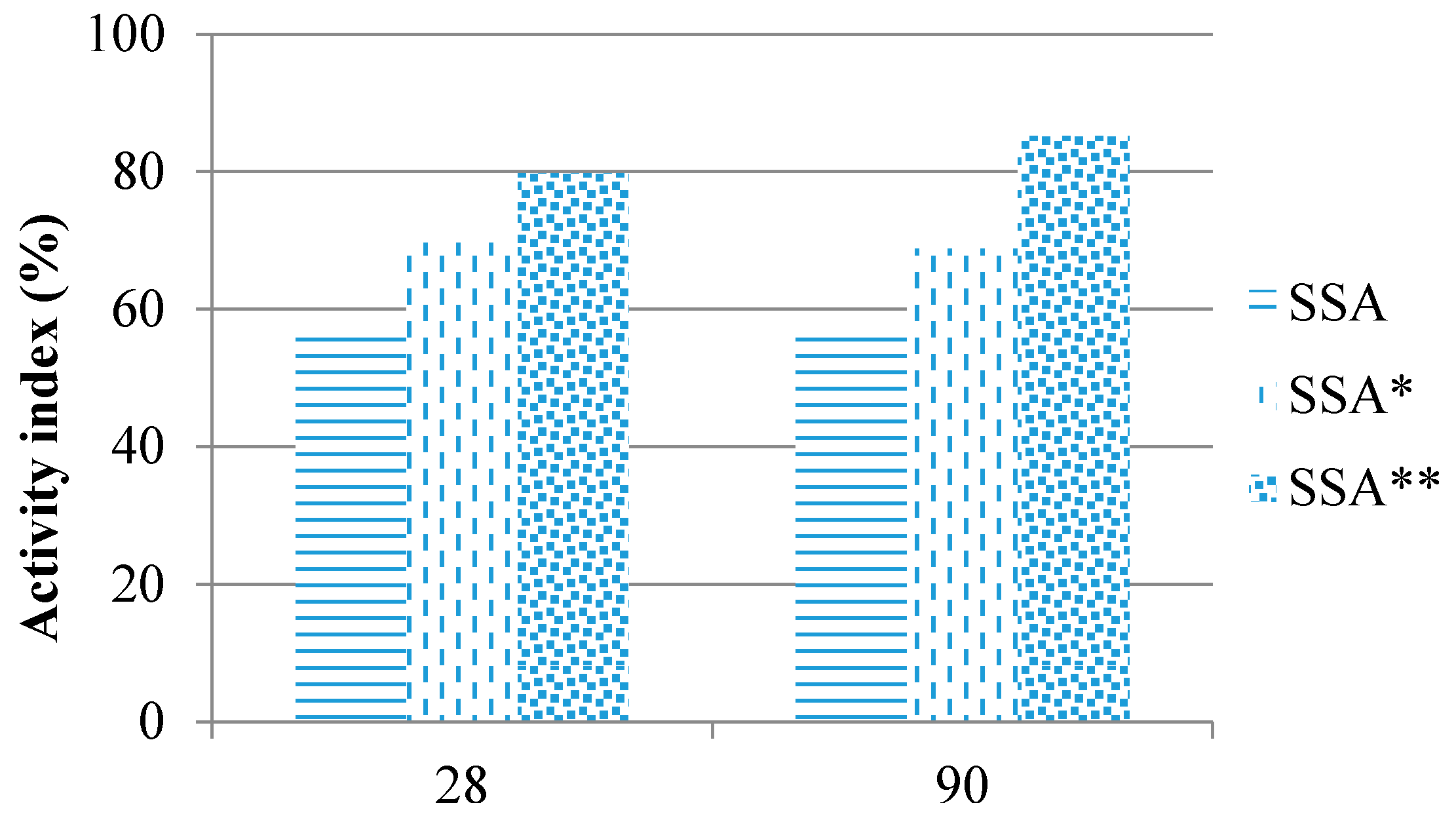

3.8. Stimulation of Pozzolanic Activity of SSA with Silica Fume

4. Conclusions

- WSA exhibits excellent pozzolanic activity, which can be attributed to a high reactive silica content and a relatively high specific surface of the ash. As the content of soybean-based ash increases, the total reactive silica content decreases, which further reduces the pozzolanic activity of the ash;

- SSA shows the highest hygroscopicity as confirmed by XRF, TGA and FTIR analyses; it also contains the largest amount of carbonates and organic matter relative to WSA and WSSA (confirmed by TGA, FTIR and XRD);

- A wider hump in XRD pattern of WSA and WSSA compared to SSA indicates that they abound in amorphous phase (silicate) which accounts for their higher pozzolanic activity to a certain extent;

- Additional grinding in the laboratory ball mill increases the level of fineness of WSSA, induces its filler effect and improves its activity index. Mechanical activation has only a minor effect on SSA reactivity, hence silica fume can be used to stimulate its pozzolanic activity;

- All types of biomass ashes are characterized with no significant leaching values of heavy metals and can be classified as inert materials, thereby satisfying ecological aspects of SCM utilization.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Thomas, B.S. Green concrete partially comprised of rice husk ash as a supplementary cementitious material—A comprehensive review. Renew. Sustain. Energy Rev. 2018, 82, 3913–3923. [Google Scholar] [CrossRef]

- Park, K.B.; Kwon, S.J.; Wang, X.Y. Analysis of the effects of rice husk ash on the hydration of cementitious materials. Constr. Build. Mater. 2016, 105, 196–205. [Google Scholar] [CrossRef]

- Memon, S.A.; Khan, M.K. Ash blended cement composites: Eco-friendly and sustainable option for utilization of corncob ash. J. Clean. Prod. 2018, 175, 442–455. [Google Scholar] [CrossRef]

- Qudoos, A.; Kim, H.G.; Rehman, A.; Ryou, J.S. Effect of mechanical processing on the pozzolanic efficiency and the microstructure development of wheat straw ash blended cement composites. Constr. Build. Mater. 2018, 193, 481–490. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Rukzon, S.; Sirivivatnanon, V. Resistance to chloride penetration of blended Portland cement mortar containing palm oil fuel ash, rice husk ash and fly ash. Constr. Build. Mater. 2015, 22, 932–938. [Google Scholar] [CrossRef]

- Moraes, J.C.B.; Akasaki, J.L.; Melges, J.L.P.; Monzó, J.; Borrachero, M.V.; Soriano, L.; Payá, J.; Tashima, M.M. Assessment of sugar cane straw ash (SCSA) as pozzolanic material in blended Portland cement: Microstructural characterization of pastes and mechanical strength of mortars. Constr. Build. Mater. 2015, 94, 670–677. [Google Scholar] [CrossRef]

- Aksoğan, O.; Binici, H.; Ortlek, E. Durability of concrete made by partial replacement of fine aggregate by colemanite and barite and cement by ashes of corn stalk, wheat straw and sunflower stalk ashes. Constr. Build. Mater. 2016, 106, 253–263. [Google Scholar] [CrossRef]

- Cociñaa, E.V.; Morales, E.V.; Santos, S.F.; Savastano, H., Jr.; Frías, M. Pozzolanic behavior of bamboo leaf ash: Characterization and determination of the kinetic parameters. Cem. Concr. Compos. 2011, 33, 68–73. [Google Scholar] [CrossRef]

- Alaneme, K.K.; Eze, H.I.; Bodunrin, M.O. Corrosion behaviour of groundnut shell ash and silicon carbide hybrid reinforced Al-Mg-Si alloy matrix composites in 3.5% NaCl and 0.3M H2SO4 solutions. Leonardo Electron. J. Pract. Technol. 2015, 26, 141–158. [Google Scholar]

- Raheem, A.A.; Ige, A.I. Chemical composition and physicomechanical characteristics of sawdust ashblended cement. J. Build. Eng. 2019, 21, 404–408. [Google Scholar] [CrossRef]

- Li, G.; Xu, X.; Chen, E.; Fan, J.; Xiong, G. Properties of cement-based bricks with oyster-shells ash. J. Clean. Prod. 2015, 91, 279–287. [Google Scholar] [CrossRef]

- Wigley, F.; Williamson, J.; Malmgren, A.; Riley, G. Ash deposition at higher levels of coal replacement by biomass. Fuel Process. Technol. 2007, 88, 1148–1154. [Google Scholar] [CrossRef]

- Risnes, H.; Fjellerup, J.; Henriksen, U.; Moilanen, A.; Norby, P.; Papadakis, K.; Posselt, D.; Sørensen, L.H. Calcium addition in straw gasification. Fuel 2003, 82, 641–651. [Google Scholar] [CrossRef]

- Demirbas, A. Combustion characteristics of different biomass fuels. Prog. Energy Combust. Sci. 2004, 30, 219–230. [Google Scholar] [CrossRef]

- Opeyemi, J.; Kolapo, O.O.; Ayobami, A.B.; Ignatius, O.O.; Ayodeji, O.O.; Lekan, M.A.; Chidiogo, J.E. Data on the pozzolanic activity in coconut shell ash (CSA) for use in sustainable construction. Data Brief 2018, 18, 1142–1145. [Google Scholar]

- Masiá, T.A.A.; Buhre, B.J.P.; Gupta, R.P.; Wall, T.F. Characterising ash of biomass and waste. Fuel Process. Technol. 2007, 88, 1071–1081. [Google Scholar] [CrossRef]

- Campos Teixeira, A.H.; Soares Junior, P.R.R.; Silva, T.H.; Barreto, R.R.; Bezerra, A.C.D.S. Low-Carbon Concrete Based on Binary Biomass Ash-Silica Fume Binder to Produce Eco-Friendly Paving Blocks. Materials 2020, 13, 1534. [Google Scholar] [CrossRef]

- Xu, W.; Lo, T.Y.; Memon, S.A. Microstructure and reactivity of rich husk ash. Constr. Build. Mater. 2012, 29, 541–547. [Google Scholar] [CrossRef]

- Josephin, A.; Dhanalakshmi, J.; Ambedkar, B. Experimental investigation on rice husk ash as cement replacement on concrete production. Constr. Build. Mater. 2016, 127, 353–362. [Google Scholar]

- Fapohunda, C.; Akinbile, B.; Shittu, A. Structure and properties of mortar and concrete with rice husk ash as partial replacement of ordinary Portland cement—A review. Int. J. Sustain. Built Environ. 2017, 6, 675–692. [Google Scholar] [CrossRef]

- Madandoust, R.; Mohammad, R.M.; Moghadamb, H.A.; Mousavi, S.Y. Mechanical properties and durability assessment of rice husk ash concrete. Biosyst. Eng. 2011, 110, 144–152. [Google Scholar] [CrossRef]

- Jankovský, O.; Pavlíková, M.; Sedmidubský, D.; Bouša, D.; Lojka, M.; Pokorný, J.; Záleská, M.; Pavlík, Z. Study on pozzolana activity of wheat straw ash as potential admixture for blended cements. Ceram.-Silik. 2017, 61, 327–339. [Google Scholar] [CrossRef]

- Khushnood, R.A.; Rizwan, S.A.; Memon, S.A.; Tulliani, J.; Ferro, G.A. Experimental investigation on use of wheat straw ash and bentonite in self-compacting cementitious system. Adv. Mater. Sci. Eng. 2014, 2014, 1–11. [Google Scholar] [CrossRef]

- Goyal, A.; Kunio, H.; Ogata, H.; Garg, M.; Anwar, A.M.; Ashraf, M.; Mandula, M. Synergic effect of wheat straw ash and rice-husk ash on strength properties of mortar. J. Appl. Sci. 2007, 7, 3256–3261. [Google Scholar] [CrossRef][Green Version]

- Biricik, H.; Akoz, F.; Turker, F.; Berktay, I. Resistance to magnesium sulfate and sodium sulfate attack of mortars containing wheat straw ash. Cem. Concr. Res. 2000, 30, 1189–1197. [Google Scholar] [CrossRef]

- The Food and Agriculture Organization (FAO). World Food Situation. Available online: http://www.fao.org/worldfoodsituation/csdb/en/ (accessed on 17 February 2019).

- Index Mundi. Agriculture. World Production. Available online: https://www.indexmundi.com/agriculture/?commodity=wheat&graph=production (accessed on 17 February 2019).

- Index Mundi. Agriculture. World Production. Available online: https://www.indexmundi.com/agriculture/?commodity=soybean-oilseed&graph=production (accessed on 17 February 2019).

- Šupić, S.; Malešev, M.; Radonjanin, V.; Radeka, M.; Laban, M. Application of Biomass Ashes as Supplementary Cementitious Materials in the Cement Mortar Production. World Academy of Science, Engineering and Technology. Int. J. Struct. Constr. Eng. 2018, 12, 703–709. [Google Scholar]

- Radonjanin, V.; Malešev, M.; Šupić, S.; Radeka, M. Influence of filler effect and pozzolanic reaction of biomass ashes on mechanical properties of cement mortars. In Interdisciplinary Approaches for Cement-Based Materials and Structural Concrete, Synergizing Expertise and Bridging Scales of Space and Time; RILEM Publications S.A.R.L.: Madeira, Portugal, 2018; Volume 1, pp. 511–516. [Google Scholar]

- Method of Testing Cement, Part 2. Chemical Analysis of Cement; EN 196-2; European Committee for Standardization (CEN): Brussels, Belgium, 2015.

- Cement-Test Methods, Part 2. Chemical Analysis by X-ray Fluorescence; ISO 29581-2; BSI: Geneva, Switzerland, 2010.

- Characterisation of Waste—Leaching—Compliance Test for Leaching of Granular Waste Materials and Sludges—Part 2: One Stage Batch Test at a Liquid to Solid Ratio of 10 l/kg for Materials with Particle Size below 4 mm (without or with Size Reduction); SRPS EN 12457-2:2008; Institute for Standarddization of Serbia: Beograd, Serbia, 2008.

- Methods of Testing Cement, Determination of Fineness; EN 196-6; European Committee for Standardization (CEN): Brussels, Belgium, 2011.

- Methods of Testing Cement, Part 3. Determination of Setting Times and Soundness; EN 196-3; European Committee for Standardization (CEN): Brussels, Belgium, 2010.

- Fly Ash for Concrete, Part 1. Definition, Specifications and Conformity Criteria; EN 450-1; European Committee for Standardization (CEN): Brussels, Belgium, 2014.

- Non-Metallic Mineral Raws, Pozzolanic Materials, Constituents for Cement Production Classification, Technical Conditions and Test Methods; SRPS B.C1.018; Institute for Standarddization of Serbia: Beograd, Serbia, 2015.

- Methods of Testing Cement, Part 1. Determination of Strength; EN 196-1; European Committee for Standardization (CEN): Brussels, Belgium, 2018.

- Mahmoud, H. Effect of Alkalis and Sulfates on Portland Cement Systems. Graduate Theses and Dissertations, University of South Florida. 2006. Available online: https://scholarcommons.usf.edu/etd/2542/ (accessed on 17 February 2019).

- Mtarfi, N.H.; Rais, Z.; Taleb, M. Effect of clinker free lime and cement fineness on the cement physicochemical properties. J. Mater. Environ. Sci. 2017, 8, 2541–2548. [Google Scholar]

- Noirfontaine, M.N.; Tusseau-Nenez, S.; Signes-Frehel, M.; Gasecki, G.; Girod-Labianca, C. Effect of phosphorus on tricalcium silicate T1: From synthesis to structural characterization. J. Am. Ceram. Soc. Wiley 2009, 92, 2337–2344. [Google Scholar] [CrossRef]

- Michael, P. Compost quality definition–legislation and standards. Work. Group Compost. Consult. Dev. Tech. Off. Agric. 2004. Annex 2. [Google Scholar]

- Council of the European Union. Council Directive 1999/31/EC of 26 April 1999 on the landfill of waste. EUR-Lex 1999, 182, 1–19. [Google Scholar]

- Evic, N.; Brunner, T.; Obernberger, I. Prediction of biomass ash melting behaviour–correlation between the data obtained from thermodynamic equilibrium calculations and simultaneous thermal analysis (STA). In Proceedings of the 20th European Biomass Conference and Exhibition, Milan, Italy, 18–22 June 2012; pp. 807–813. [Google Scholar]

- Esteves, T.C.; Rajamma, R.; Soares, D.; Silva, A.S.; Ferreira, V.M.; Labrincha, J.A. Use of biomass fly ash for mitigation of alkali-silica reaction of cement mortars. Constr. Build. Mater. 2012, 26, 687–693. [Google Scholar] [CrossRef]

- Umamaheswaran, K.; Batra, V.D. Physico-chemical characterisation of Indian biomass ashes. Fuel 2008, 87, 628–638. [Google Scholar] [CrossRef]

- Febrero, L.; Granada, E.; Pérez, C.; Patiño, D.; Arce, E. Characterisation and comparison of biomass ashes with different thermal histories using TG-DSC. J. Therm. Anal. Calorim. 2014. [Google Scholar] [CrossRef]

- Arvelakis, S.; Arendt, J.P.; Dam-Johansen, K. Simultaneous Thermal Analysis (STA) on Ash from High-Alkali Biomass. Energy Fuels 2004, 18, 1066–1076. [Google Scholar] [CrossRef]

- Mäkelä, M.; Paananen, T.; Kokkonen, T.; Makkonen, H.; Heino, J.; Dahl, O. Preliminary Evaluation of Fly Ash and Lime for Use as Supplementary Cementing Materials in Cold-Agglomerated Blast Furnace Briquetting. ISIJ Int. 2011, 51, 776–781. [Google Scholar] [CrossRef]

- Arvelakis, S.; Gehrmann, H.; Beckmann, M.; Koukios, E.G. Studying the ash behaviour of agricultural residues using Thermal Analysis. J. Therm. Anal. Calorim. 2003, 72, 1019–1030. [Google Scholar] [CrossRef]

- Bonet-Martínez, E.; García-Cobo, P.; Pérez-Villarejo, L.; Castro, E.; Eliche-Quesada, D. Effect of olive-pine bottom ash on properties of geopolymers based on metakaolin. Materials 2020, 13, 901. [Google Scholar] [CrossRef]

- Jeyageetha, C.J.; Kumar, S.P. Study of SEM/EDXS and FTIR for Fly Ash to Determine the Chemical Changes of Ash in Marine Environment. Int. J. Sci. Res. 2013, 5, 1688–1692. [Google Scholar]

- Pérez-Villarejo, L.; Bonet-Martínez, E.; Eliche-Quesada, D.; Sánchez-Soto, P.J.; Rincón-López, J.M.; Castro-Galiano, E. Biomass fly ash and aluminium industry slags-based geopolymers. Mater. Lett. 2018, 229, 6–12. [Google Scholar]

- Kalembkiewicz, J.; Galas, D.; Sitarz-Palczak, E. The Physicochemical Properties and Composition of Biomass Ash and Evaluating Directions of its Applications. Pol. J. Environ. Stud. 2018, 27, 2593–2603. [Google Scholar] [CrossRef]

- Verşan, K.M.; Ozgur, E. Characterization of lignocellulose biomass and model compounds by thermogravimetry. Energy Sources Part A Recovery Util. Environ. Eff. 2007, 39, 134–139. [Google Scholar] [CrossRef]

- Liu, Y.; Zeng, F.; Sun, B.; Jia, P.; Graham, I.T. Structural Characterizations of Aluminosilicates in Two Types of Fly Ash Samples from Shanxi Province, North China. Minerals 2019, 9, 358. [Google Scholar] [CrossRef]

- Criado, M.; Fernández-Jiménez, A.; Palomo, A. Alkali activation of fly ash: Effect of the SiO2/Na2O ratio Part I: FTIR study. Microporous Mesoporous Mater. 2007, 106, 180–191. [Google Scholar] [CrossRef]

- Vempati, R.K.; Rao, A.; Hess, T.R.; Cocke, D.L.; Lauer, H.V., Jr. Fractionation and characterization of Texas lignite class F fly ash by XRD, TGA, FTIR and SFM. Cem. Concr. Res. 1994, 24, 1153–1164. [Google Scholar] [CrossRef]

- Soltan, H.H.; Abdel-Gawwad, H.A.; Vasquez-García, S.R.; Israde-Alcantara, I.; Flores-Ramirez, N.; Rico, J.L.; Mohammed, M.S. Cleaner production of one-part white geopolymer cement using pretreated wood biomass ash and diatomite. J. Clean. Prod. 2019, 209, 1420e1428. [Google Scholar]

- Çetintaş, R.; Soyer-Uzun, S. Relations between structural characteristics and compressive strength in volcanic ash based one–part geopolymer systems. J. Build. Eng. 2018, 20, 130–136. [Google Scholar] [CrossRef]

- Assad, M.M.; Hussain, K.A.; Hassanb, M.; Liaquatb, R. Biomass ash characterization, fusion analysis and its application in catalytic decomposition of methane. Fuel 2021, 285, 119107. [Google Scholar] [CrossRef]

- Masto, R.E.; Pandit, A.; Kumar, S.; Datta, S.; Mukhopadhyay, S.; Selvi, V.A.; Dutta, P.; Sarkar, P. Comparative evaluation of aquatic biomass feedstocks for energy application and potential for extraction of plant nutrients from their ash. Biomass Bioenergy 2020, 142, 105783. [Google Scholar] [CrossRef]

- Jose, A.; Nivitha, M.R.; Murali, K.J.; Robinson, R.G. Characterization of cement stabilized pond ash using FTIR spectroscopy. Constr. Build. Mater. 2020, 263, 120136. [Google Scholar] [CrossRef]

- Cretescu, I.; Harja, M.; Teodosiu, C.; Isopescu, D.N.; Chok, M.F.; Sluser, B.M.; Salleh, M.A.M. Synthesis and characterisation of a binder cement replacement basedon alkali activation of fly ash waste. Process. Saf. Environ. Prot. 2018, 119, 23–35. [Google Scholar] [CrossRef]

- Zhang, W.; Liu, C. The effect of diesel emulsification using sodium petroleum sulfonate on carbon flotation from fly ash. Waste Manag. 2019, 98, 144–150. [Google Scholar] [CrossRef] [PubMed]

- Hernandez-Martínez, D.; Leyva-Verduzco, A.A.; Rodríguez-Felix, F.; Acosta-Elías, M.; Wong-Corral, F.J. Obtaining and characterization of silicon (Si) from wheat husk ash for its possible application in solar cells. J. Clean. Prod. 2020, 271, 122698. [Google Scholar] [CrossRef]

- Osman, N.S.; Sapawe, N. Preparation of amorphous oil palm frond ash (OPFA) via acid leaching treatment as precursor for silica synthesis. Mater. Today Proc. 2020, 31, 253–256. [Google Scholar] [CrossRef]

- Cheng, S.Y.; Liu, Y.Z.; Qi, G.S. Experimental study of CO2 capture enhanced by coal fly ash-synthesized NH2-MCM-41 coupled with high gravity technology. Chem. Eng. J. 2020, 400, 125946. [Google Scholar] [CrossRef]

- Ikubanni, P.P.; Oki, M.; Adeleke, A.A.; Adediran, A.A.; Adesina, O.S. Influence of temperature on the chemical compositions and microstructural changes of ash formed from palm kernel shell. Results Eng. 2020, 8, 100173. [Google Scholar] [CrossRef]

- Cement Composition, Specifications and Conformity Criteria for Common Cements; EN 197-1:2011; European Committee for Standardization (CEN): Brussels, Belgium, 2011.

- Fernández-Jiménez, A.; Garcia-Lodeiro, I.; Maltseva, O.; Palomo, A. Mechanical-Chemical Activation of Coal Fly Ashes: An Effective Way for Recycling and Make Cementitious. Materials. Front. Mater. 2019. [Google Scholar] [CrossRef]

- Thiedeitz, M.; Schmidt, W.; Härder, M.; Kränkel, T. Performance of Rice Husk Ash as Supplementary Cementitious Material after Production in the Field and in the Lab. Materials 2020, 13, 4319. [Google Scholar] [CrossRef]

| Silica Content (%) | Reference | |

|---|---|---|

| Rice husk ash (RHA) | 88.0 | Ki-Bong et al. [2] |

| Corn cob ash (CCA) | 61.8 | Shazim et al. [3] |

| Wheat straw ash (WSA) | 65.7 | Qudoos et al. [4] |

| Palm oil fuel ash (POFA) | 63.6 | Chindaprasirt et al. [5] |

| Sugar cane straw ash (SCSA) | 36.5 | Moraes J.C.B. et al. [6] |

| Sunflower stalk ash (SSA) | 26.0 | Aksog˘an O. et al. [7] |

| Bamboo leaf ash (BLA) | 80.4 | Cociñaa E.V. et al. [8] |

| Groundnut shell ash (GSA) | 41.4 | Alaneme K.K. et al. [9] |

| Saw dust ash (SDA) | 69.3 | Raheem A.A. et al. [10] |

| Oyster shell ash (OSA) | 4.6 | Gengying Li et al. [11] |

| Mischantus ash (MA) | 57.0 | Wigley F. et al. [12] |

| Barley ash (BA) | 31.0 | Risnes H. et al. [13] |

| Sunflower husk ash (SHA) | 29.3 | Demirbas A. et al. [14] |

| Olive husk ash (OHA) | 32.7 | Demirbas A. et al. [14] |

| Coconut shell ash (CSA) | 66.3 | Opeyemi J. et al. [15] |

| Rape straw ash (RSA) | 36.7 | Masiá T.A.A. et al. [16] |

| Eucalyptus biomass ash (EBA) | 1.2 | Teixeira A.H.C. [17] |

| Wheat Straw Ash (WSA) | Mixture of Wheat and Soybean Straw Ash (WSSA) | Soybean Straw Ash (SSA) | |

|---|---|---|---|

| Loss of ignition at 950 °C | 5.18 | 4.85 | 10.73 |

| Moisture loss at 105 °C | 0.95 | 1.00 | 3.62 |

| SiO2, % | 69.13 | 56.36 | 32.62 |

| Al2O3, % | 1.12 | 2.03 | 4.58 |

| Fe2O3, % | 0.73 | 1.53 | 1.46 |

| Na2O, % | 0.11 | 0.20 | 0.85 |

| K2O, % | 13.03 | 20.02 | 20.96 |

| MgO, % | 2.5 | 3.54 | 8.33 |

| CaO, % | 5.78 | 7.13 | 15.78 |

| SO3, % | 0.2 | 0.18 | 0.47 |

| P2O5, % | 1.72 | 3.72 | 3.72 |

| Soluble P2O5, mg/kg | 13.77 | 115.95 | <0.05 |

| Content Cl−, % | 0.060 | 0.025 | 0.127 |

| Free CaO content, % | 0.14 | 0.28 | 0.39 |

| Reactive SiO2 content, % | 67.07 | 40.99 | 24.93 |

| Chemical Requirements (EN 450-1) | Criteria | Standard | WSA | WSSA | SSA | |

|---|---|---|---|---|---|---|

| Chemical Properties | Total amount of oxides: SiO2 + Al2O3 + Fe2O3 (%) | ≥70% | EN 196-2 EN 450-1 | 71.0 | 57.12 | 39.04 |

| Loss of ignition (%) | A: Max 5% B: Max 7% C: Max 9% | EN 196-2 EN 450-1 | 5.1 CLASS B | 4.85 CLASS A | 10.93 | |

| Chloride content (%) | ≤0.1% | EN 196-2 EN 450-1 | 0.060 | 0.025 | 0.127 | |

| Sulphate content (%) | ≤3% | EN 196-2 EN 450-1 | 0.2 | 0.18 | 0.47 | |

| Free CaO content (%) | ≤1.5% | EN451-1 EN 450-1 | 0.14 | 0.28 | 0.39 | |

| Reactive SiO2 content (%) | ≥25% | EN197-1 EN 450-1 | 67.07 | 40.99 | 24.93 | |

| Total amount of alkalis (%) Na2O+0.658 K2O | ≤5% | EN 196-2 EN 450-1 | 8.68 | 13.37 | 14.64 | |

| Phosphate content (%) | ≤5% | ISO 29581-2 EN 450-1 | 1.72 | 3.72 | 3.72 | |

| Soluble phosphate content (mg/kg) | ≤100 mg/kg | EN 450-1 | 13.8 | 116 | 0.05 |

| WSA | WSSA | SSA | Cement | Limit Value | |

|---|---|---|---|---|---|

| As, mg/kg | 0.03 | 0.03 | 0.03 | 0.03 | 200 |

| Ba, mg/kg | 407.00 | 325.01 | 225.01 | 263 | - |

| Cd, mg/kg | 0.03 | 0.03 | 0.03 | 0.03 | 0.7 |

| Co, mg/kg | 0.01 | 0.01 | 0.01 | 0.01 | - |

| Cr, mg/kg | 71.25 | 87.25 | 67.50 | 97 | 70 |

| Cu, mg/kg | 84.25 | 107.75 | 172.52 | 0.01 | 70 |

| Hg, mg/kg | 0.01 | 0.01 | 0.01 | 0.01 | 0,4 |

| Mn, mg/kg | 500.00 | 587.01 | 335.12 | 470 | - |

| Mo, mg/kg | 0.01 | 0.01 | 0.01 | 0.01 | - |

| Ni, mg/kg | 0.01 | 0.01 | 0.01 | 0.01 | 25 |

| Pb, mg/kg | 0.01 | 0.01 | 0.01 | 0.01 | 45 |

| Sb, mg/kg | 0.03 | 12.50 | 335.01 | 0.05 | - |

| Sn, mg/kg | 0.05 | 0.05 | 0.05 | 0.05 | - |

| Zn, mg/kg | 5.00 | 37.50 | 51.25 | 150 | 200 |

| WSA | WSSA | SSA | Cement | |

|---|---|---|---|---|

| As, mg/kg | 0.00 | 0.00 | 0.00 | 0.00 |

| Cd, mg/kg | 0.00 | 0.00 | 0.00 | 0.00 |

| Cr, mg/kg | 1.02 | 1.25 | 0.96 | 1.39 |

| Cu, mg/kg | 1.20 | 1.54 | 2.51 | 0.00 |

| Hg, mg/kg | 0.00 | 0.00 | 0.00 | 0.00 |

| Ni, mg/kg | 0.00 | 0.00 | 0.00 | 0.00 |

| Pb, mg/kg | 0.00 | 0.00 | 0.00 | 0.00 |

| Zn, mg/kg | 0.025 | 0.187 | 0.26 | 0.75 |

| HMI sum | 2.245 | 2.98 | 3.73 | 2.14 |

| Pb | Cd | Zn | Cu | Ni | Cr | Hg | As | |

|---|---|---|---|---|---|---|---|---|

| WSA | <0.07 | 0.27 | <0.4 | 0.36 | <0.1 | 0.44 | <0.003 | <0.15 |

| WSSA | <0.07 | 0.22 | <0.4 | 1.5 | 0.13 | 0.62 | 0.01 | <0.15 |

| SSA | <0.07 | 0.25 | <0.4 | 0.84 | <0.1 | 1.70 | <0.003 | <0.15 |

| Pb | Cd | Zn | Cu | Ni | Cr | Hg | As | |

|---|---|---|---|---|---|---|---|---|

| Inert | 0.5 | 0.04 | 4 | 2 | 0.4 | 0.5 | 0.01 | 0.5 |

| Non-Hazardous | 10 | 1 | 50 | 50 | 10 | 10 | 0.2 | 2 |

| Hazardous | 50 | 5 | 200 | 100 | 40 | 70 | 2 | 25 |

| Biomass Ash/Temperature | 25–300 °C | 300–600 °C | 600–850 °C | 850–1000 °C | Total |

|---|---|---|---|---|---|

| WSA | 1.6 | 1.05 | 0.61 | 0.51 | 3.77 |

| WSSA | 3.28 | 1.66 | 0.71 | 0.48 | 6.13 |

| SSSA | 3.85 | 4.29 | 1.04 | 0.17 | 9.35 |

| Specific Gravity (kg/m3) | Specific Surface Area (Blaine) (cm2/g) | |

|---|---|---|

| WSA | 2380 | 5800 |

| WSSA | 2370 | 5500 |

| SSA | 2400 | 5600 |

| Biomass Ash | ff,av (MP)] | ff,min (MPa) | Flexural Strength Class | fc,av (MPa) | fc,min (MPa) | Compressive Strength Class | Class |

|---|---|---|---|---|---|---|---|

| WSA | 3.4 | 3.3 | 10 | 11.0 | 10.3 | 10 | 10 |

| WSSA | 3.6 | 3.3 | 10 | 9.3 | 8.75 | 5 | 5 |

| SSA | 1.6 | 1.45 | / | 4.06 | 3.84 | / | / |

| The Initial Setting Time (Minutes) | The Final Setting Time (Minutes) | Criterion 1 | Criterion 2 | |

|---|---|---|---|---|

| C | 230 | 275 | fulfilled | fulfilled |

| WSA | 220 | 320 | fulfilled | fulfilled |

| WSSA | 350 | 420 | fulfilled | fulfilled |

| SSA | 310 | 355 | fulfilled | fulfilled |

| Expansion (mm) | Criterion | |

|---|---|---|

| C | 0 | fulfilled |

| WSA | 0.5 | fulfilled |

| WSSA | 1 | fulfilled |

| SSA | 1 | fulfilled |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Šupić, S.; Malešev, M.; Radonjanin, V.; Bulatović, V.; Milović, T. Reactivity and Pozzolanic Properties of Biomass Ashes Generated by Wheat and Soybean Straw Combustion. Materials 2021, 14, 1004. https://doi.org/10.3390/ma14041004

Šupić S, Malešev M, Radonjanin V, Bulatović V, Milović T. Reactivity and Pozzolanic Properties of Biomass Ashes Generated by Wheat and Soybean Straw Combustion. Materials. 2021; 14(4):1004. https://doi.org/10.3390/ma14041004

Chicago/Turabian StyleŠupić, Slobodan, Mirjana Malešev, Vlastimir Radonjanin, Vesna Bulatović, and Tiana Milović. 2021. "Reactivity and Pozzolanic Properties of Biomass Ashes Generated by Wheat and Soybean Straw Combustion" Materials 14, no. 4: 1004. https://doi.org/10.3390/ma14041004

APA StyleŠupić, S., Malešev, M., Radonjanin, V., Bulatović, V., & Milović, T. (2021). Reactivity and Pozzolanic Properties of Biomass Ashes Generated by Wheat and Soybean Straw Combustion. Materials, 14(4), 1004. https://doi.org/10.3390/ma14041004