A Study on Machining Performances of Micro-Drilling of Multi-Directional Carbon Fiber Reinforced Plastic (MD-CFRP) Based on Nano-Solid Dry Lubrication Using Graphene NanoPlatelets

Abstract

1. Introduction

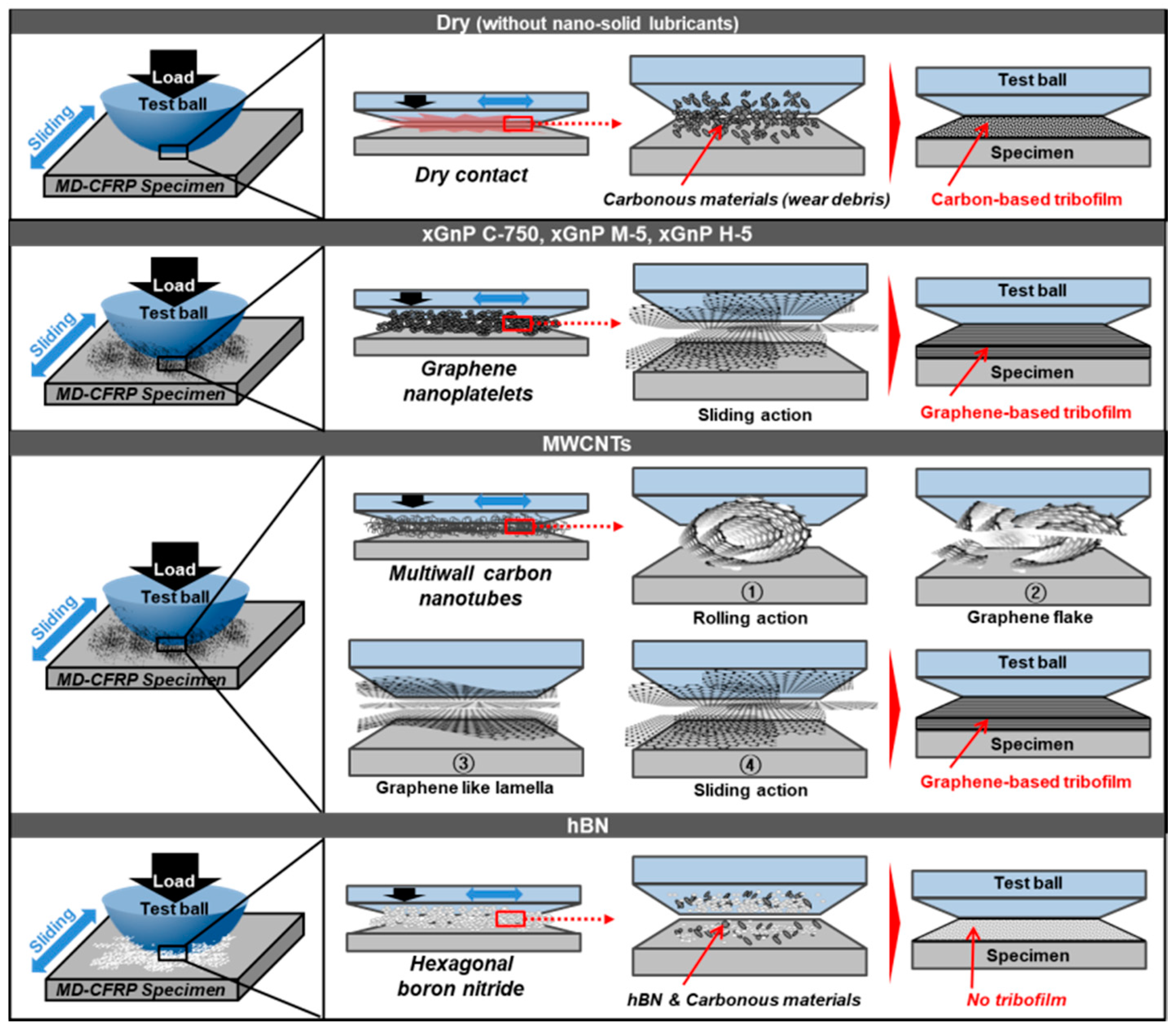

2. Tribological Test of Nano-Solid Lubricants

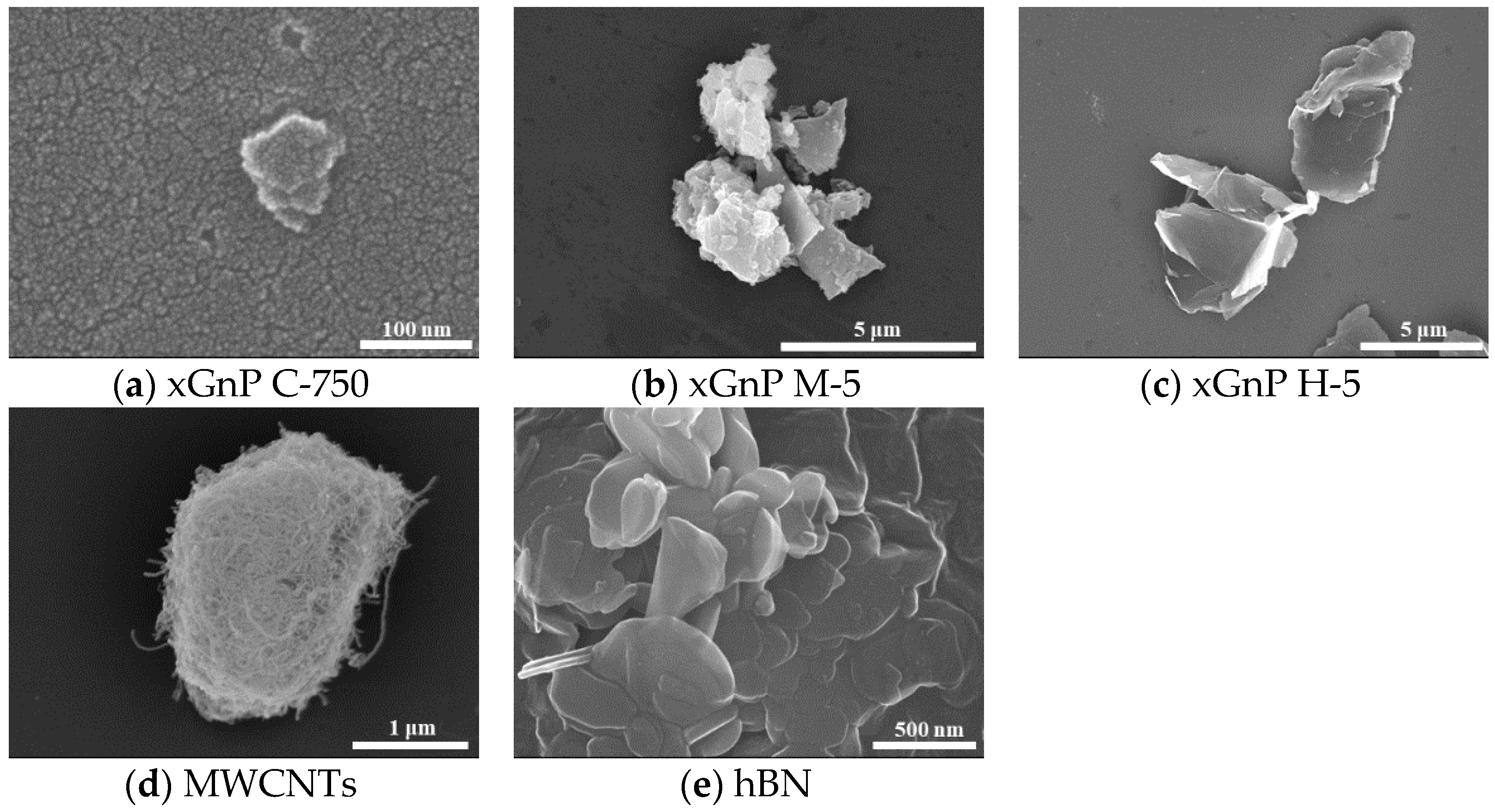

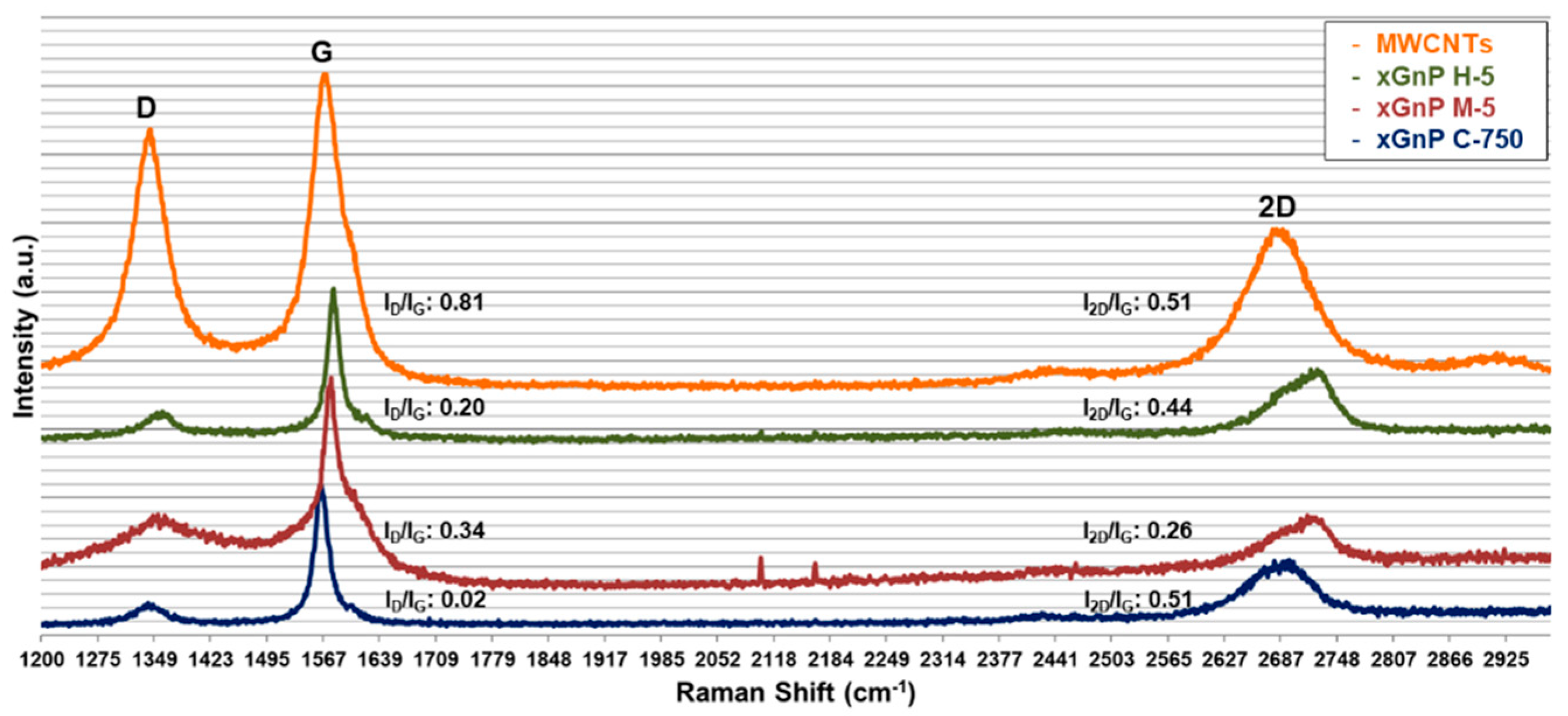

2.1. Properties of Nano-Solid Lubricants

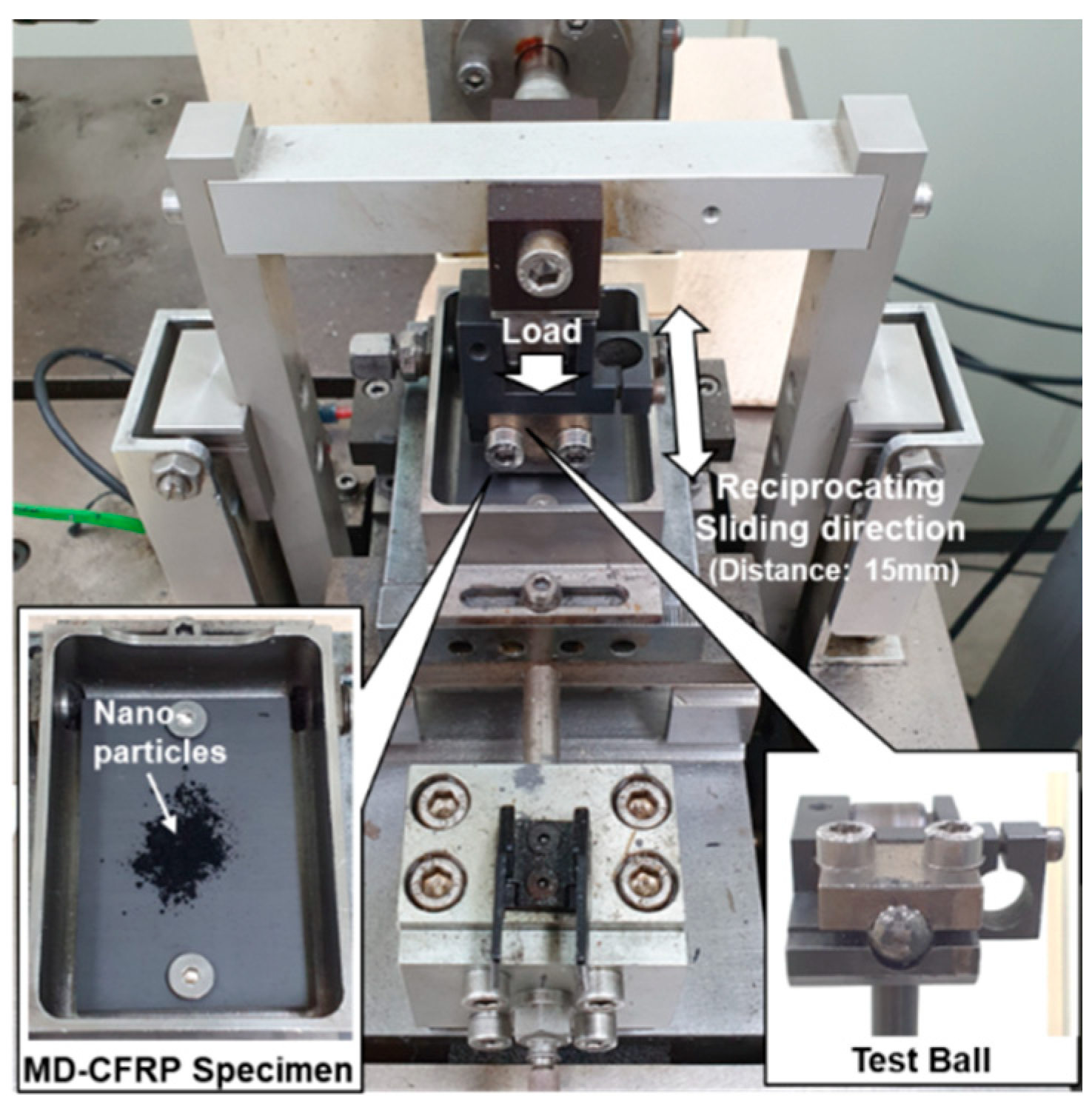

2.2. Tribological Test Design and Conditions

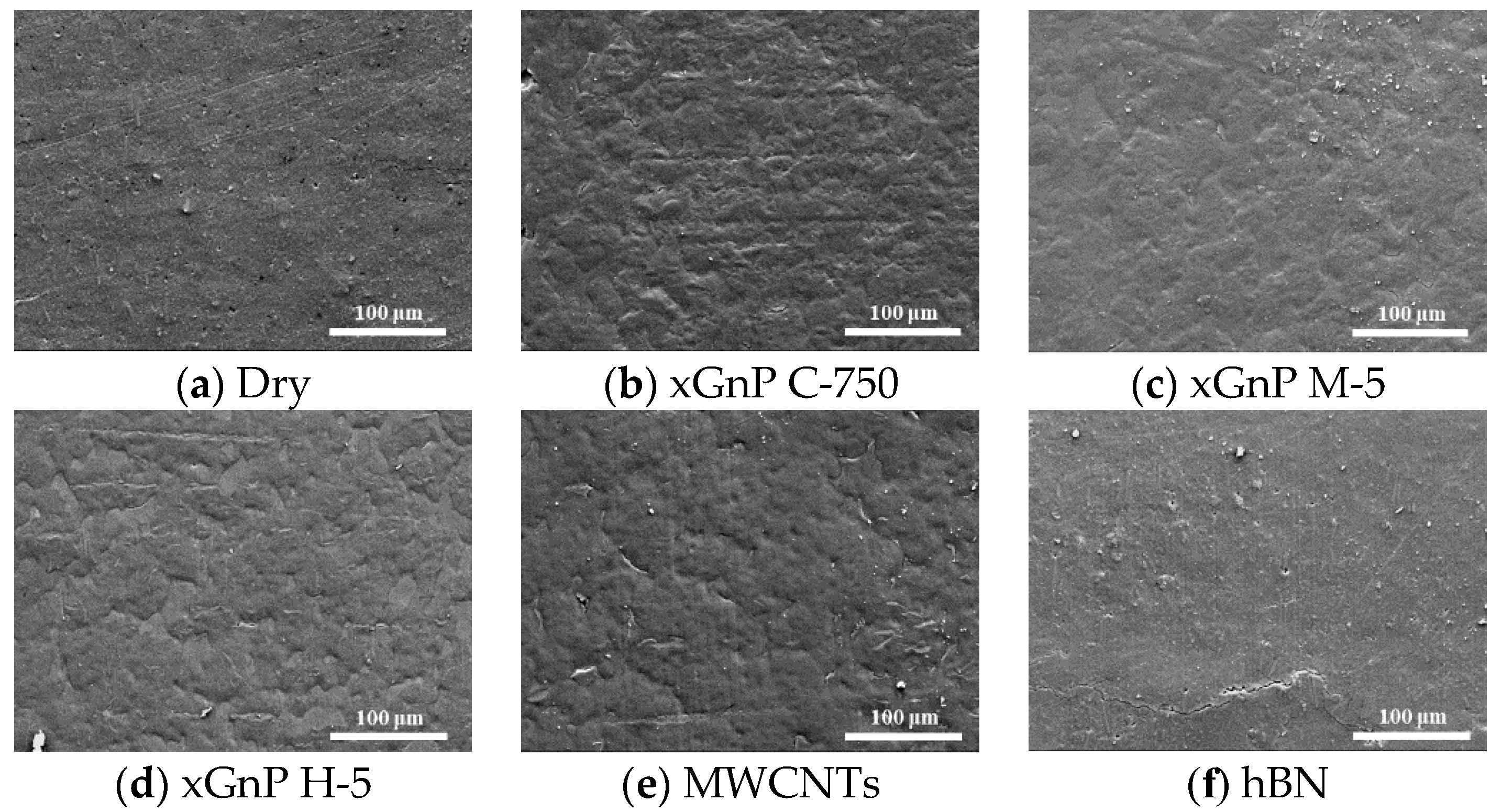

2.3. Tribological Test Results

2.4. Discussions

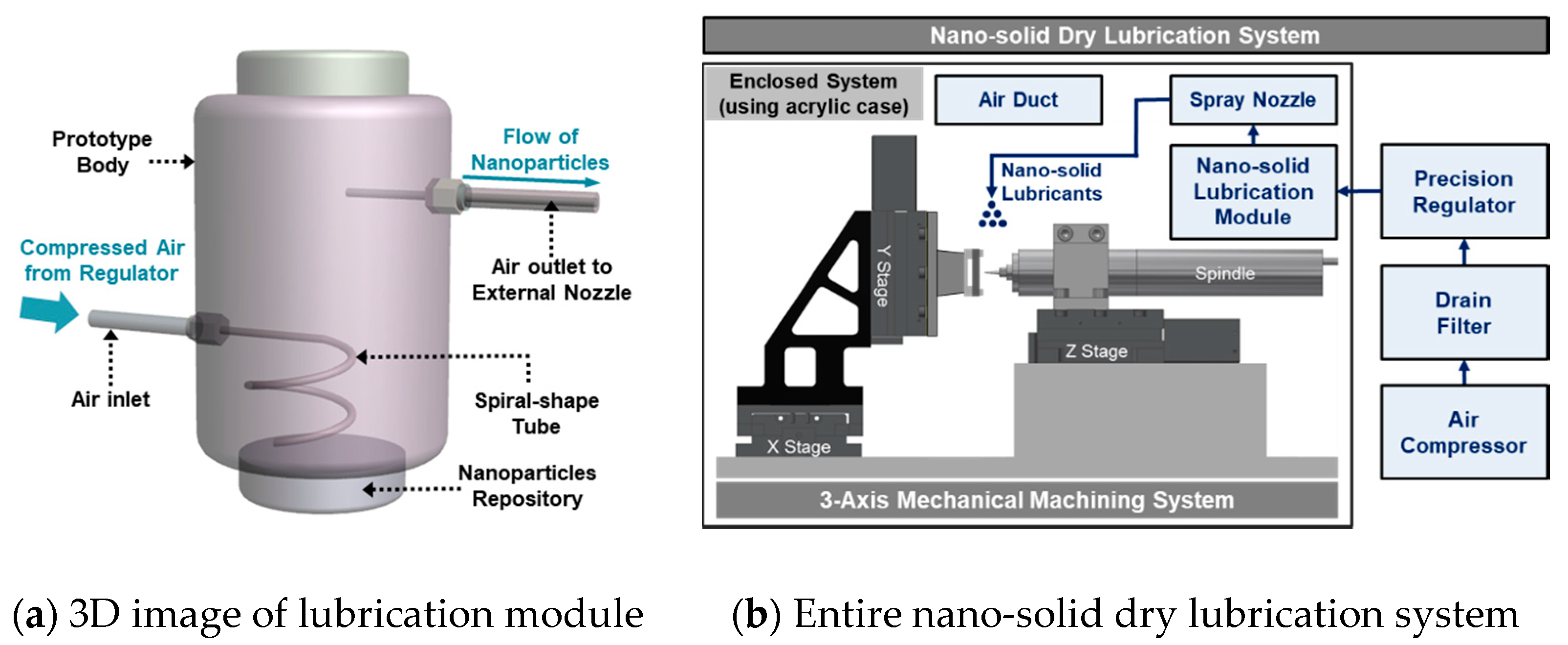

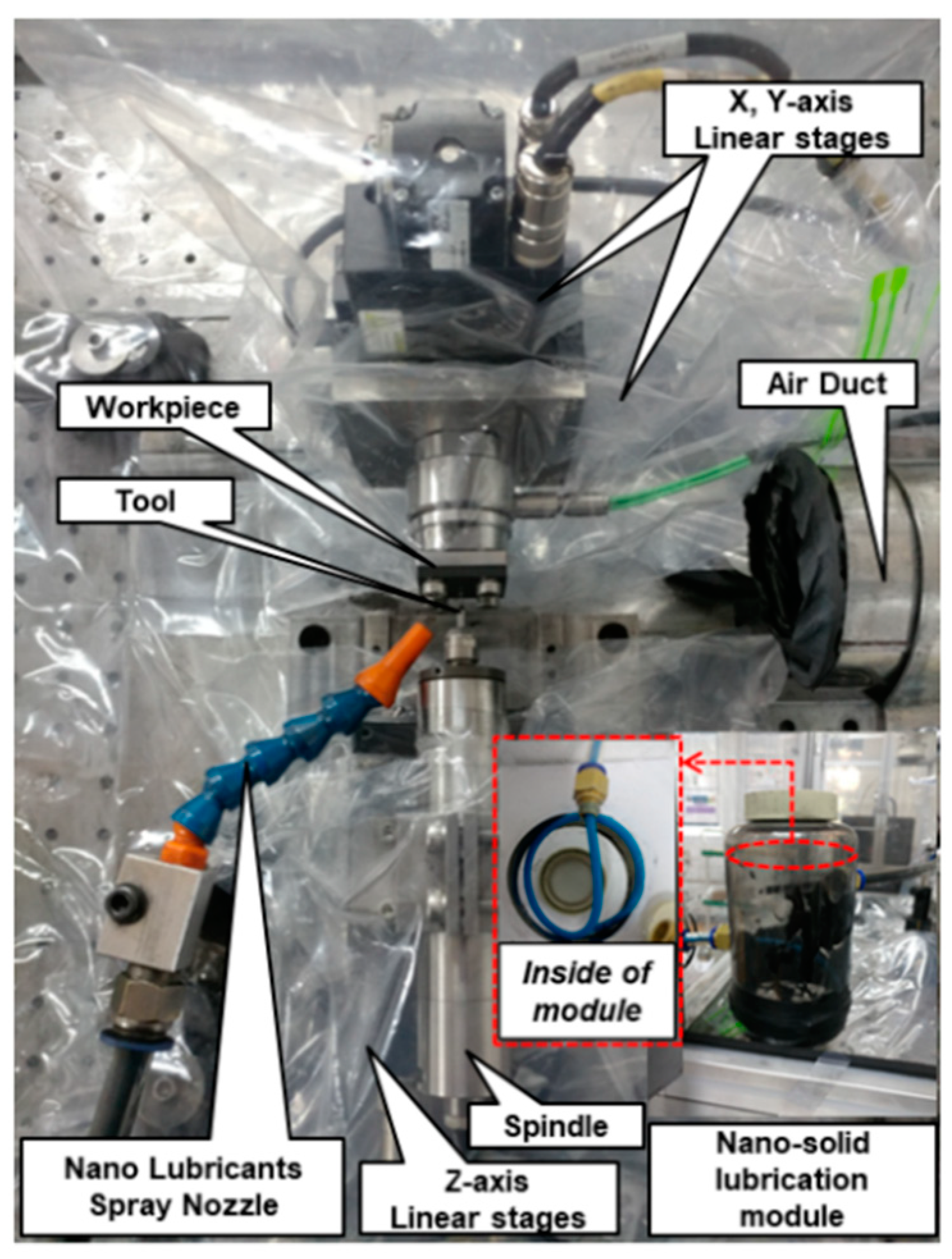

3. Micro-Drilling Experiments with Nano-Solid Lubrication

3.1. Experimental Set-Up

3.2. Experimental Design and Conditions

4. Micro-Drilling Performance Evaluation–Methods and Analysis

4.1. Delamination

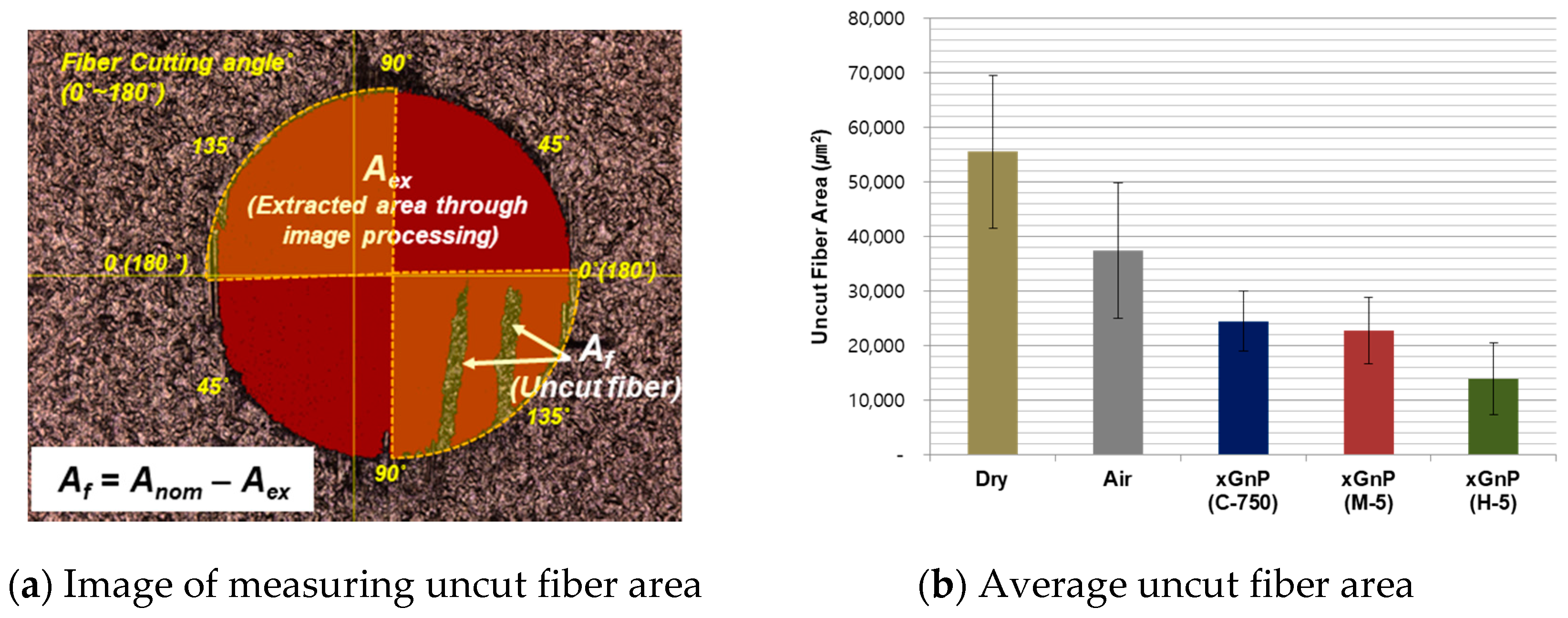

4.2. Uncut Fiber

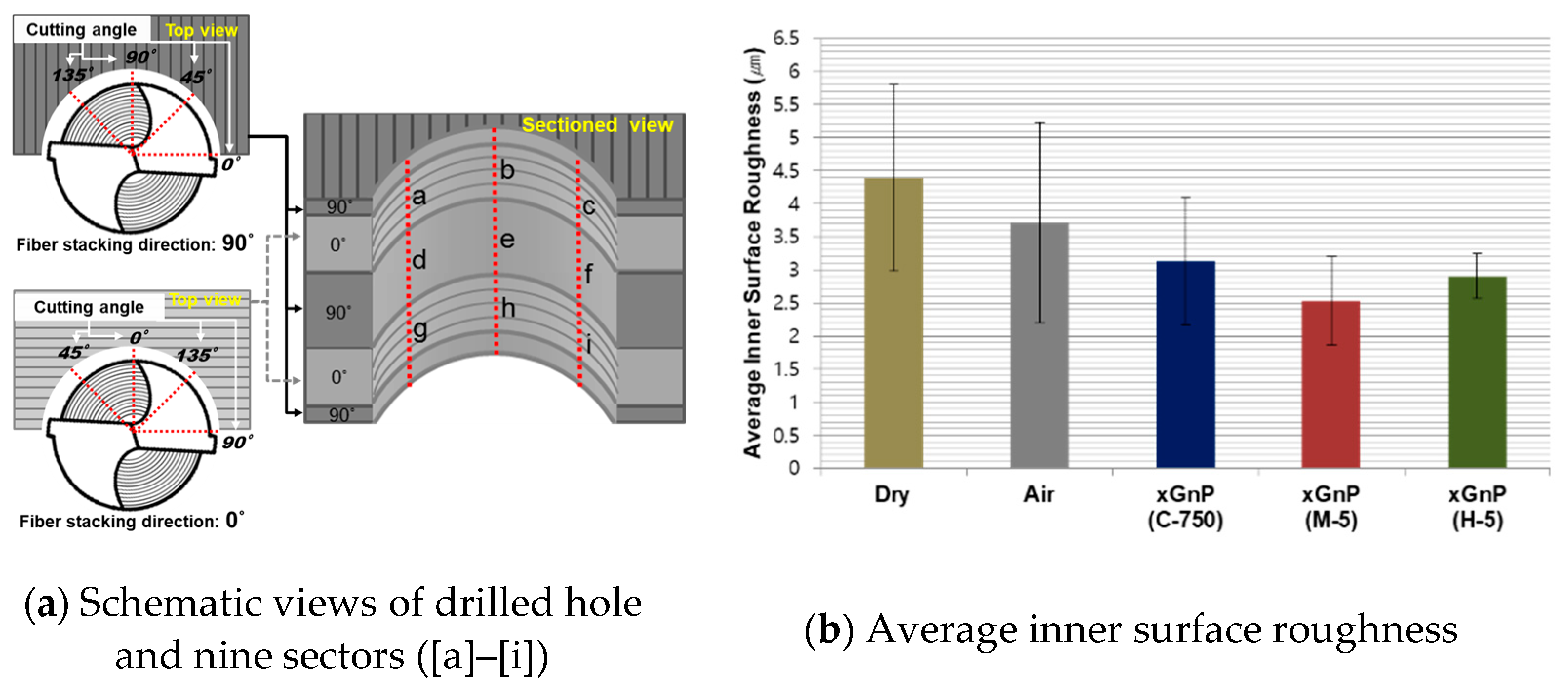

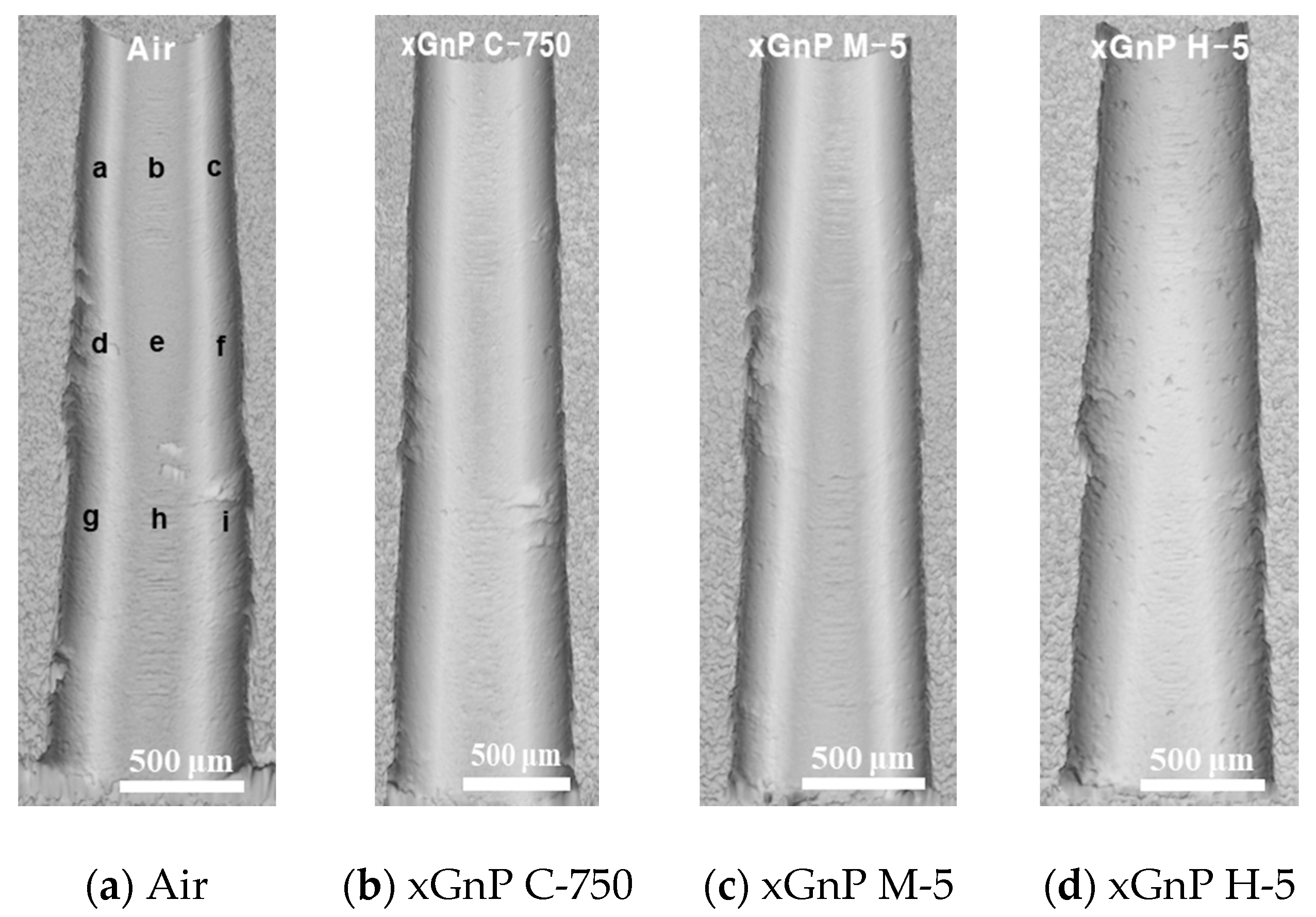

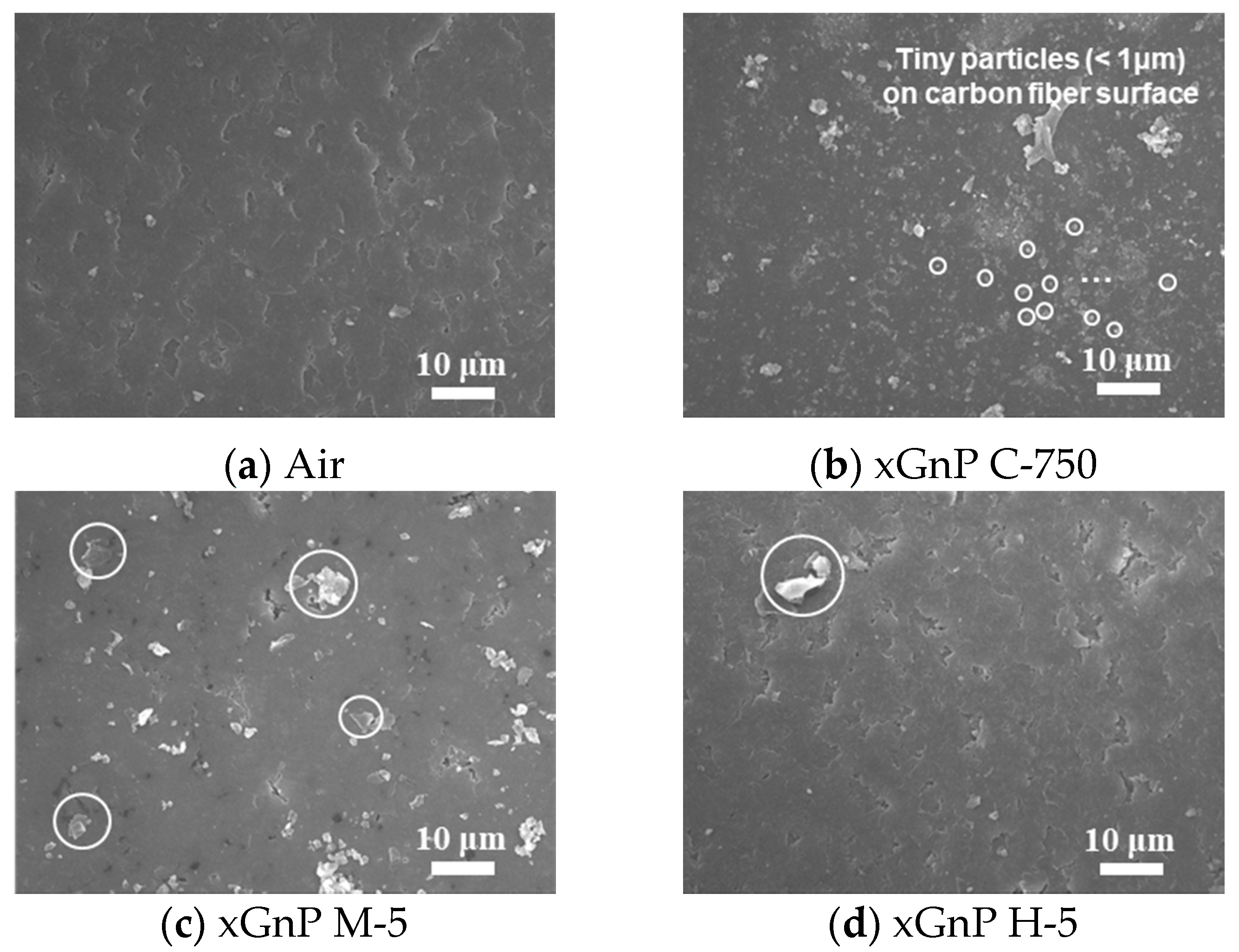

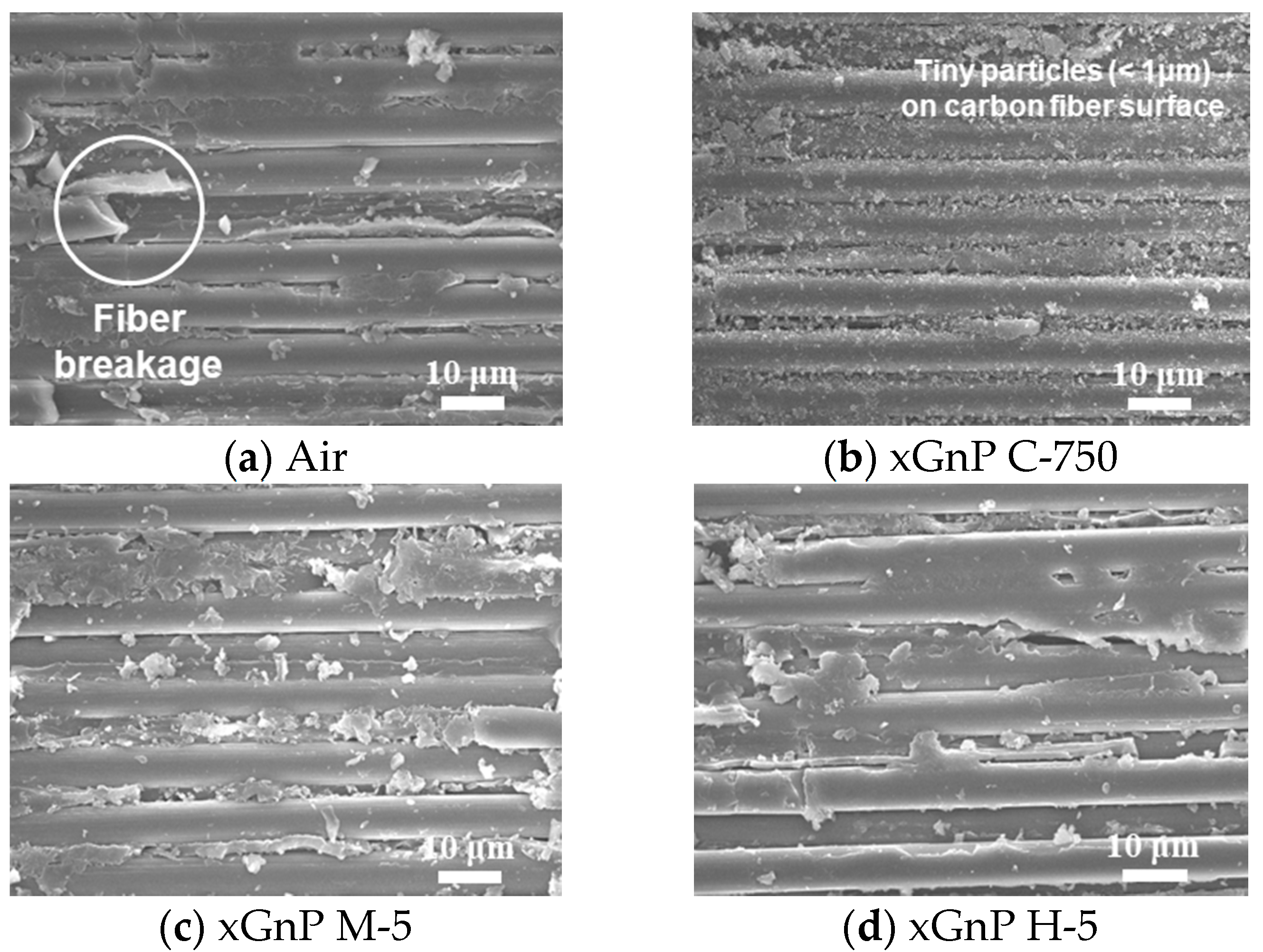

4.3. Inner Surface

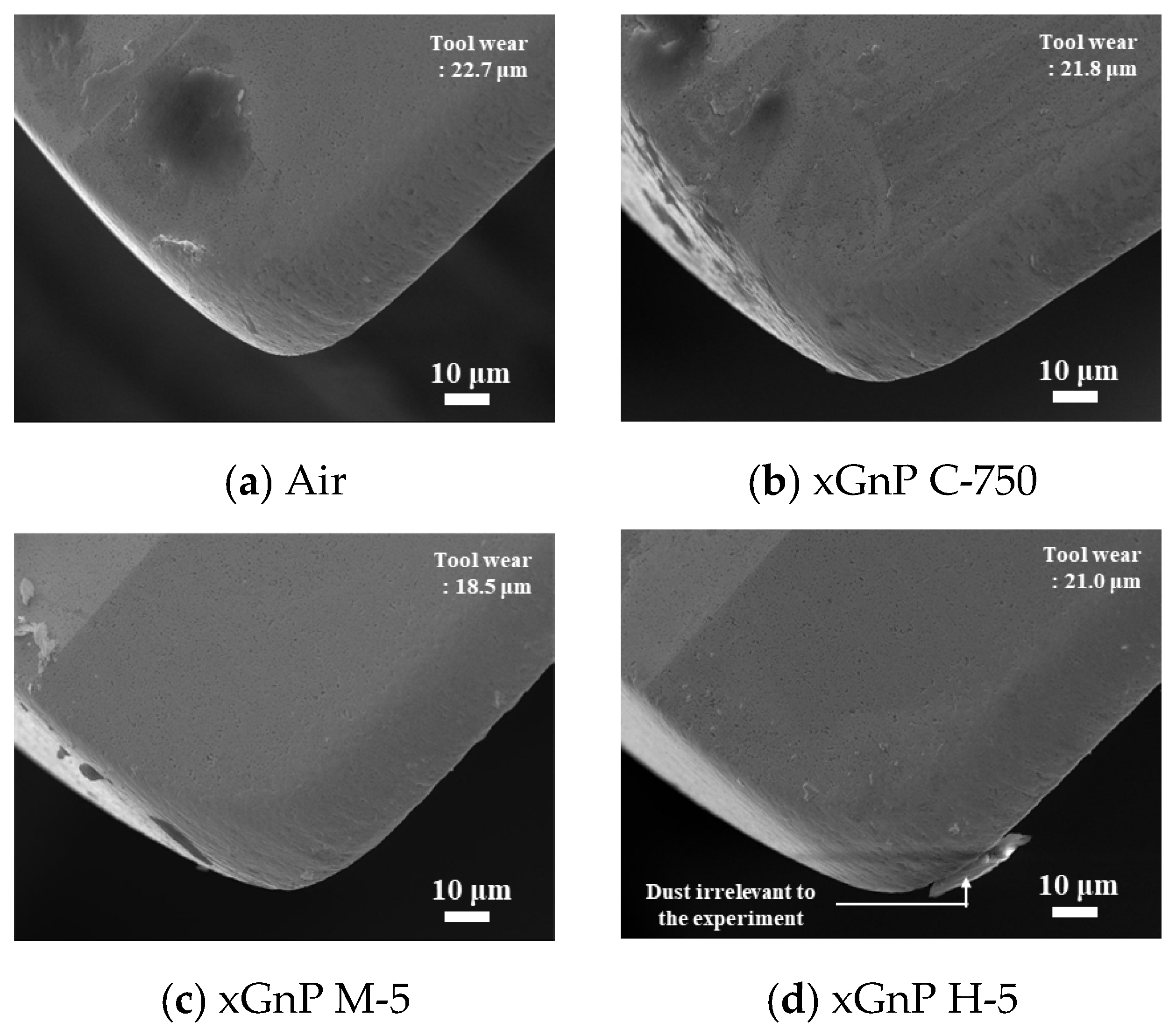

4.4. Tool Wear

4.5. Discussions

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| MD | Multi-directional |

| UD | Uni-directional |

| CFRP | Carbon fiber reinforced plastic |

| xGnPs | Graphene nanoplatelets |

| MWFs | Metal working fluids |

| MQL | Minimum quantity lubrication |

| MWCNTs | Multiwall carbon nanotubes |

| COF | Coefficient of friction |

| hBN | Hexagonal boron nitride |

| FE-SEM | Field emission scanning electron microscope |

| APS | Average particle size |

| SSA | Specific surface area |

| COF | Coefficient of friction |

| FAW | Fiber area weight |

| ID | Intensity of D band |

| IG | Intensity of G band |

| I2D | Intensity of 2D band |

| IG | Intensity of G band |

| Fd | Delamination factor |

| Dnom | Nominal diameter |

| Dmax | Maximum extension of delamination |

| Af | Uncut fiber area |

| Anom | Nominal drilled-hole area |

| Aex | Extracted area through image processing |

| Ra | Arithmetical mean height |

References

- Hegde, S.; Shenoy, B.S.; Chethan, K.N. Review on carbon fiber reinforced polymer (CFRP) and their mechanical performance. Mater. Today Proc. 2019, 19, 658–662. [Google Scholar] [CrossRef]

- Shah, S.; Karuppanan, S.; Megat-Yusoff, P.; Sajid, Z. Impact resistance and damage tolerance of fiber reinforced composites: A review. Compos. Struct. 2019, 217, 100–121. [Google Scholar] [CrossRef]

- Sugita, N.; Shu, L.; Kimura, K.; Arai, G.; Arai, K. Dedicated drill design for reduction in burr and delamination during the drilling of composite materials. CIRP Ann. 2019, 68, 89–92. [Google Scholar] [CrossRef]

- Jia, Z.-Y.; Bai, Y.; Wang, F.-J.; Hao, J.-X. Effect of tool wear on drilling unidirectional CFRP laminates in different fiber cutting angles. Int. J. Adv. Manuf. Technol. 2020, 110, 89–99. [Google Scholar] [CrossRef]

- Ismail, S.O.; Sarfraz, S.; Niamat, M.; Mia, M.; Gupta, M.K.; Pimenov, D.Y.; Shehab, E. Comprehensive Study on Tool Wear During Machining of Fiber-Reinforced Polymeric Composites. In Machining and Machinability of Fiber Reinforced Polymer Composites; Springer: Singapore, 2021; pp. 129–147. [Google Scholar]

- Nam, J.S.; Lee, P.-H.; Lee, S.W. Experimental characterization of micro-drilling process using nanofluid minimum quantity lubrication. Int. J. Mach. Tools Manuf. 2011, 51, 649–652. [Google Scholar] [CrossRef]

- Kim, J.S.; Kim, J.W.; Lee, S.W. Experimental characterization on micro-end milling of titanium alloy using nanofluid minimum quantity lubrication with chilly gas. Int. J. Adv. Manuf. Technol. 2017, 9, 2741–2749. [Google Scholar] [CrossRef]

- Lee, P.-H.; Kim, J.W.; Lee, S.W. Experimental characterization on eco-friendly micro-grinding process of titanium alloy using air flow assisted electrospray lubrication with nanofluid. J. Clean. Prod. 2018, 201, 452–462. [Google Scholar] [CrossRef]

- Almudaihesh, F.; Holford, K.; Pullin, R.; Eaton, M. The influence of water absorption on unidirectional and 2D woven CFRP composites and their mechanical performance. Compos. Part B Eng. 2020, 182, 107626. [Google Scholar] [CrossRef]

- Wu, P.; Xu, L.; Luo, J.; Zhang, X.; Bian, W. Influences of long-term immersion of water and alkaline solution on the fatigue performances of unidirectional pultruded CFRP plate. Constr. Build. Mater. 2019, 205, 344–356. [Google Scholar] [CrossRef]

- Xie, J.; Lu, Z.; Guo, Y.; Huang, Y. Durability of CFRP sheets and epoxy resin exposed to natural hygrothermal or cyclic wet-dry environment. Polym. Compos. 2019, 40, 553–567. [Google Scholar] [CrossRef]

- Kerrigan, K.; Scaife, R.J. Wet vs dry CFRP drilling: Influence of cutting fluid on tool performance. Procedia CIRP 2018, 77, 315–319. [Google Scholar] [CrossRef]

- Morden Machine Shop. Wet-Machining of Composites Crosses Boundaries. Available online: https://www.mmsonline.com/articles/wet-machining-of-composites-crosses-boundaries (accessed on 16 January 2021).

- Kim, J.W.; Nam, J.; Lee, S.W. Experimental study on micro-drilling of unidirectional carbon fiber reinforced plastic (UD-CFRP) composite using nano-solid lubrication. J. Manuf. Process. 2019, 43, 46–53. [Google Scholar] [CrossRef]

- Le, H.; Howson, A.; Ramanauskas, M.; Williams, J.A. Tribological Characterisation of Air-Sprayed Epoxy-CNT Nanocomposite Coatings. Tribol. Lett. 2012, 45, 301–308. [Google Scholar] [CrossRef]

- Moghadam, A.D.; Omrani, E.; Menezes, P.L.; Rohatgi, P.K. Mechanical and tribological properties of self-lubricating metal matrix nanocomposites reinforced by carbon nanotubes (CNTs) and grapheme—A review. Compos. Part B Eng. 2015, 77, 402–420. [Google Scholar] [CrossRef]

- Berman, D.; Erdemir, A.; Sumant, A.V. Few layer graphene to reduce wear and friction on sliding steel surfaces. Carbon 2013, 54, 454–459. [Google Scholar] [CrossRef]

- Yin, X.; Wu, F.; Chen, X.; Xu, J.; Wu, P.; Li, J.; Zhang, C.; Luo, J. Graphene-induced reconstruction of the sliding interface assisting the improved lubricity of various tribo-couples. Mater. Des. 2020, 191, 108661. [Google Scholar] [CrossRef]

- XG Sciences. Available online: https://xgsciences.com/ko/product/xgnp/ (accessed on 15 January 2021).

- Korea Nanomaterials. Available online: https://koreanano.co.kr/shop/item.php?it_id=KRU4500 (accessed on 15 January 2021).

- Lower Friction. Available online: https://www.lowerfriction.com/ (accessed on 15 January 2021).

- Quaranta, S.; Giorcelli, M.; Savi, P. Graphene and MWCNT Printed Films: Preparation and RF Electrical Properties Study. J. Nanomater. 2019, 2019, 1–9. [Google Scholar] [CrossRef]

- Ferrari, A.C.; Meyer, J.C.; Scardaci, V.; Casiraghi, C.; Lazzeri, M.; Mauri, F.; Piscanec, S.; Jiang, D.; Novoselov, K.S.; Roth, S.; et al. Raman Spectrum of Graphene and Graphene Layers. Phys. Rev. Lett. 2006, 97, 187401. [Google Scholar] [CrossRef]

- Calizo, I.; Balandin, A.A.; Bao, W.; Miao, F.; Lau, C.N. Temperature dependence of the Raman spectra of gra-phene and graphene multilayers. Nano Lett. 2007, 7, 2645–2649. [Google Scholar] [CrossRef]

- Kim, C.-D.; Truong, N.T.N.; Pham, V.T.H.; Jo, Y.; Lee, H.-R.; Park, C. Conductive electrodes based on Ni–graphite core–shell nanoparticles for heterojunction solar cells. Mater. Chem. Phys. 2019, 223, 557–563. [Google Scholar] [CrossRef]

- Toray Composite Materials America, Inc. Available online: https://www.toraycma.com/page.php?id=661 (accessed on 15 January 2021).

- Suresha, B.; Chandramohan, G.; Samapthkumaran, P.; Seetharamu, S. Three-body abrasive wear behaviour of carbon and glass fiber reinforced epoxy composites. Mater. Sci. Eng. A 2007, 443, 285–291. [Google Scholar] [CrossRef]

- Zhu, J.; Xie, F.; Dwyer-Joyce, R.S. PEEK Composites as Self-Lubricating Bush Materials for Articulating Revolute Pin Joints. Polymers 2020, 12, 665. [Google Scholar] [CrossRef] [PubMed]

- Zhao, F.; Gao, C.; Wang, H.; Wang, T.; Wetzel, B.; Jim, B.-C.; Zhang, G.; Wang, Q. Tribological Behaviors of Carbon Fiber Reinforced Epoxy Composites Under PAO Lubrication Conditions. Tribol. Lett. 2016, 62, 37. [Google Scholar] [CrossRef]

- Luo, W.; Liu, Q.; Li, Y.; Zhou, S.; Zou, H.; Liang, M. Enhanced mechanical and tribological properties in polyphe-nylene sulfide/polytetrafluoroethylene composites reinforced by short carbon fiber. Compos. Part B Eng. 2016, 91, 579–588. [Google Scholar] [CrossRef]

- Reinert, L.; Varenberg, M.; Mücklich, F.; Suárez, S. Dry friction and wear of self-lubricating car-bon-nanotube-containing surfaces. Wear 2018, 406, 33–42. [Google Scholar] [CrossRef]

- Sakka, M.M.; Antar, Z.; Elleuch, K.; Feller, J.F. Tribological response of an epoxy matrix filled with graphite and/or carbon nanotubes. Friction 2017, 5, 171–182. [Google Scholar] [CrossRef]

- DIXI Polytool. Tungsten Carbide and Diamond Precision Tools (Catalog). Available online: https://dixipolytool.ch//wp-content/uploads/special_tool/cat_18_complet_EN.pdf (accessed on 22 January 2021).

- Tran, Q.-P.; Nguyen, V.-N.; Huang, S.-C. Drilling Process on CFRP: Multi-Criteria Decision-Making with Entropy Weight Using Grey-TOPSIS Method. Appl. Sci. 2020, 10, 7207. [Google Scholar] [CrossRef]

- Barnes, S.; Bhudwannachai, P.; Dahnel, A.N. Drilling Performance of Carbon Fiber Reinforced Epoxy Composite When Machined Dry, with Conventional Cutting Fluid and With a Cryogenically Cooled Tool. In ASME International Mechanical Engineering Congress and Exposition; American Society of Mechanical Engineers: New York, NY, USA, 2013; Volume 56192, p. V02BT02A063. [Google Scholar]

- Gaugel, S.; Sripathy, P.; Haeger, A.; Meinhard, D.; Bernthaler, T.; Lissek, F.; Kaufeld, M.; Knoblauch, V.; Schneider, G. A comparative study on tool wear and laminate damage in drilling of carbon-fiber reinforced polymers (CFRP). Compos. Struct. 2016, 155, 173–183. [Google Scholar] [CrossRef]

- Voss, R.; Henerichs, M.; Rupp, S.; Kuster, F.; Wegener, K. Evaluation of bore exit quality for fibre reinforced plastics including delamination and uncut fibres. CIRP J. Manuf. Sci. Technol. 2016, 12, 56–66. [Google Scholar] [CrossRef]

- Durão, L.M.P.; Tavares, J.M.R.S.; De Albuquerque, V.H.C.; Marques, J.F.S.; Andrade, O.N. Drilling Damage in Composite Material. Materials 2014, 7, 3802–3819. [Google Scholar] [CrossRef]

- Kwon, B.-C.; Mai, N.D.D.; Cheon, E.S.; Ko, S.-L. Development of a step drill for minimization of delamination and uncut in drilling carbon fiber reinforced plastics (CFRP). Int. J. Adv. Manuf. Technol. 2019, 106, 1291–1301. [Google Scholar] [CrossRef]

- Ramulu, M. Machining and surface integrity of fibre-reinforced plastic composites. Sadhana 1997, 22, 449–472. [Google Scholar] [CrossRef]

- Keyence. Available online: https://www.keyence.com/ (accessed on 23 January 2021).

| xGnP C-750 | xGnP M-5 | xGnP H-5 | MWCNTs | hBN |

|---|---|---|---|---|

| APS: ~0.2 μm | APS: 5 μm | APS: 5 μm | Outer diameter: 10~30 nm | APS: 70 nm |

| Thickness: ~1 nm | Thickness: ~8 nm | Thickness: ~15 nm | Inner diameter: 5~10 nm | SSA: 19 m2/g |

| SSA: 750 m2/g | SSA: 120~150 m2/g | SSA: 50~80 m2/g | Length: 10~30 μm | |

| SSA: >200 m2/g | ||||

| Shape: 2D-Sheet | Shape: 2D-Sheet | Shape: 2D-Sheet | Shape: Tube-shape | Shape: Lamella structure |

| Element: Carbon I | Element: Carbon I | Element: Carbon I | Element: Carbon I | Element: Boron (B), Nitrogen (N) |

| Properties of Carbon Fiber and Prepreg | Information |

|---|---|

| Thickness of each ply | 310 μm |

| Standard of carbon fiber | T700 |

| Tensile strength | 4900 Mpa |

| Tensile modulus | 230 Gpa |

| Strain | 2.1% |

| Density | 1.80 g/cm3 |

| Filament diameter | 7 μm |

| Fiber area weight (FAW) | 150 g/m2 |

| Fiber volume | 64% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, J.W.; Nam, J.; Jeon, J.; Lee, S.W. A Study on Machining Performances of Micro-Drilling of Multi-Directional Carbon Fiber Reinforced Plastic (MD-CFRP) Based on Nano-Solid Dry Lubrication Using Graphene NanoPlatelets. Materials 2021, 14, 685. https://doi.org/10.3390/ma14030685

Kim JW, Nam J, Jeon J, Lee SW. A Study on Machining Performances of Micro-Drilling of Multi-Directional Carbon Fiber Reinforced Plastic (MD-CFRP) Based on Nano-Solid Dry Lubrication Using Graphene NanoPlatelets. Materials. 2021; 14(3):685. https://doi.org/10.3390/ma14030685

Chicago/Turabian StyleKim, Jin Woo, Jungsoo Nam, Jaehun Jeon, and Sang Won Lee. 2021. "A Study on Machining Performances of Micro-Drilling of Multi-Directional Carbon Fiber Reinforced Plastic (MD-CFRP) Based on Nano-Solid Dry Lubrication Using Graphene NanoPlatelets" Materials 14, no. 3: 685. https://doi.org/10.3390/ma14030685

APA StyleKim, J. W., Nam, J., Jeon, J., & Lee, S. W. (2021). A Study on Machining Performances of Micro-Drilling of Multi-Directional Carbon Fiber Reinforced Plastic (MD-CFRP) Based on Nano-Solid Dry Lubrication Using Graphene NanoPlatelets. Materials, 14(3), 685. https://doi.org/10.3390/ma14030685