Estimating Compressive Strength of Concrete Containing Untreated Coal Waste Aggregates Using Ultrasonic Pulse Velocity

Abstract

1. Introduction

2. Experimental Program

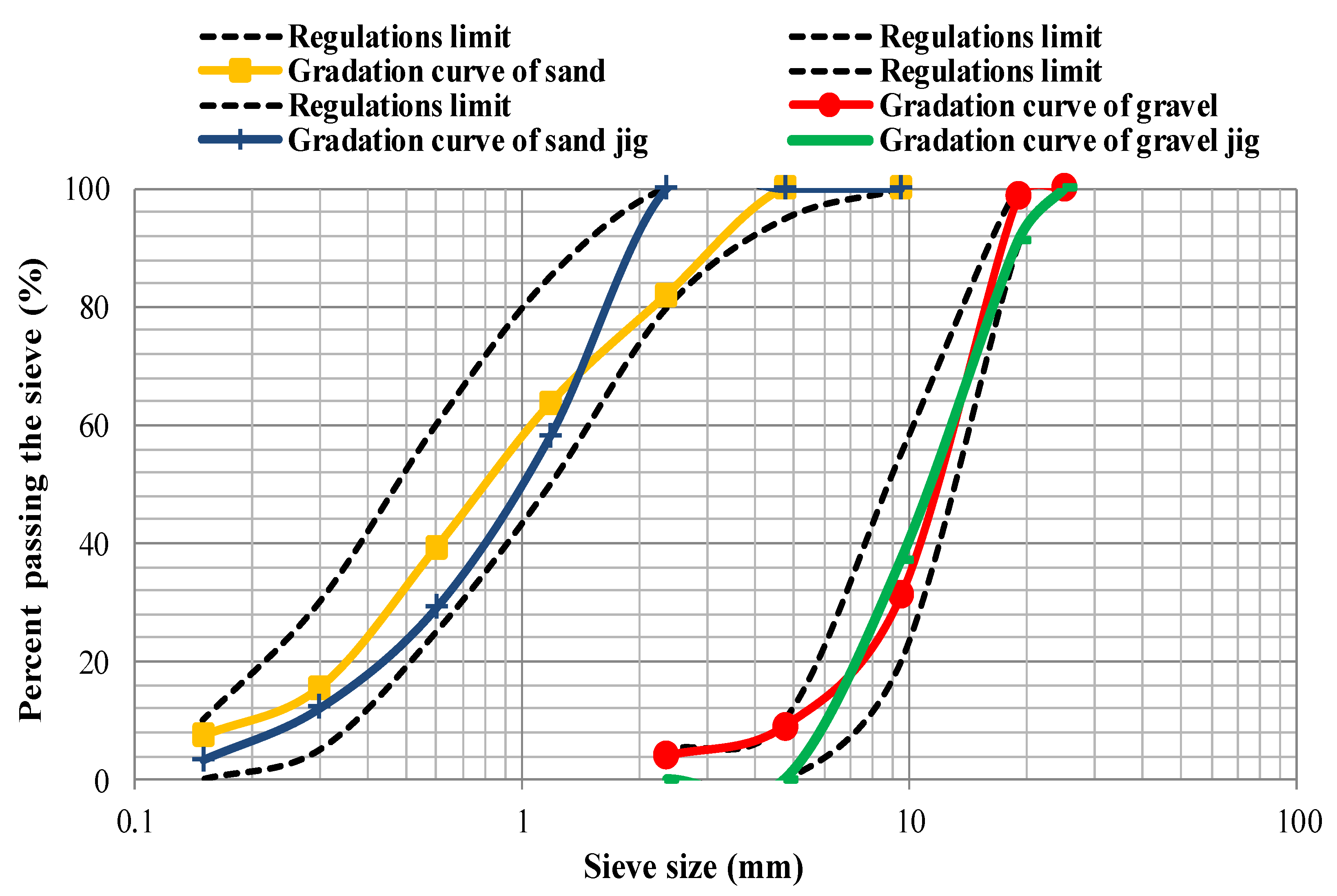

2.1. Materials and Specimens

2.2. Mixing Proportions and Specimen Preparation

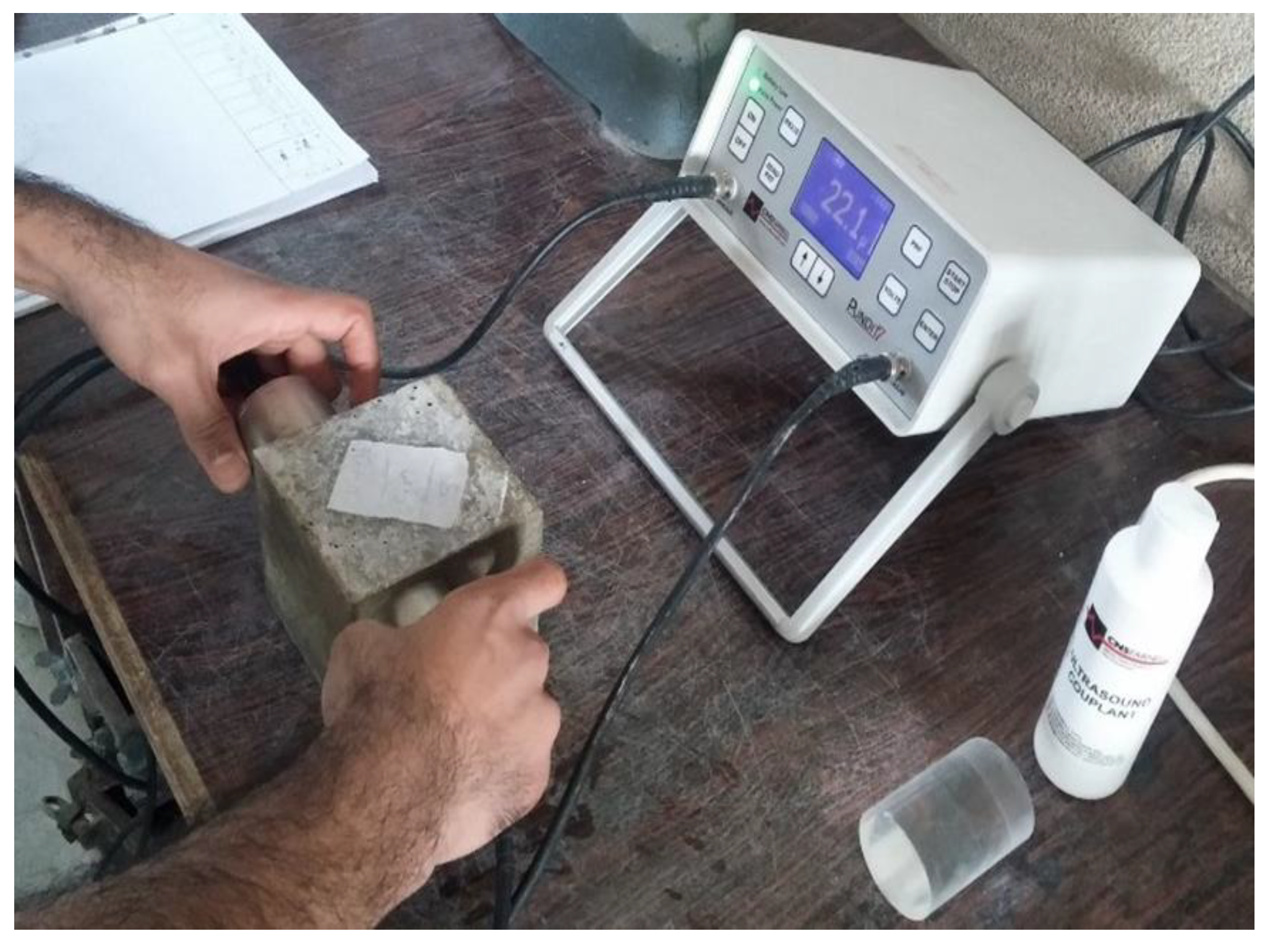

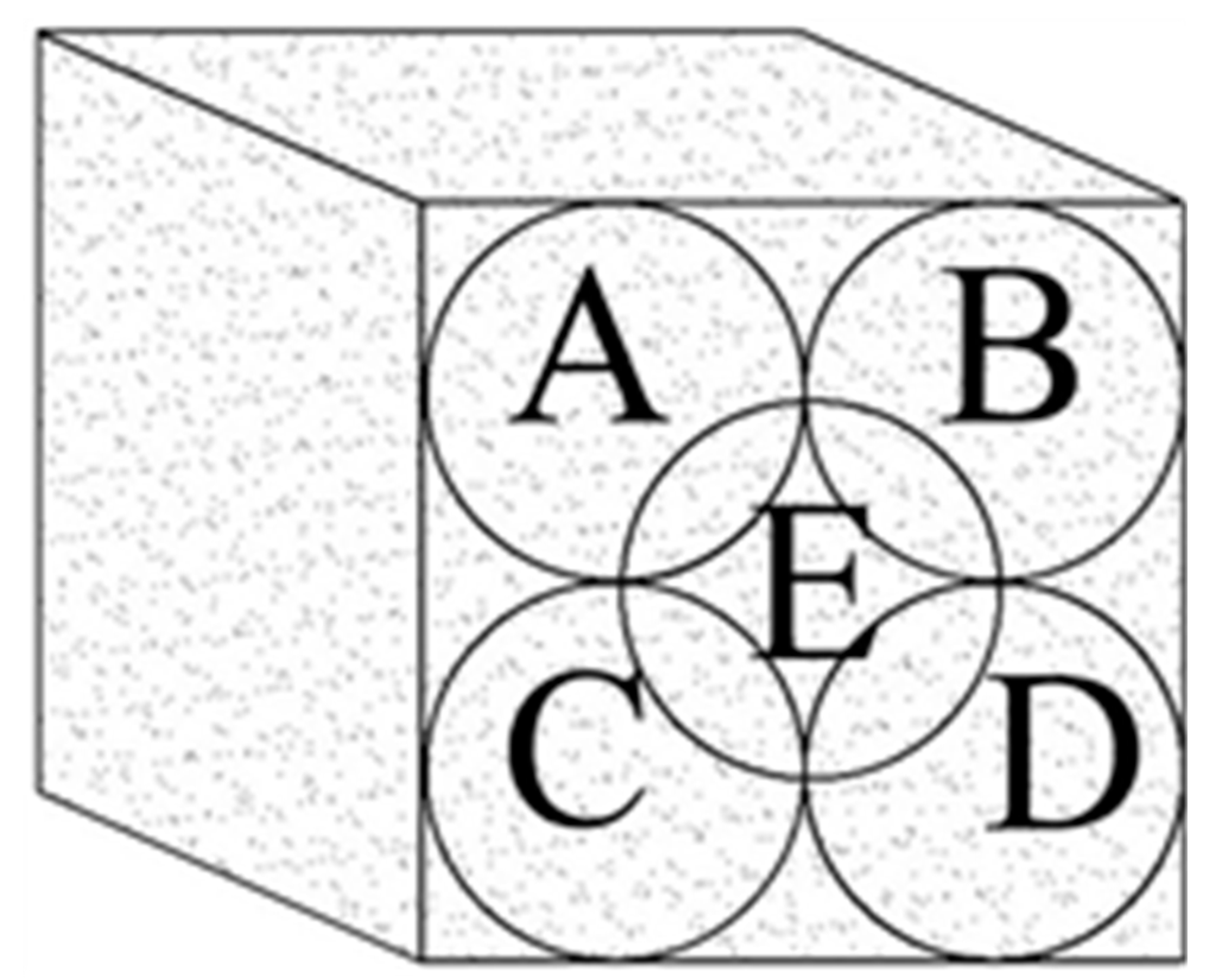

2.3. Testing Procedure

3. Results

3.1. Test Results and Discussion

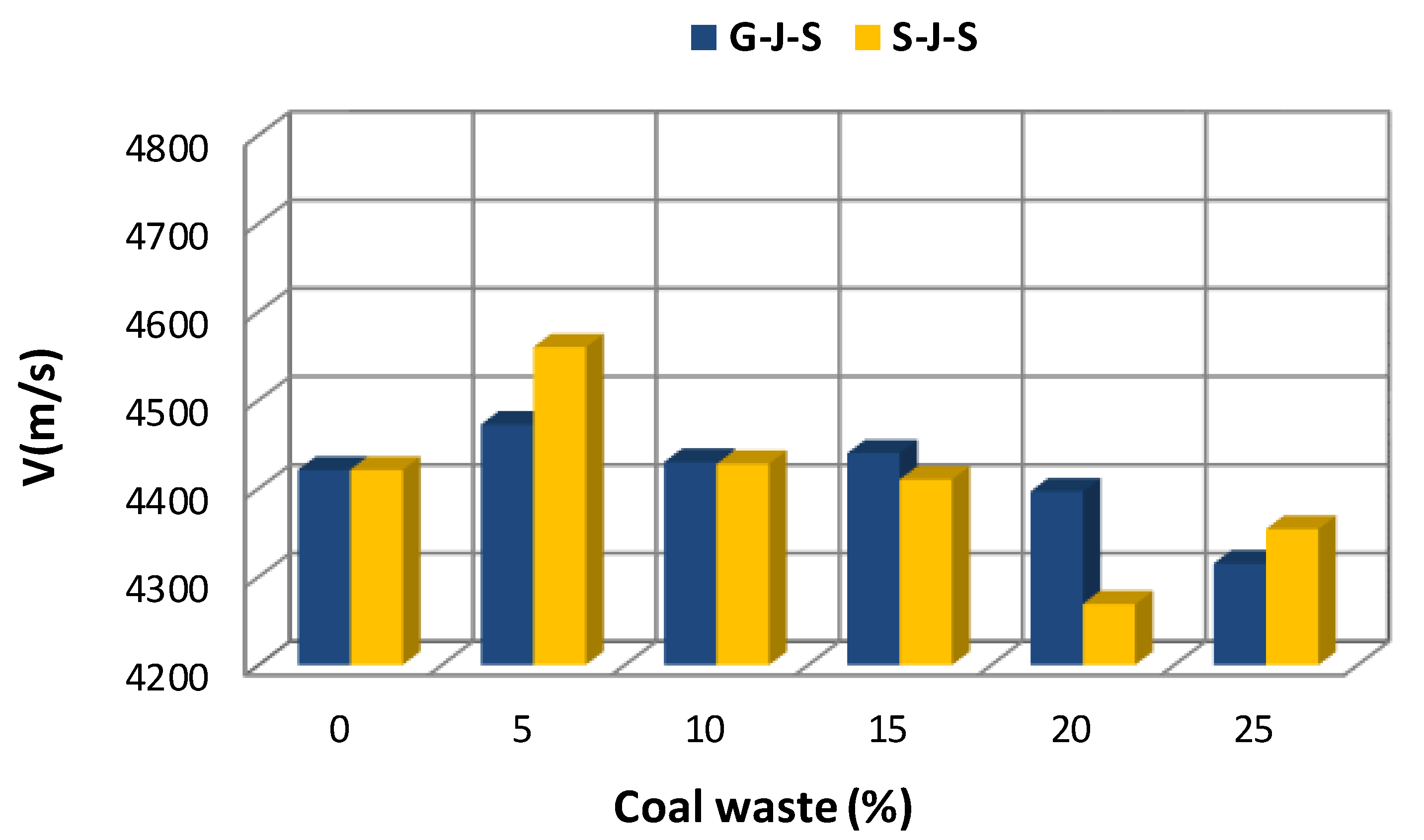

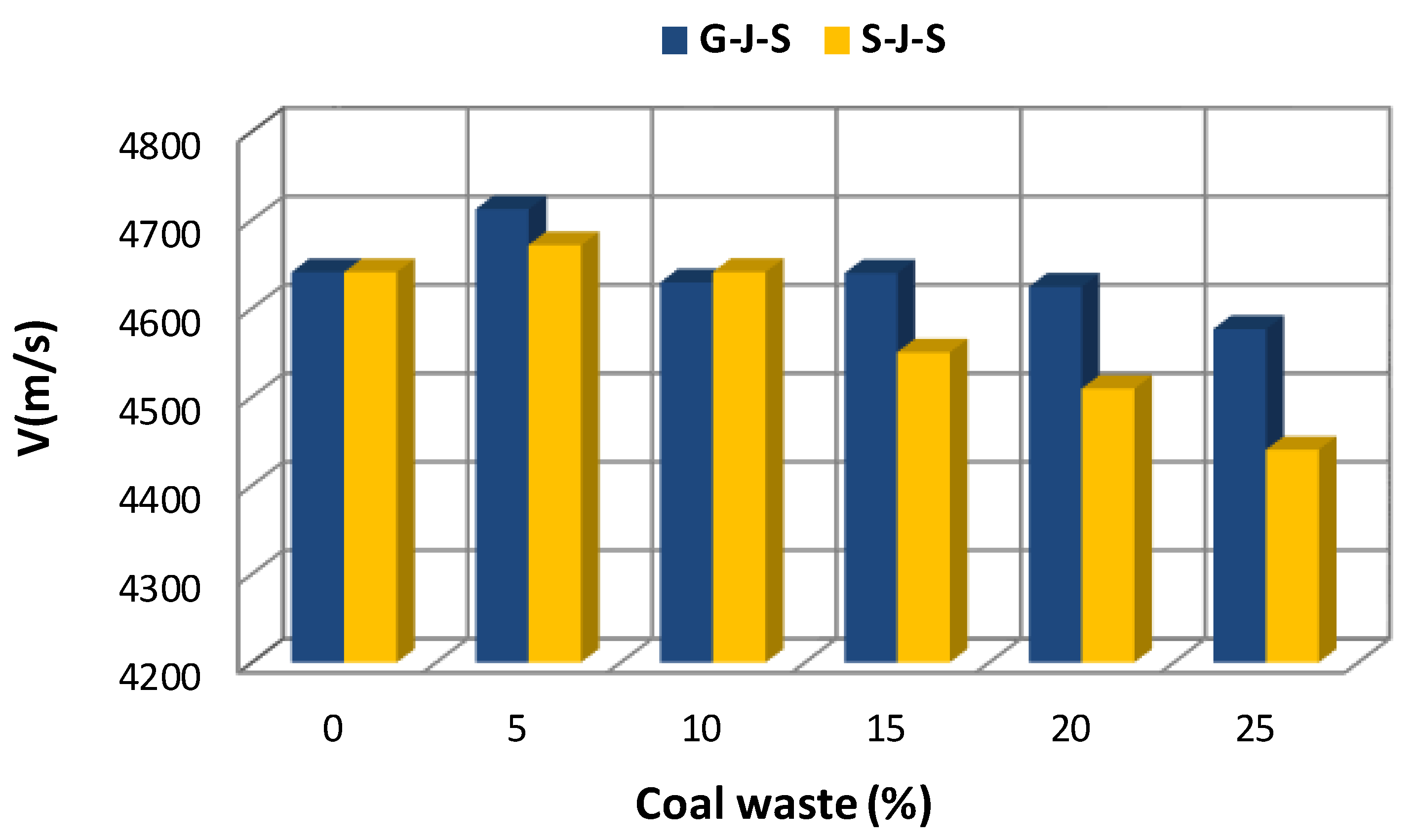

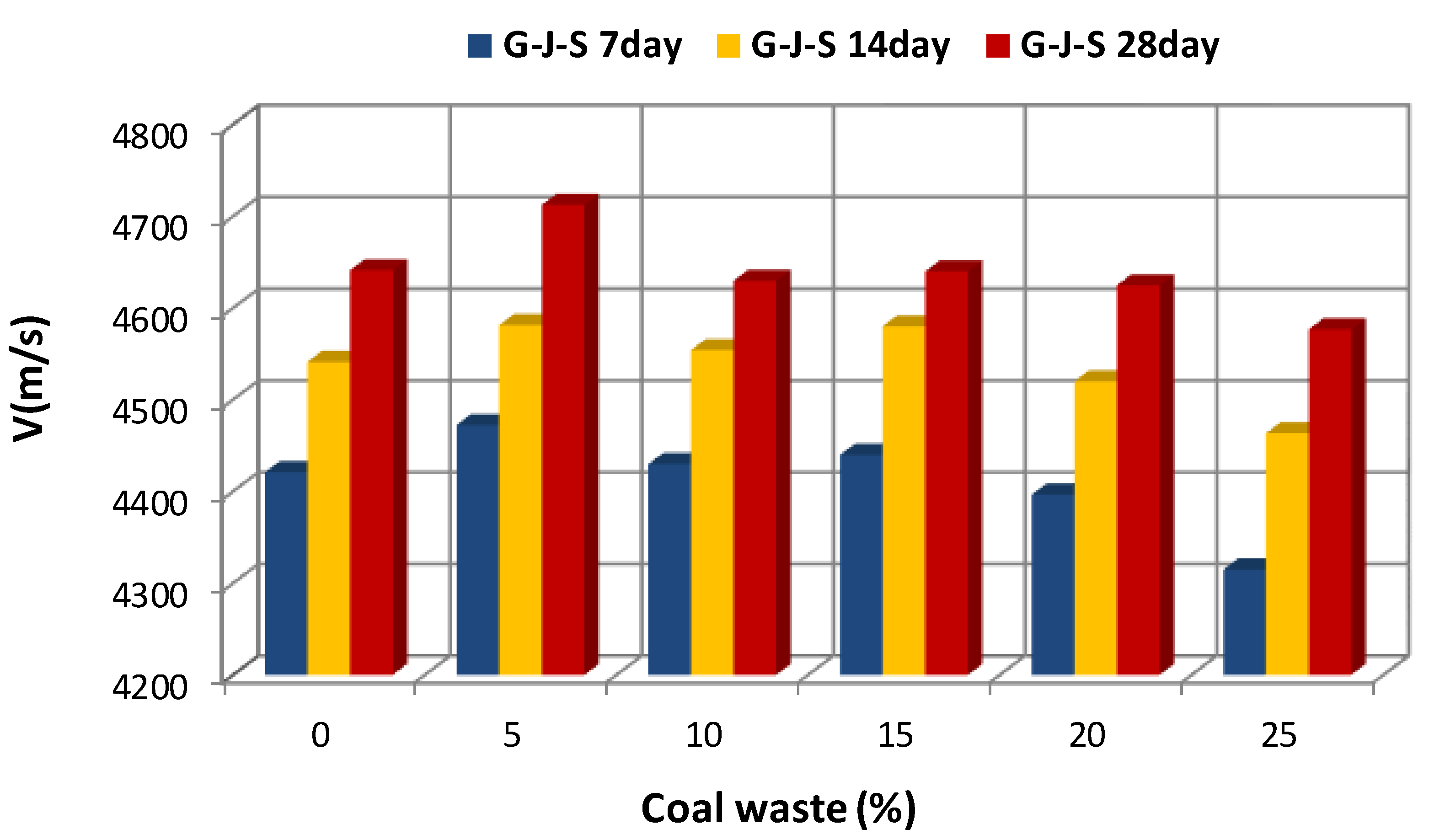

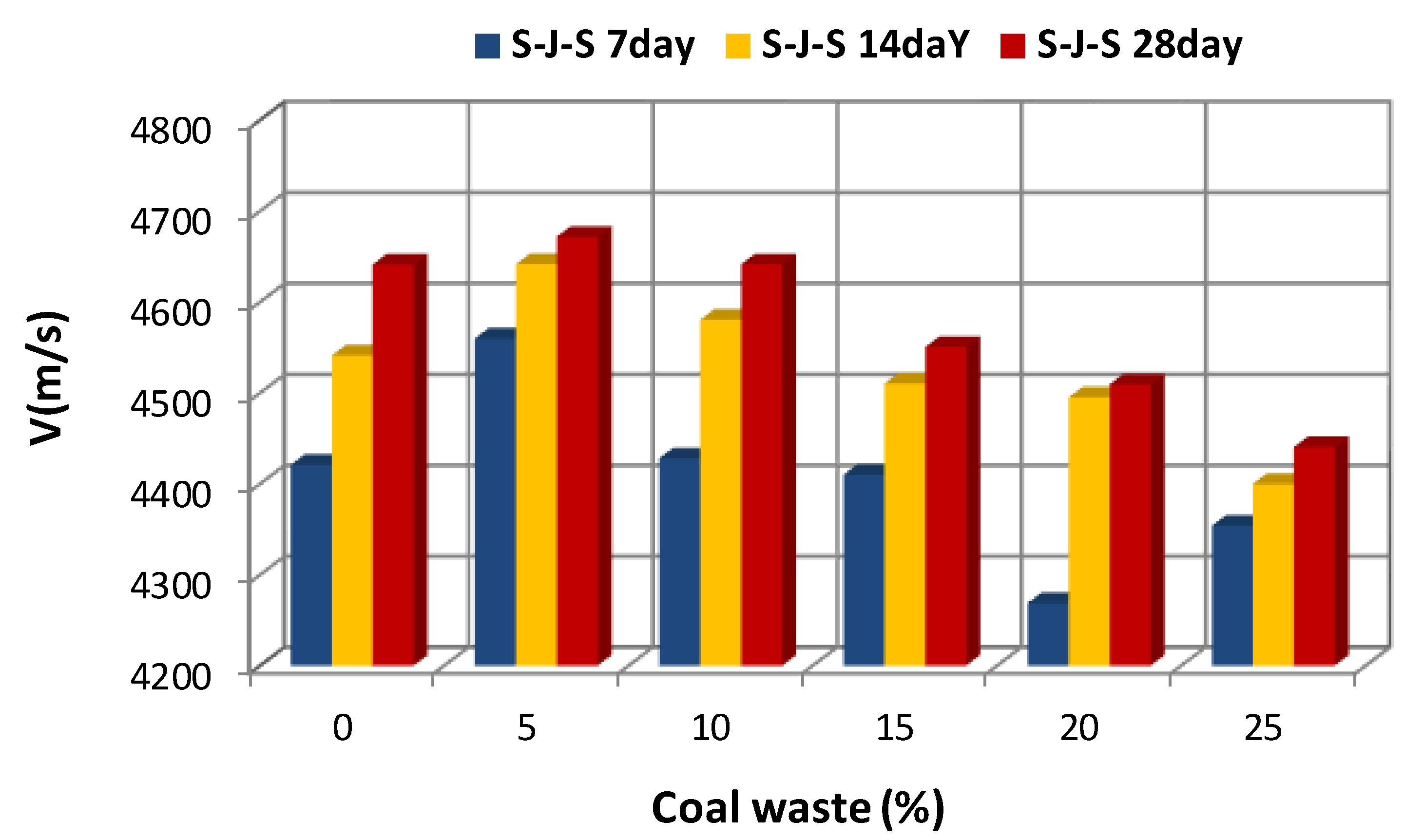

3.2. The Effect of Type and Amount of Coal Waste on UPV

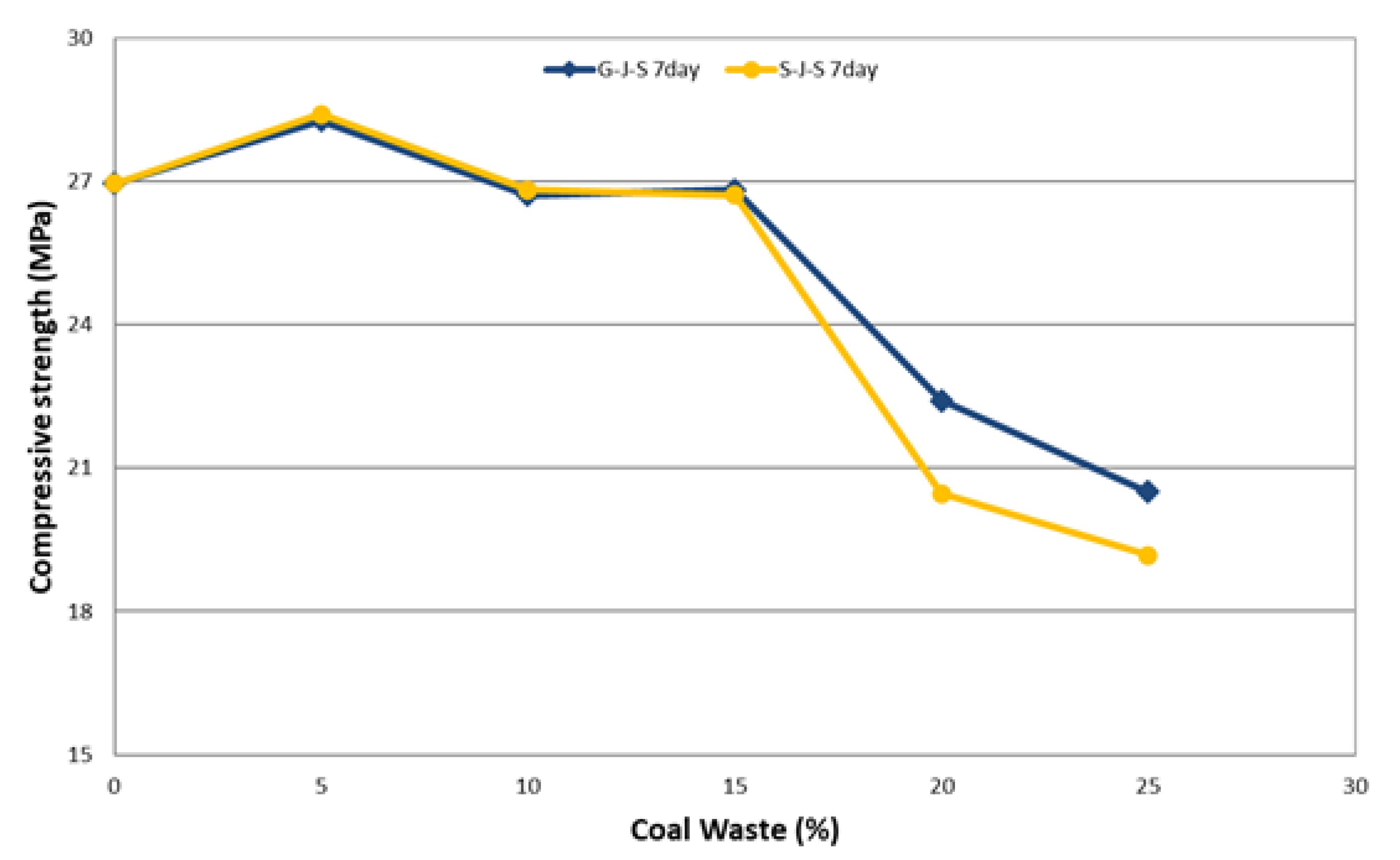

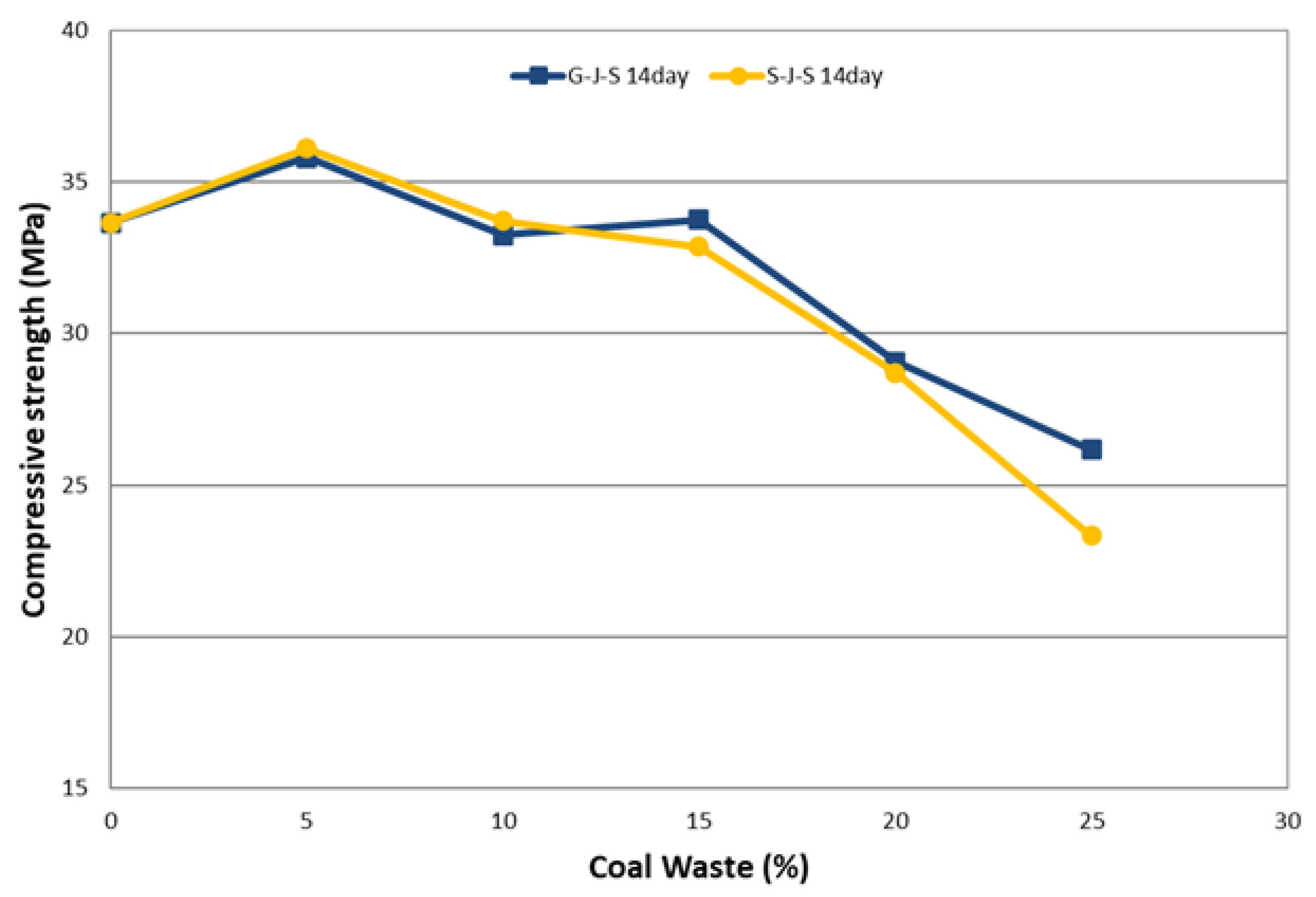

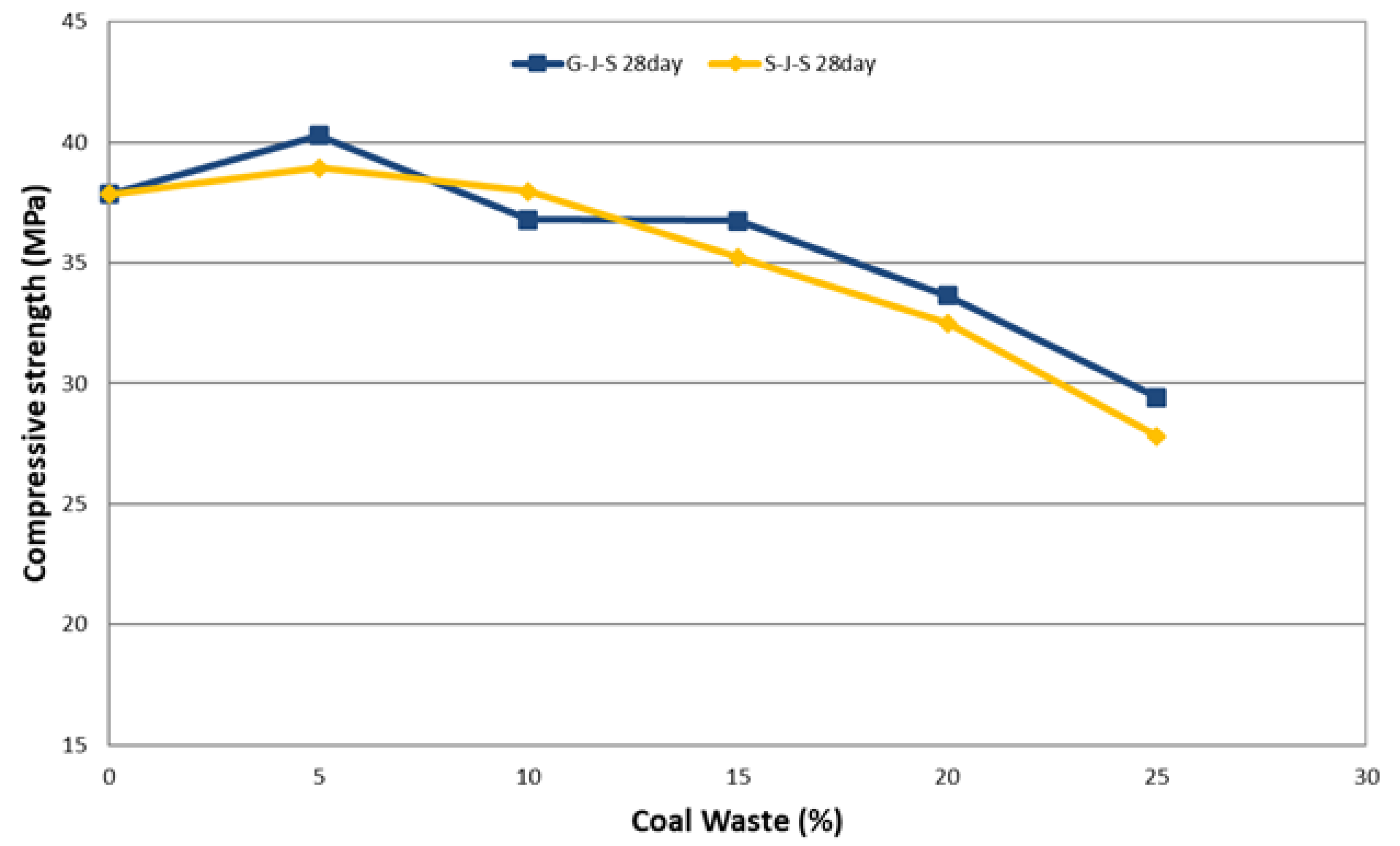

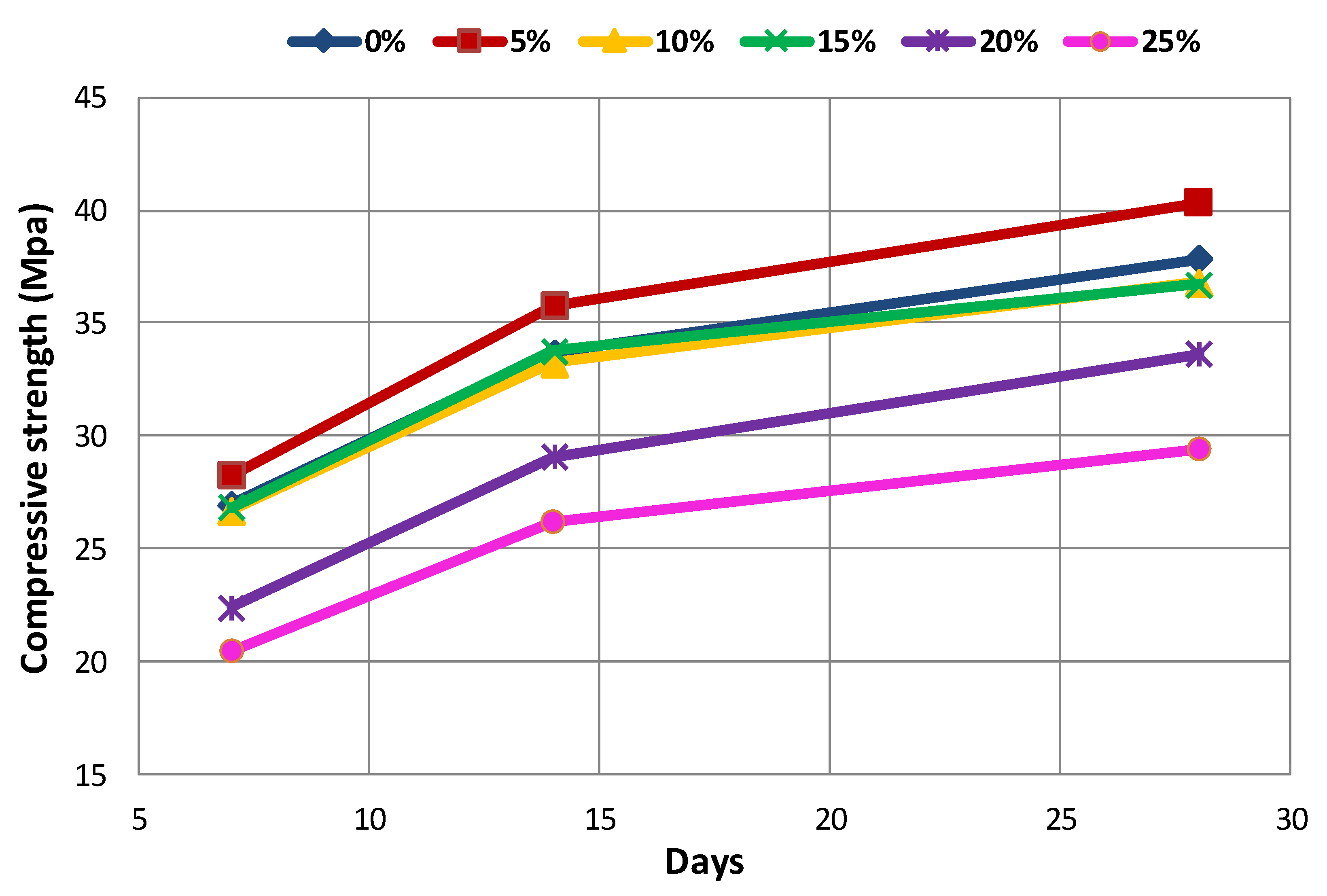

3.3. The Effect of Type and Amount of Coal Waste on Compressive Strength

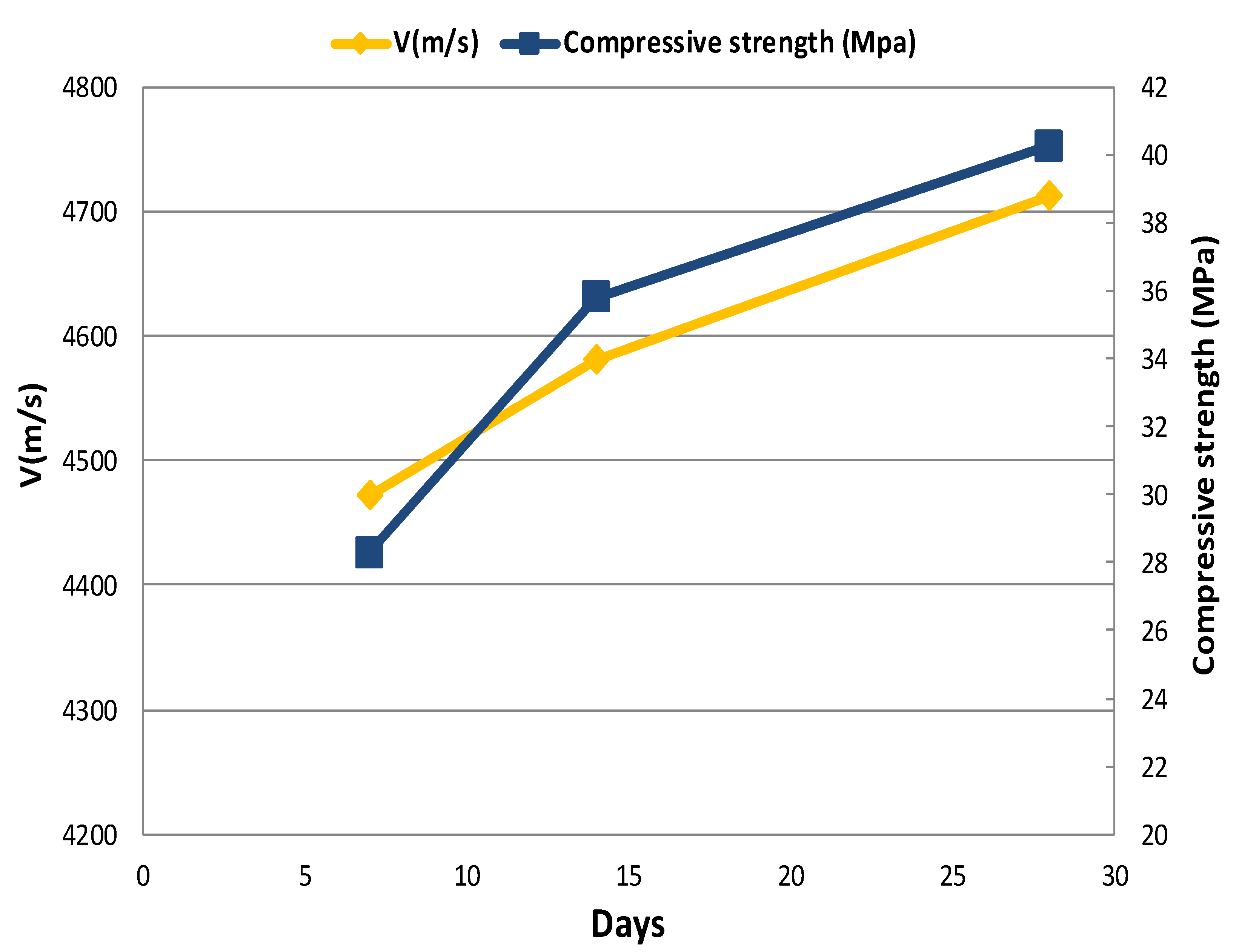

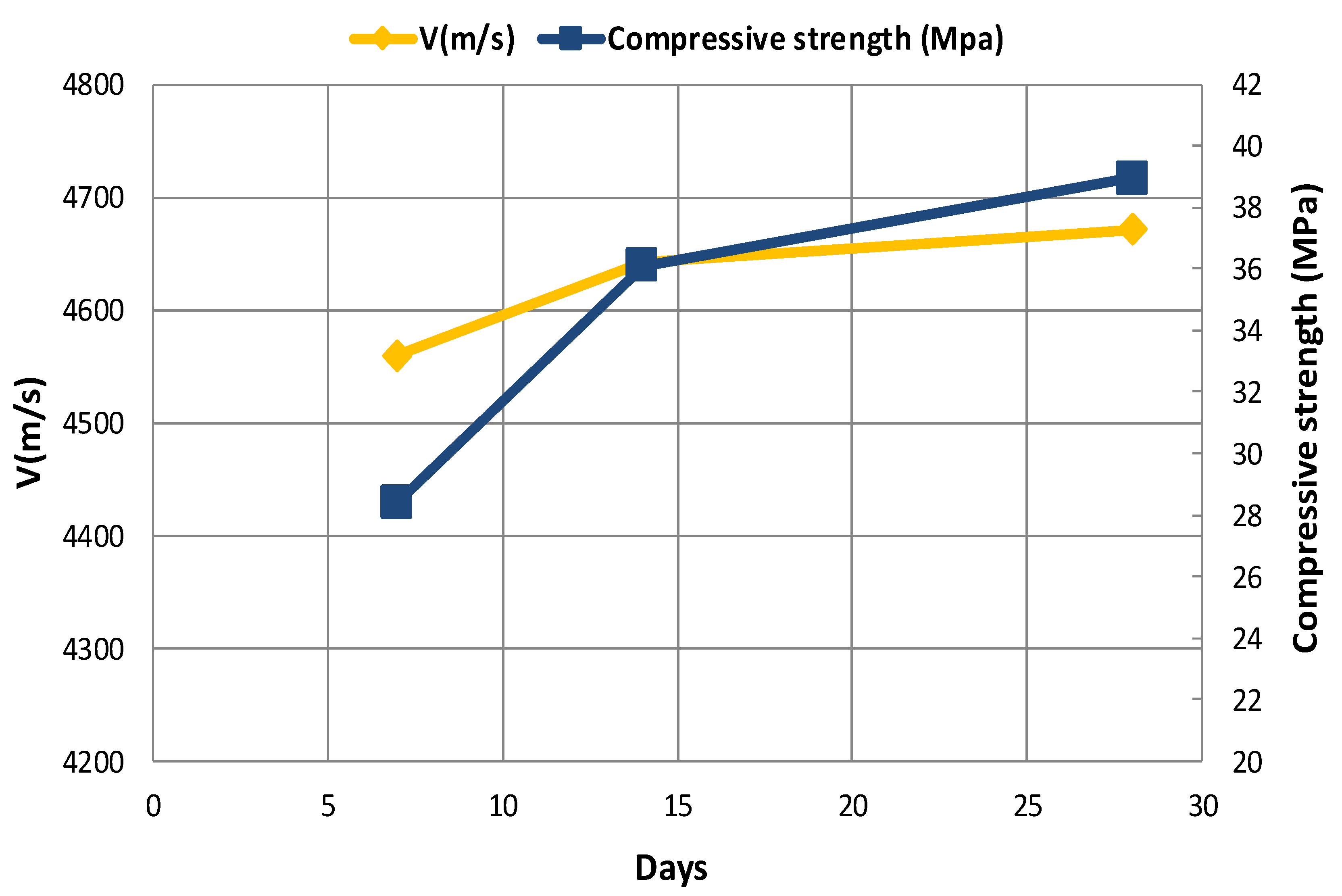

3.4. The Effect of Concrete Age on UPV and Compressive Strength

3.5. Comparing Compressive Strength and UPV

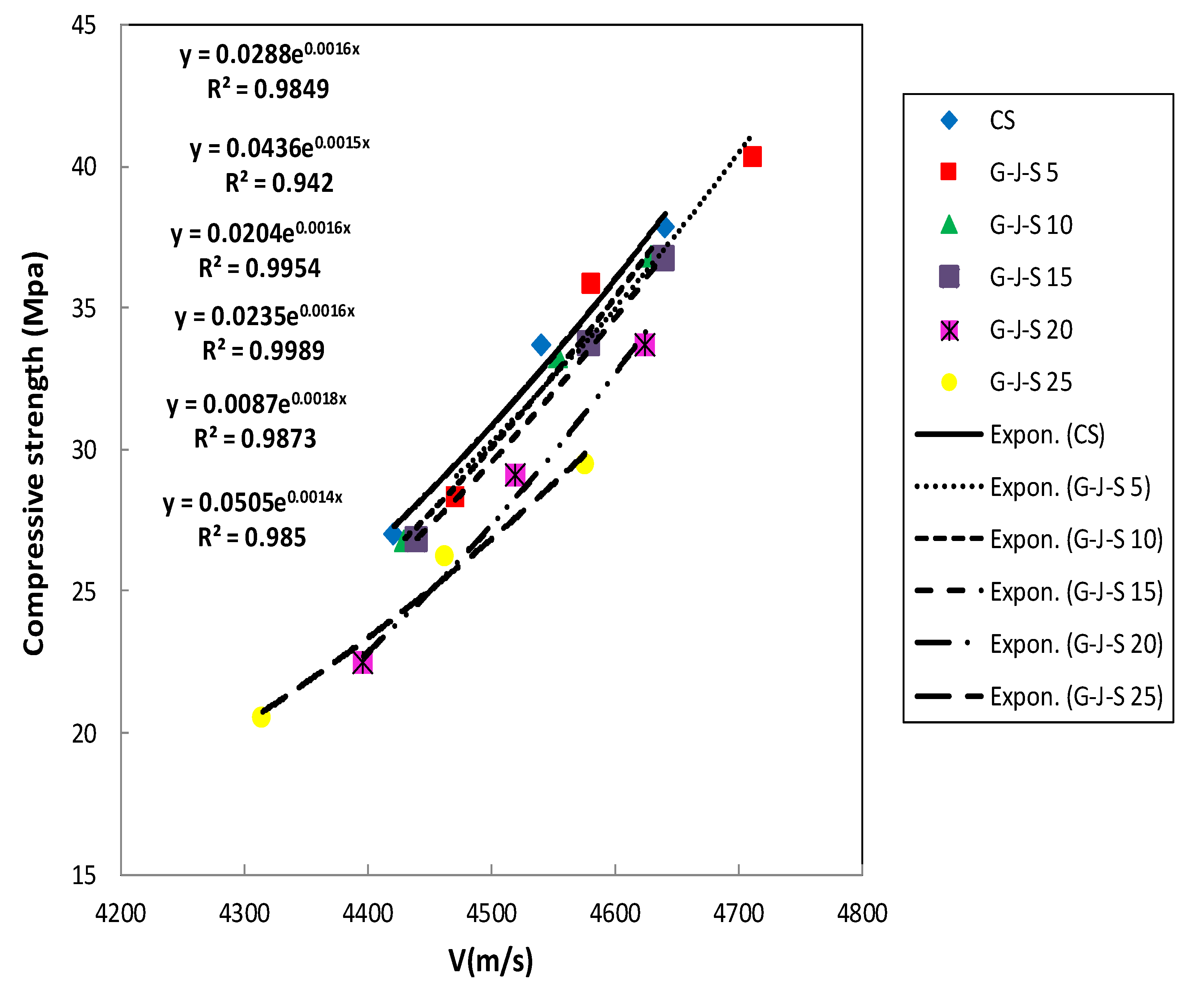

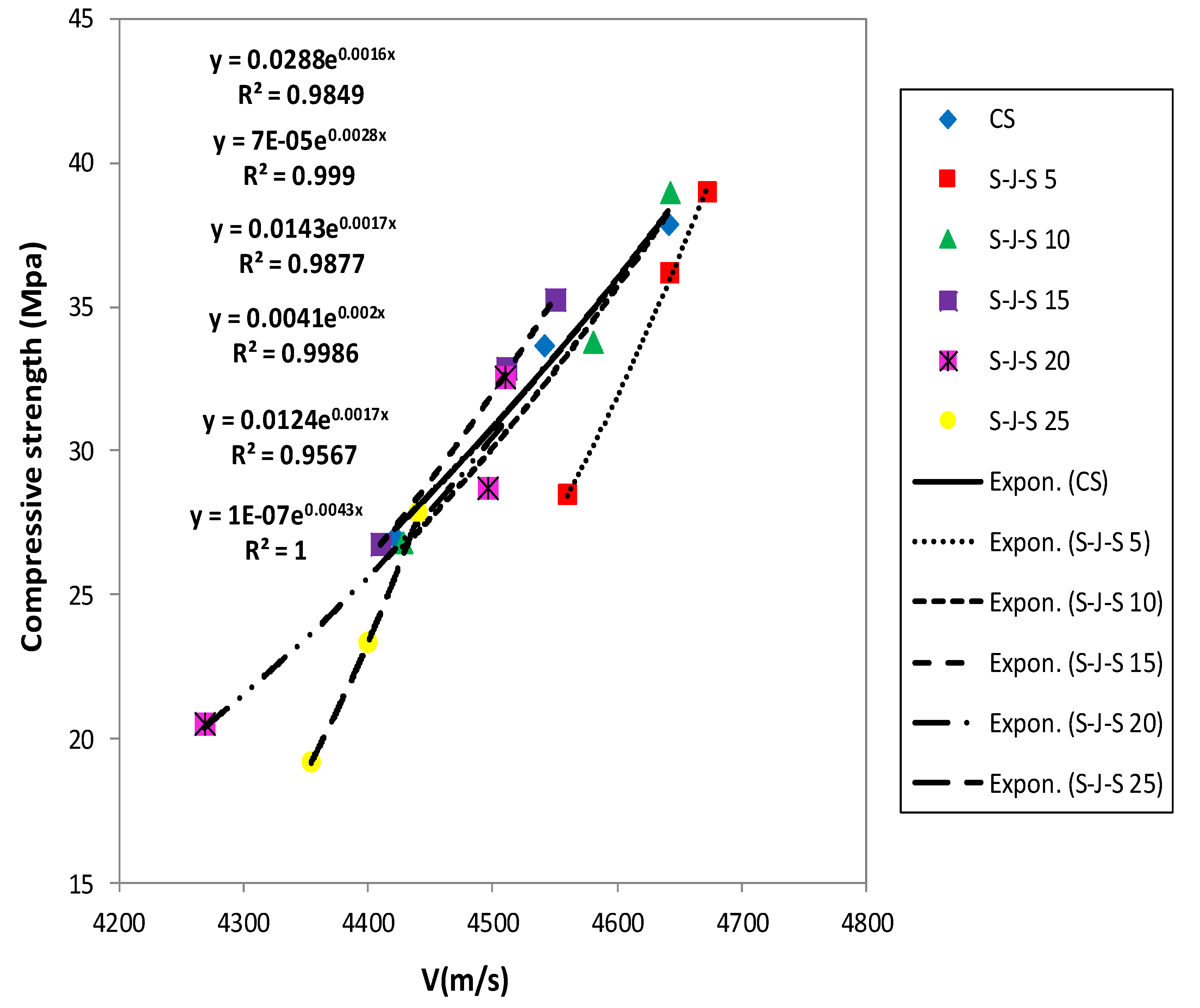

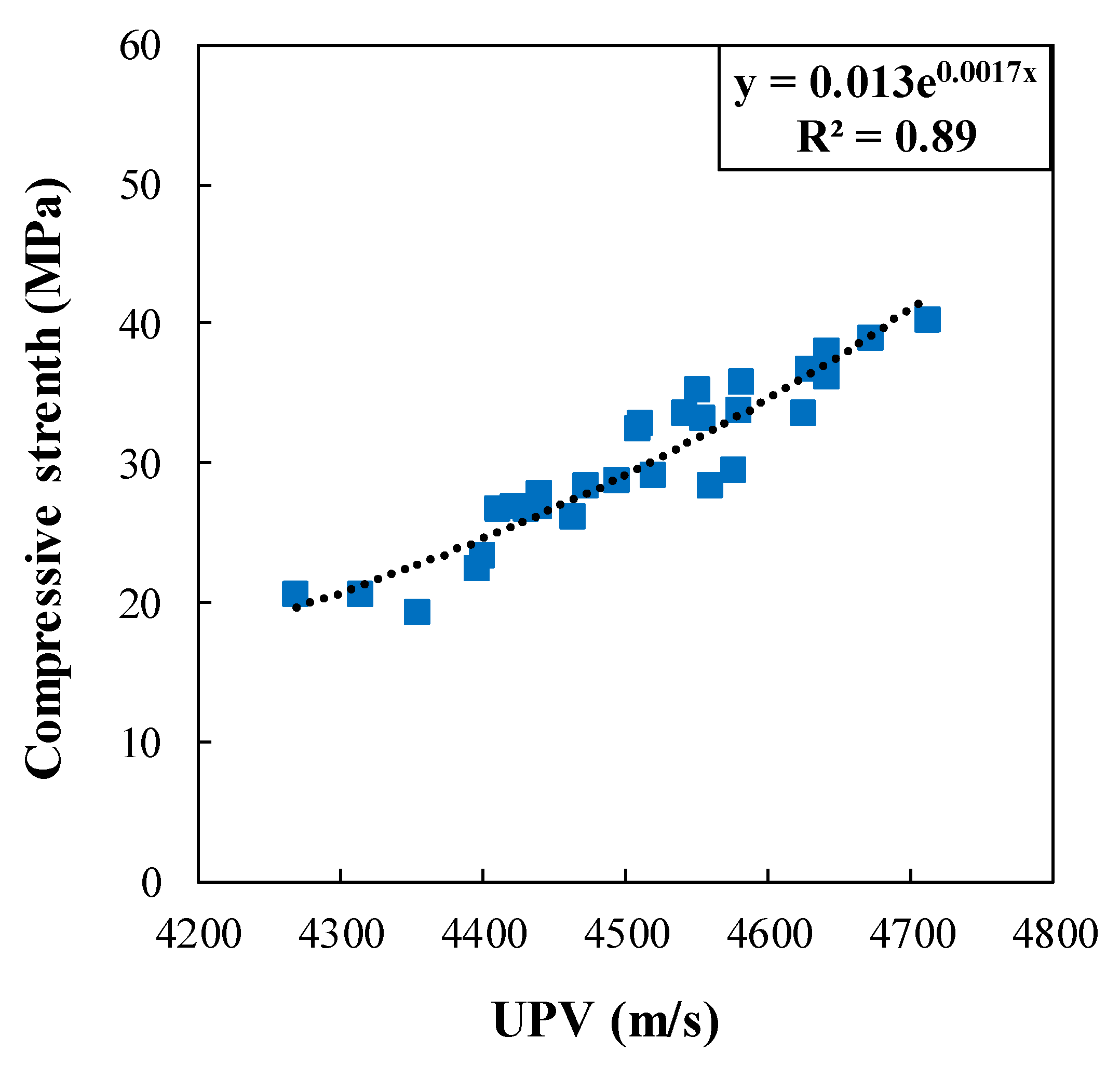

3.6. Relationship between Pulse Transmission Speed and Compressive Strength

4. Conclusions

- The UPV in concrete specimens is reduced significantly as the replacement level of coarse and fine aggregates with coal waste is increased. However, UPV is increased at 5% substitution of coal waste.

- The compressive strength of specimens is improved as 5 vol.% of natural aggregates is replaced with coal waste. However, further addition of coal decreases the compressive strength at different ages.

- As the age of concrete specimens increases, the UPV gains value. In this respect, the maximum pulse velocity corresponds to the 28-day specimen with 5% of coal waste replacing coarse aggregates. In contrast, the minimum velocity belongs to the 7-day specimen, with 20% of fine coal waste aggregates.

- The maximum compressive strength for the 28-day specimen with a replacement level of 5% of coarse coal waste is 40.3 MPa, which is approximately 6% higher than the control specimen at the same age. On the contrary, the lowest compressive strength for the 7-day specimen is 19.2 MPa with a 25% replacement of fine coal waste, indicating an approximate reduction of 29% compared to the control specimen at that age.

- The exponential relationship between the compressive strength and the transmission speed of ultrasonic pulses, obtained in this experiment, shows the acceptable regression analysis results. Therefore, a generic exponential relationship between the compressive strength and UPV was proposed for the entire concrete specimen results with different volume replacement levels of coal waste at different ages, which correlates well with the test results.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Moravvej, M.; Rashidi, M. Structural performance of self-compacting concrete. In Self-Compacting Concrete: Materials, Properties and Applications; Elsevier BV: Amsterdam, The Netherlands, 2020; pp. 371–387. [Google Scholar]

- Rashidi, M.; Joshaghani, A.; Ghodrat, M. Towards Eco-Flowable Concrete Production. Sustainability 2020, 12, 1208. [Google Scholar] [CrossRef]

- Karimipour, A. Effect of untreated coal waste as fine and coarse aggregates replacement on the properties of steel and polypropylene fibres reinforced concrete. Mech. Mater. 2020, 150, 103592. [Google Scholar] [CrossRef]

- Nematzadeh, M.; Karimi, A.; Fallah-Valukolaee, S. Compressive performance of steel fiber-reinforced rubberized concrete core detached from heated CFST. Constr. Build. Mater. 2020, 239, 117832. [Google Scholar] [CrossRef]

- Yang, I.-H.; Park, J.; Le, N.D.; Jung, S. Strength Properties of High-Strength Concrete Containing Coal Bottom Ash as a Replacement of Aggregates. Adv. Mater. Sci. Eng. 2020, 2020, 1–12. [Google Scholar] [CrossRef]

- Khataei, B.; Nasrollahi, M. Optimizing the tensile strength of concrete containing coal waste considering the cost. SN Appl. Sci. 2019, 2, 103. [Google Scholar] [CrossRef]

- Hesami, S.; Modarres, A.; Soltani Nezhad, M. Influence of coal waste powder on strength properties of roller compacted concrete pavement. JTIE 2015, 1, 1–14. Available online: https://www.sid.ir/en/journal/ViewPaper.aspx?id=540182 (accessed on 30 January 2021).

- Dos Santos, C.R.; Filho, J.R.D.A.; Tubino, R.M.C.; Schneider, I.A.H. Use of Coal Waste as Fine Aggregates in Concrete Paving Blocks. Geomaterials 2013, 3, 54–59. [Google Scholar] [CrossRef]

- Hesami, S.; Modarres, A.; Soltaninejad, M.; Madani, H. Mechanical properties of roller compacted concrete pavement containing coal waste and limestone powder as partial replacements of cement. Constr. Build. Mater. 2016, 111, 625–636. [Google Scholar] [CrossRef]

- Karimaei, M.; Dabbaghi, F.; Sadeghi-Nik, A.; Dehestani, M. Mechanical performance of green concrete produced with untreated coal waste aggregates. Constr. Build. Mater. 2020, 233, 117264. [Google Scholar] [CrossRef]

- Abo-Qudais, S.A. Effect of concrete mixing parameters on propagation of ultrasonic waves. Constr. Build. Mater. 2005, 19, 257–263. [Google Scholar] [CrossRef]

- Solís-Carcaño, R.; Moreno, E.I. Evaluation of concrete made with crushed limestone aggregate based on ultrasonic pulse velocity. Constr. Build. Mater. 2008, 22, 1225–1231. [Google Scholar] [CrossRef]

- Güçlüer, K. Investigation of the effects of aggregate textural properties on compressive strength (CS) and ultrasonic pulse velocity (UPV) of concrete. J. Build. Eng. 2020, 27, 100949. [Google Scholar] [CrossRef]

- Hosseini, R.; Rashidi, M.; Bulajić, B.; Arani, K.K.; Bulajić, B. Multi-Objective Optimization of Three Different SMA-LRBs for Seismic Protection of a Benchmark Highway Bridge against Real and Synthetic Ground Motions. Appl. Sci. 2020, 10, 4076. [Google Scholar] [CrossRef]

- Hoshyar, A.N.; Rashidi, M.; Liyanapathirana, R.; Samali, B. Algorithm Development for the Non-Destructive Testing of Structural Damage. Appl. Sci. 2019, 9, 2810. [Google Scholar] [CrossRef]

- Hedjazi, S.; Castillo, D. Relationships among compressive strength and UPV of concrete reinforced with different types of fibers. Heliyon 2020, 6, e03646. [Google Scholar] [CrossRef]

- Hernández, M.; Izquierdo, M.; Ibáñez, A.; Anaya, J.; Ullate, L. Porosity estimation of concrete by ultrasonic NDE. Ultrasonics 2000, 38, 531–533. [Google Scholar] [CrossRef]

- Bogas, J.A.; Gomes, M.G.; Gomes, A. Compressive strength evaluation of structural lightweight concrete by non-destructive ultrasonic pulse velocity method. Ultrasonics 2013, 53, 962–972. [Google Scholar] [CrossRef]

- Washer, G.J.; Fuchs, P.; Graybeal, B.A.; Hartmann, J.L. Ultrasonic testing of reactive powder concrete. Ultrason. Ferroelectr. Freq. Control. 2004, 51, 193–201. [Google Scholar] [CrossRef]

- Nematzadeh, M.; Fallah-Valukolaee, S. Effectiveness of fibers and binders in high-strength concrete under chemical corrosion. Struct. Eng. Mech. 2017, 64, 243–257. [Google Scholar] [CrossRef]

- Sadeghi-Nik, A.; Omran, O.L. Estimation of compressive strength of self-compacted concrete with fibers consisting nano-SiO2 using ultrasonic pulse velocity. Constr. Build. Mater. 2013, 44, 654–662. [Google Scholar] [CrossRef]

- Kim, S.S.; Qudoos, A.; Jakhrani, S.H.; Lee, J.B.; Kim, H.G. Influence of Coarse Aggregates and Silica Fume on the Mechanical Properties, Durability, and Microstructure of Concrete. Materials 2019, 12, 3324. [Google Scholar] [CrossRef] [PubMed]

- ASTM C33. Standard Specification for Concrete Aggregates; ASTM: Philadelphia, PA, USA, 2004. [Google Scholar]

- ACI Committee 211.1-91. Standard Practice for Selecting Proportions for Normal, Heavyweight, and Mass Concrete; American Concrete Institute: Farmington Hills, MI, USA, 2000; p. 38. [Google Scholar]

- American Society for Testing and Materials International. ASTM C143/C143M-20 Standard Test Method for Slump of Hydraulic-Cement Concrete; ASTM: Philadelphia, PA, USA. Available online: https://www.astm.org/Standards/C143 (accessed on 30 January 2021).

- ASTM C192. Standard Practice for Making and Curing Concrete Test Specimens in the Laboratory; ASTM: Philadelphia, PA, USA, 2004. [Google Scholar]

- American Society for Testing and Materials International. ASTM C597-9. Standard Test Method for Pulse Velocity Through Concrete; ASTM: Philadelphia, PA, USA, 2016. [Google Scholar]

- British Standards Institution. BS EN 12390-3:2019-Testing Hardened Concrete. Compressive Strength of Test Specimens. Available online: https://shop.bsigroup.com/ProductDetail?pid=000000000030360097 (accessed on 30 January 2021).

- Mohammed, B.S.; Azmi, N.J.; Abdullahi, M. Evaluation of rubbercrete based on ultrasonic pulse velocity and rebound hammer tests. Constr. Build. Mater. 2011, 25, 1388–1397. [Google Scholar] [CrossRef]

- Mohammed, B.S.; Adamu, M.; Liew, M.S. Evaluating the effect of crumb rubber and nano silica on the properties of high volume fly ash roller compacted concrete pavement using non-destructive techniques. Case Stud. Constr. Mater. 2018, 8, 380–391. [Google Scholar] [CrossRef]

- Irrigaray, M.A.P.; Pinto, R.C.D.A.; Padaratz, I.J. A new approach to estimate compressive strength of concrete by the UPV method. Rev. IBRACON de Estrut. e Mater. 2016, 9, 395–402. [Google Scholar] [CrossRef]

- Nematzadeh, M.; Tayebi, M.; Samadvand, H. Prediction of ultrasonic pulse velocity in steel fiber-reinforced concrete containing nylon granule and natural zeolite after exposure to elevated temperatures. Constr. Build. Mater. 2021, 273, 121958. [Google Scholar] [CrossRef]

| Aggregate | Sand | Gravel |

|---|---|---|

| Specific gravity (g/cm3) | 2.76 | 2.5 |

| Unit weight (g/cm3) | 1.73 | 1.57 |

| Moisture content (%) | 0.3 | 0.14 |

| Moisture of saturated surface dry (%) | 0.5 | 0.4 |

| Fines modulus (FM) | 2.92 | - |

| Sand equivalent value (SE) (%) | 82 | - |

| Items | SiO2 | AL2O3 | Fe2O3 | MgO | CaO | P2O5–P2O3 | Na2O | K2O | MnO | TiO2 | L.O.I |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Untreated Coal waste | 37.8 | 13.14 | 2.85 | 0.73 | 0.76 | 0.27 | 0.28 | 2.02 | 0.02 | 1.17 | 40.96 |

| Chemical Properties | % |

|---|---|

| SiO2 | 21.9 |

| Al2O3 | 4.86 |

| Fe2O3 | 3.3 |

| CaO | 63.32 |

| MgO | 1.15 |

| SO3 | 2.1 |

| Loss on ignition | 2.4 |

| Physical Properties | |

| Specific gravity | 3.15 |

| Specific surface (m2/gr) | 0.305 |

| Initial setting time (min) | 140 |

| Final setting time (min) | 190 |

| Mechanical Properties | |

| Compressive strength (MPa) | 18.14 (3 days) |

| 28.93 (7 days) | |

| 37.17 (28 days) |

| Mix No. | Mixture ID | UCW (%) | W/C | Water | Cement | Coarse Agg. | Fine Agg. | UCW | Slump(mm) |

|---|---|---|---|---|---|---|---|---|---|

| (Kg/m3) | |||||||||

| 1 | CS | 0 | 0.55 | 215 | 391 | 854 | 855 | 0 | 80 |

| 2 | G-J-S | 5 | 0.55 | 215 | 391 | 811.3 | 855 | 32.04 | 80 |

| 3 | 10 | 0.55 | 215 | 391 | 768.6 | 855 | 60.70 | 70 | |

| 4 | 15 | 0.55 | 215 | 391 | 725.9 | 855 | 86.00 | 75 | |

| 5 | 20 | 0.55 | 215 | 391 | 683.2 | 855 | 107.92 | 80 | |

| 6 | 25 | 0.55 | 215 | 391 | 640.5 | 855 | 126.47 | 82 | |

| 7 | S-J-S | 5 | 0.55 | 215 | 391 | 854 | 812.25 | 29.11 | 70 |

| 8 | 10 | 0.55 | 215 | 391 | 854 | 769.5 | 55.15 | 70 | |

| 9 | 15 | 0.55 | 215 | 391 | 854 | 726.75 | 78.14 | 68 | |

| 10 | 20 | 0.55 | 215 | 391 | 854 | 684 | 98.05 | 60 | |

| 11 | 25 | 0.55 | 215 | 391 | 854 | 641.25 | 114.91 | 58 | |

| Mix No. | Group | Coal Waste | 7 Days | 14 Days | 28 Days | |||

|---|---|---|---|---|---|---|---|---|

| V(m/s) | V(m/s) | V(m/s) | ||||||

| 1 | CS | 0 | 26.96 | 4421 | 33.66 | 4541.2 | 37.85 | 4641.2 |

| 2 | G-J-S | 5 | 28.28 | 4472.4 | 35.8 | 4581.4 | 40.28 | 4712.4 |

| 3 | 10 | 26.71 | 4430 | 33.24 | 4554.2 | 36.8 | 4629.5 | |

| 4 | 15 | 26.82 | 4440 | 33.75 | 4580 | 36.74 | 4640 | |

| 5 | 20 | 22.42 | 4396.6 | 29.07 | 4520 | 33.65 | 4624.7 | |

| 6 | 25 | 20.5 | 4315 | 26.17 | 4463.5 | 29.43 | 4576.8 | |

| 7 | S-J-S | 5 | 28.41 | 4560 | 36.12 | 4641.7 | 38.94 | 4671.7 |

| 8 | 10 | 26.82 | 4428 | 33.72 | 4580.4 | 37.98 | 4641.4 | |

| 9 | 15 | 26.71 | 4410 | 32.86 | 4510.3 | 35.23 | 4550.5 | |

| 10 | 20 | 20.47 | 4354 | 28.71 | 4495.1 | 32.51 | 4509.3 | |

| 11 | 25 | 19.18 | 4268.9 | 23.33 | 4400 | 27.81 | 4440.4 | |

| Mix no | Group | Coal Waste (%) | A | B | R2 |

|---|---|---|---|---|---|

| 1 | CS | 0 | 0.0288 | 0.0016 | 0.9849 |

| 2 | G-J-S | 5 | 0.0436 | 0.0015 | 0.942 |

| 3 | 10 | 0.0204 | 0.0016 | 0.9954 | |

| 4 | 15 | 0.0235 | 0.0016 | 0.9989 | |

| 5 | 20 | 0.0087 | 0.0018 | 0.9873 | |

| 6 | 25 | 0.0505 | 0.0014 | 0.985 | |

| 7 | S-J-S | 5 | 0.00007 | 0.0028 | 0.999 |

| 8 | 10 | 0.0143 | 0.0017 | 0.9877 | |

| 9 | 15 | 0.0041 | 0.002 | 0.9986 | |

| 10 | 20 | 0.0124 | 0.0017 | 0.9567 | |

| 11 | 25 | 0.0000001 | 0.0043 | 1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Karimaei, M.; Dabbaghi, F.; Dehestani, M.; Rashidi, M. Estimating Compressive Strength of Concrete Containing Untreated Coal Waste Aggregates Using Ultrasonic Pulse Velocity. Materials 2021, 14, 647. https://doi.org/10.3390/ma14030647

Karimaei M, Dabbaghi F, Dehestani M, Rashidi M. Estimating Compressive Strength of Concrete Containing Untreated Coal Waste Aggregates Using Ultrasonic Pulse Velocity. Materials. 2021; 14(3):647. https://doi.org/10.3390/ma14030647

Chicago/Turabian StyleKarimaei, Mahmood, Farshad Dabbaghi, Mehdi Dehestani, and Maria Rashidi. 2021. "Estimating Compressive Strength of Concrete Containing Untreated Coal Waste Aggregates Using Ultrasonic Pulse Velocity" Materials 14, no. 3: 647. https://doi.org/10.3390/ma14030647

APA StyleKarimaei, M., Dabbaghi, F., Dehestani, M., & Rashidi, M. (2021). Estimating Compressive Strength of Concrete Containing Untreated Coal Waste Aggregates Using Ultrasonic Pulse Velocity. Materials, 14(3), 647. https://doi.org/10.3390/ma14030647