Delamination Fracture Behavior of Unidirectional Carbon Reinforced Composites Applied to Wind Turbine Blades

Abstract

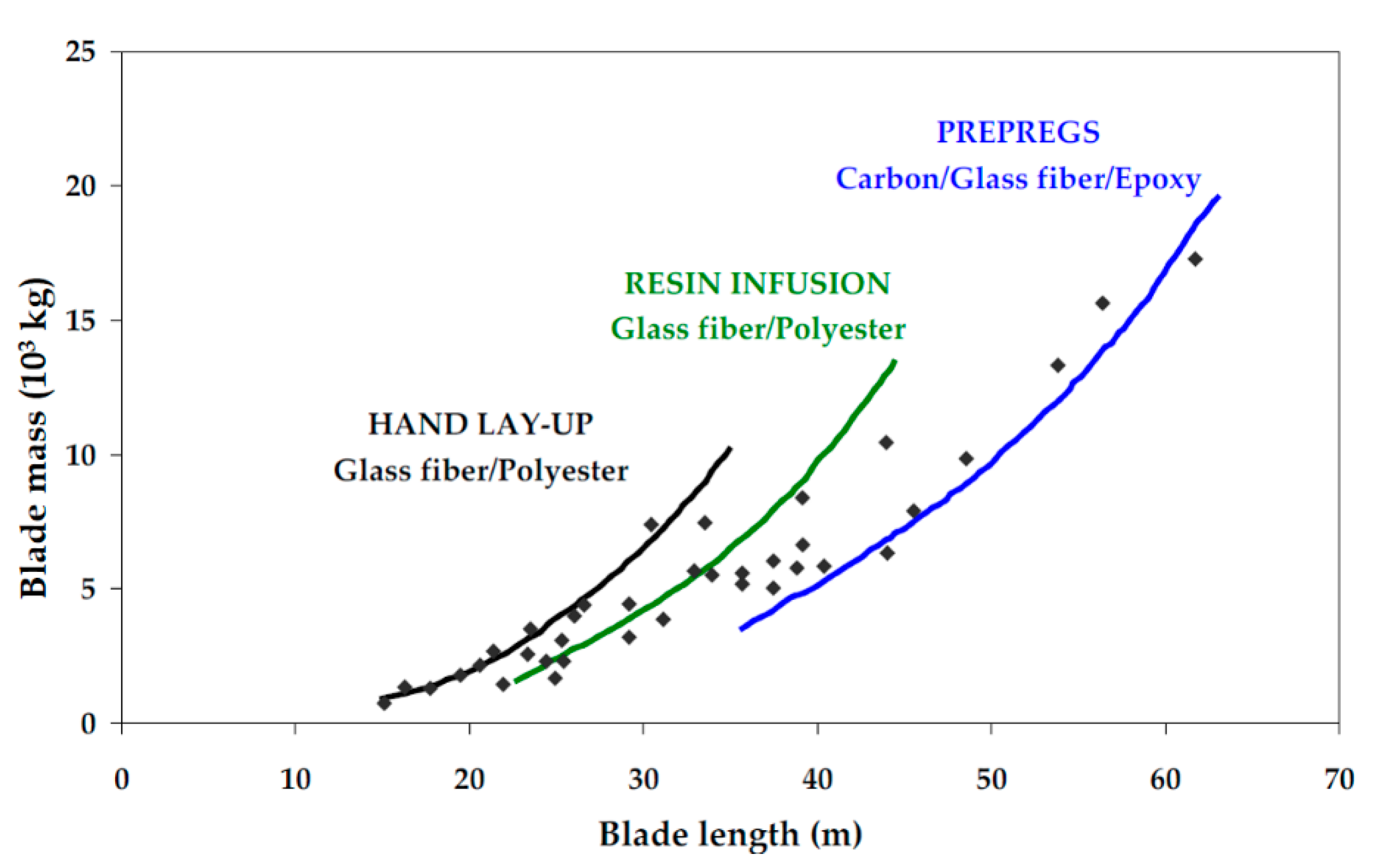

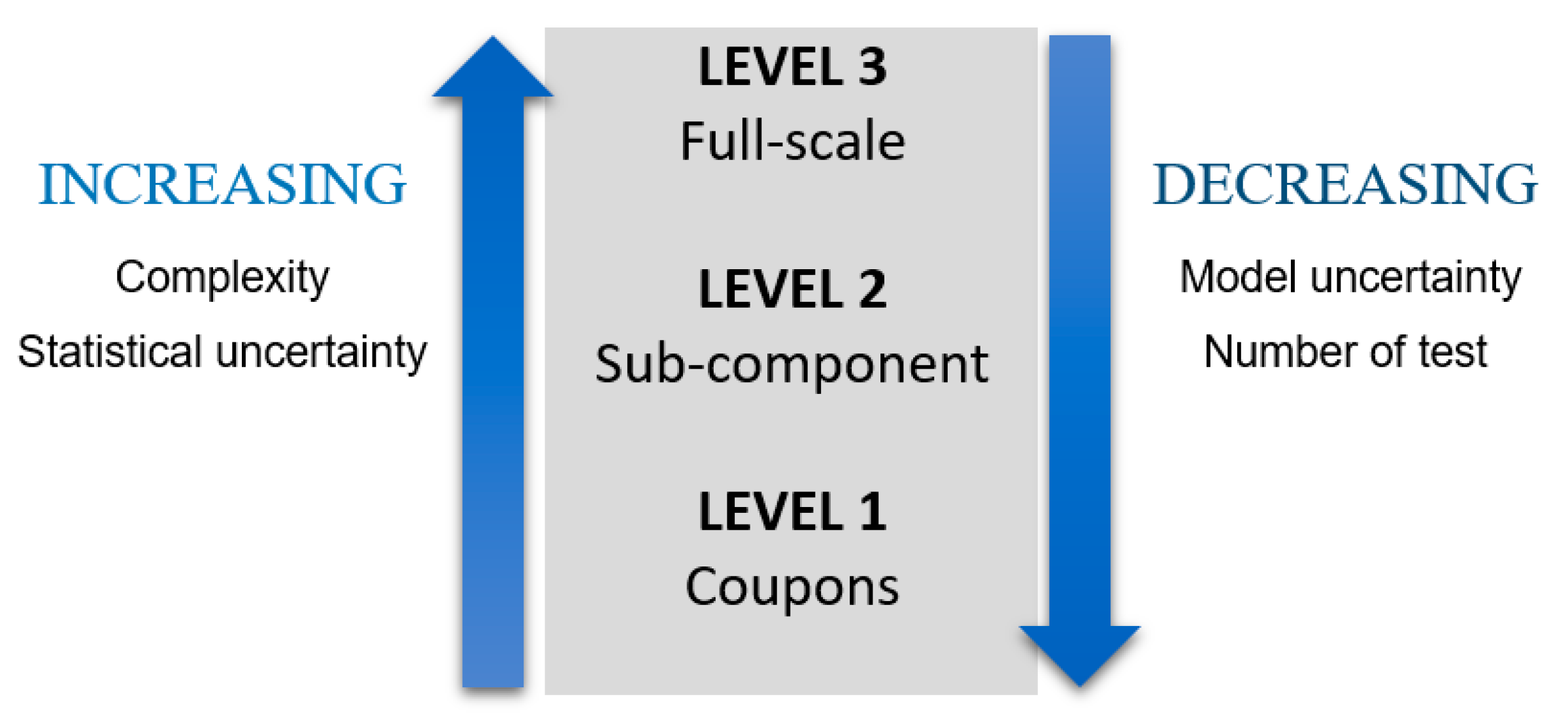

1. Introduction

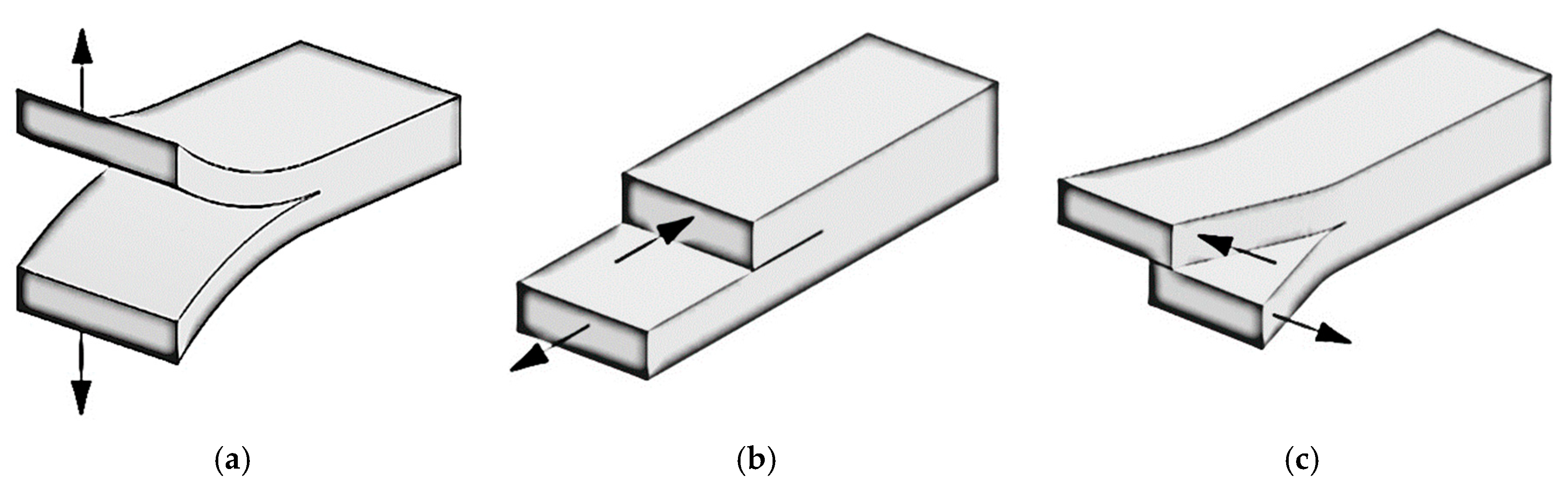

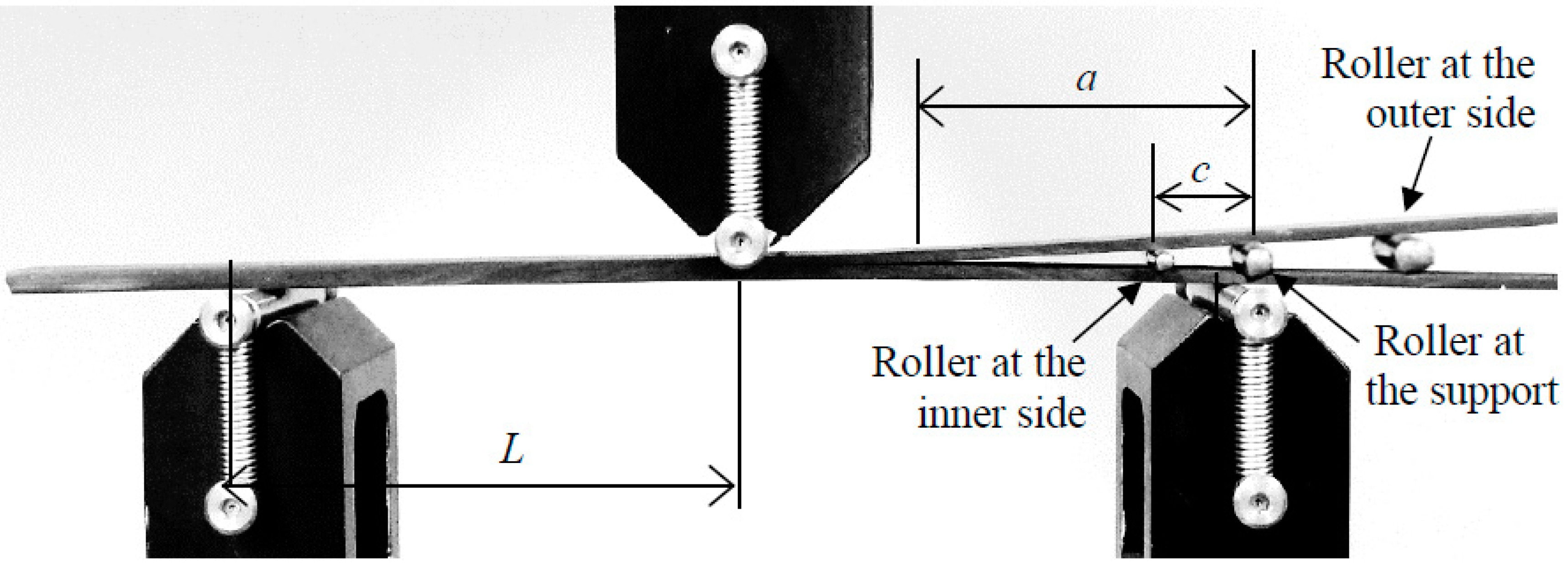

2. Some Aspects on Fracture Mechanics and Delamination Tests

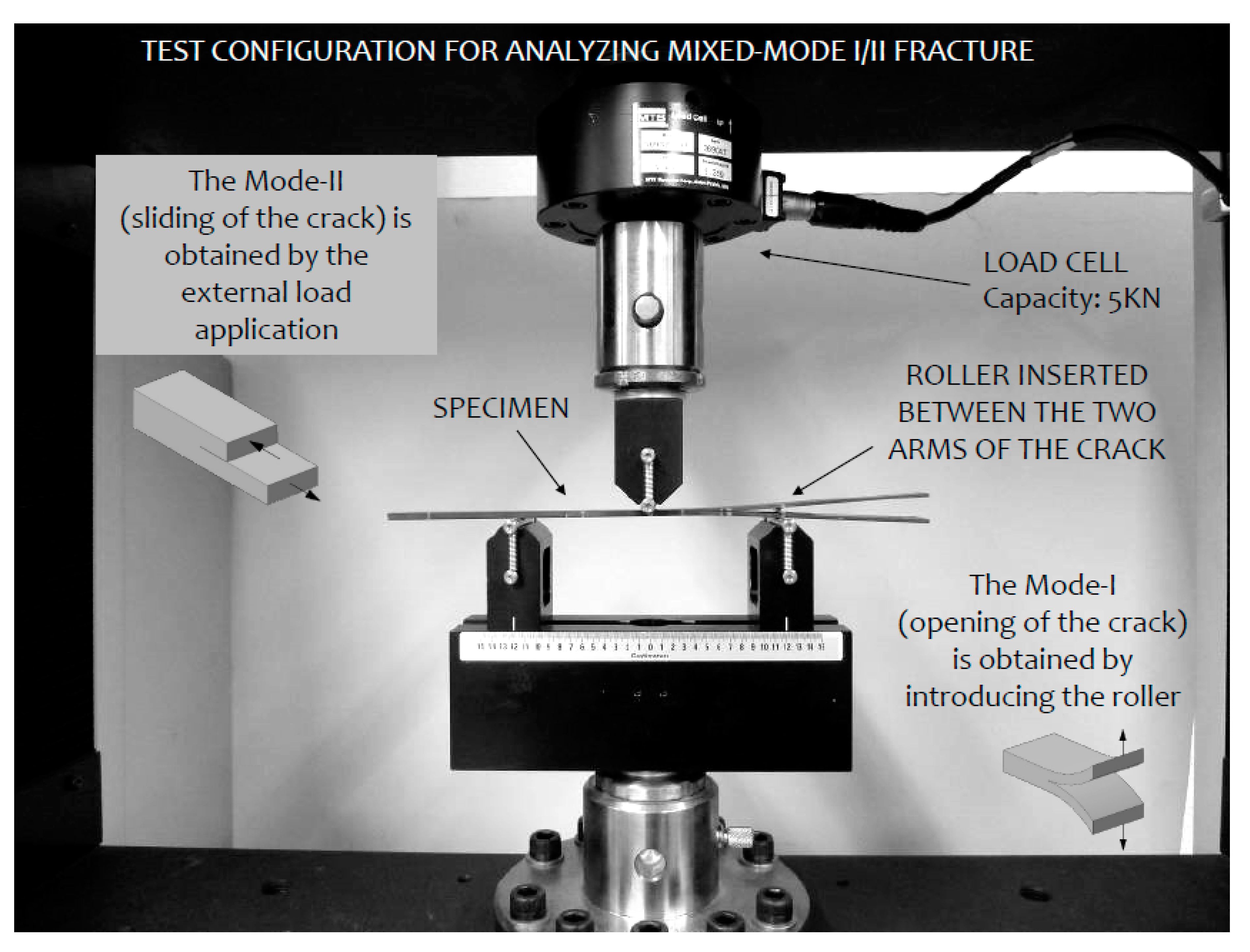

3. Test Description

4. Experimental Results

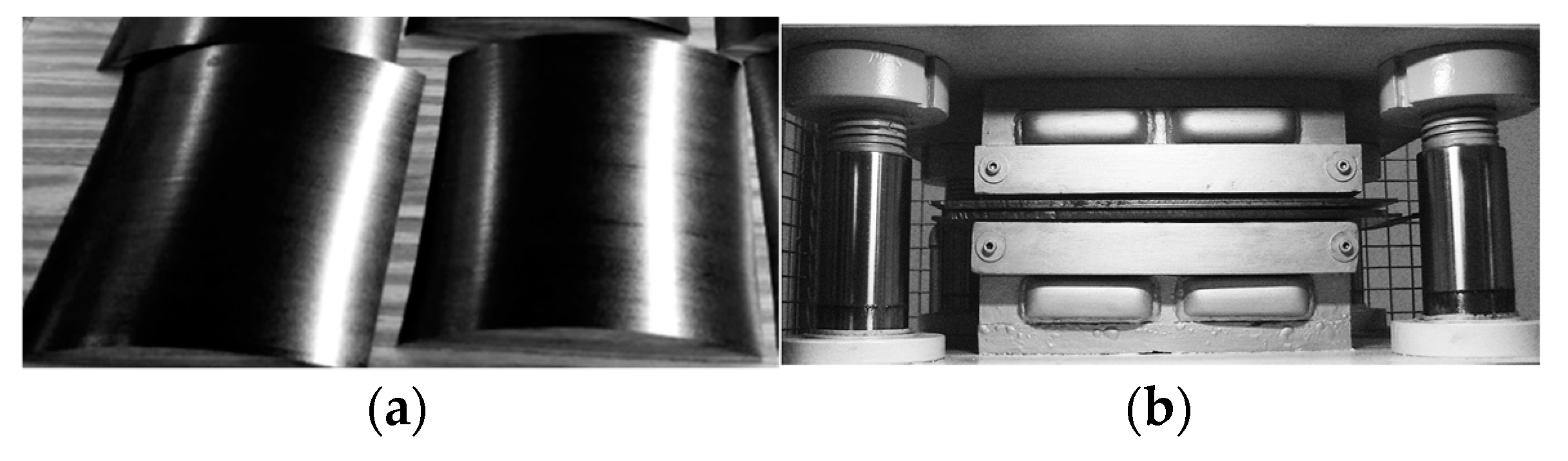

4.1. Materials and Test Apparatus

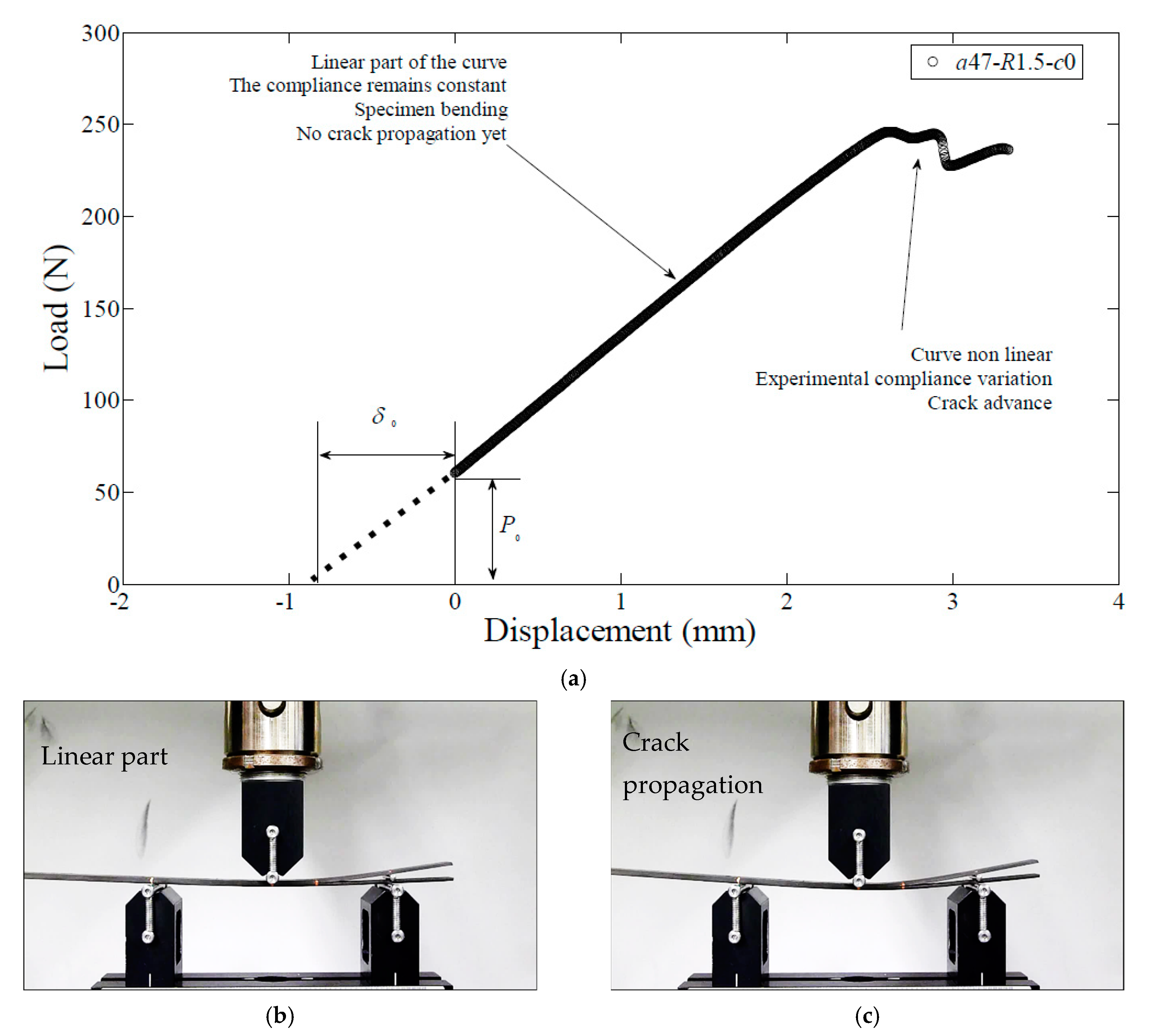

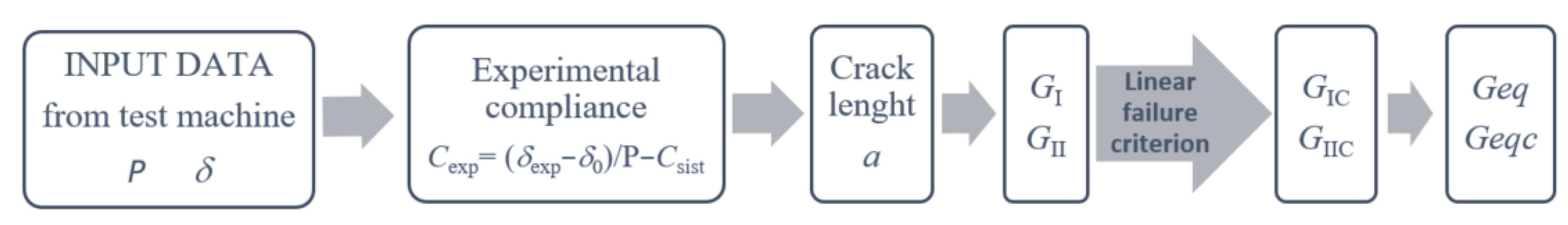

4.2. Test Methodology

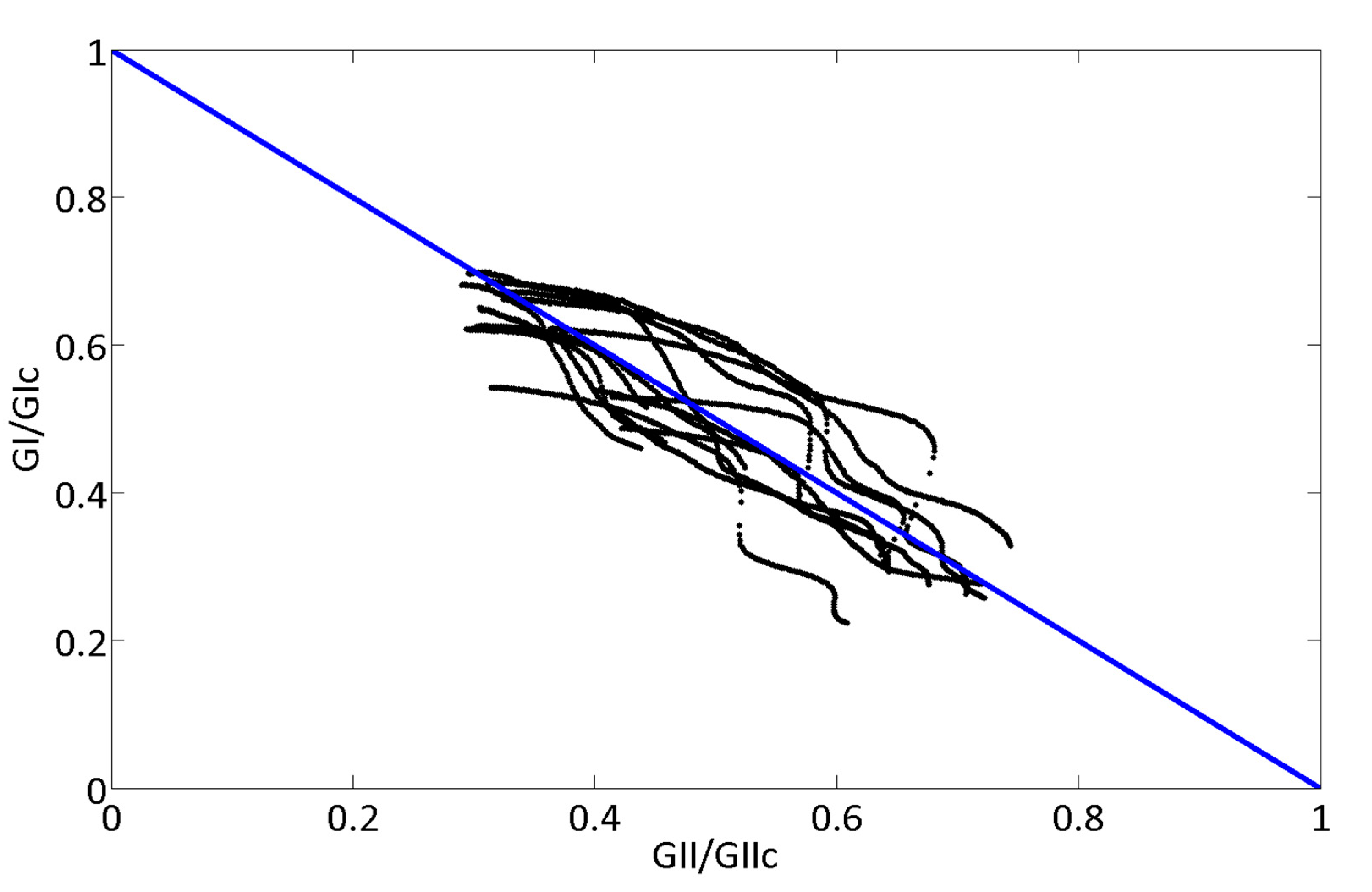

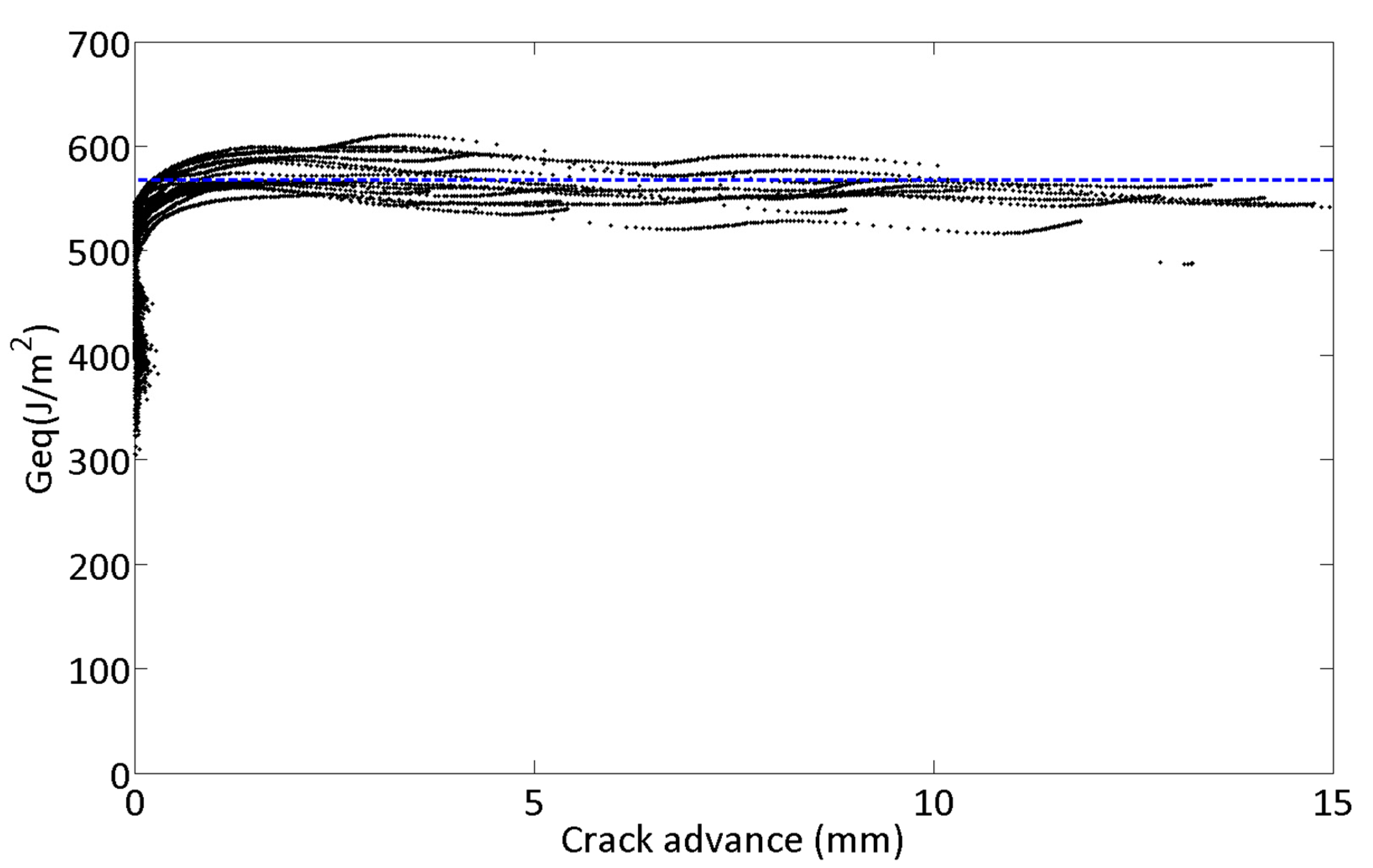

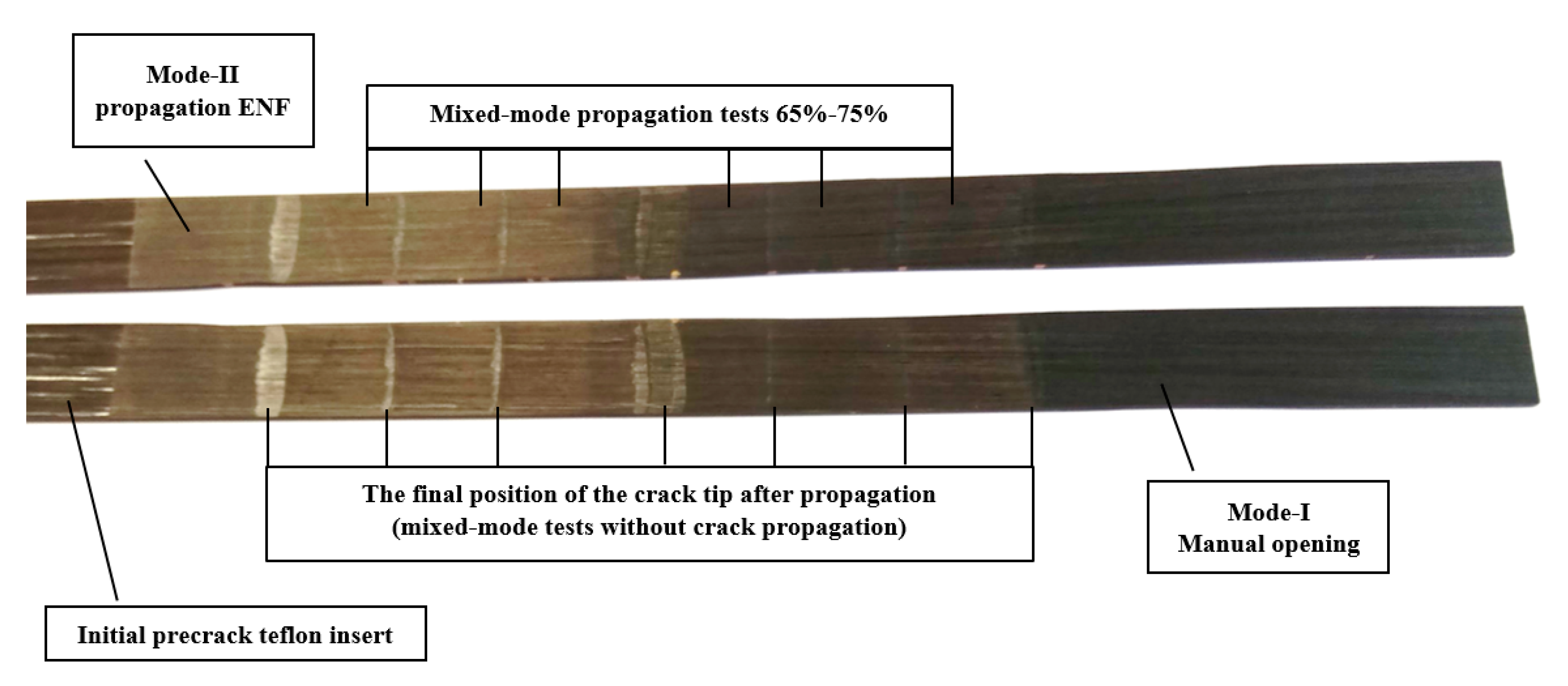

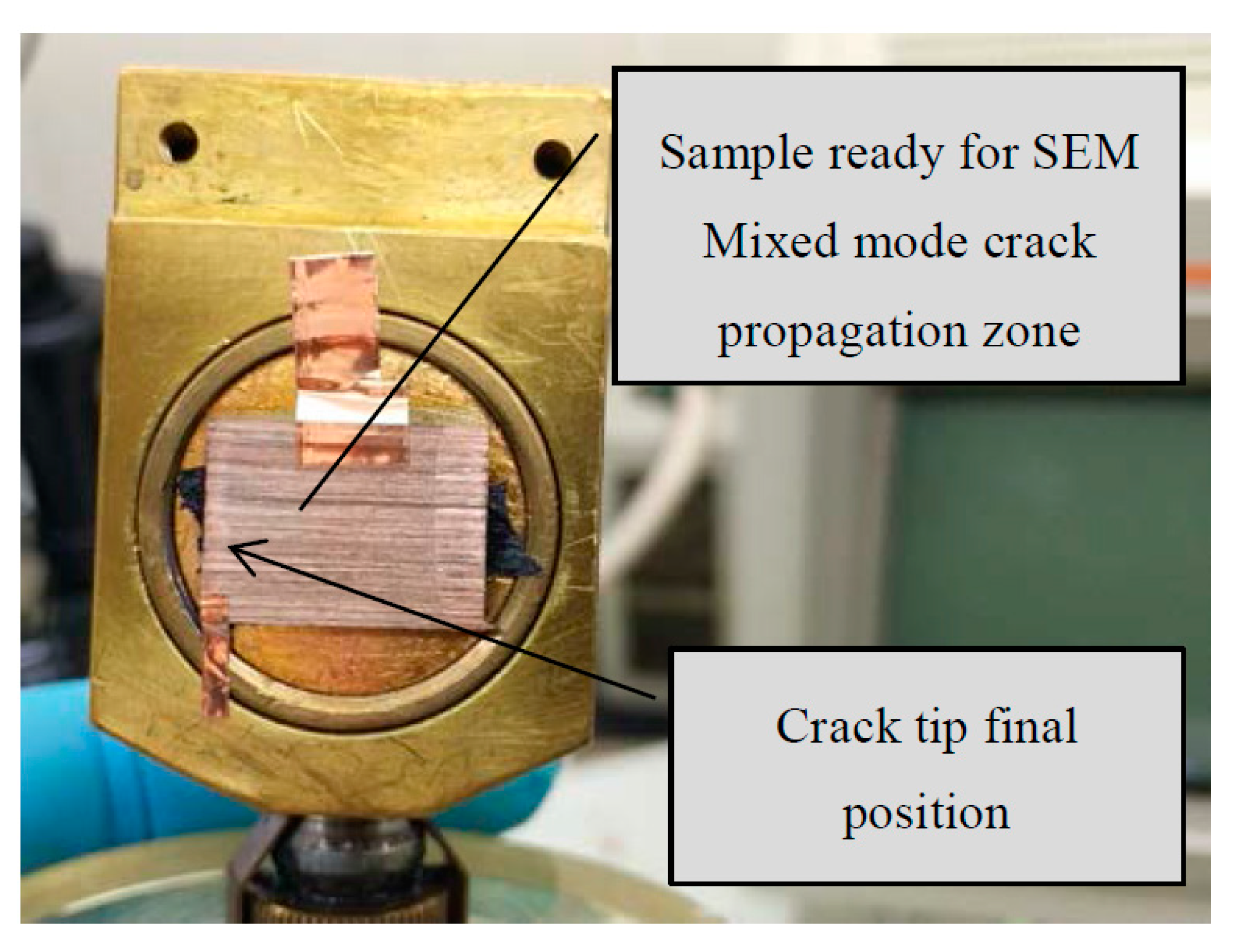

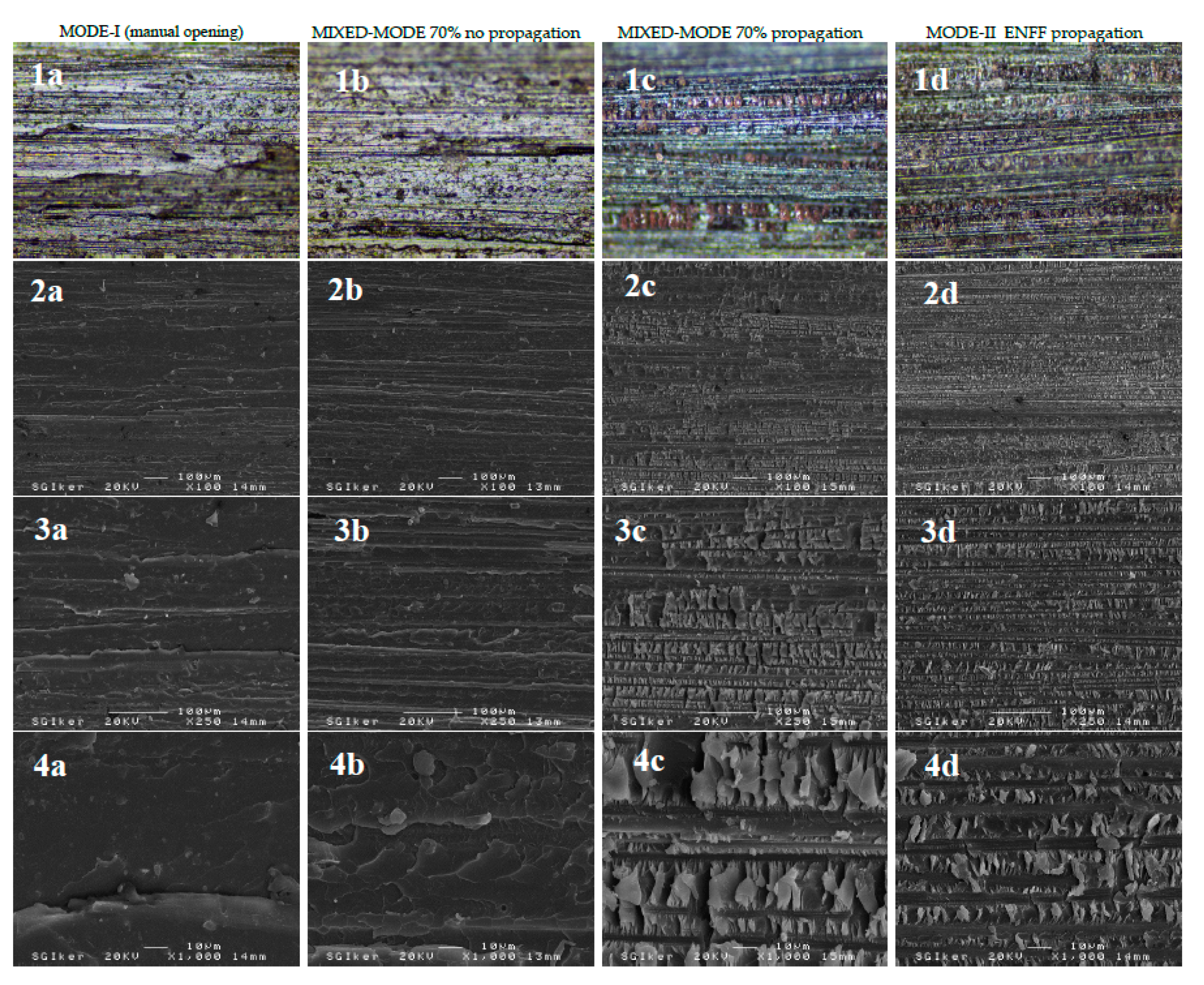

4.3. Results and Discussion

5. Summary and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wind Europe. Wind Energy in Europe: Outlook to 2020; Wind Europe: Brussels, Belgium, 2017. [Google Scholar]

- Mishnaevsky, L. Repair of Wind Turbine Blades: Review of Methods and Related Computational Mechanics Problems. Renew. Energy 2019, 140, 828–839. [Google Scholar] [CrossRef]

- Eder, M.A.; Bitsche, R. Fracture Analysis of Adhesive Joints in Wind Turbine Blades. Wind Energy 2015, 18, 1007–1022. [Google Scholar] [CrossRef]

- Swolfs, Y. Perspective for Fibre-Hybrid Composites in Wind Energy Applications. Materials 2017, 10, 1281. [Google Scholar] [CrossRef] [PubMed]

- Fernández, J.A.R.; Puig, J.M. Simulation of Current Distribution in a Wind Turbine Blade Using the FDTD Method. Electr. Power Syst. Res. 2020, 185, 106350. [Google Scholar] [CrossRef]

- Lee, S.-L.; Shin, S. Preliminary Design Procedure for Large Wind Turbine Blades Based on the Classical Lamination Theory. Adv. Compos. Mater. 2020, 51, 1–18. [Google Scholar] [CrossRef]

- Lagdani, O.; Tarfaoui, M.; Nachtane, M.; Trihi, M.; Laaouidi, H. Numerical Investigation of Ice Accretion on an Offshore Composite Wind Turbine under Critical Loads. Int. J. Energy Res. 2020, in press. [Google Scholar] [CrossRef]

- Al-Rubaye, M.; Manalo, A.; Alajarmeh, O.; Ferdous, W.; Lokuge, W.; Benmokrane, B.; Edoo, A. Flexural Behaviour of Concrete Slabs Reinforced with GFRP Bars and Hollow Composite Reinforcing Systems. Compos. Struct. 2020, 236, 111836. [Google Scholar] [CrossRef]

- Mohammed, A.A.; Manalo, A.C.; Ferdous, W.; Zhuge, Y.; Vijay, P.V.; Pettigrew, J. Experimental and Numerical Evaluations on the Behaviour of Structures Repaired Using Prefabricated FRP Composites Jacket. Eng. Struct. 2020, 210, 110358. [Google Scholar] [CrossRef]

- Lee, J.-M.; Min, B.-J.; Park, J.-H.; Kim, D.-H.; Kim, B.-M.; Ko, D.-C. Design of Lightweight CFRP Automotive Part as an Alternative for Steel Part by Thickness and Lay-Up Optimization. Materials 2019, 12, 2309. [Google Scholar] [CrossRef]

- Böhm, R.; Hornig, A.; Weber, T.; Grüber, B.; Gude, M. Experimental and Numerical Impact Analysis of Automotive Bumper Brackets Made of 2D Triaxially Braided CFRP Composites. Materials 2020, 13, 3554. [Google Scholar] [CrossRef]

- Hiremath, N.; Young, S.; Ghossein, H.; Penumadu, D.; Vaidya, U.; Theodore, M. Low Cost Textile-Grade Carbon-Fiber Epoxy Composites for Automotive and Wind Energy Applications. Compos. Part B Eng. 2020, 198, 108156. [Google Scholar] [CrossRef]

- Wang, Z.; Kurita, H.; Nagaoka, H.; Narita, F. Potassium Sodium Niobate Lead-Free Piezoelectric Nanocomposite Generators Based on Carbon-Fiber-Reinforced Polymer Electrodes for Energy-Harvesting Structures. Compos. Sci. Technol. 2020, 199, 108331. [Google Scholar] [CrossRef]

- Karalis, G.; Tzounis, L.; Lambrou, E.; Gergidis, L.N.; Paipetis, A.S. A Carbon Fiber Thermoelectric Generator Integrated as a Lamina within an 8-Ply Laminate Epoxy Composite: Efficient Thermal Energy Harvesting by Advanced Structural Materials. Appl. Energy 2019, 253, 113512. [Google Scholar] [CrossRef]

- Alsaadi, A.; Shi, Y.; Pan, L.; Tao, J.; Jia, Y. Vibration Energy Harvesting of Multifunctional Carbon Fibre Composite Laminate Structures. Compos. Sci. Technol. 2019, 178, 1–10. [Google Scholar] [CrossRef]

- Ennis, B.L.; Kelley, C.L.; Naughton, B.T.; Norris, B.; Das, S.; Lee, D.; Miller, D. Optimized Carbon Fiber Composites in Wind Turbine Blade Design; Sandia National Lab. (SNL-NM): Albuquerque, NM, USA, 2019. [Google Scholar]

- Lekou, D. Scaling Limits & Costs Regarding WT Blades; Project Upwind: Pikermi, Greece, 2010. [Google Scholar]

- Zhou, B.; Yu, F.; Luo, Y.; Li, H. Detecting Defects in the Main Spar of a Wind Turbine Blade. J. Renew. Sustain. Energy 2020, 12, 053304. [Google Scholar] [CrossRef]

- Chen, X. Experimental Investigation on Structural Collapse of a Large Composite Wind Turbine Blade under Combined Bending and Torsion. Compos. Struct. 2017, 160, 435–445. [Google Scholar] [CrossRef]

- Chen, X.; Xu, J.Z. Structural Failure Analysis of Wind Turbines Impacted by Super Typhoon Usagi. Eng. Fail. Anal. 2016, 60, 391–404. [Google Scholar] [CrossRef]

- Chen, X.; Zhao, W.; Zhao, X.L.; Xu, J.Z. Failure Test and Finite Element Simulation of a Large Wind Turbine Composite Blade under Static Loading. Energies 2014, 7, 2274–2297. [Google Scholar] [CrossRef]

- Chen, X.; Zhao, W.; Zhao, X.L.; Xu, J.Z. Preliminary Failure Investigation of a 52.3 m Glass/Epoxy Composite Wind Turbine Blade. Eng. Fail. Anal. 2014, 44, 345–350. [Google Scholar] [CrossRef]

- Elhadi Ibrahim, M.; Medraj, M. Water Droplet Erosion of Wind Turbine Blades: Mechanics, Testing, Modeling and Future Perspectives. Materials 2020, 13, 157. [Google Scholar] [CrossRef]

- Mandell, J.F.; Cairns, D.S.; Samborsky, D.D.; Morehead, R.B.; Haugen, D.J. Prediction of Delamination in Wind Turbine Blade Structural Details. J. Sol. Energy Eng. Trans. ASME 2003, 125, 522–530. [Google Scholar] [CrossRef]

- Salimi-Majd, D.; Azimzadeh, V.; Mohammadi, B. Loading Analysis of Composite Wind Turbine Blade for Fatigue Life Prediction of Adhesively Bonded Root Joint. Appl. Compos. Mater. 2015, 22, 269–287. [Google Scholar] [CrossRef]

- Mishnaevsky, L.; Branner, K.; Petersen, H.N.; Beauson, J.; McGugan, M.; Sørensen, B.F. Materials for Wind Turbine Blades: An Overview. Materials 2017, 10, 1285. [Google Scholar] [CrossRef] [PubMed]

- Asl, M.E.; Niezrecki, C.; Sherwood, J.; Avitabile, P. Design of scaled-down composite I-beams for dynamic characterization in subcomponent testing of a wind turbine blade. In Shock & Vibration, Aircraft/Aerospace, Energy Harvesting, Acoustics & Optics; Springer: Berlin/Heidelberg, Germany, 2016; Volume 9, pp. 197–209. [Google Scholar]

- Sørensen, B. Materials and Structures for Wind Turbine Rotor Blades—An Overview. In Proceedings of the 17th International Conference on Composite Materials, Edinburgh, UK, 27–31 July 2009; pp. 27–31. [Google Scholar]

- Salviato, M.; Kirane, K.; Bažant, Z.P.; Cusatis, G. Mode I and II Interlaminar Fracture in Laminated Composites: A Size Effect Study. J. Appl. Mech. 2019, 86, 1–36. [Google Scholar] [CrossRef]

- Huang, Z.-M.; Li, P. Prediction of Laminate Delamination with No Iteration. Eng. Fract. Mech. 2020, 238, 107248. [Google Scholar] [CrossRef]

- Giannis, S.; Hansen, P.L.; Martin, R.H.; Jones, D.T. Mode I Quasi-Static and Fatigue Delamination Characterisation of Polymer Composites for Wind Turbine Blade Applications. Energy Mater. 2008, 3, 248–256. [Google Scholar] [CrossRef]

- Zarouchas, D.S.; Makris, A.A.; Sayer, F.; Hemelrijck, D.V.; Wingerde, A.M.V. Investigations on the Mechanical Behavior of a Wind Rotor Blade Subcomponent. Compos. Part B Eng. 2012, 43, 647–654. [Google Scholar] [CrossRef]

- Shah, O.R.; Tarfaoui, M. Effect of Adhesive Thickness on the Mode I and II Strain Energy Release Rates. Comparative Study between Different Approaches for the Calculation of Mode I & II SERR’s. Compos. Part B Eng. 2016, 96, 354–363. [Google Scholar] [CrossRef]

- Shah, O.R.; Tarfaoui, M. Determination of Mode I & II Strain Energy Release Rates in Composite Foam Core Sandwiches. An Experimental Study of the Composite Foam Core Interfacial Fracture Resistance. Compos. Part B Eng. 2017, 111, 134–142. [Google Scholar] [CrossRef]

- Al-Khudairi, O.; Ghasemnejad, H. To Improve Failure Resistance in Joint Design of Composite Wind Turbine Blade Materials. Renew. Energy 2015, 81, 936–951. [Google Scholar] [CrossRef]

- Wang, Y.; Soutis, C. Fatigue Behaviour of Composite T-Joints in Wind Turbine Blade Applications. Appl. Compos. Mater. 2016, 24, 461–475. [Google Scholar] [CrossRef]

- Sørensen, B.F.; Jørgensen, K.; Jacobsen, T.K.; Østergaard, R.C. DCB-Specimen Loaded with Uneven Bending Moments. Int. J. Fract. 2006, 141, 163–176. [Google Scholar] [CrossRef]

- Murray, R.E.; Roadman, J.; Beach, R. Fusion Joining of Thermoplastic Composite Wind Turbine Blades: Lap-Shear Bond Characterization. Renew. Energy 2019, 140, 501–512. [Google Scholar] [CrossRef]

- Boyano, A.; Mollón, V.; Bonhomme, J.; Gracia, J.D.; Arrese, A.; Mujika, F. Analytical and Numerical Approach of an End Notched Flexure Test Configuration with an Inserted Roller for Promoting Mixed Mode I/II. Eng. Fract. Mech. 2015, 143, 63–79. [Google Scholar] [CrossRef]

- Anderson, T.L.; Anderson, T.L. Fracture Mechanics: Fundamentals and Applications; CRC Press: Boca Raton, FL, USA, 2005. [Google Scholar]

- Kaw, A.K. Mechanics of Composite Materials; CRC Press: Boca Raton, FL, USA, 1997; ISBN 0-8493-9656-5. [Google Scholar]

- Boyano, A.; Ansoategui, I.; Fernandez-Gamiz, U.; Zulueta, E.; Lopez-Guede, J.M.; Mujika, F. One Application of the ENFR Fracture Test: Coupon Testing for Wind Turbine Blade Materials. Int. J. Mech. Eng. 2017, 2, 51–57. [Google Scholar]

- Sayer, F.; Antoniou, A.; van Wingerde, A. Investigation of Structural Bond Lines in Wind Turbine Blades by Sub-Component Tests. Int. J. Adhes. Adhes. 2012, 37, 129–135. [Google Scholar] [CrossRef]

- ASTM D7905/D7905M-14. Standard Test Method for Determination of the Mode II Interlaminar Fracture Toughness of Unidirectional Fiber-Reinforced Polymer Matrix Composites; ASTM International: West Conshohocken, PA, USA, 2014. [Google Scholar]

- Reeder, J. An Evaluation of Mixed-Mode Delamination Failure Criteria; National Aeronautics and Space Administration: Hampton, VA, USA, 1992.

- Camanho, P.P.; Davila, C.G.; De Moura, M. Numerical Simulation of Mixed-Mode Progressive Delamination in Composite Materials. J. Compos. Mater. 2003, 37, 1415–1438. [Google Scholar] [CrossRef]

- Mujika, F. On the Effect of Shear and Local Deformation in Three-Point Bending Tests. Polym. Test. 2007, 26, 869–877. [Google Scholar] [CrossRef]

- ISO 14125: 1998 (E). Fibre Reinforced Plastic Composites—Determination of Flexural Properties; ISO: Geneva, Switzerland, 1998. [Google Scholar]

- Arrese, A.; Insausti, N.; Mujika, F.; Perez-Galmés, M.; Renart, J. A Novel Experimental Procedure to Determine the Cohesive Law in ENF Tests. Compos. Sci. Technol. 2019, 170, 42–50. [Google Scholar] [CrossRef]

- Arrese, A.; Carbajal, N.; Vargas, G.; Mujika, F. A New Method for Determining Mode II R-Curve by the End-Notched Flexure Test. Eng. Fract. Mech. 2010, 77, 51–70. [Google Scholar] [CrossRef]

- Gracia, J.D.; Boyano, A.; Arrese, A.; Mujika, F. A New Approach for Determining the R-Curve in DCB Tests without Optical Measurements. Eng. Fract. Mech. 2015, 135, 274–285. [Google Scholar] [CrossRef]

- Walpole, R.E.; Myers, R.H.; Myers, S.L.; Ye, K.E. Probability & Statistics for Engineers & Scientists, 9th ed.; Pearson Education: London, UK, 2012; ISBN 978-607-32-1417-9. [Google Scholar]

- Ebrahimnezhad-Khaljiri, H.; Eslami-Farsani, R.; Khosravi, H.; Shahrabi-Farahani, A. Improving the Flexural Properties of E-Glass Fibers/Epoxy Isogrid Stiffened Composites through Addition of 3-Glycidoxypropyltrimethoxysilane Functionalized Nanoclay. Silicon 2020, 12, 2515–2523. [Google Scholar] [CrossRef]

| Test Number | Crack Length a (mm) | Roller Radius R (mm) | Roller Position c (mm) | Initial GII/G (%) |

|---|---|---|---|---|

| 1 | 40 | 1 | 5 | 65 |

| 2 | 42 | 0.9 | 8 | 65 |

| 3 | 43 | 0.9 | 8 | 66 |

| 4 | 41 | 1 | 5 | 66 |

| 5 | 42 | 1.5 | 0 | 67 |

| 6 | 43 | 0.9 | 8 | 67 |

| 7 | 41 | 1 | 5 | 68 |

| 8 | 42 | 1.5 | 0 | 68 |

| 9 | 45 | 1 | 8 | 68 |

| 10 | 40 | 1.25 | 0 | 71 |

| 11 | 43 | 1.5 | 0 | 72 |

| 12 | 45 | 1.5 | 0 | 74 |

| 13 | 46 | 1.5 | 0 | 77 |

| 14 | 47 | 1.5 | 0 | 77 |

| 15 | 40 | 0.5 | 10 | 79 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Boyano, A.; Lopez-Guede, J.M.; Torre-Tojal, L.; Fernandez-Gamiz, U.; Zulueta, E.; Mujika, F. Delamination Fracture Behavior of Unidirectional Carbon Reinforced Composites Applied to Wind Turbine Blades. Materials 2021, 14, 593. https://doi.org/10.3390/ma14030593

Boyano A, Lopez-Guede JM, Torre-Tojal L, Fernandez-Gamiz U, Zulueta E, Mujika F. Delamination Fracture Behavior of Unidirectional Carbon Reinforced Composites Applied to Wind Turbine Blades. Materials. 2021; 14(3):593. https://doi.org/10.3390/ma14030593

Chicago/Turabian StyleBoyano, Ana, Jose Manuel Lopez-Guede, Leyre Torre-Tojal, Unai Fernandez-Gamiz, Ekaitz Zulueta, and Faustino Mujika. 2021. "Delamination Fracture Behavior of Unidirectional Carbon Reinforced Composites Applied to Wind Turbine Blades" Materials 14, no. 3: 593. https://doi.org/10.3390/ma14030593

APA StyleBoyano, A., Lopez-Guede, J. M., Torre-Tojal, L., Fernandez-Gamiz, U., Zulueta, E., & Mujika, F. (2021). Delamination Fracture Behavior of Unidirectional Carbon Reinforced Composites Applied to Wind Turbine Blades. Materials, 14(3), 593. https://doi.org/10.3390/ma14030593