Spectroscopic Ellipsometry Characterization of As-Deposited and Annealed Non-Stoichiometric Indium Zinc Tin Oxide Thin Film

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

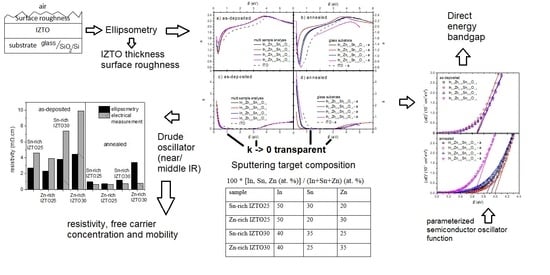

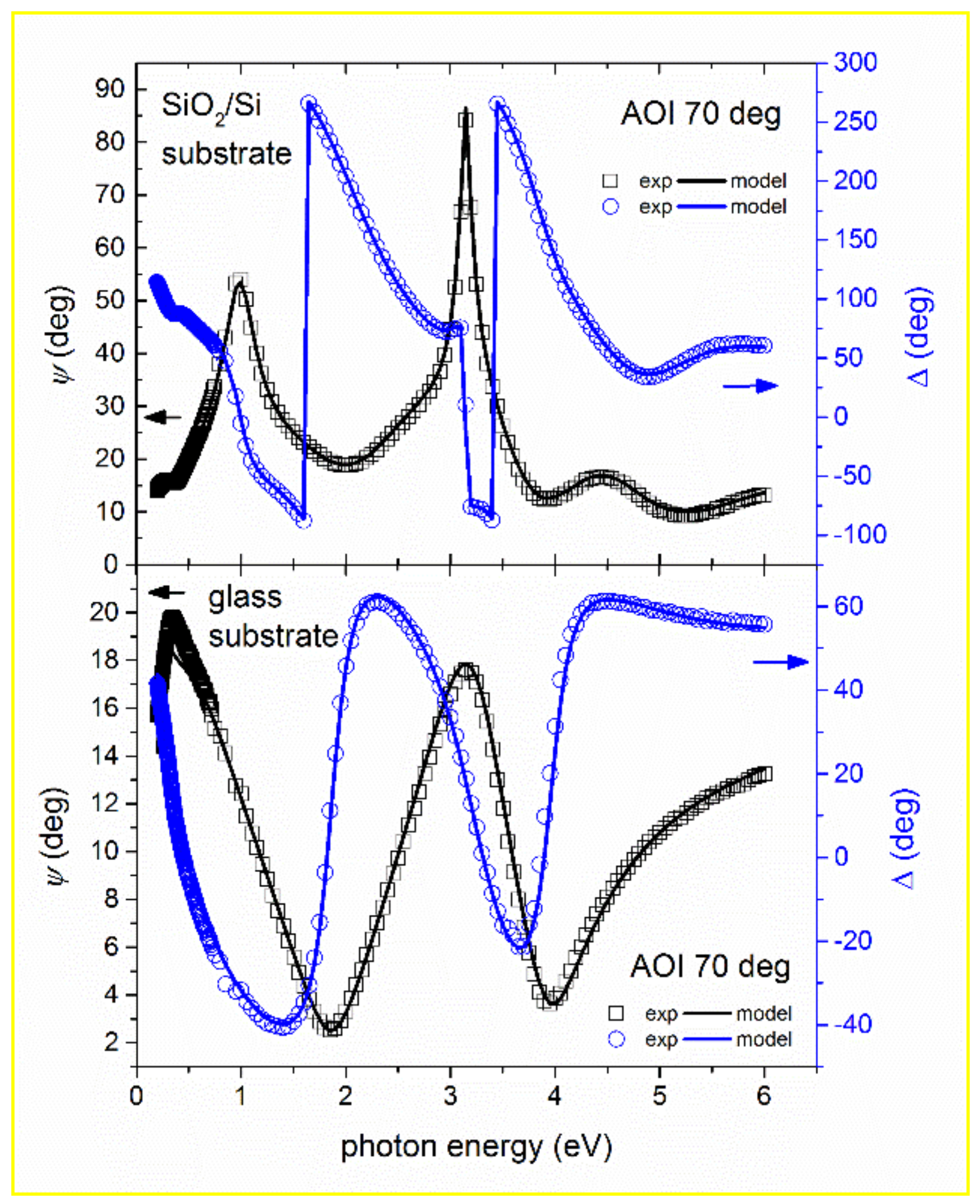

3.1. Structure Model and Model Dielectric Function

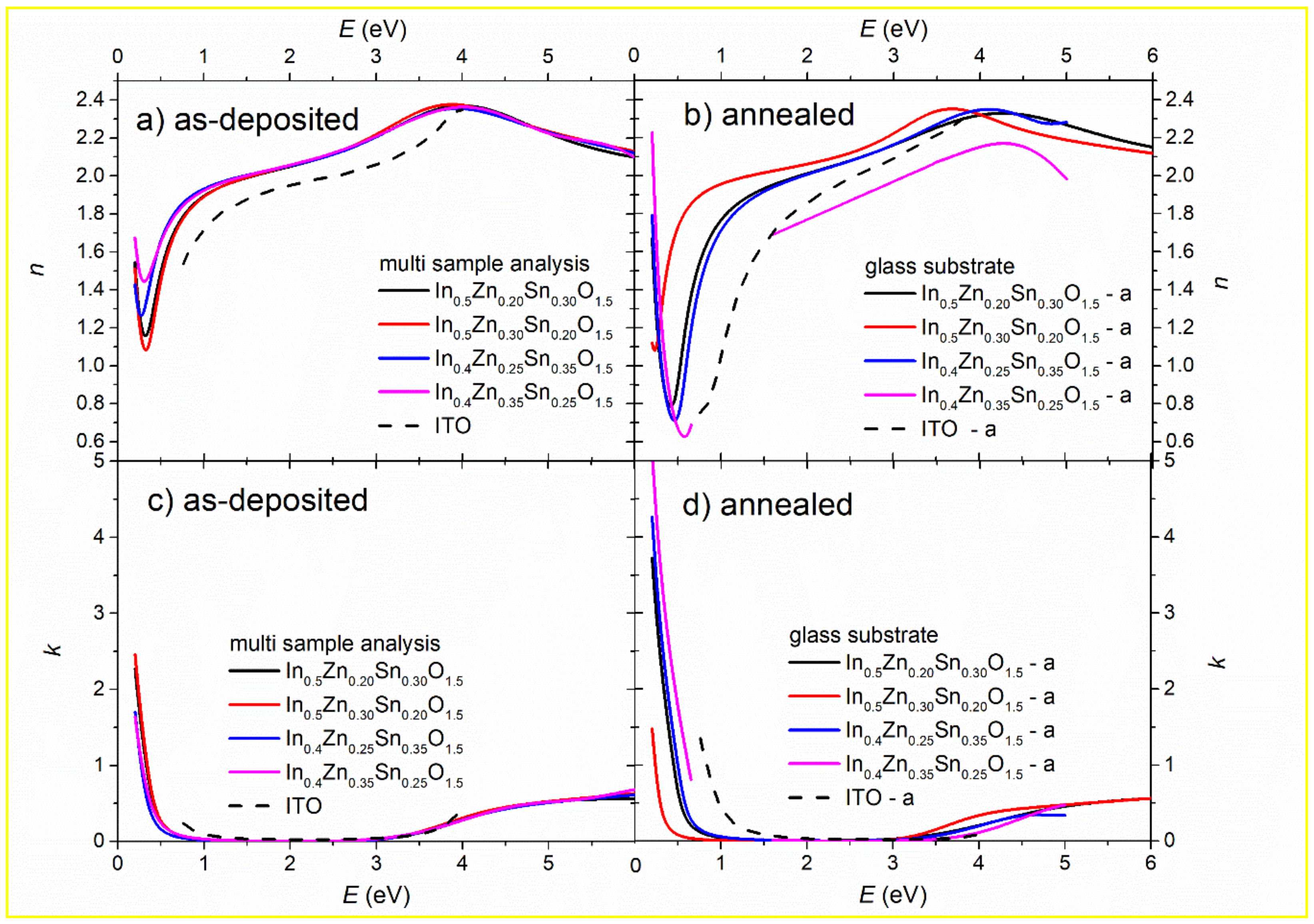

3.2. Optical Constants of Non-Stoichiometric IZTO in Wide Spectral Range

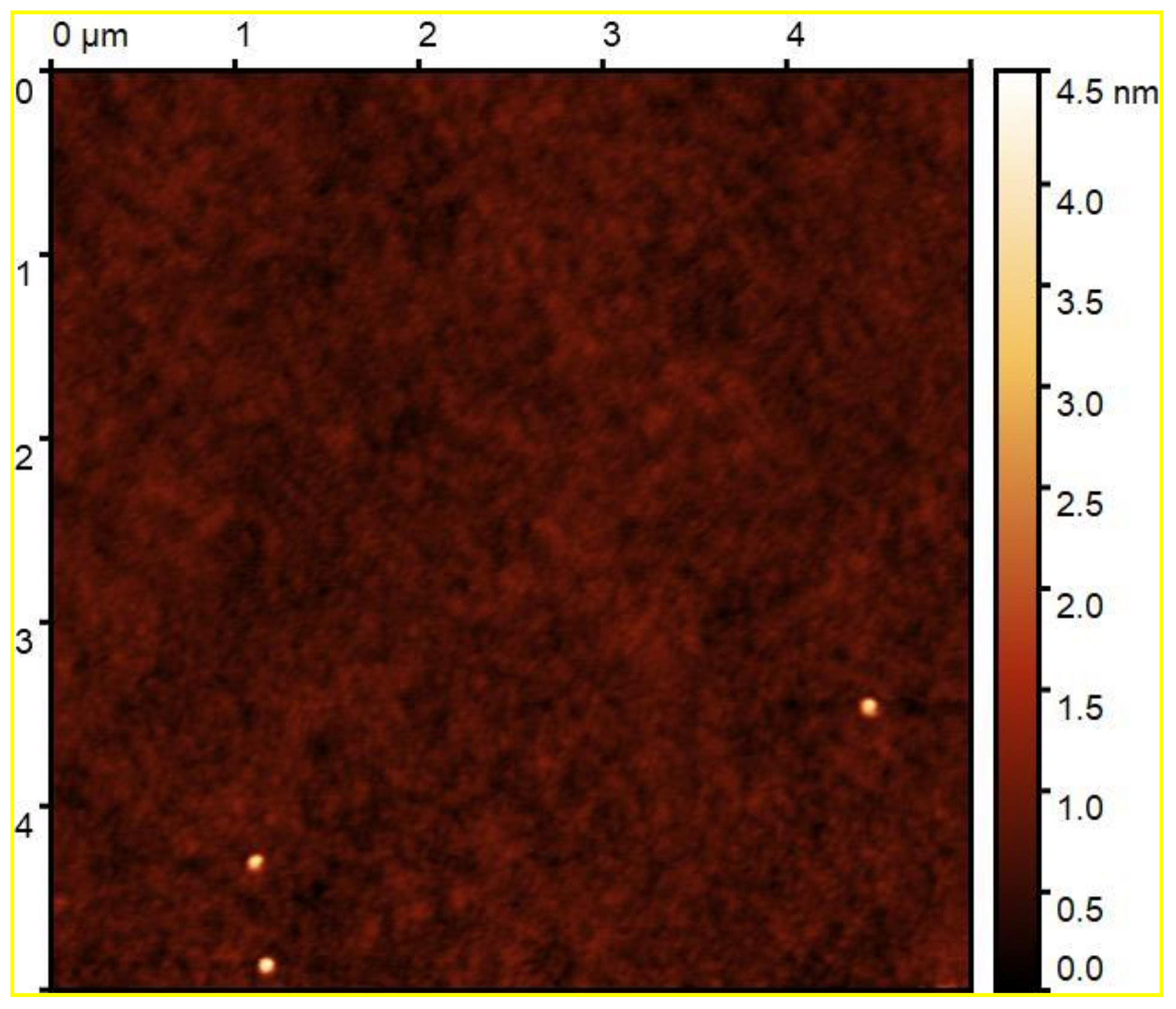

3.3. Film Thickness and Surface Roughness

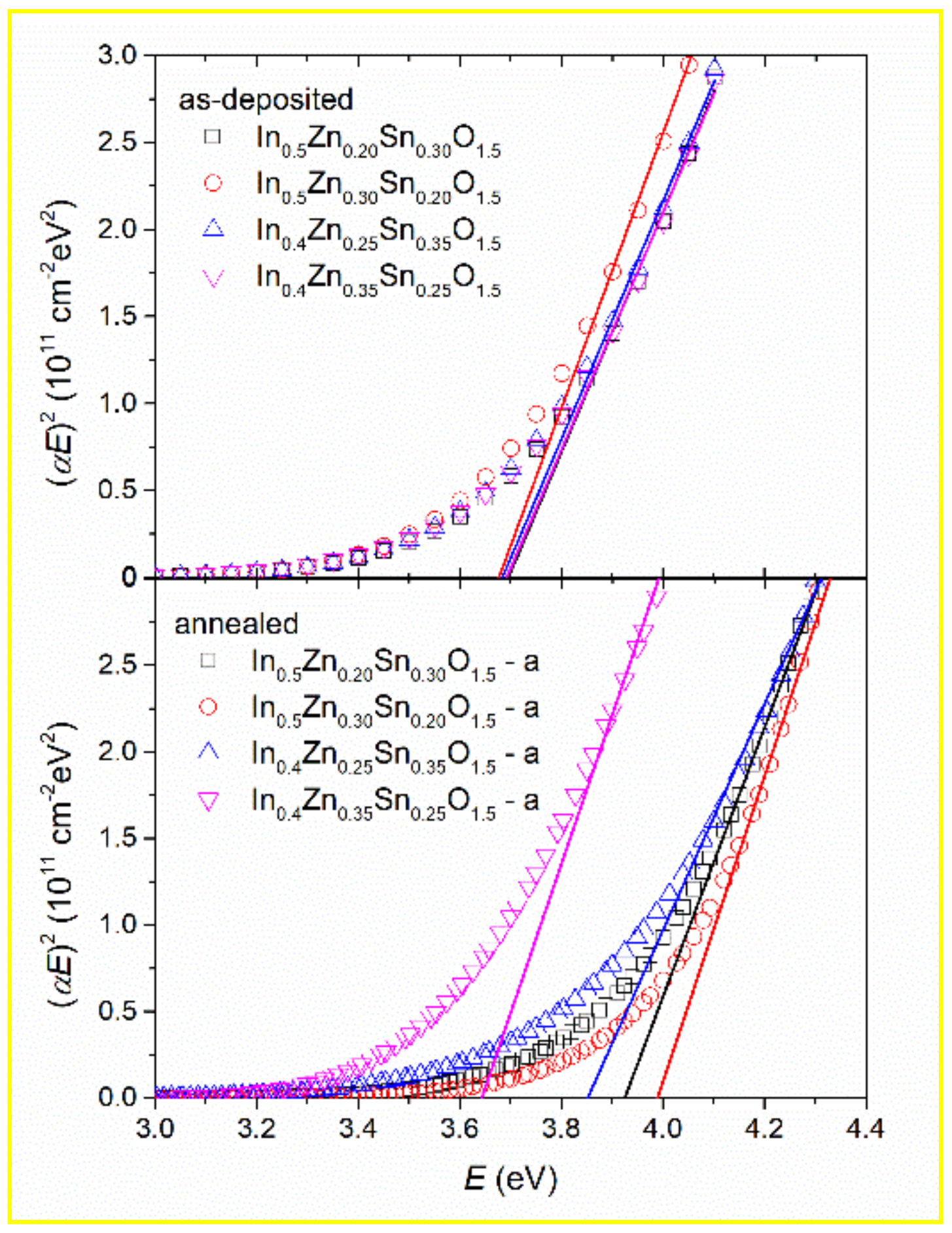

3.4. Determination of Optical Bandgap

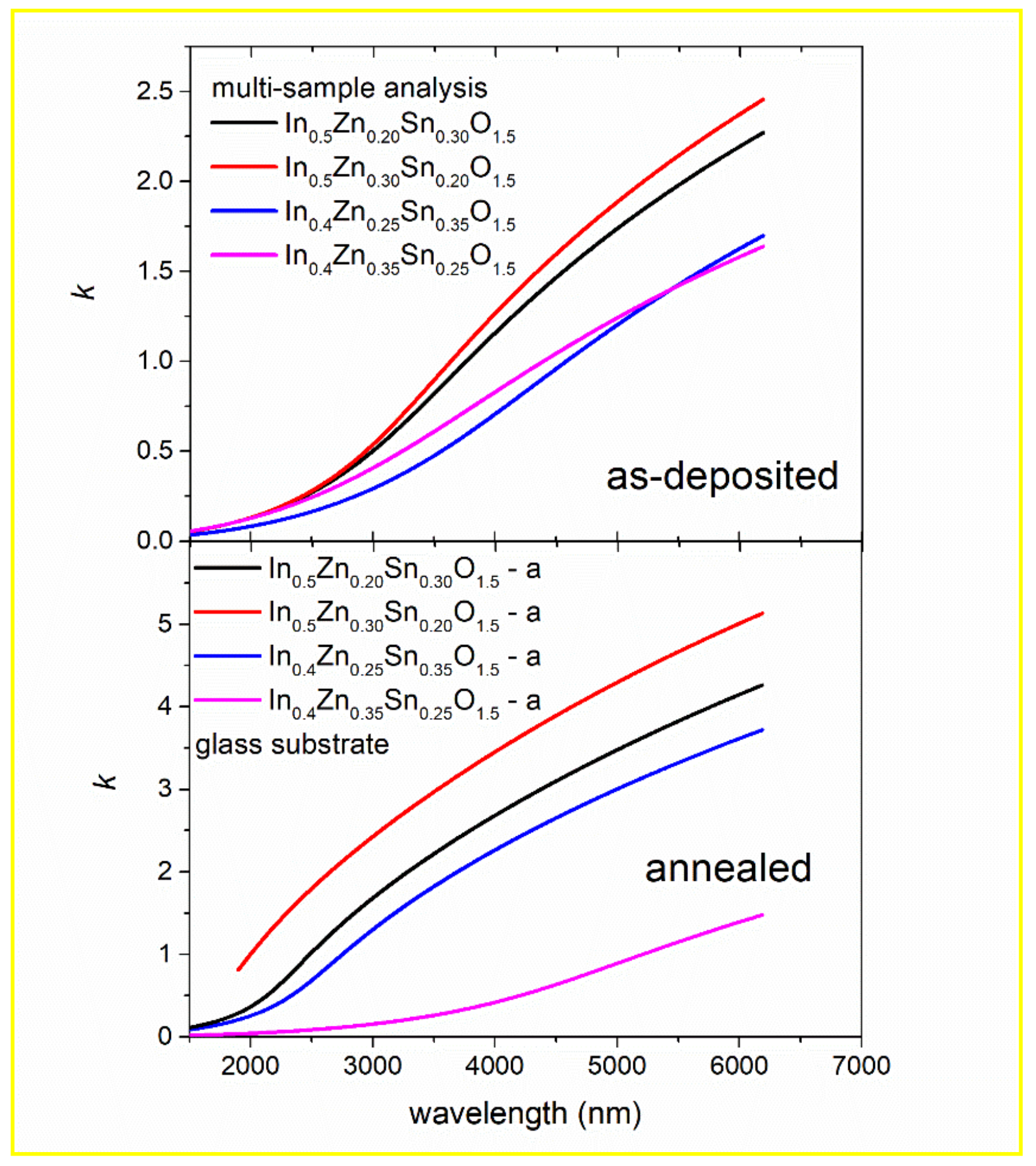

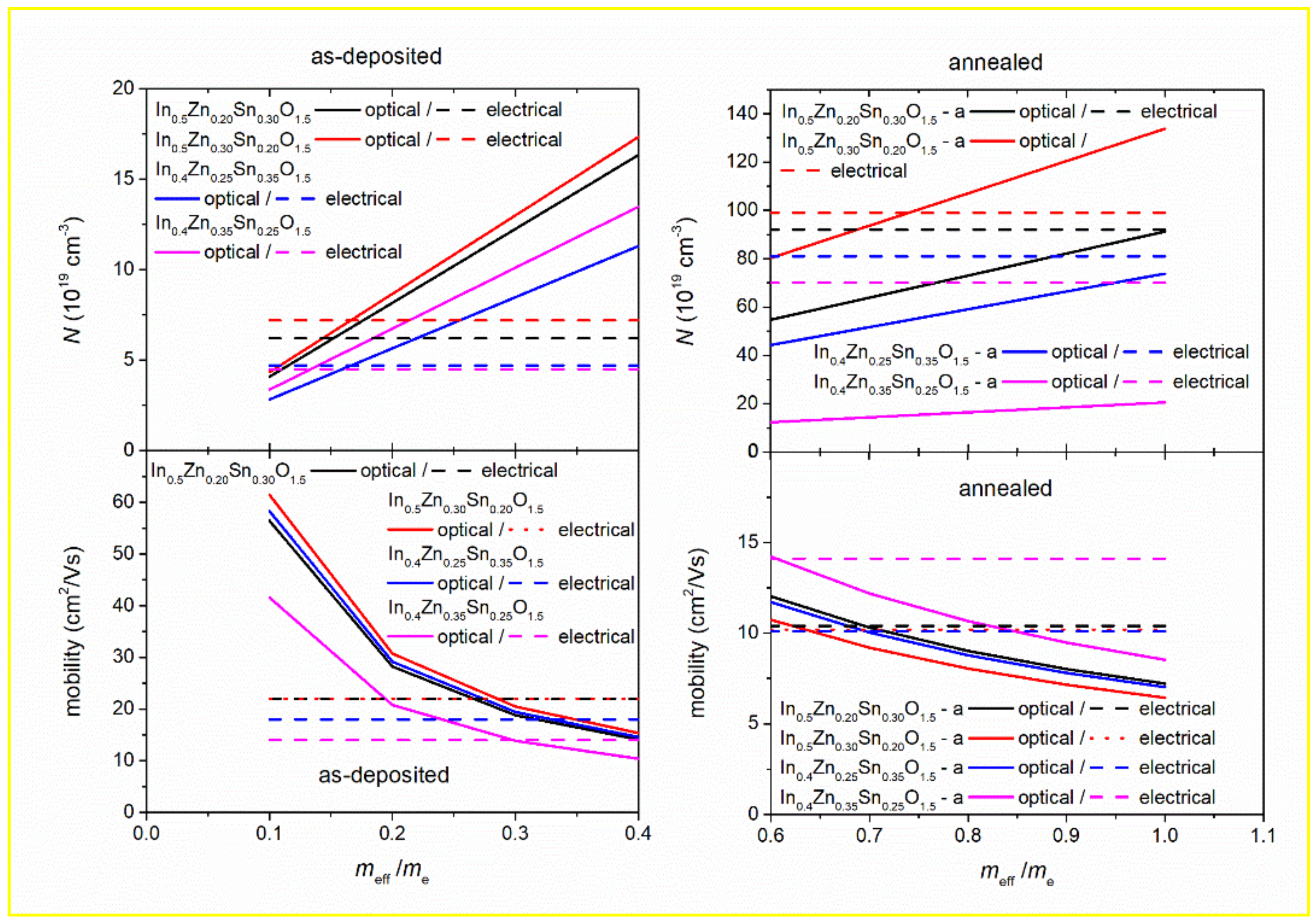

3.5. Free Electron Absorption in the NIR Part of Spectra

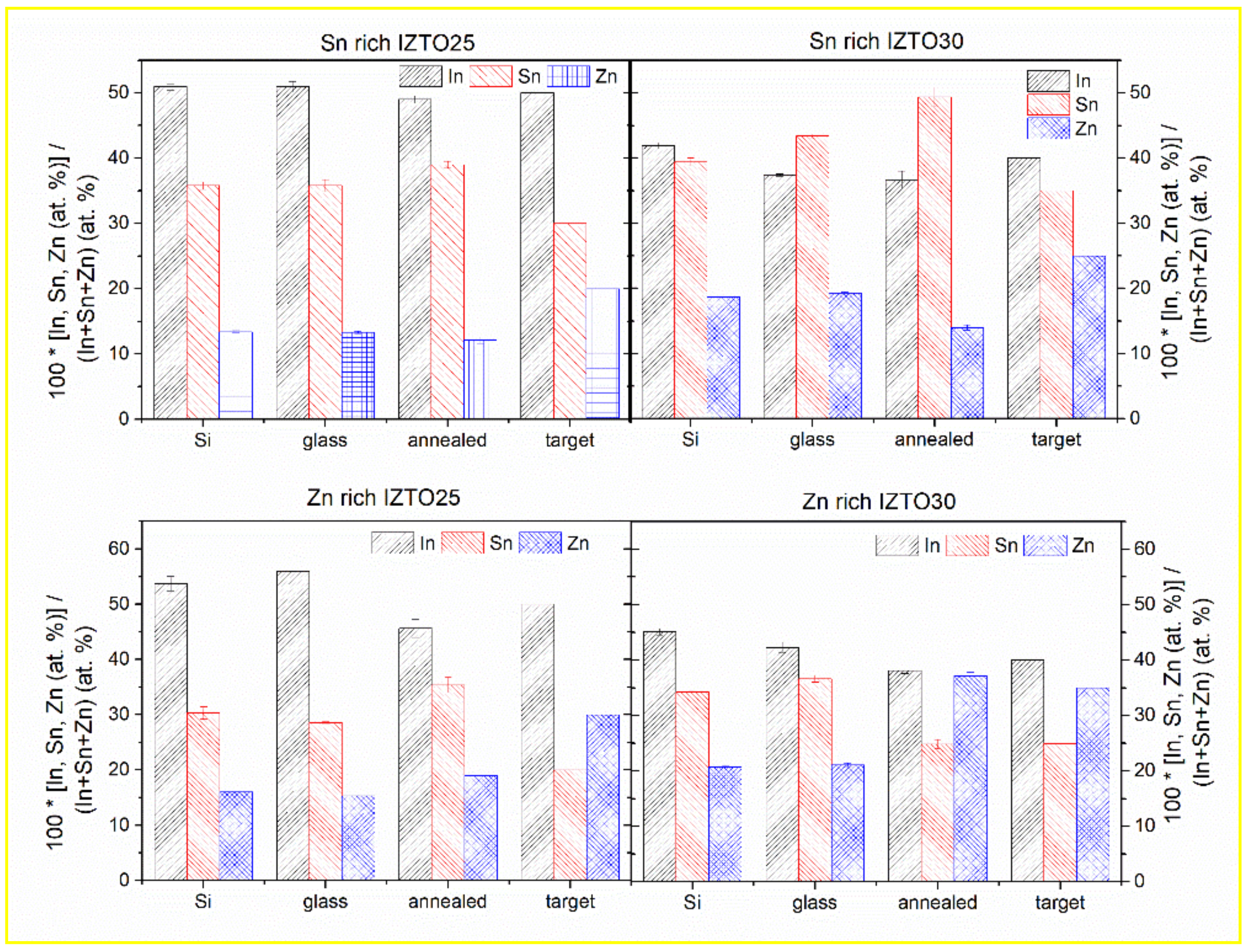

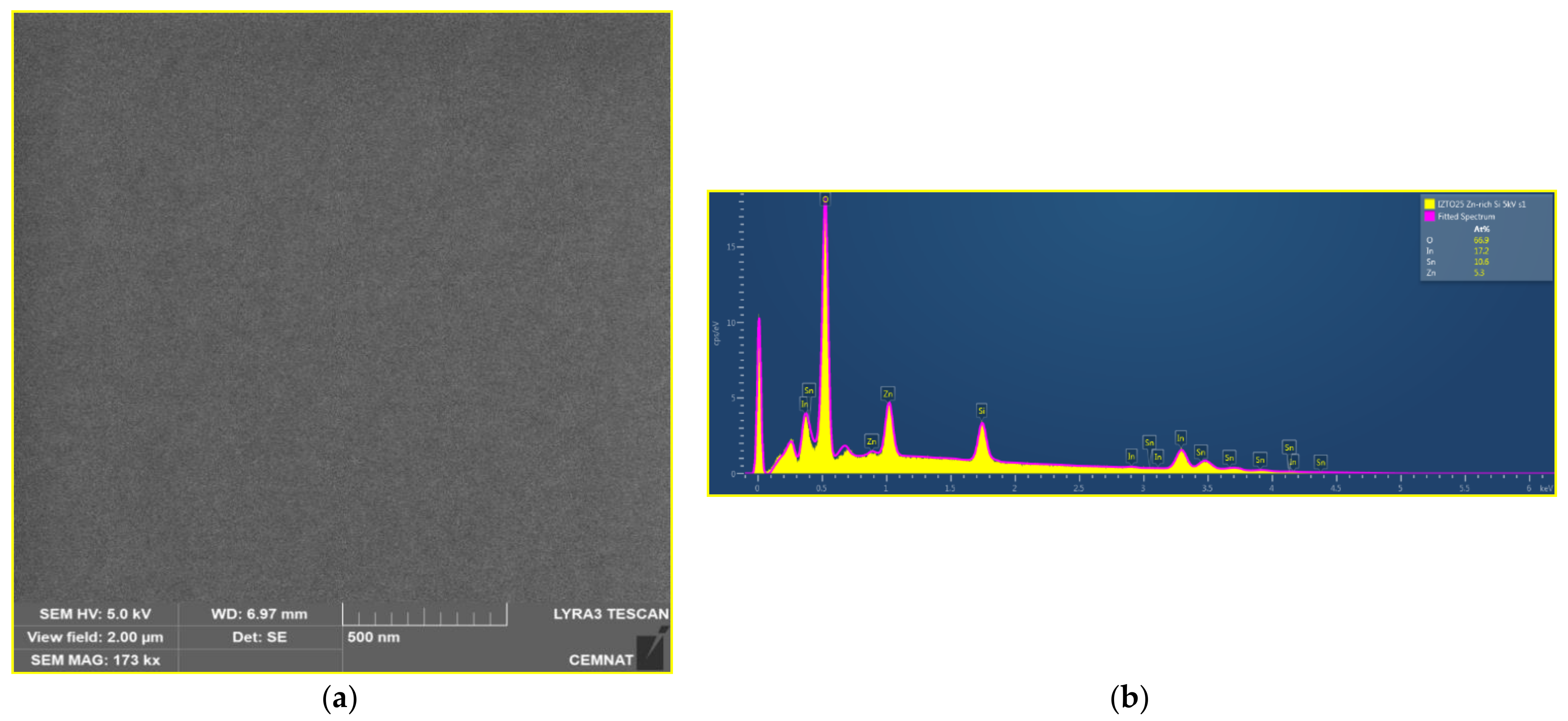

3.6. Results from SEM

4. Conclusions

- The thickness of the studied films, as well as surface roughness, was determined.

- The specific electrical resistivity calculated by using a simple Drude oscillator in the near–mid-infrared part of spectra agreed well with the results obtained from electrical measurements.

- A decrease of electrical resistivity induced by annealing reported earlier was confirmed by electrical, as well as optical, measurements.

- The comparison of free carrier concentration and free carrier mobility obtained using a simple Drude oscillator and the results from electrical measurement suggests an increase of effective mass induced by annealing.

- The shift of direct energy bandgap estimated from the Tauc plot due to the change of free carrier concentration was observed, i.e., the Moss–Burstein effect, which was even more pronounced for annealed samples.

- The negligible influence of a different substrate on thickness, surface roughness, refractive index, and extinction coefficient for as-deposited non-stoichiometric IZTO films was found, suggesting very good repeatability of the sputtering process.

- The negligible extinction coefficient and the similarity of the refractive index for the visible part of the spectrum allow the utilization of as-deposited non-stoichiometric IZTO films and hence the decrease of In content without the substantial change of the optical properties.

- The change of the refractive index of non-stoichiometric IZTO layers after annealing does not significantly influence their high transparency, and a wide transparent window of non-stoichiometric IZTO layers is preserved after annealing.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lee, J.-A.; Lee, J.-H.; Heo, Y.-W.; Kim, J.-J.; Lee, H.Y. Characteristics of Sn and Zn co-substituted In2O3 thin films prepared by RF magnetron sputtering. Curr. Appl. Phys. 2012, 12, S89–S93. [Google Scholar] [CrossRef]

- Damisih, I.; Ma, H.C.; Finanda, F.; Kim, J.-J.; Lee, H.Y. Effect of Composition on Transparent Conducting Indium Zinc Tin Oxide Thin Films Deposited by RF Magnetron Sputtering. J. Nanoelectron. Optoelectron. 2012, 7, 1–5. [Google Scholar] [CrossRef]

- Ma, H.C.; Damisih, I.; Putri, M.; Cheon, J.H.; Kim, J.H.; Lee, H.Y. The Effect of Post-annealing Treatment on the Characteristics of a Dye-sensitized Solar Cell with an Indium Zinc Tin Oxide Electrode. J. Korean Phys. Soc. 2012, 61, 1994–1999. [Google Scholar] [CrossRef]

- Minami, T. Present status of transparent conducting oxide thin-film development for Indium-Tin-Oxide (ITO) substitutes. Thin Solid Film. 2008, 516, 5822–5828. [Google Scholar] [CrossRef]

- Alam, M.J.; Cameron, D.C. Optical and electrical properties of transparent conductive ITO thin films deposited by sol-gel process. Thin Solid Film. 2000, 377–378, 455–459. [Google Scholar] [CrossRef]

- Badawy, W.A.; Afify, H.H.; Elgiar, E.M. Optical and Photovoltaic Characteristics of In-Modified SnO2 Thin Films. J. Electrochem. Soc. 1990, 137, 1592–1595. [Google Scholar] [CrossRef]

- Kang, M.; Kim, I.; Chu, M.; Kim, S.W.; Ryu, J.-W. Optical Properties of Sputtered Indium-tin-oxide Thin Films. J. Korean Phys. Soc. 2011, 59, 3280–3283. [Google Scholar] [CrossRef]

- Boussoum, O.; Belkaid, M.S.; Renard, C.; Halais, G.; Farhati, F. Effect of the annealing gas and RF power sputtering in the electrical, structural and optical properties of ITO thin films. J. Nano Electron. Phys. 2019, 11, 02010. [Google Scholar] [CrossRef]

- Rasheed, M.; Barillé, R. Optical constants of DC sputtering derived ITO, TiO2 and TiO2:Nb thin films characterized by spectrophotometry and spectroscopic ellipsometry for optoelectronic devices. J. Non-Cryst. Solids 2017, 476, 1–14. [Google Scholar] [CrossRef]

- Tamanai, A.; Dao, T.D.; Sendner, M.; Nagao, T.; Pucci, A. Mid-infrared optical and electrical properties of indium tin oxide films. Phys. Status Solidi A 2017, 214, 1600467. [Google Scholar] [CrossRef]

- Damisih, I.; Ma, H.C.; Yoon, D.J.; Kim, J.-J.; Lee, H.Y. Transparent Conductive Indium Zinc Tin Oxide Thin Films for Solar Cell Applications. J. Nanoelectron. Optoelectron. 2011, 6, 223–229. [Google Scholar] [CrossRef]

- Carreras, P.; Antony, A.; Roldán, R.; Nos, O.; Frigeri, P.A.; Asensi, J.M.; Bertomeu, J. Transparent conducting thin films by co-sputtering of ZnO-ITO targets. Phys. Status Solidi C 2010, 7, 953–956. [Google Scholar] [CrossRef]

- Ko, Y.-D.; Kim, J.-Y.; Joung, H.-C.; Ahn, S.-H.; Jang, K.-S.; Lee, Y.-J.; Yi, J. Low temperature deposited transparent conductive ITO and IZTO films for flat panel display applications. J. Ceram. Process. Res. 2013, 14, 183–187. [Google Scholar]

- Putri, M.; Koo, C.Y.; Lee, J.-A.; Kim, J.-J.; Lee, H.Y. Transparent conducting indium zinc tin oxide thin films with low indium content deposited by radio frequency magnetron sputtering. Thin Solid Film. 2014, 559, 44–48. [Google Scholar] [CrossRef]

- Noviyana, I.; Lestari, A.D.; Putri, M.; Won, M.-S.; Bae, J.-S.; Heo, Y.-W.; Lee, H.Y. High Mobility Thin Film Transistors Based on Amorphous Indium Zinc Tin Oxide. Materials 2017, 10, 702. [Google Scholar] [CrossRef]

- Kim, K.H.; Putri, M.; Lee, H.J.; Koo, C.Y.; Lee, J.-A.; Kim, J.-J.; Lee, H.Y. Non-Stoichiometric Indium Zinc Tin Oxide Thin Films Prepared by RF Magnetron Sputtering. J. Nanoelectron. Optoelectron. 2015, 10, 541–545. [Google Scholar] [CrossRef]

- Putri, M.; Kim, K.H.; Koo, C.Y.; Lee, J.-A.; Kim, J.-J.; Baikie, I.D.; Grain, A.C.; Lee, H.Y. Effect of Annealing Treatment on the Properties of Stoichiometric Indium Zinc Tin Oxide (IZTO) Thin Films. J. Nanoelectron. Optoelectron. 2017, 12, 611–616. [Google Scholar] [CrossRef]

- Lee, H.J.; Noviyana, I.; Koo, C.Y.; Lee, J.-A.; Kim, J.-J.; Lestari, A.D.; Jeong, Y.; Lee, Y.; Lee, H.Y. Organic Photovoltaics with Non-Stoichiometric InZnSnO Thin Film Cathodes. J. Nanosci. Nanotechnol. 2017, 17, 4822–4826. [Google Scholar] [CrossRef]

- Herzinger, C.M.; Johs, B.; McGahan, W.A.; Woollam, J.A.; Paulson, W. Ellipsometric determination of optical constants for silicon and thermally grown silicon dioxide via a multi-sample, multi-wavelength, multi-angle investigation. J. Appl. Phys. 1998, 83, 3323–3336. [Google Scholar] [CrossRef]

- Pujar, P.; Gandla, S.; Singh, M.; Gupta, B.; Tarafder, K.; Gupta, D.; Nohd, Y.-Y.; Mandal, S. Development of low temperature stoichiometric solution combustion derived transparent conductive ternary zinc tin co-doped indium oxide electrodes. RSC Adv. 2017, 7, 48253–48262. [Google Scholar] [CrossRef]

- J.A. Woollam Co. Inc. Guide to Using WVASE32 Software for Spectroscopic Ellipsometry Data Acquisition and Analysis; J.A. Woollam Co. Inc.: Lincoln, NE, USA, 2000. [Google Scholar]

- Ihn, Y.S.; Kim, T.J.; Ghong, T.H.; Kim, Y.D.; Aspnes, D.E.; Kossut, J. Parametric modeling of the dielectric functions of Cd1-xMgxTe alloy films. Thin Solid Film. 2004, 455, 222–227. [Google Scholar] [CrossRef]

- Johs, B.; Herzinger, C.M.; Dinan, J.H.; Cornfeld, A.; Benson, J.D. Development of a parametric optical constant model for Hg1-xCdxTe for control of composition by spectroscopic ellipsometry during MBE growth. Thin Solid Film. 1998, 313, 137–142. [Google Scholar] [CrossRef]

- Tiwald, T.E.; Thompson, D.W.; Woollam, J.A.; Paulson, W.; Hance, R. Application of IR variable angle spectroscopic ellipsometry to the determination of free carrier concentration depth profiles. Thin Solid Film. 1998, 313, 661–666. [Google Scholar] [CrossRef]

- Bruggeman, D.A.G. Berechnung verschiedener physikalischer Konstanten von heterogenen Substanzen. I. Dielektrizitätskonstanten und Leitfähigkeiten der Mischkörper aus isotropen Substanzen. Ann. Phys. 1935, 24, 636–664. [Google Scholar] [CrossRef]

- Janicek, P.; Niang, K.M.; Mistrik, J.; Palka, K.; Flewitt, A.J. Spectroscopic ellipsometry characterization of ZnO:Sn thin films with various Sn composition deposited by remote-plasma reactive sputtering. Appl. Surf. Sci. 2017, 421, 557–564. [Google Scholar] [CrossRef]

- Janicek, P.; Slang, S.; Palka, K.; Vlcek, M. Spectroscopic ellipsometry characterization of spin-coated Ge25S75 chalcogenide thin films. Pure Appl. Chem. 2017, 89, 437–449. [Google Scholar] [CrossRef]

- Tauc, J. (Ed.) Amorphous and Liquid Semiconductors; Plenum Press: New York, NY, USA, 1974. [Google Scholar]

- Burstein, E. Anomalous Optical Absorption Limit in InSb. Phys. Rev. 1954, 93, 632. [Google Scholar] [CrossRef]

- Moss, T.S. The Interpretation of the Properties of Indium Antimonide. Proc. Phys. Soc. 1954, B76, 775–782. [Google Scholar] [CrossRef]

- Lu, Y.-B.; Li, Y.H.; Ling, Z.C.; Cong, W.-Y.; Zhang, P.; Xin, Y.Q.; Yang, T.L. Geometric, electronic and optical properties of zinc/tin codoped In2O3 modulated by the bixbyite/corundum phase transition. J. Phys. D Appl. Phys. 2016, 49, 065105. [Google Scholar] [CrossRef]

- Han, Y.; Kim, D.; Cho, J.-S.; Koh, S.-K.; Song, Y.S. Tin-doped indium oxide (ITO) film deposition by ion beam sputtering. Sol. Energy Mater. Sol. Cells 2001, 65, 211–218. [Google Scholar] [CrossRef]

| Sample | Thickness of Samples (on Glass) (nm) | Thickness of Samples (on Si) (nm) | Surface Roughness (on Glass) (nm) | Surface Roughness (on Si) (nm) | MSE Glass/Si Substrate | AFM Surface Roughness Glass/Si Substrate (nm) |

|---|---|---|---|---|---|---|

| In0.5Zn0.20Sn0.30O1.5 (Sn-rich IZTO25) | (88.3 ± 0.3) 1 (1224 ± 2) 2 | (88.5 ± 0.2) 1 | (4.9 ± 0.3) 1 (9.9 ± 0.3) 2 | (2.6 ± 0.3) 1 | (11.2/4.1) 1 (9.9) 2 | (0.10/0.18) 1 (0.38) 2 |

| In0.5Zn0.30Sn0.20O1.5 (Zn-rich IZTO25) | (82.6 ± 0.3) 1 (1074 ± 6) 2 | (83.3 ± 0.3) 1 | (2.3 ± 0.3) 1 (6.6 ± 0.9) 2 | (2.8 ± 0.3) 1 | (10.9/4.3) 1 (35.0) 2 | (0.14/0.13) 1 (1.41) 2 |

| In0.4Zn0.25Sn0.35O1.5 (Sn-rich IZTO30) | (91.2 ± 0.3) 1 (121.1 ± 0.3) 2 | (90.4 ± 0.3) 1 | (1.8 ± 0.3) 1 (3.8 ± 0.3) 2 | (2.1 ± 0.3) 1 | (11.4/3.7) 1 (3.2) 2 | (0.17/0.14) 1 (0.07) 2 |

| In0.4Zn0.35Sn0.25O1.5 (Zn-rich IZTO30) | (79.3 ± 0.3) 1 (149.0 ± 0.3) 2 | (79.9 ± 0.3) 1 | (2.9 ± 0.3) 1 (4.6 ± 0.3) 2 | (2.6 ± 0.3) 1 | (11.0/3.7) 1 (1.6) 2 | (0.25/0.14) 1 (0.11) 2 |

| Sample/Egopt (eV) | As-Deposited/Multi-Sample Analysis | Annealed/Glass Substrate |

|---|---|---|

| In0.5Zn0.20Sn0.30O1.5 (Sn-rich IZTO25) | 3.70 | 3.92 |

| In0.5Zn0.30Sn0.20O1.5 (Zn-rich IZTO25) | 3.68 | 3.95 |

| In0.4Zn0.25Sn0.35O1.5 (Sn-rich IZTO30) | 3.68 | 3.85 |

| In0.4Zn0.35Sn0.25O1.5 (Zn-rich IZTO30) | 3.69 | 3.64 |

| Sample | ADrude (eV) | BDrude (eV) | ρ (mΩ⋅cm) | τ (fs) |

|---|---|---|---|---|

| In0.5Zn0.20Sn0.30O1.5 (Sn-rich IZTO25) | (2.75/2.74) 1 (7.84) 2 | (0.205/0.199) 1 (0.160) 2 | (2.9/2.7) 1 (1.0) 2 | (2.9/3.3) 1 (4.0) 2 |

| In0.5Zn0.30Sn0.20O1.5 (Zn-rich IZTO25) | (3.17/3.25) 1 (10.26) 2 | (0.188/0.186) 1 (0.180) 2 | (2.7/2.3) 1 (0.7) 2 | (3.1/3.5) 1 (3.6) 2 |

| In0.4Zn0.25Sn0.35O1.5 (Sn-rich IZTO30) | (1.96/1.97) 1 (6.18) 2 | (0.199/0.199) 1 (0.165) 2 | (3.8/3.8) 1 (1.2) 2 | (3.3/3.3) 1 (4.0) 2 |

| In0.4Zn0.35Sn0.25O1.5 (Zn-rich IZTO30) | (1.67/1.69) 1 (2.09) 2 | (0.278/0.280) 1 (0.136) 2 | (5.1/4.4) 1 (3.4) 2 | (2.4/2.4) 1 (4.9) 2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Janicek, P.; Putri, M.; Kim, K.H.; Lee, H.J.; Bouska, M.; Šlang, S.; Lee, H.Y. Spectroscopic Ellipsometry Characterization of As-Deposited and Annealed Non-Stoichiometric Indium Zinc Tin Oxide Thin Film. Materials 2021, 14, 578. https://doi.org/10.3390/ma14030578

Janicek P, Putri M, Kim KH, Lee HJ, Bouska M, Šlang S, Lee HY. Spectroscopic Ellipsometry Characterization of As-Deposited and Annealed Non-Stoichiometric Indium Zinc Tin Oxide Thin Film. Materials. 2021; 14(3):578. https://doi.org/10.3390/ma14030578

Chicago/Turabian StyleJanicek, Petr, Maryane Putri, Ki Hwan Kim, Hye Ji Lee, Marek Bouska, Stanislav Šlang, and Hee Young Lee. 2021. "Spectroscopic Ellipsometry Characterization of As-Deposited and Annealed Non-Stoichiometric Indium Zinc Tin Oxide Thin Film" Materials 14, no. 3: 578. https://doi.org/10.3390/ma14030578

APA StyleJanicek, P., Putri, M., Kim, K. H., Lee, H. J., Bouska, M., Šlang, S., & Lee, H. Y. (2021). Spectroscopic Ellipsometry Characterization of As-Deposited and Annealed Non-Stoichiometric Indium Zinc Tin Oxide Thin Film. Materials, 14(3), 578. https://doi.org/10.3390/ma14030578