Warsaw Glacial Quartz Sand with Different Grain-Size Characteristics and Its Shear Wave Velocity from Various Interpretation Methods of BET

Abstract

1. Introduction

- the characteristics of received signals in both the time and frequency domains over a wide range of excitation frequencies and wavelengths;

- how changes of particle size alter the characteristics of received signals;

- the performance of different interpretation methods under a variety of combinations of test; and

- conditions (i.e., grain size, excitation frequency, and confining stress).

2. Materials and Methods

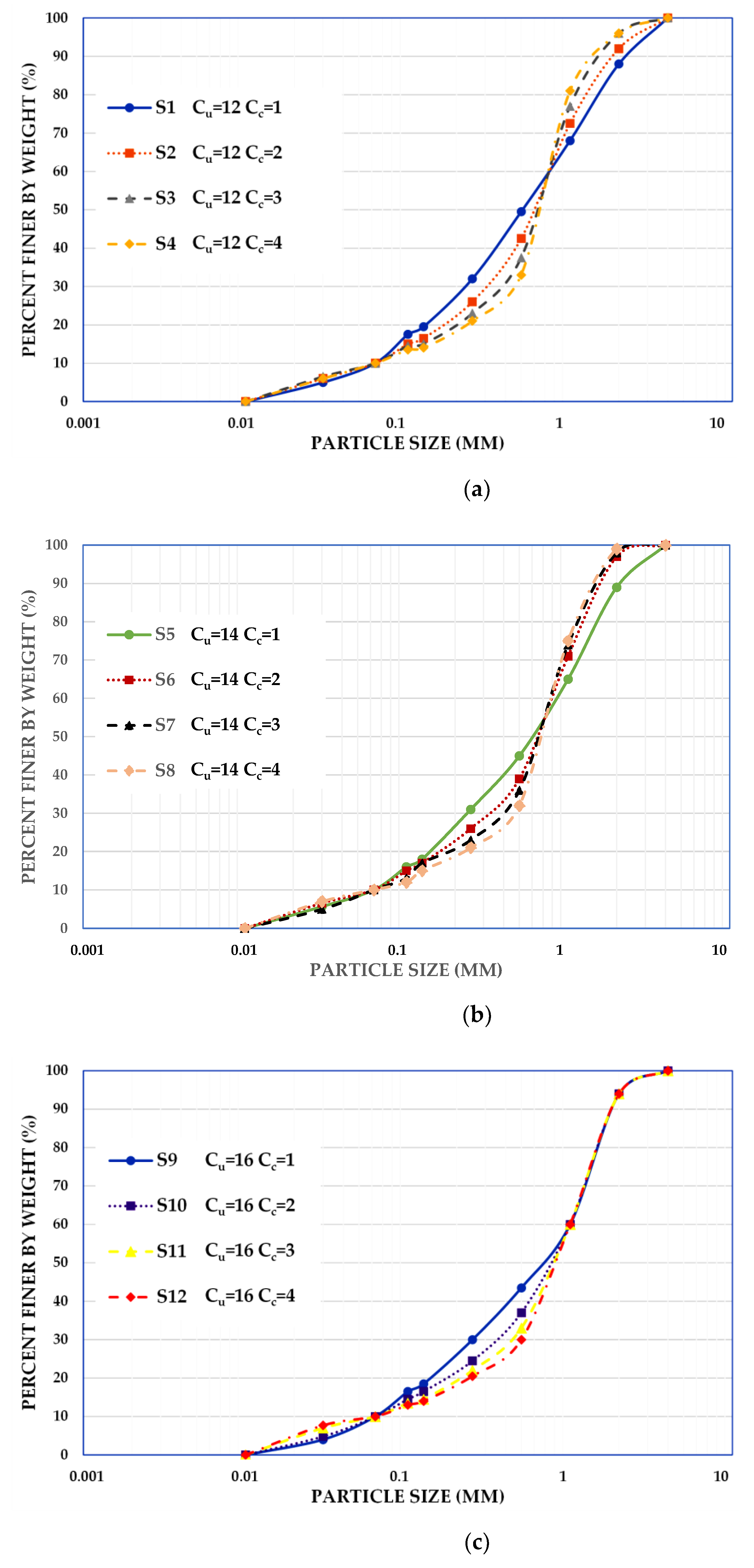

2.1. Characterization of Materials Used

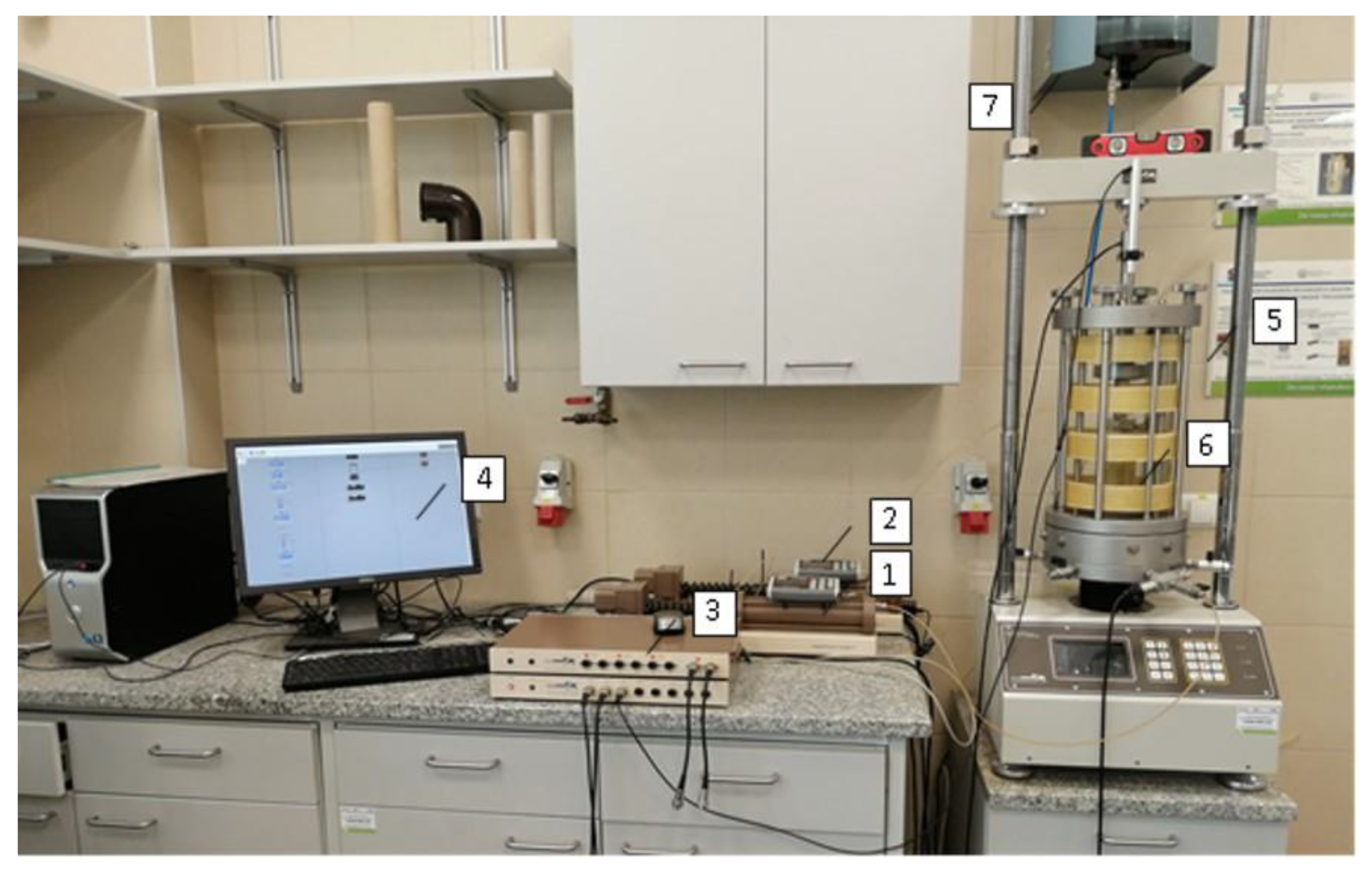

2.2. Experimental Equipment, Specimens Preparation, and Testing Program

3. Experimental Results and Discussion

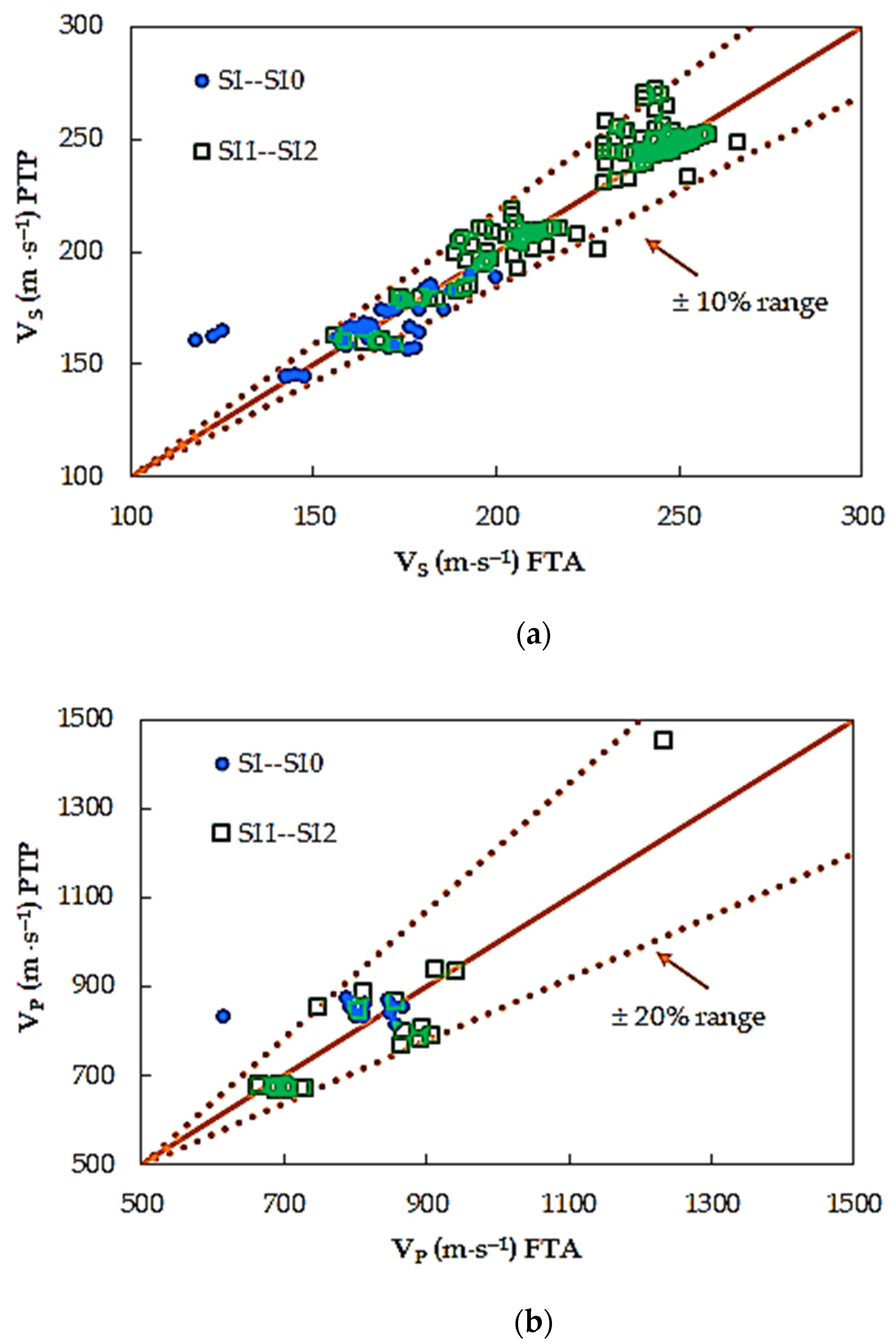

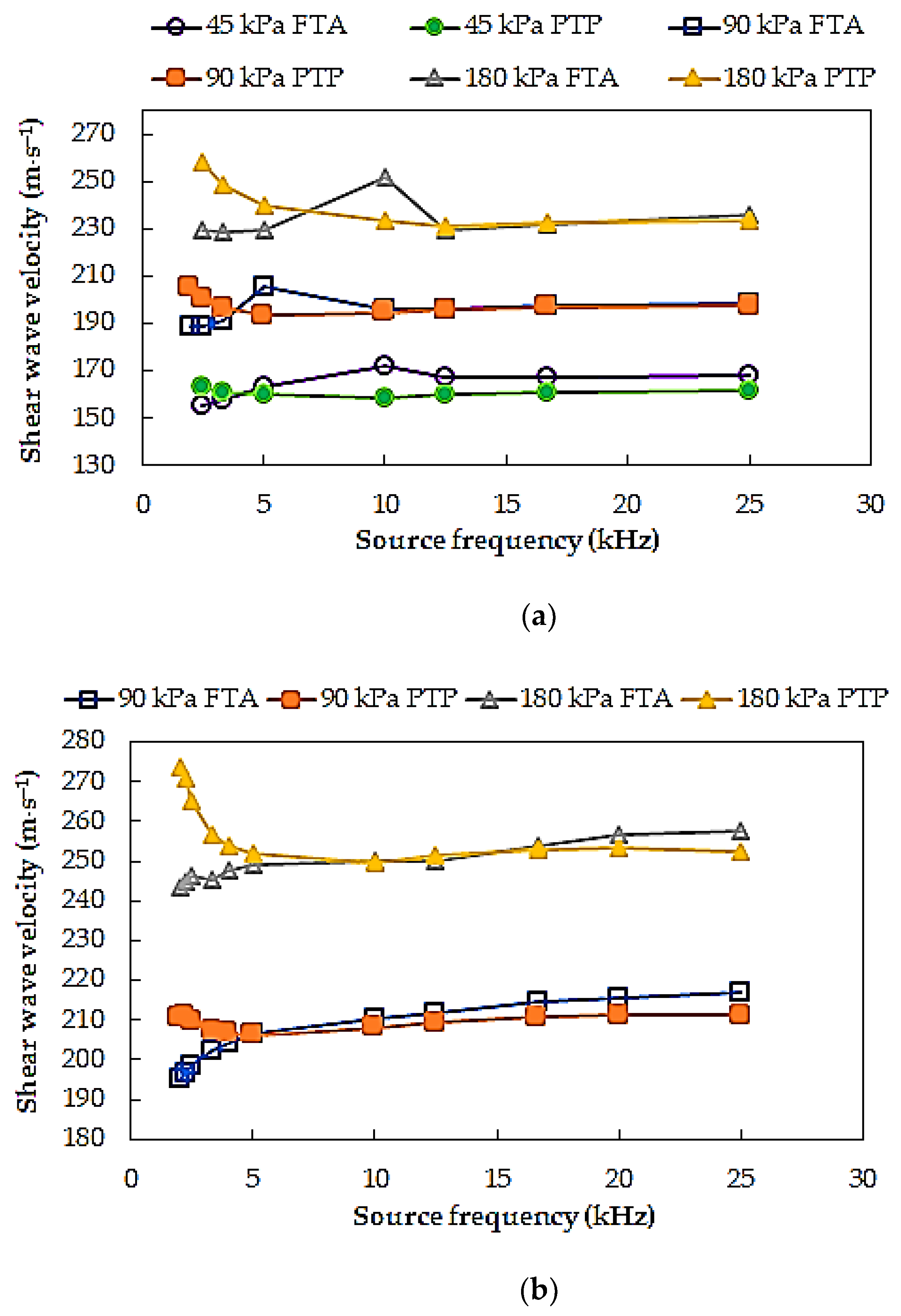

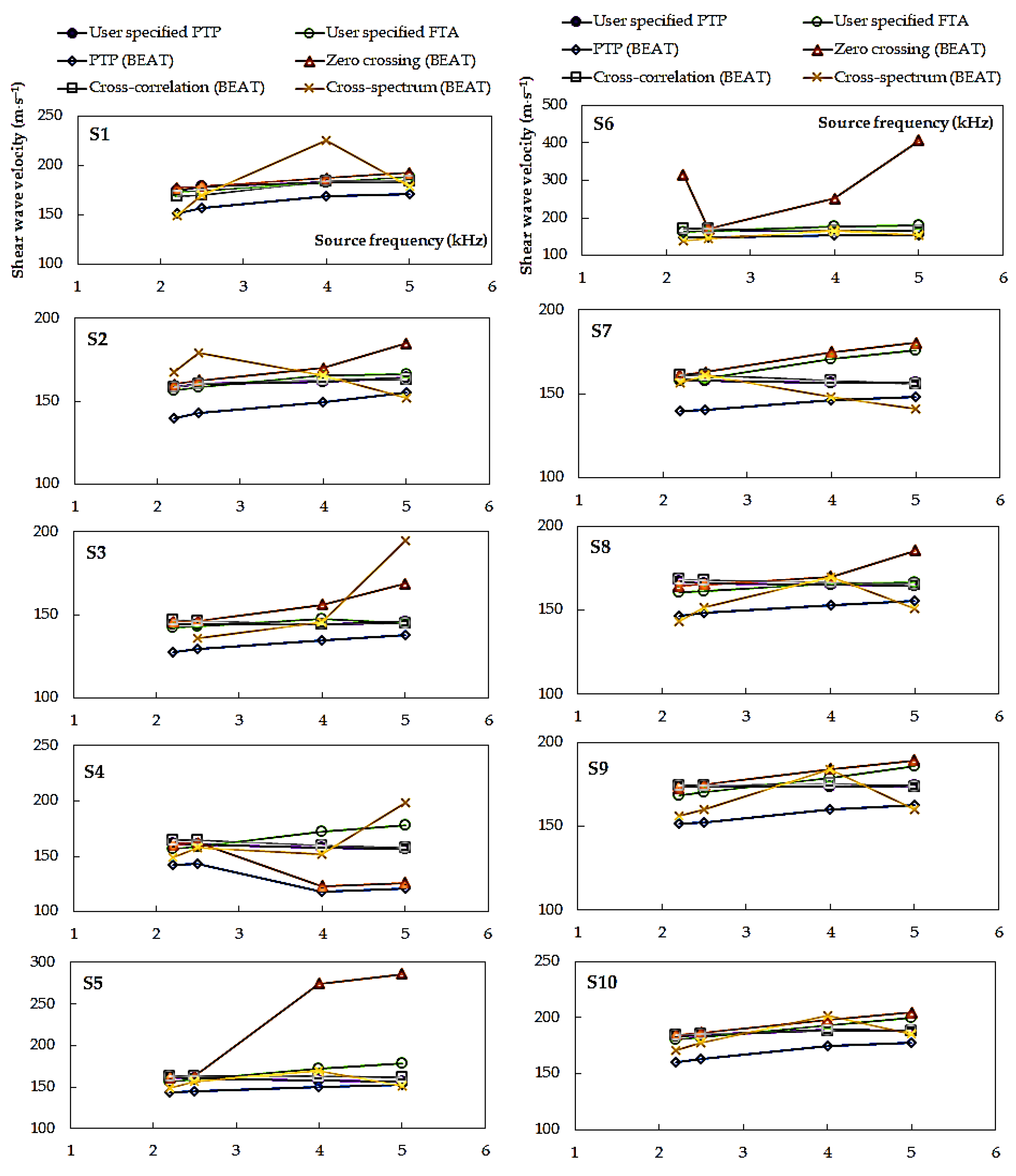

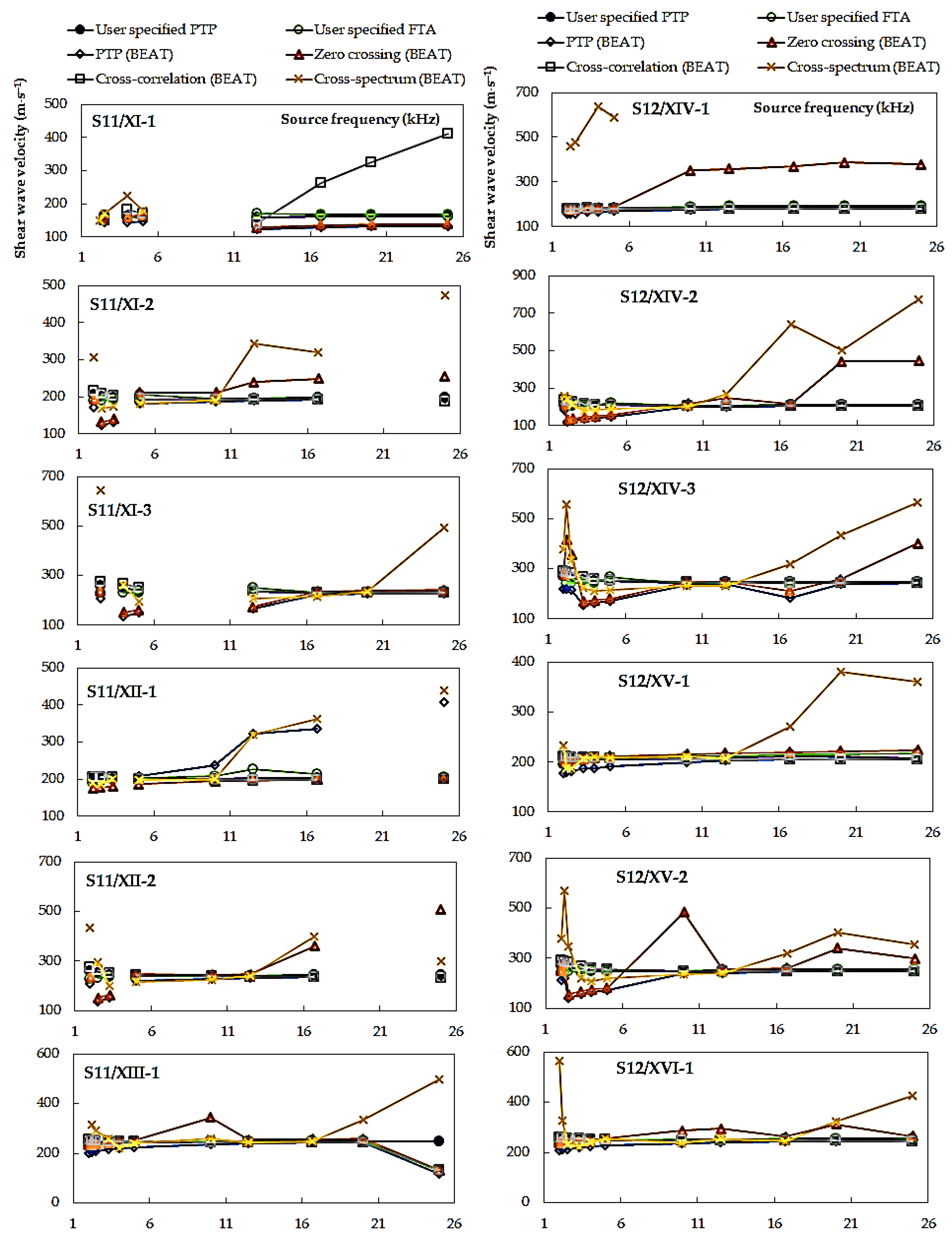

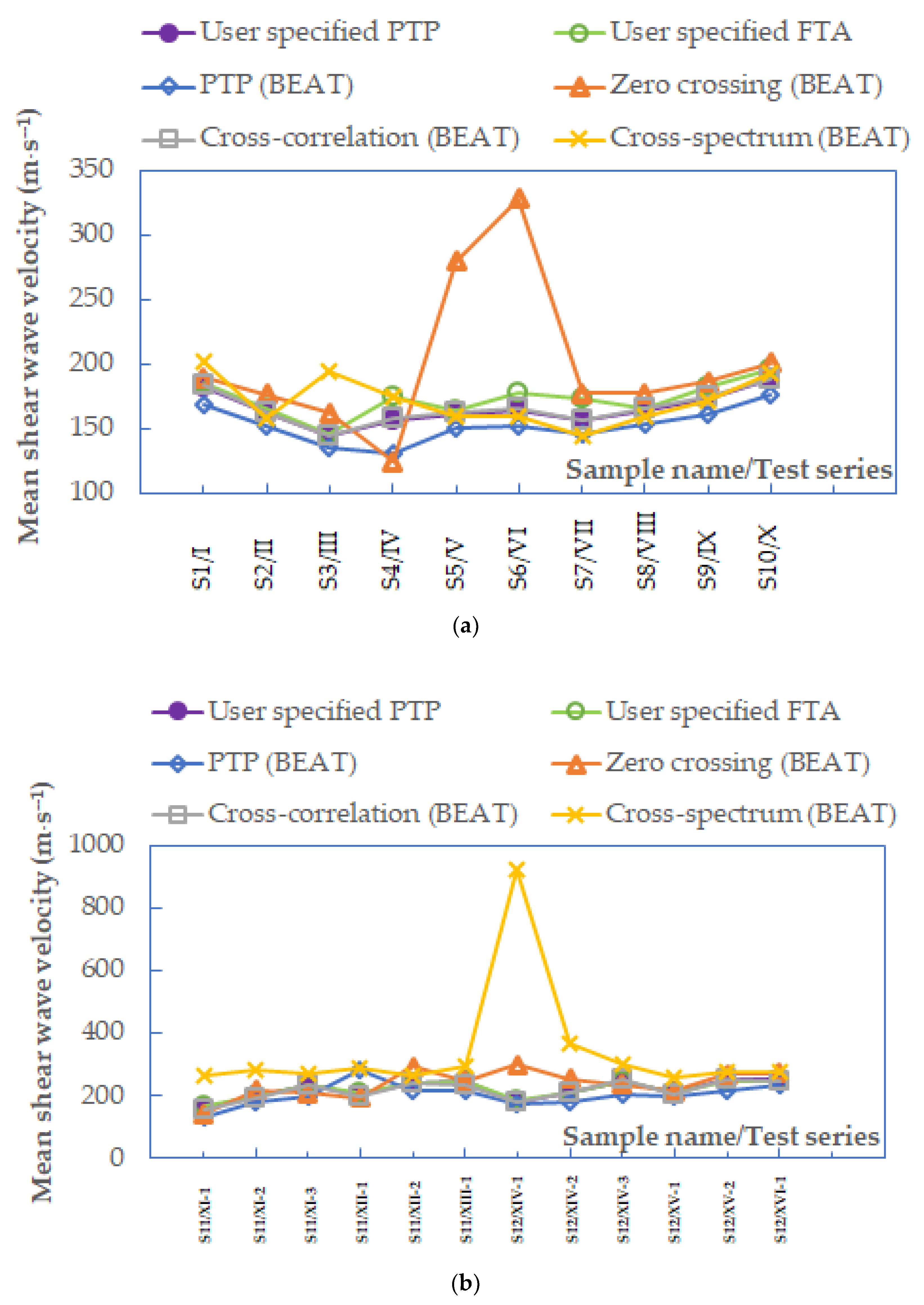

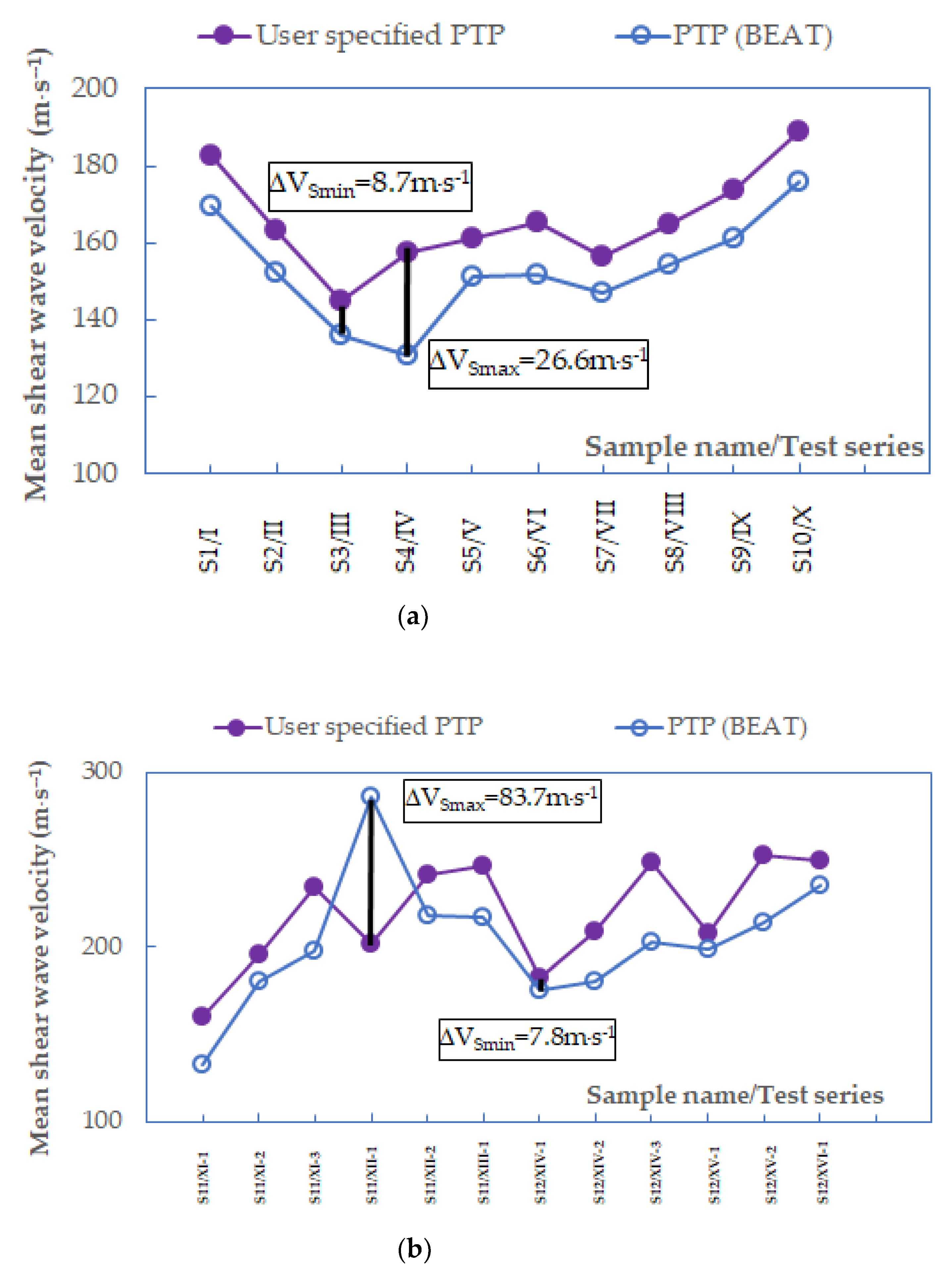

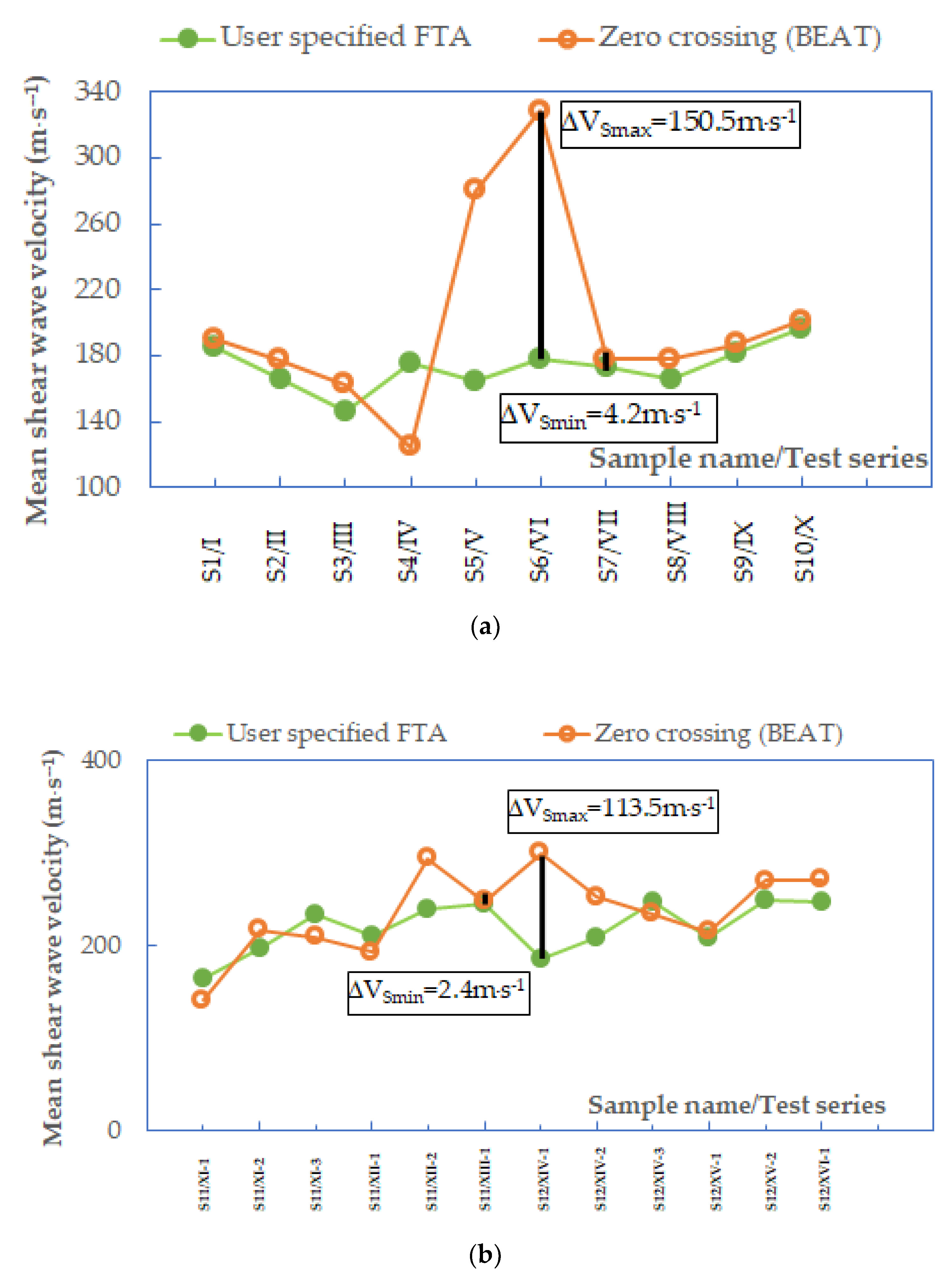

3.1. Synopsis of Experimental Results

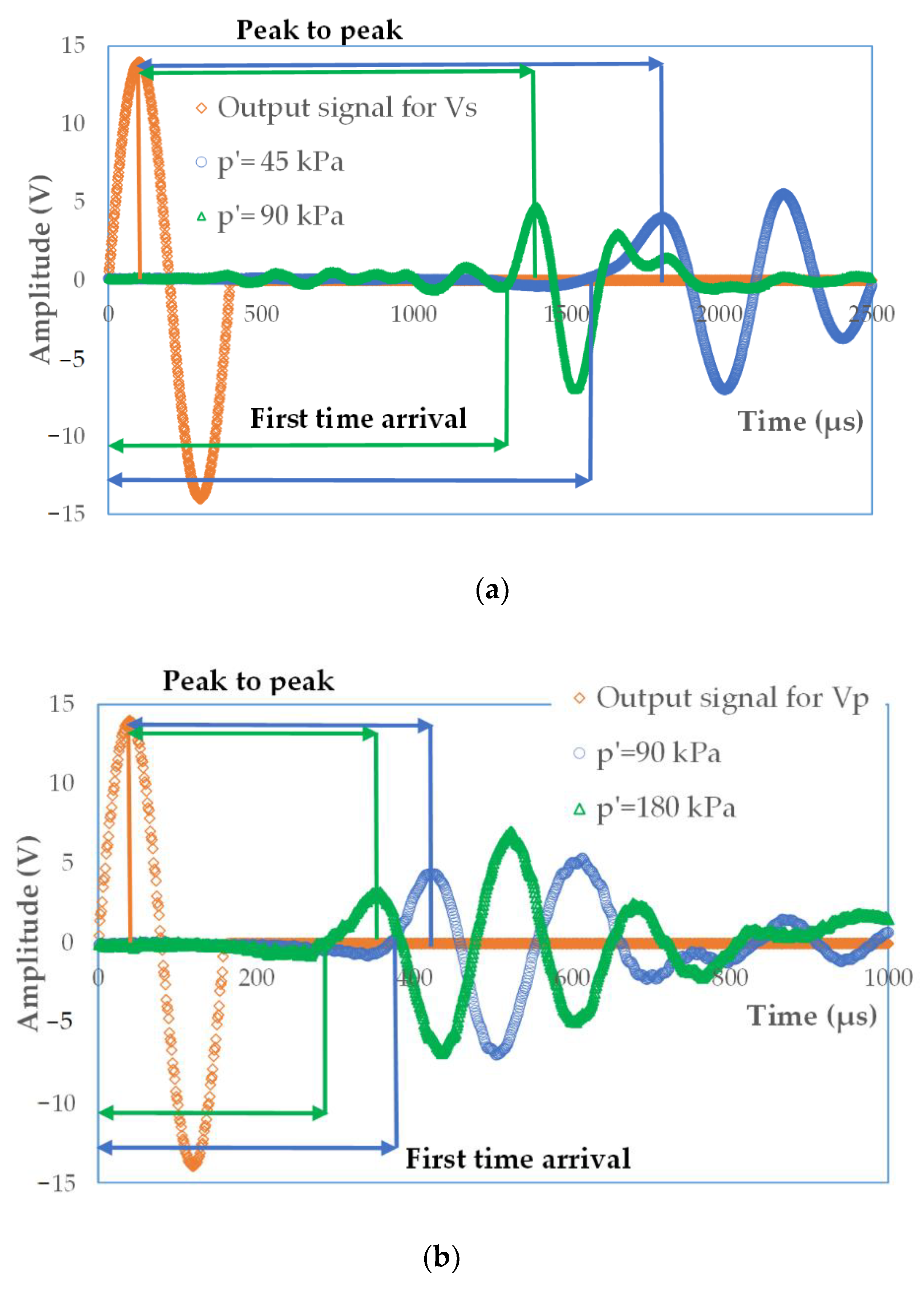

3.1.1. Piezo-Elements Signal Analysis

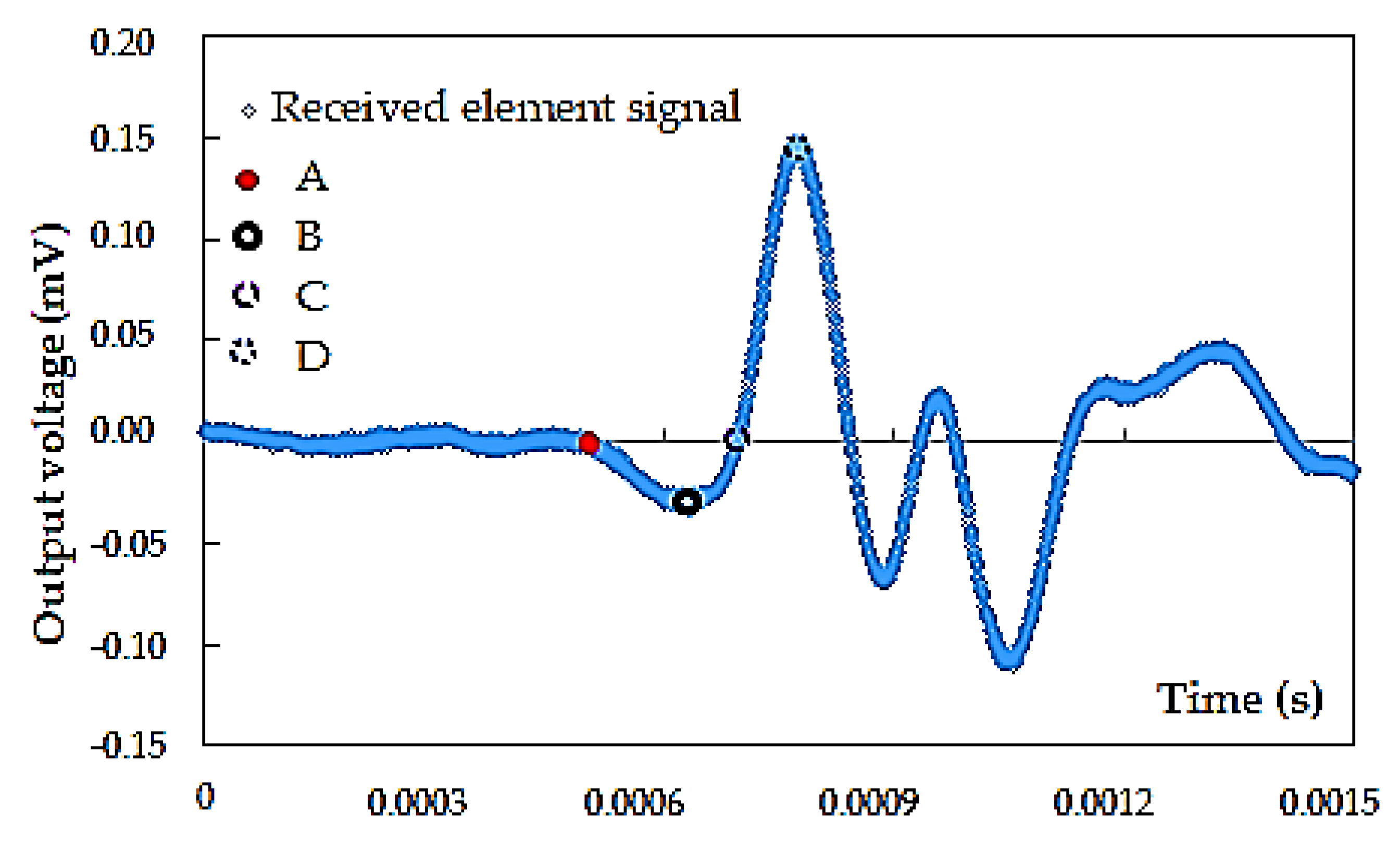

3.1.2. Multi-Method Automated Tool for Travel Time Analyses—GDS BEAT

- observation of points of interest within the received wave signal via software algorithm (time-domain technique),

- cross-correlation of the source and received signals (time-domain technique), and

- a cross-power spectrum calculation of the signals (frequency-domain method).

- The operation of the program is mainly based on one specific method of numerical analysis of the obtained results, using three factors:

- objective marking of points A, B, C, D (Figure 8) with the help of a software algorithm;

- mutual connection of generating and receiving elements signals; and

- calculation of the signal power curve spectrum for time estimation in the frequency-domain method.

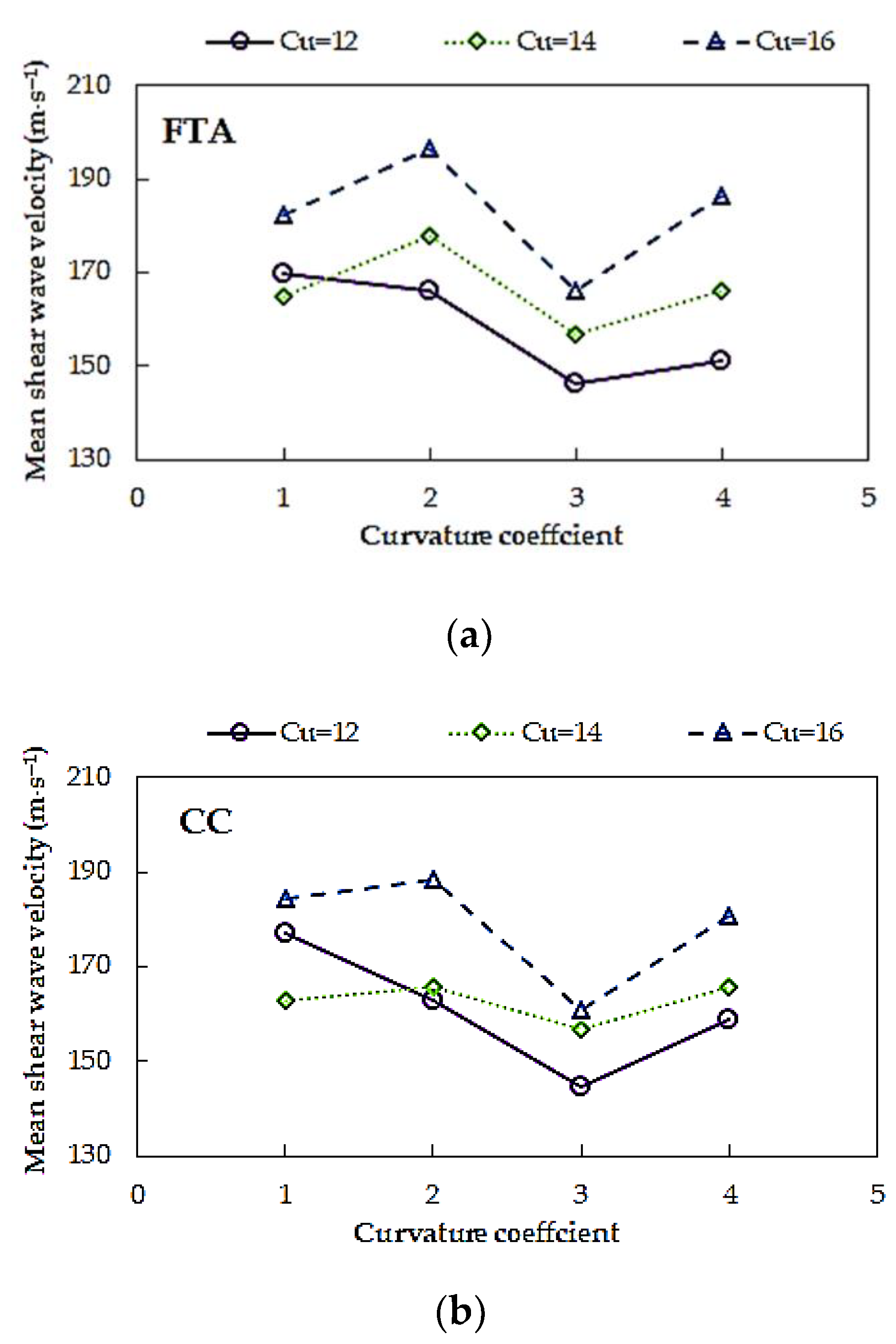

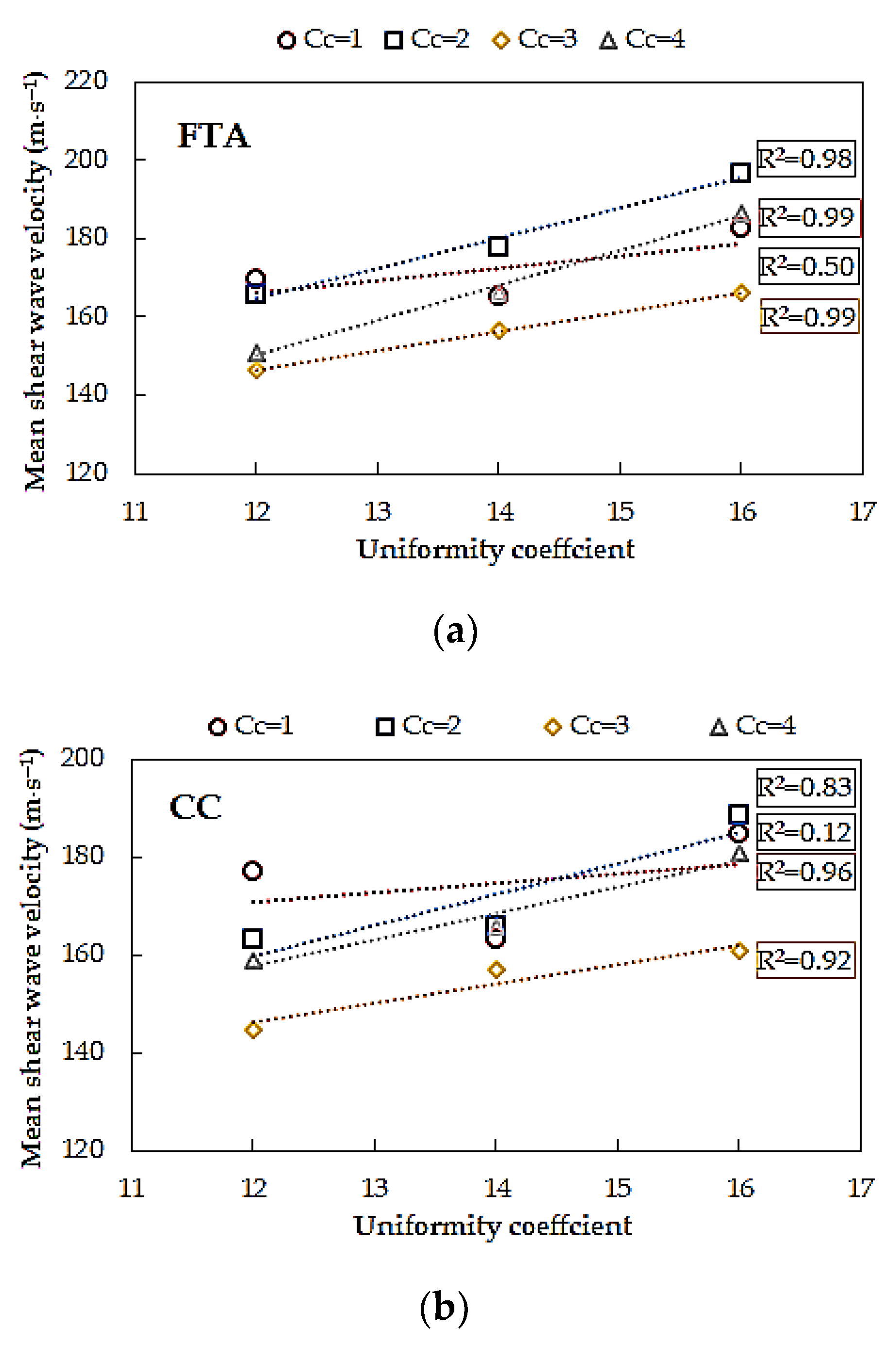

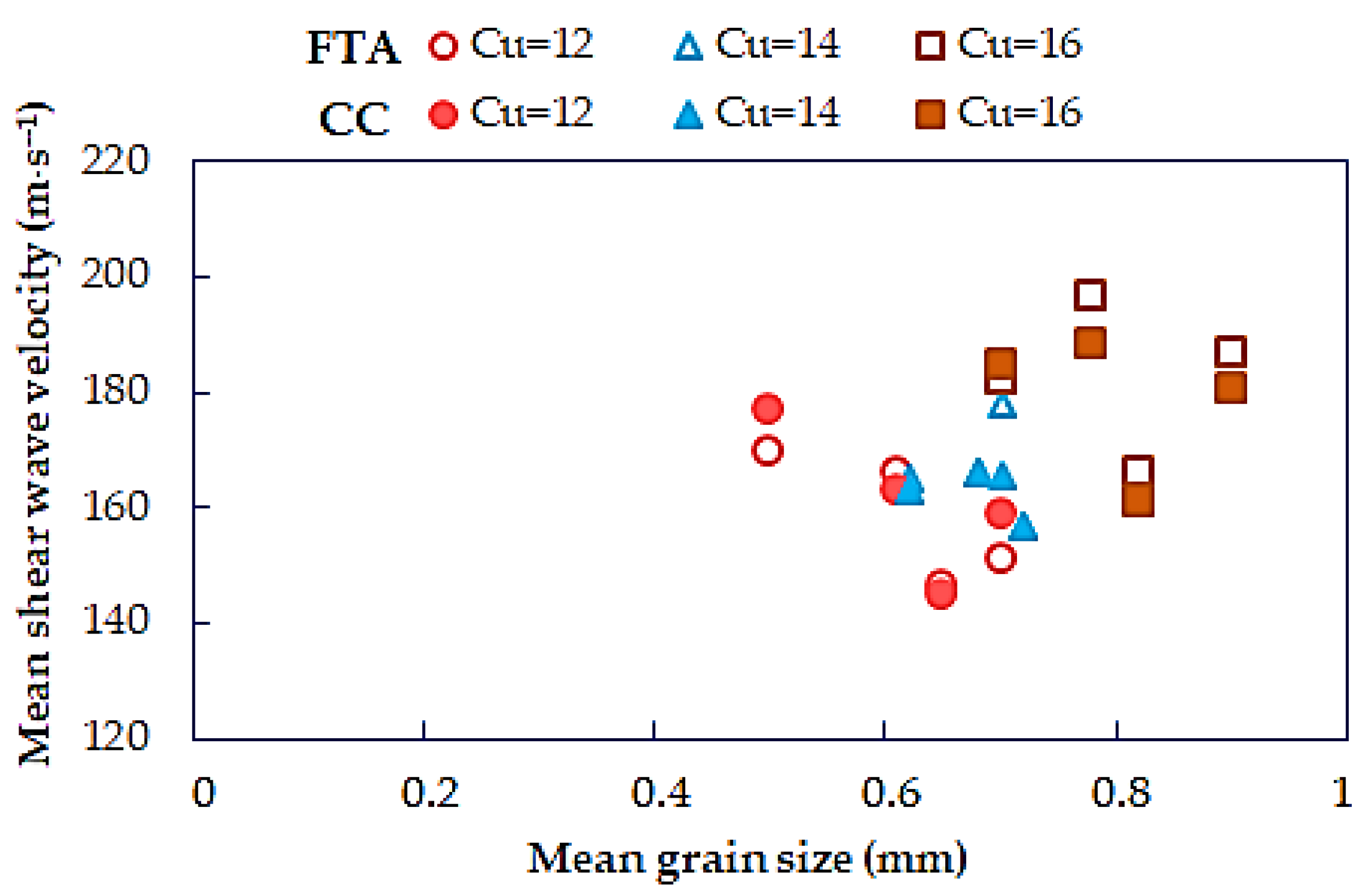

3.2. Effect of Grain Size Characteristics

4. Concluding Remarks

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kulkarni, M.P.; Patel, A.; Singh, D.N. Application of shear wave velocity for characterizing clays from coastal regions. KSCE J. Civ. Eng. 2010, 14, 307–321. [Google Scholar] [CrossRef]

- Karray, M.; Hussien, M.N. Shear wave velocity as a function of cone penetration resistance and grain size for Holocene-age uncemented soils: A new perspective. Acta Geotech. 2017, 12, 1129–1158. [Google Scholar] [CrossRef]

- Zekkos, D.; Sahadewa, A.; Woods, R.D.; Stokoe, K.H. Development of Model for Shear Wave Velocity of 419 Municipal Solid Waste. J. Geotech. Geoenviron. Eng. 2014, 140, 04013030. [Google Scholar] [CrossRef]

- Lee, M.-J.; Choo, H.; Kim, J.; Lee, W. Effect of artificial cementation on cone tip resistance and small strain shear modulus of sand. Bull. Eng. Geol. Environ. 2011, 70, 193–201. [Google Scholar] [CrossRef]

- Sas, W.; Gabryś, K.; Szymański, A. Experimental studies of dynamic properties of Quaternary clayey soils. Soil Dyn. Earthq. Eng. 2017, 95, 29–39. [Google Scholar] [CrossRef]

- Ingale, R.; Patel, A.; Mandal, A. Performance analysis of piezoceramic elements in soil: A review. Sens. Actuators A Phys. 2017, 262, 46–63. [Google Scholar] [CrossRef]

- Shirley, D.J.; Hampton, L.D. Shear-wave measurements in laboratory sediments. J. Acoust. Soci. Am. 1978, 63, 607–613. [Google Scholar] [CrossRef]

- Kramer, S. Geotechnical Earthquake Engineering; Prentice-Hall: Upper Saddle River, NJ, USA, 1996. [Google Scholar]

- Donovan, J.O.; Marketos, G.; Sullivan, C.O. Novel Methods of Bender Element Test Analysis. In Geomechanics from Micro to Marco; Soga, K., Kumar, K., Biscontin, G., Kuo, M., Eds.; Taylor & Francis Group: London, UK, 2015; pp. 311–316. [Google Scholar]

- Camacho-Tauta, J.F.; Reyes-Ortiz, O.J.; Alvarez, J.D.J. Comparison between resonant-column and bender element tests on three types of soils. Dyna 2013, 80, 163–172. [Google Scholar]

- Dyvik, R.; Madhus, C. Lab measurements of Gmax using bender elements. In Advance in the Art of Testing Soils under Cyclic Conditions; Koshla, V., Ed.; ASCE: New York, NY, USA, 1985; pp. 186–196. [Google Scholar]

- Yamashita, S.; Kawaquchi, T.; Nakata, Y.; Mikami, T.; Fujiwara, T.; Shibuya, S. Interpretation of interpretation parallel test on the measurement of Gmax using bender element. Soils Found. 2009, 49, 631–650. [Google Scholar] [CrossRef]

- Da Fonseca, A.V.; Ferreira, C.; Fahey, M. A framework interpreting bender element tests, combining time-domain and frequency-domain methods. Geotech. Test. J. 2009, 32, 1–17. [Google Scholar]

- Arulnathan, R.; Boulanger, R.W.; Riemer, M.F. Analysis of bender element tests. Geotech. Test. J. 1998, 21, 120–131. [Google Scholar]

- Viggiani, G.; Atkinson, J.H. Interpretation of bender element tests. Géotechnique 1995, 45, 149–154. [Google Scholar] [CrossRef]

- Greening, P.D.; Nash, D.F.T. Frequency Domain Determination of G0 Using Bender Elements. Geotech. Test. J. 2004, 27, 1–7. [Google Scholar] [CrossRef]

- Airey, D.; Mohsin, A.K.M. Evaluation of Shear Wave Velocity from Bender Elements Using Cross-Correlation. Geotech. Test. J. 2013, 36, 506–514. [Google Scholar] [CrossRef]

- Jovičic, V.; Coop, M.R.; Simic, M. Objective criteria for determining Gmax from bender element tests. Géotechnique 1996, 46, 357–362. [Google Scholar] [CrossRef]

- Blewett, J.; Blewett, I.J.; Woodward, P.K. Phase and Amplitude Responses Associated with the Measurement of Shear-Wave Velocity in Sand by Bender Elements. Can. Geotech. J. 2000, 37, 1348–1357. [Google Scholar] [CrossRef]

- Godlewski, T.; Szczepański, T. Metody Określania Sztywności Gruntów W Badaniach Geotechnicznych (In Polish) Methods for Determining Soil Stiffness in Geotechnical Investigations; Poradnik ITB: Warsaw, Poland, 2015. [Google Scholar]

- Camacho-Tauta, J.F.; Alvarez, J.D.J.; Reyes-Ortiz, O.J. A procedure to calibrate and perform the bender element test. Dyna 2012, 79, 10–18. [Google Scholar]

- Arroyo, M. Pulse Tests in Soils Samples. Ph.D. Thesis, University of Bristol, Bristol, England, 2001. [Google Scholar]

- Rio, J. Advances in Laboratory Geophysics Using Bender Elements. Ph.D. Thesis, University of London, London, UK, 2006. [Google Scholar]

- Sas, W.; Gabryś, K.; Soból, E.; Szymański, A. Dynamic Characterization of Cohesive Material Based on Wave Velocity Measurements. Appl. Sci. 2016, 6, 49. [Google Scholar] [CrossRef]

- Boonyatee, T.; Chan, K.H.; Mitachi, T. Effect of bender element installation in clay samples. Géotechnique 2010, 60, 287–291. [Google Scholar] [CrossRef]

- Yang, J.; Gu, X.Q. Shear stiffness of granular material at small strains: Does it depend on grain size? Géotechnique 2013, 63, 165–179. [Google Scholar] [CrossRef]

- Liu, X.; Yang, J.; Wang, G.H.; Chen, L.Z. Small-strain shear modulus of volcanic granular soil: An experimental investigation. Soil Dyn. Earthq. Eng. 2016, 86, 15–24. [Google Scholar] [CrossRef]

- Ruan, B.; Miao, Y.; Cheng, K.; Yao, E.-l. Study on the small strain shear modulus of saturated sand-fines mixtures by bender element test. Eur. J. Environ. Civ. Eng. 2018, 25, 1–11. [Google Scholar] [CrossRef]

- Cho, G.-C.; Dodds, J.; Santamarina, C.J. Particle shape effects on packing density, stiffness, and strength: Natural and crushed sands. J. Geotech. Geoenviron. Eng. 2006, 132, 591–602. [Google Scholar] [CrossRef]

- Krumbein, W.C.; Sloss, L.L. Stratigraphy and Sedimentation, 2nd ed.; Freeman: San Francisco, CA, USA, 1963. [Google Scholar]

- Liu, X.; Yang, J. Shear wave velocity in the sand: Effect of grain shape. Géotechnique 2017, 68, 1–7. [Google Scholar] [CrossRef]

- Wichtmann, T.; Triantafyllidis, T. Influence of the grain-size distribution curve of quartz sand on the small-strain shear modulus Gmax. J. Geotech. Geoenviron. Eng. 2009, 135, 1404–1418. [Google Scholar] [CrossRef]

- Iwasaki, T.; Tatsuoka, F. Effects of grain size and grading on dynamic shear moduli of sands. Soils Found. 1977, 17, 19–35. [Google Scholar] [CrossRef]

- Patel, A.; Bartake, P.; Singh, D. An Empirical Relationship for Determining Shear Wave Velocity in Granular Materials Accounting for Grain Morphology. Geotech. Test. J. 2009, 32, 1–10. [Google Scholar] [CrossRef]

- Bartake, P.P.; Singh, D.N. Studies on the determination of shear wave velocity in sands. Geomech. Geoengin. 2007, 2, 41–49. [Google Scholar] [CrossRef]

- Sharifipour, M.; Dano, C.; Hicher, P.Y. Wave velocities in assemblies of glass beads using bender-extender elements. In Proceedings of the 17th ASCE Engineering Mechanics Conference, Newark, DE, USA, 13–16 June 2004. [Google Scholar]

- Menq, F.Y.; Stokoe, K.H., II. Linear dynamic properties of sandy and gravelly soils from large-scale resonant tests. In Deformation Characteristics of Geomaterials; Benedetto, D., Doanh, T., Geoffroy, H., Sauzéat, C., Eds.; Swets & Zeitlinger: Lisse, The Netherlands, 2003; pp. 63–71. [Google Scholar]

- Lontou, P.B.; Nikolopoulou, C.P. Effect of Grain Size on Dynamic Shear Modulus of Sands: An Experimental Investigation (In Greek); Department of Civil Engineering, University of Patras: Patras, Greece, 2004. [Google Scholar]

- Altuhafi, F.N.; Coop, M.R.; Georgiannou, V.N. Effect of Particle Shape on the Mechanical Behavior of Natural Sands. J. Geotech. Geoenviron. Eng. 2016, 142, 04016071. [Google Scholar] [CrossRef]

- Payan, M.; Khoshghalb, A.; Senetakis, K.; Khalili, N. Effect of particle shape and validity of Gmax models for sand: A critical review and a new expression. Comput. Geotech. 2016, 72, 28–41. [Google Scholar] [CrossRef]

- Wang, M.; Pande, G.; Kong, L.; Feng, Y. Comparison of Pore-Size Distribution of Soils Obtained by Different Methods. Int. J. Geomech. 2016, 17, 06016012. [Google Scholar] [CrossRef]

- Clayton, C.R.I. Stiffness at small strain: Research and practice. Géotechnique 2011, 61, 5–38. [Google Scholar] [CrossRef]

- Wang, Y.; Benahmed, N.; Ciu, Y.-J.; Tang, A.-M. A novel method for determining the small-strain shear modulus of soil using bender elements technique. Can. Geotech. J. 2016, 54, 280–289. [Google Scholar] [CrossRef]

- PN-EN ISO 14688-2: 2006. Badania Geotechniczne. Oznaczanie I klasyfikowanie Gruntów. Część 2: Zasady Klasyfikowania. Available online: https://sklep.pkn.pl/pn-en-iso-14688-2-2018-05p.html (accessed on 27 November 2019).

- Szymański, A. Mechanika Gruntów; Wydawnictwo SGGW: Warsaw, Poland, 2007. [Google Scholar]

- ISO 17892-4:2016 Geotechnical Investigation and Testing—Laboratory Testing of Soil—Part 4: Determination of Particle Size Distribution. Available online: https://sklep.pkn.pl/pn-en-iso-17892-4-2017-01e.html (accessed on 18 January 2018).

- PN-88/B-04481. Grunty Budowlane. Badania Próbek Gruntu. Available online: https://sklep.pkn.pl/pn-b-04481-1988p.html (accessed on 30 June 1988).

- Leong, E.C.; Cahyadi, J.; Rahardjo, H. Measuring shear and compression wave velocities of soil using bender-extender elements. Can. Geotech. J. 2009, 46, 792–812. [Google Scholar] [CrossRef]

- Tatsuoka, T.; Iwasaki, T.; Yoshida, S.; Fukushima, S.; Sudo, H. Shear modulus and damping by drained test on clean sand specimens reconstituted by various methods. Soils Found. 1979, 19, 39–54. [Google Scholar] [CrossRef]

- Gabryś, K.; Sas, W.; Soból, E.; Głuchowski, A. Application of bender elements technique in the testing of anthropogenic soil-recycled concrete aggregate and its mixture with rubber chips. Appl. Sci. 2017, 7, 741. [Google Scholar] [CrossRef]

- Pennington, D.S.; Nash, D.F.T.; Lings, M.L. Horizontally Mounted Bender Elements for Measuring Anisotropic Shear Moduli in Triaxial Clay Specimens. Geotech. Test. J. 2001, 24, 133–144. [Google Scholar] [CrossRef]

- Wang, Y.H.; Lo, K.F.; Yan, W.M.; Dong, X.B. Measurement Biases in the Bender Element Test. J. Geotech. Geoenviron. Eng. 2007, 133, 564–574. [Google Scholar] [CrossRef]

- Leong, E.C.; Yeo, S.H.; Rahardjo, H. Measuring Shear Wave Velocity Using Bender Elements. Geotech. Test. J. 2005, 28, 488–498. [Google Scholar] [CrossRef]

- Ogino, T.; Kawaguchi, T.; Yamashita, S.; Kawajiri, S. Measurement Deviations for Shear Wave Velocity of Bender Element Test Using Time Domain, Cross-Correlation, and Frequency Domain Approaches. Soils Found. 2015, 55, 329–342. [Google Scholar] [CrossRef]

- Rees, S.; Le Compte, A.; Snelling, K. A new tool for the automated travel time analyses of bender element tests. In Proceedings of the 18th International Conference on Soil Mechanics and Geotechnical Engineering, Paris, France, 2–6 September 2013; pp. 2843–2846. [Google Scholar]

- Lee, J.S.; Santamarina, J.C. Bender elements: Performance and signal interpretation. J. Geotech. Geoenviron. Eng. 2005, 131, 1063–1070. [Google Scholar] [CrossRef]

- Patel, A.; Singh, D.N.; Singh, K.K. Performance analysis of piezo-ceramic elements in soils. Geotech. Geol. Eng. 2010, 28, 681–694. [Google Scholar] [CrossRef]

- Brignoli, E.; Gotii, M.; Stokoe, K. Measurement of shear waves in laboratory specimens by means of piezoelectric transducers. Geotech. Test. J. 1996, 19, 384–397. [Google Scholar]

- Sánchez-Salinero, I.; Roesset, J.M.; Stokoe, K.H., II. Analytical Studies of Body Wave Propagation and Attenuation. Geotechnical Engineering Report; GR86-15; University of Texas: Austin, TX, USA, 1986. [Google Scholar]

- Styler, M.A.; Howie, J.A. Comparing frequency and time domain interpretations of bender element shear wave velocities. In Proceedings of the GeoCongress 2012, Oakland, CA, USA, 25–29 March 2012. [Google Scholar]

| Sample Name | Gradation | |||||||

|---|---|---|---|---|---|---|---|---|

| d10 (mm) | d30 (mm) | d50 (mm) | d60 (mm) | emin (-) | emax (-) | mopt (%) | ρdmax (g/cm3) | |

| S1 | 0.063 | 0.220 | 0.50 | 0.760 | 0.221 | 0.568 | 6.7 | 2.22 |

| S2 | 0.063 | 0.310 | 0.61 | 0.760 | 0.227 | 0.577 | 7.3 | 2.20 |

| S3 | 0.063 | 0.379 | 0.65 | 0.760 | 0.233 | 0.596 | 8.4 | 2.17 |

| S4 | 0.063 | 0.440 | 0.70 | 0.760 | 0.244 | 0.596 | 9.1 | 2.12 |

| S5 | 0.063 | 0.240 | 0.62 | 0.885 | 0.221 | 0.577 | 6.8 | 2.22 |

| S6 | 0.063 | 0.340 | 0.70 | 0.885 | 0.244 | 0.596 | 7.2 | 2.20 |

| S7 | 0.063 | 0.410 | 0.72 | 0.885 | 0.238 | 0.596 | 7.6 | 2.16 |

| S8 | 0.063 | 0.480 | 0.68 | 0.885 | 0.233 | 0.587 | 7.5 | 2.16 |

| S9 | 0.063 | 0.250 | 0.70 | 1 | 0.227 | 0.596 | 7.3 | 2.21 |

| S10 | 0.063 | 0.355 | 0.78 | 1 | 0.233 | 0.577 | 7.1 | 2.21 |

| S11 | 0.063 | 0.435 | 0.82 | 1 | 0.221 | 0.523 | 6.9 | 2.21 |

| S12 | 0.063 | 0.500 | 0.90 | 1 | 0.238 | 0.559 | 7.0 | 2.19 |

| Test Series | Sample Name | Wave Period (ms); Mean Effective Stress (kPa) | |

|---|---|---|---|

| (TS; p′) | (TP; p′) | ||

| I | S1 | (0.2, 0.25, 0.4, 0.45; 45) | (0.02, 0.05; 45) |

| II | S2 | (0.2, 0.25, 0.4, 0.45; 45) | |

| III | S3 | (0.2, 0.25, 0.4, 0.45; 45) | (0.05; 45) |

| IV | S4 | (0.2, 0.25, 0.4, 0.45; 45) | (0.02, 0.05; 45) |

| V | S5 | (0.2, 0.25, 0.4, 0.45; 45) | (0.02, 0.05; 45) |

| VI | S6 | (0.2, 0.25, 0.4, 0.45; 45) | (0.02, 0.05; 45) |

| VII | S7 | (0.2, 0.25, 0.4, 0.45; 45) | |

| VIII | S8 | (0.2, 0.25, 0.4, 0.45; 45) | (0.02, 0.05; 45) |

| IX | S9 | (0.2, 0.25, 0.4, 0.45; 45) | (0.02, 0.05; 45) |

| X | S10 | (0.2, 0.25, 0.4, 0.45; 45) | |

| XI -1 | S11 | (0.06, 0.08, 0.1, 0.2, 0.3, 0.4, 0.5; 45) | |

| XI - 2 | (0.04, 0.06, 0.08, 0.1, 0.2, 0.3, 0.4, 0.5; 90) | (0.03; 90) | |

| XI - 3 | (0.06, 0.08, 0.1, 0.2, 0.3, 0.4, 0.5; 180) | ||

| XII - 1 | (0.04, 0.06, 0.08, 0.1, 0.2, 0.3, 0.4, 0.5; 90) | (0.02; 90) | |

| XII - 2 | (0.04, 0.06, 0.08, 0.1, 0.2, 0.3, 0.4, 0.5; 180) | (0.02, 0.03; 180) | |

| XIII - 1 | (0.04, 0.05, 0.06, 0.08, 0.1, 0.2, 0.25, 0.3, 0.4, 0.45, 0.5; 180) | (0.01, 0.02, 0.03, 0.04; 180) | |

| XIV -1 | S12 | (0.04, 0.05, 0.06, 0.08, 0.1, 0.2, 0.25, 0.3, 0.4, 0.45, 0.5; 45) | (0.03, 0.04, 0.05, 0.06; 45) |

| XIV- 2 | (0.04, 0.05, 0.06, 0.08, 0.1, 0.2, 0.25, 0.3, 0.4, 0.45, 0.5; 90) | (0.03, 0.04, 0.05, 0.06, 0.08; 90) | |

| XIV - 3 | (0.04, 0.05, 0.06, 0.08, 0.1, 0.2, 0.25, 0.3, 0.4, 0.45, 0.5; 180) | (0.03, 0.04, 0.05, 0.06, 0.08; 180) | |

| XV - 1 | (0.04, 0.05, 0.06, 0.08, 0.1, 0.2, 0.25, 0.3, 0.4, 0.45, 0.5; 90) | (0.08, 0.1; 90) | |

| XV - 2 | (0.04, 0.05, 0.06, 0.08, 0.1, 0.2, 0.25, 0.3, 0.4, 0.45, 0.5; 180) | (0.02, 0.03, 0.04, 0.06, 0.08, 0.1; 180) | |

| XVI - 1 | (0.04, 0.05, 0.06, 0.08, 0.1, 0.2, 0.25, 0.3, 0.4, 0.45, 0.5; 180) | (0.04, 0.06, 0.08, 0.1; 180) | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gabryś, K.; Soból, E.; Sas, W.; Šadzevičius, R.; Skominas, R. Warsaw Glacial Quartz Sand with Different Grain-Size Characteristics and Its Shear Wave Velocity from Various Interpretation Methods of BET. Materials 2021, 14, 544. https://doi.org/10.3390/ma14030544

Gabryś K, Soból E, Sas W, Šadzevičius R, Skominas R. Warsaw Glacial Quartz Sand with Different Grain-Size Characteristics and Its Shear Wave Velocity from Various Interpretation Methods of BET. Materials. 2021; 14(3):544. https://doi.org/10.3390/ma14030544

Chicago/Turabian StyleGabryś, Katarzyna, Emil Soból, Wojciech Sas, Raimondas Šadzevičius, and Rytis Skominas. 2021. "Warsaw Glacial Quartz Sand with Different Grain-Size Characteristics and Its Shear Wave Velocity from Various Interpretation Methods of BET" Materials 14, no. 3: 544. https://doi.org/10.3390/ma14030544

APA StyleGabryś, K., Soból, E., Sas, W., Šadzevičius, R., & Skominas, R. (2021). Warsaw Glacial Quartz Sand with Different Grain-Size Characteristics and Its Shear Wave Velocity from Various Interpretation Methods of BET. Materials, 14(3), 544. https://doi.org/10.3390/ma14030544