1. Introduction

Finite element (FE) analysis is effective for investigating the nonlinear behavior of reinforced concrete (RC) structures and performing parametric studies at lower costs than experimental tests. The nonlinear FE analysis of RC members has been extensively reported, and good agreement is often achieved between numerical and experimental results [

1,

2,

3]. However, the comparison and application of the existing FE models are difficult owing to the differences in the adopted modeling strategies, which involve a considerable number of options, e.g., regarding the concrete constitutive models, critical parameters, bond between the concrete and the steel reinforcement, and numerical analysis procedures. Nonlinear FE analyses for blind predictions of the ultimate capacity and cracking of simple RC structural members have been associated with large uncertainty [

4,

5].

The major challenges in the nonlinear FE analysis of RC structures include the following: (1) defining the concrete tensile and compressive behaviors with the proper consideration of the strain localization in fracture zones [

6], (2) efficiently assigning proper bond–slip behavior between the concrete and the steel reinforcement [

2], (3) solving convergence difficulties commonly observed in the modeling of concrete with high nonlinearity [

7,

8], and (4) the misinterpretation of the processing logic of the FE software in the derivation and definition of input data. These challenges, which are described in detail below, render nonlinear FE analyses of RC complex and time-consuming; thus, such nonlinear analyses are rarely performed by practicing engineers.

Concrete cracking in tension: The cracking of tensile concrete is usually modeled by either discrete or smeared crack approach in practical FE analyses. In the discrete crack approach, physical cracks are modeled as displacement discontinuities in a concrete continuum. Although it allows the precise prediction of localized deformation at cracks, the discrete crack approach requires pre-defining tensile fracture zones when the finite element is generated. However, the position of the cracks is not known beforehand for most structural analyses. To overcome this limitation, automated re-meshing techniques are required to adapt the configuration of finite elements in accordance with the propagating cracks [

9,

10]. Although recent research has been devoted to developing discrete crack models allowing arbitrary crack initiation and propagation (e.g., the extended FE method [

11]), the sophisticated modeling methods are not suitable for practical application by engineering practitioners. The ease of application motivates the wide use of the smeared crack approach in practical FE analyses. In the smeared crack approach, a crack width is transformed into an equivalent cracking strain smearing over a certain length (referred to as the “smeared length” in this paper). The numerical results correspond to reality only if the widths of the simulated fracture process zones (i.e., the cracking regions) are equal to the assumed smeared length [

6,

12,

13]. To assure the reliability of the numerical results, the smeared length should be properly determined and incorporated into the definition of the constitutive law of concrete in tension.

Concrete crushing in compression: The constitutive model for concrete in uniaxial compression is usually provided as a stress–strain relationship in design codes, e.g., Model Codes [

14,

15] and ACI 318 [

16]. However, such as a compressive strain, i.e., the “mean strain” obtained by smearing the measured deformation over the length of the standard test specimen, cannot describe the local strain-softening behavior in the critical fracture damaged zone of concrete. Studies since the 1980s [

17,

18,

19] have investigated the effects of the strain localization on deriving the concrete compressive constitutive models. The challenge faced when considering the strain localization in FE analyses is that the actual size of simulated fracture zones is not known in advance, but it must be determined and used to modify the constitutive model of concrete as input data for the FE analyses. Zandi Hanjari et al. [

20] modified the post-peak branch of the stress–strain relationship proposed by Thorenfeldt et al. [

21], assuming that concrete crushing occurred in one row of concrete elements in the FE analyses of RC members. To properly define the concrete compressive behavior and reliably predict the capacity of RC members governed by concrete crushing, it is necessary to (1) clarify the principle of modifying the concrete compressive constitutive model with consideration of the strain localization and (2) develop a practical approach for determining the size of the fracture zones.

Bond–slip behavior between concrete and steel reinforcement: In the nonlinear FE analyses of RC structures, the definition of the bond–slip behavior between the concrete and the steel reinforcement is critical for the accurate prediction of the structural responses, crack patterns, and crack widths [

2,

3]. However, there is a lack of guidelines and different methods are used in the literature to assign the steel-concrete interaction, requiring different input data and workarounds to overcome implementation difficulties, which are often not described in detail [

22,

23]. Therefore, it is important for the research community to evaluate the existing approaches [

2,

24,

25] for assigning the bond–slip behavior and to develop new approaches involving simple application procedures.

Convergence difficulties: The softening behavior and stiffness degradation of cracking or crushing concrete cause severe convergence difficulties in the static analysis of concrete [

8,

26]. Instead of solving the problem in static analyses, researchers implemented dynamic analysis procedures adopting implicit [

7] or explicit [

1] integration methods. However, such a dynamic approach requires additional effort to carefully select, e.g., the time integration algorithm, loading scheme, loading time, damping ratio, and time increment size, to achieve a good balance between minimizing the inertial forces (for a better approximation of the static problem) and reducing the computational time (by using a shorter time to model the static event in an accelerated manner). Therefore, it remains important to develop a simple solution strategy to perform the static analysis procedure with a high convergence rate.

Misinterpretation: Misinterpretation refers to the users’ misunderstanding of the processing logic of FE software packages. Misinterpretation may cause the incorrect definition of input data, which may lead to errors in numerical results or aborted analyses [

27]. For instance, in nonlinear FE analyses of concrete structures, the definition of the post-peak softening behavior of concrete constitutive laws or the stiffness degradation of damaged concrete is not straightforward. Furthermore, such analyses require to assign a lot of input data and to make a great number of modeling choices, which are rarely reported in a very detailed way in the literature. This is explained by the fact that such details do not constitute the focus of the investigation and are usually software specific. Nevertheless, if the approach for obtaining critical input data is not reported, it can undermine the reliability and reproducibility of the FE analyses.

In light of these challenges, the objective of this study was to develop a robust and reliable modeling strategy to capture the tensile cracking and compressive crushing behavior of RC structures associated with low computational costs and ease of implementation, based on the well-established constitutive relations from fib Model Codes [

14,

15]. The strategy was implemented to simulate the flexural behavior of an RC beam as reference and another identical RC beam strengthened with an externally bonded carbon-reinforced polymer (CFRP) laminate; both beams were tested in four-point bending until failure. Modeling of crack opening after the reinforcement yielding stage and ultimate concrete crushing were carefully studied on the reference beam to ensure a reliable basis for the modeling of the strengthened beam. The nonlinear FE analyses presented herein were performed using the concrete damaged plasticity (CDP) model implemented in the commercial software ABAQUS [

26], as it is widely used in both academia and industry to analyze RC structures [

28,

29,

30,

31,

32]. The focus of this paper was to provide reliable, practical, and computationally cost-efficient implementation guidelines for nonlinear FE analyses of concrete structures, which can be used as a basis for more complex cases and support the application of nonlinear analyses to real-world engineering problems, e.g., for load-bearing assessment, strengthening assessment, structural health monitoring, and damage identification of building and civil engineering structures. For instance, the use of externally bonded FRP laminates for strengthening and rehabilitation of concrete or masonry structural members [

33,

34,

35] has emerged as an effective technique and found strong interest in both research and practice, which supported the consideration of such a case in this work. The experimental setup is shown in

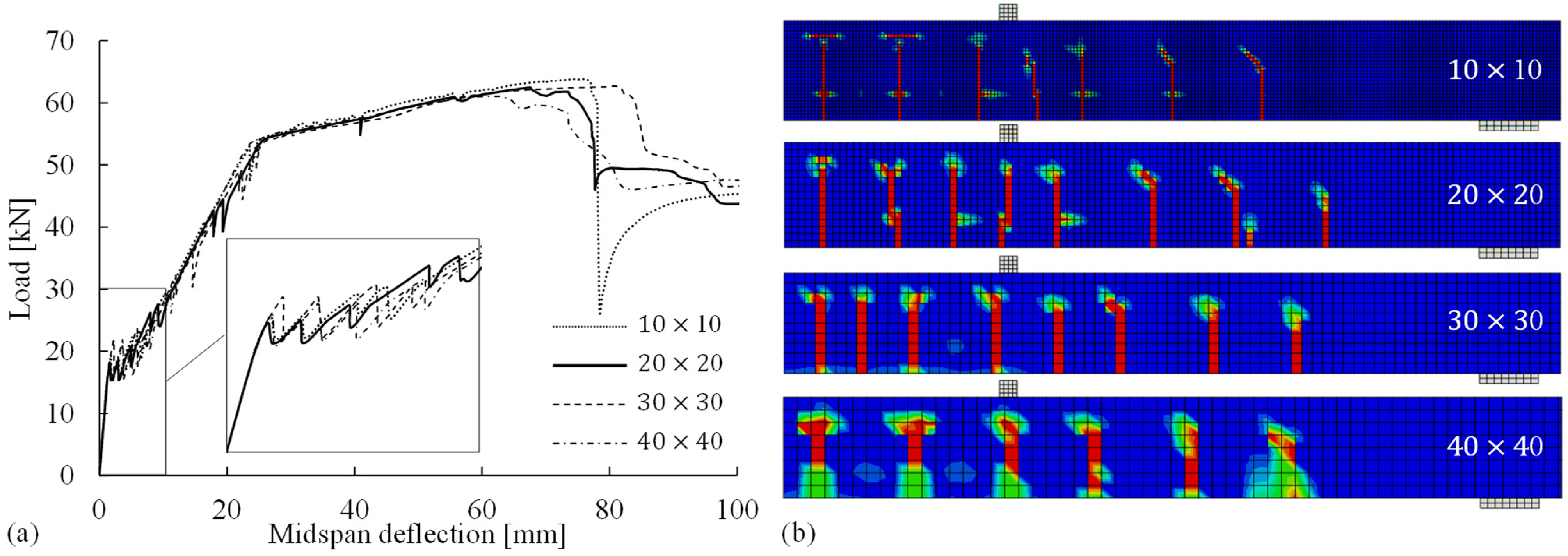

Section 2. In

Section 3, the modeling procedures and recommendations for overcoming the aforementioned challenges are presented in detail. In

Section 4, the proposed modeling strategy is demonstrated, and modeling choices are validated by parametric studies considering the reference RC beam. In

Section 5, the numerical results of the reference beam are compared with the experimental measurements regarding load-deformation relationship, cracking, flexural failure due to concrete crushing, and CFRP debonding initiated by intermediate cracks.

2. Experimental Test

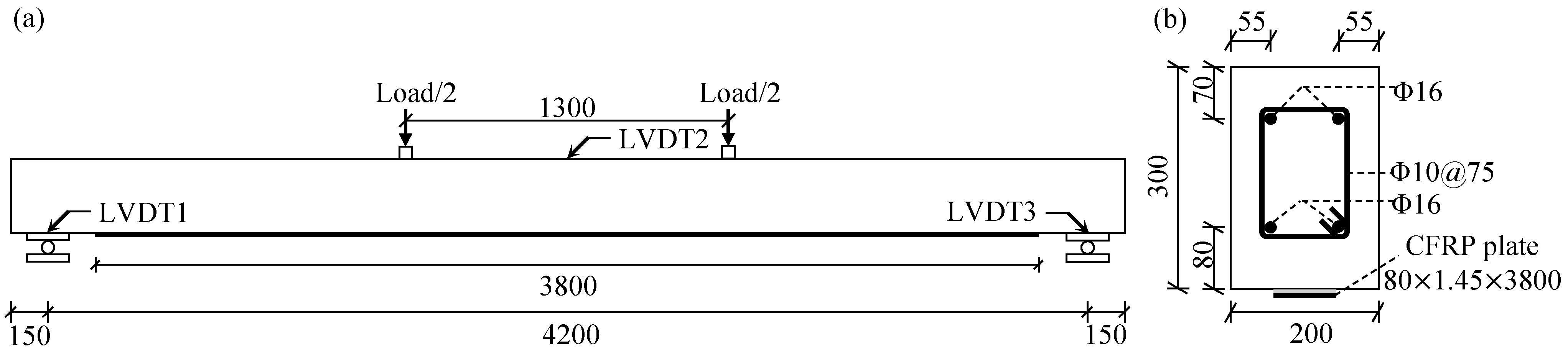

The RC members modeled in the present FE study included two slender RC beams subjected to four-point bending in the laboratory, see

Figure 1a. The RC beams were cast at a workshop using C35/45 concrete. One beam served as reference; the other one, with identical dimensions, was strengthened with an externally bonded CFRP laminate on the tensile side of the beam. The cross-sectional dimensions of the beams are shown in

Figure 1b, including main steel rebars, shear reinforcement, and externally bonded CFRP plate (for the strengthened beam only). A two-component epoxy adhesive (StoPox SK41, StoCretec GmbH, Kriftel, Germany) was applied to bond the CFRP plate; whose layer design thickness was 1 mm. Mechanical properties of the above-mentioned materials used for the FE analyses are listed in

Table 1: the elastic modulus

, compressive strength

, and tensile strength

of concrete C35/45 at the age of 287 days were estimated according to Eurocode 2 [

36]; the Poisson’s ratio of concrete

was defined according to Model Code 2010 [

15]; the elastic modulus

, yield strength

, ultimate strength

, and ultimate strain

of steel reinforcement were measured by laboratory tests on bars with a diameter of 16 mm (Φ16) according to ASTM A615 [

37]; the elastic modulus

and ultimate tensile strain

of the CFRP plate were measured according to standard tensile tests as reported in [

38]; the elastic modulus

, tensile strength

and Poisson’s ratio

of the epoxy adhesive were reported in [

39].

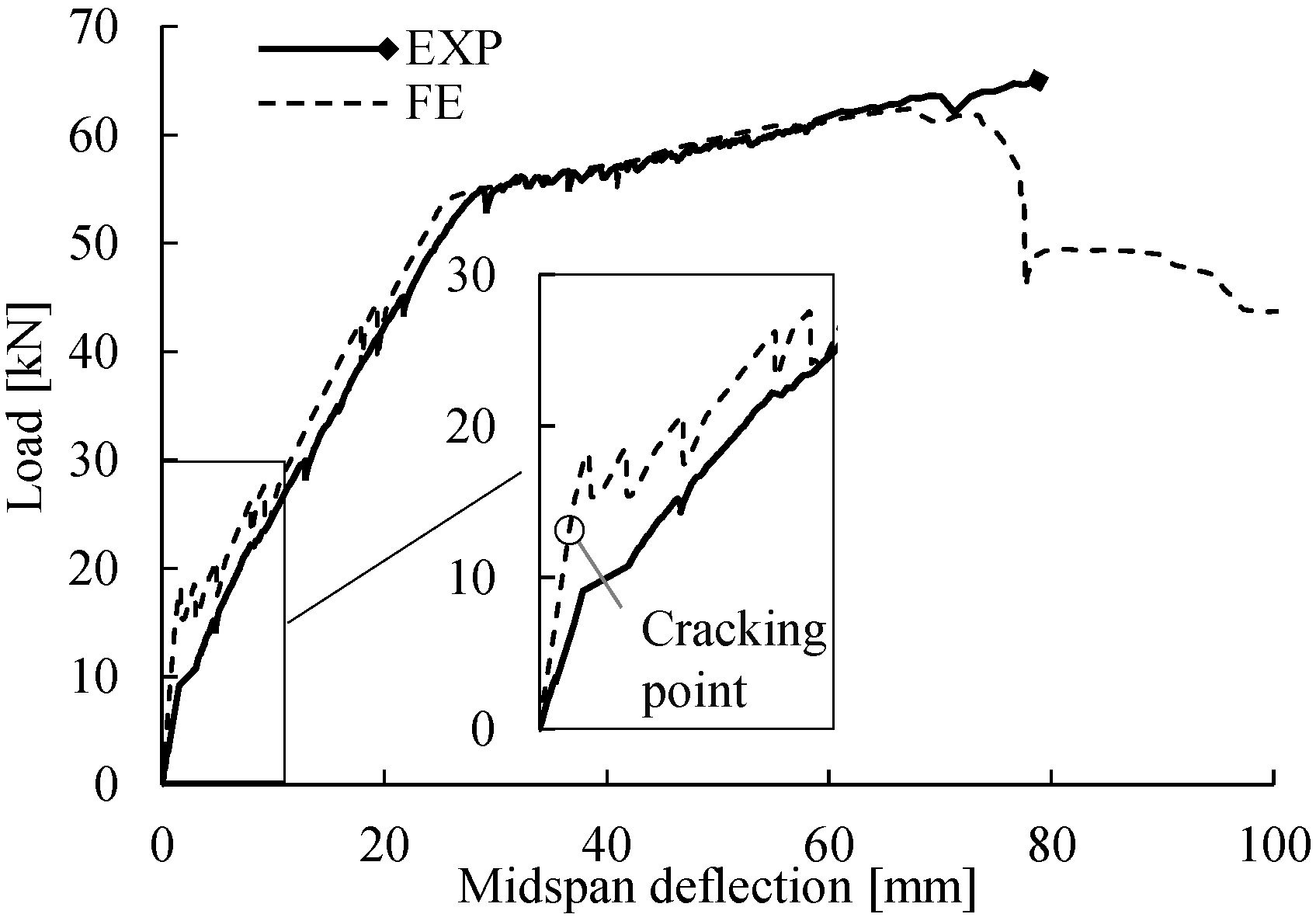

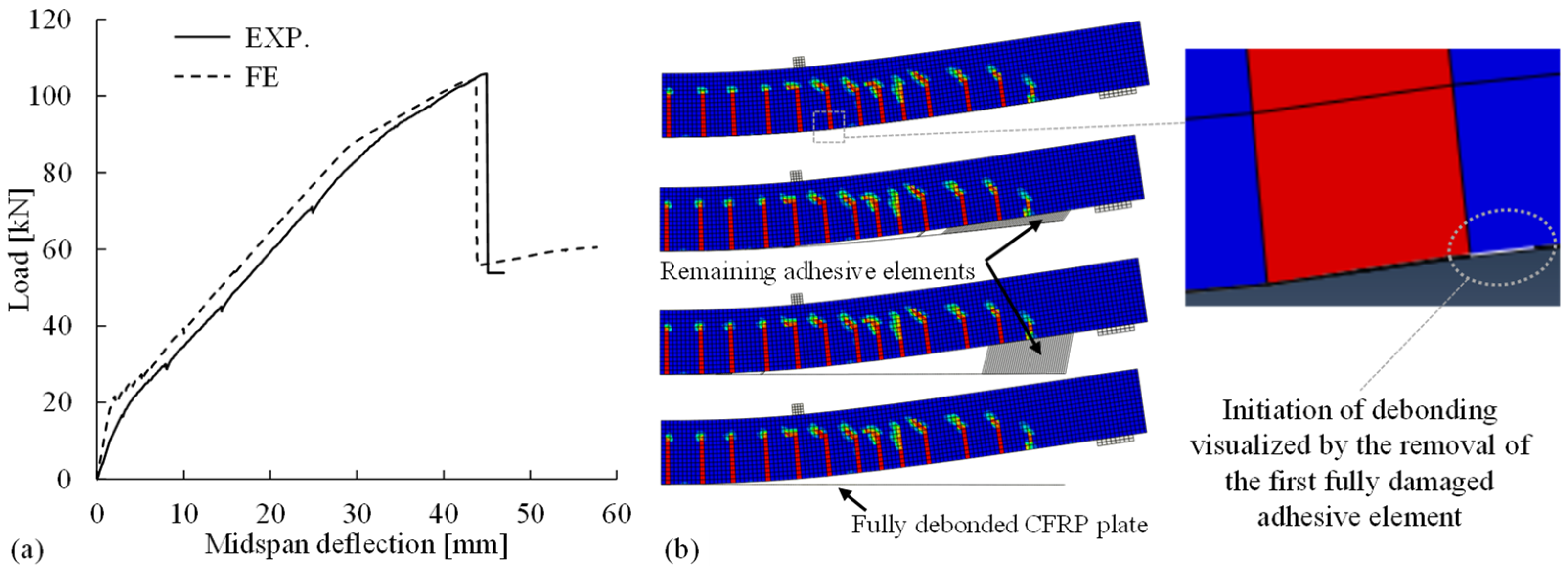

In the four-point bending tests, the beams were simply supported on two movable steel supports, giving an effective span of 4.2 m. The steel support at each end consisted of two identical steel plates (170 × 30 × 200 mm3) and one steel cylinder roller (diameter of and length of ). External loading was applied via two synchronized hydraulic jacks using displacement control. The foot of each hydraulic jack rested on a steel plate (50 × 50 × 200 mm3) to distribute the load to the RC beam. The beams were loaded to failure. In the reference beam, flexural failure after yielding of the reinforcement was governed by concrete crushing in the compressive side of the beam; the failure of the strengthened beam was due to premature debonding of the CFRP plate initiated by intermediate flexural cracks.

During the test, strain gauges and linear variable differential transducers (LVDTs) were used to monitor the beam specimens. Two strain gauges were installed at the midspan cross-section on the tensile steel reinforcement, and three LVDTs were used to obtain the net deflection at the midspan, as shown in

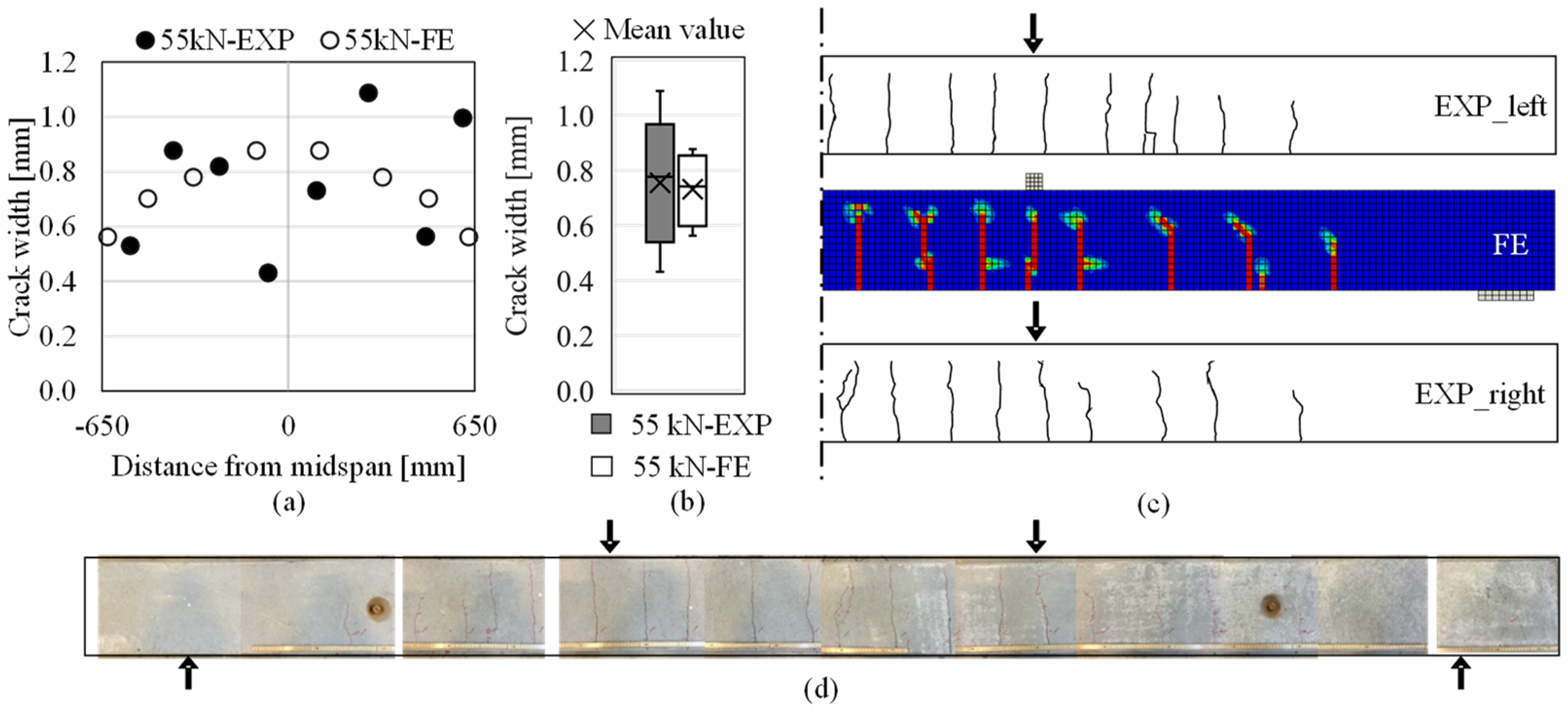

Figure 1. Cracks in the RC beams were monitored during the test; the crack widths were measured at the height of the tensile steel reinforcement using a digital handheld microscope (AM4115ZT, Dino-Lite Europe, Almere, The Netherlands) at load levels of 15, 30, 45, 55 (reference beam only), and 70 kN (strengthened beam only).

3. FE Modeling Strategy

The proposed modeling strategy is discussed in detail, in this section, with special focus on proper modeling of RC considering strain-softening in fracture zones and bond–slip between steel reinforcement and concrete to ensure the reliable prediction of cracking and crushing. The strategy is adapted to the modeling of the RC beams introduced in

Section 2. However, common critical issues in the nonlinear FE modeling of RC structures are addressed in a general manner, which makes these recommendations applicable to other types of RC beam and frame structures. The nonlinear FE analyses were conducted using the commercial FE package ABAQUS/CAE, version 6.14 [

26].

Considering that the beam geometry and the test configuration were symmetric about the midspan, only one half of the RC beam was modeled in the current FE analyses to reduce the computational cost. The vertical load acting on the beam was defined as a boundary condition in the FE model, inducing a vertical displacement on the top of the steel plate between the load and the beam. The interaction between the steel plate and the beam was set as surface-to-surface contact, which defined the interfacial constraints in the normal direction (i.e., “hard” contact) and friction in the tangential direction. The coefficient of tangential friction was assumed to be 0.57 according to a previous recommendation [

40]. The same contact settings were used at the interfaces between the beam and steel support. On the bottom side of the movable steel support, boundary conditions were defined at the middle point to constrain the degree of freedom in the vertical direction but allow translation in the horizontal direction. The concrete beam, steel plate under the loading point, and movable steel support were modeled with 2D shell, discretized into structured meshes, and assigned with element type CPS4 (4-node plane stress quadrilateral elements with four integration points). Steel reinforcement and CFRP plate, modeled as one-dimensional (1D) wire, were assigned with truss (T2D2) and beam (B21) elements, respectively. Material properties of the concrete, steel reinforcement, and CFRP were defined according to the values in

Table 1. Details about the modeling of concrete, the interaction at the concrete and steel reinforcement interface and the concrete and CFRP plate interface, and the numerical solution strategy are described below according to the proposed modeling strategy.

3.1. Modeling of Concrete

The concrete material is defined in the CDP model implemented in ABAQUS [

26], including the definition of the concrete plasticity, the tensile behavior, the compressive behavior, and the damage evolution of the stiffness.

3.1.1. Concrete Plasticity

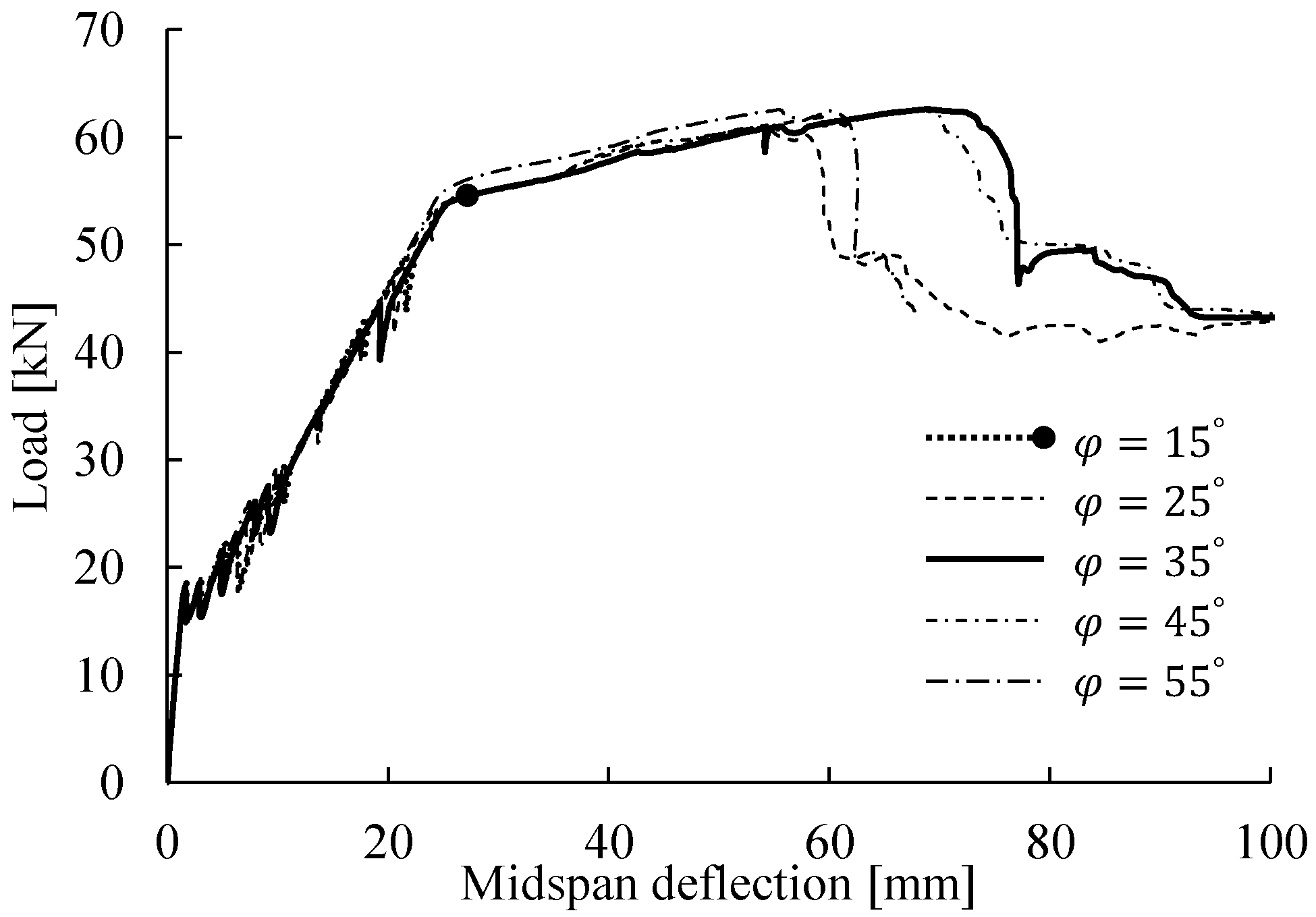

The concrete plasticity parameters to be defined in the CDP model include (1) dilation angle

and eccentricity factor

related to the flow potential given by the Drucker–Prager hyperbolic function; (2) factors

and

related to the yield surface based on the function presented by Lubliner et al. [

41] with the modifications proposed by Lee and Fenves [

42] to account for the evolution of strength in tension and compression; and (3) the viscosity parameter

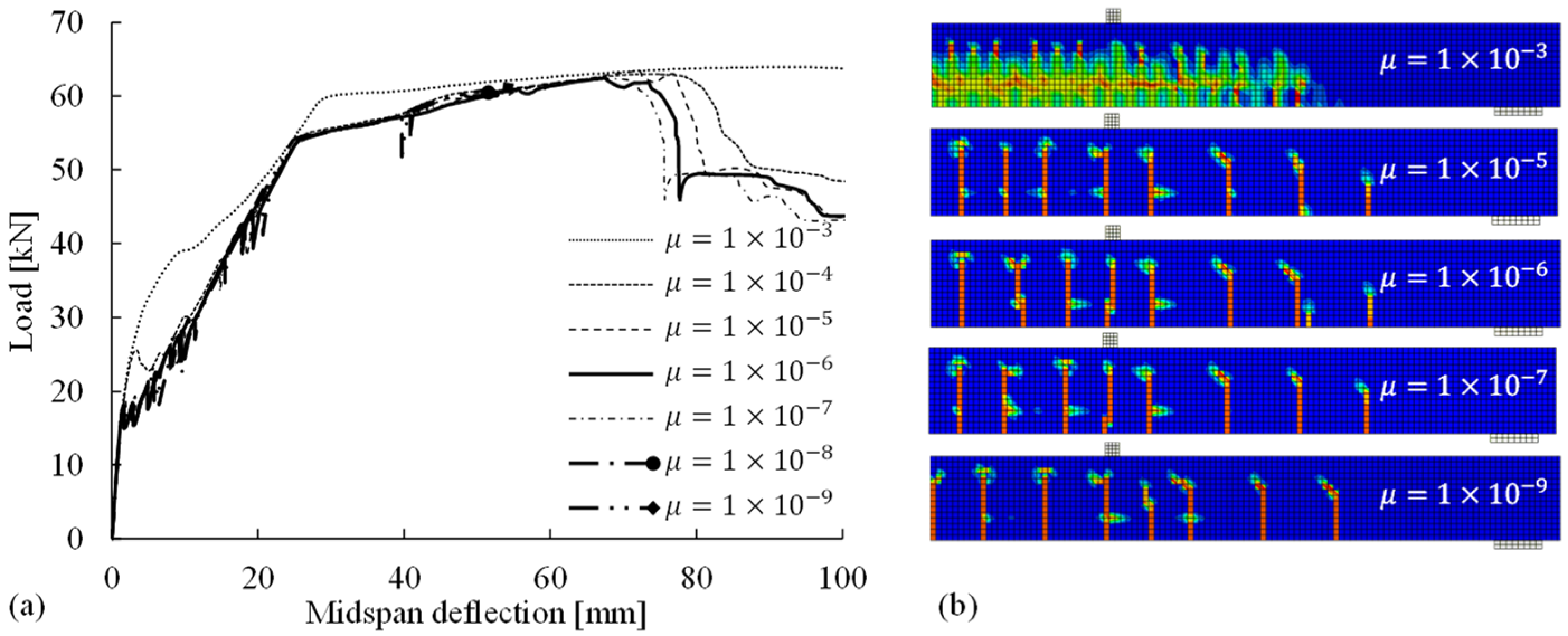

to introduce viscoplastic regularization. The values of these parameters defined in the reference FE model are presented in

Table 2. Default values of

,

, and

are assigned according to the design manual of ABAQUS [

26]; the values of

and

are defined based on the validation discussed in

Section 4.1 and

Section 4.2.

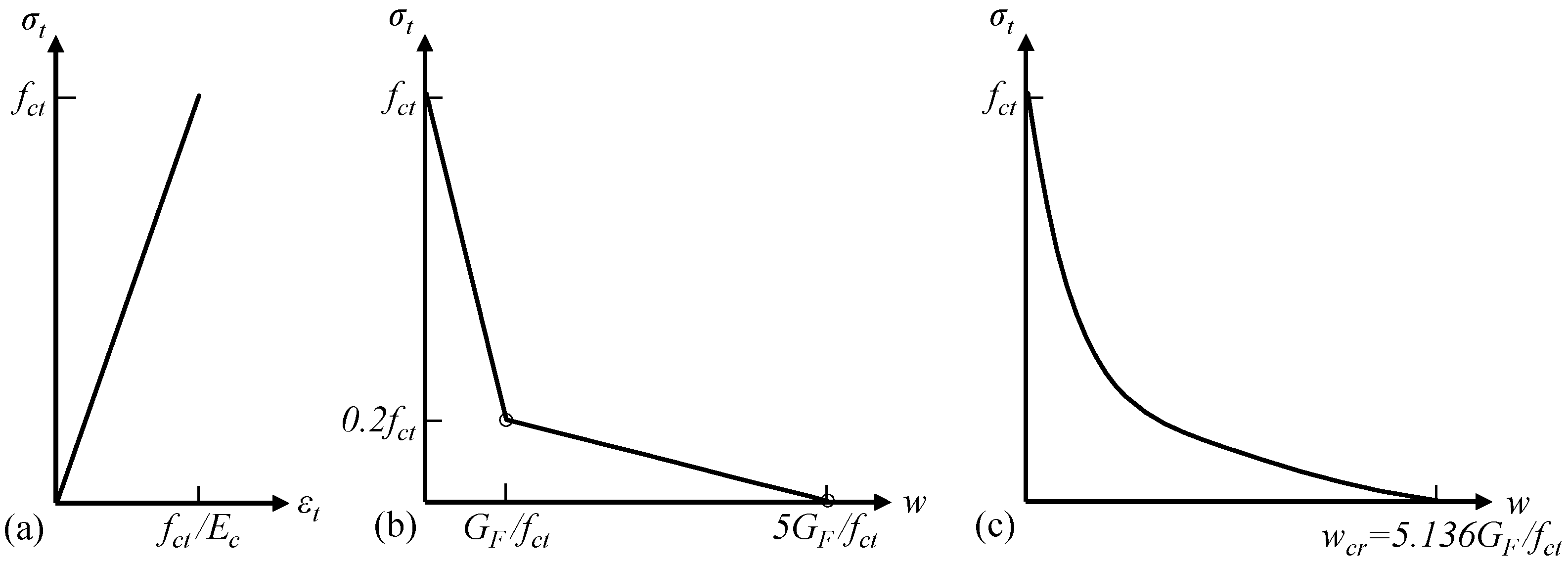

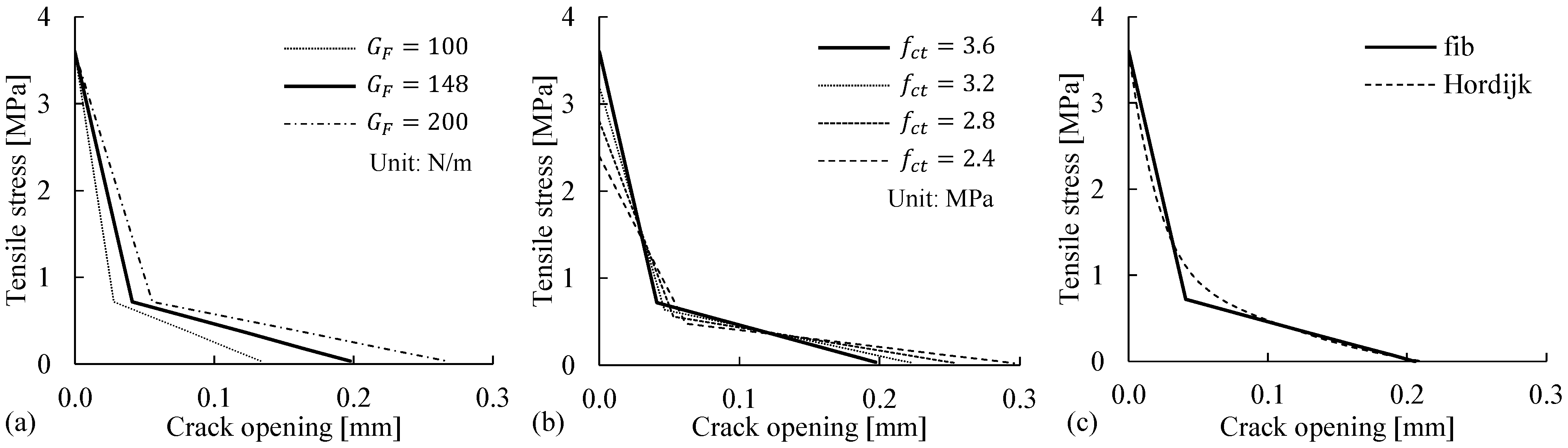

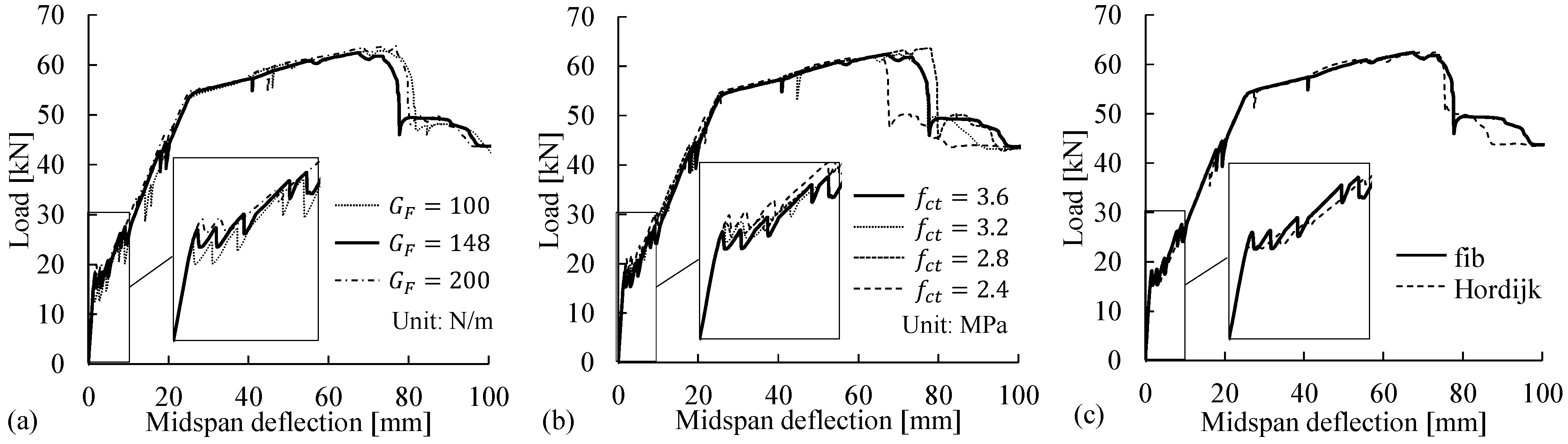

3.1.2. Concrete Tensile Behavior

The tensile behavior of concrete is characterized by a linear elastic stress–strain relationship before the concrete reaches the tensile strength

(

Figure 2a) and a bilinear stress

-crack width

relationship for the post-peak softening behavior according to Model Code 2010 [

15]. The Model Code relationship, as shown in

Figure 2b, is determined by the tensile strength

and the fracture energy

. The fracture energy

describes the amount of energy required to propagate a tensile crack of unit area; for normal-strength concrete,

(in N/m or J/m

2) can be estimated using Equation (1) according to Mode Code 2010 [

15]:

where

represents the mean compressive strength of concrete in MPa.

To validate the adopted concrete tensile behavior, the effects of different modeling choices on the numerical results were investigated and are discussed in

Section 4.3. This included (1) a comparison between the bilinear Model Code relation and another commonly used post-peak softening model, i.e., the exponential descending

-

relation (

Figure 2c) proposed by Hordijk [

43], and (2) parametric studies of the assumed tensile strength

and fracture energy

. The Hordijk

-

relation is expressed by Equation (2):

where,

,

,

.

Smeared crack method: To simulate the cracks in concrete, the CDP model adopted in the present FE study employs the smeared crack method, where the cracking concrete is treated as a continuum and a physical crack opening

is characterized as an equivalent cracking strain

smearing over a certain length (the smeared length

). Thus, the post-peak tensile behavior defined in the CDP model complies with stress–cracking strain relationship, which is converted from the selected stress–crack width model given

. The numerical results correspond to reality only if the width of the simulated fracture process zone

is equal to the assumed smeared length

. As indicated by Equation (3), the inelastic deformation

of cracking concrete at a certain stress level

is not dependent on the assumed

but determined by the selected stress–crack width relation in the present FE analyses.

Crack band approach: To define the smeared length

in accordance with the size of the simulated fracture zone

, the crack band approach—a simple technique for practical engineering computations—is adopted. In this approach, it is assumed that the strain-softening of cracking concrete is localized into a clear band of elements running across the concrete mesh and thus forming a “crack band.” Thus, the size of the simulated fracture zone

becomes the width of the crack band

, and

can be estimated and assigned to the smeared length

to adjust the strain-softening behavior of the concrete in the post-peak regime [

6]. The crack band approach, which is widely applicable and utilized in many FE packages, is based on pioneering studies performed in the 1980s [

12,

13,

44,

45]. Theoretically, the width of crack bands

is a function of not only the element topology, e.g., the type, shape, size, and integration scheme, but also the crack band orientation [

6]. However, the width of crack bands

implemented in common FE packages, e.g., ABAQUS [

26], is simply estimated as the square root of the element area (for two-dimensional elements) or the cubic root of the element volume (for three-dimensional elements). This simplified estimation may induce substantial error and mesh sensitivity for elements with large aspect ratios. It is recommended to use elements having aspect ratios close to 1 (e.g., square or cubic elements) to reduce the mesh sensitivity [

26]. Even for square or cubic elements, there may be errors if the crack band is not aligned with the mesh line. For instance, for a two-dimensional mesh of square elements with side length

a, it is reasonable to estimate the band width

automatically in ABAQUS only if the crack band is parallel to the element sides. If the crack band runs along the element diagonal, the appropriate width of the band is

instead of

. Accordingly, when using the crack band approach in FE modeling, it is recommended to define the post-peak tensile behavior of concrete by the input data of the stress–cracking strain relationship, which allows users to evaluate and determine the crack band width

. For a detailed discussion regarding the estimation of the crack band width with consideration of the element topology and crack band orientation, readers are referred to [

12,

46,

47].

In the present FE analyses, the crack bands developed in the concrete mesh mainly ran parallel to the mesh lines, owing to the predominant bending effect on the beam. Thus, the crack band width was determined as the width of square-shaped concrete elements for deriving the stress–cracking strain input data.

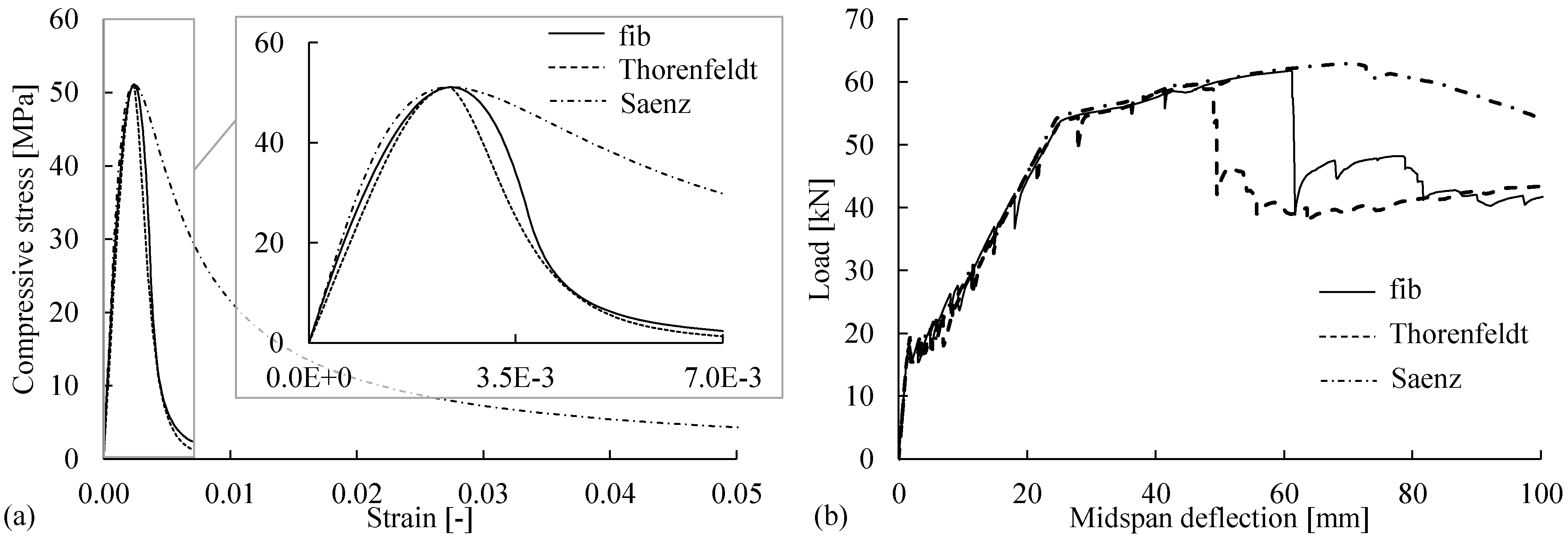

3.1.3. Concrete Compressive Behavior

For the FE analysis of RC beams in bending, the concrete compressive behavior is widely defined according to a stress–strain relationship obtained from uniaxial compression tests of standard concrete cylinders. However, the strain in the standard compressive test is the “mean” strain obtained by smearing the measured displacement over the total length of the specimen. Considering that the compressive failure of concrete is initiated by a local shear band formed in one of the fracture zones and the post-peak deformation mainly arises from such a local zone, the “mean” strain naturally underestimates the strain in the critical fracture zone. If the post-peak deformation is expressed by the mean strain, the strain-softening curve tends to depend on the geometry of the specimen [

17,

18]—the descent of the post-peak branch is faster for a longer specimen. For instance, the compressive stress–strain relationship provided in Model Codes [

14,

48] is reasonably accurate for a concrete specimen length of approximately 200 mm.

In the present FE study, the relationship based on Model Code 1990 [

14] and Model Code 2010 [

15] is selected as the reference constitutive model for concrete in compression. Model Code 1990 provides the part of the descending branch with strains exceeding the concrete ultimate/limit strain

. To highlight the differences among existing constitutive models for concrete compressive behavior and the impacts of these differences on the predicted ultimate crushing failure of the concrete beam, two other commonly used models are also studied for comparison (see

Section 4.5): the Thorenfeldt relationship and the Saenz relationship. As shown in

Table 3, the Thorenfeldt relationship is based on previous studies by Tomaszewicz [

49] and Thorenfeldt et al. [

21], with the modifications proposed by Collins and Porasz in CEB Bulletin 193 [

50]. The Saenz relationship includes modifications [

51] based on a previous discussion of the compressive stress–strain equation [

52].

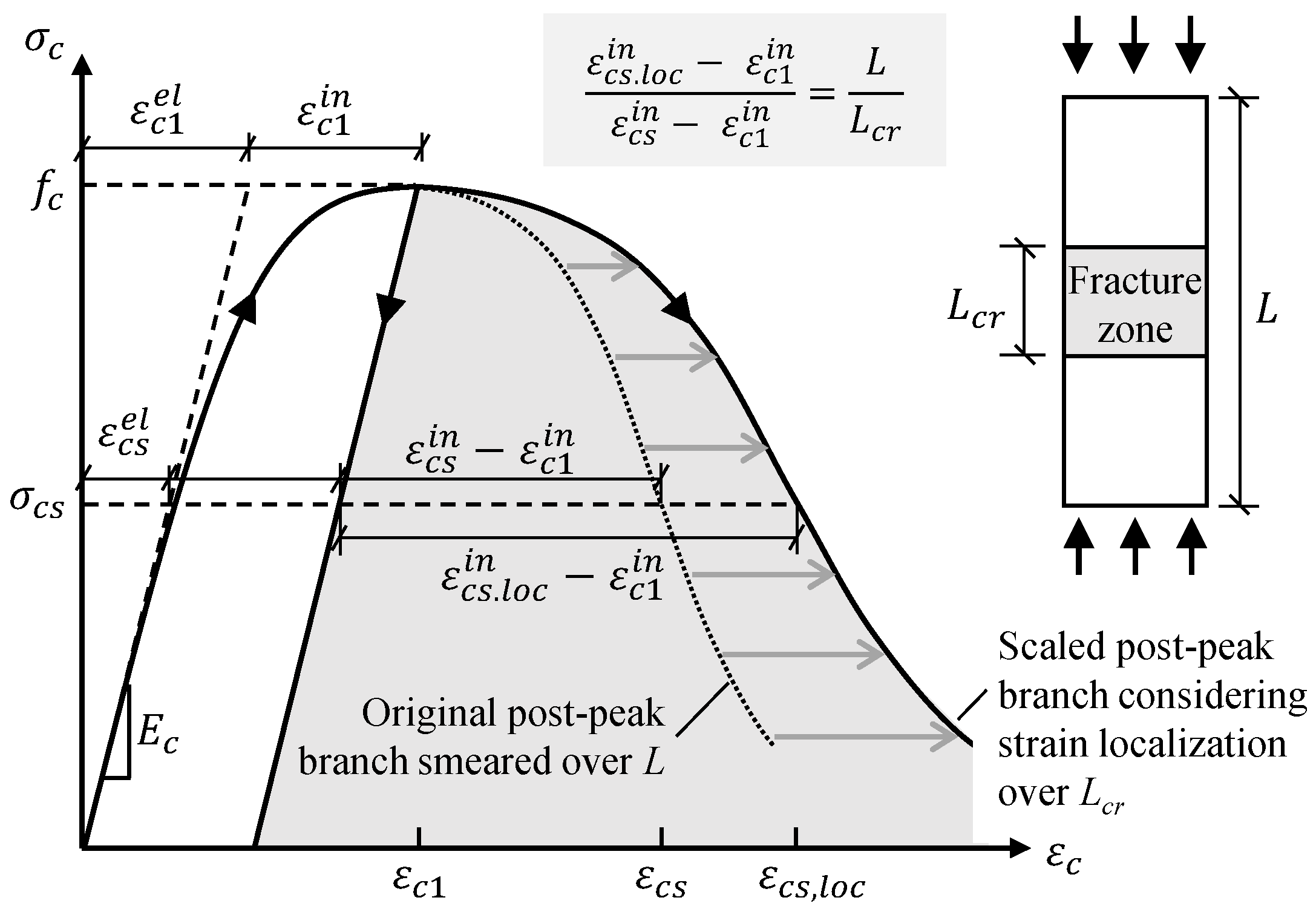

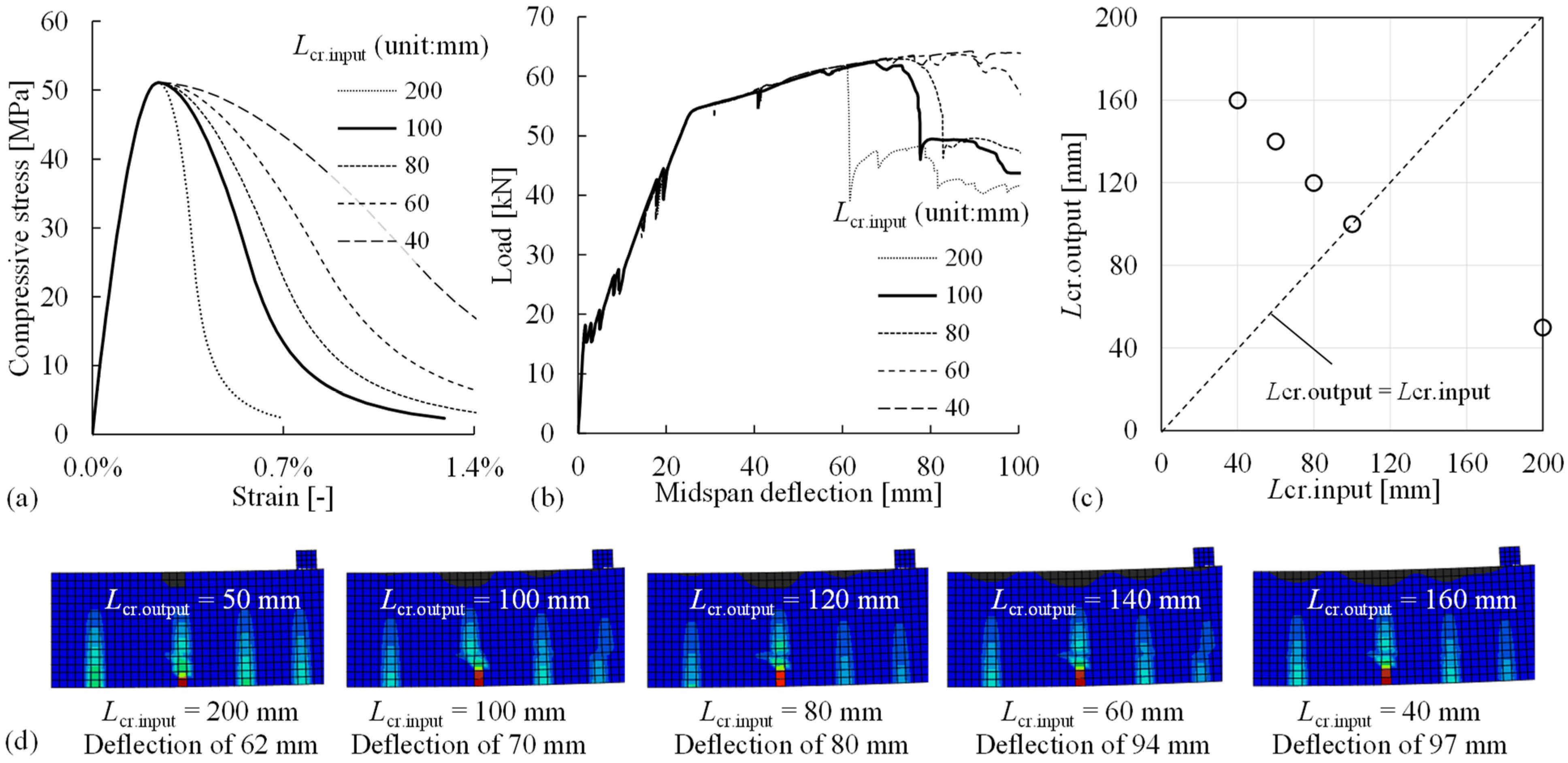

To obtain reliable predictions of the ultimate capacity and the crushing failure of the beam in flexural loading, the post-peak strain localization should be considered in the definition of the constitutive law. The original constitutive model based on the mean strain—mainly the post-peak softening branch—must be modified to better describe the localized strain softening in the critical fracture zone with a reasonable size. The assumed size should be verified according to the size of the simulated crushing zone.

Modified compressive behavior considering strain localization: The procedure for modifying the post-peak branch is presented in

Figure 3. If the stress–mean strain relationship and the length

L of the tested specimen are known, the increased post-peak deformation

can be obtained from the stress–strain relationship using Equation (4):

where,

and

represent the strains (mean strains smeared over the whole specimen) corresponding to the concrete compressive strength

and the stress level

in the softening branch, respectively.

Considering the strain localization, instead of using Equation (4), the increased deformation after the peak stress

is reached can be calculated using Equation (5), taking into account the strain-softening in the fracture zone with the length of

and the elastic unloading due to the reduction in the compressive stress from the peak stress

to

:

where,

represents the change in elastic strain due to the stress reduction from

to

in the post-peak regime,

represents the inelastic strain localized in the critical fracture process zone, and

represents the inelastic strain at peak stress.

The transitivity between Equations (4) and (5) implies that,

which can be rewritten as,

The scaling rule for determining the localized inelastic strain

in the critical fracture zone is expressed by Equation (7), as shown in

Figure 3.

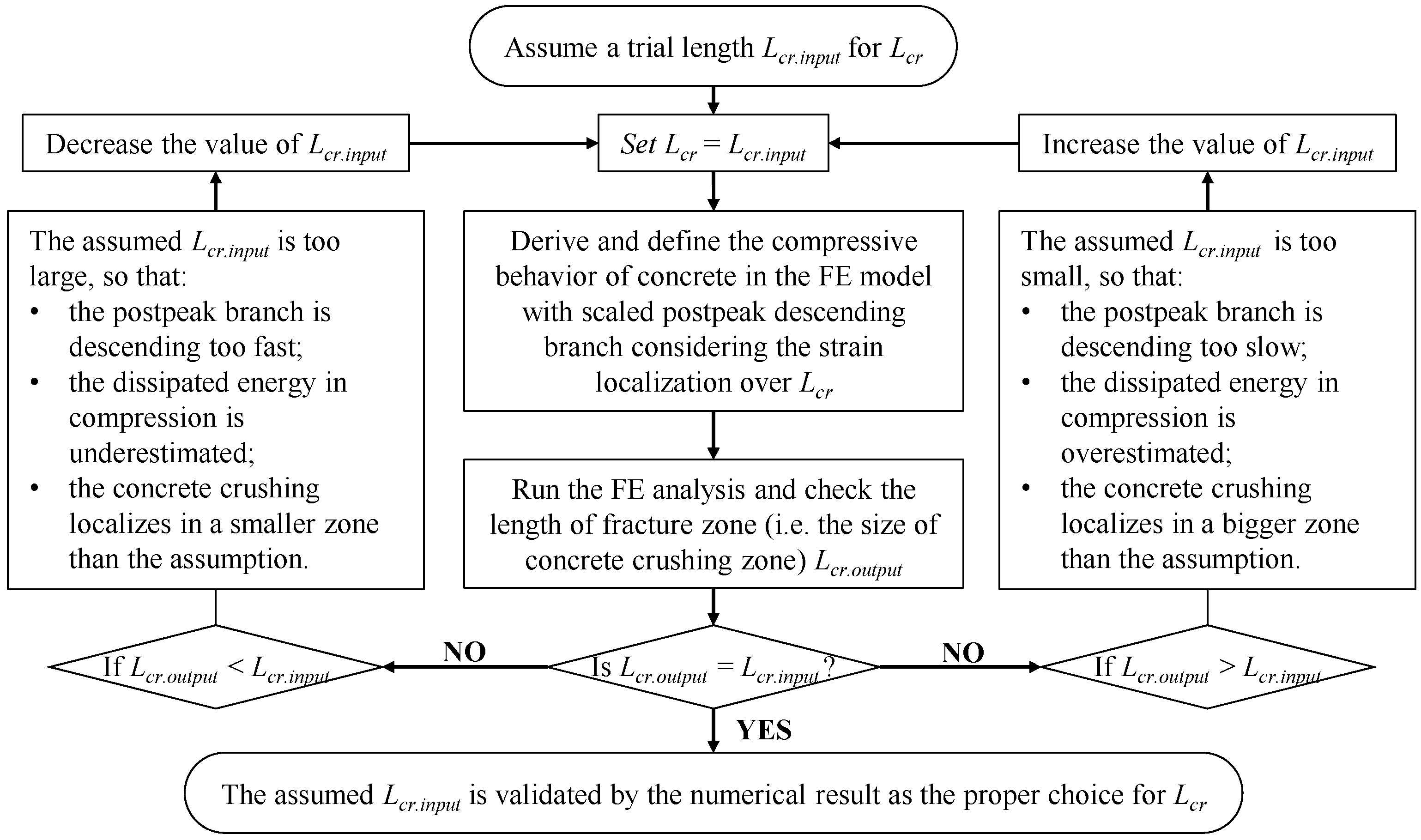

Identifying the size of crushing zone: The modification of the post-peak strain-softening behavior also requires a proper assumption of the size of the critical fracture zone

, which should be validated according to the size of the simulated crushing zone in the FE analysis. Herein, an iterative procedure is proposed for identifying the value of

via a reasonable approach. As indicated by the flowchart of

Figure 4, the assumed value

used to modify the post-peak branch of the compressive behavior as input data should be verified according to the observed length

of the simulated crushing zone in the numerical result.

can be visualized by contour plots highlighting the regions with compressive strains larger than

.

As the reference constitutive model adopted in the present FE analysis, the Model Code relation is reasonably accurate for specimens with a length of approximately 200 mm [

14], providing a fair benchmark to modify the post-peak branch with the specified length

according to the scaling rule in

Figure 3. The reasonable length of the critical fracture zone is identified as

via the proposed iterative procedure shown in

Figure 4. Details regarding the identification of

are presented in

Section 4.5.

3.1.4. Concrete Damage Evolution

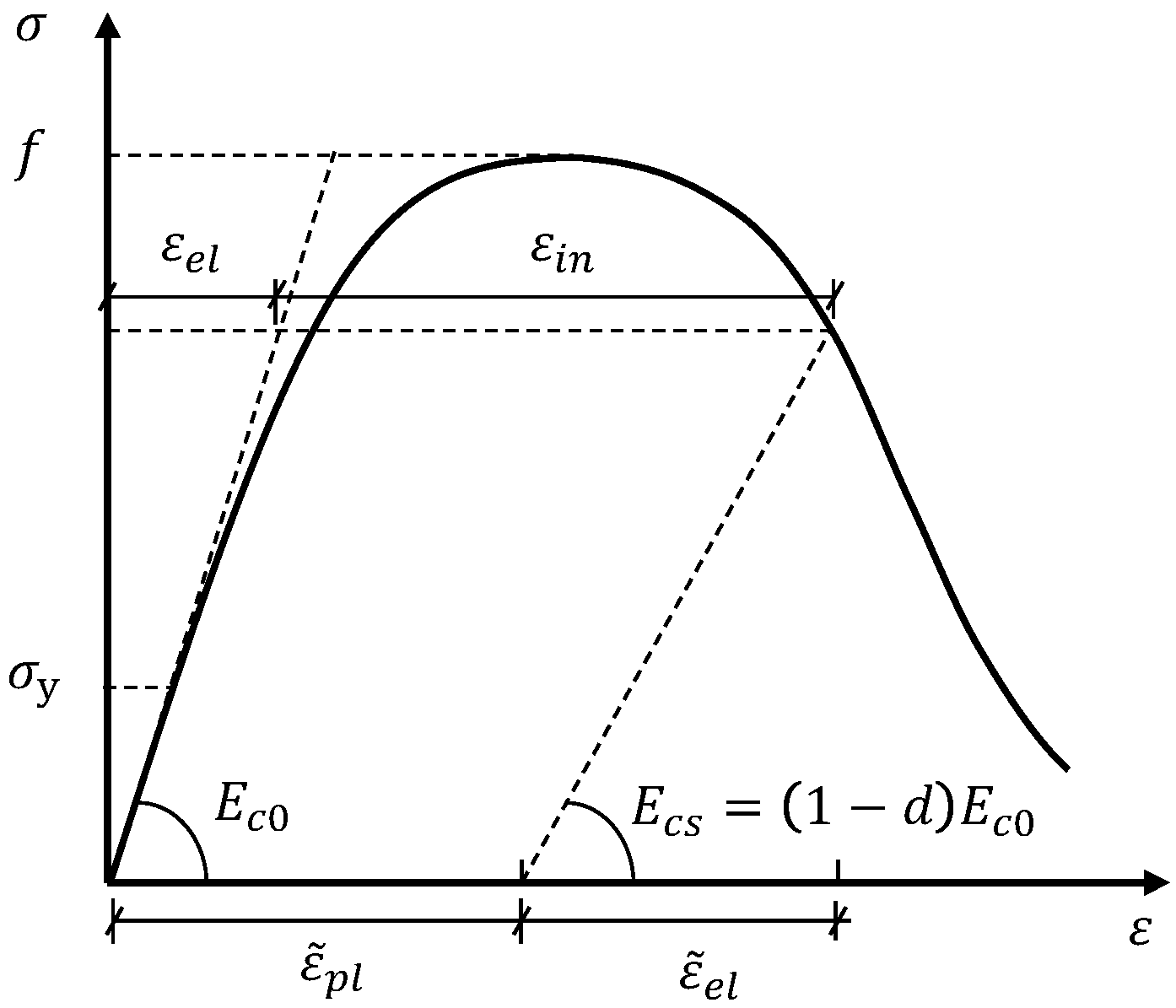

In the adopted CDP model, the concrete damage evolution is characterized by the degradation of the material stiffness (i.e., the elastic modulus of concrete) in the post-peak regime of the constitutive law.

Figure 5 presents a generic stress–strain relationship (Equation (8)) for concrete in uniaxial tension or compression:

where

,

, and

represents the elastic, inelastic, and total strains, respectively, at a given stress

; the inelastic strain is

when

(the inelastic strain

is commonly referred to as the cracking strain

in the description of concrete in tension).

represents the initial elastic modulus of undamaged concrete.

Considering the damage evolution beyond the peak stress, the initial elastic strain

in

Figure 5 changes to

owing to the degradation of the elastic modulus from

to

according to Equation (9).

where,

is the damage factor to be defined for characterizing the damage evolution.

In the present FE analyses, the damage model proposed by Lubliner et al. [

41] is adopted, which assumes that in the post-peak regime, the degraded material stiffness is proportional to the residual cohesion of the material. Considering that the material cohesion can be correlated to the stress state, this leads to:

where

and

represent the material cohesion in the yield criteria corresponding to the stress level

and peak stress

, respectively. For concrete,

represents the concrete tensile strength

or compressive strength

.

Substituting Equation (10) into Equation (9) yields the damage variable, as follows:

Importantly, the defined damage variable must satisfy the condition that the equivalent plastic strain should not decrease as the damage variable increases.

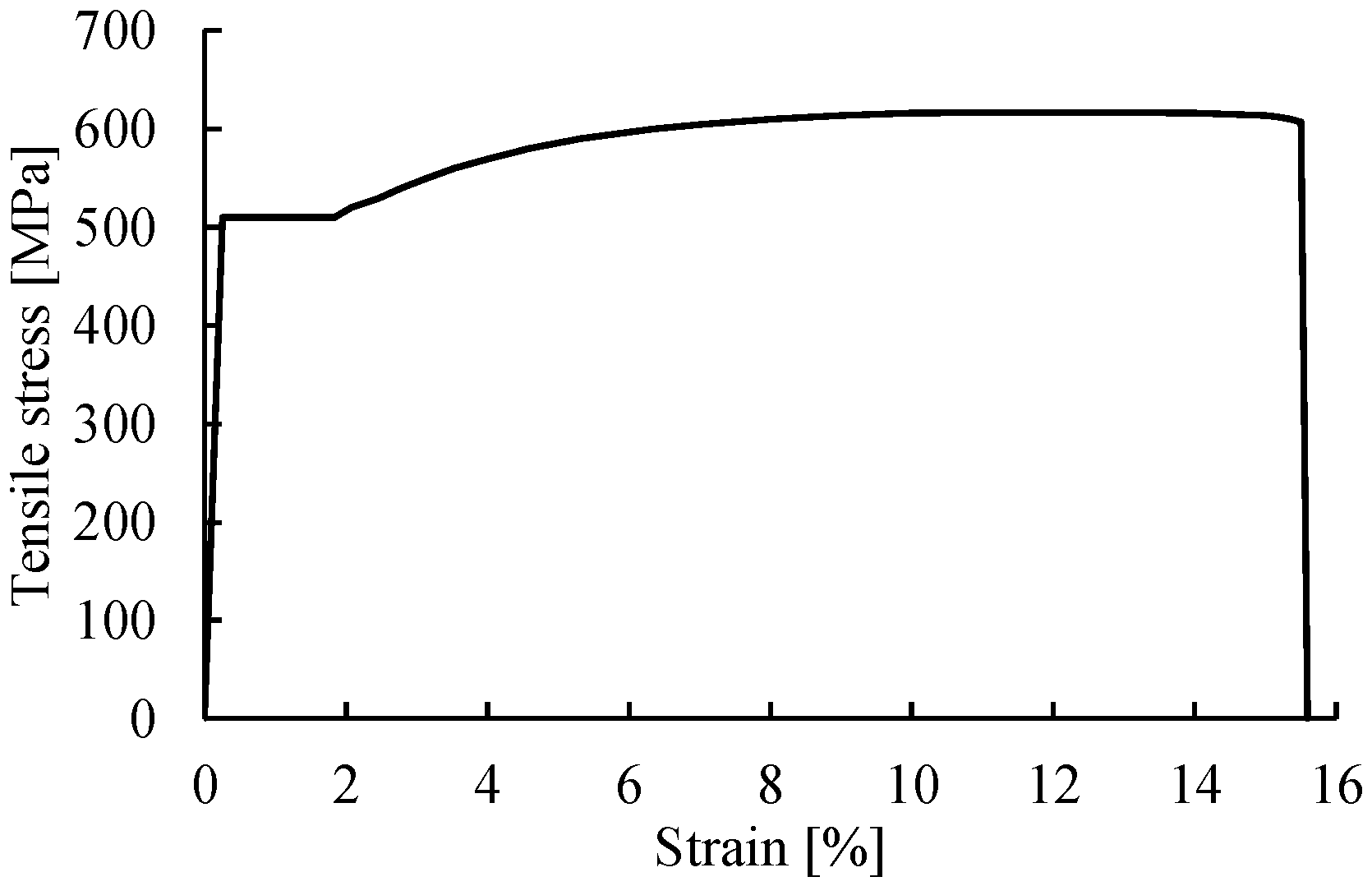

3.2. Modeling of Steel Reinforcement

The steel reinforcement, including the longitudinal reinforcing bars and the transverse stirrups, is modeled as a one-dimensional wire, to which the element type

truss is assigned. The material properties of the steel reinforcement are defined according to the results of standard tensile tests performed in the laboratory.

Figure 6 shows the tensile stress–strain relationship defined for the steel reinforcement in the FE analyses, which is characterized by the elastic modulus

, the yielding stress

, the ultimate tensile strength

, the ultimate strain

, and the rupture strain

.

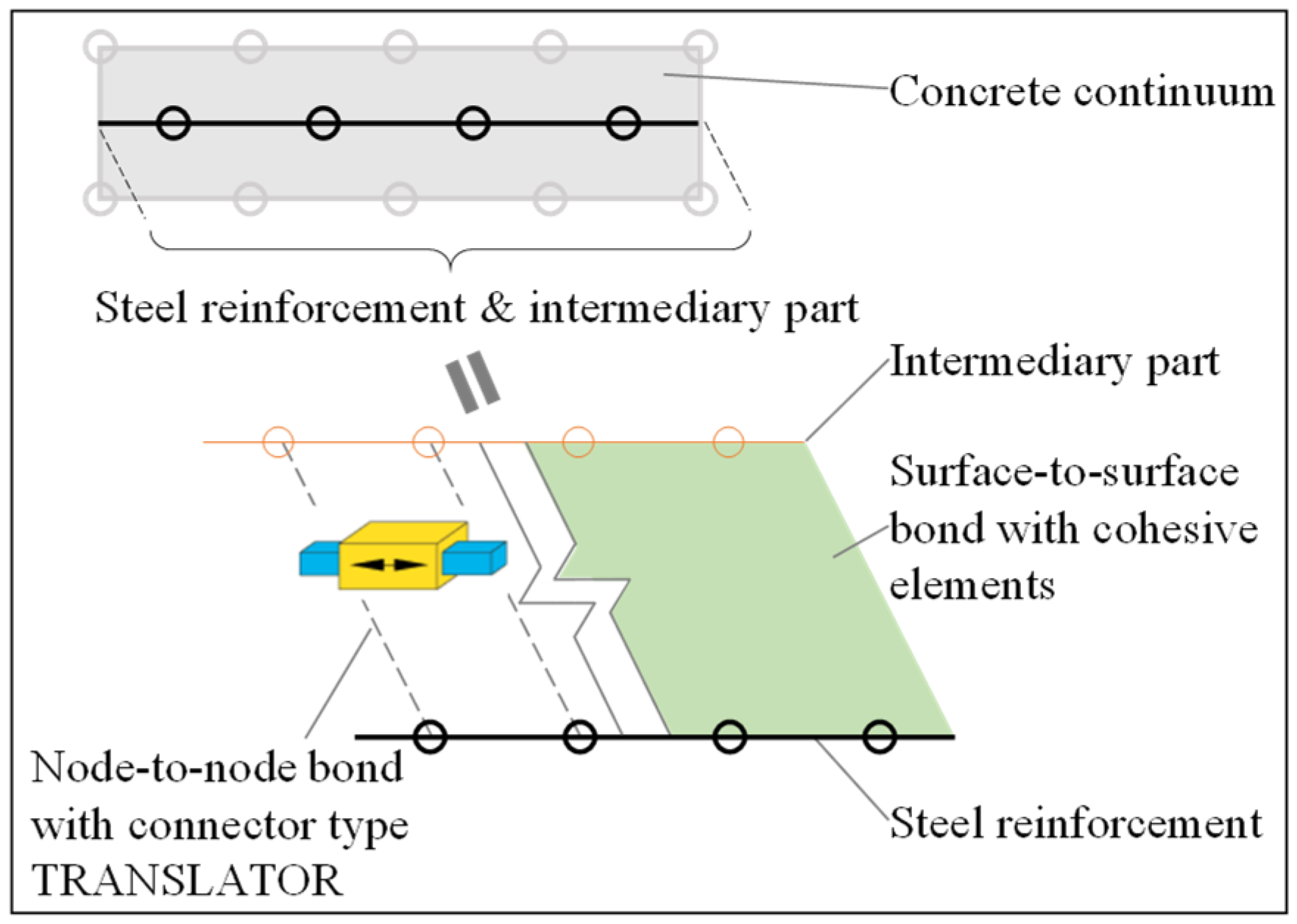

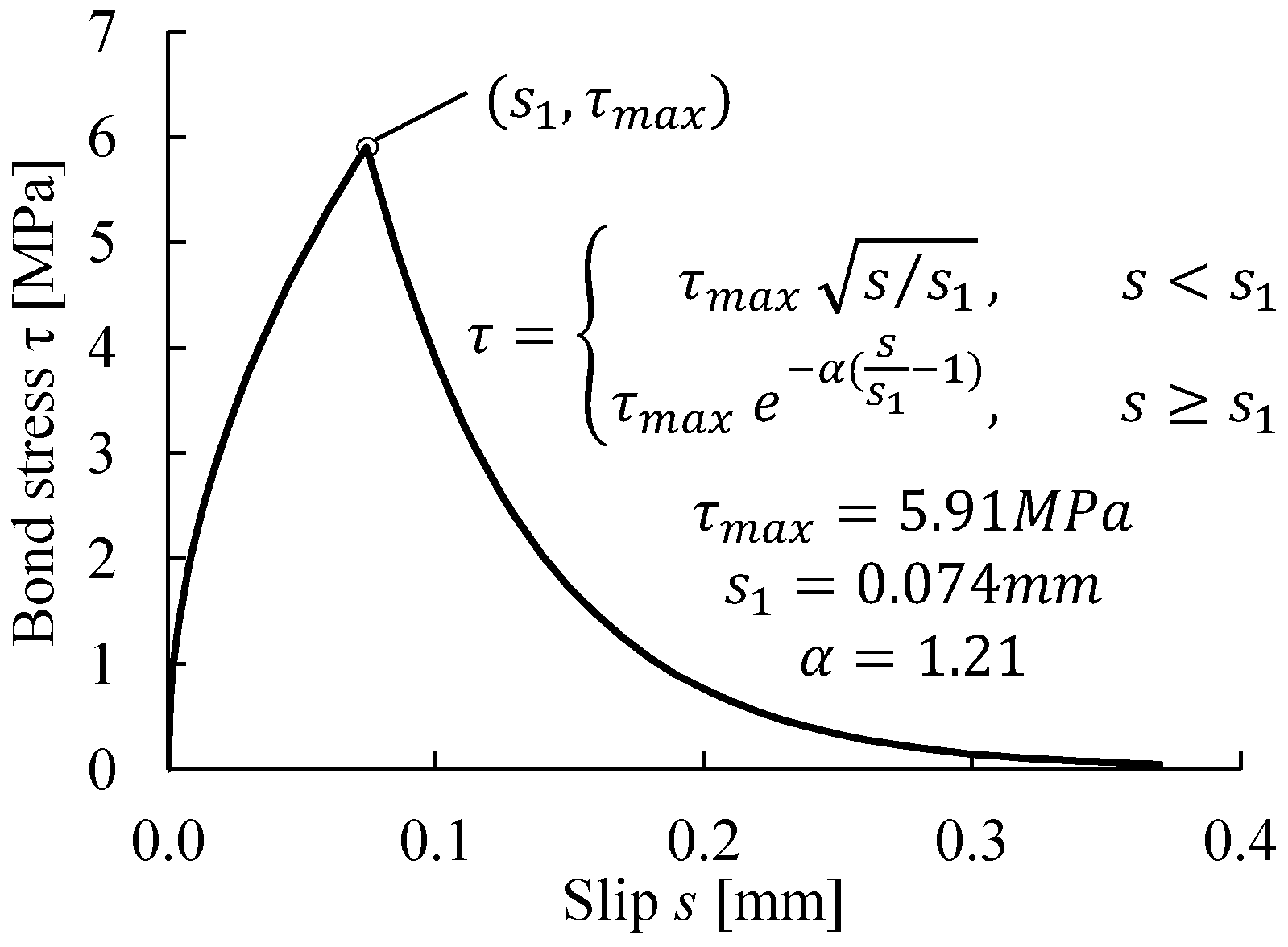

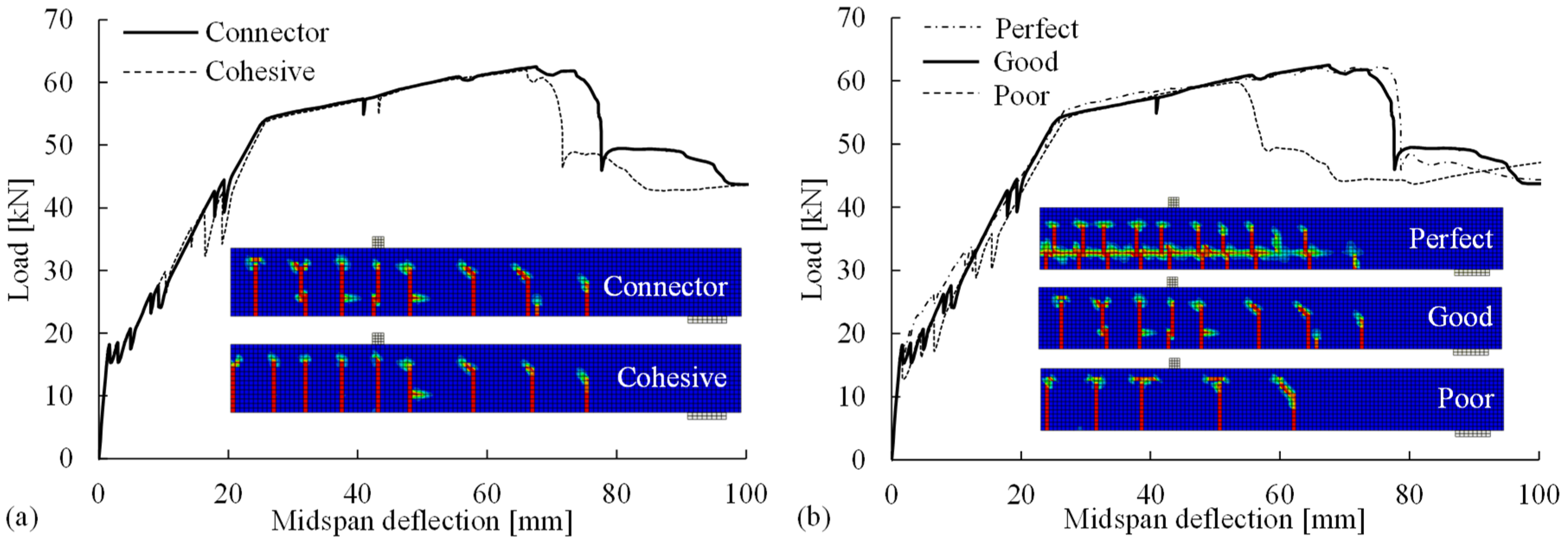

3.3. Interaction between Concrete and Steel Reinforcement

The proper modeling of the bond–slip behavior between the concrete and the embedded steel reinforcement is critical for obtaining clear discrete crack bands in the simulated beam model and reasonable flexural responses after the cracking point. In the present FE analyses, the bond between the longitudinal reinforcement and the concrete was assumed to be in good condition, and the bond–slip relationship according to Model Code 2010 [

15] is adopted. The Model Code bond–slip relationship is shown in

Figure 7, where

,

,

,

, and

. The interaction between the stirrups and the concrete was modeled as embedded, assuming a perfect bond with no relative slip (a simplification with negligible effects).

To implement the bond–slip behavior in the FE model, the use of connectors to build the node-to-node bond is proposed as a reference method. Another commonly applied method using cohesive elements [

2,

54] is implemented for comparison. These two methods are referred to as the connector method and the cohesive method, and corresponding schemes are presented in

Figure 8. An intermediary part is created as a copy of the steel reinforcement wire but with a significantly lower material stiffness (e.g., 0.1% of

). The intermediary part is embedded (i.e., nodes are fully constrained) in the concrete continuum at the position of the steel reinforcement. The real steel reinforcement wire is connected to the intermediary part instead of the concrete continuum, using either connectors or cohesive elements. The chosen bond–slip relationship is finally assigned to the connectors or cohesive elements. The main benefit of introducing such an additional intermediary part is that the interaction properties assigned to the connectors or cohesive elements are not affected by the mesh refinement of the concrete continuum.

3.3.1. Node-to-Node Connector Method

In the connector method, the bond–slip interaction is created using connectors (type: translator) between the nodes of the steel reinforcement and the nodes of the concrete. This method is adopted in the FE analyses as the reference modeling choice to assign the bond–slip behavior. To facilitate the assignment of node-to-node connectors, a Python script is developed to automatically implement multiple wire features between the neighboring nodes of the reinforcement and concrete. These wires can be efficiently defined using a suitable type of connector called translator, which allows uniaxial translation only in the direction of the steel reinforcement between the connected nodes. Considering that the bond–slip behavior is realized by discrete node-to-node connections, the bond force

, rather than the bond stress

, should be derived to define the bond at a given relative slip

s between the steel reinforcement and the concrete, as indicated by Equation (12). When the connector method is used, for obtaining an accurate simulation of the nodal bond forces and crack widths, the connector spacing (and the length of the steel reinforcement elements) should not exceed the size of the concrete elements.

where,

represents the total circumference of the steel reinforcement, and

represents the distance between two neighboring node-to-node connectors.

3.3.2. Surface-to-Surface Cohesive Method

The cohesive method in ABAQUS can model the interfacial bond behavior in either cohesive-contact or cohesive-element approach. The cohesive-contact approach defines the cohesive behavior as part of a contact model with zero interface thickness. For instance, this approach is used in [

24,

25] to efficiently define multiple interfacial responses in Mode I and Mode II. As an alternative, the cohesive-element approach utilizes cohesive elements to model the bond interface with a finite thickness; thus the interfacial response is characterized by the constitutive behavior assigned to the cohesive elements [

2]. The cohesive-element approach allows to easily track damage evolution in the interface and visualize the bond failure by removing the damaged cohesive elements. This is critical to capture the debonding process of the CFRP plate in the current study (see

Section 3.4). Therefore, the cohesive-element approach is also used here for modeling the steel-concrete interaction in order to compare it with the proposed node-to-node connector method. The layer of cohesive elements has a negligible thickness (1 µm in the current FE models) between the steel reinforcement wire and the concrete continuum. The constitutive response of cohesive elements was defined to represent the bond stress–relative slip relationship in

Figure 7; damage evolution was introduced to characterize the nonlinear response of softening and degradation of elasticity.

3.4. Interaction between CFRP Plate and Concrete

In the modeling of the CFRP-strengthened beam, the bond between the CFRP plate and the concrete was modeled in the cohesive-element approach, as described in

Section 3.3.2, in order to capture the debonding process induced by intermediate cracks. The 1 mm-thick adhesive layer was modeled with cohesive elements. The constitutive response of the cohesive elements was defined to represent the bond–slip model proposed by Lu et al. [

55], see

Figure 9.

3.5. Numerical Solution Strategy

The static analysis procedure is used for the reference FE model to solve the nonlinear response of the RC beam subjected to monotonic loading. To overcome severe convergence difficulties in the static analysis [

8,

26], the technique of viscoplastic regularization is implemented and recommended (see

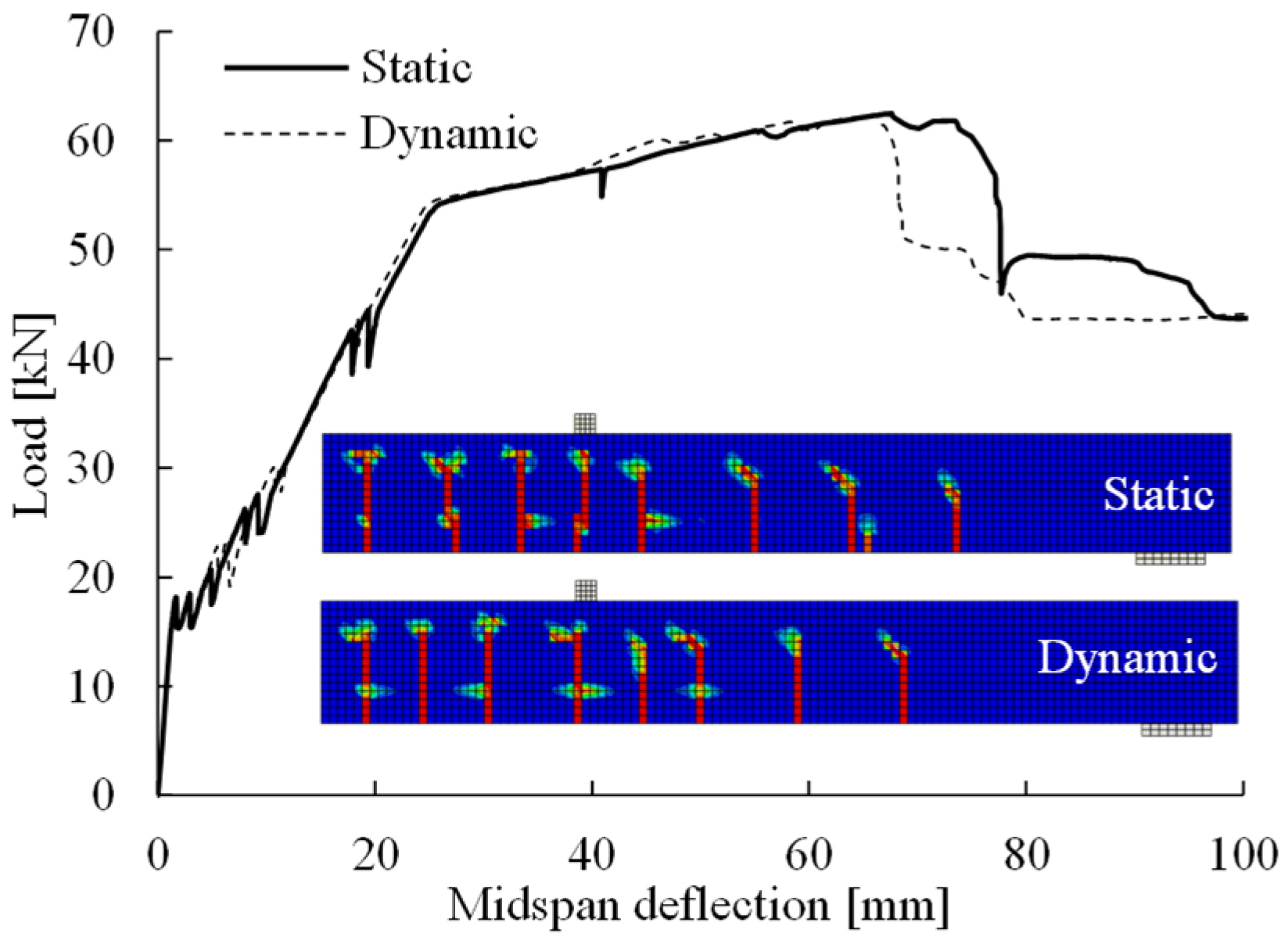

Section 4.2). As an alternative to the static method, numerical analyses can be performed in a dynamic procedure adopting an implicit or explicit solution method. In

Section 4.7, the dynamic analysis approach based on the implicit Hilber–Hughes–Taylor–α solution method proposed by Chen et al. (2015) [

7] is implemented in comparison with the static analysis solution for validation.