Chemical Changes of Wood Treated with Caffeine

Abstract

1. Introduction

2. Materials and Methods

2.1. Wood Specimens

2.2. Chemicals

2.3. Preparations of Wood Specimens

2.4. Chemical Analysis

2.4.1. Elementary Analysis

2.4.2. Fourier Transform Infrared (FTIR) Analysis

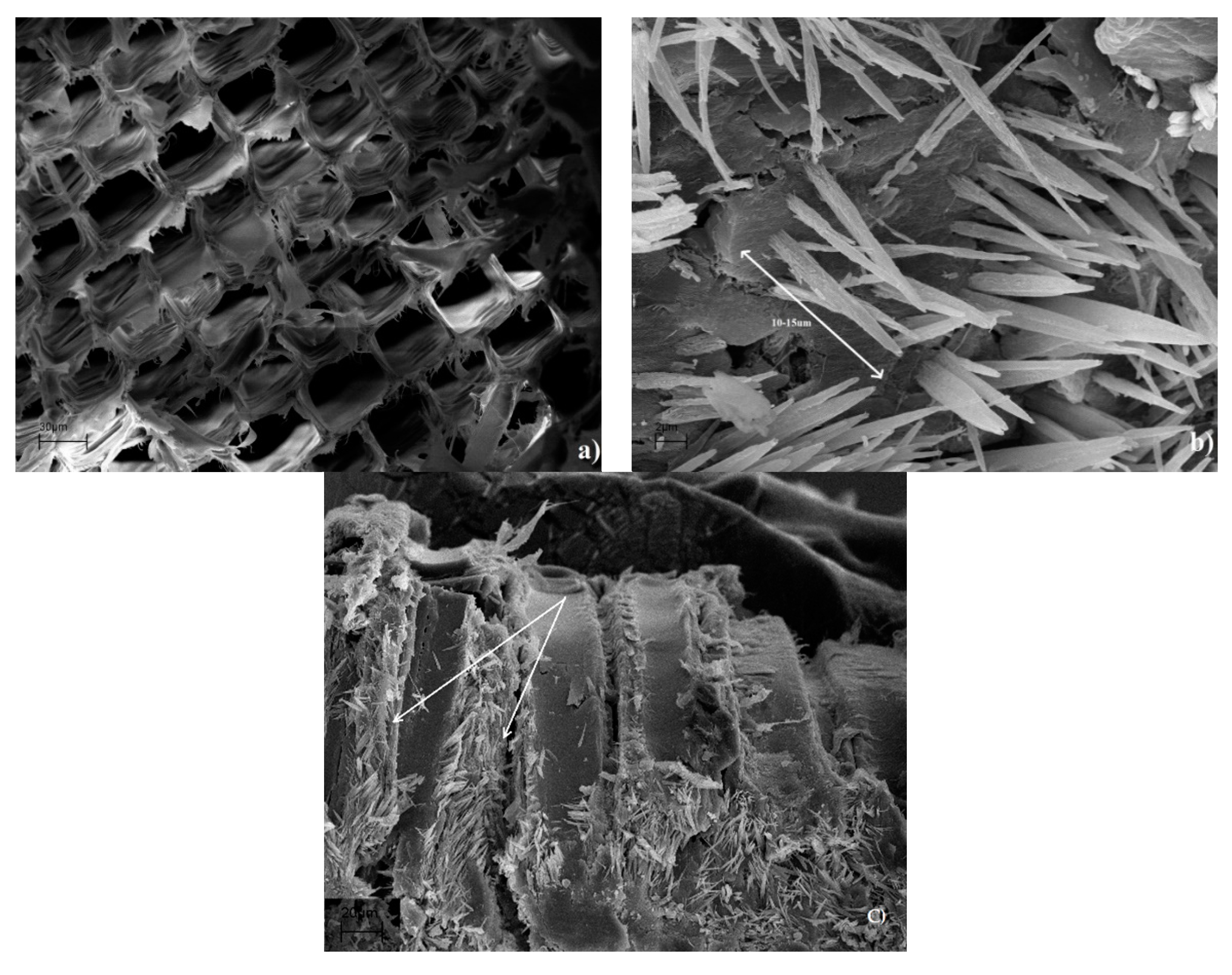

2.4.3. Scanning Electron Microscopy of the Treated Sample

2.5. Computational Studies

2.6. Statistical Analysis

3. Results and Discussion

3.1. Elementary Analysis

3.2. FTIR Analysis

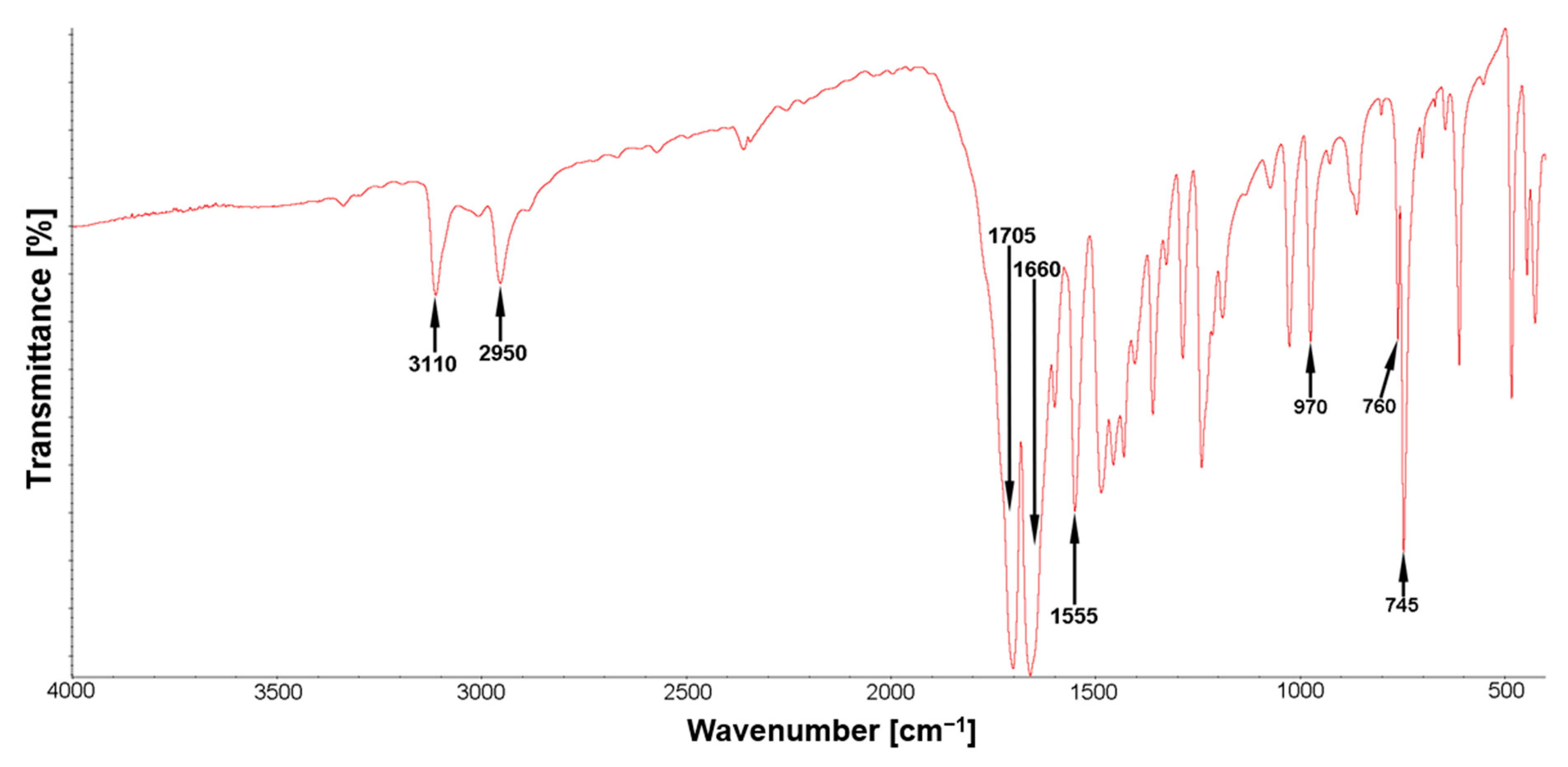

3.2.1. Analysis of Pure Caffeine

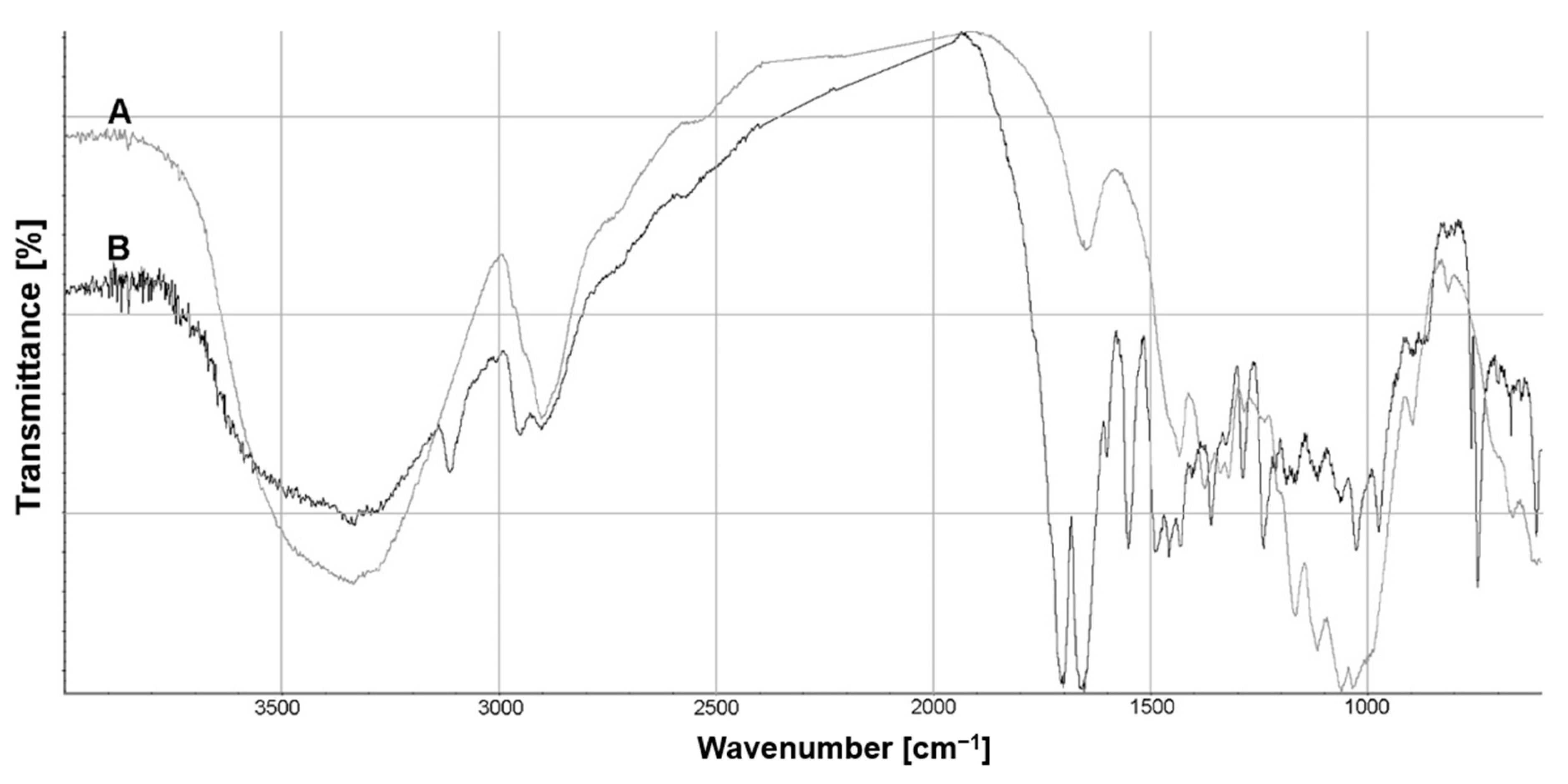

3.2.2. Analysis of Cellulose after Reaction with Caffeine

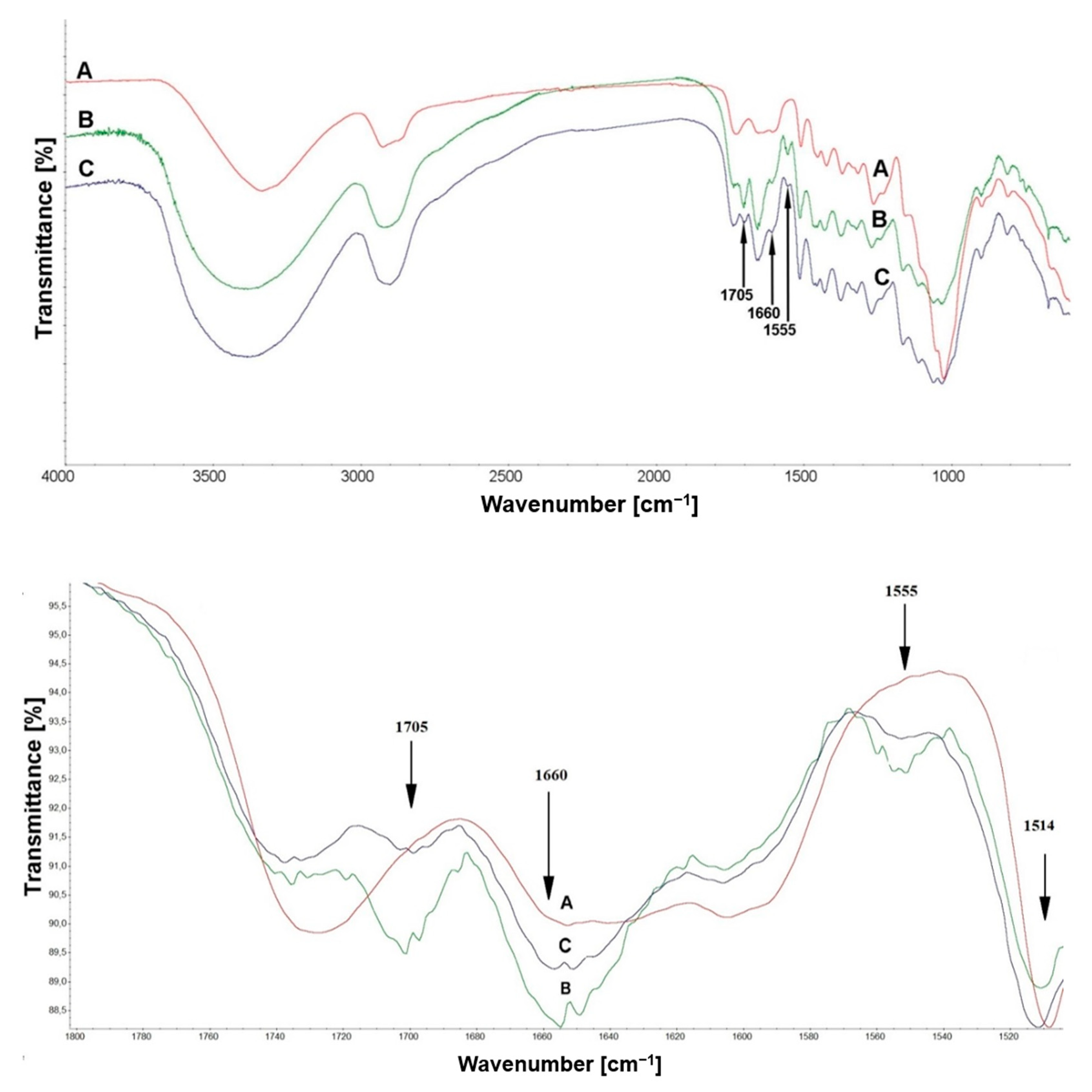

3.2.3. Analysis of Lignin after Reaction with Caffeine

3.2.4. Analysis of Treated Wood

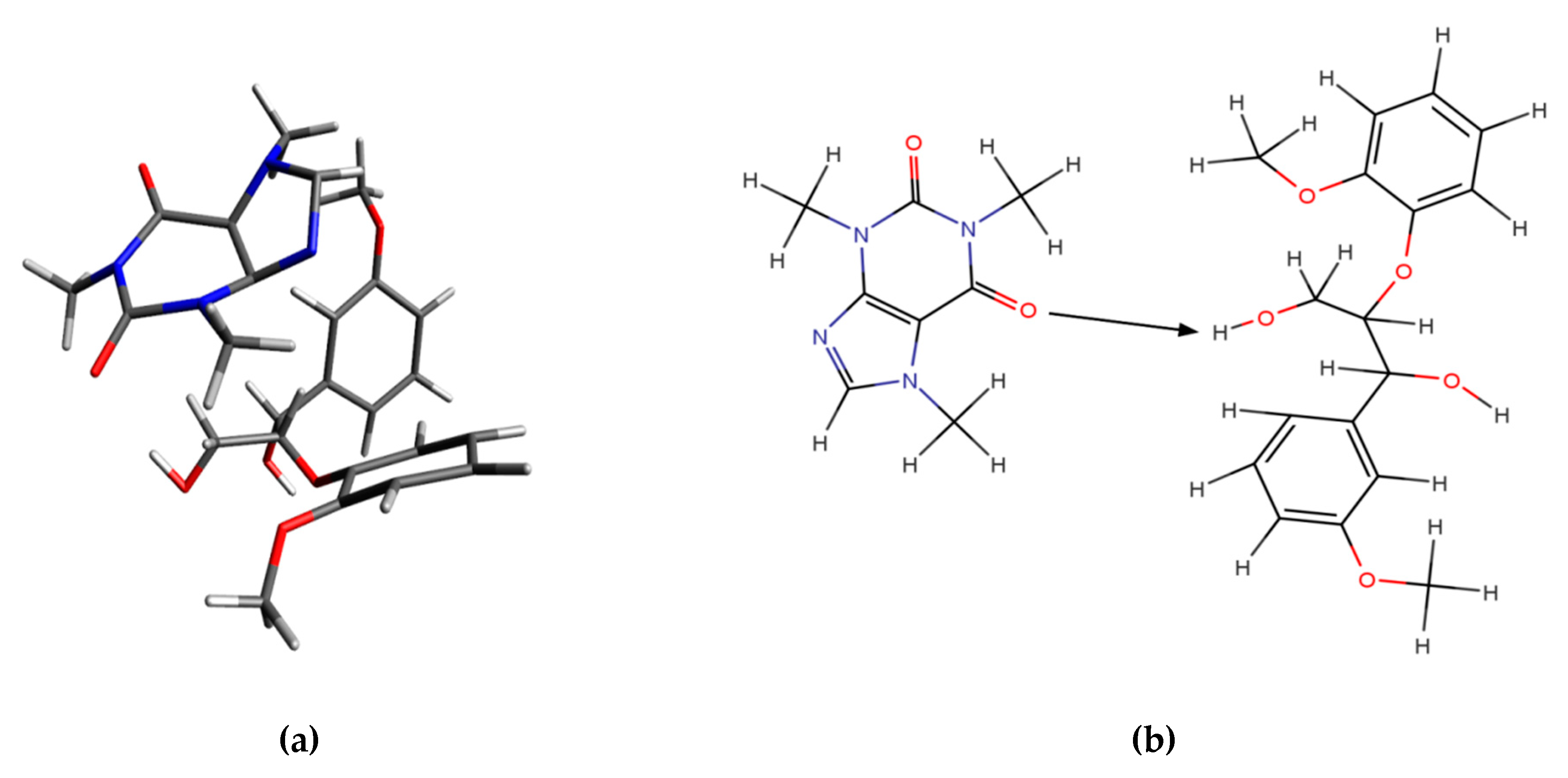

3.3. Computational Studies

4. Conclusions

- Caffeine is significantly leached from the wood structure after aging. This was evidenced by the reduced (about 52%) content of nitrogen in the treated wood subjected to leaching in comparison to the unleached treated wood. A low penetration of caffeine led to an accumulation of caffeine in the wood surface, which also leached out more easily.

- The FTIR analysis demonstrated that there were no chemical interactions between caffeine and cellulose. No relevant changes and no visible bands from new vibrations resulting from the interaction of caffeine with cellulose were observed.

- The changes observed in the FTIR spectra involved the intensity of the C=O(6) caffeine carbonyl group and the signals from guaiacyl units. This might indicate a weakened self-assembling of caffeine molecules and evidence favorable interactions between caffeine and lignin. It might be possible that caffeine is bound or in complex with the cell wall phenolics. Various vibrations common for the lignin structure changed after treatment with caffeine.

- The results of molecular modeling demonstrate that these interactions occurred between the carbonyl (C=O) groups of caffeine and the methylene group on the guaiacyl aromatic ring. The results of theoretical research on the interactions of caffeine with the guaiacyl β-O-4 model compound showed that the distance between oxygen (O6) and hydrogen was 2.185 Å. Additionally, the SEM observations suggest that caffeine was accumulated in the middle lamella and the primary walls, which were composed mainly of lignin.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

Appendix B

| Atomic Coordinates of Gu_Caf Complexes | ||||||

|---|---|---|---|---|---|---|

| Cluster 1 | Cluster 2 | |||||

| Atom | x | y | z | x | y | z |

| C | −15.05000 | −7.18400 | −13.37900 | −9.45900 | −2.00800 | −3.12100 |

| C | −15.53900 | −6.87100 | −14.70700 | −8.48800 | −2.15400 | −4.15500 |

| C | −13.95200 | −6.47400 | −12.77300 | −9.99700 | −3.28400 | −2.54300 |

| C | −13.61900 | −5.10600 | −13.27700 | −9.09500 | −4.44600 | −2.50600 |

| C | −14.10500 | −4.75100 | −14.60200 | −8.35000 | −4.66800 | −3.78300 |

| C | −15.30000 | −5.47500 | −15.11500 | −7.80300 | −3.44800 | −4.34300 |

| O | −13.82200 | −3.69700 | −15.14300 | −7.78300 | −5.70900 | −4.05700 |

| O | −12.64400 | −4.56600 | −12.77200 | −9.54200 | −5.40100 | −1.90000 |

| C | −12.92800 | −3.65000 | −11.98500 | −9.11200 | −5.77500 | −0.85900 |

| C | −12.87800 | −2.27300 | −12.43800 | −8.48600 | −7.08400 | −0.85200 |

| O | −11.93300 | −1.76300 | −12.87400 | −9.17200 | −8.10900 | −0.97100 |

| C | −12.19600 | −3.70600 | −10.68400 | −9.95100 | −5.81900 | 0.35200 |

| O | −11.01800 | −3.60200 | −10.75900 | −10.92400 | −6.51900 | 0.25100 |

| C | −12.78200 | −4.74100 | −9.82500 | −10.32600 | −4.58100 | 0.87000 |

| C | −12.13700 | −6.06500 | −9.67600 | −11.19200 | −3.49700 | 0.40800 |

| C | −14.16800 | −4.62000 | −9.32800 | −9.38300 | −4.07600 | 1.86300 |

| C | −12.65400 | −7.07500 | −8.78700 | −11.46400 | −2.32600 | 1.17400 |

| C | −14.61400 | −5.56100 | −8.28200 | −9.43300 | −2.81200 | 2.62800 |

| C | −13.99500 | −6.87900 | −8.30600 | −10.28600 | −1.84300 | 1.96300 |

| O | −15.73700 | −5.41300 | −7.84600 | −8.46200 | −2.55800 | 3.28300 |

| C | −15.93700 | −4.92400 | −6.74900 | −8.49300 | −2.57900 | 4.47800 |

| C | −13.04400 | −3.54500 | −16.07800 | −8.13900 | −6.26600 | −5.04900 |

| H | −15.21800 | −8.19900 | −13.12300 | −9.92800 | −1.11400 | −2.81700 |

| H | −16.24100 | −7.51100 | −15.25000 | −7.97600 | −1.25800 | −4.62500 |

| H | −13.69600 | −6.71600 | −11.71100 | −10.76300 | −3.19200 | −1.70300 |

| H | −15.69800 | −5.13200 | −16.05600 | −7.01900 | −3.65700 | −5.07900 |

| H | −13.97200 | −3.91800 | −11.76100 | −8.30700 | −5.05800 | −0.68700 |

| H | −13.22000 | −1.56600 | −11.70000 | −8.01900 | −7.12600 | 0.10700 |

| H | −13.59900 | −2.07200 | −13.27500 | −7.69900 | −7.29800 | −1.56300 |

| H | −12.40500 | −0.97200 | −12.59700 | −9.46300 | −8.15800 | −1.81300 |

| H | −12.53400 | −2.86100 | −10.11800 | −9.38300 | −6.37700 | 1.14400 |

| H | −10.62400 | −4.36300 | −11.17100 | −11.28500 | −6.41600 | −0.63900 |

| H | −11.12300 | −6.09500 | −10.03400 | −11.90400 | −3.67300 | −0.39400 |

| H | −14.57500 | −3.56100 | −9.25300 | −8.81000 | −4.86800 | 2.38600 |

| H | −12.42100 | −8.04800 | −9.10300 | −12.31700 | −1.77000 | 0.79200 |

| H | −14.35700 | −7.67000 | −7.62200 | −10.43400 | −0.87700 | 2.49600 |

| H | −15.35800 | −3.95200 | −6.62700 | −8.94800 | −3.56400 | 4.78600 |

| H | −16.98000 | −4.62800 | −6.54600 | −7.49000 | −2.38900 | 4.86500 |

| H | −15.53600 | −5.55800 | −5.97000 | −9.10800 | −1.90900 | 4.91500 |

| H | −12.05800 | −3.78500 | −15.73300 | −9.21000 | −6.43000 | −4.95300 |

| H | −13.33900 | −4.08100 | −16.98800 | −7.94900 | −5.60900 | −5.86200 |

| H | −13.10100 | −2.55800 | −16.28200 | −7.61900 | −7.27100 | −5.14200 |

| C | −16.41100 | −2.18000 | −13.77600 | −4.27100 | −3.52600 | −3.86200 |

| N | −16.19000 | −1.53600 | −12.59700 | −4.68200 | −3.38800 | −2.58000 |

| C | −16.22300 | −2.46400 | −11.58800 | −4.72100 | −2.02000 | −2.31300 |

| N | −17.12500 | −3.49800 | −11.72300 | −4.54300 | −1.14500 | −3.31600 |

| C | −18.01800 | −3.39600 | −10.68000 | −5.47500 | −0.06600 | −3.15400 |

| N | −17.61700 | −2.41300 | −9.77600 | −6.04600 | −0.16600 | −1.91800 |

| C | −17.60500 | −2.76400 | −8.43800 | −5.91600 | 0.93500 | −1.01600 |

| C | −16.47200 | −1.84800 | −10.28200 | −5.68600 | −1.44500 | −1.41100 |

| C | −16.31200 | −0.34900 | −10.19400 | −6.56900 | −2.34700 | −0.80300 |

| O | −16.68100 | 0.22600 | −9.23500 | −7.34700 | −1.93400 | 0.03100 |

| N | −15.63000 | 0.33100 | −11.19900 | −6.00400 | −3.62700 | −0.77100 |

| C | −14.65000 | 1.28800 | −10.88000 | −6.28400 | −4.44900 | 0.29300 |

| C | −15.59400 | −0.17500 | −12.50900 | −5.53800 | −4.27500 | −1.96100 |

| O | −14.82900 | 0.26500 | −13.31700 | −5.43900 | −5.46100 | −2.07900 |

| H | −16.54900 | −3.26900 | −13.76100 | −4.97000 | −3.92500 | −4.50500 |

| H | −15.69900 | −1.98000 | −14.55300 | −3.53900 | −4.33600 | −3.89600 |

| H | −17.26200 | −1.76800 | −14.19300 | −3.88300 | −2.66700 | −4.30200 |

| H | −18.00200 | −4.27100 | −10.10400 | −5.11500 | 0.94500 | −3.33600 |

| H | −18.03600 | −3.75300 | −8.46900 | −6.48100 | 0.74700 | −0.13400 |

| H | −16.59300 | −2.59900 | −8.19600 | −4.96300 | 1.00100 | −0.58000 |

| H | −18.19000 | −1.93800 | −7.85000 | −6.18600 | 1.79600 | −1.60700 |

| H | −13.80500 | 1.23400 | −11.53900 | −5.82700 | −5.39900 | 0.27900 |

| H | −14.31500 | 1.19400 | −9.86200 | −7.34900 | −4.72100 | 0.33700 |

| H | −15.15400 | 2.22800 | −11.01500 | −6.07900 | −3.86600 | 1.17300 |

| Atomic Coordinates of Gu_Caf Complexes | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Cluster 3 | Cluster 4 | Cluster 5 | |||||||

| Atom | x | y | z | x | y | z | x | y | z |

| C | −13.15800 | −6.70000 | −15.40500 | −8.15800 | −1.29400 | −15.39700 | −10.44800 | −5.00000 | −6.43400 |

| C | −13.56600 | −7.89600 | −14.74100 | −7.21000 | −1.92100 | −14.49000 | −9.41500 | −5.82700 | −6.92400 |

| C | −12.79800 | −6.74100 | −16.82300 | −8.30900 | −1.84200 | −16.71300 | −10.23900 | −4.51600 | −5.11400 |

| C | −13.46400 | −7.72000 | −17.70300 | −8.02500 | −3.26300 | −16.96100 | −8.97200 | −4.61300 | −4.35000 |

| C | −13.80600 | −9.00400 | −17.09600 | −6.85300 | −3.75800 | −16.12700 | −8.00100 | −5.57600 | −4.91800 |

| C | −14.13900 | −8.94700 | −15.61000 | −6.80700 | −3.32800 | −14.73600 | −8.07200 | −5.86700 | −6.31200 |

| O | −14.48100 | −9.78500 | −17.72000 | −6.43800 | −4.84400 | −16.49100 | −6.91500 | −5.60100 | −4.37100 |

| O | −13.38400 | −7.59900 | −18.88200 | −8.34700 | −3.84600 | −17.97700 | −8.96200 | −4.38300 | −3.16300 |

| C | −14.26000 | −7.00600 | −19.49300 | −9.06200 | −4.84100 | −17.92100 | −8.37300 | −3.42800 | −2.74800 |

| C | −14.83000 | −7.79200 | −20.55600 | −8.47400 | −6.08800 | −18.40000 | −7.10900 | −3.70900 | −2.03800 |

| O | −14.18700 | −8.14800 | −21.48800 | −7.97600 | −6.18600 | −19.48200 | −7.10200 | −4.37700 | −1.00800 |

| C | −13.91600 | −5.68900 | −20.04800 | −10.38500 | −4.81300 | −18.59600 | −9.12500 | −2.51300 | −1.88500 |

| O | −13.11800 | −5.74200 | −20.95500 | −10.33300 | −4.74500 | −19.77700 | −9.46300 | −3.04600 | −0.88600 |

| C | −13.76100 | −4.58500 | −19.12700 | −11.31800 | −3.90300 | −18.01600 | −10.21300 | −1.82700 | −2.58800 |

| C | −12.44900 | −4.16000 | −18.79500 | −11.45500 | −2.56200 | −18.67600 | −11.54300 | −2.47100 | −2.84300 |

| C | −14.89500 | −4.20400 | −18.26700 | −11.98000 | −4.10700 | −16.75100 | −9.67900 | −0.88800 | −3.58700 |

| C | −12.30200 | −3.07800 | −17.90000 | −12.56600 | −1.69600 | −18.26500 | −12.38100 | −1.90200 | −3.90300 |

| C | −14.78400 | −3.06200 | −17.32600 | −13.12300 | −3.19600 | −16.34700 | −10.53600 | −0.39000 | −4.63200 |

| C | −13.42500 | −2.73000 | −17.00100 | −13.05600 | −1.87800 | −16.88700 | −11.77100 | −1.12400 | −4.94900 |

| O | −15.77500 | −2.65400 | −16.81400 | −13.57200 | −3.35000 | −15.27900 | −10.19400 | 0.45000 | −5.41800 |

| C | −16.20700 | −1.60700 | −17.10100 | −14.58700 | −3.98300 | −15.25600 | −10.36500 | 1.61600 | −5.20800 |

| C | −13.98300 | −10.74600 | −18.24100 | −5.34600 | −4.94300 | −16.91600 | −6.44300 | −6.46300 | −3.71900 |

| H | −12.56400 | −5.94200 | −14.95700 | −8.31000 | −0.23500 | −15.21900 | −11.20100 | −4.82900 | −7.09500 |

| H | −13.78700 | −7.88800 | −13.66600 | −6.94900 | −1.41100 | −13.44700 | −9.39900 | −5.82900 | −7.97600 |

| H | −12.61700 | −5.79200 | −17.39100 | −8.91300 | −1.30300 | −17.37100 | −10.97000 | −3.72600 | −4.78600 |

| H | −14.34200 | −9.87600 | −15.22600 | −6.19700 | −3.92300 | −14.06900 | −7.32000 | −6.51400 | −6.71700 |

| H | −15.10900 | −7.01500 | −18.82400 | −9.16700 | −4.98700 | −16.83200 | −8.09000 | −2.77000 | −3.57100 |

| H | −15.72700 | −7.35200 | −20.97400 | −9.13800 | −6.92800 | −18.24600 | −6.39100 | −2.92500 | −1.85600 |

| H | −15.18800 | −8.77800 | −20.10800 | −7.73700 | −6.34500 | −17.70700 | −6.52600 | −4.31900 | −2.77800 |

| H | −13.52100 | −8.76300 | −21.26200 | −8.57800 | −6.13700 | −20.21400 | −7.65400 | −4.04000 | −0.35000 |

| H | −14.88900 | −5.31500 | −20.46400 | −10.73900 | −5.74600 | −18.36200 | −8.42000 | −1.72100 | −1.60700 |

| H | −13.49200 | −6.37700 | −21.56900 | −11.23300 | −4.84900 | −20.06400 | −10.22500 | −3.57200 | −1.02600 |

| H | −11.73200 | −4.27700 | −19.52000 | −10.96500 | −2.55400 | −19.61700 | −11.96500 | −2.99100 | −2.04500 |

| H | −15.87700 | −4.39500 | −18.58600 | −11.93100 | −5.06900 | −16.25000 | −8.78300 | −0.42500 | −3.42100 |

| H | −11.36100 | −2.88100 | −17.56500 | −12.57600 | −0.65600 | −18.59300 | −13.20000 | −2.53300 | −4.20500 |

| H | −13.40100 | −1.91200 | −16.26400 | −13.87400 | −1.15300 | −16.61900 | −12.43100 | −0.53900 | −5.59800 |

| H | −15.40400 | −0.93400 | −16.86700 | −14.53300 | −5.02600 | −15.56900 | −9.92000 | 1.88300 | −4.24400 |

| H | −16.26300 | −1.41700 | −18.16700 | −15.11200 | −4.10100 | −14.34600 | −9.92200 | 2.22100 | −5.90400 |

| H | −17.12100 | −1.37800 | −16.66800 | −15.26100 | −3.57400 | −15.98600 | −11.43500 | 1.79100 | −5.20800 |

| H | −13.19800 | −10.49000 | −18.97400 | −5.32700 | −5.86500 | −17.45400 | −6.94100 | −6.64700 | −2.83300 |

| H | −13.62500 | −11.45700 | −17.51100 | −5.03500 | −4.16400 | −17.65200 | −6.30400 | −7.42900 | −4.25100 |

| H | −14.71700 | −11.33000 | −18.71900 | −4.67100 | −4.90700 | −16.11100 | −5.39200 | −6.10100 | −3.52100 |

| C | −18.09000 | −9.45100 | −16.01200 | −12.45100 | −7.26000 | −15.14200 | −6.67000 | 1.93500 | −5.72000 |

| N | −17.97800 | −8.09400 | −16.51400 | −11.02800 | −7.20100 | −14.97200 | −6.36900 | 0.56900 | −6.13500 |

| C | −17.42700 | −7.08100 | −15.67400 | −10.52400 | −6.46400 | −13.88100 | −5.35500 | −0.13600 | −5.40400 |

| N | −17.63900 | −7.01900 | −14.29300 | −11.28500 | −5.35600 | −13.59600 | −5.08800 | 0.01300 | −4.04500 |

| C | −18.20100 | −5.87400 | −13.86900 | −10.40100 | −4.35200 | −13.17500 | −5.03900 | −1.21800 | −3.45300 |

| N | −18.27300 | −5.00400 | −14.98000 | −9.12800 | −4.93000 | −13.11800 | −5.00500 | −2.28400 | −4.31600 |

| C | −17.88300 | −3.71400 | −14.72800 | −8.62700 | −4.79100 | −11.80600 | −3.91100 | −3.12200 | −4.19900 |

| C | −17.76500 | −5.75200 | −16.06500 | −9.17000 | −6.13700 | −13.73700 | −5.17900 | −1.61600 | −5.55600 |

| C | −18.13200 | −5.43700 | −17.43800 | −8.16300 | −6.66100 | −14.60900 | −6.06900 | −2.25300 | −6.44500 |

| O | −18.37700 | −4.34100 | −17.86300 | −7.02800 | −6.63500 | −14.24200 | −5.85700 | −3.44500 | −6.64800 |

| N | −18.00600 | −6.53000 | −18.37700 | −8.70300 | −7.62000 | −15.45200 | −7.05200 | −1.49800 | −7.16800 |

| C | −18.16000 | −6.34100 | −19.79100 | −7.84500 | −8.70400 | −15.82600 | −7.95000 | −2.27600 | −7.88600 |

| C | −18.02500 | −7.86000 | −17.90400 | −10.04000 | −7.75200 | −15.80400 | −7.29900 | −0.14900 | −6.91200 |

| O | −17.89000 | −8.77700 | −18.67500 | −10.41500 | −8.47000 | −16.64800 | −8.21000 | 0.43500 | −7.42100 |

| H | −18.30600 | −10.16600 | −16.85000 | −12.88000 | −6.61200 | −14.34700 | −6.65500 | 1.86000 | −4.64200 |

| H | −18.81300 | −9.59700 | −15.25800 | −12.79900 | −8.23300 | −15.16700 | −7.57900 | 2.23300 | −6.29300 |

| H | −17.17700 | −9.63200 | −15.44700 | −12.64300 | −6.91900 | −16.14500 | −5.86800 | 2.61400 | −5.92000 |

| H | −17.53000 | −5.45700 | −13.14300 | −10.68200 | −3.92800 | −12.17200 | −4.11600 | −1.19500 | −2.85000 |

| H | −17.50600 | −3.63500 | −13.68500 | −7.91800 | −3.98400 | −11.69600 | −3.61700 | −3.05700 | −3.16300 |

| H | −17.07200 | −3.56300 | −15.42000 | −9.45600 | −4.40800 | −11.18900 | −4.33700 | −4.04600 | −4.49400 |

| H | −18.63500 | −3.10700 | −15.08900 | −8.18800 | −5.65300 | −11.27100 | −3.11300 | −2.91400 | −4.85100 |

| H | −18.13300 | −7.28000 | −20.35300 | −7.12300 | −8.38900 | −16.56000 | −8.86200 | −2.08900 | −7.60300 |

| H | −17.47900 | −5.60700 | −20.11100 | −8.48800 | −9.46400 | −16.40400 | −7.74400 | −3.30600 | −7.86000 |

| H | −19.05800 | −5.82600 | −20.05600 | −7.44600 | −9.26200 | −15.00200 | −7.84300 | −1.93600 | −8.95200 |

| System Consisted of αR, βR Guiacyl β-O-4 and Caffeine | Vacuum | Water | ||||||

|---|---|---|---|---|---|---|---|---|

| Counterpoise Corrected Energy [Hartree] | BSSE Energy [Hartree] | Sum of Monomers [Hartree] | Interaction Energy (Raw) [kcal/mol] | Interaction Energy (Corrected) [kcal/mol] | Energy [Hartree] | Sum of Monomers [Hartree] | Interaction Energy [kcal/mol] | |

| Clust1 | −1715.089733 | 0.003167 | −1715.072141 | −13.0 | −11.0 | −1715.117115 | −1715.098914 | −11.4 |

References

- Kokociński, W. Technologia drewna. In Drewno. Pomiary Właściwości Fizycznych i Mechanicznych (Wood. Measurement of Physical and Mechanical Properties); Prodruk: Poznań, Poland, 2004; ISBN 8388518755. [Google Scholar]

- Surmiński, J. Wood Properties and Uses; Forestry Sciences; Springer: Dordrecht, The Netherlands, 2007; Volume 78, pp. 333–342. [Google Scholar]

- Ugolev, B.N. Wood as a natural smart material. Wood Sci. Technol. 2013, 48, 553–568. [Google Scholar] [CrossRef]

- Cichy, W.; Witczak, M.; Walkowiak, M. Fuel Properties of Woody Biomass from Pruning Operations in Fruit Orchards. Bioresources 2017, 12, 6458–6470. [Google Scholar] [CrossRef]

- Fengel, D.; Wegener, G. Wood: Chemistry, Ultrastructure, Reactions; De Gruyter: Berlin, Germany, 2011; ISBN 9783110839654. [Google Scholar]

- Tjeerdsma, B.F.; Militz, H. Chemical changes in hydrothermal treated wood: FTIR analysis of combined hydrothermal and dry heat-treated wood. Holz Roh Werkst. 2005, 63, 102–111. [Google Scholar] [CrossRef]

- Hatakeyama, H.; Hatakeyama, T. Lignin Structure, Properties, and Applications. Adv. Polymer Sci. 2009, 232, 1–63. [Google Scholar] [CrossRef]

- Rowell, R.M. Chapter 3: Cell Wall Chemistry. In Handbook of Wood Chemistry and Wood Composites; CRC Press: Boca Raton, FL, USA, 2013. [Google Scholar]

- Andersson, S.; Wikberg, H.; Pesonen, E.; Maunu, S.L.; Serimaa, R. Studies of crystallinity of Scots pine and Norway spruce cellulose. Trees 2004, 18, 346–353. [Google Scholar] [CrossRef]

- Pandey, K.K. A study of chemical structure of soft and hardwood and wood polymers by FTIR spectroscopy. J. Appl. Polym. Sci. 1999, 71, 1969–1975. [Google Scholar] [CrossRef]

- Daniel, G. Microview of Wood under Degradation by Bacteria and Fungi. In Wood Deterioration and Preservation; American Chemical Society (ACS): Washington, DC, USA, 2003; Volume 845, pp. 34–72. [Google Scholar]

- Hill, C.A.S. Wood Modification: Chemical, Thermal and Other Processes; John Wiley and Sons: Chichester, UK, 2006; ISBN 9780470021729. [Google Scholar]

- Goodell, B.; Nicholas, D.D.; Schultz, T.P. Introduction to Wood Deterioration and Preservation. ACS Symp. Ser. 2003, 845, 2–7. [Google Scholar] [CrossRef]

- Obanda, D.N.; Shupe, T.F.; Barnes, H.M. Reducing leaching of boron-based wood preservatives—A review of research. Bioresour. Technol. 2008, 99, 7312–7322. [Google Scholar] [CrossRef]

- Heiden, P.; Matuana, L.; Dawson-Andoh, B. Nanotechnology: A Novel Approach to Prevent Biocide Leaching. 2016. Available online: https://archive.epa.gov/ncer/publications/web/html/heiden.html (accessed on 20 January 2021).

- Jämsä, S.; Mahlberg, R.; Holopainen, U.R.M.; Ropponen, J.; Savolainen, A.; Ritschkoff, A.-C. Slow release of a biocidal agent from polymeric microcapsules for preventing biodeterioration. Prog. Org. Coatings 2013, 76, 269–276. [Google Scholar] [CrossRef]

- Singh, T.; Singh, A.P. A review on natural products as wood protectant. Wood Sci. Technol. 2011, 46, 851–870. [Google Scholar] [CrossRef]

- Fabiyi, J.S.; McDonald, A.G.; Morrell, J.J.; Freitag, C. Effects of wood species on durability and chemical changes of fungal decayed wood plastic composites. Compos. Part A Appl. Sci. Manuf. 2011, 42, 501–510. [Google Scholar] [CrossRef]

- Ratajczak, I.; Woźniak, M.; Kwaśniewska-Sip, P.; Szentner, K.; Cofta, G.; Mazela, B. Chemical characterization of wood treated with a formulation based on propolis, caffeine and organosilanes. Holz Roh Werkst. 2017, 76, 775–781. [Google Scholar] [CrossRef]

- Kwaśniewska-Sip, P.; Cofta, G.; Nowak, P.B. Resistance of fungal growth on Scots pine treated with caffeine. Int. Biodeterior. Biodegradation 2018, 132, 178–184. [Google Scholar] [CrossRef]

- Kwaśniewska−Sip, P.; Bartkowiak, M.; Cofta, G.; Nowak, P.B. Resistance of Scots pine (Pinus sylvestris L.) after treatment with caffeine and thermal modification against Aspergillus niger. BioResources 2019, 14, 1890–1898. [Google Scholar]

- Wood Preservatives—Accelerated Ageing of Treated Wood Prior to Biological Testing—Leaching Procedure; BS EN 84:1997; Eur. Stand: Brussels, Belgium, 1997; pp. 1–8.

- Besombes, S.; Mazeau, K. Molecular Dynamics Simulations of a Guaiacyl β−O−4 Lignin Model Compound: Examination of Intramolecular Hydrogen Bonding and Conformational Flexibility. Biopolymers 2004, 73, 301–315. [Google Scholar] [CrossRef]

- Best, R.B.; Zhu, X.; Shim, J.; Lopes, P.E.M.; Mittal, J.; Feig, M.; MacKerell, A.D. Optimization of the additive CHARMM all−atom protein force field targeting improved sampling of the backbone φ, ψ and side−chain χ1 and χ2 Dihedral Angles. J. Chem. Theory Comput. 2012, 8, 3257–3273. [Google Scholar] [CrossRef]

- Saam, J.; Ivanov, I.; Walther, M.; Holzhütter, H.G.; Kuhn, H. Molecular dioxygen enters the active site of 12/15−lipoxygenase via dynamic oxygen access channels. Proc. Natl. Acad. Sci. USA 2007, 104, 13319–13324. [Google Scholar] [CrossRef]

- Humphrey, W.; Dalke, A.; Schulten, K. VMD: Visual molecular dynamics. J. Mol. Graph. 1996, 14, 33–38. [Google Scholar] [CrossRef]

- Becke, A.D. Density-functional exchange-energy approximation with correct asymptotic behavior. Phys. Rev. A 1988, 38, 3098–3100. [Google Scholar] [CrossRef]

- Reed, A.E.; Weinstock, R.B.; Weinhold, F. Natural population analysis. J. Chem. Phys. 1985, 83, 735–746. [Google Scholar] [CrossRef]

- Gaussian 09. Available online: https://gaussian.com/g09citation/ (accessed on 20 January 2021).

- Phillips, J.C.; Braun, R.; Wang, W.; Gumbart, J.; Tajkhorshid, E.; Villa, E.; Chipot, C.; Skeel, R.D.; Kalé, L.; Schulten, K. Scalable molecular dynamics with NAMD. J. Comput. Chem. 2005, 26, 1781–1802. [Google Scholar] [CrossRef] [PubMed]

- Allen, M.P.; Tildesley, D.J.; Banavar, J.R. Computer Simulation of Liquids. Phys. Today 1989, 42, 105–106. [Google Scholar] [CrossRef]

- Heyer, L.J.; Kruglyak, S.; Yooseph, S. Exploring Expression Data: Identification and Analysis of Coexpressed Genes. Genome Res. 1999, 9, 1106–1115. [Google Scholar] [CrossRef] [PubMed]

- Trujillo, C.; Previtali, V.; Rozas, I. A theoretical model of the interaction between phosphates in the ATP molecule and guanidinium systems. Theor. Chem. Accounts 2016, 135, 260. [Google Scholar] [CrossRef]

- Chai, J.-D.; Head-Gordon, M. Long-range corrected hybrid density functionals with damped atom–atom dispersion corrections. Phys. Chem. Chem. Phys. 2008, 10, 6615–6620. [Google Scholar] [CrossRef]

- Paradkar, M.; Irudayaraj, J. A Rapid FTIR Spectroscopic Method for Estimation of Caffeine in Soft Drinks and Total Methylxanthines in Tea and Coffee. J. Food Sci. 2002, 67, 2507–2511. [Google Scholar] [CrossRef]

- Tavagnacco, L.; Di Fonzo, S.; D’Amico, F.; Masciovecchio, C.; Brady, J.W.; Cesàro, A. Stacking of purines in water: The role of dipolar interactions in caffeine. Phys. Chem. Chem. Phys. 2016, 18, 13478–13486. [Google Scholar] [CrossRef]

- Falk, M.; Gil, M.; Iza, N. Self-association of caffeine in aqueous solution: An FT-IR study. Can. J. Chem. 1990, 68, 1293–1299. [Google Scholar] [CrossRef]

- Weldegebreal, B.; Redi-Abshiro, M.; Chandravanshi, B.S. Development of new analytical methods for the determination of caffeine content in aqueous solution of green coffee beans. Chem. Central J. 2017, 11, 126. [Google Scholar] [CrossRef]

- Silva, N.H.C.S.; Drumond, I.; Almeida, I.F.; Costa, P.; Rosado, C.F.; Neto, C.P.; Freire, C.S.R.; Silvestre, A.J.D. Topical caffeine delivery using biocellulose membranes: A potential innovative system for cellulite treatment. Cellulose 2014, 21, 665–674. [Google Scholar] [CrossRef]

- Nonthakaew, A.; Matan, N.; Aewsiri, T.; Matan, N. Antifungal Activity of Crude Extracts of Coffee and Spent Coffee Ground on Areca Palm Leaf Sheath (Areca catechu) Based Food Packaging. Packag. Technol. Sci. 2015, 28, 633–645. [Google Scholar] [CrossRef]

- Marta, R.A.; Wu, R.; Eldridge, K.R.; Martens, J.; McMahon, T.B. Infrared vibrational spectra as a structural probe of gaseous ions formed by caffeine and theophylline. Phys. Chem. Chem. Phys. 2010, 12, 3431–3442. [Google Scholar] [CrossRef] [PubMed]

- Agarwal, V.; Huber, G.W.; Conner, W.C.; Auerbach, S.M. Simulating infrared spectra and hydrogen bonding in cellulose Iβ at elevated temperatures. J. Chem. Phys. 2011, 135, 134506. [Google Scholar] [CrossRef] [PubMed]

- De Taeye, J.; Zeegers-Huyskens, T. Infrared study of the interaction between caffeine and hydroxylic derivatives. J. Pharm. Sci. 1985, 74, 660–663. [Google Scholar] [CrossRef] [PubMed]

- Gosselink, R.J.; Abächerli, A.; Semke, H.; Malherbe, R.; Käuper, P.; Nadif, A.; Van Dam, J. Analytical protocols for characterisation of sulphur-free lignin. Ind. Crop. Prod. 2004, 19, 271–281. [Google Scholar] [CrossRef]

- Alekhina, M.; Ershova, O.; Ebert, A.; Heikkinen, S.; Sixta, H. Softwood kraft lignin for value-added applications: Fractionation and structural characterization. Ind. Crop. Prod. 2015, 66, 220–228. [Google Scholar] [CrossRef]

- Huang, Y.; Wang, L.; Chao, Y.; Nawawi, D.S.; Akiyama, T.; Yokoyama, T.; Matsumoto, Y. Analysis of Lignin Aromatic Structure in Wood Based on the IR Spectrum. J. Wood Chem. Technol. 2012, 32, 294–303. [Google Scholar] [CrossRef]

- Boeriu, C.G.; Bravo, D.; Gosselink, R.J.; Van Dam, J.E. Characterisation of structure-dependent functional properties of lignin with infrared spectroscopy. Ind. Crop. Prod. 2004, 20, 205–218. [Google Scholar] [CrossRef]

- Lionetto, F.; Del Sole, R.; Cannoletta, D.; Vasapollo, G.; Maffezzoli, A. Monitoring Wood Degradation during Weathering by Cellulose Crystallinity. Materials 2012, 5, 1910–1922. [Google Scholar] [CrossRef]

- Abidi, N.; Cabrales, L.; Haigler, C.H. Changes in the cell wall and cellulose content of developing cotton fibers investigated by FTIR spectroscopy. Carbohydr. Polym. 2014, 100, 9–16. [Google Scholar] [CrossRef]

- Müller, G.; Schöpper, C.; Vos, H.; Kharazipour, A.; Polle, A. FTIR−ATR spectroscopic analyses of changes in wood properties during particleand fibreboard production of hardand softwood trees. BioResources 2009, 4, 49–71. [Google Scholar]

- Besombes, S.; Mazeau, K. The cellulose/lignin assembly assessed by molecular modeling. Part 1: Adsorption of a threo guaiacyl β-O-4 dimer onto a Iβ cellulose whisker. Plant Physiol. Biochem. 2005, 43, 299–308. [Google Scholar] [CrossRef] [PubMed]

- Bhawani, S.A.; Fong, S.S.; Ibrahim, M.N.M. Spectrophotometric Analysis of Caffeine. Int. J. Anal. Chem. 2015, 2015, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Akiyama, T.; Goto, H.; Nawawi, D.S.; Syafii, W.; Matsumoto, Y.; Meshitsuka, G. Erythro/threo ratio of β-O-4-5 structures as an important structural characteristic of lignin. Part 4: Variation in the erythro/threo ratio in softwood and hardwood lignins and its relation to syringyl/guaiacyl ratio. Holzforschung 2005, 59, 276–281. [Google Scholar] [CrossRef]

- Furtado, L.M.; Hilamatu, K.C.; Balaji, K.; Ando, R.A.; Petri, D.F.S. Miscibility and sustained release of drug from cellulose acetate butyrate/caffeine films. J. Drug Deliv. Sci. Technol. 2020, 55, 101472. [Google Scholar] [CrossRef]

- Hardy, I.J.; Windberg-Baarup, A.; Neri, C.; Byway, P.V.; Booth, S.W.; Fitzpatrick, S. Modulation of drug release kinetics from hydroxypropyl methyl cellulose matrix tablets using polyvinyl pyrrolidone. Int. J. Pharm. 2007, 337, 246–253. [Google Scholar] [CrossRef]

- Lavoine, N.; Desloges, I.; Bras, J. Microfibrillated cellulose coatings as new release systems for active packaging. Carbohydr. Polym. 2014, 103, 528–537. [Google Scholar] [CrossRef]

- Lavoine, N.; Guillard, V.; Desloges, I.; Gontard, N.; Bras, J. Active bio-based food-packaging: Diffusion and release of active substances through and from cellulose nanofiber coating toward food-packaging design. Carbohydr. Polym. 2016, 149, 40–50. [Google Scholar] [CrossRef]

- Widjaja, T.; Altway, A.; Zata, F.; Iswanto, T. Two−Stage Pre−treatment of Coffee Pulp Waste to Optimize the Reducing Sugar Production using Enzymatic Hydrolysis. Malaysian J. Fundam. Appl. Sci. 2019, 15, 878–884. [Google Scholar]

- van Breda, S.V.; van der Merwe, C.F.; Robbertse, H.; Apostolides, Z. Immunohistochemical localization of caffeine in young Camellia sinensis (L.) O. Kuntze (tea) leaves. Planta 2013, 237, 849–858. [Google Scholar] [CrossRef]

- Penttilä, P.A.; Altgen, M.; Awais, M.; Österberg, M.; Rautkari, L.; Schweins, R. Bundling of cellulose microfibrils in native and polyethylene glycol-containing wood cell walls revealed by small-angle neutron scattering. Sci. Rep. 2020, 10, 1–9. [Google Scholar] [CrossRef] [PubMed]

| Parameter | CHNS Analysis |

|---|---|

| Oven temperature | 950 °C |

| Chromatographic column temperature | 65 °C |

| Gas flow | He–140 mL min−1 O2–250 mL min−1 |

| Time of analysis | 660 s |

| Samples | Content of Element [%] | ||

|---|---|---|---|

| N | C | H | |

| Untreated | 0.074 a* ± 0.006 | 47.389 a ± 0.081 | 6.309 a ± 0.027 |

| Unleached | 0.980 c ± 0.041 | 47.592 a ± 0.006 | 6.259 a ± 0.042 |

| Leached | 0.469 b ± 0.003 | 47.536 a ± 0.070 | 6.309 a ± 0.174 |

| Samples | Band Frequency (cm−1) | ||

|---|---|---|---|

| A1705/1515 ν C=O | A1660/1515 ν N−H | A1555/1515 ν C=N | |

| Control | - | - | - |

| Unleached | 0.9290 b* | 1.0919 a | 0.8082 c |

| Leached | 0.9153 b | 0.9040 b | 0.7768 c |

| Interaction Energy [kcal/mol] | ||

|---|---|---|

| System Consisting of αR, the βR Guiacyl β-O-4 Model Compound and Caffeine | In Vacuo | In an Aqueous Solution |

| Cluster 1 | −11.0 | −11.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kwaśniewska-Sip, P.; Woźniak, M.; Jankowski, W.; Ratajczak, I.; Cofta, G. Chemical Changes of Wood Treated with Caffeine. Materials 2021, 14, 497. https://doi.org/10.3390/ma14030497

Kwaśniewska-Sip P, Woźniak M, Jankowski W, Ratajczak I, Cofta G. Chemical Changes of Wood Treated with Caffeine. Materials. 2021; 14(3):497. https://doi.org/10.3390/ma14030497

Chicago/Turabian StyleKwaśniewska-Sip, Patrycja, Magdalena Woźniak, Wojciech Jankowski, Izabela Ratajczak, and Grzegorz Cofta. 2021. "Chemical Changes of Wood Treated with Caffeine" Materials 14, no. 3: 497. https://doi.org/10.3390/ma14030497

APA StyleKwaśniewska-Sip, P., Woźniak, M., Jankowski, W., Ratajczak, I., & Cofta, G. (2021). Chemical Changes of Wood Treated with Caffeine. Materials, 14(3), 497. https://doi.org/10.3390/ma14030497