Method for Mitigating Stray Current Corrosion in Buried Pipelines Using Calcareous Deposits

Abstract

:1. Introduction

2. Materials and Methods

2.1. Specimen and Solution Preparation

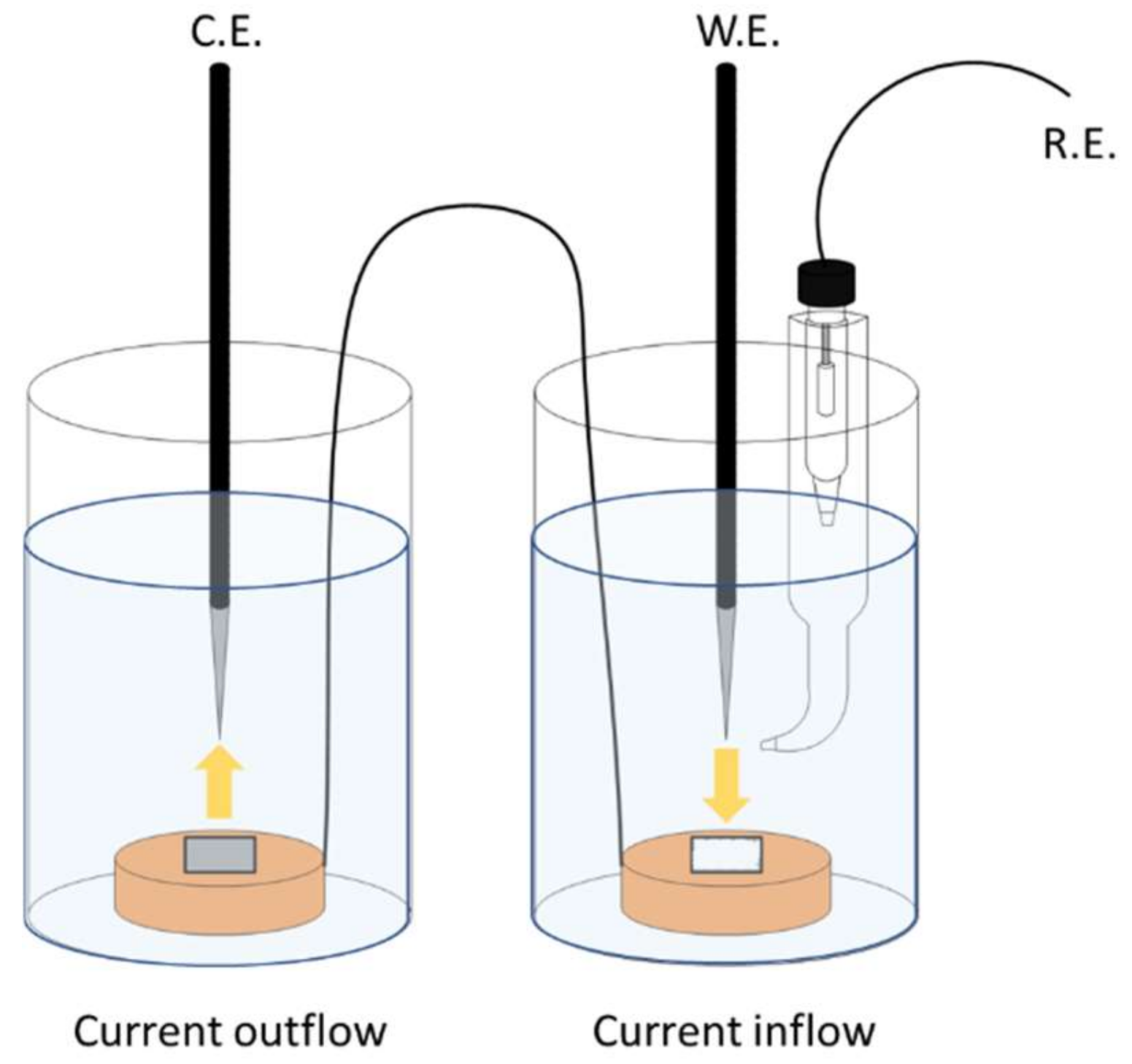

2.2. Formation of Calcareous Deposits

2.3. Surface Analyses

2.4. Electrochemical Test

3. Results

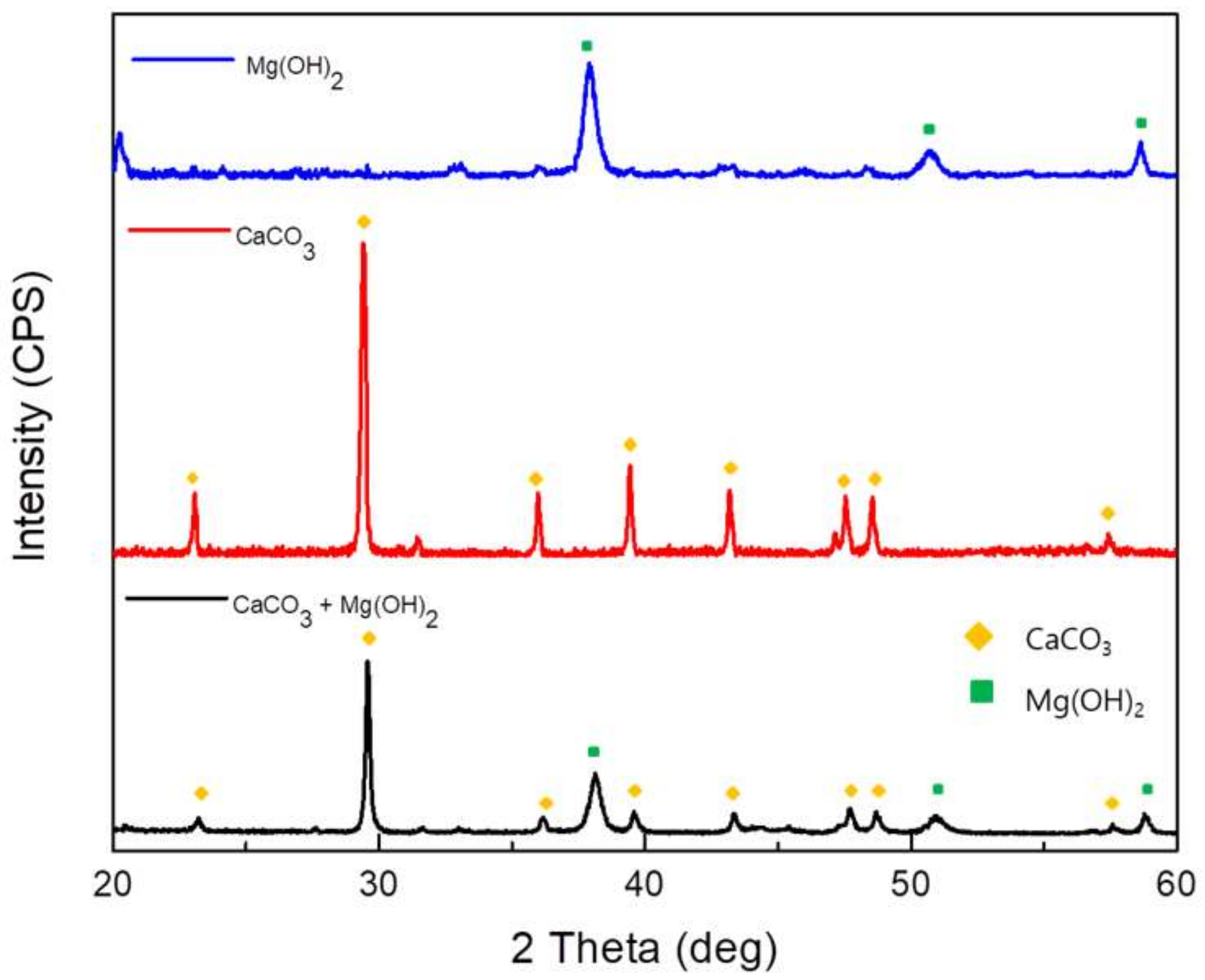

3.1. Formation of Calcareous Deposits

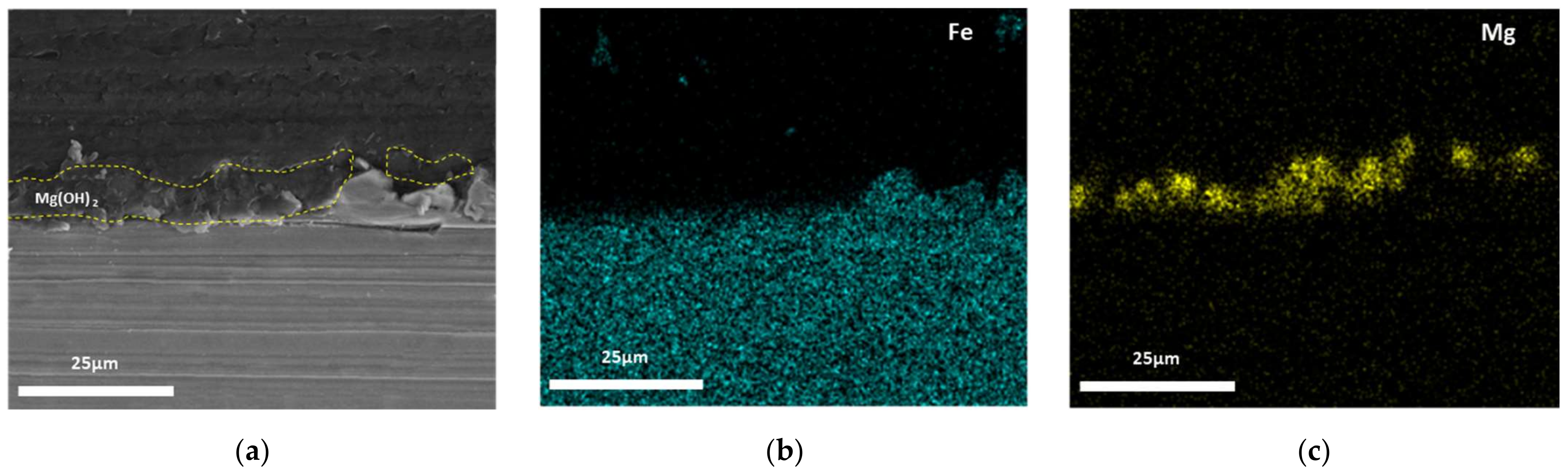

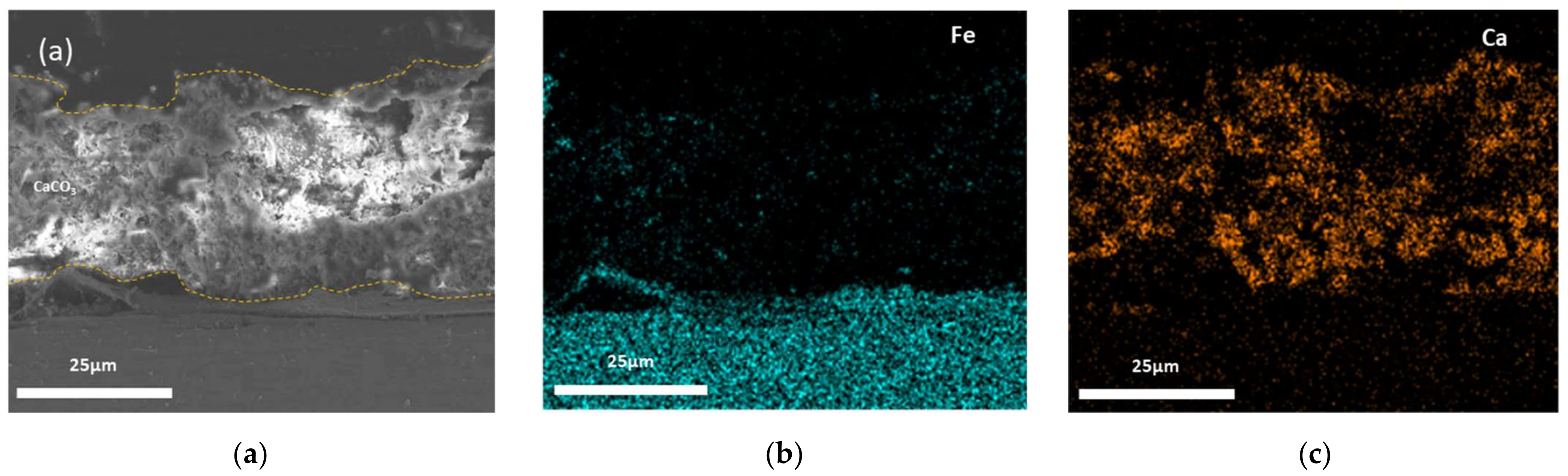

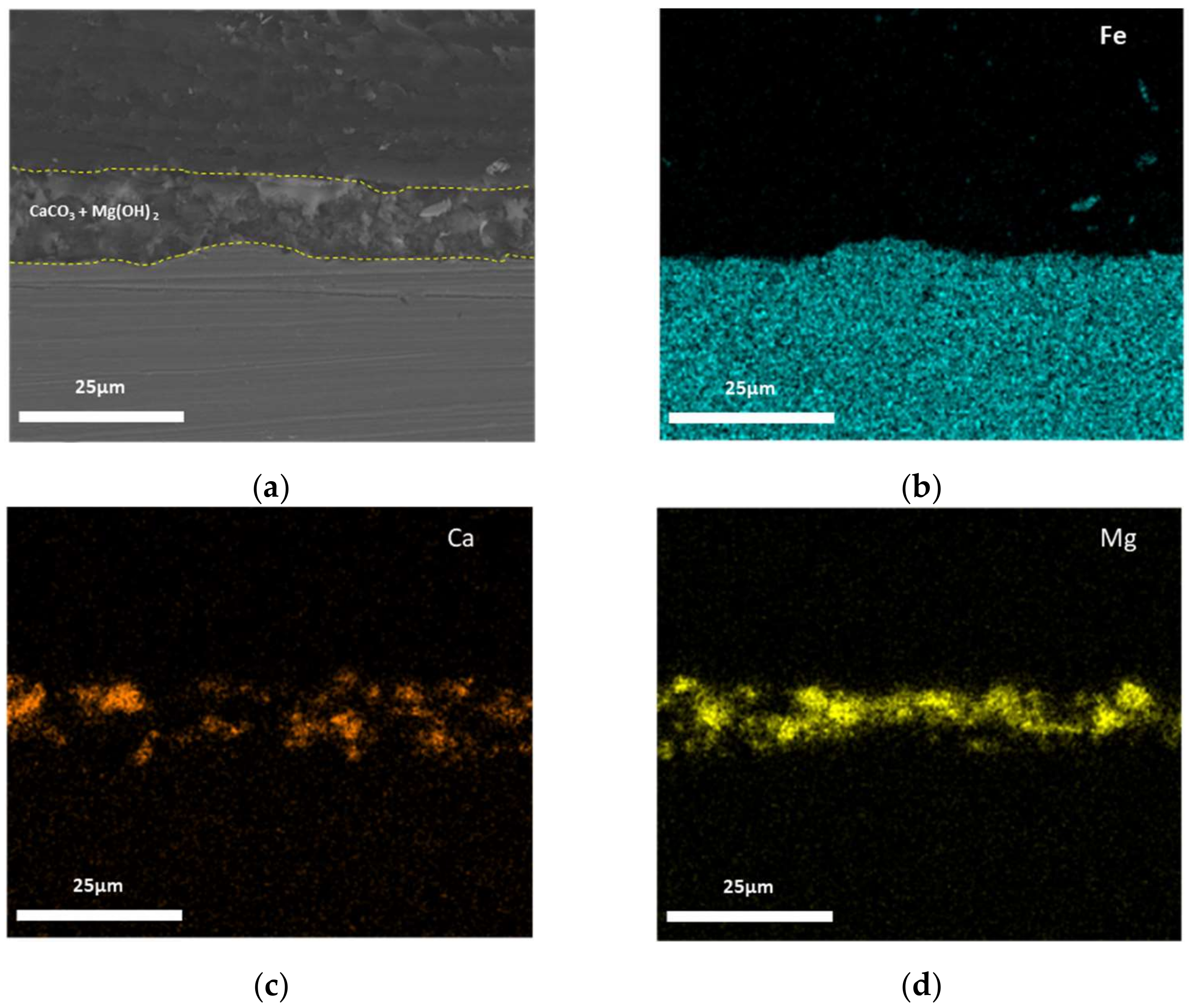

3.2. Surface Analysis

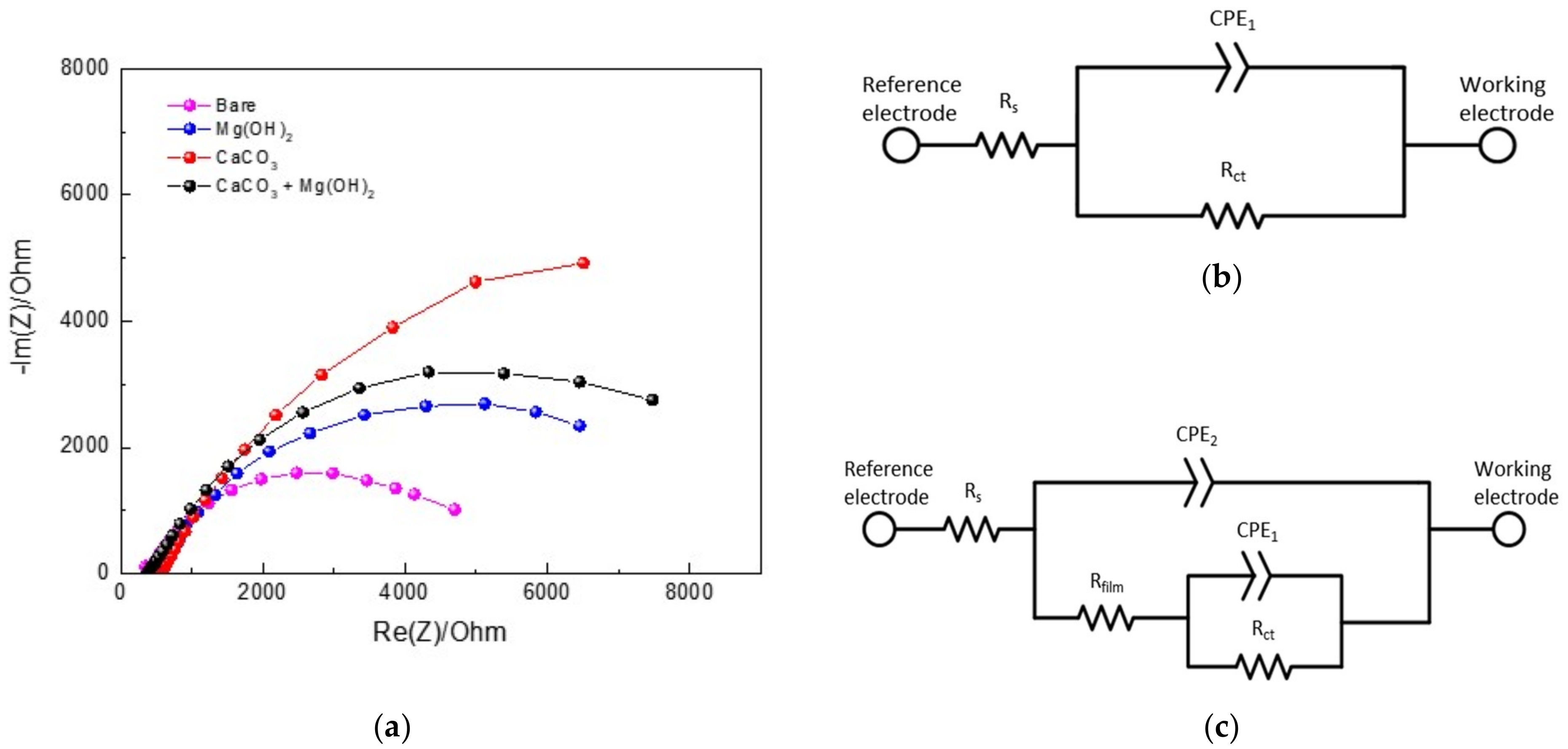

3.3. Electrochemical Impedance Spectroscopy

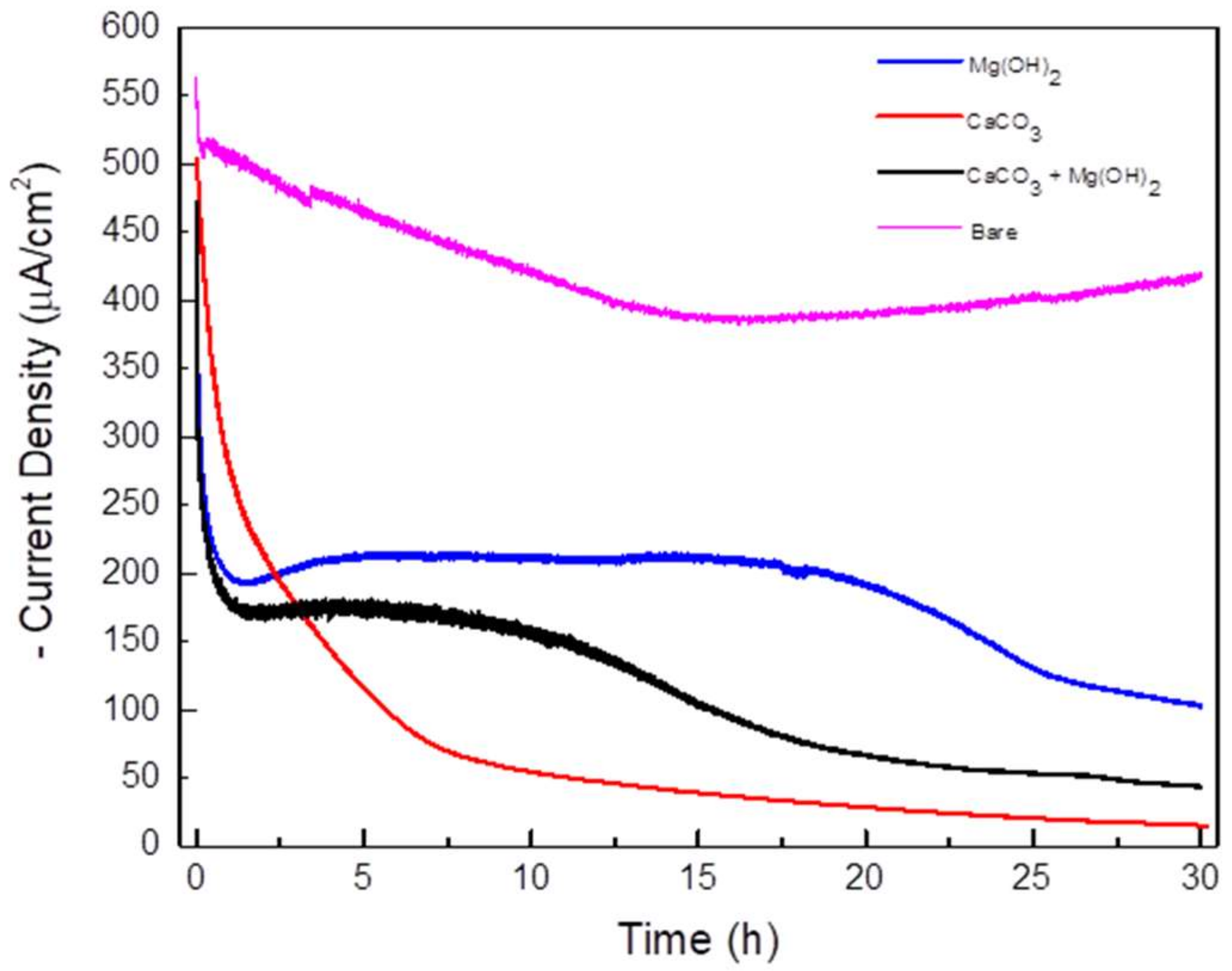

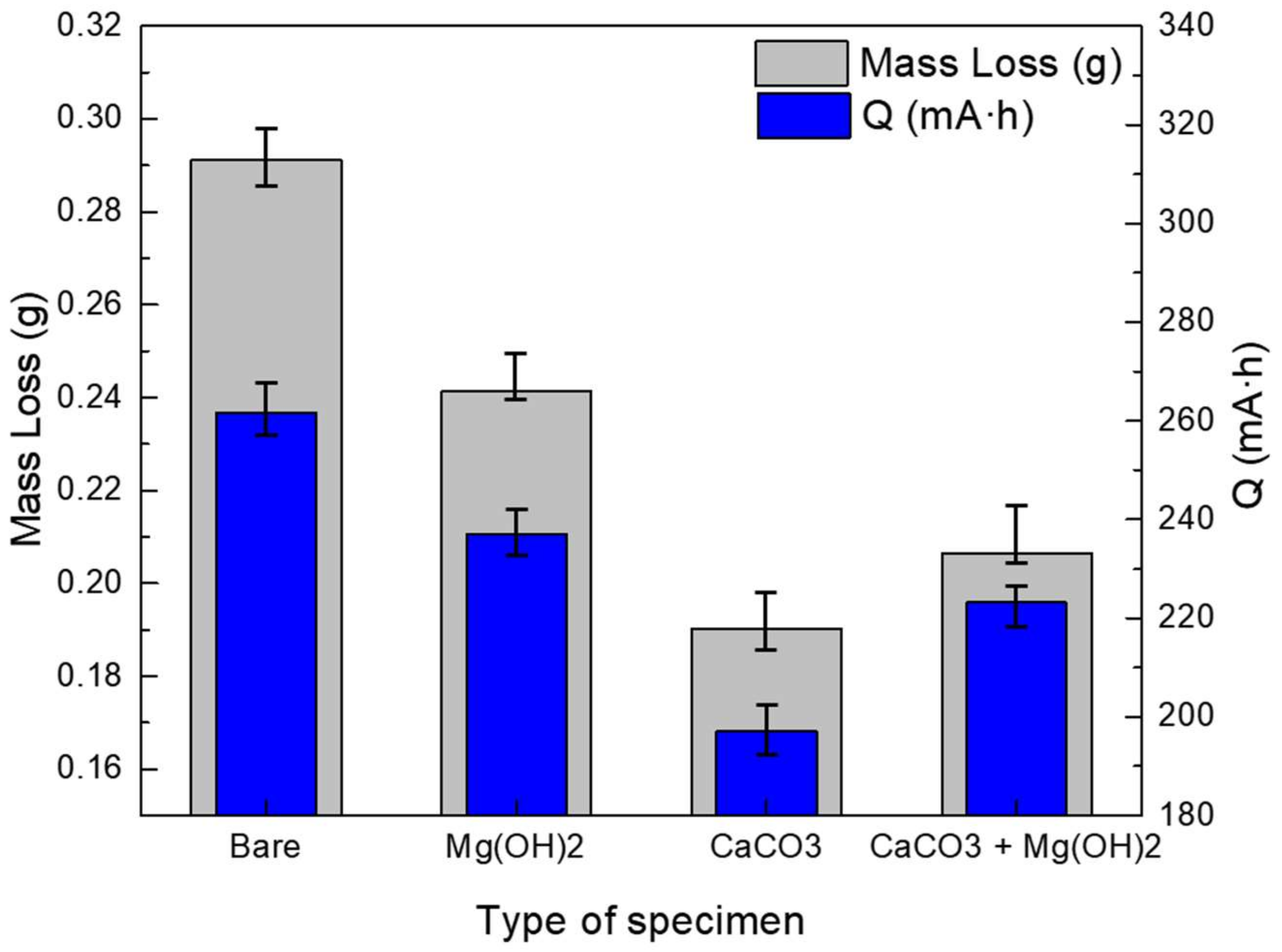

3.4. Corrosion Acceleration Test

4. Conclusions

- In the potentiostatic test, the current densities in all types of calcareous deposit layers decreased with the test time;

- The specimen with the CaCO3 layer had the lowest current density. In the surface analysis, the specimen in the CaCO3 solution has the thickest layer compared to the Mg(OH)2 and mixed solutions;

- In the EIS test, the specimen immersed in the CaCO3 solution had the highest Rfilm and Rct, indicating that the calcareous deposit of CaCO3 is the most protective layer;

- The potentiostatic acceleration test demonstrated that the CaCO3 layer had the lowest total electric charge among the specimens with calcareous deposits. In addition, the mass loss by the current outflow was the lowest in those with a CaCO3 layer.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, Z.; Koleva, D.; van Breugel, K. A review on stray current-induced steel corrosion in infrastructure. Corros. Rev. 2017, 35, 397–423. [Google Scholar] [CrossRef]

- Yoo, Y.H.; Nam, T.H.; Choi, Y.S.; Kim, J.G.; Chung, L. A galvanic sensor system for detecting the corrosion damage of the steel embedded in concrete structures: Laboratory tests to determine the cathodic protection and stray-current. Met. Mater. Int. 2011, 17, 623–629. [Google Scholar] [CrossRef]

- Guo, Y.B.; Liu, C.; Wang, D.G.; Liu, S.H. Effects of alternating current interference on corrosion of X60 pipeline steel. Pet. Sci. 2015, 12, 316–324. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.; Wang, Z.; Chen, Y.; Song, X.; Yang, Y. Effect of a DC stray current on the corrosion of X80 pipeline steel and the cathodic disbondment behavior of the protective 3PE coating in 3.5% NaCl solution. Coatings 2019, 9, 29. [Google Scholar] [CrossRef] [Green Version]

- Chao, Y.; Gan, C.; Zili, L.; Yalei, Z.; Chengbin, Z. Study the influence of DC stray current on the corrosion of X65 steel using electrochemical method. Int. J. Electrochem. Sci. 2015, 10, 10223–10231. [Google Scholar]

- Riskin, J. Electrocorrosion and Protection of Metals: General Approach with Particular Consideration to Electrochemical Plants; Elsevier Science: Amsterdam, Netherlands, 2008. [Google Scholar]

- Bertolini, L.; Carsana, M.; Pedeferri, P. Corrosion behaviour of steel in concrete in the presence of stray current. Corros. Sci. 2007, 49, 1056–1068. [Google Scholar] [CrossRef]

- Chen, Z.; Qin, C.; Tang, J.; Zhou, Y. Experiment research of dynamic stray current interference on buried gas pipeline from urban rail transit. J. Nat. Gas Sci. Eng. 2013, 15, 76–81. [Google Scholar] [CrossRef]

- Richard, W.S.; David, D.; Carl, E.L., Jr. Stray Current Corrosion Due to Utility Cathodic Protection; Structural Engineering and Engineering Materials SM Report No. 45; University of Kansas Center for Research, Inc.: Lawrence, KS, USA, 1997; Chapter 2; pp. 10–17. [Google Scholar]

- Zhu, Q.; Cao, A.; Zaifend, W.; Song, J.; Shengli, C. Stray current corrosion in buried pipeline. Anti-Corros. Methods Mater. 2011, 58, 234–237. [Google Scholar] [CrossRef]

- Lin, Y.; Li, K.; Su, M.; Meng, Y. Research on stray current distribution of Metro based on Numerical Simulation. In Proceedings of the 2018 IEEE International Symposium on Electromagnetic Compatibility and 2018 IEEE Asia-Pacific Symposium on Electromagnetic Compatibility (EMC/APEMC), Suntec City, Singapore, 14–18 May 2018. [Google Scholar]

- Kim, Y.S.; Kim, J.G. Failure analysis of a thermally insulated pipeline in a district heating system. Eng. Fail. Anal. 2018, 83, 193–206. [Google Scholar] [CrossRef]

- Hong, M.S.; So, Y.S.; Kim, J.G. Optimization of cathodic protection design for pre-insulated pipeline in district heating system using computational simulation. Materials 2019, 12, 1761. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tang, K. Stray current induced corrosion of steel fibre reinforced concrete. Cem. Concr. Res. 2017, 100, 445–456. [Google Scholar] [CrossRef] [Green Version]

- Szeliga, M.J. “Stray Current Corrosion”, in: Peabody’s Control of Pipeline Corrosion, 2nd ed.; NACE International: Houston, TX, USA, 2001; p. 211. [Google Scholar]

- Wang, C. Stray Current Distributing Model in the Subway System: A review and outlook. Int. J. Electrochem. Sci. 2018, 13, 1700–1727. [Google Scholar] [CrossRef]

- Du, G.; Wang, J.; Jiang, X.; Zhang, D.; Yang, L.; Hu, Y. Evaluation of Rail Potential and Stray Current with Dynamic Traction Networks in Multitrain Subway Systems. IEEE Trans. Transp. Electrif. 2020, 6, 784–796. [Google Scholar] [CrossRef]

- Ghanbari, E.; Lillard, R.S. The influence of CaCO3 scale formation on AC corrosion rates of pipeline steel under cathodic protection. Corrosion 2017, 74, 551–565. [Google Scholar] [CrossRef]

- Barchiche, C.; Deslouis, C.; Gil, O.; Refait, P.; Tribollet, B. Characterisation of calcareous deposits by electrochemical methods: Role of sulphates, calcium concentration and temperature. Electrochim. Acta 2004, 49, 2833–2839. [Google Scholar] [CrossRef]

- Ce, N.; Paul, S. The effect of temperature and local pH on calcareous deposit formation in damaged thermal spray aluminum (TSA) coatings and its implication on corrosion mitigation of offshore steel structures. Coatings 2017, 7, 52. [Google Scholar] [CrossRef] [Green Version]

- Devos, O.; Jakab, S.; Gabrielli, C.; Joiret, S.; Tribollet, B.; Picart, S. Nucleation-growth process of scale electrodeposition – influence of the magnesium ions. J. Cryst. Growth 2009, 311, 4334–4342. [Google Scholar] [CrossRef]

- Zhang, L.; Shen, H.-J.; Sun, J.-Y.; Sun, Y.-N.; Fang, Y.-C.; Cao, W.-H.; Xing, Y.-Y.; Lu, M.-X. Effect of calcareous deposits on hydrogen permeation in X80 steel under cathodic protection. Mater. Chem. Phys. 2018, 207, 123–129. [Google Scholar] [CrossRef]

- Hong, M.S.; Hwang, J.H.; Kim, J.H. Optimization of the cathodic protection design in consideration of the temperature variation for offshore structures. Corrosion 2018, 74, 123–133. [Google Scholar] [CrossRef]

- Yan, J.-F.; Nguyen, T.V.; White, R.E.; Griffin, R.B. Mathematical modeling of the formation of calcareous deposits on cathodically protected steel in seawater. J. Electrochem. Soc. 1993, 140, 733–742. [Google Scholar] [CrossRef]

- Deslouis, C.; Festy, D.; Gil, O.; Rius, G.; Touzain, S.; Tribollet, B. Characterization of calcareous deposits in artificial sea water by impedance techniques-I. Deposit of CaCO3 without Mg(OH)2. Electrochim. Acta 1998, 43, 1891–1901. [Google Scholar] [CrossRef]

- Li, C.J.; Du, M. The growth mechanism of calcareous deposits under various hydrostatic pressures during the cathodic protection of carbon steel in seawater. RSC Adv. 2017, 7, 28819–28825. [Google Scholar] [CrossRef] [Green Version]

- Deslouis, C.; Festy, D.; Gil, O.; Maillot, V.; Touzain, S.; Tribollet, B. Characterization of calcareous deposits in artificial sea water by impedances techniques: 2-deposit of Mg(OH)2 without CaCO3. Electrochim. Acta 2000, 45, 1837–1845. [Google Scholar] [CrossRef]

- Carré, C.; Zanibellato, A.; Jeannin, M.; Sabot, R.; Gunkel-Grillon, P.; Serres, A. Electrochemical calcareous deposition in seawater. A review. Environ. Chem. Lett. 2020, 18, 1193–1208. [Google Scholar] [CrossRef]

- Barchiche, C.; Deslouis, C.; Festy, D.; Gil, O.; Refait, P.; Touzain, S.; Tribollet, B. Characterization of calcareous deposits in artificial seawater by impedance techniques 3- Deposit of of CaCO3 in the presence of Mg(OH)2. Electrochim. Acta 2003, 48, 1645–1654. [Google Scholar] [CrossRef]

- Kim, Y.-S.; Kim, S.-H.; Kim, J.-G. Effect of 1, 2, 3-benzotriazole on the corrosion properties of 316L stainless steel in synthetic tap water. Met. Mater. Int. 2015, 21, 1013–1022. [Google Scholar] [CrossRef]

- An, J.-H.; Lee, J.; Kim, Y.-S.; Kim, W.-C.; Kim, J.-G. Effects of Post Weld Heat Treatment on Mechanical and Electrochemical Properties of Welded Carbon Steel Pipe. Met. Mater. Int. 2018, 25, 304–312. [Google Scholar] [CrossRef]

- Zhang, P.Q.; Wu, J.X.; Zhang, Q.; Lu, X.Y.; Wang, K. Pitting mechanism for passive 304 stainless steel in sulphuric acid media containing chloride ions. Corros. Sci. 1993, 34, 1343–1354. [Google Scholar] [CrossRef]

- Lopez, D.A.; Simison, S.N.; De Sanchez, S.R. The influence of steel microstructure on CO2 corrosion. EIS studies on the inhibition efficiency of benzimidazole. Electrochim. Acta 2003, 48, 845–854. [Google Scholar] [CrossRef]

- Lee, D.Y.; Kim, W.C.; Kim, J.G. Effect of nitrite concentration on the corrosion behaviour of carbon steel pipelines in synthetic tap water. Corros. Sci. 2012, 64, 105–114. [Google Scholar] [CrossRef]

- Hong, M.S.; So, Y.S.; Lim, J.M.; Kim, J.G. Evaluation of internal corrosion property in district heating pipeline using fracture mechanics and electrochemical acceleration kinetics. J. Ind. Eng. Chem. 2021, 94, 253–263. [Google Scholar] [CrossRef]

- Silva, J.C.D.E.; Panicali, A.R.; Barbosa, C.F.; Caetano, C.E.F.; Paulino, J.O.S. Electric charge flow in linear circuits. Electr. Power Syst. Res. 2019, 170, 57–63. [Google Scholar] [CrossRef]

| Fe | C | P | S | Si | Mn |

|---|---|---|---|---|---|

| Bal | 0.130 max. | 0.018 max. | 0.070 max. | 0.240 max. | 0.560 max. |

| CaCl2 | MgSO4 7H2O | NaHCO3 | H2SO4 | HNO3 |

|---|---|---|---|---|

| 133.2 | 59.0 | 208.0 | 48.0 | 21.8 |

| Type of Deposit | Rs | CPE1 | Rfilm | CPE2 | Rct | ||

|---|---|---|---|---|---|---|---|

| (Ω·cm2) | CPE | Y0 (0 < n < 1) | (Ω·cm2) | CPE | Y0 (0 < n < 1) | (Ω·cm2) | |

| Bare | 393.7 | 1.912 × 10−4 | 0.7527 | - | - | - | 4785 |

| Mg(OH)2 | 511.3 | 2.955 × 10−4 | 0.8693 | 523.5 | 3.893 × 10−4 | 0.7953 | 6100 |

| CaCO3 | 568.2 | 5.955 × 10−4 | 0.7615 | 865.9 | 1.702 × 10−4 | 0.7231 | 15,210 |

| CaCO3 + Mg(OH)2 | 375.9 | 2.923 × 10−4 | 0.7533 | 643.4 | 1.795 × 10−4 | 0.7959 | 8872 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kang, S.-J.; Hong, M.-S.; Kim, J.-G. Method for Mitigating Stray Current Corrosion in Buried Pipelines Using Calcareous Deposits. Materials 2021, 14, 7905. https://doi.org/10.3390/ma14247905

Kang S-J, Hong M-S, Kim J-G. Method for Mitigating Stray Current Corrosion in Buried Pipelines Using Calcareous Deposits. Materials. 2021; 14(24):7905. https://doi.org/10.3390/ma14247905

Chicago/Turabian StyleKang, Sin-Jae, Min-Sung Hong, and Jung-Gu Kim. 2021. "Method for Mitigating Stray Current Corrosion in Buried Pipelines Using Calcareous Deposits" Materials 14, no. 24: 7905. https://doi.org/10.3390/ma14247905

APA StyleKang, S.-J., Hong, M.-S., & Kim, J.-G. (2021). Method for Mitigating Stray Current Corrosion in Buried Pipelines Using Calcareous Deposits. Materials, 14(24), 7905. https://doi.org/10.3390/ma14247905